Vacuum preparing device and application method

A technology of vacuum batching and batching barrels, applied in mixing methods, chemical instruments and methods, mixers with rotating stirring devices, etc., can solve the problems of poor mixing effect, easy introduction of impurities, air bubbles, etc., achieve uniform batching, improve circulation Use performance, anti-deposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

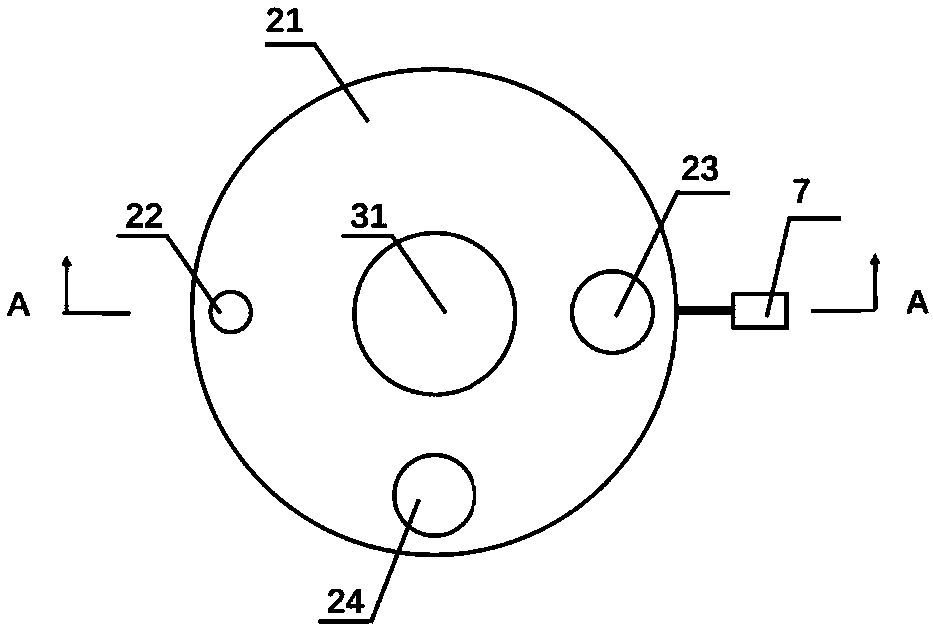

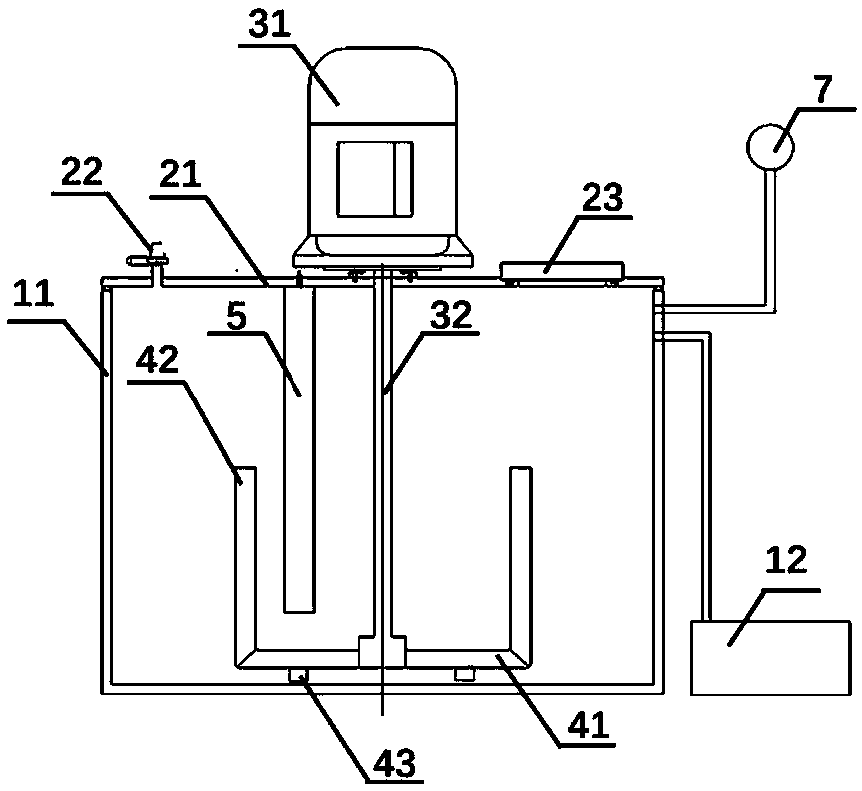

[0053] like figure 1 , 2 As shown, a vacuum batching device includes a cylinder body 11 and a cylinder head 21, the cylinder head 21 covers the top of the cylinder body, a cavity is formed between the cylinder body 11 and the cylinder head 21, and the cylinder body 11 and the cylinder body Cover 21 is separable between the two, which is convenient for dismounting. A seal is provided on the contact surface between the cylinder body 11 and the cylinder head 21 to ensure the sealing performance. One side of the cylinder body 11 is sealed and connected to the vacuum pump 12 for vacuuming. The upper surface of the cylinder head 21 is provided with a valve 22. When the valve 22 is opened, the cavity communicates with the external atmosphere, and when the valve 22 is closed, the cavity is isolated from the external atmosphere, thereby forming an airtight seal. The environment enables the batching process to be carried out in a vacuum environment, which is conducive to improving the...

Embodiment 2

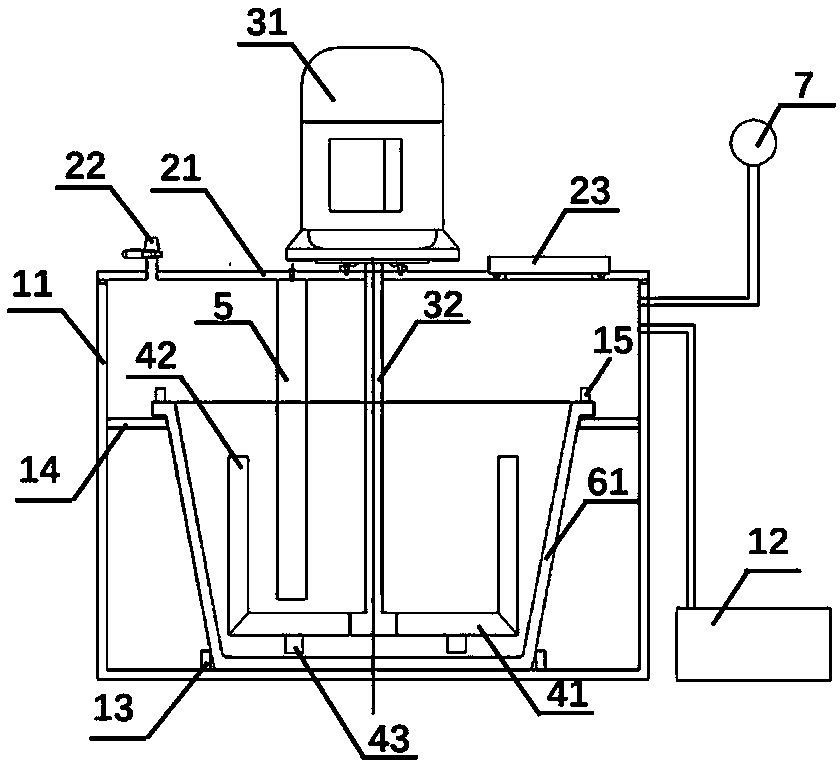

[0069] like image 3 As shown, the difference between this embodiment and Embodiment 1 is that a batching bucket 62 is set inside the cylinder body 11, a groove 13 is set at the bottom of the cylinder body 11, and the bottom of the batching bucket 61 is snapped into the concave In slot 13. The stirring paddle 41 , the first sub-stirring paddle 42 , the second sub-stirring paddle 43 , and the stirring blocking part 5 are all accommodated in the batching barrel 61 . By arranging the batching barrel 62 inside the cylinder 11, the raw materials can be placed in the batching barrel 62 for stirring, and the bottom of the batching barrel 62 is clamped with the bottom of the cylinder 11, and is arranged as a detachable structure, so the batching barrel 62 is replaceable. When the batching barrel 62 is used for a long time or the proportion of raw materials needs to be changed, the batching barrel 62 can be replaced to avoid mutual influence between raw materials with different propor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com