Electric furnace burden process with high efficiency and low cost

A low-cost, charge-based technology, applied in the direction of electric furnace, process efficiency improvement, furnace, etc., can solve problems such as difficulty in furnace cover rotation, power failure, decarburization and dephosphorization, and high quality requirements, so as to improve the end point composition and temperature hit rate, and ensure Steel quality, the effect of improving the quality of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

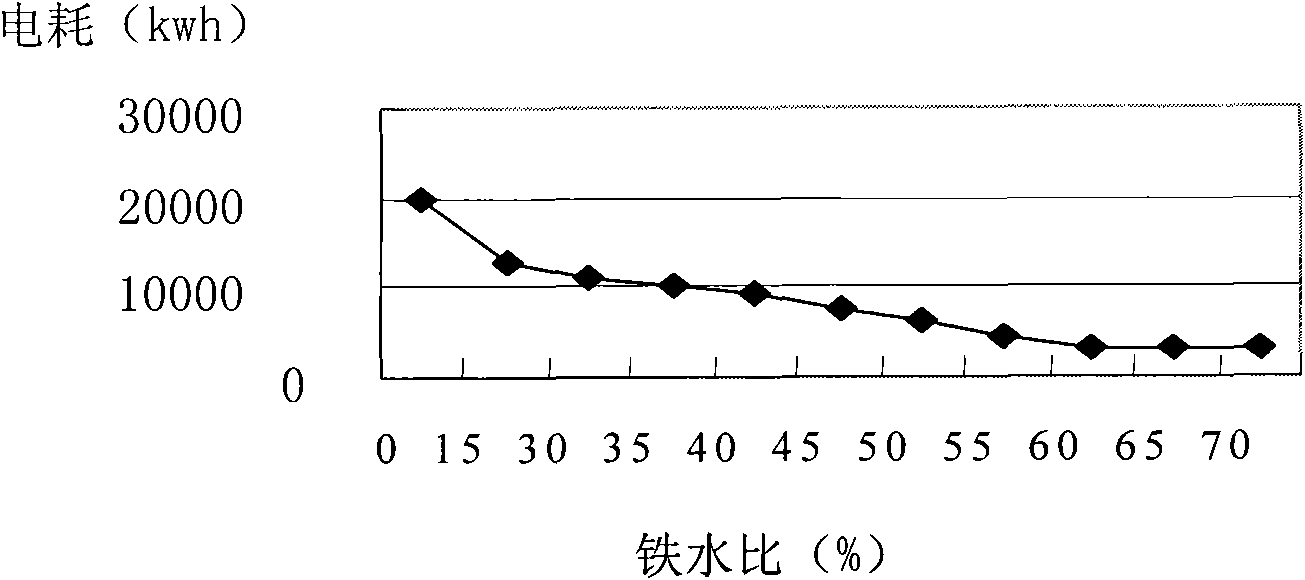

Embodiment 1

[0024] The new charge structure is effectively applied to the production of 50-ton electric arc furnace in Laigang Special Steel Plant. The composition and temperature hit rate of the end point of the electric arc furnace are increased from 67% to 91%, the power supply time is shortened by 6 minutes, and the power consumption of smelting is reduced by 58kWh / t steel. The electrode consumption is reduced by 0.30kg / t steel, the total oxygen content of steel is significantly reduced, and the production cost is reduced by 167 yuan / ton steel. The purpose of improving the quality of molten steel, shortening the smelting cycle and reducing consumption is achieved.

[0025] 1 Furnace charges loaded

[0026] Main ingredients: molten iron accounts for 30% of the metal addition, high-quality steel scrap accounts for 30% of the metal addition, and cheap steel scrap accounts for 40% of the metal addition;

[0027] Auxiliary materials: auxiliary materials are added according to a certain pr...

Embodiment 2

[0056] Others are with embodiment 1. The difference is:

[0057] Main ingredients: molten iron accounts for 60% of the metal addition, high-quality steel scrap accounts for 5% of the metal addition, and cheap steel scrap accounts for 35% of the metal addition;

[0058] Auxiliary materials: 3.0% of lime and 1.5% of lightly burned dolomite should be added to each ton of molten steel;

Embodiment 3

[0060] Other is with embodiment 1, and difference is:

[0061] Main ingredients: molten iron accounts for 40% of the metal addition, high-quality steel scrap accounts for 30% of the metal addition, and cheap steel scrap accounts for 30% of the metal addition;

[0062] Auxiliary materials: 3.5% of lime and 1.0% of lightly burned dolomite should be added to each ton of molten steel;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com