Auto-control system for electrolysis ingredient of aluminum

A technology of automatic control system and batching system, which is applied in the field of control system of aluminum electrolysis production process, can solve the problems of inaccurate measurement, failure to meet the downstream process-material conveying system, and impossible to achieve uniform batching, so as to achieve uniform batching , Solve the continuous effect of continuous discharge and material conveying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

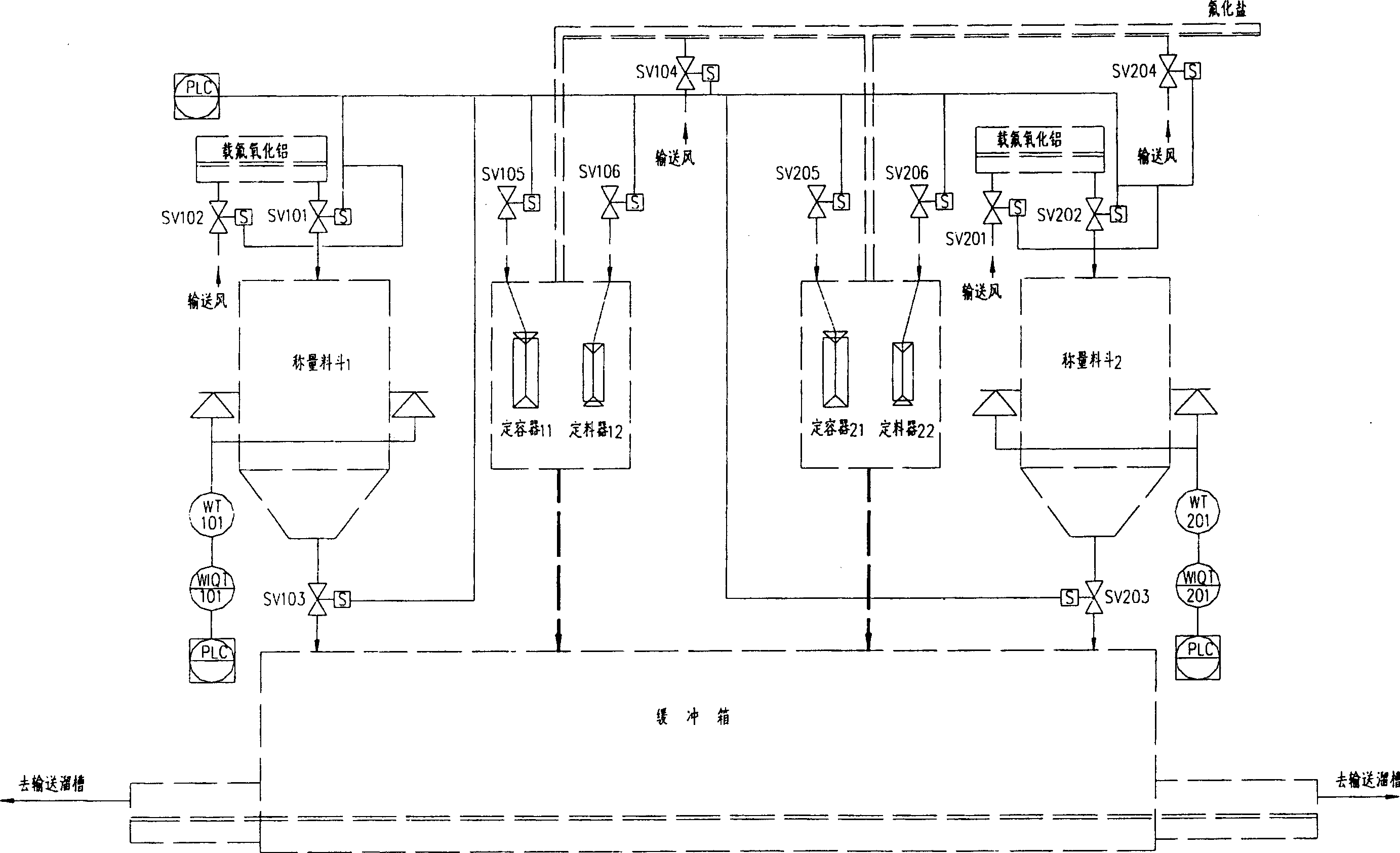

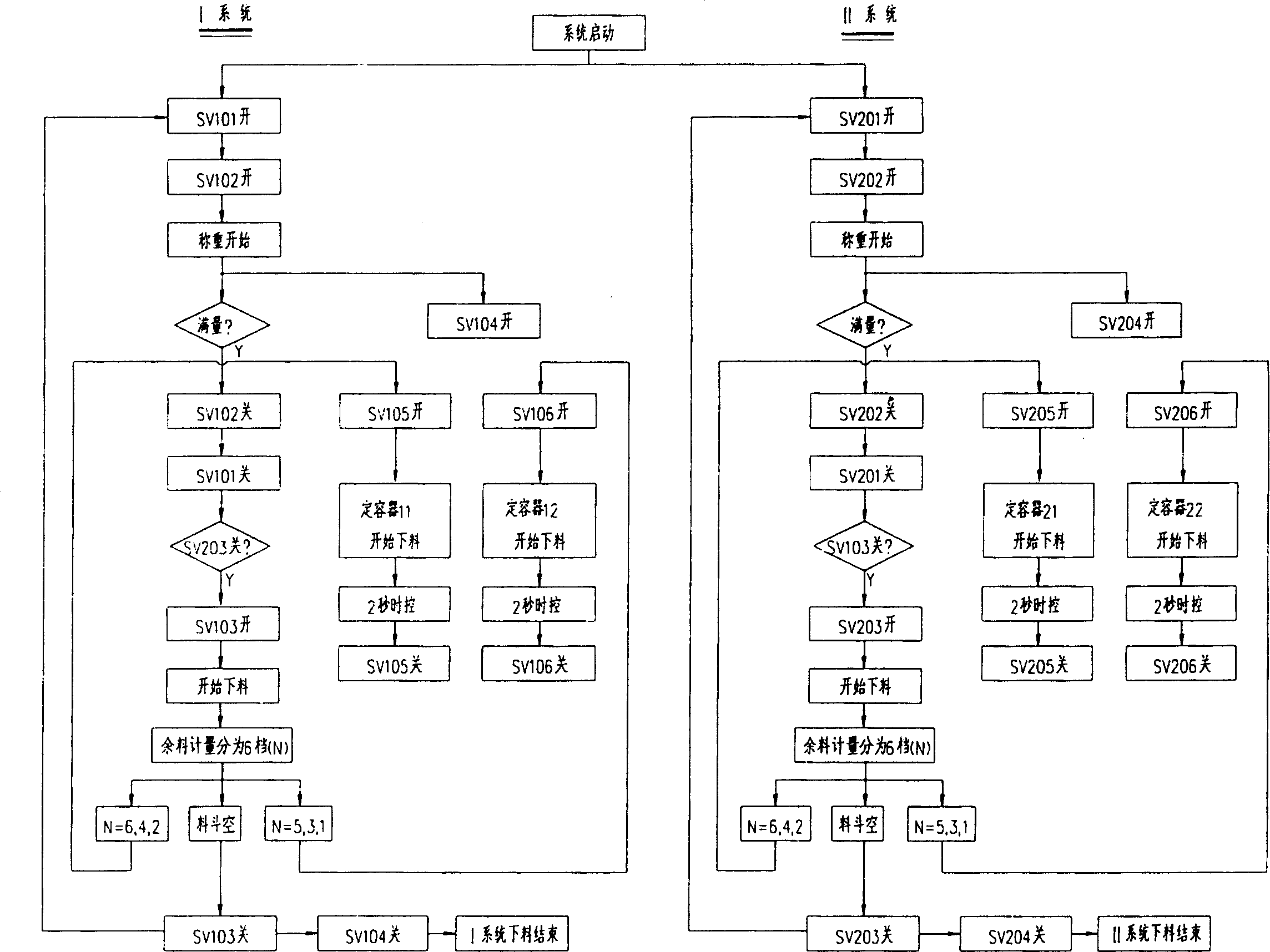

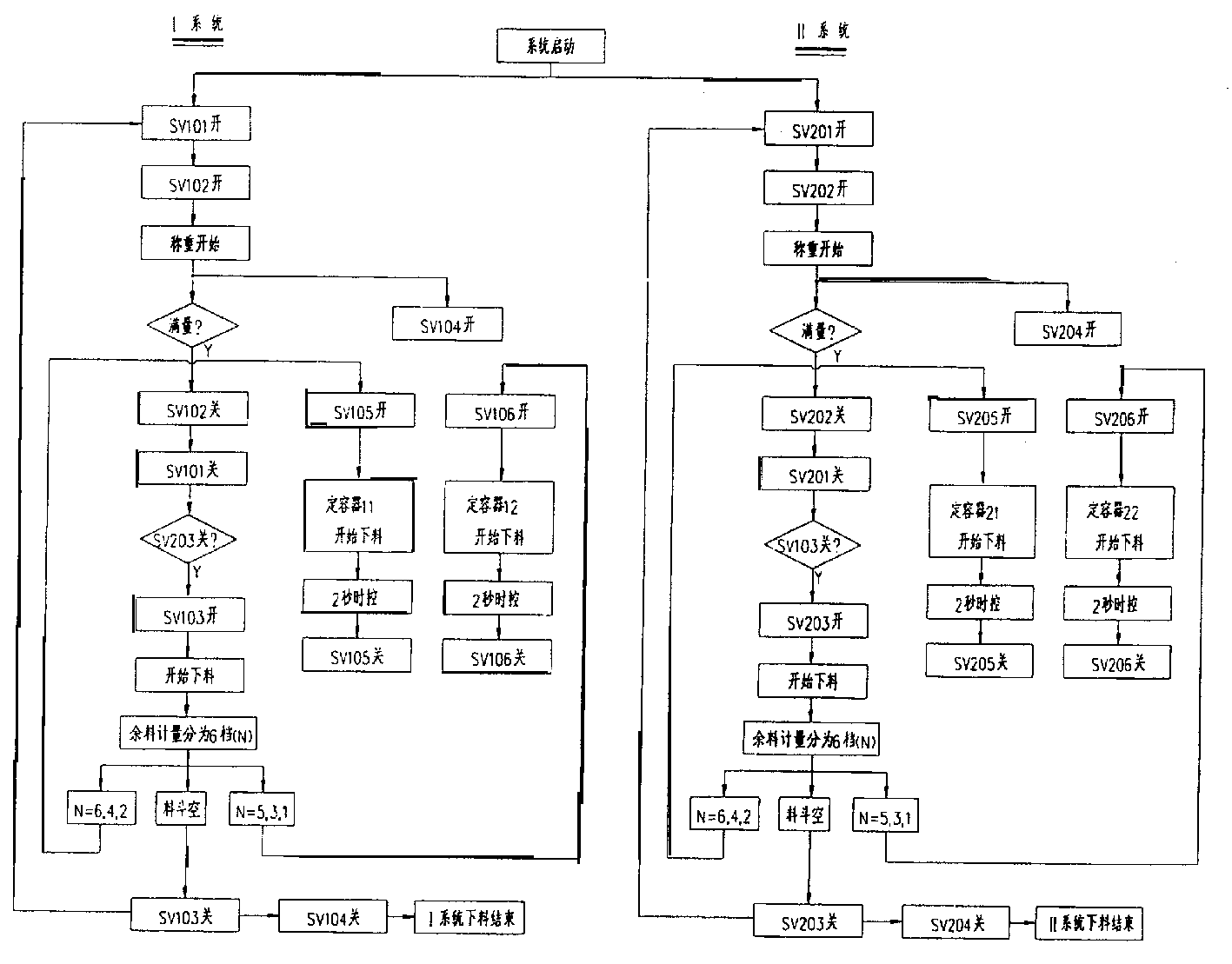

[0011] Fluorine-loaded alumina weighing hopper 1, constant containers 11 and 12 in the fluoride salt feed box, solenoid valves SV101, SV102, SV103, SV104, SV105, SV106, pressure sensors and secondary instruments for weighing, fluorine-loaded alumina Fluidized bed, etc., form a system, referred to as I system; fluorine-loaded alumina weighing hopper 2, fixed containers 21 and 22 in the fluoride salt feed box, and electromagnetic valves SV201, SV202, SV203, SV204, SV205, SV206, used for weighing The pressure sensor and secondary instrument, fluorine-carrying alumina ebullating bed, etc., form another system, referred to as II system.

[0012] There is a fluorine-loaded alumina bin above the two fluoride-loaded alumina weighing hoppers, and a pneumatic chute for conveying fluoride salt is above the two fluoride salt feed boxes. The batching system composed of the I system and the II system shares a buffer box, and there is a pneumatic chute at the lower part of the buffer box, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com