Gear precision grinding machining oil and preparation method thereof

A precision grinding and processing oil technology, which is applied in the field of grinding oil, can solve the problems of blackening, corrosion, insufficient lubricating performance and non-compliance of the workpiece processing end face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

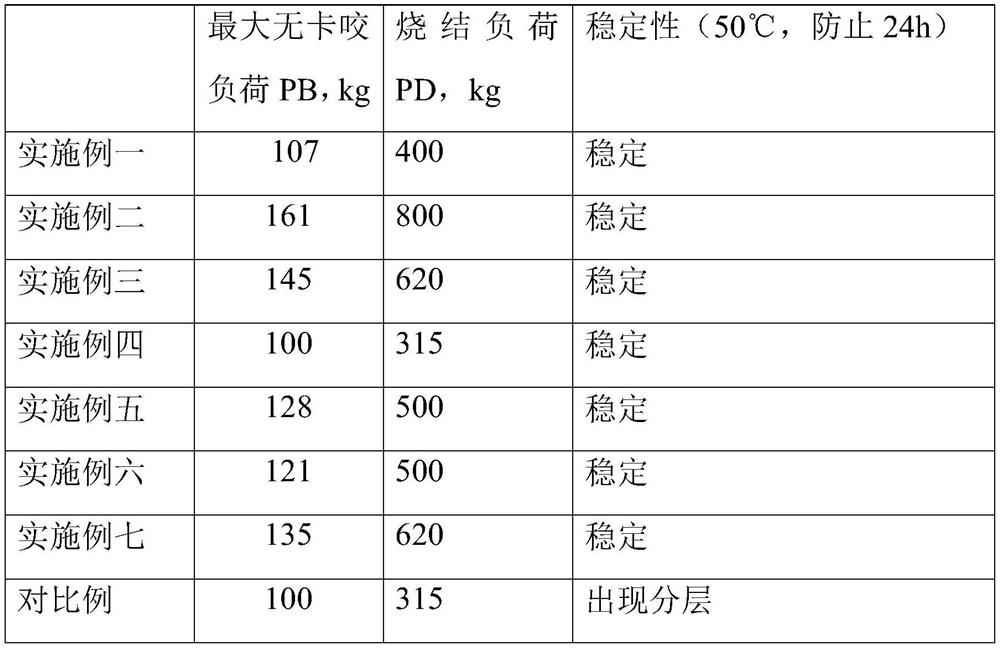

Examples

preparation example Construction

[0038] The present invention also provides a method for preparing the above-mentioned gear precision grinding oil, comprising the following steps:

[0039] Put the secondary hydrogenated paraffin-based mineral oil into the container, heat up to 40°C-50°C, and stir until transparent;

[0040] Stop heating, put sulfurized fatty acid ester and polymer polyisobutylene into the container, and stir until transparent;

[0041] Put pentaerythritol oleate and overbase calcium sulfonate into the container, and stir until transparent;

[0042] Filter the liquid in the container and take the filtrate to obtain gear precision grinding oil.

[0043]Wherein, the stirring speed after adding the secondary hydrogenated paraffin-based mineral oil and the antioxidant is 400r / min-600r / min, and the stirring time is 40min-50min. After adding sulfurized fatty acid ester and polymer polyisobutylene, the stirring speed is 400r / min-600r / min, and the stirring time is 50min-70min. After adding pentaery...

Embodiment 1

[0047] This embodiment provides a gear precision grinding oil, which is composed of the following components in parts by weight: 72.1 parts of secondary hydrogenated paraffin-based mineral oil, 14 parts of pentaerythritol oleate, 2 parts of overbased calcium sulfonate, sulfurized 7 parts of fatty acid ester, 4 parts of high molecular polyisobutylene, and 0.9 part of 2,6-di-tert-butyl-p-cresol. The preparation method of the gear precision grinding oil described in this embodiment is as follows: the secondary hydrogenated paraffin-based mineral oil and 2,6-di-tert-butyl-p-cresol are put into the reaction kettle, the temperature is raised to 45°C, and the stirring is carried out. until transparent; stop heating, put sulfurized fatty acid ester and macromolecular polyisobutylene in the reaction kettle, and stir until transparent; put pentaerythritol oleate and high basic value calcium sulfonate in the reaction kettle, and stir until transparent; put the inside of the reaction kettl...

Embodiment 2

[0049] This embodiment provides a gear precision grinding oil, which is composed of the following components in parts by weight: 74.9 parts of secondary hydrogenated paraffin-based mineral oil, 5 parts of pentaerythritol oleate, 5 parts of overbased calcium sulfonate, vulcanized 15 parts of fatty acid ester, 1 part of high molecular polyisobutylene, and 0.1 part of 2,6-di-tert-butyl-p-cresol. The preparation method of the gear precision grinding oil described in this embodiment is as follows: put secondary hydrogenated paraffin-based mineral oil and 2,6-di-tert-butyl-p-cresol into a reaction kettle, heat up to 50°C, and stir until Transparent; stop heating, put sulfurized fatty acid ester and polymer polyisobutylene in the reaction kettle, and stir until transparent; put pentaerythritol oleate and high base number calcium sulfonate in the reaction kettle, and stir until transparent; The liquid is filtered with a 5μm bag filter, and the filtrate is taken to obtain gear precisio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com