Equipment for processing culture medium

A culture medium and equipment technology, which is applied in the field of production equipment for processing the culture medium required for the growth of edible fungi, can solve the problems of large occupation space, reduced production efficiency, large construction investment, etc., and achieves small equipment occupation space, improved production efficiency, The effect of a clean working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

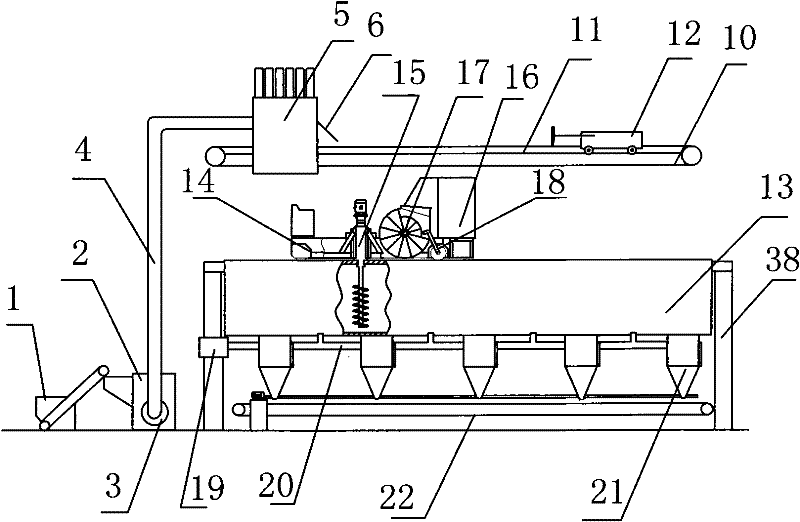

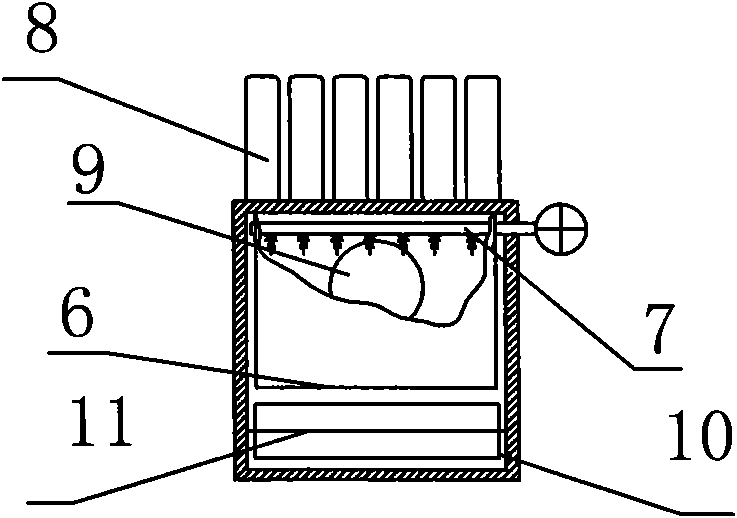

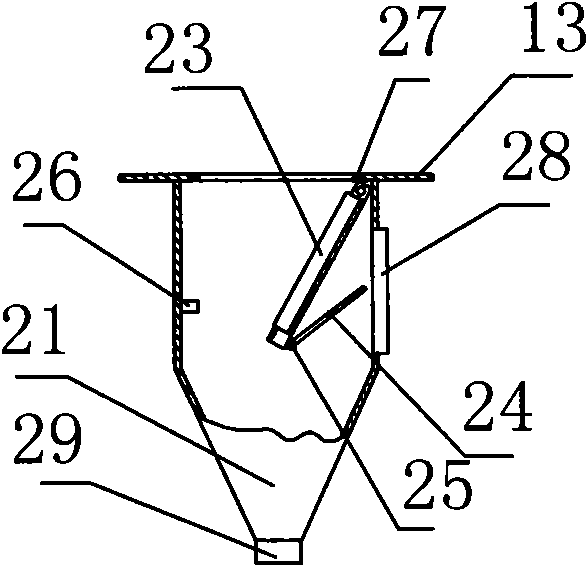

[0022] like figure 1 As shown, the pulverizing device is composed of a feeder 1, a material pulverizer 2, a centrifugal fan 3 and a pulverized material conveying pipeline 4 sequentially connected in series. The feeder 1 is connected to the feed inlet at the upper end of the material pulverizer 2 through a material conveyor belt, the air inlet of the centrifugal fan 3 is connected to the discharge port at the lower end of the material pulverizer 2, and the air outlet of the centrifugal fan 3 is connected to the The connection hole 9 of the dust removal box 5 is provided with a dust-proof curtain 6 on the other side of the dust removal box 5. The left end of the crushed material conveyor belt bracket 10 passes through the lower part of the dust removal box 5, and the crushed material conveyor belt 11 is installed on the crushed material conveyor belt. On the support 10, a blanking car 12 is provided on the pulverized material conveyor belt 11, and the blanking car 12 is made up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com