Multistage dispensing equipment applied to production of regenerative polypropylene

A technology of grade batching and equipment, applied in the field of recycled polypropylene production equipment, can solve the problems of uneven batching and low batching efficiency, and achieve the effect of improving batching efficiency, improving quality and uniform batching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

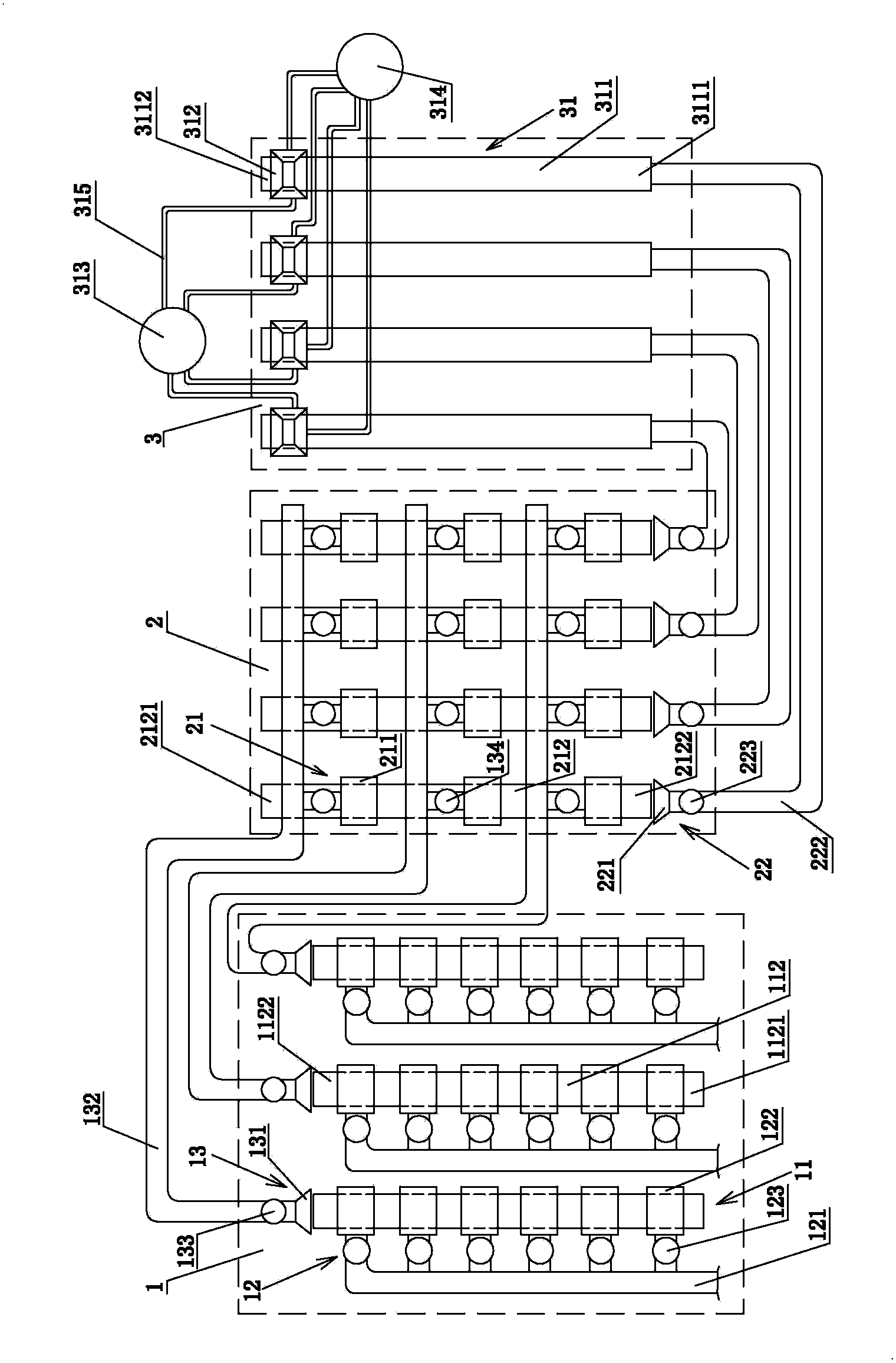

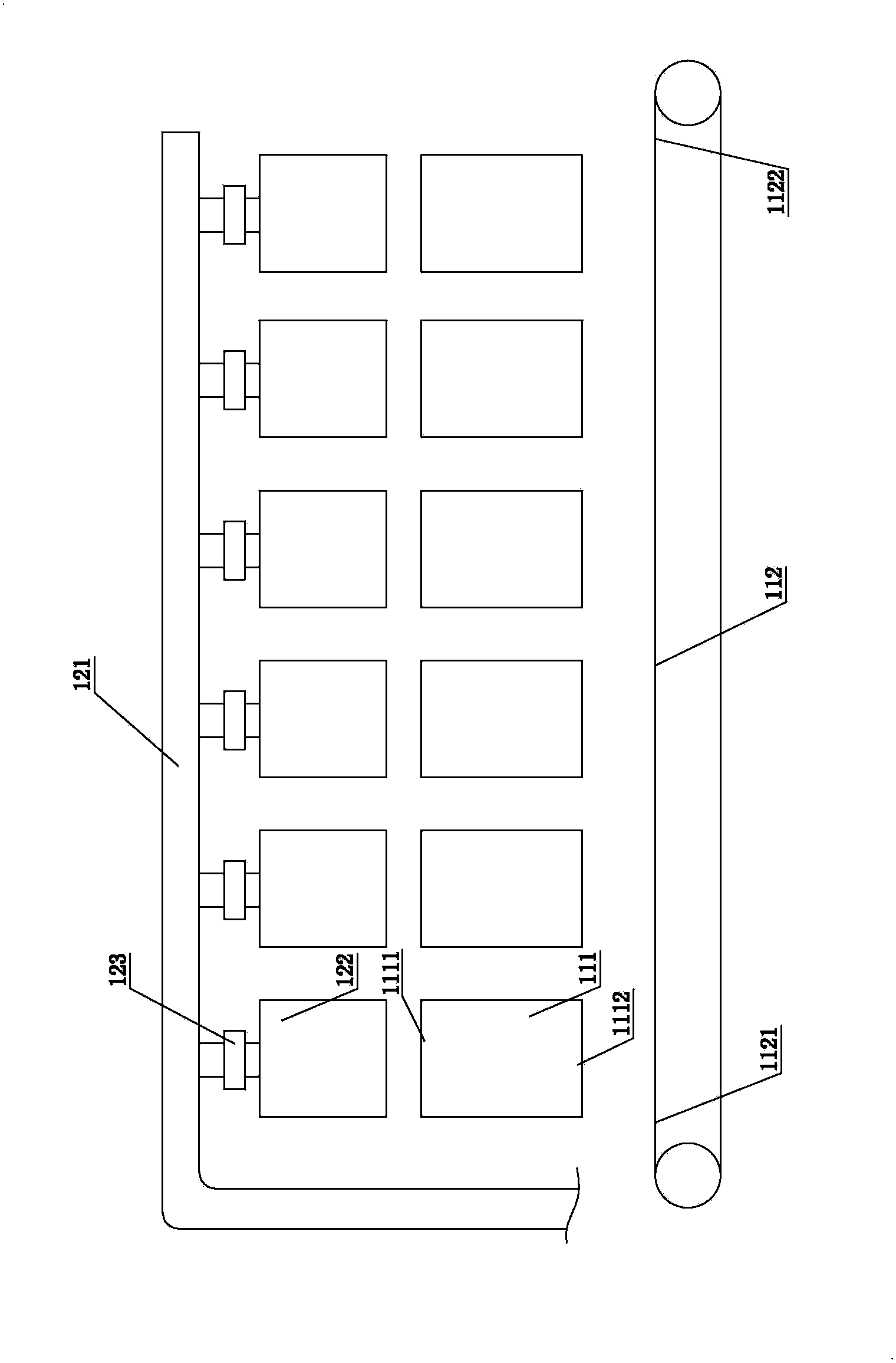

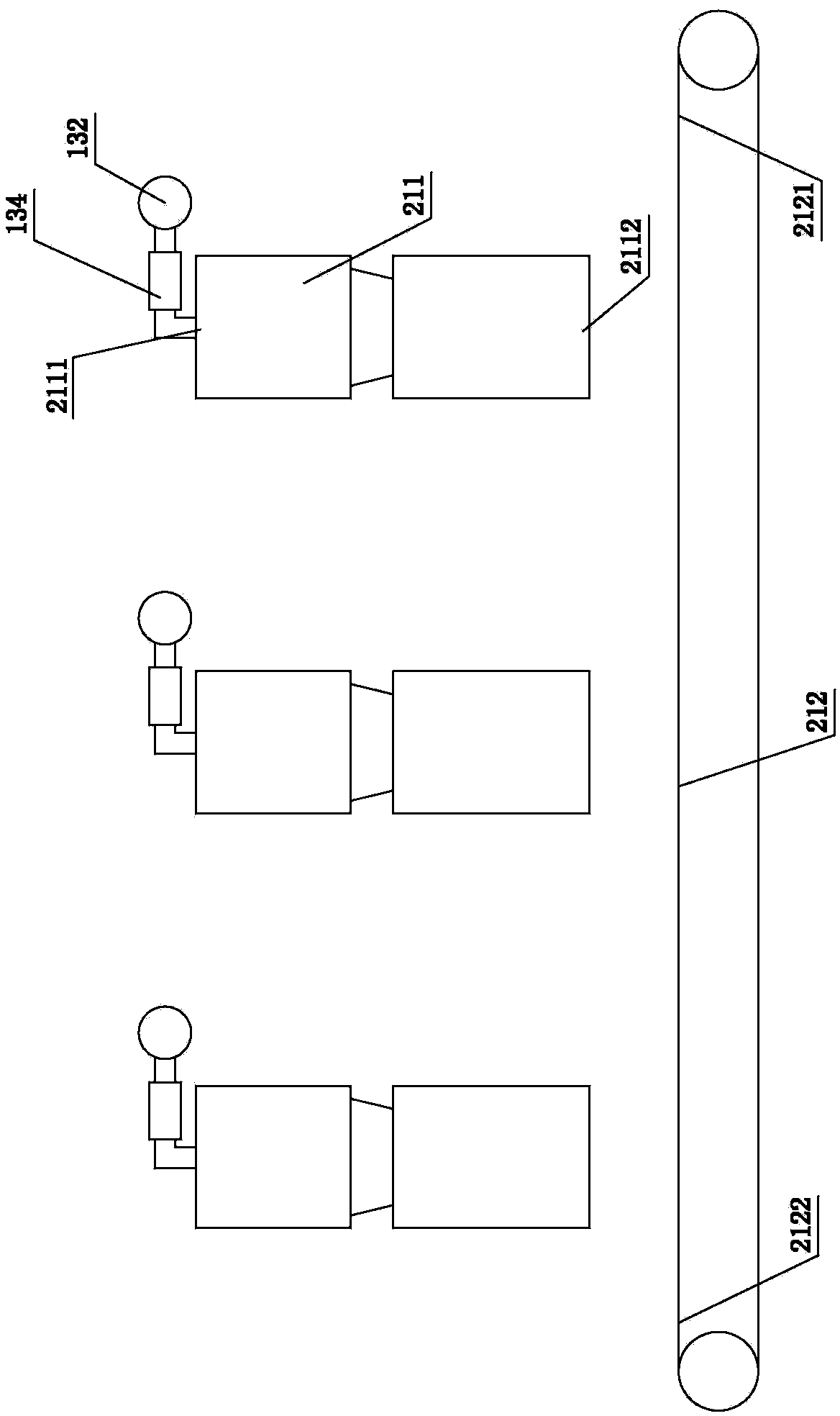

[0018] refer to figure 1 . The multi-level batching equipment applied to the production of recycled polypropylene includes a first-level batching device 1, a second-level batching device 2, and a third-level batching device 3. The first-level batching device 1 includes a plurality of mixing primary materials into secondary materials. The first batching line 11, the secondary batching device 2 includes a plurality of second batching lines 21 that mix the secondary material into a tertiary material, and the tertiary batching device 3 includes a plurality of adding additives to the tertiary material and mixing it into a The third batching line 31 of the fourth grade material. Each of the first batching lines 11 sends the primary material to the first batching line 11 through the first feeding mechanism 12 for mixing ingredients, and each of the first batching lines 11 sends the secondary material through the second feeding mechanism 13. Send to the multiple second batching line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com