Cast-in-place pile and construction method thereof

A technology of cast-in-situ piles and pile bodies, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as low strength and poor fit, and achieve the effect of improving strength and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is attached Figure 1-5 The application is described in further detail.

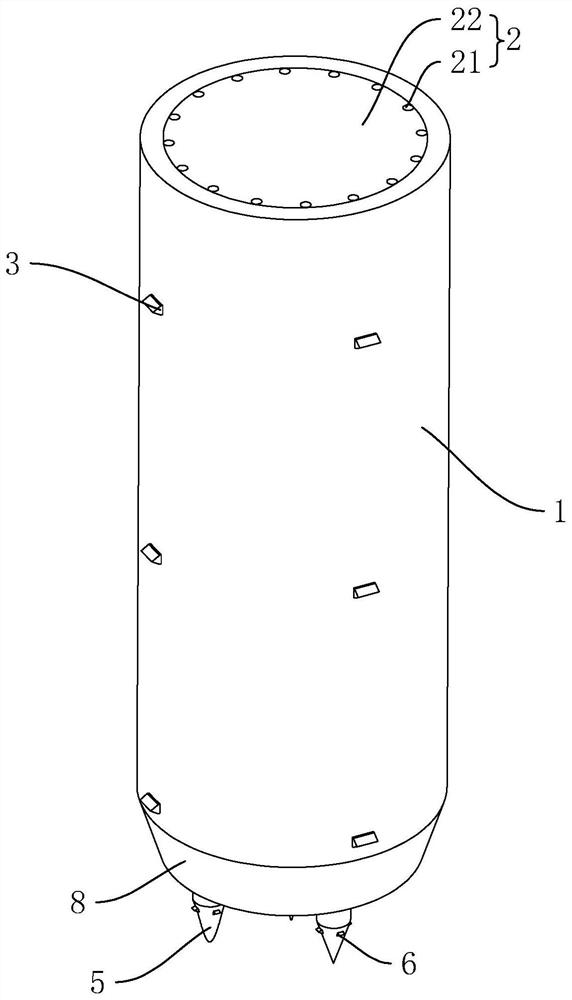

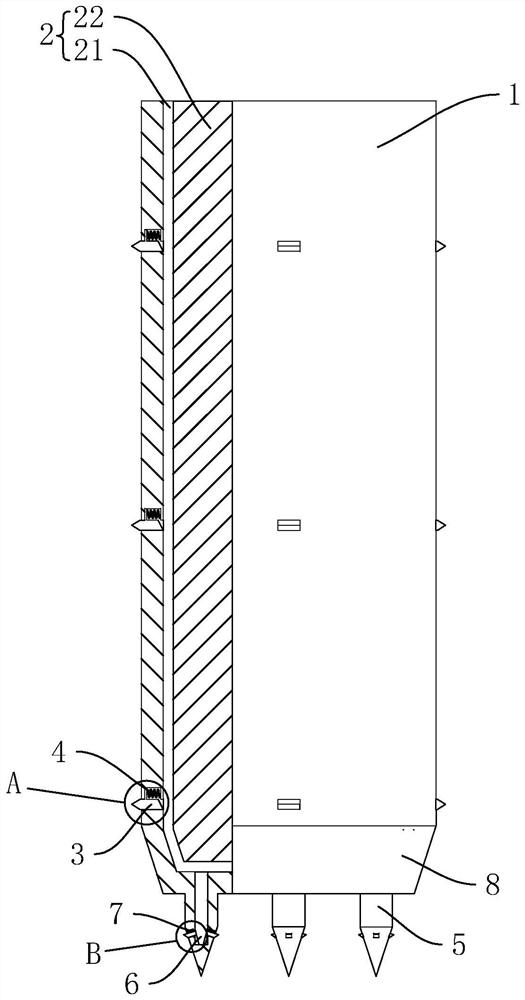

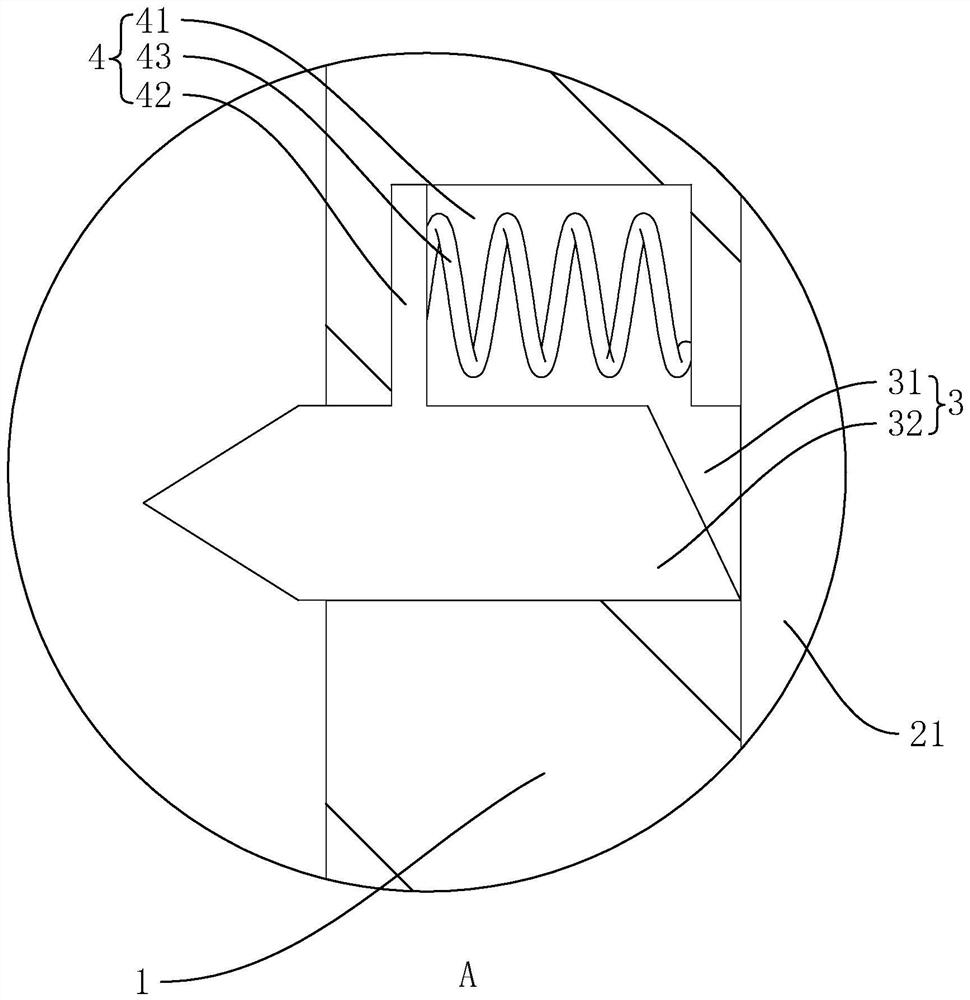

[0045] The embodiment of the present application discloses a cast-in-situ pile, which includes a pile body 1 and a concrete column 2 poured in the pile body 1. The pile body 1 is a cylindrical column body, and a pouring groove is provided in the pile body 1, and the pouring groove is along the length of the pile body 1. The direction extends and runs through one end of the pile body 1 in the length direction. The concrete column 2 is poured from the end of the pouring groove through the pouring groove into the pouring groove. The length direction is divided into three pairs, and each pair has four groups evenly arranged in the circumferential direction of the pile body 1. The reinforcement component 3 includes a reinforcement groove 31 set on the pile body 1 perpendicular to the pile body 1 and a reinforcement groove 31 slidingly arranged in the reinforcement groove 31. Block 32, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com