Sagger for sintering lithium transition metal oxides and preparation method thereof

A technology of lithium transition metals and saggers, applied in the field of lithium transition metal oxide materials, can solve the problems of saggars' easily eroded surfaces, poor strength of saggers, and poor thermal shock resistance, so as to inhibit surface shedding and easily eliminate stress , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

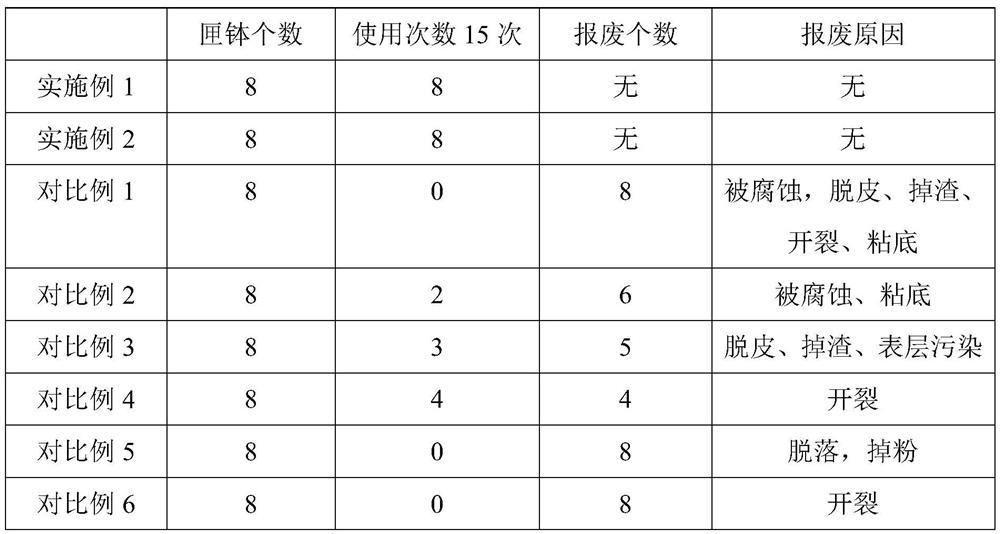

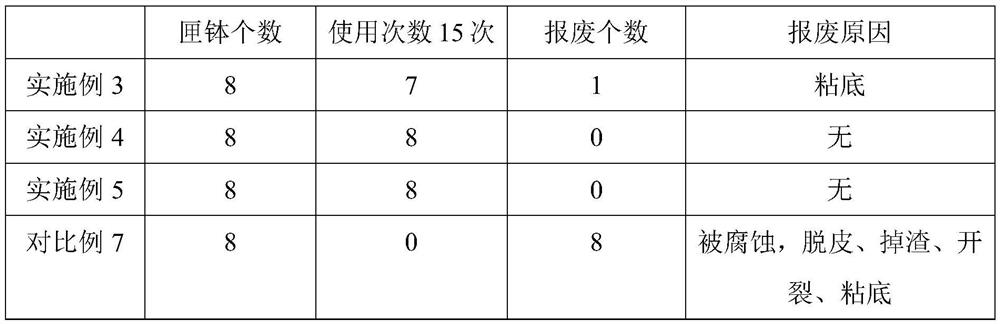

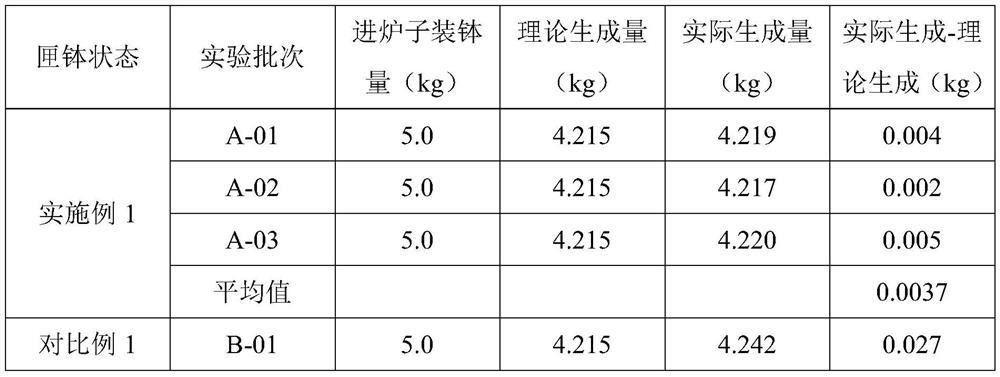

Examples

Embodiment 1

[0042] A preparation method for lithium transition metal oxide sintering sagger, comprising the following steps:

[0043] (1) 100 parts of raw materials for the base layer, prepare 70 parts of high-purity silicon carbide powder, 5 parts of magnesia-aluminum spinel, 10 parts of alumina-magnesium oxide-yttrium oxide composite fiber and 5 parts of zircon powder, and then add the matrix Silica-alumina sol with 10% of the total mass of the layer raw materials is used as a binder;

[0044] (2) The base layer raw material in step (1) is mixed and pulped with deionized water as a medium, and the amount of deionized water is 6% of the total mass of the base layer raw material. After the mixed slurry is evenly stirred, it is aged for 15 hours, and then Press the slurry through the molding equipment to obtain the primary green body;

[0045] (3) 100 parts of the total shallow layer raw materials, prepare 50 parts of high-purity silicon carbide powder, 20 parts of magnesia-aluminum spine...

Embodiment 2

[0050] A preparation method for lithium transition metal oxide sintering sagger, comprising the following steps:

[0051] (1) 100 parts of raw materials for the base layer, prepare 65 parts of high-purity silicon carbide powder, 10 parts of magnesia-aluminum spinel, 15 parts of alumina-magnesium oxide-yttrium oxide composite fiber and 5 parts of zircon powder, and then add the base Silica-alumina sol with 5% of the total mass of the layer raw materials is used as a binder;

[0052] (2) The base layer raw materials of step (1) are mixed and pulped with deionized water as a medium, and the amount of deionized water is 10% of the total mass of the base layer raw materials. After the mixed slurry is evenly stirred, it is aged for 15 hours, and then Press the slurry through the molding equipment to obtain the primary green body;

[0053] (3) 100 parts of the total raw materials for the shallow layer, prepare 40 parts of high-purity silicon carbide powder, 20 parts of magnesia-alum...

Embodiment 3

[0058] The steps of Example 3 are the same as those of Example 1, except that the binding agent used in Example 3 is polyether-modified polydimethylsilane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com