Dedicated anti-corrosive paint for chemical pipeline and preparation method thereof

A technology for anti-corrosion coatings and chemical pipelines. It is applied in anti-corrosion coatings, fire-proof coatings, asphalt coatings, etc. It can solve the problems of poor acid and alkali corrosion resistance and small temperature application range, and achieve stability, prolong service life, and mechanical properties. and excellent insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

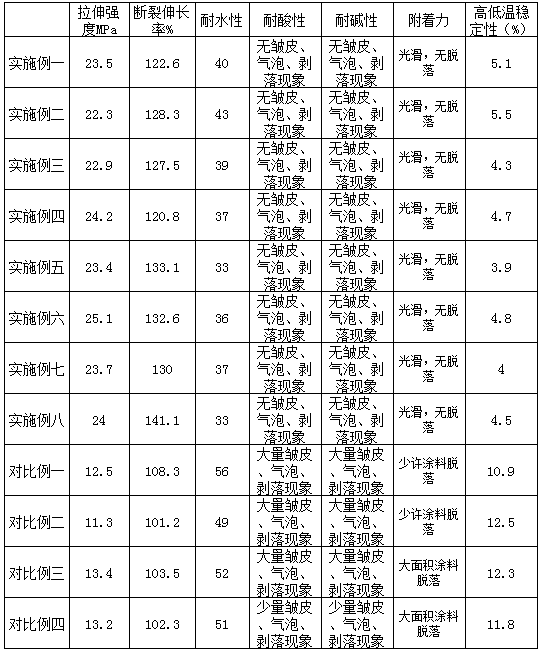

Examples

Embodiment 1

[0025] A special anti-corrosion coating for chemical pipelines. The components and their parts by weight are: 60 parts of asphalt emulsion, 30 parts of epoxy emulsion, 3 parts of anti-corrosion agent, 1 part of vulcanizing agent, 12 parts of nano oxide, 3.8 parts of silane coupling agent 20 parts, 20 parts of acetone, 0.5 parts of stabilizer, 0.8 parts of anionic dispersant, 7 parts of deionized water.

[0026] The nano-oxide is a mixture of nano-magnesia, nano-silicon dioxide and nano-titanium dioxide, and the weight ratio of nano-magnesia: nano-silicon dioxide: nano-titanium dioxide is 4:3:3.

[0027] The anti-corrosion agent is a mixture of hexamethylenetetramine and cinnamaldehyde, and the weight ratio of hexamethylenetetramine: cinnamaldehyde is 7:3.

[0028] The preparation method of the special anticorrosion coating for chemical pipelines according to the embodiment of the present invention comprises the following steps: 1) After drying 12 parts by weight of nano-oxides...

Embodiment 2

[0032] A special anti-corrosion coating for chemical pipelines. The components and their parts by weight are: 63 parts of asphalt emulsion, 32 parts of epoxy emulsion, 3.2 parts of corrosion resistance agent, 1.2 parts of vulcanizing agent, 13 parts of nano oxide, 3.9 parts of silane coupling agent parts, 22 parts of acetone, 0.5 parts of stabilizer, 0.8 parts of anionic dispersant, and 8 parts of deionized water.

[0033] The nano-oxide is a mixture of nano-magnesia, nano-silicon dioxide and nano-titanium dioxide, and the weight ratio of nano-magnesia: nano-silicon dioxide: nano-titanium dioxide is 4:3:3.

[0034] The corrosion resistant agent is hexamethylenetetramine.

[0035] Described stabilizing agent is the mixture of magnesium stearate and aluminum stearate, and weight ratio magnesium stearate: aluminum stearate is 7:3.

[0036] The preparation method of the special anti-corrosion coating for chemical pipelines according to the embodiment of the present invention comp...

Embodiment 3

[0040] A special anti-corrosion coating for chemical pipelines. The components and their parts by weight are: 65 parts of asphalt emulsion, 34 parts of epoxy emulsion, 3.4 parts of anti-corrosion agent, 1.4 parts of vulcanizing agent, 15 parts of nano oxide, 4 parts of silane coupling agent 23 parts of acetone, 0.6 parts of stabilizer, 1 part of anionic dispersant, 9 parts of deionized water.

[0041] The nano-oxide is a mixture of nano-magnesia, nano-silicon dioxide and nano-titanium dioxide, and the weight ratio of nano-magnesia: nano-silicon dioxide: nano-titanium dioxide is 4:3:3.

[0042] The corrosion resistant agent is hexamethylenetetramine.

[0043] Described stabilizing agent is the mixture of magnesium stearate and aluminum stearate, and weight ratio magnesium stearate: aluminum stearate is 7:3.

[0044] The preparation method of the special anticorrosion coating for chemical pipelines according to the embodiment of the present invention comprises the following ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com