Patents

Literature

76results about How to "Anti-rust effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

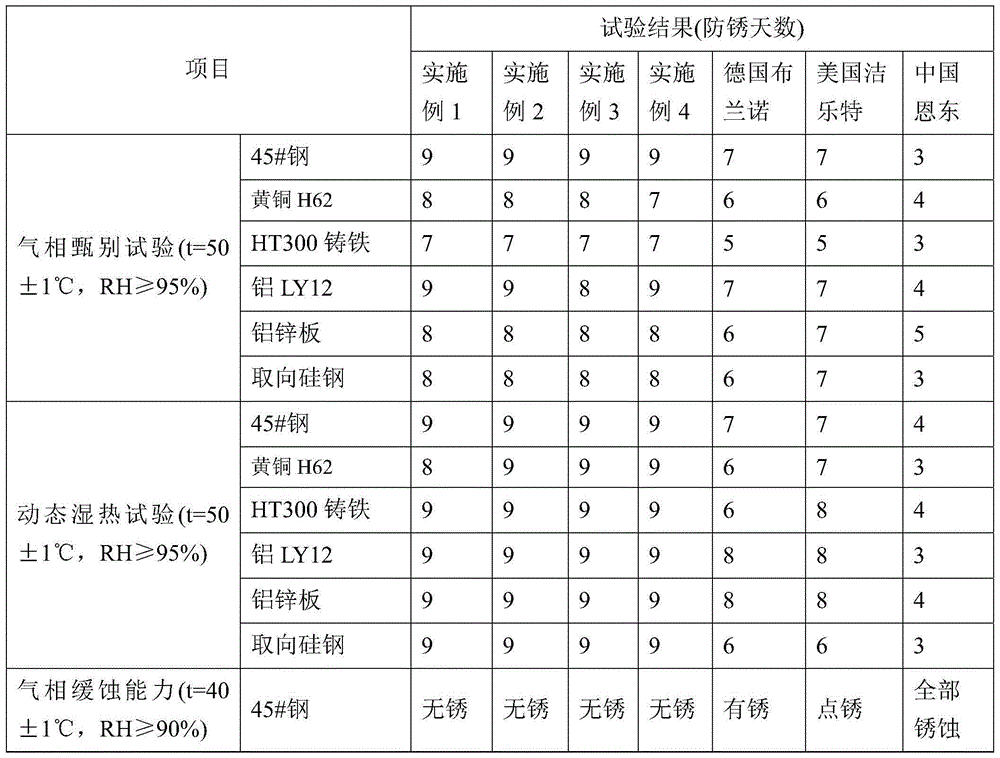

Phytic-acid type gas-phase antirust masterbatch, and preparation method and application thereof

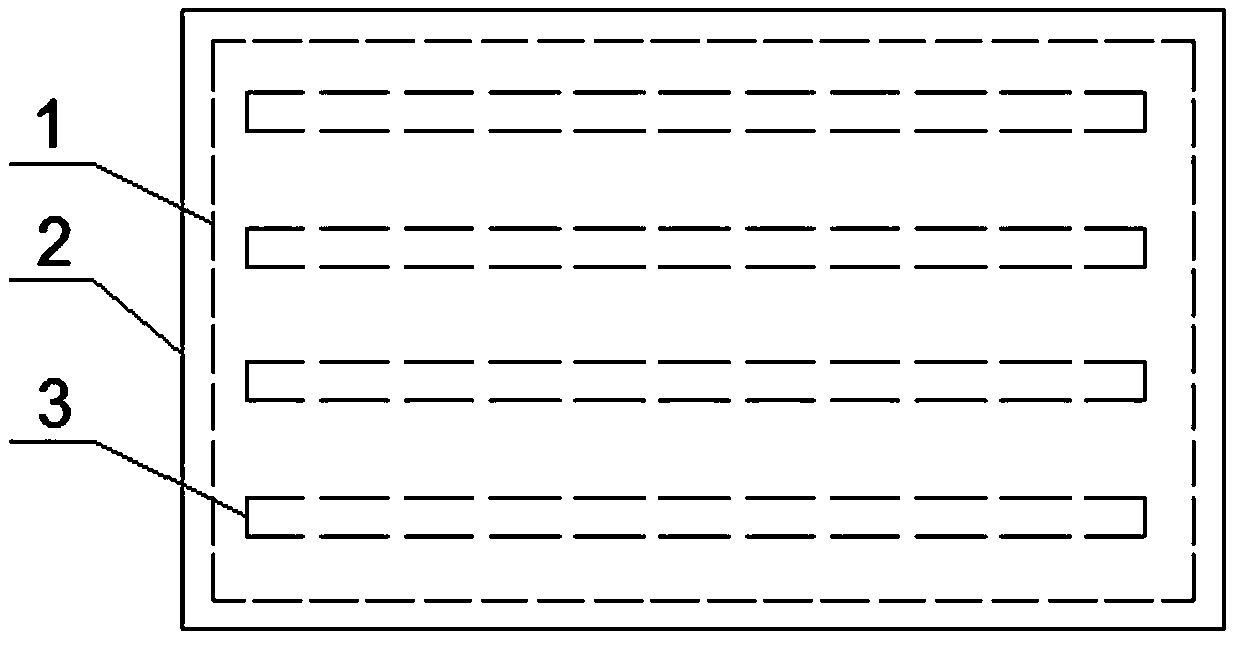

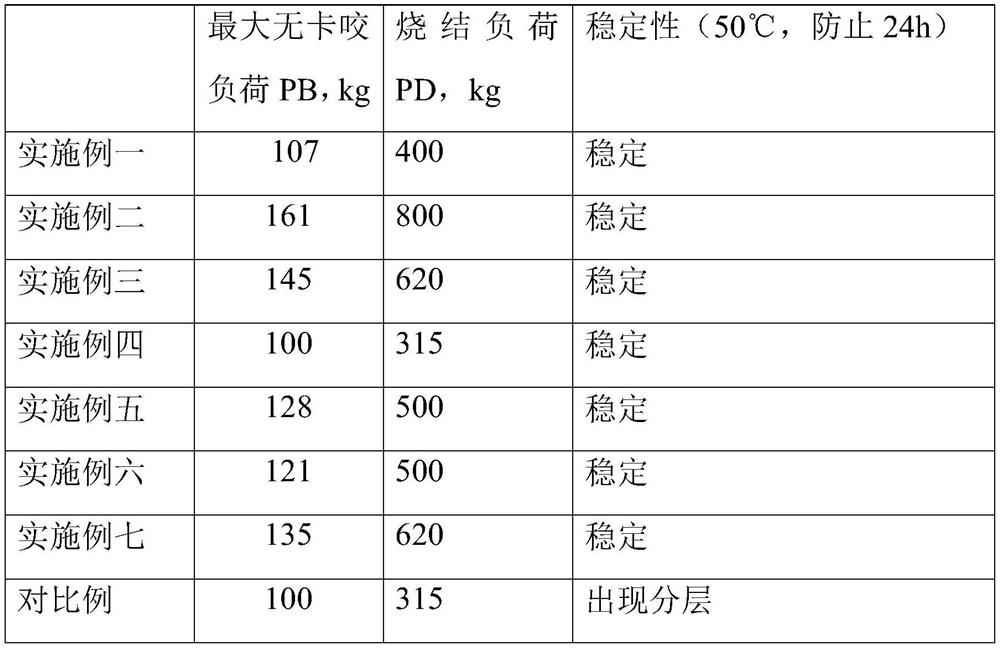

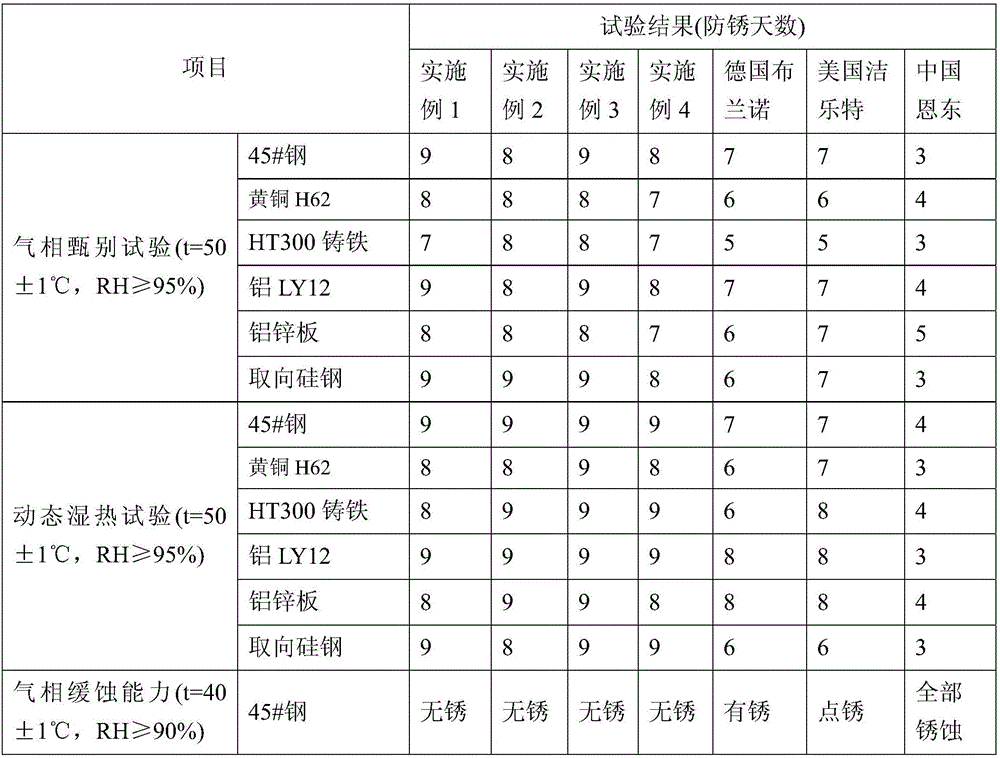

The invention discloses a phytic-acid type gas-phase antirust masterbatch, and a preparation method and application thereof. The antirust masterbatch comprises the following components by weight: 30 to 50% a compound antirust agent, 40 to 60% parts of carrier plastic and 10 to 20% parts of an additive, wherein the compound antirust agent is prepared by mixing sodium benzoate, phytic acid, triethanolamine borate and monoethaneamine benzoate according to a mass ratio of 1.0-1.5: 2.5-3.2: 2.0-3.0: 1.0-1.3, and the additive is prepared by mixing sodium silicate, silicon dioxide, octadecanamide and an antioxidant 1076 according to a mass ratio of 1.0-1.3: 5.0-6.5: 2.5-3.3: 0.8-1.1. According to the invention, a strong chelating agent--alkaline phytic acid is used as a gas-phase corrosion inhibitor; triethanolamine borate is used as the additive; and the compound antirust agent has good dispersion and antirust effects and certain polarity, can penetrate the carrier plastic and volatilize to the surface of wrapped metal so as to form a protective film to block erosion by external corrosion substances, and is also exempt from frost precipitation due to incompatibility with a carrier caused by excessively-strong polarity of the compound antirust agent.

Owner:广州市科迩曼塑料科技有限公司

Multi-metal anti-rusting master batch as well as preparation method and application thereof

The invention discloses multi-metal anti-rusting master batch as well as a preparation method and application thereof. The anti-rusting master batch comprises the following components in percentage by mass: 30-50% of a compounded anti-rusting agent, 40-60% of carrier plastic and 10-20% of an additive, wherein the compounded anti-rusting agent is prepared by mixing sodium benzoate, sebacic acid, triethanolamine boric acid ester and benzotriazole in a mass ratio of (1-1.3):(1.1-1.5):(2.2-3.2):(0.8-1.2); the additive is prepared by mixing stearic acid amino, coarse whiting, sucrose fatty acid ester and an antioxidant 1076 in a mass ratio of (0.9-1.3):(4.8-6.5):(2.5-3.3):(0.8-1.1). When being used as an additive, the triethanolamine boric acid ester has both a dispersion function and an anti-rusting function, the compounded anti-rusting agent has certain polarity and can penetrate the carrier plastic to be volatilized to the surface of packaged metal to form a protecting film, so that corrosion of external corrosive substances is prevented, and the phenomenon that frost separation is generated as the compounded anti-rusting agent is not compatible with the carrier plastic because of the too high polarity is avoided. The multi-metal anti-rusting master batch is free of harmful component, is environment-friendly and safe to use, and has the anti-rusting function on multiple metals.

Owner:青岛鑫盈鑫包装材料有限公司 +1

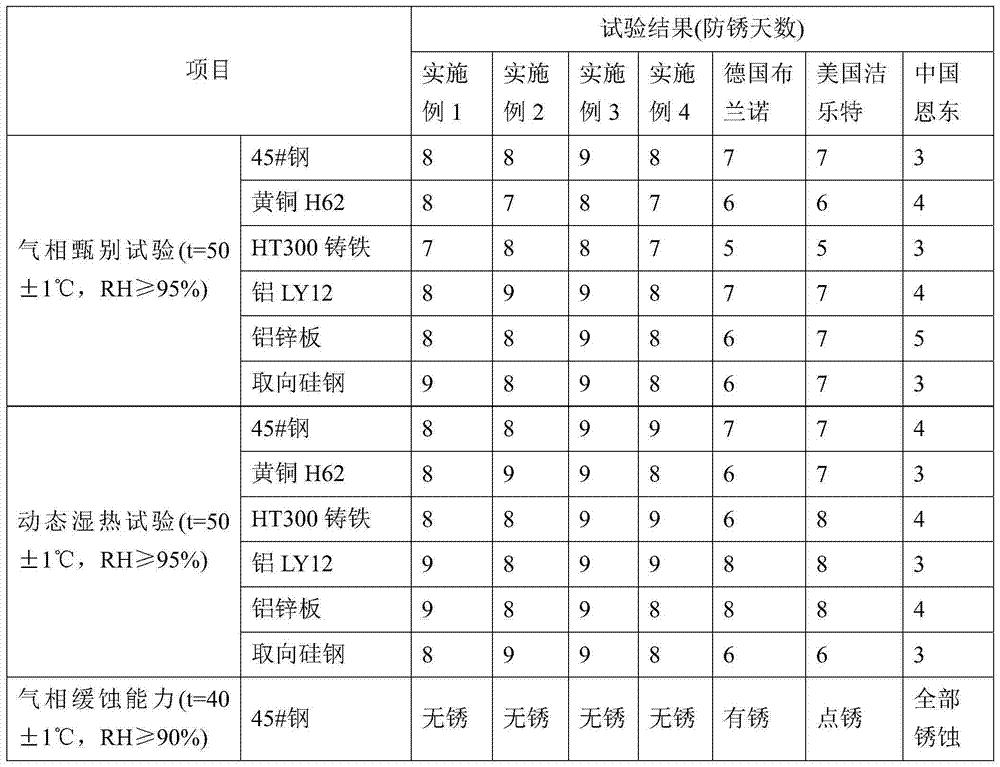

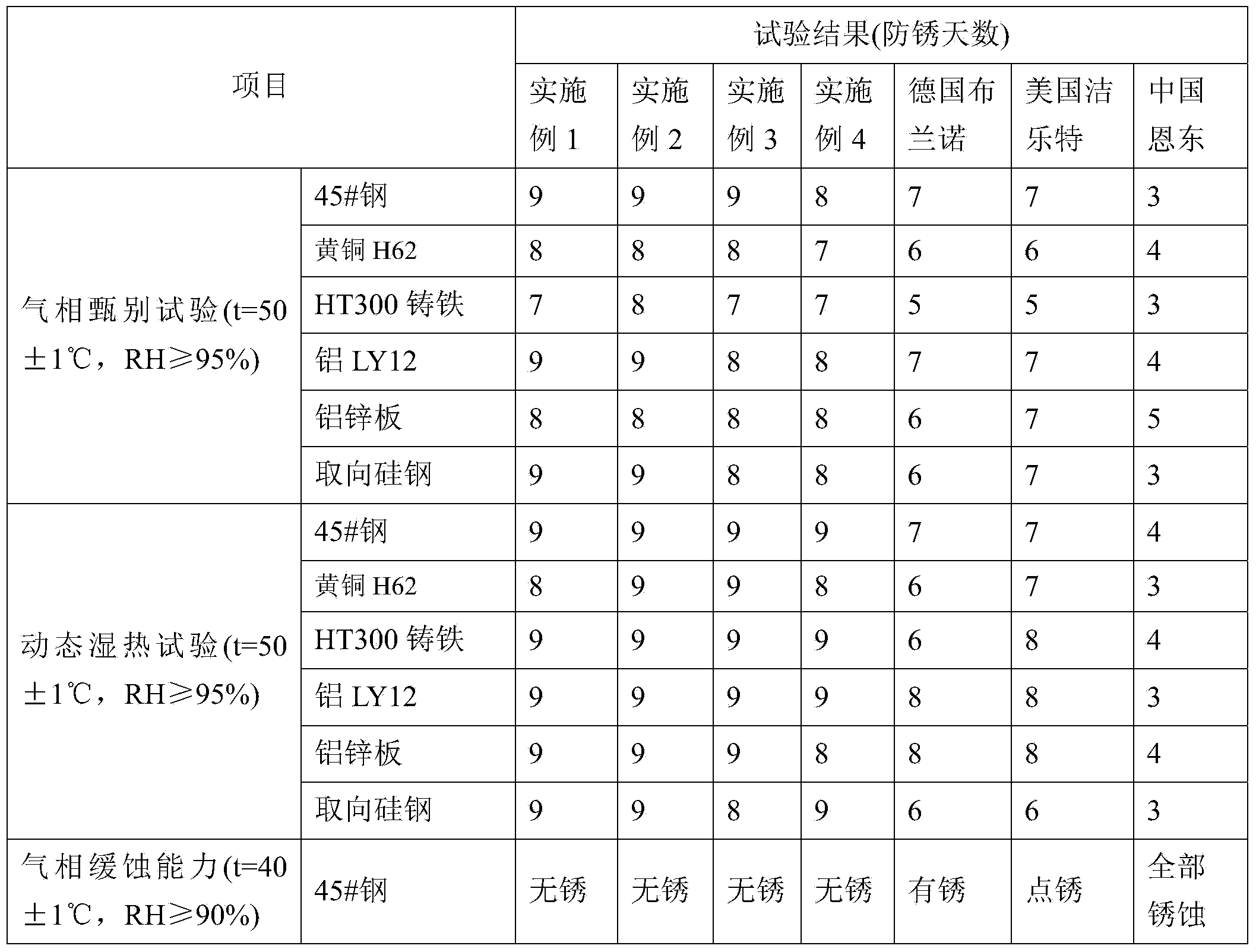

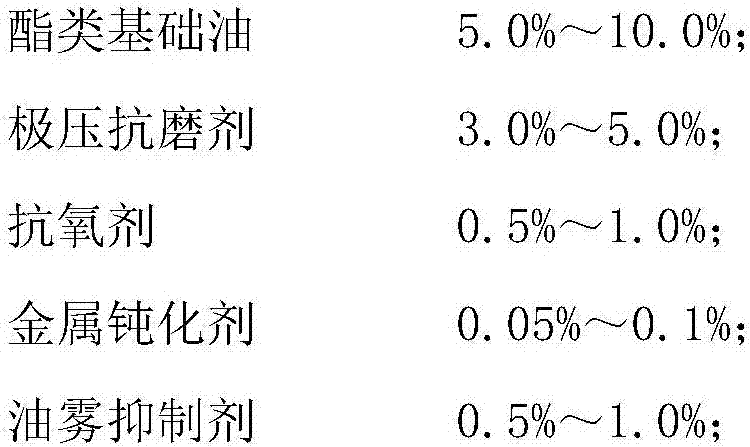

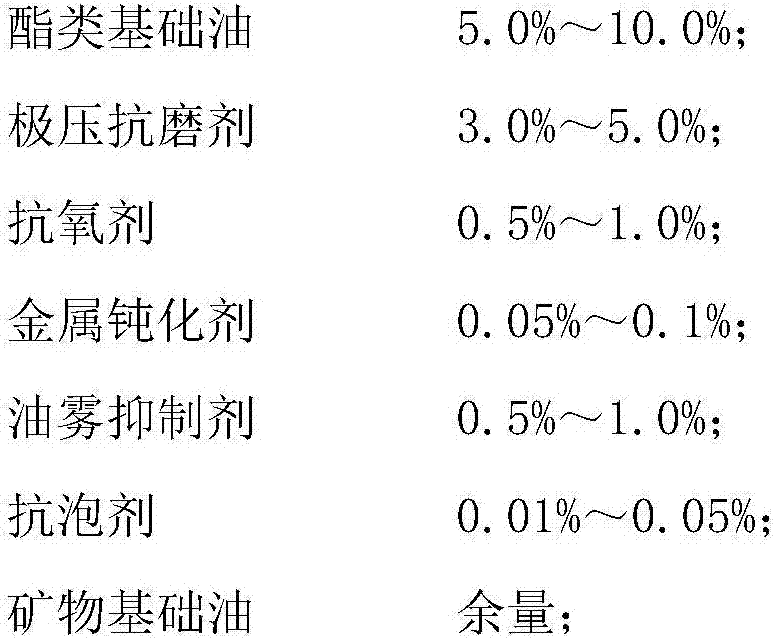

Environmentally-friendly super-finishing grinding oil and preparation method thereof

The invention relates to environmentally-friendly super-finishing grinding oil and a preparation method thereof. The environmentally-friendly super-finishing grinding oil is prepared from, by weight, 5.0%-10.0% of ester base oil, 3.0%-5.0% of an extreme-pressure and anti-wear agent, 0.5%-1.0% of an antioxygen, 0.05%-0.1% of a metal desactivation agent, 0.5%-1.0% of an oil mist inhibitor, 0.01%-0.05% of an anti-foaming agent and mineral base oil balance. The sum of the percentages of the above components is 100%. The environmentally-friendly super-finishing grinding oil has high lubrification, cooling, rust protection and corrosion protection performances; meanwhile, heavy metals, chlorine and low oil mist do not exist in the environmentally-friendly super-finishing grinding oil, so that the environmental-friendly super-finishing grinding oil is harmless to an operator and the environment.

Owner:辽宁海华科技股份有限公司

Water-soluble environment-friendly anti-rusting agent, and preparation method and application thereof

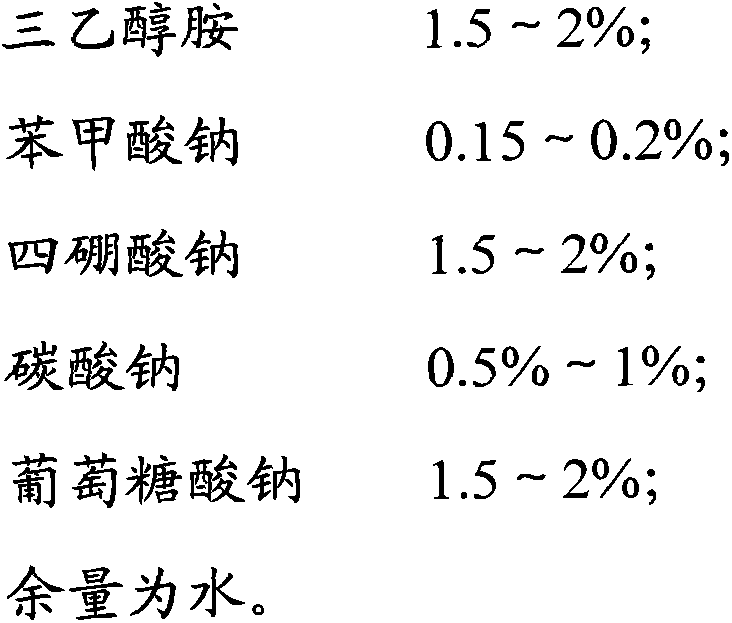

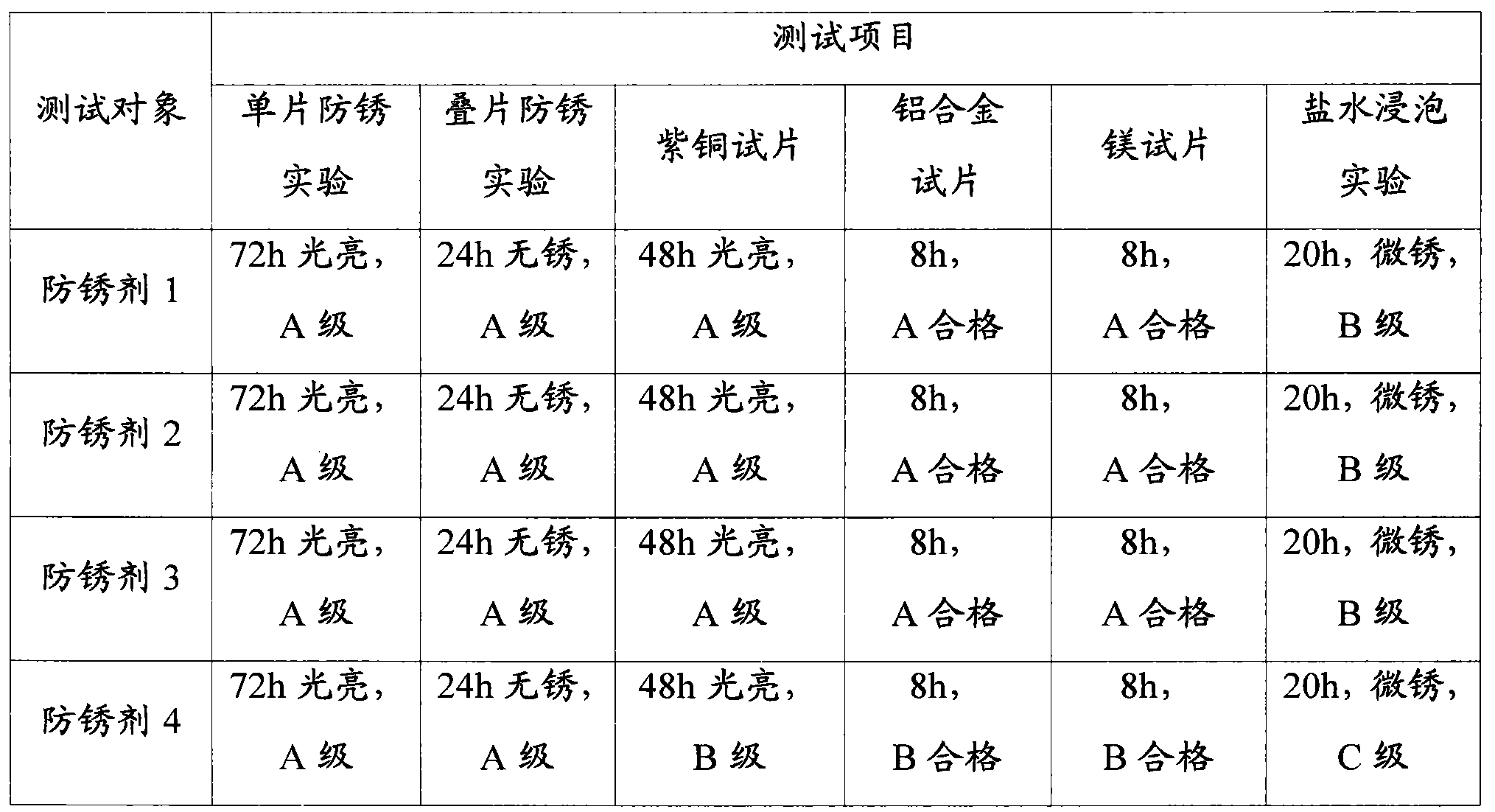

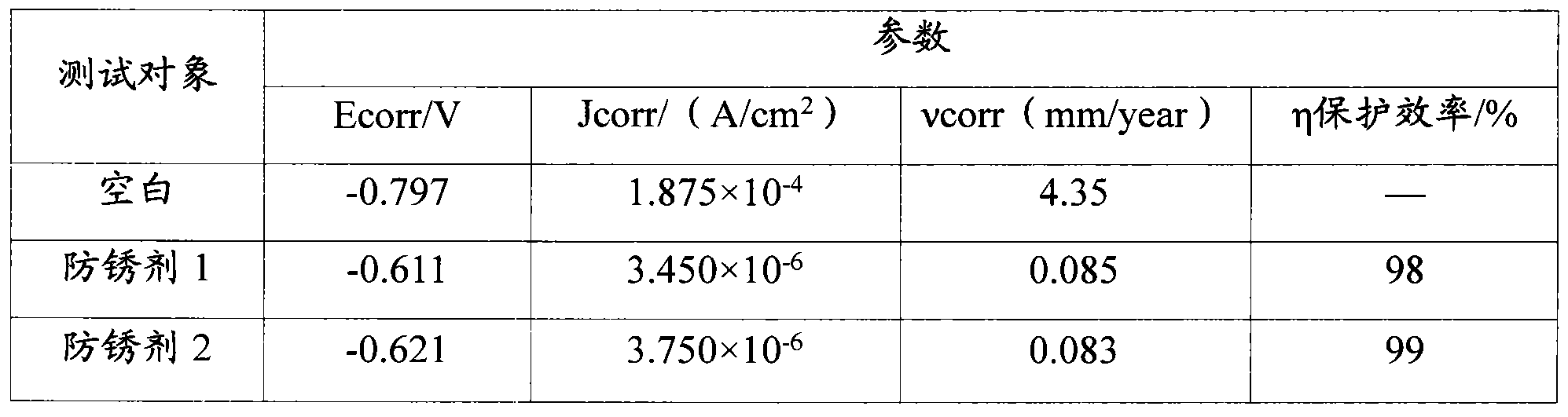

The invention provides a water-soluble environment-friendly anti-rusting agent, and a preparation method and application thereof. The water-soluble environment-friendly anti-rusting agent comprises the following components in percentage by mass: 1.5 to 2 percent triethanolamine, 0.15 to 0.2 percent of sodium benzoate, 1.5 to 2 percent of sodium tetraborate, 0.5 to 1 percent of sodium carbonate, 1.5 to 2 percent of sodium gluconate and the balance of water. The anti-rusting agent is prepared by mixing and uniformly stirring the components, and the pH value of the anti-rusting agent is adjusted to be 8 to 10 by adjusting the amount of each component in a mixing and stirring process. The water-soluble environment-friendly anti-rusting agent can be used for the anti-rusting protection of ferrous metal such as cast iron and steel and nonferrous metal such as copper, aluminum and magnesium, is free of environmental pollution, harmless to a human body, low in cost and easy to prepare, has superior anti-rusting effects, and is applied to the anti-rusting of various kinds of metal, and the required components are simple and easily available.

Owner:SOUTHWEST UNIVERSITY

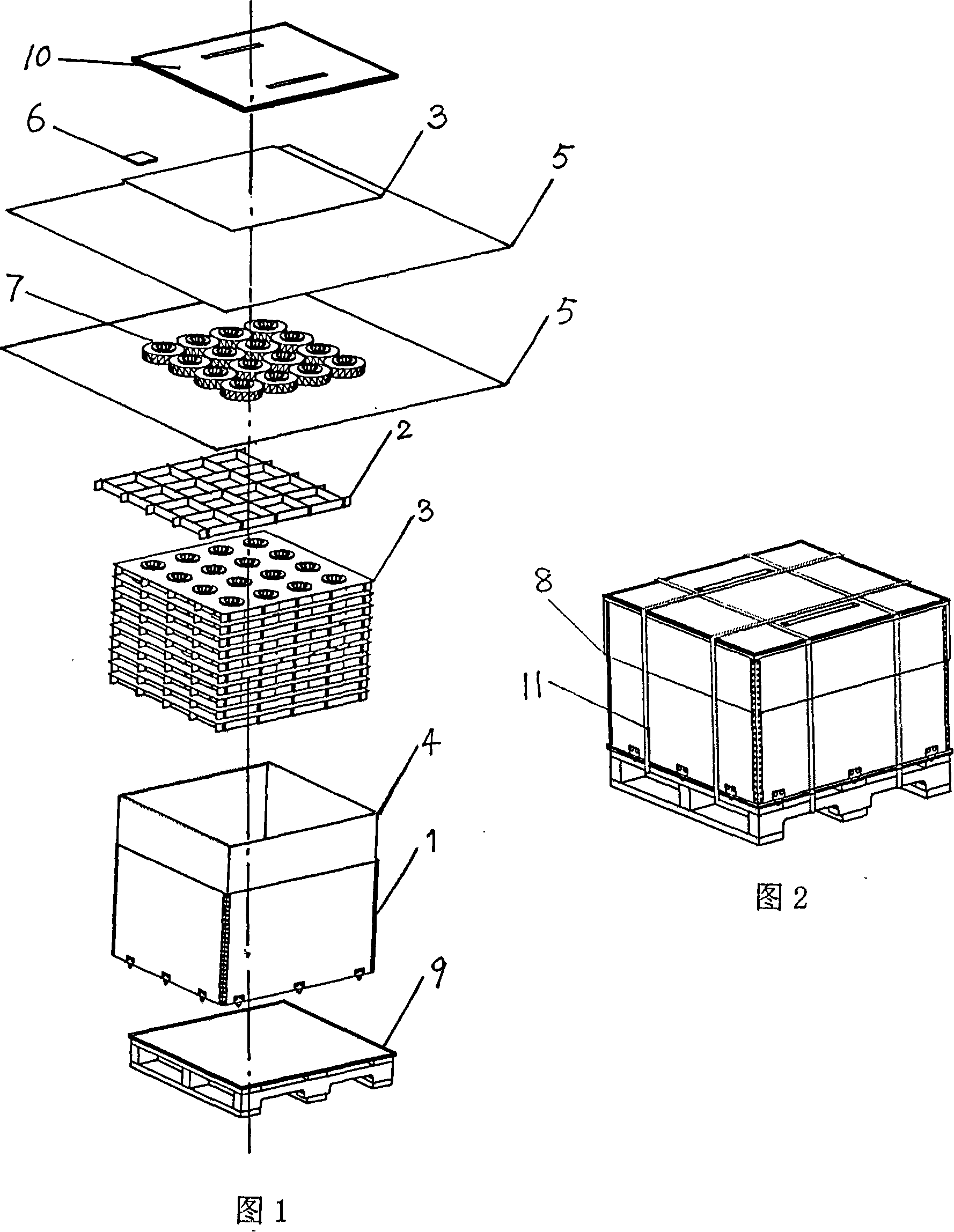

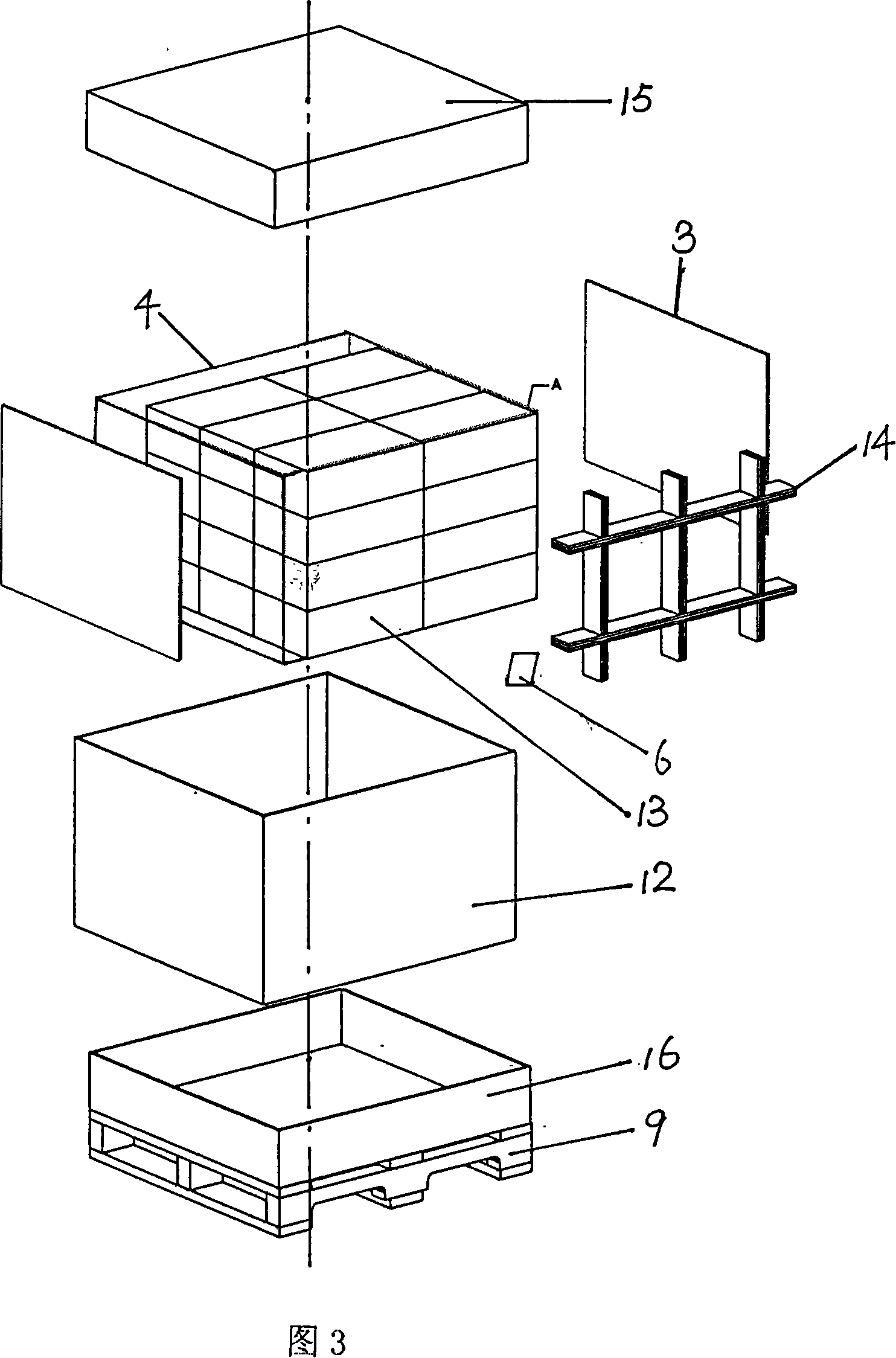

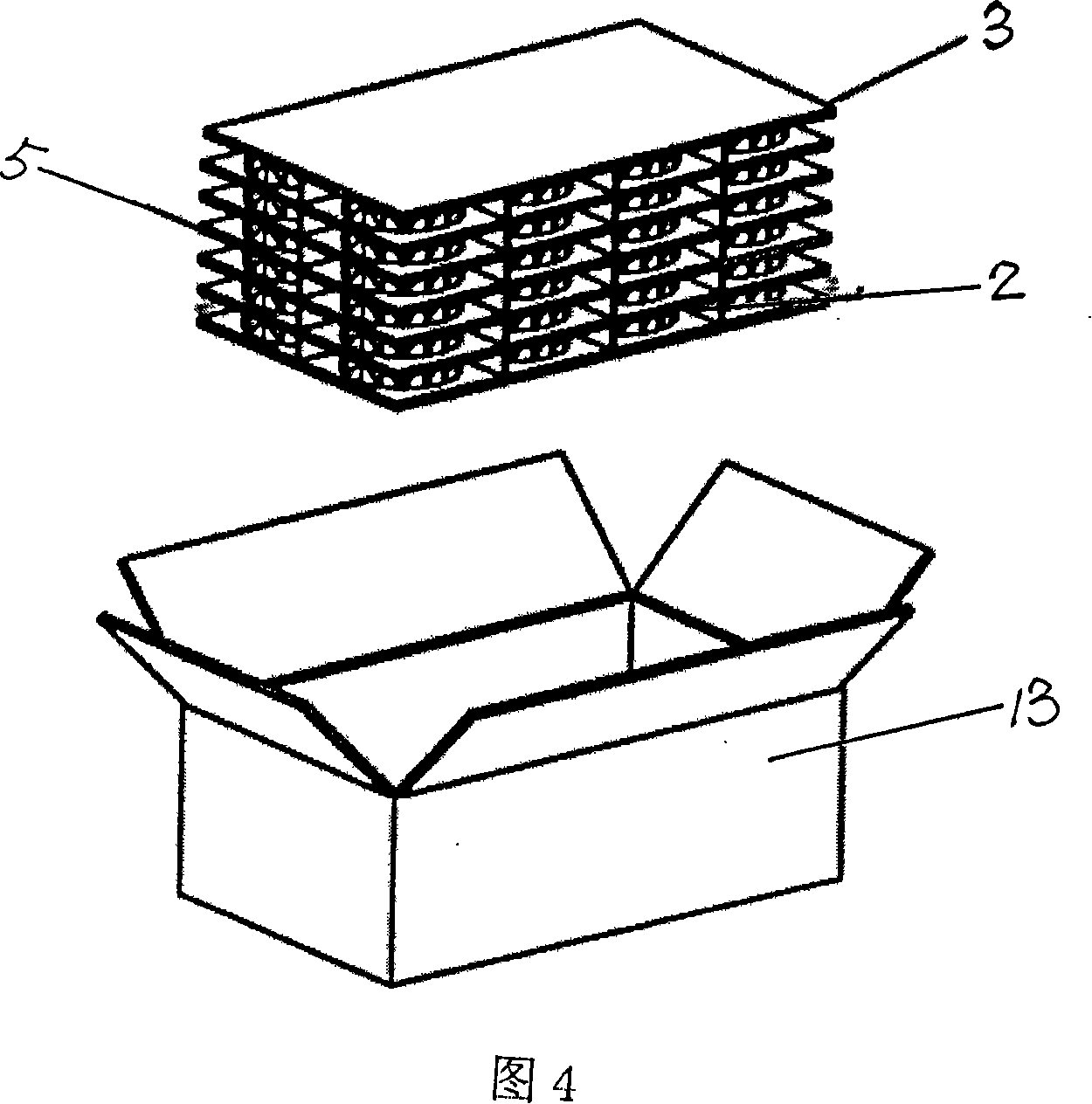

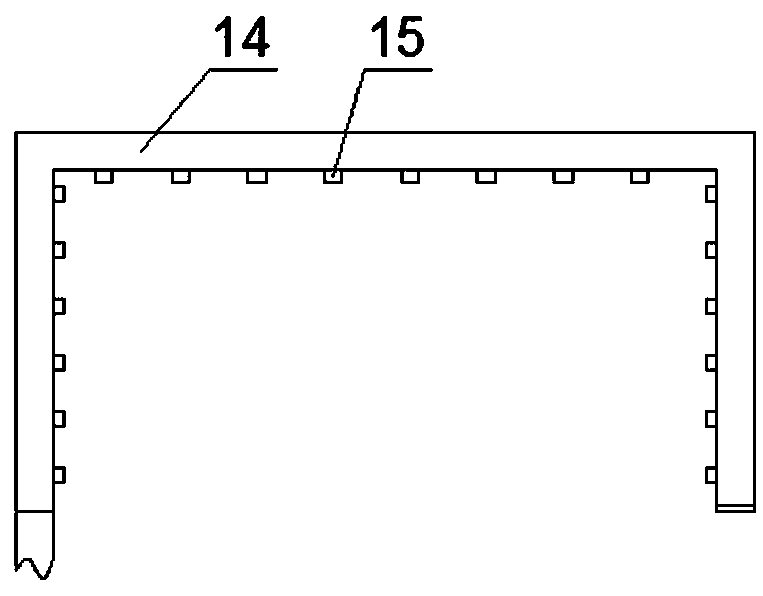

Rust prevention packaging method of metallic product

InactiveCN101108679AAvoid contactPrevent rust and corrosionRigid containersContainers with multiple articlesGas phaseEngineering

The invention belongs to the technology field of the metal product package, in particular to an anti-rust package method of the metal product. The invention solves the problems of poor anti-rust effect or high package cost existing in the anti-rust package of the current metal product. The procedure of the anti-rust package method of the metal product is as follows: an outer package is arranged with gas phase anti-rust bags inside, corrugated boards are rolled out; corrugated paper is added in to separate; gas phase anti-rust films are added; the metal product is filled; the gas phase anti-rust films are covered; the corrugated boards and dryers are added; gas phase anti-rust bags are arranged; the outer package is closed and is externally covered with PE rainproof films and PET is bound. The invention has the beneficial effects of oil-saving, environmental protection, anti rust, firm structure, simple technic, long anti-rust period and high reliability.

Owner:SHANXI DATONG GEAR GROUP

Anticorrosive paint for building materials and preparation method thereof

InactiveCN111363443AGood film formingStrong adhesionAnti-corrosive paintsArchitectural engineeringGraphite

The invention discloses an anticorrosive paint for building materials. The anticorrosive paint is prepared from the following raw materials in parts by weight: 40-50 parts of modified acrylic emulsion, 0.8-1 part of modified graphene, 9-13 parts of titanium dioxide, 8-10 parts of talcum powder, 1.2-1.6 parts of an antirust additive, 5-6 parts of an assistant and 20-30 parts of deionized water. Theinvention also discloses a preparation method of the anticorrosive paint. Modified acrylic emulsion is used as a film-forming substance of the paint, so that the paint not only has a good film-forming property and adhesive force, but also has excellent water resistance and aging resistance. By adding the antirust additive, an antirust effect can be achieved, and a corrosion inhibition function isachieved. Modified graphene is added to serve as an excellent shielding layer, so that the contact between building materials and a corrosive medium is prevented, and the corrosion resistance is enhanced. The paint is better combined with a matrix, and plays corresponding effects more easily. The aqueous anticorrosive paint has an excellent comprehensive performance and is suitable for protectingmetal building materials.

Owner:杨海青

Novel water-based flame-retardant paint

InactiveCN105349016AStrong corrosion resistanceStrong adhesionFireproof paintsAnti-corrosive paintsSolventEmulsion

The invention discloses novel water-based flame-retardant paint. The novel water-based flame-retardant paint is prepared from, by weight, 100-150 parts of water-based polyurethane emulsion, 40-60 parts of epoxy resin, 15-20 parts of hydroxyethyl cellulose, 32-45 parts of aluminum triphosphate, 20-40 parts of mixed solvent of absolute ethyl alcohol and N,N-dimethylformamide by the volume ratio of 1:20-1:2, 14-28 parts of a nitrogen-phosphorous compound flame retardant, 6.5-7.3 parts of methyl dimethyl phosphate, 3.8-4.5 parts of an isocyanate compound and 1.4-2.8 parts of a defoaming agent. The paint is high in flame-retardant property and paint adhesion, has an anti-rust effect and high water resistance on a smearing face, reduces environmental pollution, is small in damage to the human body and reaches the environmental protection standard of paint.

Owner:NANJING CHANGJIANG PAINT

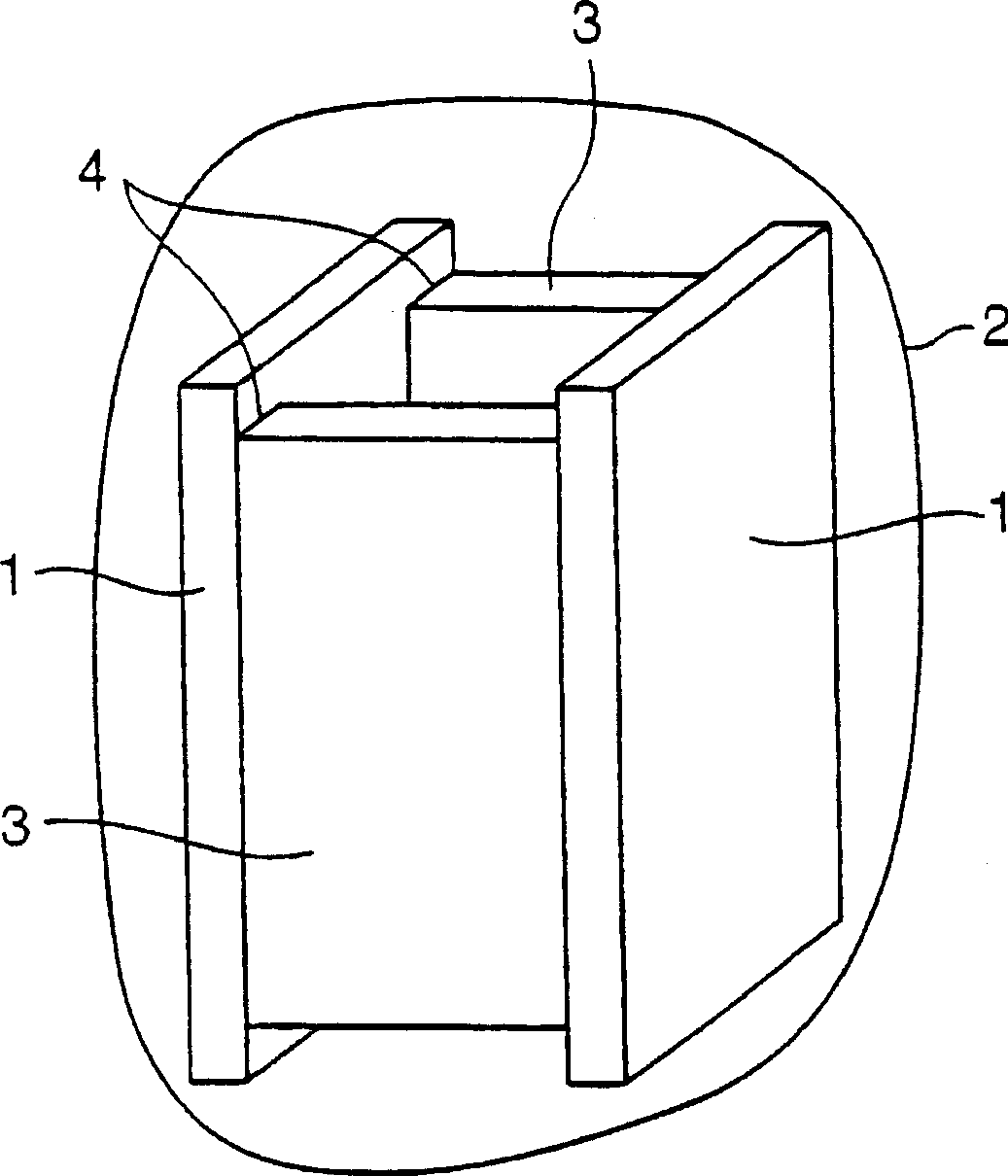

Volatile corrosion inhibitor, and forming material and formed article using the same

A volatile corrosion inhibitor to be kneaded into a resin of the present invention comprises a nitrous acid metal salt, a benzoic acid metal salt, a saturated polycarboxylic acid or a metal salt thereof, and an anticorrosive component for nonferrous metals. The volatile corrosion inhibitor to be kneaded into a resin does not cause melting, gasification, decomposition, vaporization even when exposed to a high temperature condition for molding a thermoplastic resins into an article in a form of films, sheets or fibers. Further, the volatile corrosion inhibitor is free of generation of offensive odor or dust caused by sublimation. As the result, working environment does not deteriorate, and superior anticorrosive ability with respect to nonferrous metal materials such as copper as well as to iron based metal materials is exhibited. In addition, the present invention relates also to a volatile anticorrosive molding material obtained by kneading the volatile corrosion inhibitor into a resin.

Owner:CHUBU KIRESUTO +1

Composite steel bar rust inhibitor

The invention discloses a composite steel bar rust inhibitor. The steel bar rust inhibitor comprises the following components in percentage by weight: 0.5%-1.5% of sodium silicate, 0.5%-1.0% of sodium molybdate, 0.5%-1.0% of sodium acetate, 0.1%-0.5% of thiourea and the balance of water. The composite steel bar rust inhibitor disclosed by the invention adopts an anode type rust inhibition component, a cathode type rust inhibition component and a hybrid rust inhibition component for compounding, further has the advantages of small using quantity, strong rust inhibition action, strong adsorbability with steel bars and good applicability to concrete, can be directly coated on the surfaces of the steel bars to generate a compact protective film, can improve the effective utilization rate of the rust inhibitor, play a rust inhibition role while not affecting the performances of the concrete, and effectively retard and prevent the corrosion of the steel bars in the reinforced concrete, has the characteristics of no nitrites, no alkali, no toxin, no pollution and the like, and can be widely used for reinforced concrete structures of water conservation, railway, civil buildings and the like.

Owner:LUOYANG INST OF SCI & TECH

Environment-friendly metal antirust paint

InactiveCN103497655ARaise the ratioLow costAnti-corrosive paintsPolyester coatingsAcetic acidIron oxide

The invention discloses an environment-friendly metal antirust paint. The environment-friendly metal antirust paint is formed by mixing the following components in percentage by volume: 10%-20% of alkyd resin, 10%-12% of barium sulfate, 5-7% of iron oxide red, 1%-2% of titanium dioxide, 10%-20% of hydroxyacetic acid, 5%-10% of eleostearic acid, 1%-2% of sodium nitrite and the balance of deionized water. The environment-friendly metal antirust paint has the advantages of being simple in matching, low in cost, colorless, tasteless, environment-friendly and practical and having an anti-rust effect.

Owner:QINGDAO SANLI XINYUAN ELECTRICAL APPLIANCES

High-performance steel bar corrosion inhibitor

The invention discloses a high-performance steel bar corrosion inhibitor, belonging to the technical field of building materials. The corrosion inhibitor is composed of the following components in percentage by mass: 0.2-0.4% of sodium molybdate, 0.2-0.4% of sodium citrate, 0.02-0.04% of thiocarbamide, 0.02-0.04% of neodymium sulfate and the balance of water. By compounding the anode corrosion inhibition component with the mixed corrosion inhibition component, the corrosion inhibitor has the advantages of high adsorptive power with steel bars, favorable adaptability to concrete and high corrosion resistance, can be directly incorporated into concrete, can form a compact protective film on the steel bar surface, does not influence the concrete performance, can perform the corrosion inhibition function on the steel bars, has the characteristics of high efficiency, no toxicity, no pollution and the like, is a high-performance steel bar corrosion inhibitor, and can be used for reinforced concrete structures in water conservancy, railways, civil buildings and the like.

Owner:LUOYANG INST OF SCI & TECH

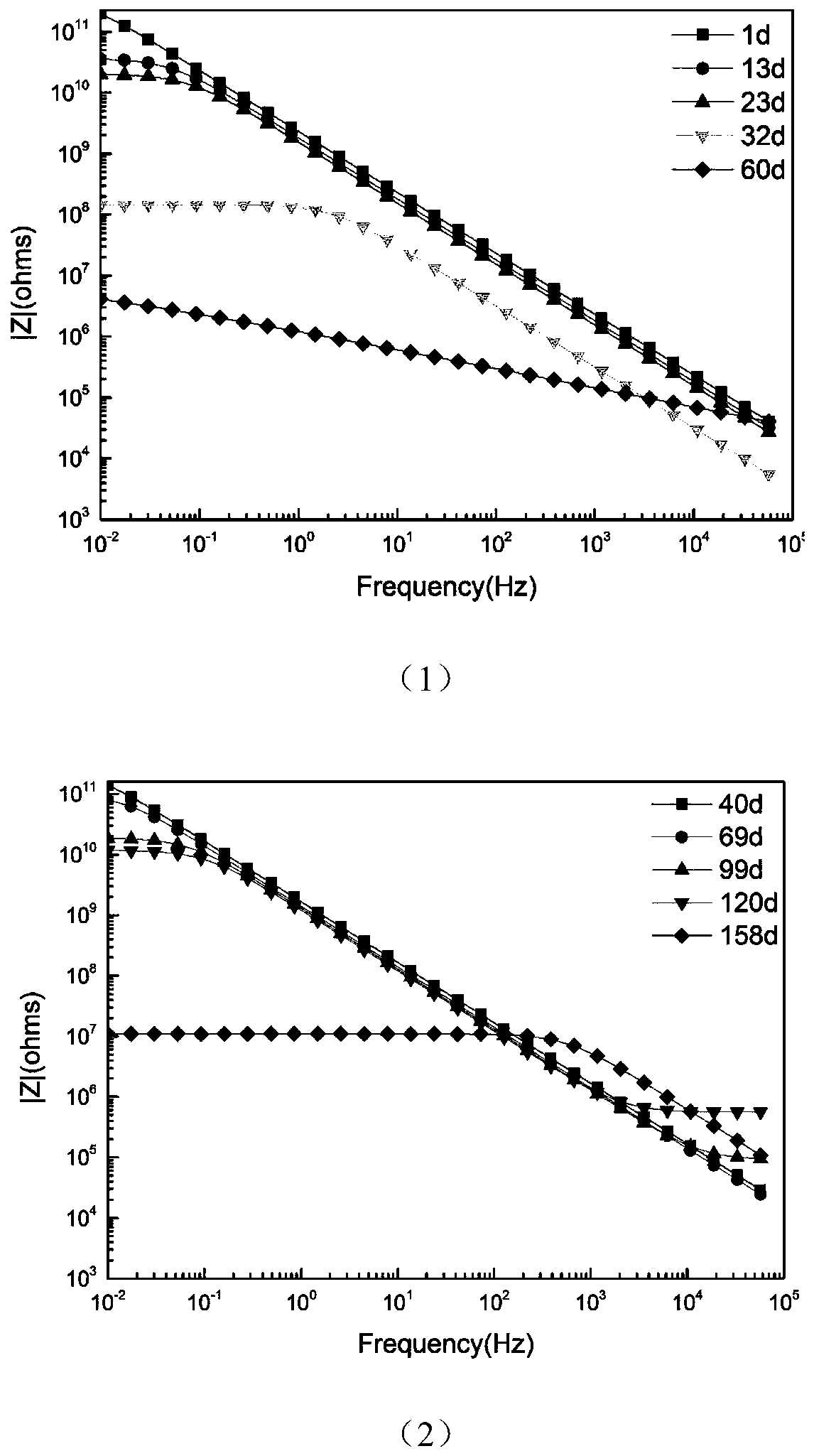

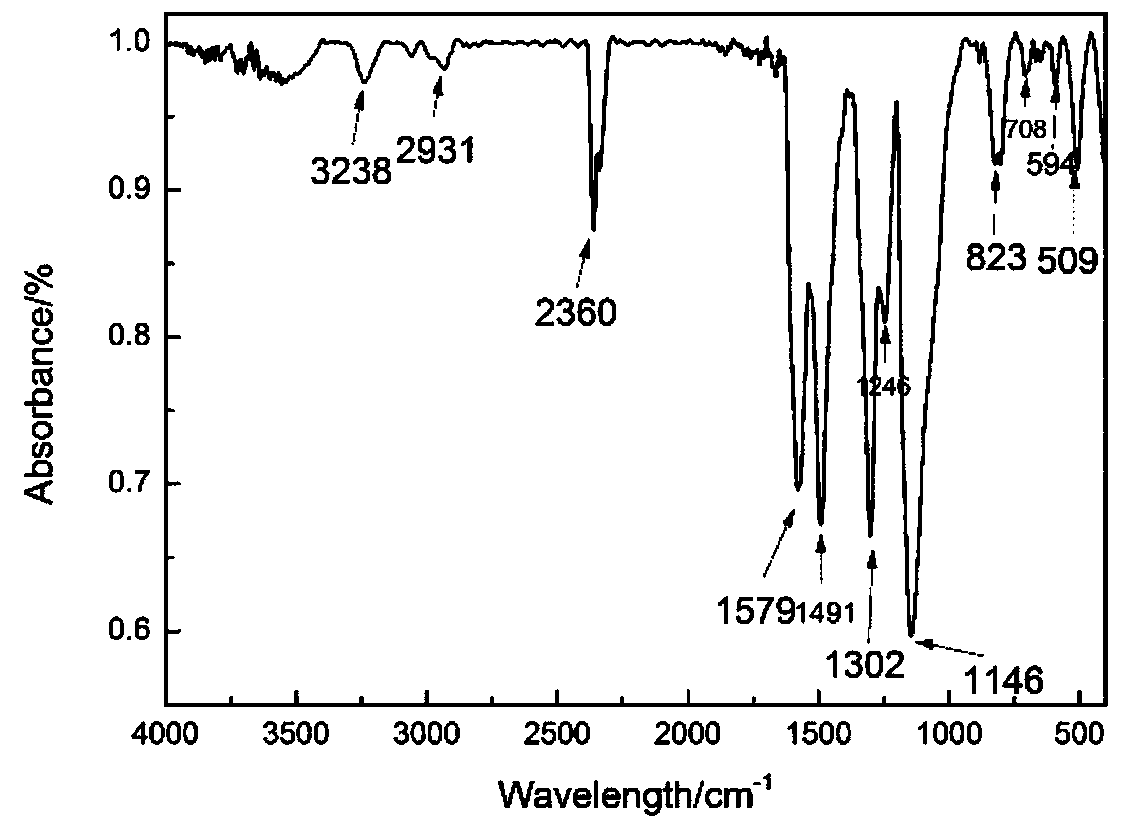

Phytic acid-doped polyaniline/polyphenylene sulfone coating composition and preparation method thereof

ActiveCN110684462AGood chemical stabilityStrong impact toughnessAnti-corrosive paintsPolymer sciencePhytic acid

The invention discloses a phytic acid-doped polyaniline / polyphenylene sulfone coating composition and a preparation method thereof, belonging to the technical field of coatings. The phytic acid-dopedpolyaniline / polyphenylene sulfone coating composition with excellent corrosion resistance is prepared by firstly preparing phytic acid-doped polyaniline and then adding the phytic acid-doped polyaniline into polyphenylene sulfone. According to the invention, the corrosion resistance of the polyphenylene sulfone coating is improved in the manner of forming a passive film between polyaniline and metal by utilizing the unique oxidation-reduction capability of the phytic acid-doped polyaniline; meanwhile, polyphosphoric acid groups carried by phytic acid are used for further promoting the coatingto form the passive film, so the corrosion resistance and adhesive force of the coating are enhanced, and a certain rust inhibition effect is achieved in the surface drying period of the coating.

Owner:JILIN UNIV

Phosphorus-free cleaning agent for metal surface treatment and preparation method thereof

The invention discloses a phosphorus-free cleaning agent for metal surface treatment. The cleaning agent comprises, by weight, 0.5-10 parts of sodium gluconate, 0.5-10 parts of sodium formate, 0.5-10 parts of sodium acetate, 1-10 parts of EDTA tetrasodium, 1-20 parts of potassium hydroxide, 0.5-10 parts of sodium carbonate and 20-90 parts of water, wherein the sodium gluconate, the sodium formate, the sodium acetate and the EDTA tetrasodium are used as main agents, and the potassium, the sodium carbonate and the water are used as auxiliary agents. 1-10 parts of polyether and 0.1-5 parts of fatty alcohol-polyoxyethylene ether are used as assistants, and finally, 0.1-5 parts of vinyl succinic anhydride are added as additives for mixing to obtain the cleaning agent. The phosphorus-free cleaning agent is high in cleaning capacity, contains no such harmful substances as phosphorus and nitrite, is low in foam, and can achieve the antirust effect on cleaned metal.

Owner:河南恒润昌环保科技有限公司

Antirust master batches for various metals as well as preparation method and application of antirust master batches

The invention discloses antirust master batches for various metals as well as a preparation method and application of the antirust master batches. The antirust master batches comprise the following components in percentage by mass: 30-50% of a compounded antirust agent, 40-60% of carrier plastic and 10-20% of an auxiliary agent, wherein the compounded antirust agent is prepared by mixing disodium sebacate, sodium molybdate and diglycolamide oleate borate according to a mass ratio of (1-1.3):(1.1-1.5):(2.2-3.2); and the auxiliary agent is prepared by mixing stearic acid amide, silicon dioxide, sucrose fatty acid ester and an antioxidant 1076 according to a mass ratio of (0.9-1.3):(4.8-6.5):(2.5-3.3):(0.8-1.1). The diglycolamide oleate borate is adopted as an additive and has a dispersion effect and an antirust effect, and the compounded antirust agent has certain polarity, can penetrate through the carrier plastic and volatilize to the surface of a packed metal to form a protective film so as to prevent corrosion of external corrosive substances, and cannot be incompatible with the carrier plastic to generate frost due to too strong polarity. The antirust master batches do not contain harmful ingredients, are environment-friendly and safe to use, and can achieve an antirust effect on various metals.

Owner:青岛鑫盈鑫包装材料有限公司 +1

Antirust paint for metals

The invention discloses an antirust paint for metals. An environment-friendly antirust paint for metals is prepared by mixing the following ingredients by volume: 5%-10% of inositol hexaphosphate, 10%-12% of barium sulfate, 5%-7% of iron oxide red, 10%-20% of antirust pigments, 5%-10% of eleostearic acid, 1%-2% of oil-based curing agent and the balance of deionized water. The environment-friendly antirust paint for the metals has the advantages of being simple in preparation and low in cost, not only being capable of playing an antirust role, but also being colorless, odorless, environment-friendly and practical.

Owner:QINGDAO HAOYUAN ENVIRONMENTAL ENG TECH

Preparation method for environment-friendly type anti-wearing hydraulic oil

InactiveCN106867634AImprove wear resistanceStrong extreme pressureLubricant compositionDispersion stabilityEcological environment

The invention relates to a preparation method for environment-friendly type anti-wearing hydraulic oil, and belongs to the technical field of hydraulic oil. The preparation method comprises the following steps of: performing freezing treatment on soybean oil to remove components which are liable to crystallize at a low temperature; catalyzing oleic acid in soybean oil by potassium permanganate and glacial acetic acid to generate oxidization reaction, enabling generated short-chain carboxylic acid and n-butyl alcohol to generate esterification reaction, and drying to prepare 2# dried oil liquid; and finally, mixing the 2# dried oil liquid with nano aluminum oxide modified by a silane coupling agent, and adding auxiliaries such as tea saponin, thereby preparing the environment-friendly type anti-wearing hydraulic oil. According to the preparation method disclosed by the invention, soya bean is taken as a raw material, and is modified to improve stability thereof in a working process; the nano aluminum oxide is modified by the silane coupling agent to improve dispersion stability performance, in base oil, of the nano aluminum oxide; and the obtained hydraulic oil can be biologically degraded after being discarded, is environmental-friendly, and solves the problem that pollution is caused on an ecological environment after conventional phosphate type hydraulic oil is discarded.

Owner:常州梦泰照明科技有限公司

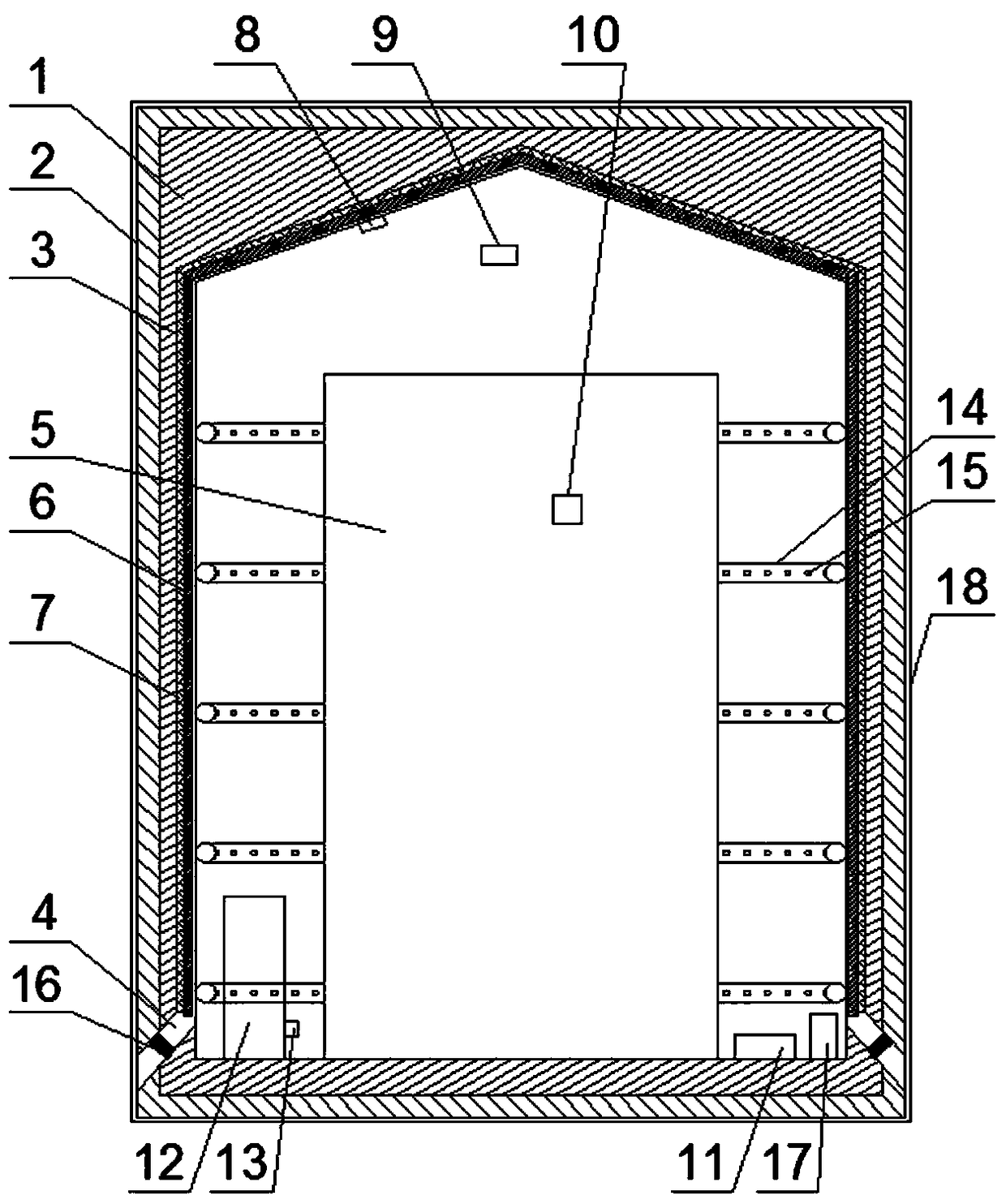

Switch cabinet condensation prevention device

ActiveCN108963786ALight in massImprove adhesionSubstation/switching arrangement casingsAnti-corrosive paintsEngineeringSwitchgear

The invention discloses a switch cabinet condensation prevention device comprising a cabinet body. The outer surface of the cabinet body is provided with a heat preservation layer. The top of the inner side of the cabinet body is conical, and the inner wall of the cabinet body is provided with multiple grooves along the vertical direction. The lower part of the cabinet body is provided with inclined drain holes. The grooves are internally provided with cold iron bars. Semiconductor refrigeration sheets are arranged between the cold iron bars and the grooves. The inner wall of the cabinet bodyis provided with a first temperature sensor. The cabinet body is internally provided with a dew point instrument which is used for detecting the inner air temperature. The outer surface of the electrical equipment in the cabinet body is provided with a second temperature sensor. The cabinet body is internally provided with a drying mechanism which is used for drying the electrical equipment. The cold iron bars of which the temperature is lower than that of the surface of the electrical equipment in the switch cabinet can be provided and the condensation phenomenon is enabled to occur on the surface of the cold iron bars by priority so that the probability of condensation on the electrical equipment in the switch cabinet can be greatly reduced; besides, the electrical equipment can be driedby using the drying mechanism in the cabinet body so as to further avoid the condensation phenomenon on the electrical equipment.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Manufacturing method of rustproof alloy wheel hub

ActiveCN109797324AImprove rust resistanceAnti-rust effectLiquid surface applicatorsSpraying apparatusFilm coatingMaterials science

The invention belongs to the technical field of auto parts, and particularly relates to a manufacturing method of a rustproof alloy wheel hub. The manufacturing method of the rustproof alloy wheel hubcomprises the following steps that A, an aluminum alloy material is heated to a liquid state, zirconium oxide is added into an aluminum alloy solution, and even stirring is conducted; B, a solution obtained in the step A is injected into a wheel hub mold for two passes of cooling, the temperature in the first pass of cooling is 665 DEG C to 670 DEG C, and the temperature in the second pass of cooling is the room temperature; C, a cooling-formed semi-finished wheel hub is separated from the mold, the outer side of the semi-finished wheel hub faces downwards, half immersed in wax film rustproofoil liquid for a period of time and then taken out for still standing; D, the inner side of the semi-finished wheel hub obtained in the step C is sprayed with rustproof liquid; and E, the semi-finished wheel hub obtained in the step D is subjected to overall film coating through activated carbon, and thus a finished wheel hub is obtained. The wheel hub manufactured through the manufacturing method is resistant to the high temperature and corrosion, can resist corrosion of various corrosive substances of gas, liquid and solid, and is not prone to rusting.

Owner:ZHEJIANG PDW IND CO LTD

Environmentally friendly high-performance corrosion inhibitor for reinforcing steel bars

InactiveCN106630722AAnti-rust effectSlow and stop corrosionEnvironmental resistanceDiethylenetriamine

The invention discloses an environmentally friendly high-performance corrosion inhibitor for reinforcing steel bars. The environmentally friendly high-performance corrosion inhibitor for reinforcing steel bars consists of the following raw materials in parts by weight: sodium benzoate 5-20 parts, sodium silicate 5-8 parts, gluconic acid 2-7 parts, dicyclohexyl amine nitrite 5-15 parts, flyash 4-12 parts, nitrite 7-14 parts, sodium hexametaphosphate 5-10 parts, diethylenetriamine 6-12 parts, sodium molybdate 2-8 parts, sodium citrate 2-4 parts, sodium monofluorophosphate 5-8 parts, gluconate 1-10 parts and borate 1-5 parts. The environmentally friendly high-performance corrosion inhibitor for reinforcing steel bars is good in corrosion inhibition effect and does not have bad influence on performance of concrete.

Owner:青建集团股份公司

Gear precision grinding machining oil and preparation method thereof

InactiveCN113773893AReduce surface residueGuaranteed machining accuracyLubricant compositionAntioxidantMaterials science

The invention belongs to the technical field of grinding machining oil and relates to gear precision grinding oil and a preparation method thereof. The gear precision grinding machining oil comprises the following components of: secondary hydrogenation paraffin-based mineral oil, pentaerythritol oleate, high-base-number calcium sulfonate, sulfurized fatty acid ester, high-molecular polyisobutene and an antioxidant. The preparation method of the gear precision grinding machining oil comprises the following steps of: putting secondary hydrogenation paraffin-based mineral oil and an antioxidant into a container, heating the materials to 40-50 DEG C, and stirring the materials until the materials is transparent; stopping heating, adding sulfurized fatty acid ester and high-molecular polyisobutene into the container, and performing stirring until the mixture is transparent; adding pentaerythritol oleate and high-base-number calcium sulfonate into the container, and performing stirring until the mixture is transparent; and filtering the liquid in the container, and taking filtrate to obtain the gear precision grinding machining oil. The gear precision grinding machining oil is small in harm to the environment and human bodies, good in lubricating performance, high in rust resistance, corrosion resistance and the like, and capable of reducing the machining precision of workpieces.

Owner:AMER TECH CO LTD

Lauric acid diethanolamide borate vapor phase antirust masterbatch and its preparation method and application

The invention discloses a lauroyl diethanolamide borate VCI (Volatile Corrosion Inhibitor) masterbatch as well as a preparation method and applications thereof. The VCI masterbatch comprises components in percentage by weight as follows: 30-50% of a compound rust inhibitor, 40-60% of a carrier plastic and 10-20% of an addition agent; the compound rust inhibitor is prepared by mixing sodium benzoate, sodium sebacate, lauroyl diethanolamide borate and hexamethylene tetramine in a weight ratio of (1-1.4):(1.1-1.6):(2.2-3.5):(0.9-1.2); the addition agent is prepared by mixing octadecanamide, ground calcium carbonate, sucrose fatty acid ester and an antioxidant 246 in a weight ratio of (0.9-1.3):(4.8-6.5):(2.5-3.3):(0.8-1.1). According to the preparation method, lauroyl diethanolamide borate is adopted as an additive, so that the masterbatch has a dispersion effect and a corrosion inhibition effect; the compound rust inhibitor has a certain polarity, can penetrate the carrier plastic and volatilize to the surface of packed metal to form a protection film which can obstruct corrosion of external corrosive substances, and avoids frost precipitation caused by incompatibility with the carrier plastic due to too strong polarity; and the lauroyl diethanolamide borate VCI masterbatch does not contain harmful components, is environment-friendly and safe when being used, and can play a corrosion inhibition action on various metals.

Owner:青岛鑫盈鑫包装材料有限公司

A kind of epoxy zinc-rich primer and preparation method thereof

ActiveCN103483983BEasy to dryImprove adhesionAnti-corrosive paintsEpoxy resin coatingsPolyamideSolvent

The invention discloses an epoxy zinc-rich primer and a preparation method thereof. The epoxy zinc-rich primer comprises the following components in percentage by mass: component A: 10-15% of E20 epoxy resin, 0.2-0.4% of dispersant, 2-4% of barium petroleum sulfonate, 30-50% of zinc powder, 10-20% of composite iron-titanium, 5-10% of sericite, 1-1.2% of organic bentonite, and 18.25-21.6% of mixed solvent; component B: 15-30% of cardanol-modified polyamide resin, 1-2% of epoxy accelerator, and 68-84% of mixed solvent. The preparation method for the component A comprises the following steps: adopting the mixed solvent to dissolve each component respectively, then adjusting the viscosity to a desired value through the mixed solvent; the preparation method for the component B comprises the following steps: dissolving each component through the mixed solvent. During use, the volume ratio of the component A and the component B is (3-5):1.

Owner:JIANGSU HUAXIA PAINT MAKING

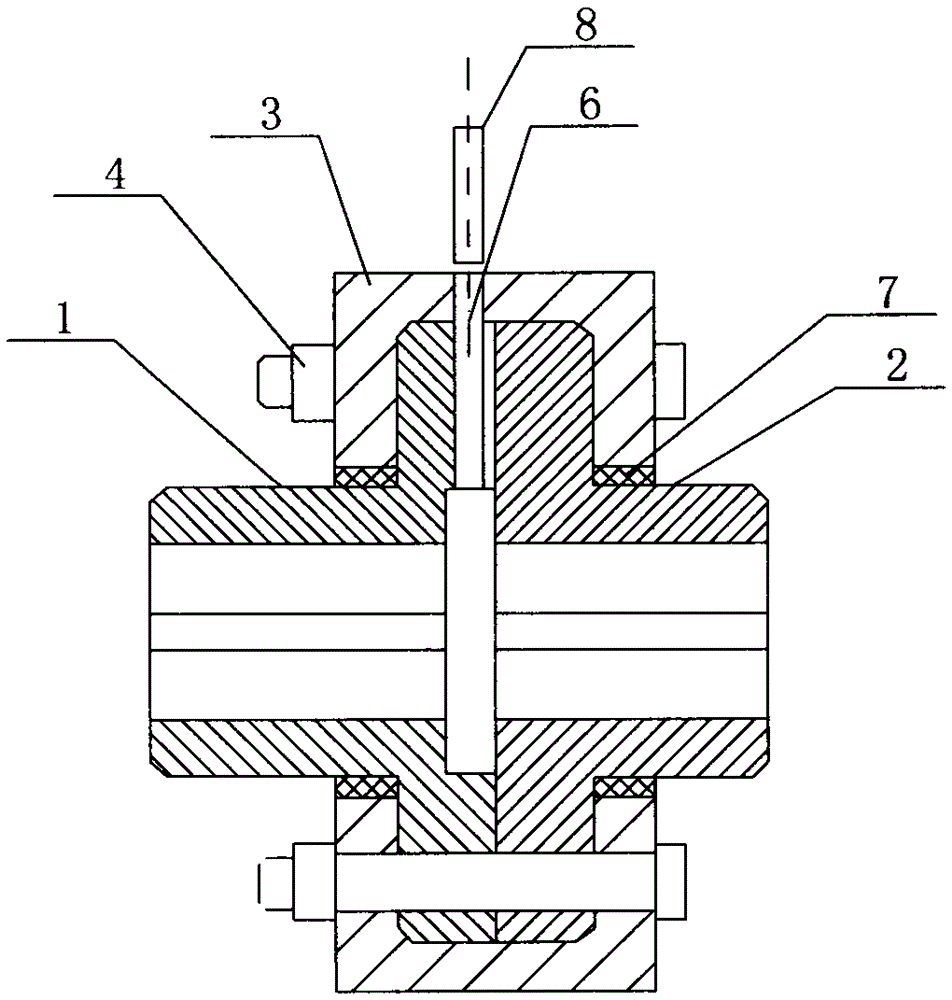

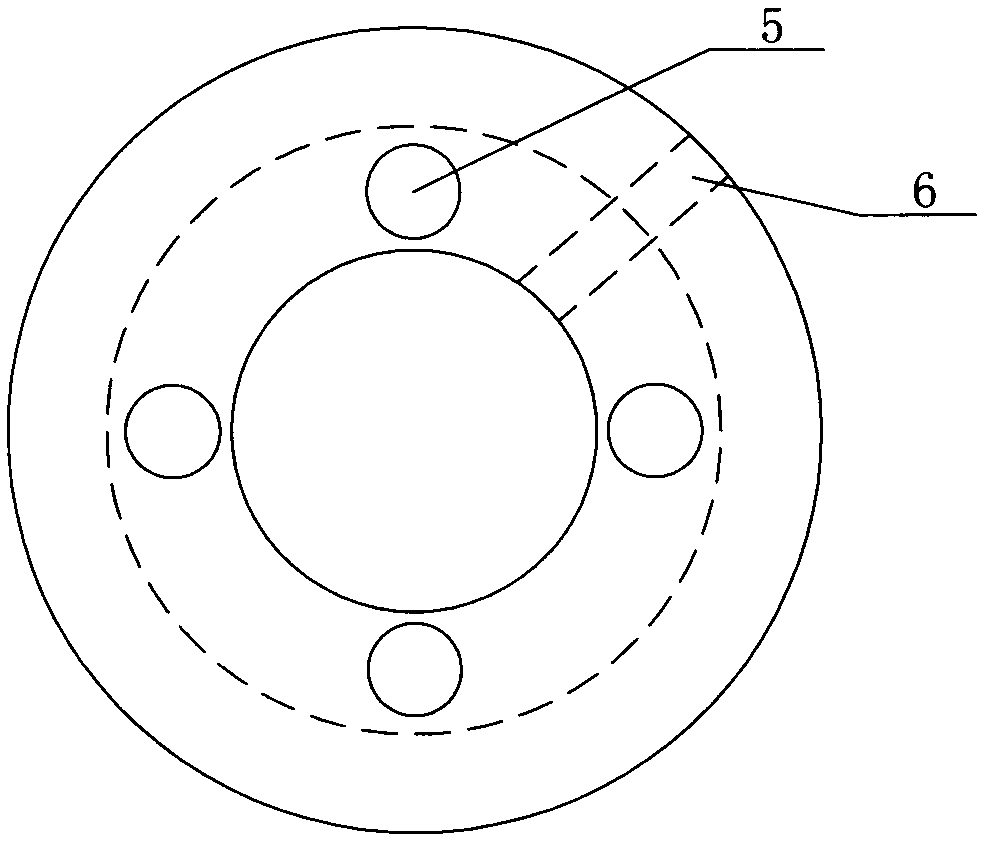

Oiling rust-proof coupling

The invention relates to the technical field of couplings, in particular to an oiling rust-proof coupling. The oiling rust-proof coupling comprises a left half coupling body and a right half coupling body. The right half coupling body is arranged on one side of the left half coupling body. The oiling rust-proof coupling further comprises a sealing end cover, and fixed through holes are formed in the sealing end cover, the left half coupling body and the right half coupling body; the sealing end cover is fixedly connected with the left half coupling body and the right half coupling body through fixed bolts; and oiling holes are formed in the sealing end cover. The oiling rust-proof coupling has a good rust-proof function, the problems that due to the fact that the oiling rust-proof coupling is not used for a long time, rusty spots are generated, and dismounting is not easy are solved, and the service life of the coupling is effectively prolonged.

Owner:镇江市润州联轴器厂

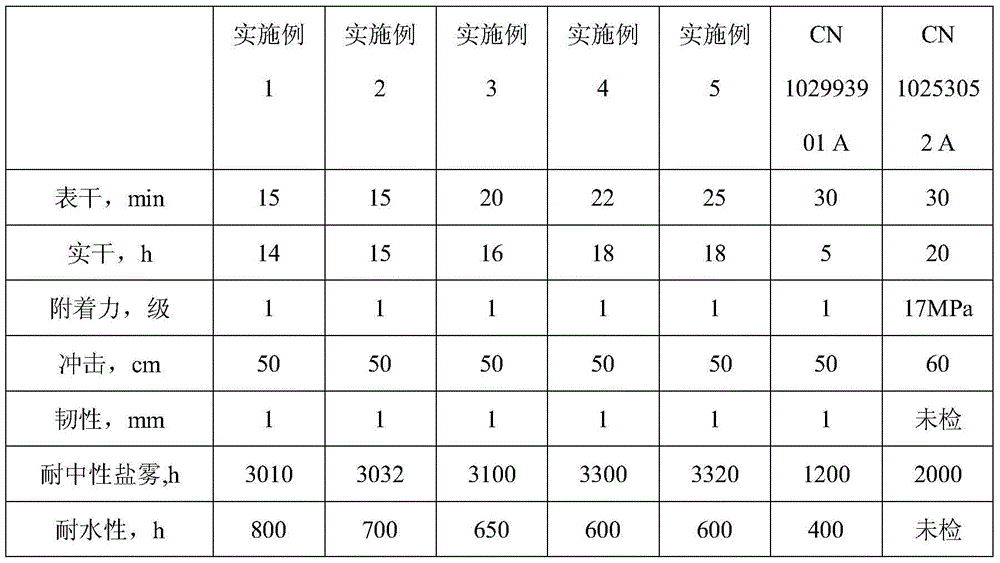

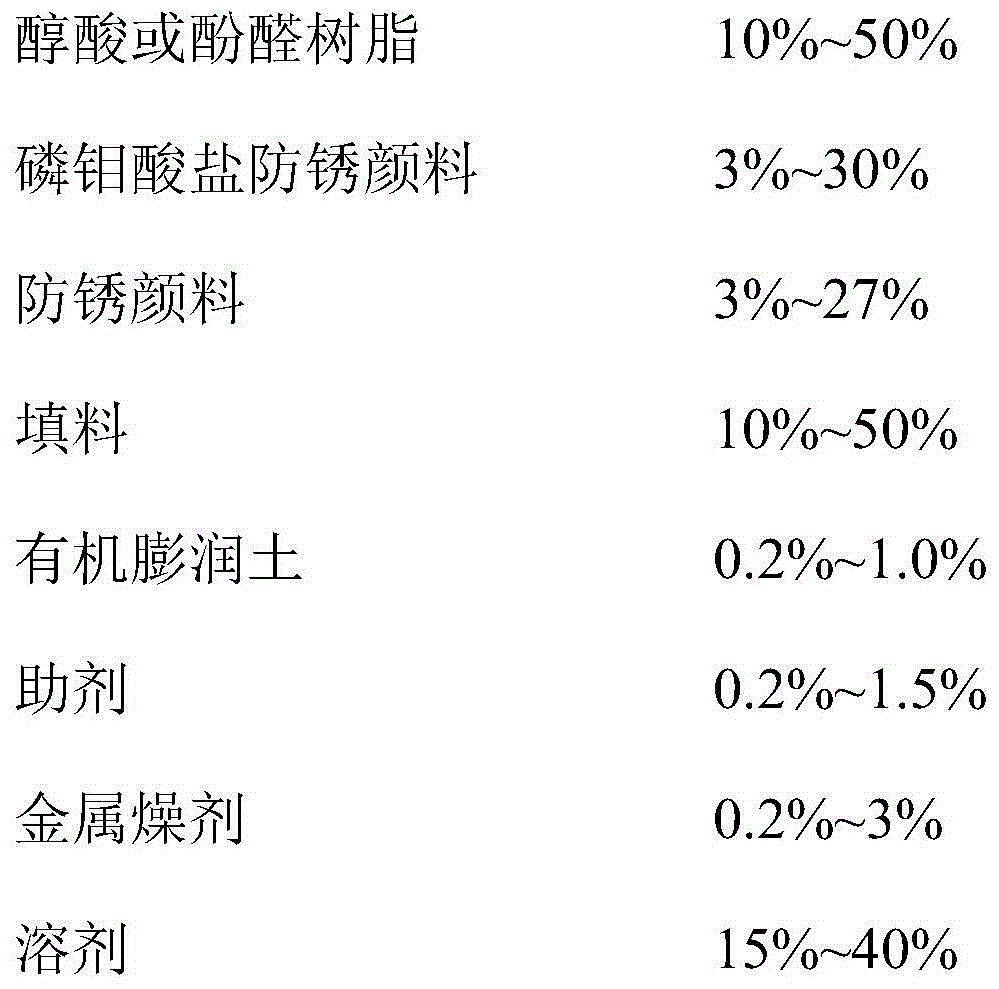

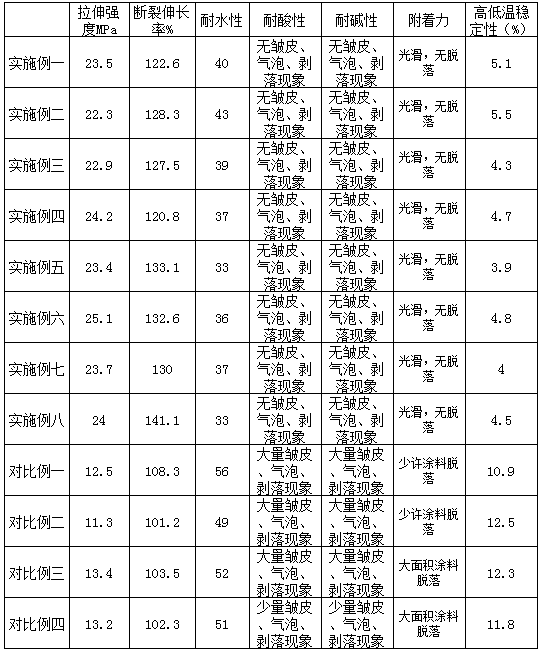

Environment-friendly phosphomolybdate anti-rust paint

InactiveCN105694686AReduce addGood for healthAnti-corrosive paintsPolyester coatingsAlcoholSodium Bentonite

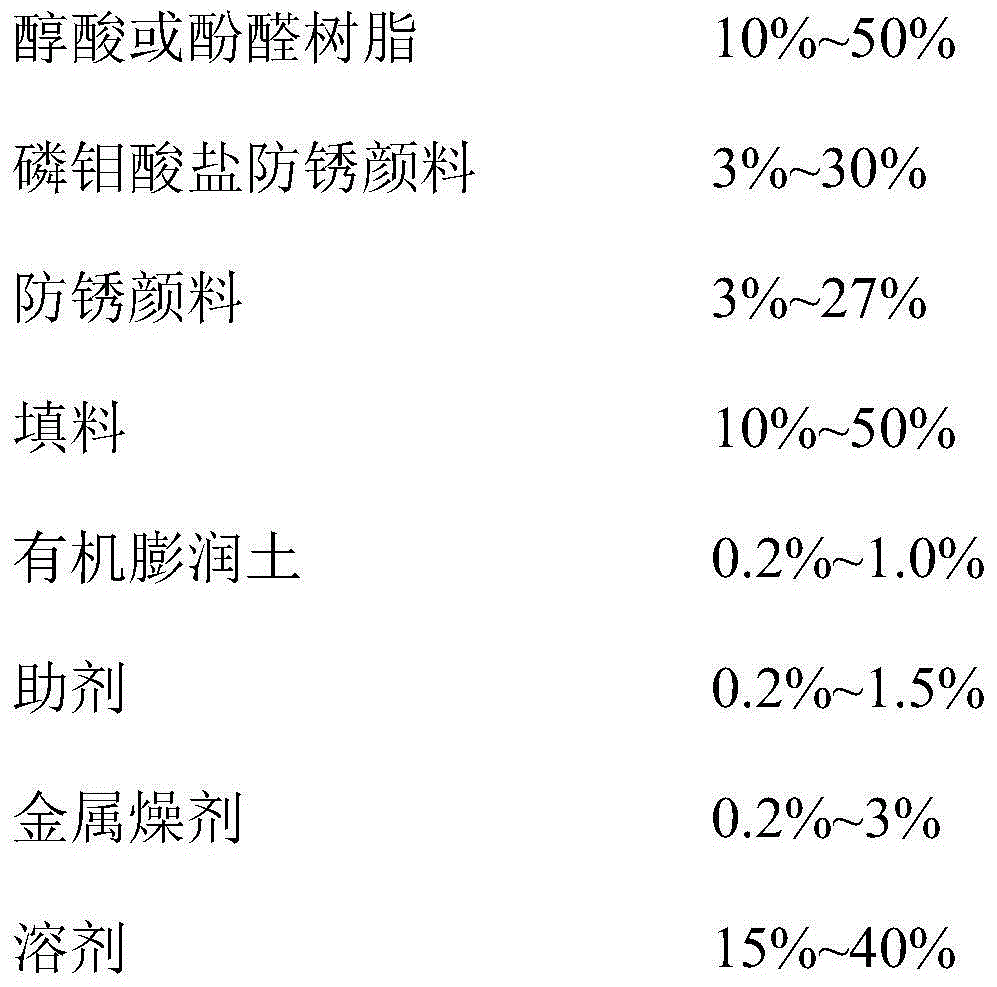

The invention provides an environment-friendly phosphomolybdate antirust paint, which is composed of the following components by weight percentage: 10% to 50% of alkyd or phenolic resin, 3% to 30% of phosphomolybdate antirust pigment, antirust 3% to 27% of rust pigment, 10% to 50% of filler, 0.2% to 1.0% of organic bentonite, 0.2% to 1.5% of auxiliary agent, 0.2% to 3% of metal desiccant, and 15% to 40% of solvent. The invention has better anti-rust effect, is environmentally friendly and practical, does not use red lead powder banned internationally, has better salt spray resistance than alkyd red lead anti-rust paint, has no irritating smell, is beneficial to the health of construction workers, and is an environmentally friendly , anti-rust paint that is non-toxic to the environment.

Owner:上海华谊精细化工有限公司上海开林造漆厂

Waterborne environment-friendly epoxy zinc-rich primer and preparation method thereof

InactiveCN107523181AEasy to adaptAnti-rust effectAnti-corrosive paintsEpoxy resin coatingsDefoaming AgentsEnvironmentally friendly

The invention provides waterborne environment-friendly epoxy zinc-rich primer and a preparation method thereof. The waterborne environment-friendly epoxy zinc-rich primer is prepared from the following components by weight percent: 40 to 50 percent of waterborne epoxy resin, 15 to 20 percent of antirust agent, 10 to 15 percent of inorganic filler, 15 to 20 percent of water, 0.8 to 1.2 percent of co-solvent, 0.4 to 0.6 percent of dispersing agent, 0.2 to 0.3 percent of moisturizing agent, 0.2 to 0.3 percent of flatting agent, 0.1 to 0.16 percent of defoaming agent, 0.4 to 0.6 percent of thickening agent and 0.3 to 0.4 percent of anti-settling agent. The antirust agent is prepared from zinc powder, zinc oxide and zinc phosphate. The preparation method comprises the following steps: 1) uniformly mixing and stirring the antirust agent, the inorganic filler and the water, wherein the stirring time is 25 to 35 min, grinding, and obtaining a mixture A; and 2) adding waterborne epoxy resin into the mixture A, uniformly stirring for 25 to 35 min, then adding the co-solvent, the dispersing agent, the moisturizing agent, the flatting agent, the defoaming agent, the thickening agent and the anti-settling agent, and uniformly mixing, thus obtaining the waterborne environment-friendly epoxy zinc-rich primer. The primer is environmentally friendly, economical and good in antirust performance.

Owner:厦门日盛隆新材料科技有限公司

Dedicated anti-corrosive paint for chemical pipeline and preparation method thereof

ActiveCN109337584AHigh mechanical strengthGood flexibilityFireproof paintsAnti-corrosive paintsTectorial membraneEpoxy

The invention discloses a dedicated anti-corrosive paint for a chemical pipeline and a preparation method thereof, and belongs to the technical field of the anti-corrosive paint. The dedicated anti-corrosive paint is prepared from the following components in parts by weight: 60-80 parts of asphalt emulsion, 30-40 parts of epoxy emulsion, 3-5 parts of an anti-corrosive agent, 1-2 parts of a sulfurizing agent, 12-17 parts of nano oxide, 3.8-5.5 parts of a silane coupling agent, 20-26 parts of acetone, 0.5-0.8 part of a stabilizing agent, 0.8-1.5 parts of an anion dispersing agent and 7-12 partsof deionized water. The dedicated anti-corrosive paint for the chemical pipeline disclosed by the invention is excellent in mechanical performance and insulation performance, resistant to water, hightemperature, low temperature and chemical corrosion, strong in adhesive force, and capable of maintaining the stability in the long-term acid-alkali environment, capable of being used for a long timeat the environment of -50 to 100 DEG C, and excellent in comprehensive performance. The paint can form a layer of dense protective film on the surface of the chemical pipeline, an anti-rust effect isplayed when the corrosion resistance is realized, thereby prolonging the service life of the chemical pipeline.

Owner:ZHENGZHOU INST OF TECH

Environment-friendly reinforcing bar corrosion inhibitor

The invention discloses an environment-friendly reinforcing bar corrosion inhibitor comprising the following components in percentage by mass: 0.5-1.5% of sodium benzoate, 0.5-1.5% of sodium silicate, 0.5-1.5% of gluconic acid, 0.5-1.5% of citric acid and the balance of water. According to the invention, the anode type corrosion inhibiting components are compounded with mixed type corrosion inhibiting components, so that the environment-friendly reinforcing bar corrosion inhibitor is little in dosage, strong in corrosion inhibiting effect, strong in reinforcing bar adsorption force and good in concrete adaptability and can be directly coated on the surface of the reinforcing bar to form a compact protective film to ensure that the effective utilization rate of the corrosion inhibitor is increased and a corrosion inhibiting effect is provided while the concrete performances are not influenced at the same time; and the corrosion inhibitor is capable of effectively slowing down and preventing the corrosion of the reinforcing bar in the reinforced concrete, has the characteristics of no nitrite, no alkali, no toxin, no pollution and the like and can be widely used for reinforced concrete structures such as water conservancy, railways and civil architectures.

Owner:LUOYANG INST OF SCI & TECH

Preparation method of printing ink cleaning agent for printing machine

InactiveCN108373644ATo achieve the purpose of removing inkLarge particle sizeChemical paints/ink removersPolymeric surfaceSodium Bentonite

The invention discloses a preparation method of a printing ink cleaning agent for a printing machine, belonging to the technical field of printing ink cleaning agents. According to the preparation method, an AAA-type polymeric surfactant is synthesized from alpha-olefin sodium sulfonate, acrylic acid and allyl polyoxyethylene ether and is used for modifying bentonite, the surface of bentonite is coated with an anionic surfactant, ion groups and anions on printing ink particles generate electrostatic adsorption, the printing ink is gathered to form printing ink particles with relatively large particle sizes, and the printing ink is removed by virtue of a flotation method; environment-friendly anti-rusting emulsion is prepared from butyl acrylate, styrene and methylacrylic acid and is takenas a main film form substance, and a uniform dense film is formed on the surface of metal and is capable of blocking the entry of oxygen molecules and preventing rusting, so that the problem that theprinting machine is corroded is avoided; and the problems that the printing ink cleaning agent in the current market is not ideal enough, high in pollution and strong in corrosivity are solved.

Owner:郭跃

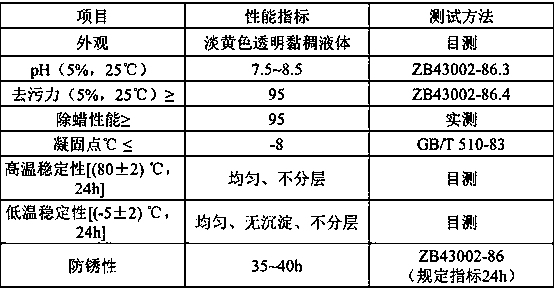

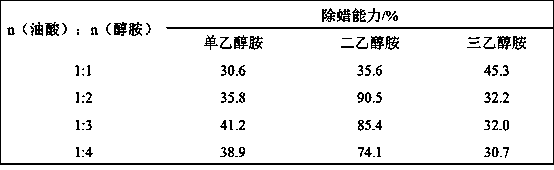

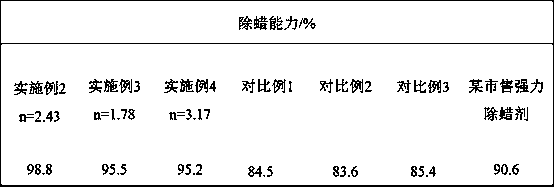

A water-based anti-rust, degreasing and wax-removing cleaning agent and its preparation method and application

The invention provides a water-based rust-proofing, degreasing and wax removing cleaning agent and a preparation method and application thereof. The cleaning agent comprises a high molecular surfactant, diethanol amine oleic soap, alkylolamide phosphate 6503, diallyl succinimide T154, sodium tripolyphosphate, sodium metasilicate, a penetrant TA-2, zinc dialkyl dithiophosphate, polyethylene glycol 400 and deionized water. The cleaning agent is applicable to manufacturing of various metals; dirt such as polishing wax, grinding wax, grease and greasy dirt on the metal surface can be cleaned under normal temperature, instead of being cleaned under high temperature; the cleaning agent is low in use concentration, high in permeability, low in foam, high in wax removing efficiency, free from strong acid and sodium hydroxide, free from damage to a matrix, high in physicochemical stability, long in service life, free from APEO (alkylphenol ethoxylates) nonionic surfactant, green, nontoxic, and high in rust-proofing performance.

Owner:惠州市恒杰化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com