Continuous type vacuum dough mixer and using method thereof

A dough mixer, continuous type technology, applied in the direction of dough mixer, application, structural components of mixing/kneading machinery, etc., can solve the problems that continuous production of flour products cannot be realized, and achieve simple structure, reasonable design, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

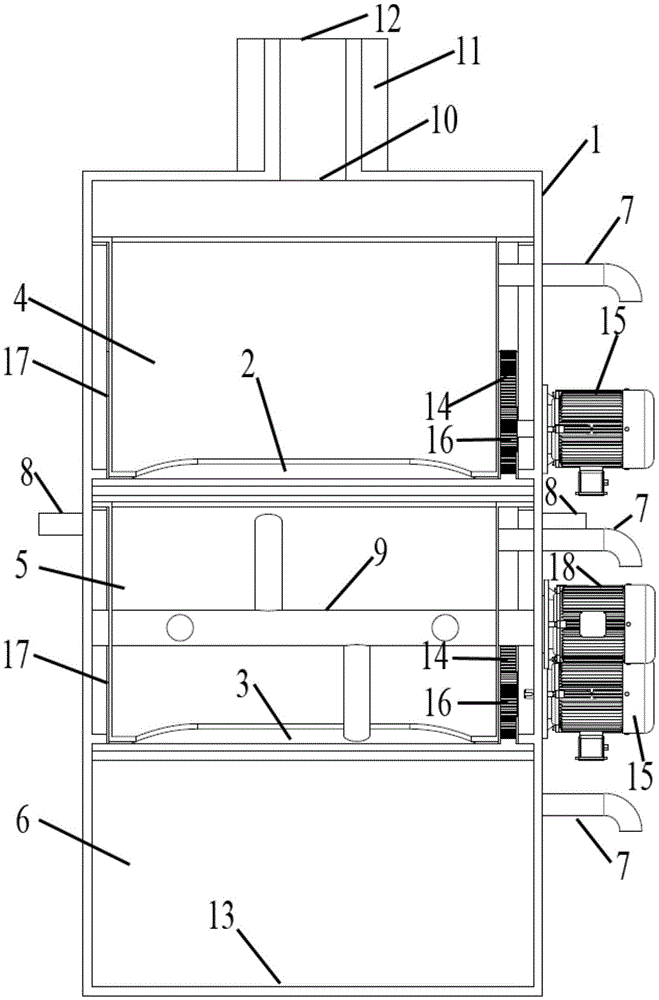

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0039] The invention provides a continuous vacuum dough mixing machine, comprising:

[0040] The housing 1 is divided into three continuous sealed working chambers by the openable first door 2 and the second door 3, and the three continuous sealed working chambers are flour storage chamber 4 and noodle chamber 5 in turn. And the dough holding chamber 6;

[0041] A vacuuming device is connected to the three consecutive sealed working chambers through pipelines, so that the three consecutive sealed working chambers are selectively vacuumed during the process of feeding, kneading and coming out. Wherein, the vacuum device includes a vacuum tube 7 and a vacuum pump connected thereto.

[0042] In order to complete the kneading operation, the kneading room is also provided with: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com