Online monitoring device for sheet resistance of metallized film

A metallized film and monitoring device technology, applied in measurement devices, optical devices, instruments, etc., can solve problems affecting coating quality, contact measurement, difficult measurement, etc., to ensure vacuum environment, improve quality, and realize online monitoring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

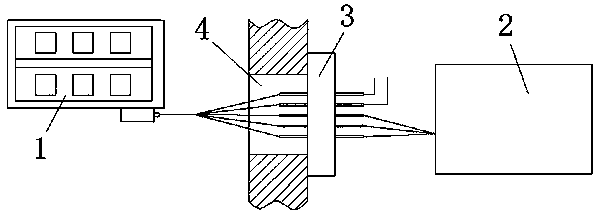

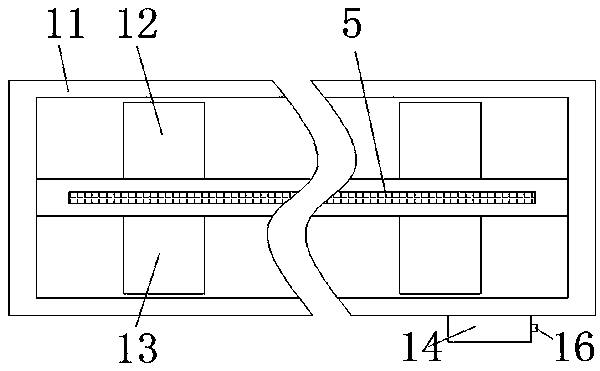

[0017] Such as Figure 1-2 As shown, a metallized film square resistance online monitoring device of the present invention includes a measurement and control host (1) installed in a vacuum evaporation chamber, a man-machine interface (2) installed outside a vacuum evaporation chamber, and a vacuum for electrical connection. Vacuum electrode flanges (3) inside and outside the evaporation chamber; the measurement and control host includes a frame (11), a controller (14) fixed on the vertical surface of the frame (11), a controller (14) fixed on the frame (11) At least one pair of light source emitting heads (12) and light source receiving heads (13) on the horizontal plane, the controller (14) at least includes a pair of light source emitting output ports and light source receiving input ports for realizing optical density testing, and for The electric interface (16) that realizes the power supply of the measurement and control host (1) and the communication of the man-machine i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com