A method for manufacturing a display substrate, a display device, and a color filter substrate

A technology for display substrates and color film substrates, applied in nonlinear optics, instruments, optics, etc., can solve problems such as residual water stains, insufficient drying of substrates, scratches, etc., to reduce fluid resistance, reduce surface residues, increase The effect of surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The features and principles of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

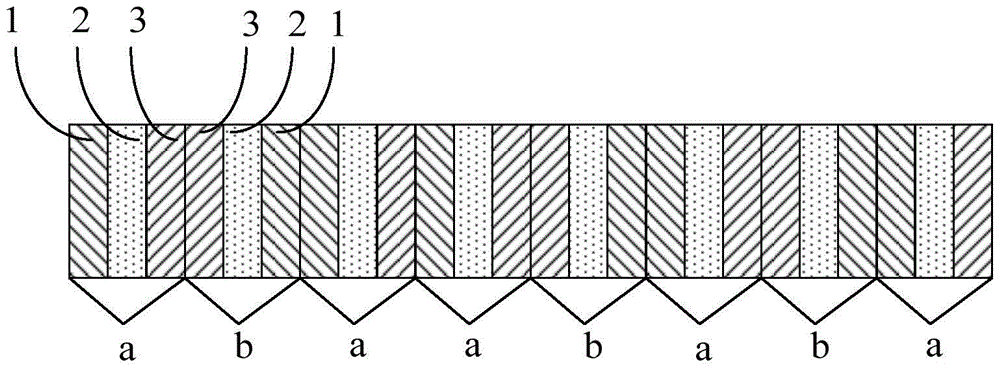

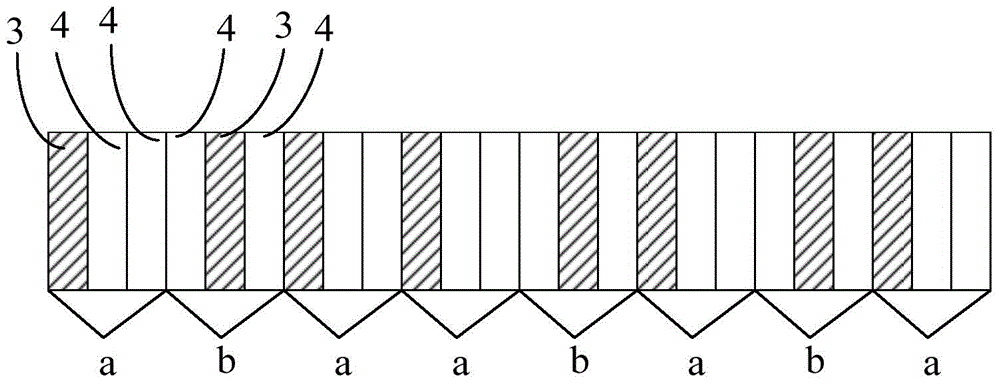

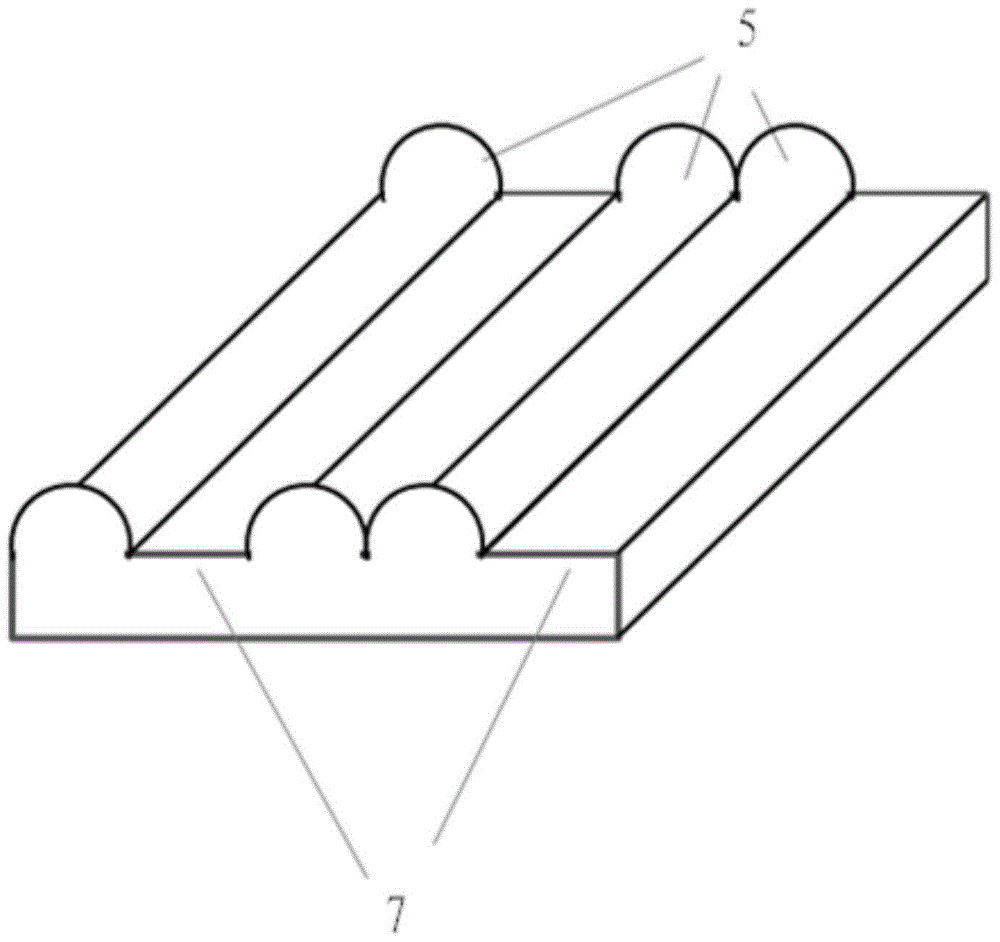

[0033] This embodiment provides a display substrate, including at least two different types of pixel units, the two different types of pixel units have different color settings, and at least two types of pixel units are arranged in a one-dimensional quasi-crystal manner.

[0034] At least two types of pixel units on the display substrate are arranged in a one-dimensional quasi-crystal manner, which reduces fluid resistance on the surface of the display substrate, increases surface energy, and reduces surface residues of water stains.

[0035] Preferably, at least two types of pixel units are set according to Fibonacci sequence.

[0036] In order to facilitate the specific description of the display substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com