A kind of epoxy zinc-rich primer and preparation method thereof

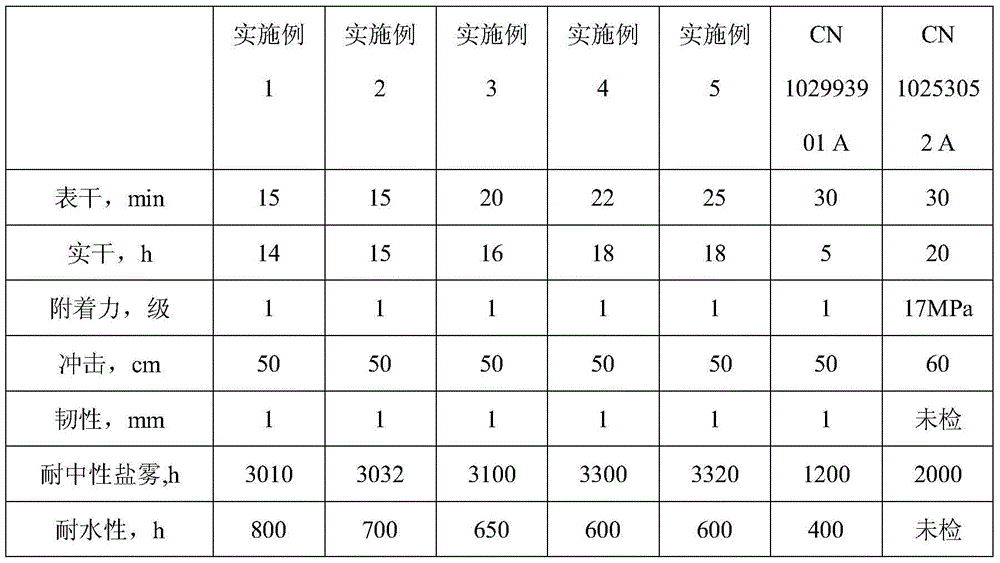

A technology of epoxy zinc-rich primer and epoxy accelerator, which is applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of poor salt spray resistance and high cost, and improve salt spray resistance Performance, increase product cost, effect of anti-rust performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The source and the type of reagent used in the following examples are shown in the table below:

[0019] component name

Specifications

source

E20 epoxy resin

601

Jiangsu Sanmu Chemical Industry Co., Ltd.

Dispersant

9086

Taiwan Deqian Chemical

T-705A

petrochemical company

500 mesh zinc powder

Jiangsu Shenlong Zinc Industry Co., Ltd.

Composite iron titanium powder

X-500

Changzhou Zhongpu Technology Co., Ltd.

A4

Chuzhou Wanqiao sericite

Organic bentonite

HY-758

Zhejiang Hongyu New Material Co., Ltd.

Cardanol modified polyamide resin

JMX558

Changzhou Jiemeixin

epoxy accelerator

K54

American Gas Chemical

mixed solvent

commercially available

[0020] The above-mentioned mixed solvent is composed of toluene, xylene, n-butanol, ethanol, isopropanol, ethyl ester...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com