Patents

Literature

42results about How to "Reduce surface residue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon wafer chemical and mechanical polishing composition with high stability

InactiveCN102093820AWide applicabilityPracticalOther chemical processesPolishing compositions with abrasivesOrganic acidCompound (substance)

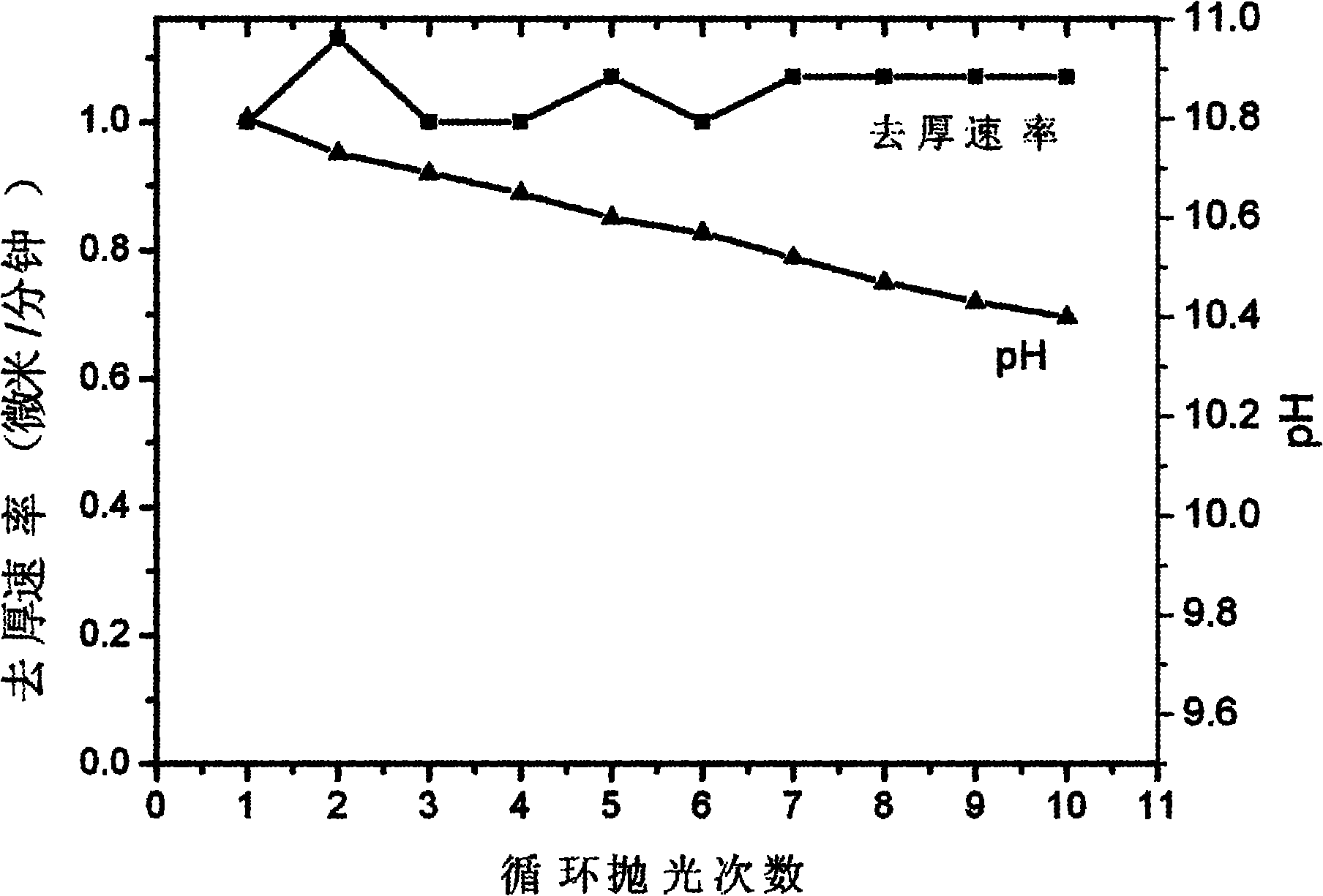

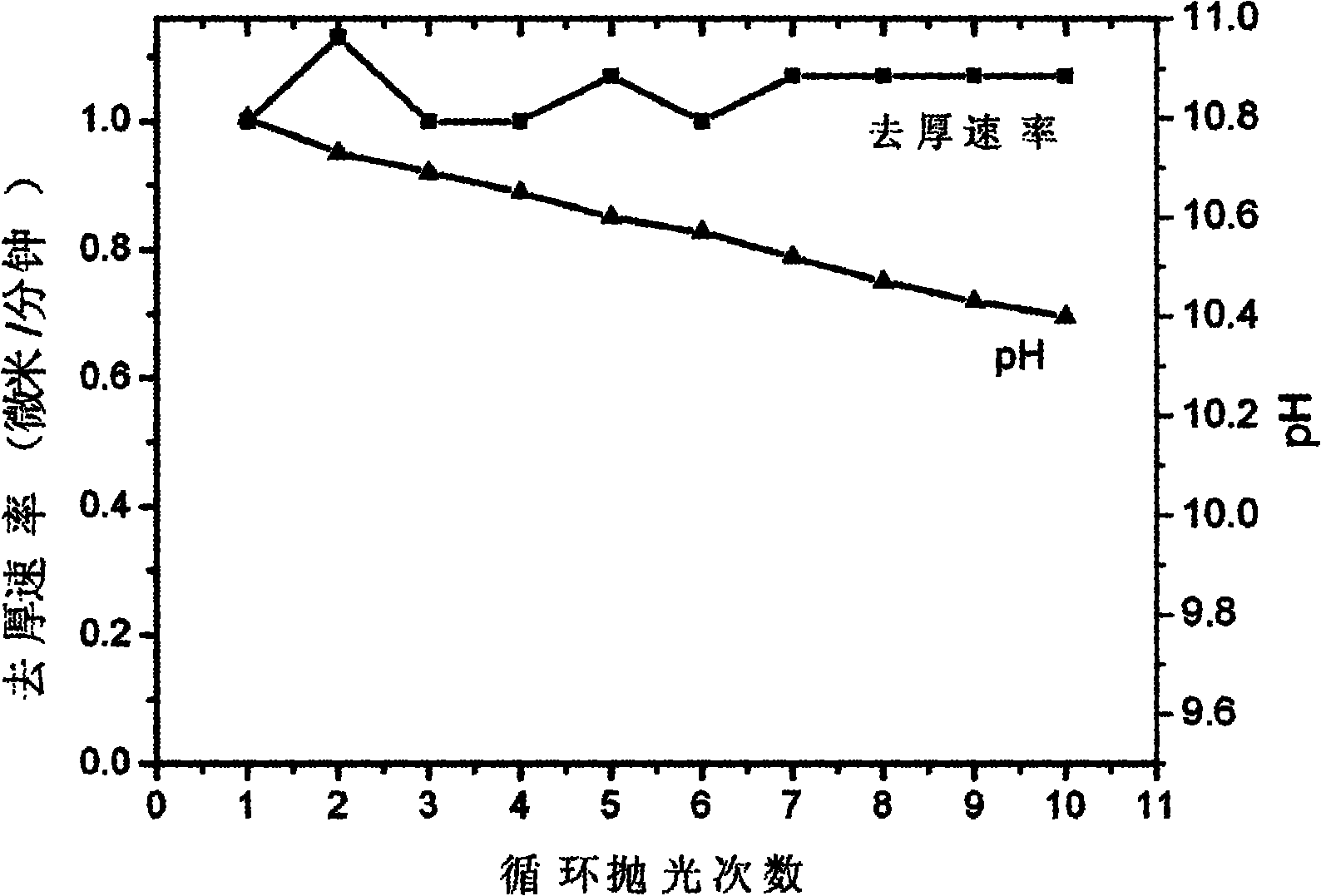

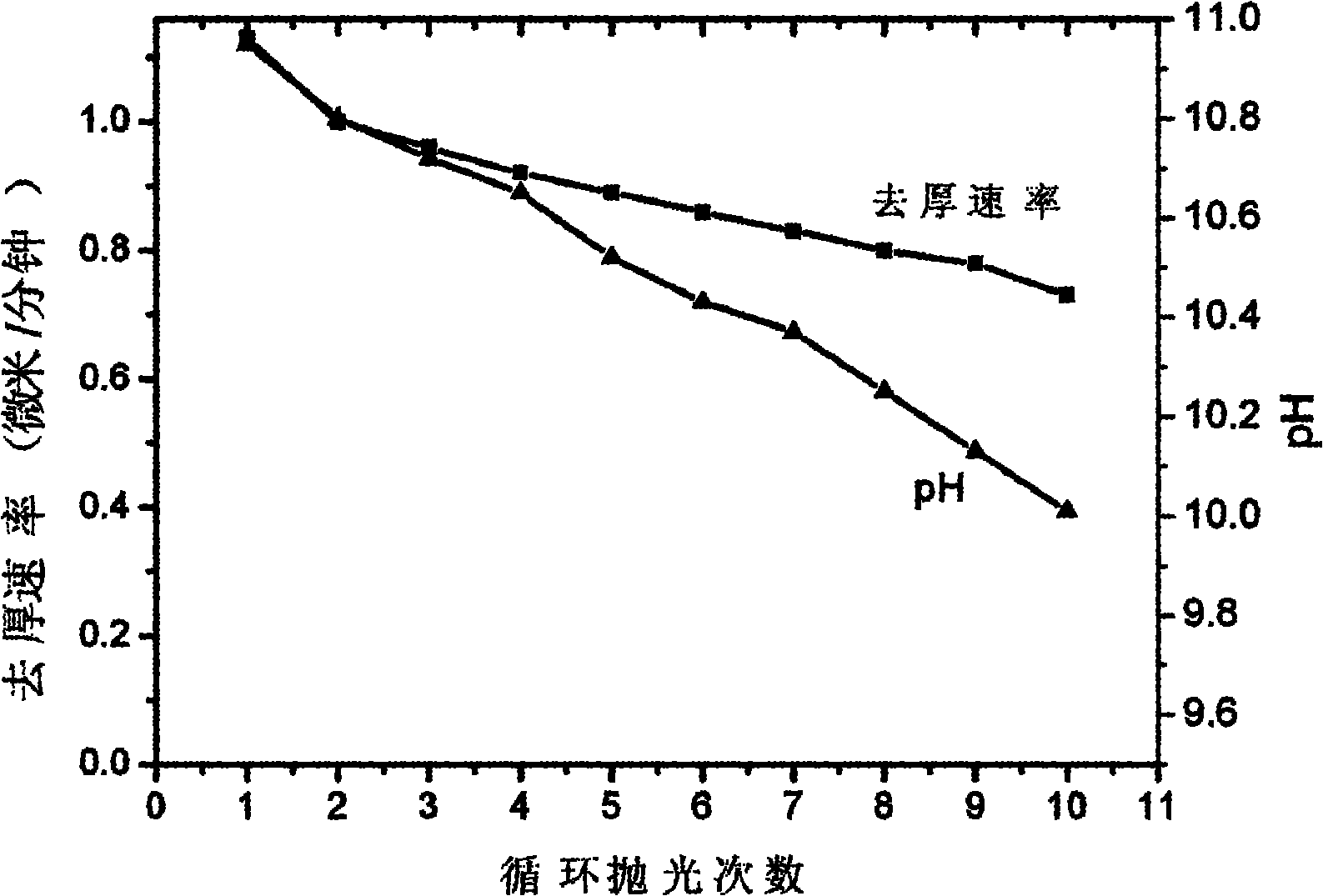

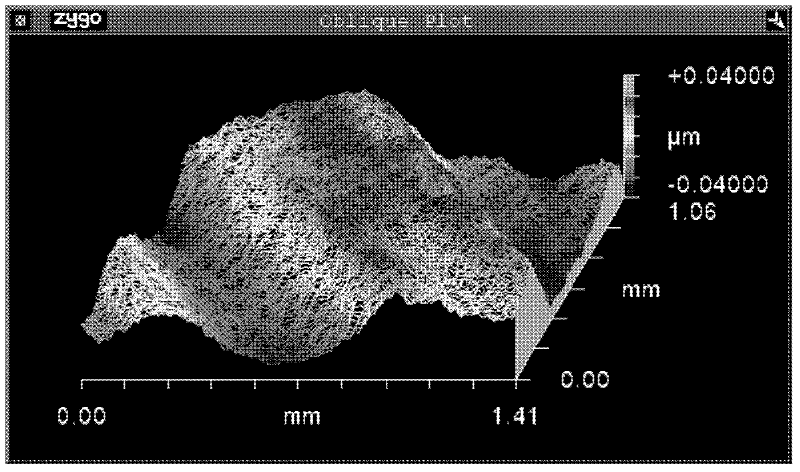

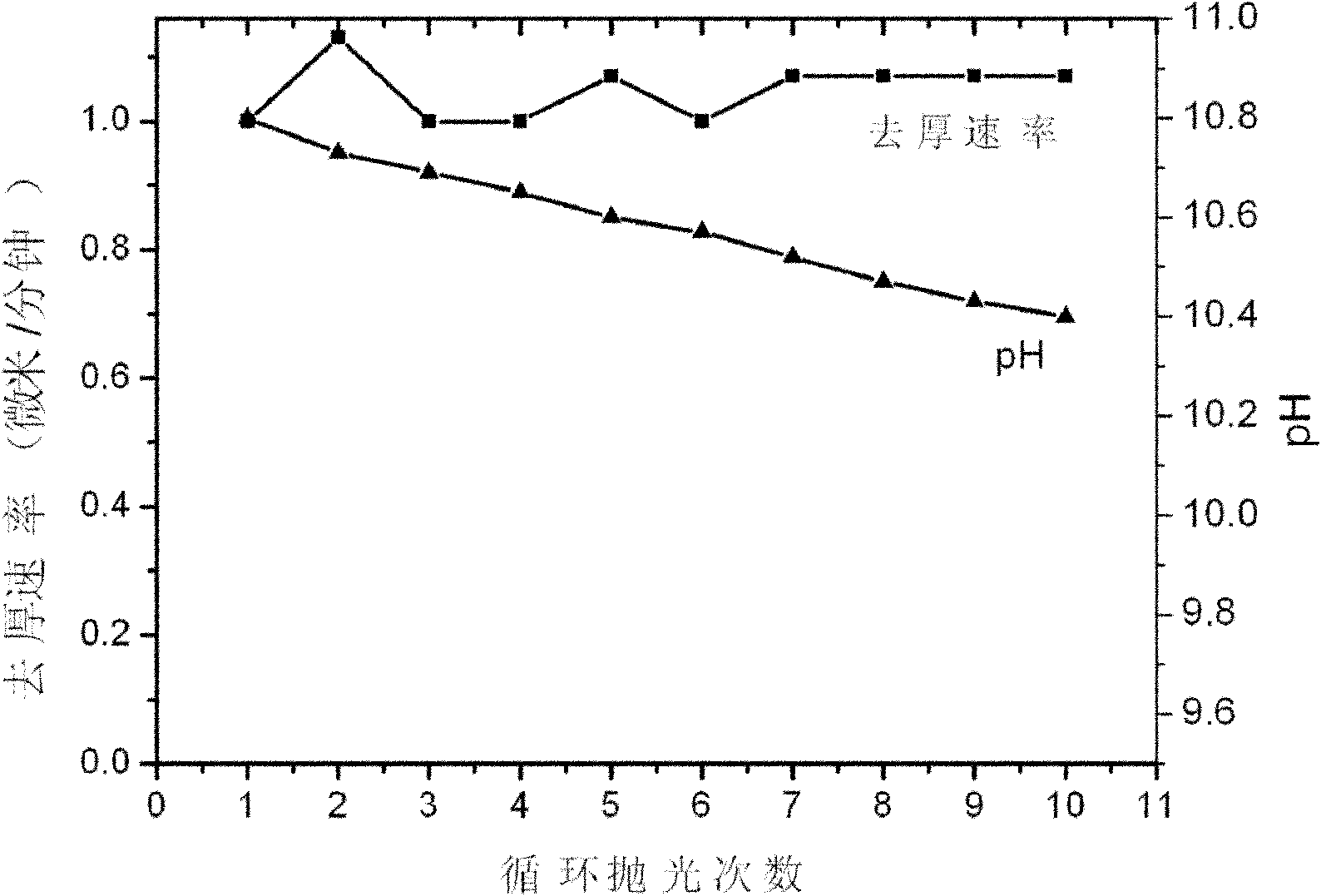

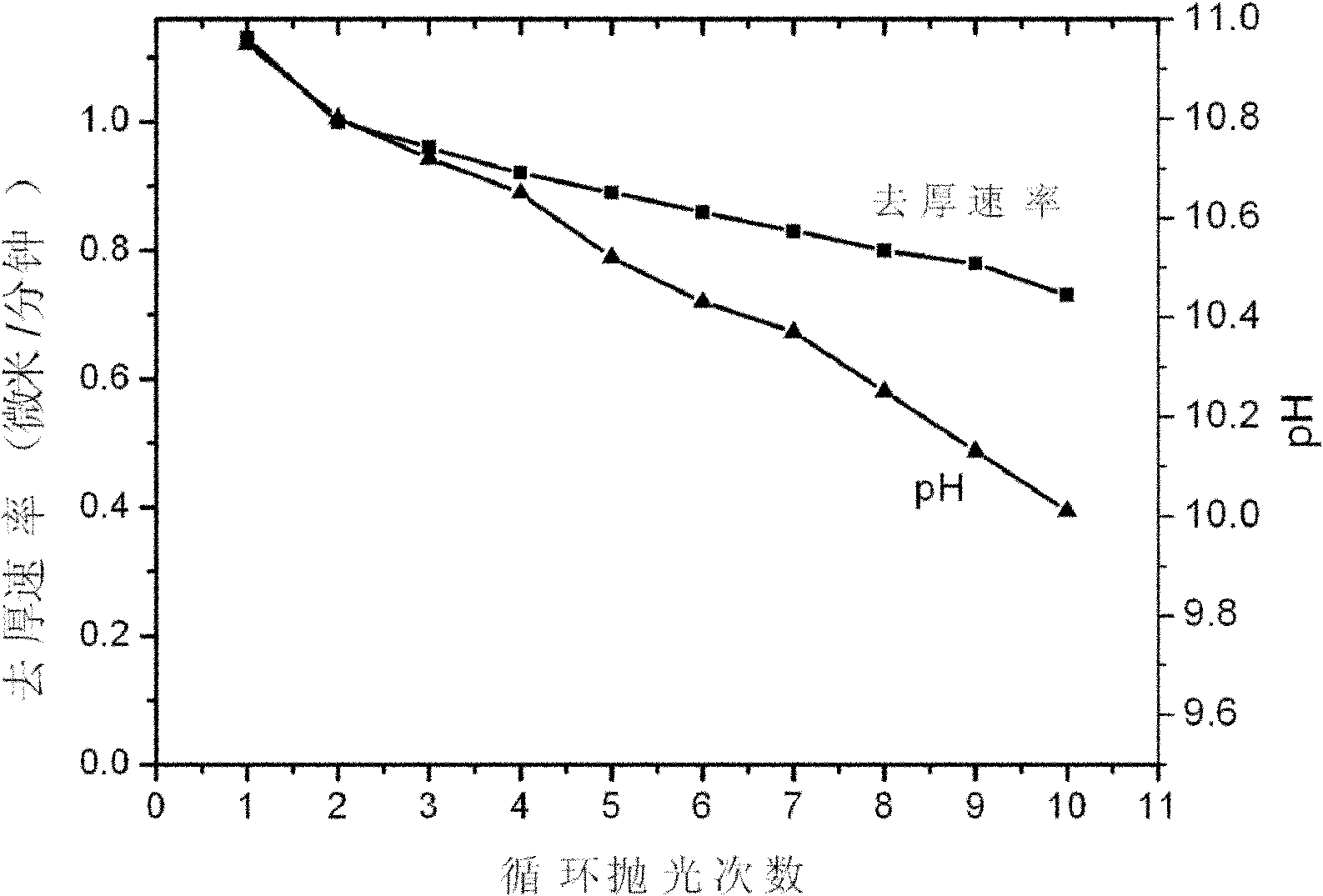

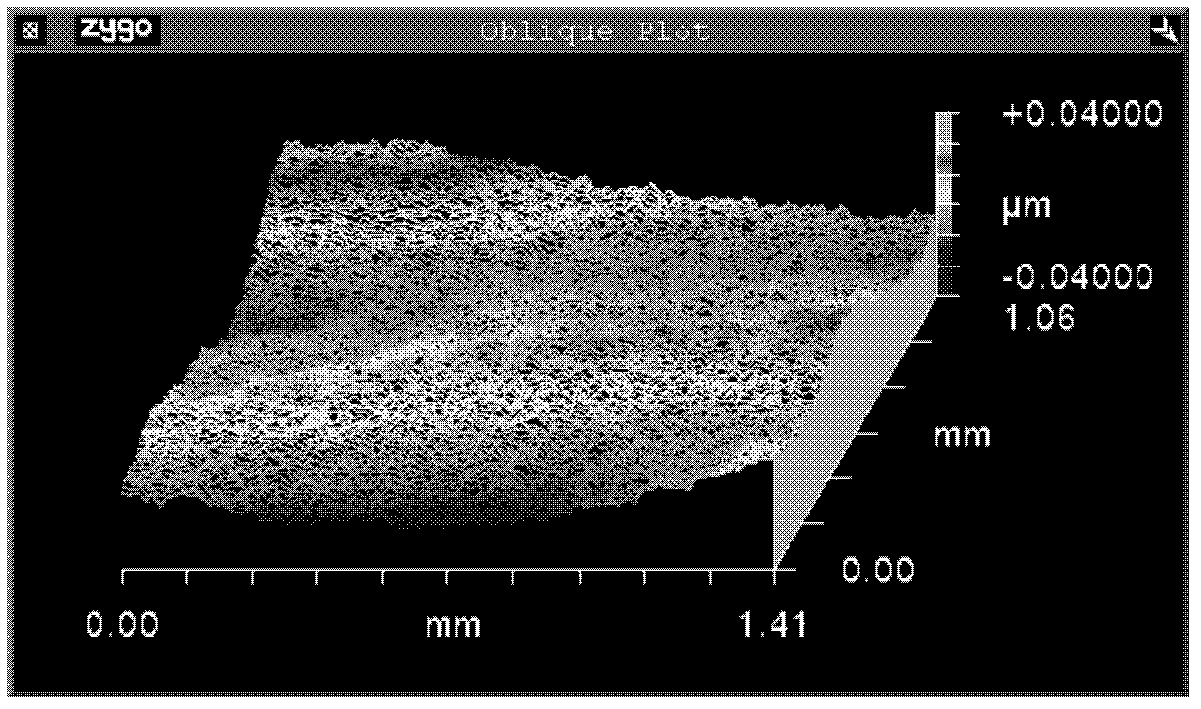

The invention discloses a silicon wafer chemical and mechanical polishing composition with high stability, belonging to the technical field of polishing compositions for roughlly polishing a semiconductor silicon substrate material. The polishing composition comprises the following components in percentage by weight: 0.5-50 percent of silicon dioxide abrasive particles, 0.01-10 percent of silicon-containing stabilizer, 0.01-20 percent of organic alkali corrosive, 0.01 -10 percent of organic acid chelating agent, 0.01-5.0 percent of other functional auxiliaries and the balance of deionized water. The polishing solution has a stabilization period of over 2 years, can perform repeated polishing or cyclic polishing, and has stable pH value and removal speed, wherein the number of cyclic polishing times can be up to 10. Meanwhile, the polishing composition has high silicon wafer removal rate up to over 1.0 mum / min, and the cyclic polishing removal rate in multiple times can be stable. The polishing solution is convenient to prepare and easy to use, has low cost, and is suitable for the rough polishing of silicon wafers of various types and sizes in the semiconductor industry.

Owner:TSINGHUA UNIV +2

Copper chemical and mechanical polishing combination

InactiveCN102329572AReduce surface residueReduce surface corrosion defectsPolishing compositions with abrasivesCompound (substance)Copper

The invention discloses a copper chemical and mechanical polishing combination, which belongs to the technical field of microelectronic auxiliary materials and ultra-precision machining processes. The copper chemical and mechanical polishing combination comprises abrasive particles, an oxidant, a complexing agent, a polishing accelerating agent and a pH regulator. The copper chemical and mechanical polishing combination is characterized by further comprising a long chain corrosion inhibitor and a surface active agent. By using the polishing combination provided by the invention, surface residues, particularly surface granular residues, can be obviously decreased; surface corrosion defects can be obviously decreased; a higher removal speed rate is obtained; and the polishing combination provided by the invention further has the advantages of simple process, cheap price, low cost and the like.

Owner:SHENZHEN LEAGUER MATERIAL +2

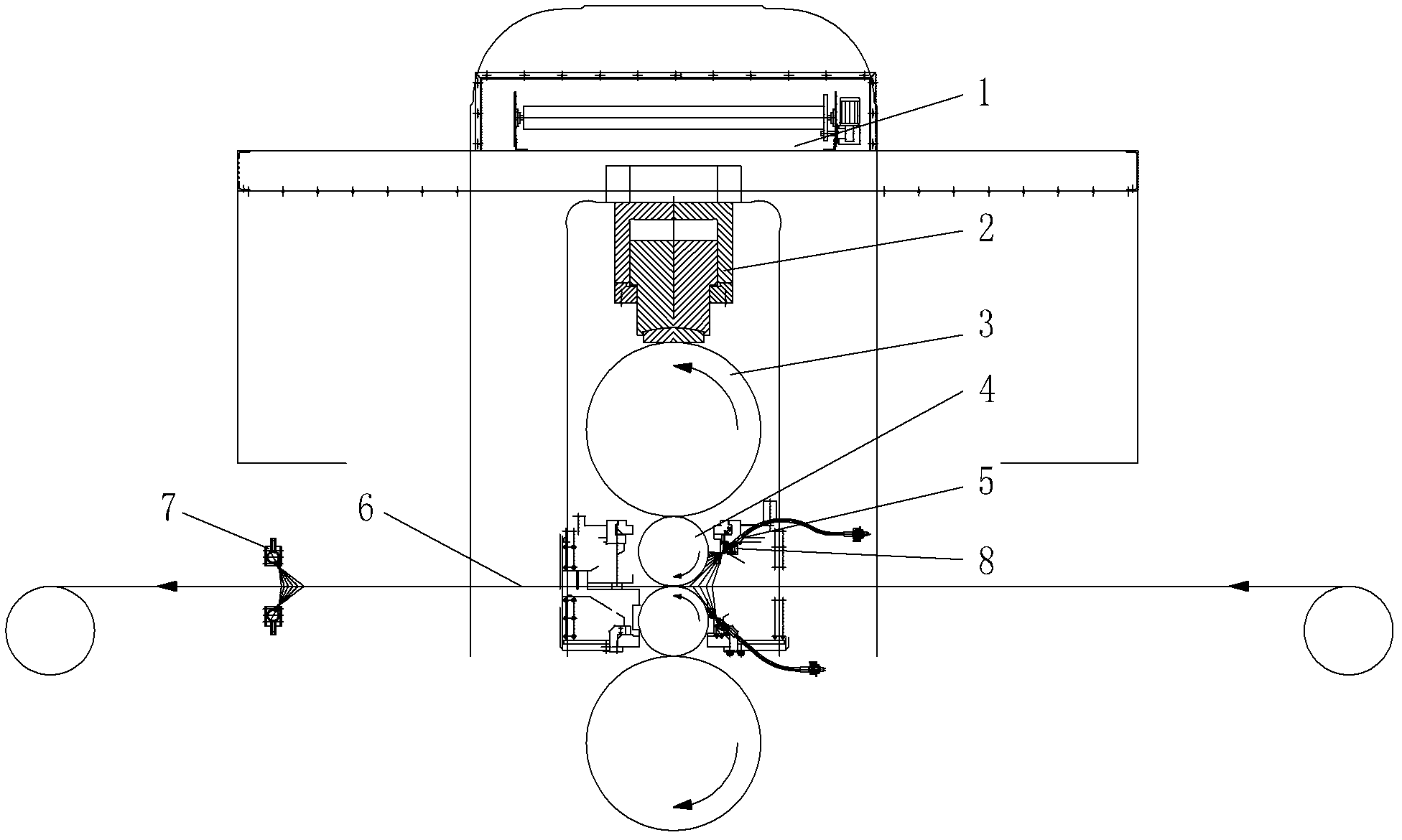

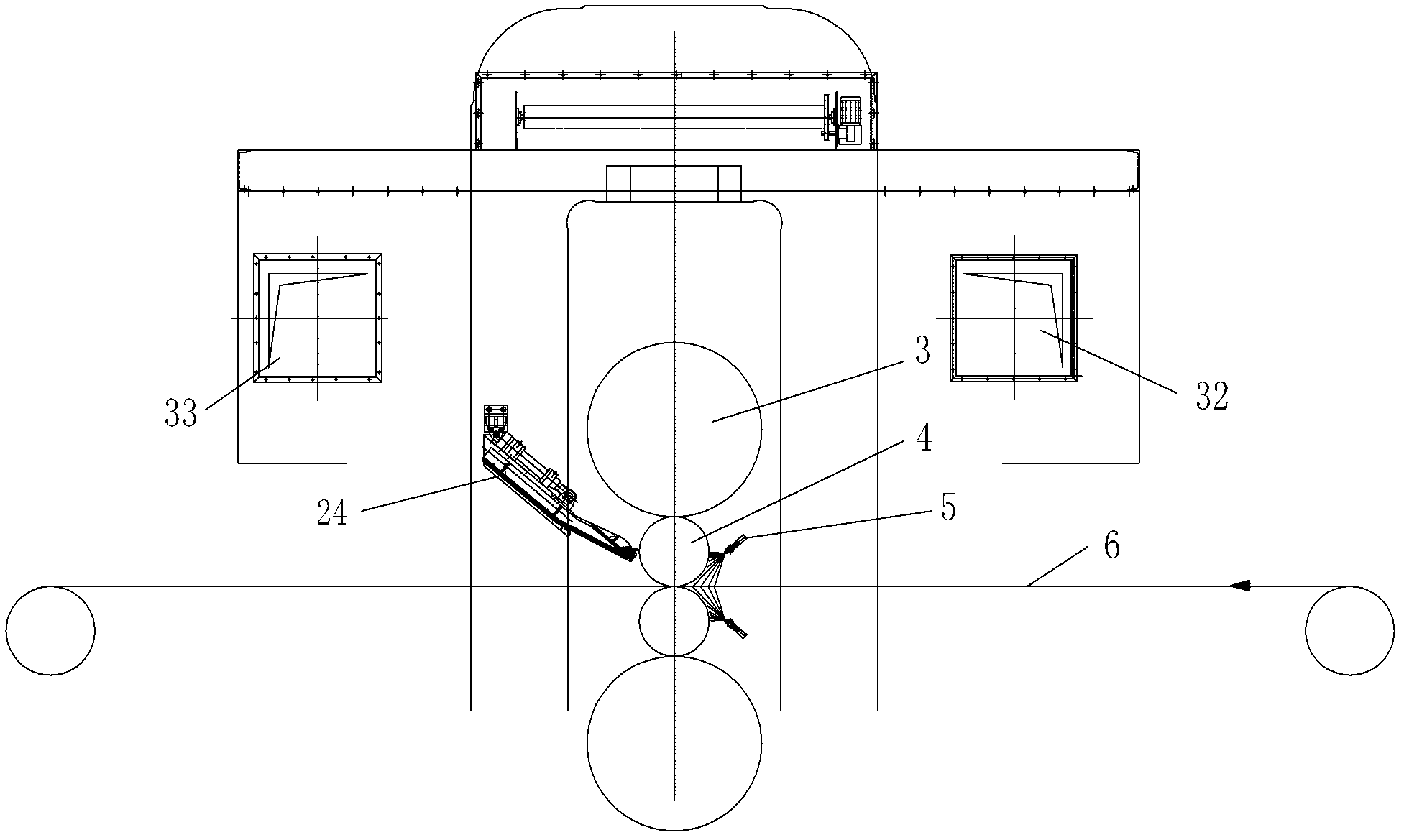

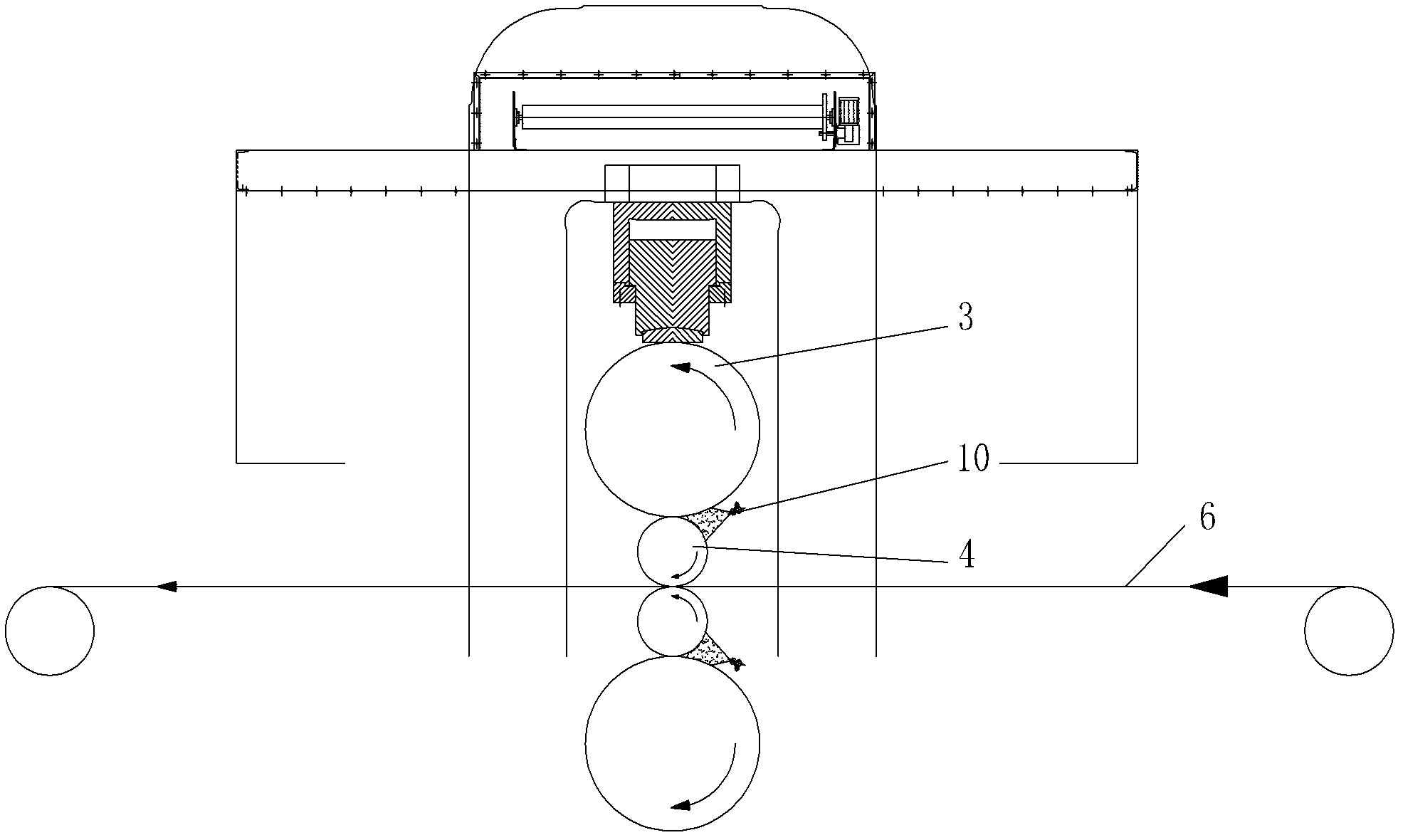

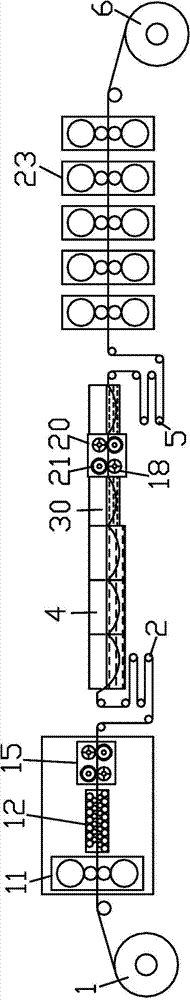

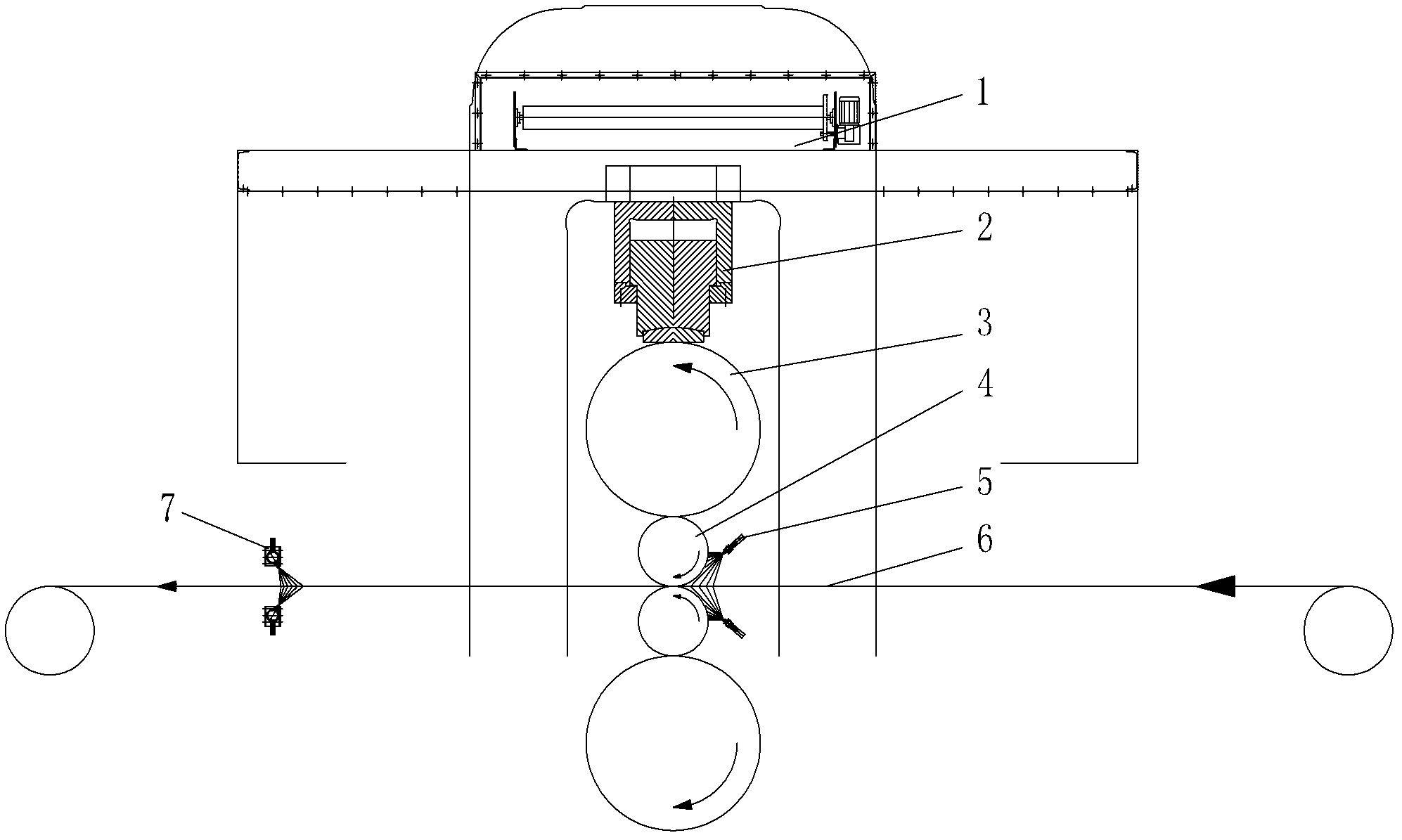

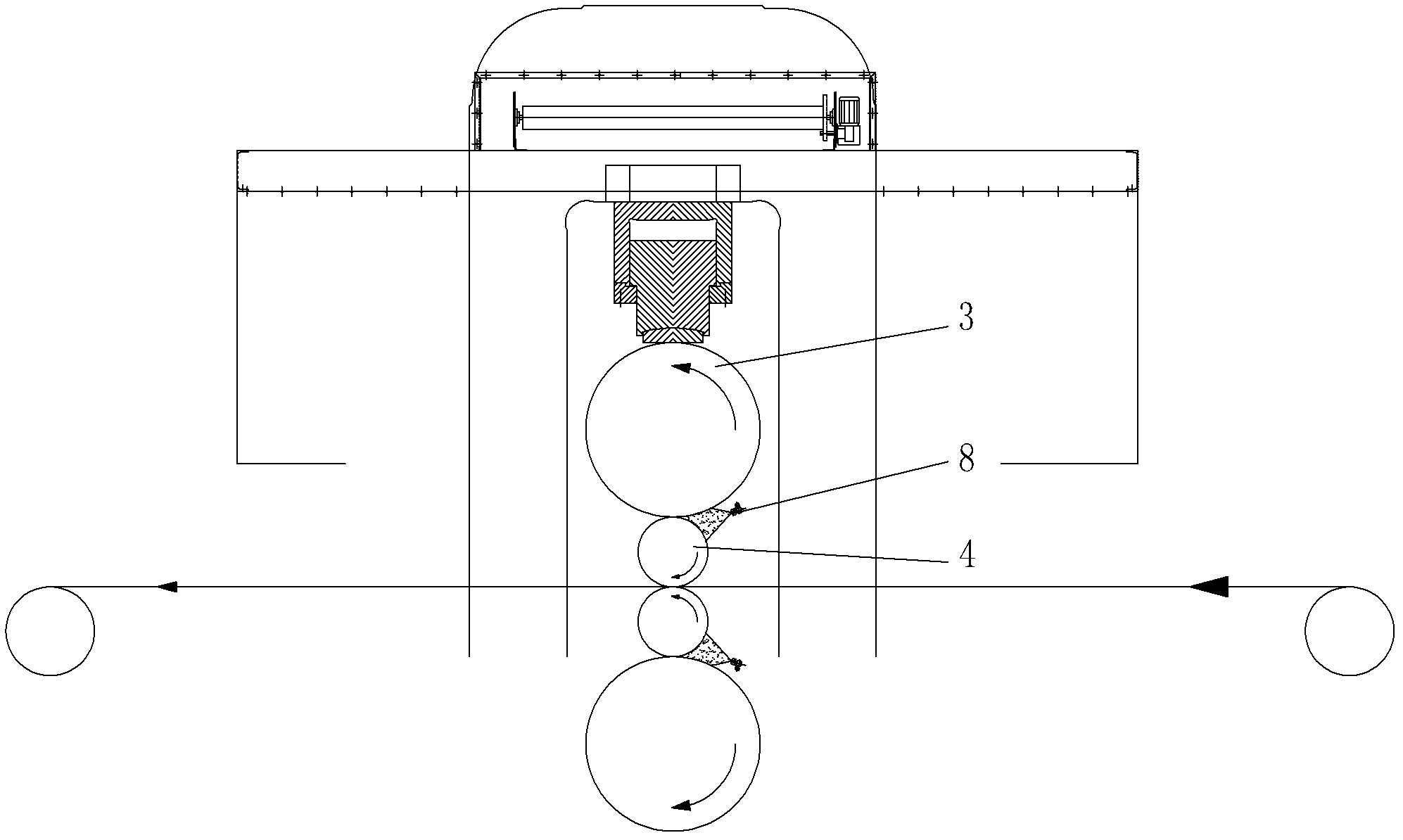

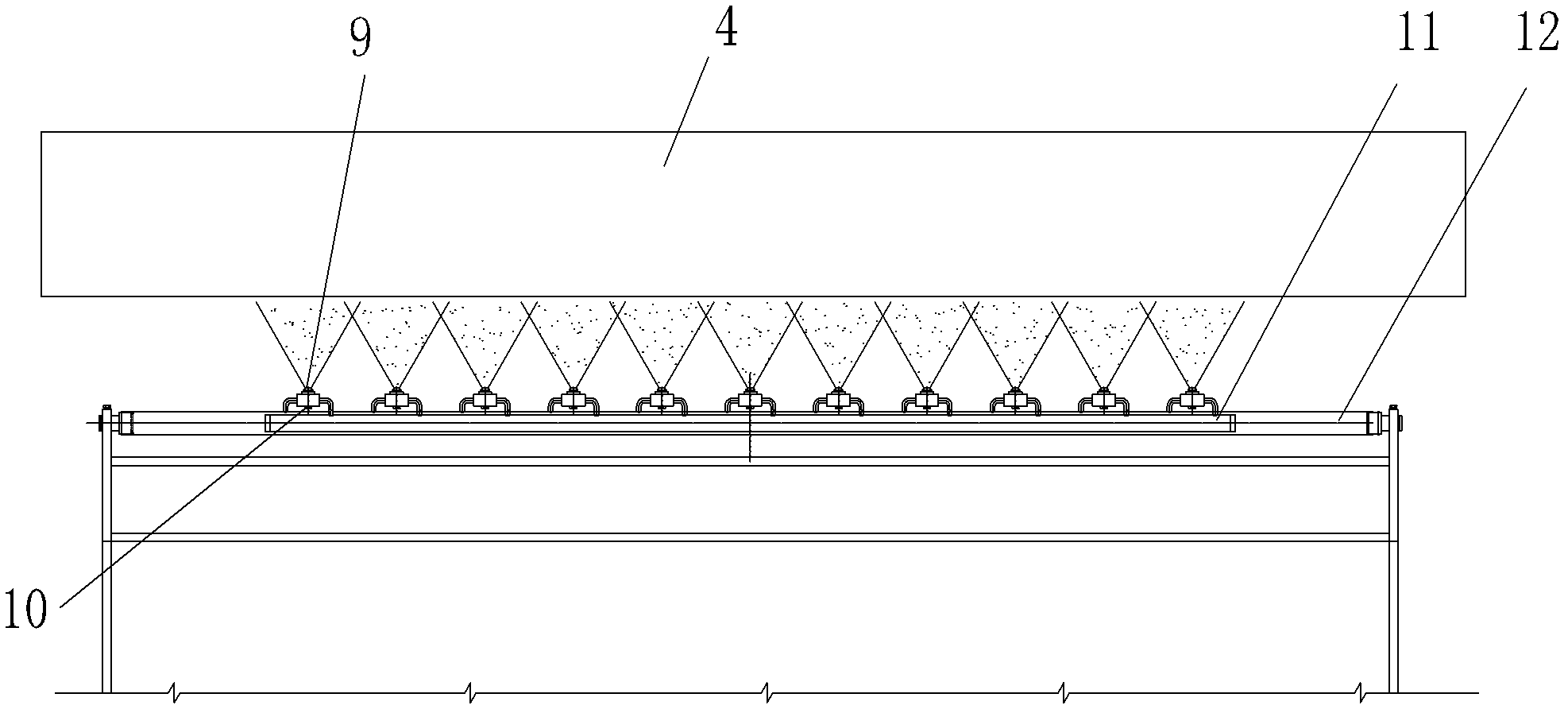

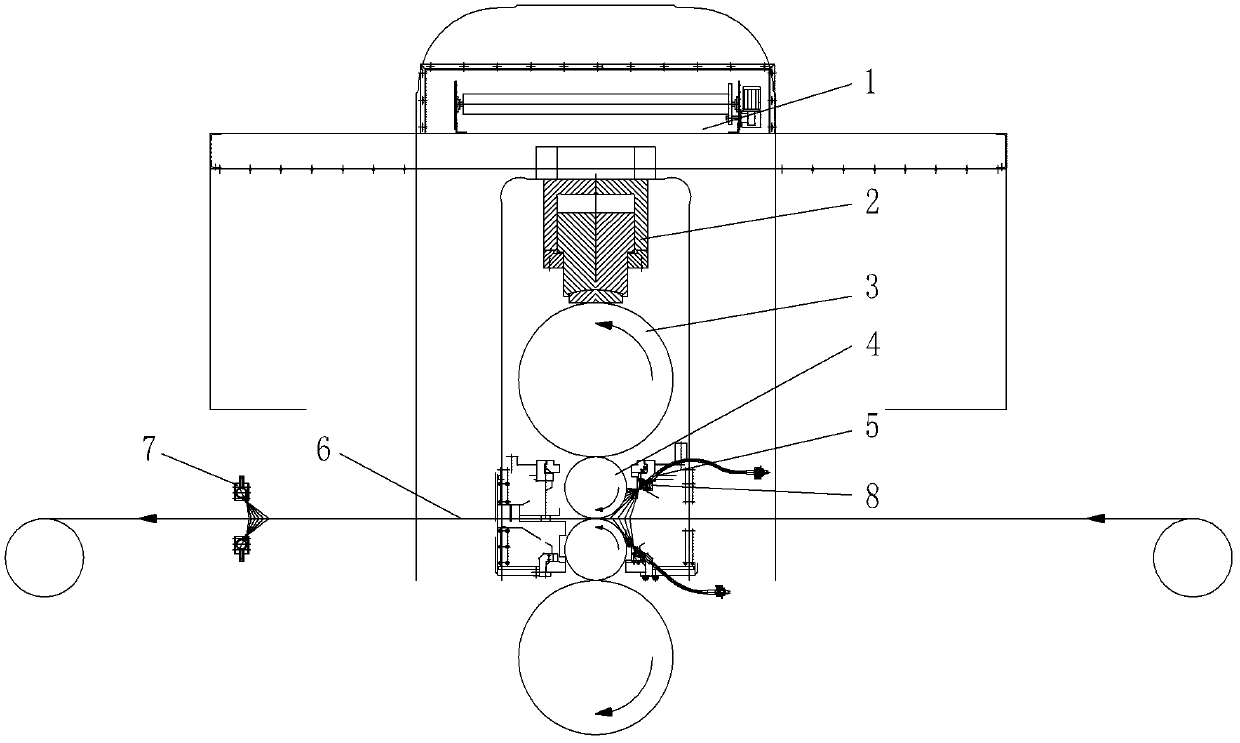

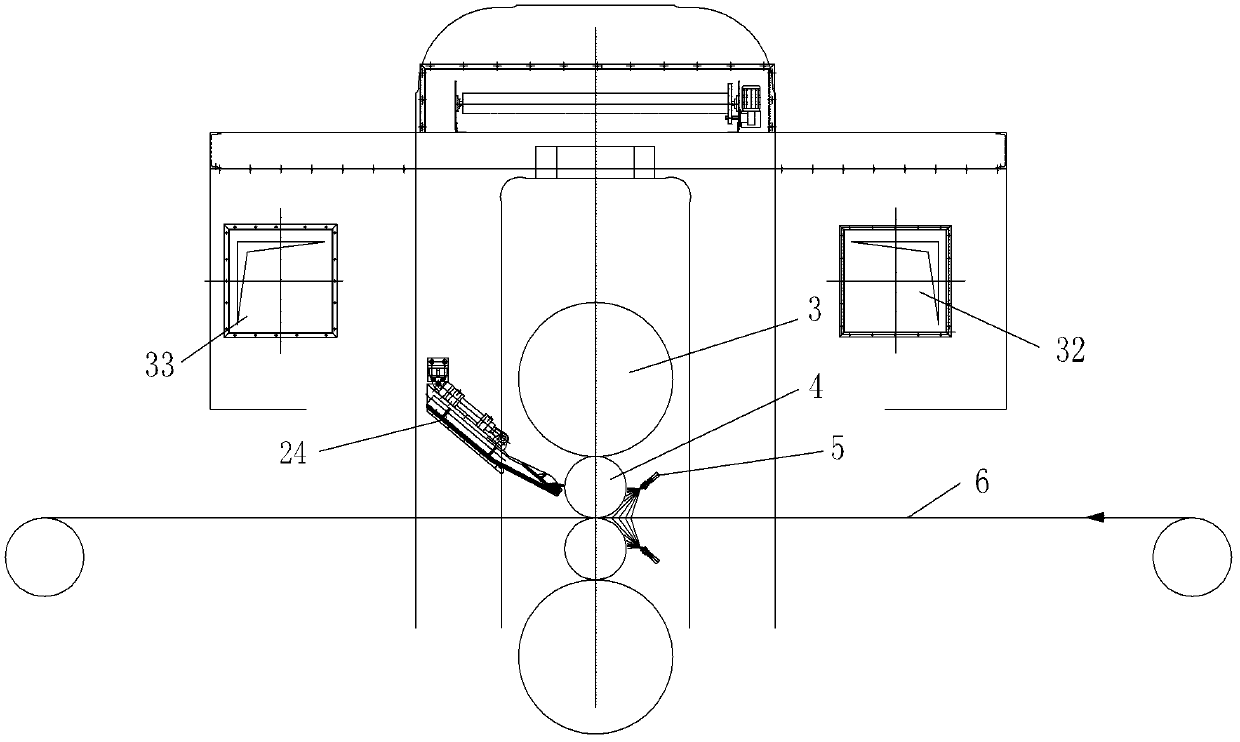

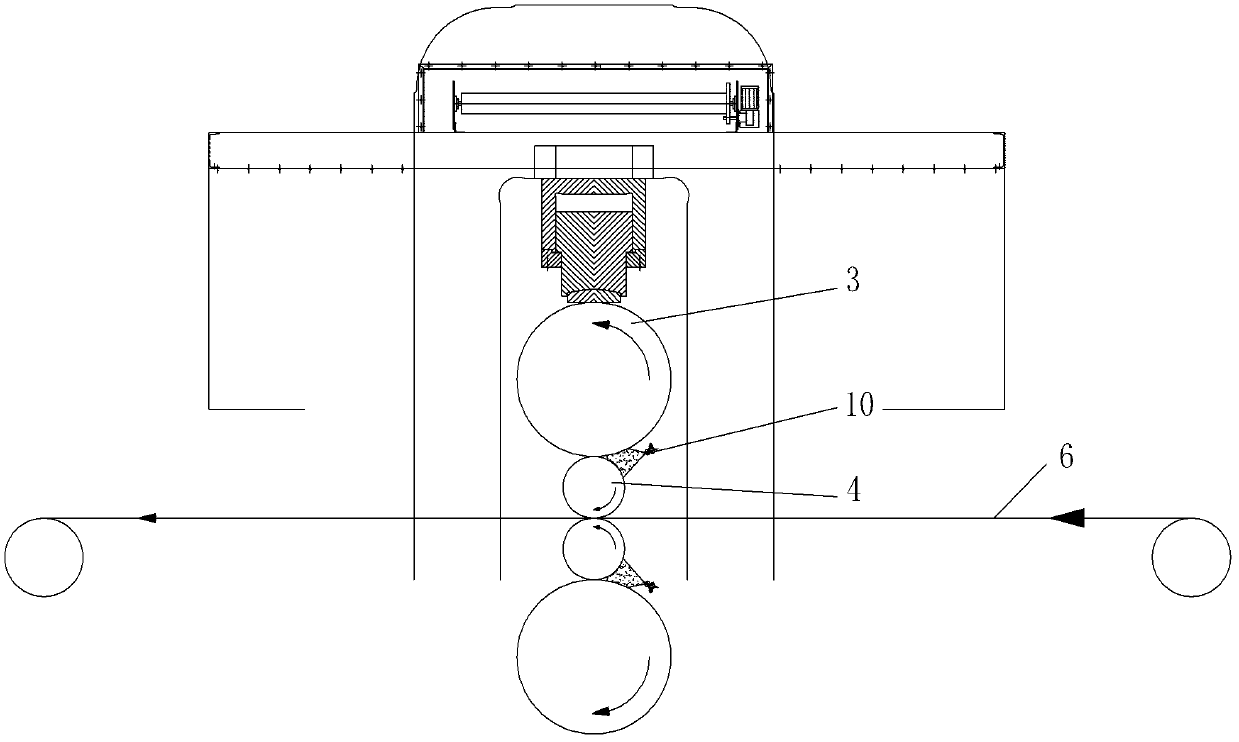

Water mist skin leveling system in cold rolling wet skin leveling production

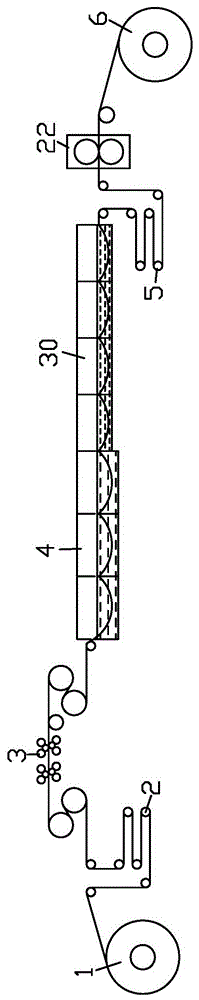

ActiveCN102284519ASolve the problem of residual smooth spotsReduce consumptionWork treatment devicesMetal rolling arrangementsEngineeringStrip steel

The invention relates to a system for performing a leveling production by means of water mist leveling. A water mist leveling system in a cold-rolling wet leveling production, which is characterized by being composed of a water mist leveling-spraying device and a water mist leveling and suction dust removal system, wherein the water mist leveling-spraying device comprises a water mist leveling-spraying beam, a telescoping mechanism and a leveling mist spraying device; the leveling mist spraying device is fixed on the water mist leveling-spraying beam; the water mist leveling-spraying beam is connected with a connection cross beam via the telescoping mechanism, and the both ends of the cross beam are fixed on the frame of a wet leveling mill respectively; the water mist leveling and suction dust removal system comprises an anti-wrapping guide plate and an inlet side air suction tube; the lower port of the anti-wrapping guide plate is a first air suction opening; the inlet side air suction tube is disposed at the inlet side of the wet leveling mill, and the lower port of the inlet side air suction tube is a second air suction opening. The system can increase the quality of strip steel surface and decrease the production energy consumption.

Owner:WISDRI ENG & RES INC LTD

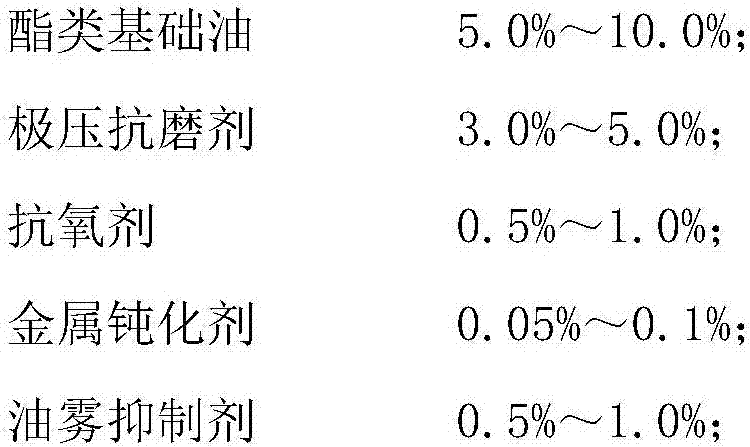

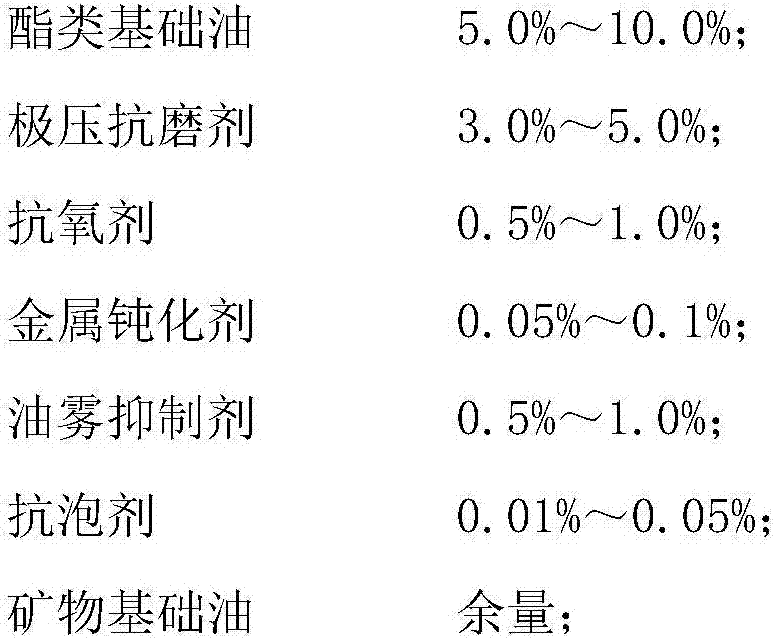

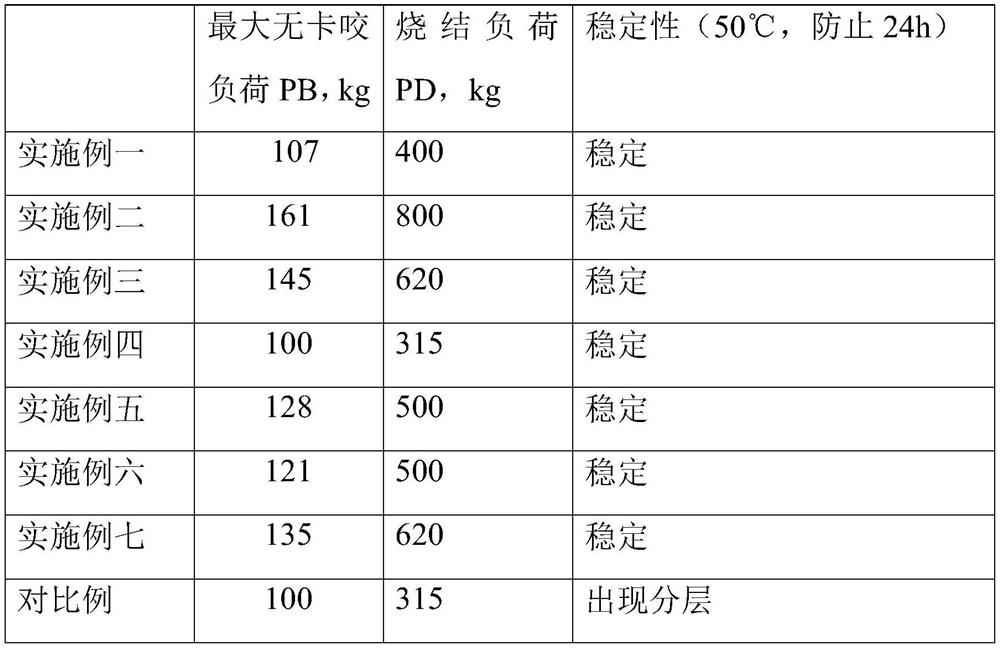

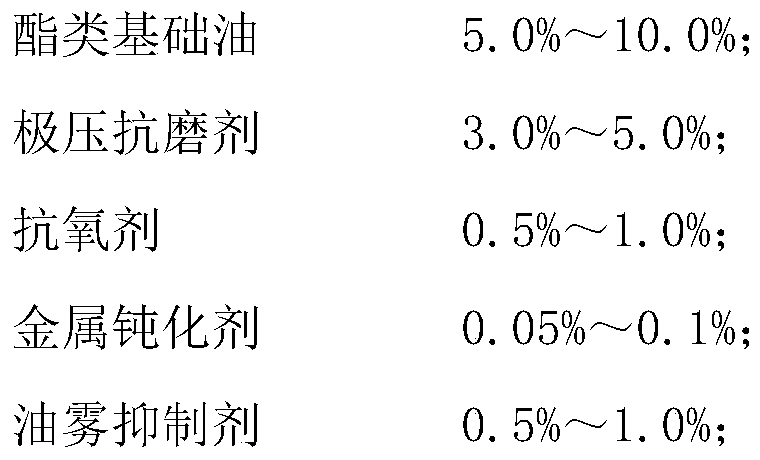

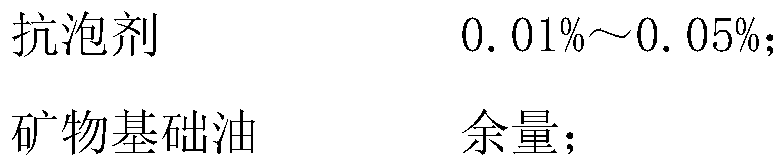

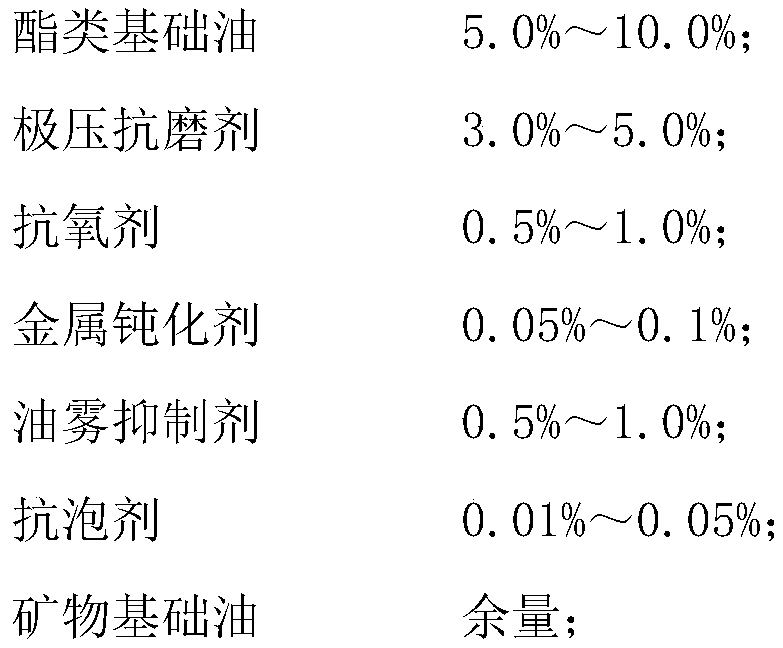

Environmentally-friendly super-finishing grinding oil and preparation method thereof

The invention relates to environmentally-friendly super-finishing grinding oil and a preparation method thereof. The environmentally-friendly super-finishing grinding oil is prepared from, by weight, 5.0%-10.0% of ester base oil, 3.0%-5.0% of an extreme-pressure and anti-wear agent, 0.5%-1.0% of an antioxygen, 0.05%-0.1% of a metal desactivation agent, 0.5%-1.0% of an oil mist inhibitor, 0.01%-0.05% of an anti-foaming agent and mineral base oil balance. The sum of the percentages of the above components is 100%. The environmentally-friendly super-finishing grinding oil has high lubrification, cooling, rust protection and corrosion protection performances; meanwhile, heavy metals, chlorine and low oil mist do not exist in the environmentally-friendly super-finishing grinding oil, so that the environmental-friendly super-finishing grinding oil is harmless to an operator and the environment.

Owner:辽宁海华科技股份有限公司

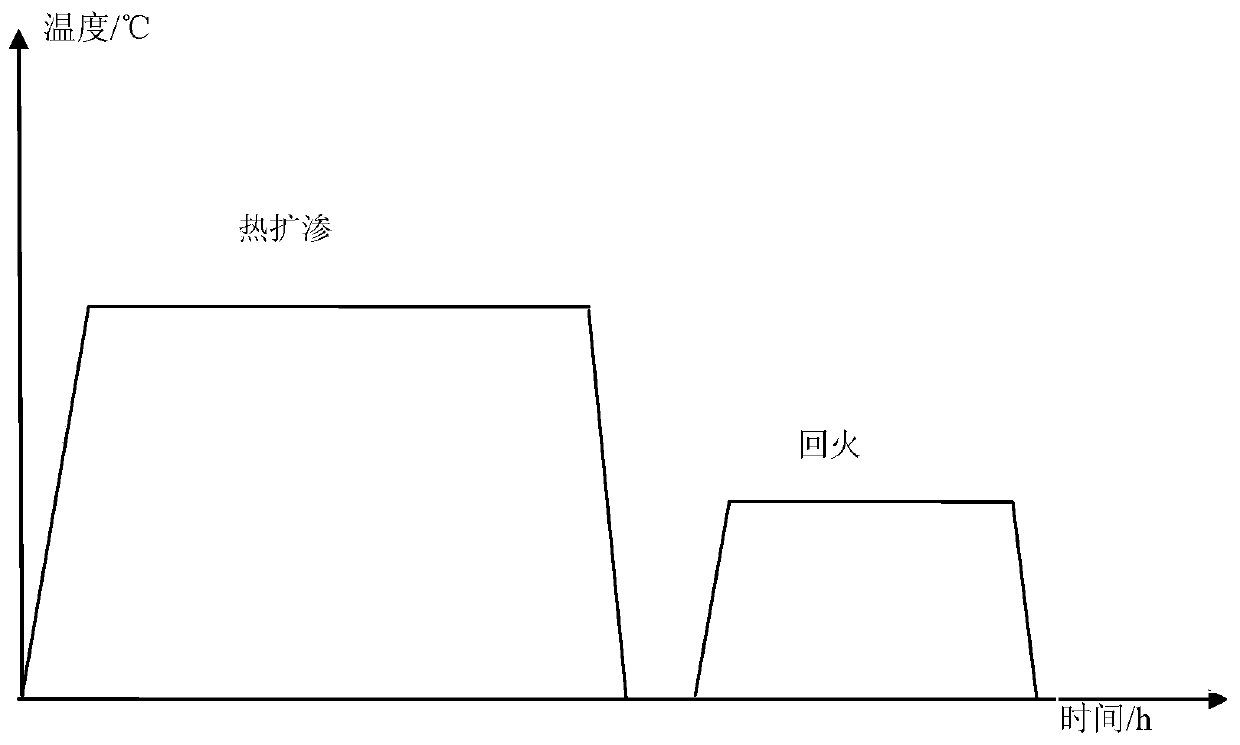

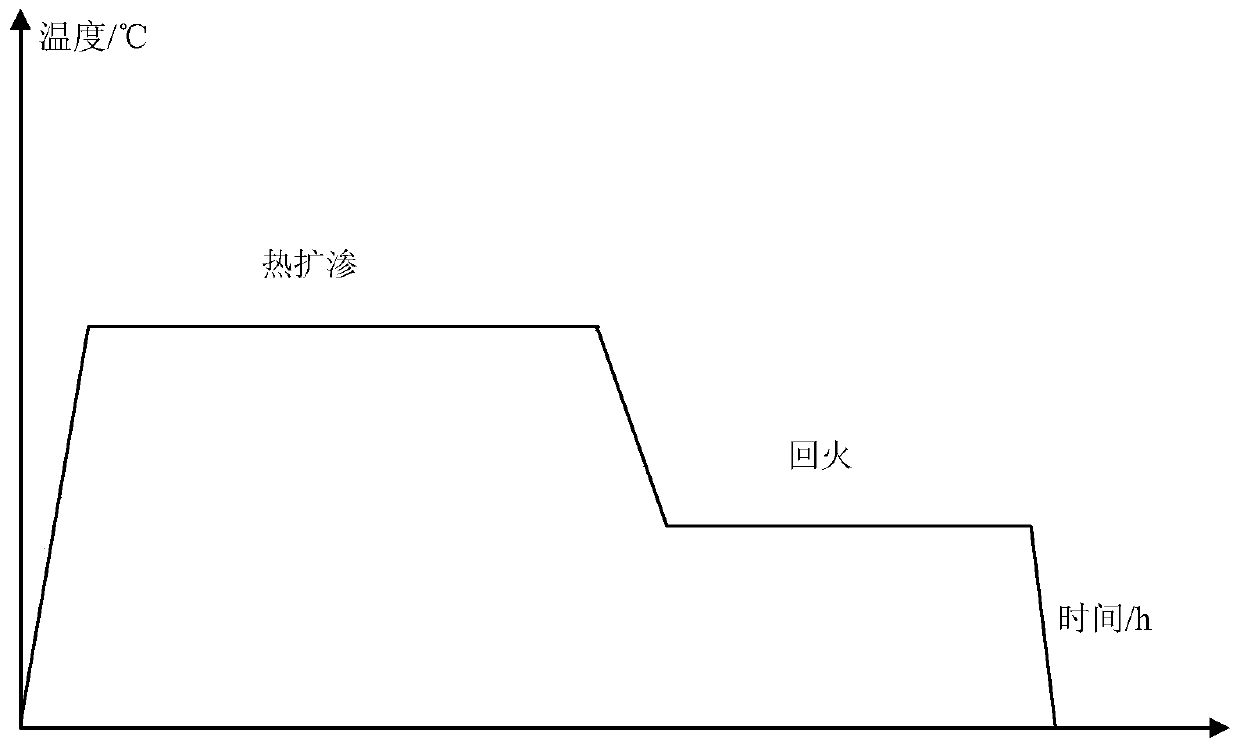

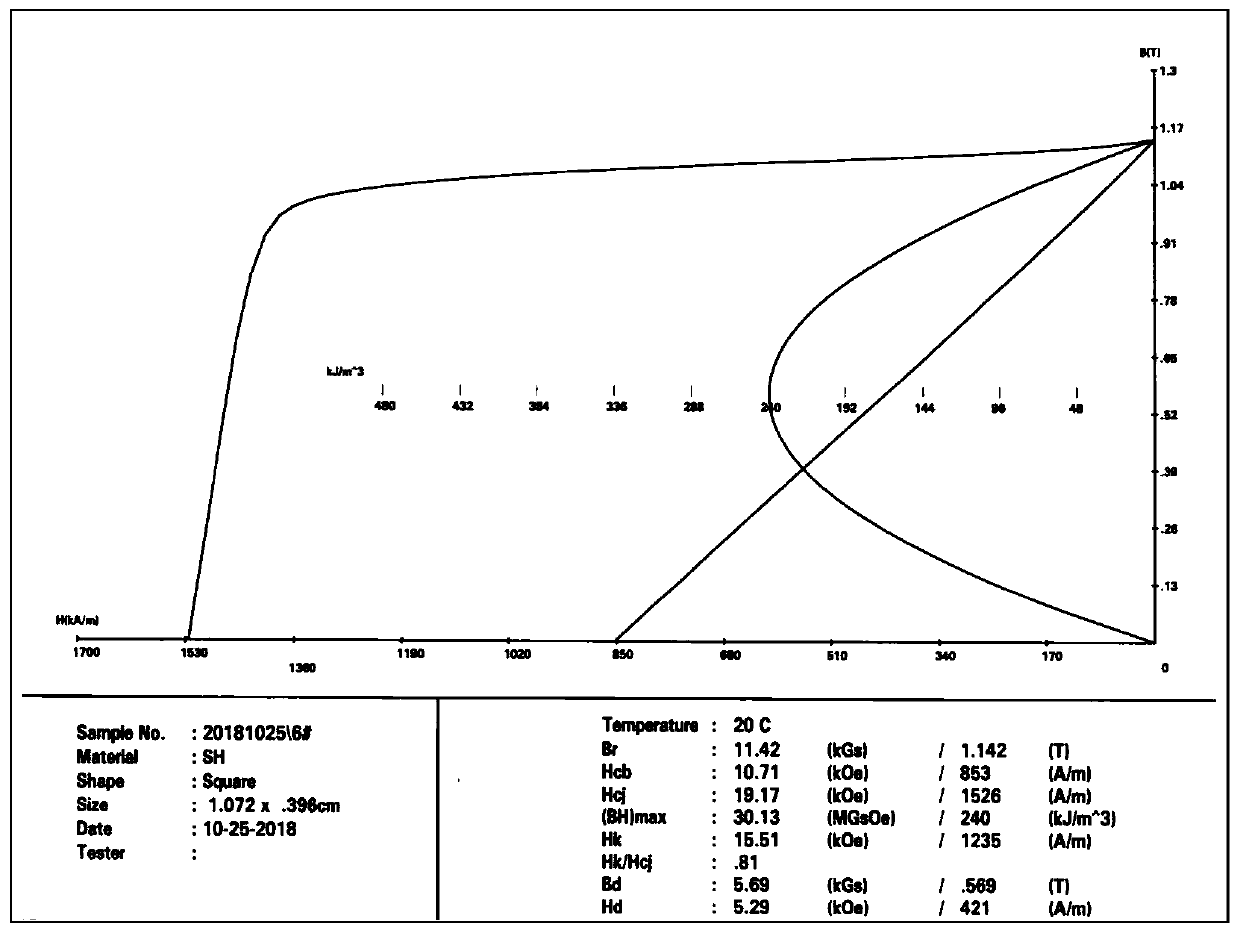

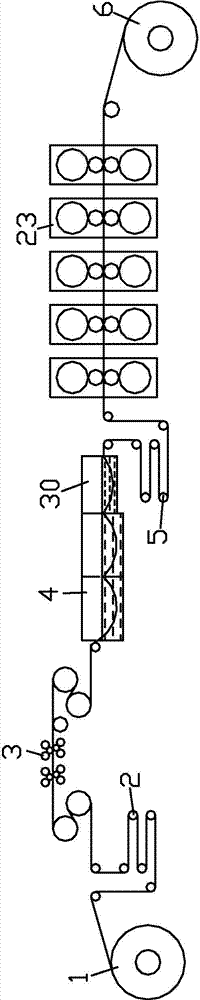

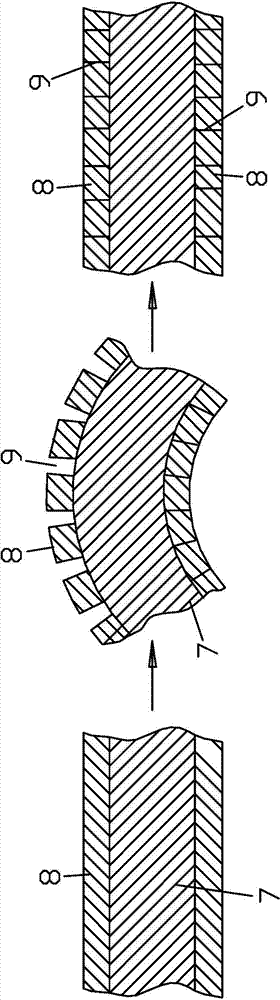

Neodymium iron boron rare-earth permanent magnet heavy rare-earth thermal diffusion coating liquid and preparation method and application thereof

InactiveCN109695015AStickyAdjustable thicknessTransportation and packagingMetal-working apparatusSurface cleaningRare earth

The invention relates to neodymium iron boron rare-earth permanent magnet heavy rare-earth thermal diffusion coating liquid and a preparation method and application thereof, and belongs to the technical field of rare-earth permanent magnet surface treatment. The neodymium iron boron rare-earth permanent magnet heavy rare-earth thermal diffusion coating liquid is prepared from the components: 25-50% of heavy rare-earth powder, 0-5% of a penetration-promoting agent, 2-15% of a binder, 1-3% of a surfactant, 1-3% of a dispersing agent and the balance of a diluent. The preparation method comprisesthe steps of mixing the heavy rare-earth powder, the penetration-prompting agent and the diluent, and adding residual raw materials. The method is applied to a neodymium iron boron rare-earth permanent magnet heavy rare-earth thermal diffusion process, and the process comprises the specific steps that surface cleaning treatment is carried out on the neodymium iron boron rare-earth permanent magnet, surface coating treatment is carried out by centrifugal immersion or spraying, and then thermal expansion is carried out. According to the neodymium iron boron rare-earth permanent magnet heavy rare-earth thermal diffusion coating liquid, the coercive force can be greatly improved after the thermal diffusion, meanwhile, the coating efficiency is improved, the waste of the heavy rare-earth powderis reduced, and a bottleneck of the prior coating art is broken.

Owner:NORTHEASTERN UNIV

Production method for 1100-H14 state aluminum alloy strip for processing high-end cosmetic bottle cap

ActiveCN110102580ARaise the finishing temperatureImprove surface propertiesProfile control deviceMetal rolling arrangementsPunchingHigh surface

The invention belongs to the technical field of aluminum alloy processing, and discloses a production method for a 1100-H14 state aluminum alloy strip for processing a high-end cosmetic bottle cap. The production method comprises the following steps of smelting, adopting of a semi-continuous-method casting ingot, homogenizing heat treatment, head cutting, tail cutting and face milling, hot rolling, primary cold rolling, primary intermediate annealing, secondary cold rolling, secondary intermediate annealing, third-time cold rolling until the finished product thickness is 0.7 mm or less, cleaning and tension correction. By means of the production method, the hot rolling and cold rolling processes are optimized, the rolling texture and the annealing texture after a heat treatment system andfinal cold rolling deformation are balanced, the rolled finished product thickness is less than 1 mm, meanwhile, the earing ratio after material punching is reduced, the high surface characteristics of the material after anodic oxidation and coloring are ensured, the color is uniform after oxidation and coloring, and the appearance is high in metal texture, and the using requirements of high-end cosmetic cover material substrates are met.

Owner:河南明晟新材料科技有限公司

Medicament foil rolling additive composition

The invention discloses a medicament foil rolling additive composition. The composition consists of the following components by weight: (A) 0.04-2.0% of low-temperature antioxidant, (B) 80-95% of fatty acid methyl ester, (C) 0.06-1.0% of phosphide anti-wear agent, (D) 1-15% of polyhydric alcohol and (E) 0.04-2.0% of high-temperature antioxidant, wherein the component (C) phosphide anti-wear agent is one or more of triaryl phosphate, tricresyl phosphate and phosphate amine salt; the component (D) polyhydric alcohol is one or more of trimethylolpropane, pentaerythritol and diethylene glycol. By compounding the carbon chain fatty acid methyl ester, the phosphide anti-wear agent and the polyhydric alcohol, the chemical adsorption capability and the flow cleaning performance are enhanced, the surface residue of a medicament foil product is greatly reduced on the premise of ensuring the lubricating capability, and the dyne value and peeling strength of a medicament foil are effectively improved.

Owner:石家庄新泰特种油有限公司

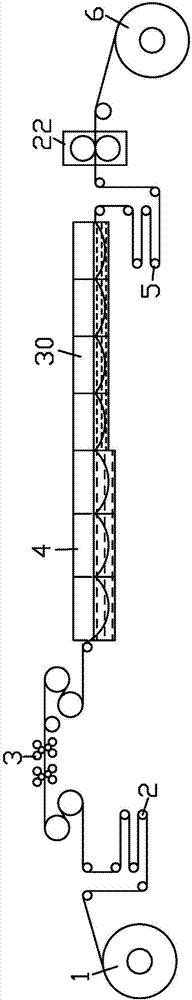

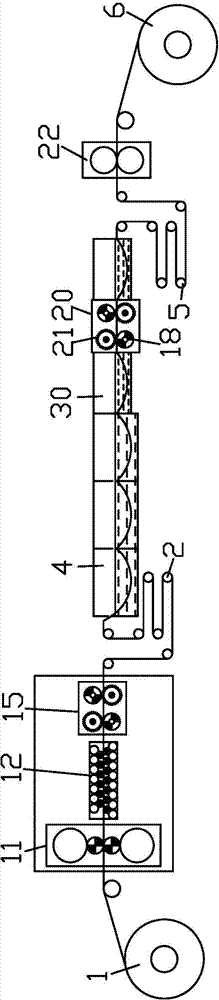

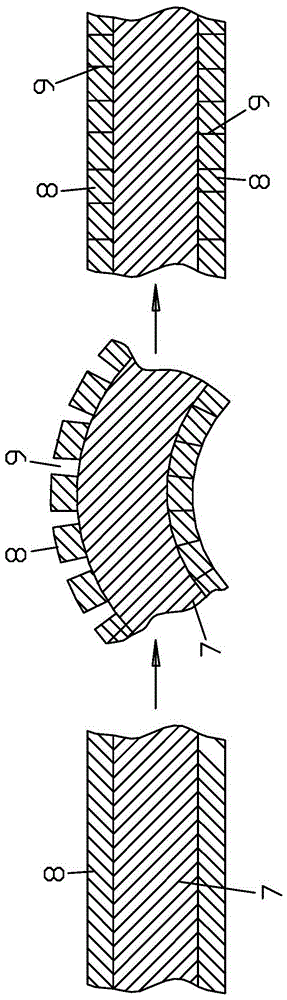

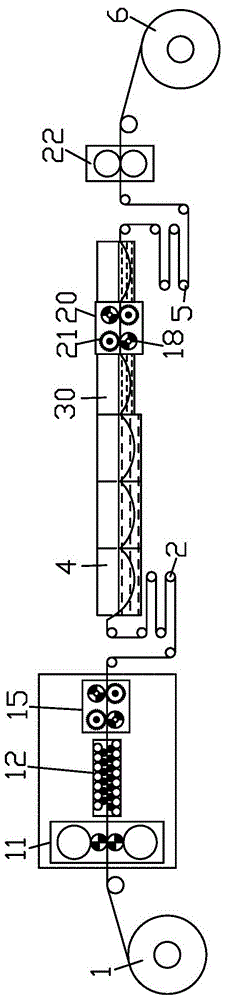

Production method of low-consumption corrosion-resistant cold-rolled product

ActiveCN103920710AResidue reductionHigh mechanical phosphorus removal efficiencyWork treatment devicesMetal rolling arrangementsStrip steelCorrosion resistant

The invention relates to a production method of a low-consumption corrosion-resistant cold-rolled product. The method specifically includes the following steps: uncoiling via an uncoiler; breaking and stripping oxides on the surface of strip steel via a leveler; further breaking and stripping the oxides on the surface of the strip steel via a multi-roll straightener; removing the shed and loose oxides of the surface of the strip steel via a scrubbing device; subjecting the treated strip steel to acid pickling and rinsing; removing surface residues of the strip steel mechanically; then subjecting the strip steel to cold rolling; recoiling via a recoiler. Through the method, the surface oxides of the strip steel have more cracks and are large in clearance, and efficiency of acid pickling is improved; part of the oxides is removed while scale breaking, reacting dose of acid pickling is decreased, and acid consumption is lowered; the added value of yield strength of the strip steel after scale breaking is lowered, and convenience is brought to subsequent cold rolling; the strip steel is subjected to leveling prior to cold rolling, so that profile precision of the finished product is improved; chloride ion residues on the surface of the product are decreased, and corrosion resistance of the product is enhanced.

Owner:WISDRI ENG & RES INC LTD

Low acid consumption anti-corrosion hot-replacing-cold product production method

ActiveCN103924254AResidue reductionHigh mechanical phosphorus removal efficiencyWork treatment devicesMetal rolling arrangementsSurface roughnessBrush device

The invention relates to a low acid consumption anti-corrosion hot-replacing-cold product production method. The low acid consumption anti-corrosion hot-replacing-cold product production method comprises the following steps: uncoiling by adopting an uncoiler; breaking and stripping oxide on the surface of strip steel by adopting a temper mill; further breaking and stripping the oxide on the surface of the strip steel by adopting a multi-roll straighter; eliminating the oxide which falls off and is loose on the surface of the strip steel by adopting a brushing device; carrying out acid pickling and rinsing on the treated strip steel; then eliminating residue on the surface of the strip steel by adopting a mechanical way; carrying out surface roughness homogenization finishing on the strip steel; recoiling by adopting a recoiler. By virtue of the technical scheme, the low acid consumption anti-corrosion hot-replacing-cold product production method has the advantages that firstly more cracks and large gaps are formed in the oxide on the surface of the strip steel, so that acid pickling efficiency is high; secondly, eliminating part of oxide while breaking scale, so that acid picking reacting dose is reduced, and acid consumption is reduced; thirdly, added value of yield strength of the strip steel after processing is low; fourthly, a Luders strip is avoided from being formed on the surface of a common hot rolling product; fifthly, chlorine ion residue on the surface of a product is reduced, and corrosion resistance of the product is improved.

Owner:WISDRI ENG & RES INC LTD

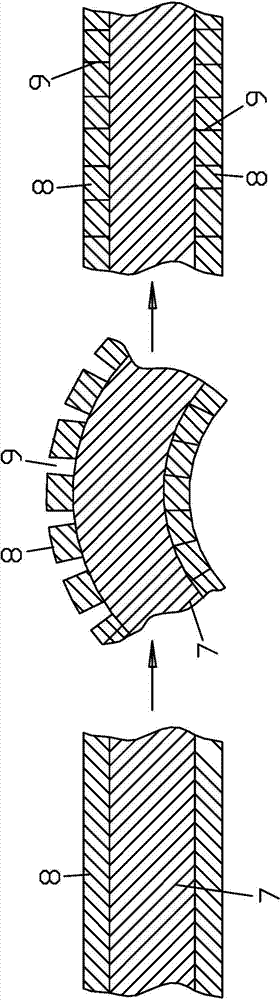

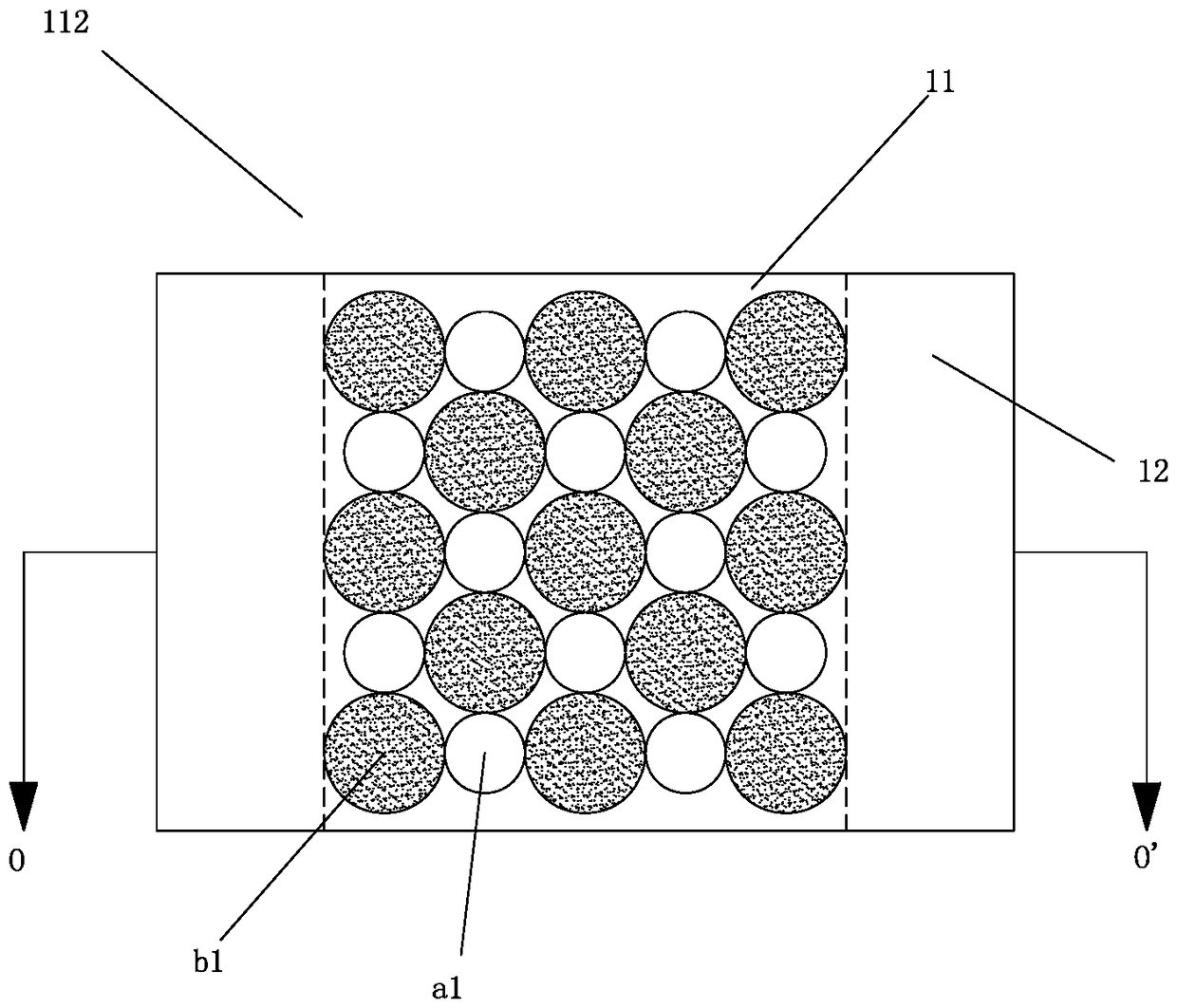

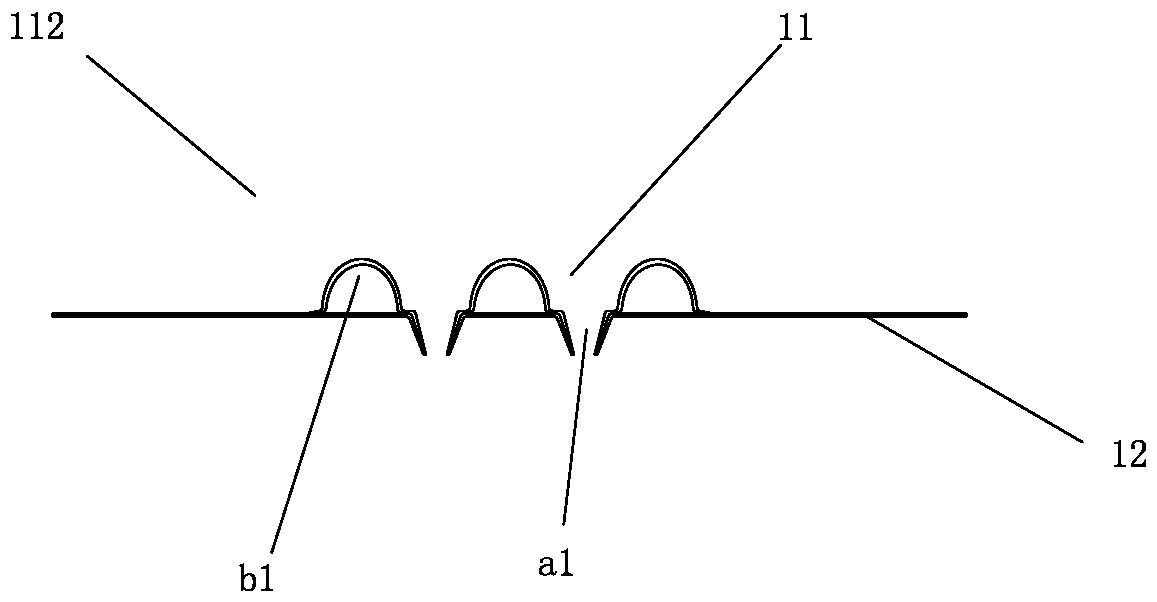

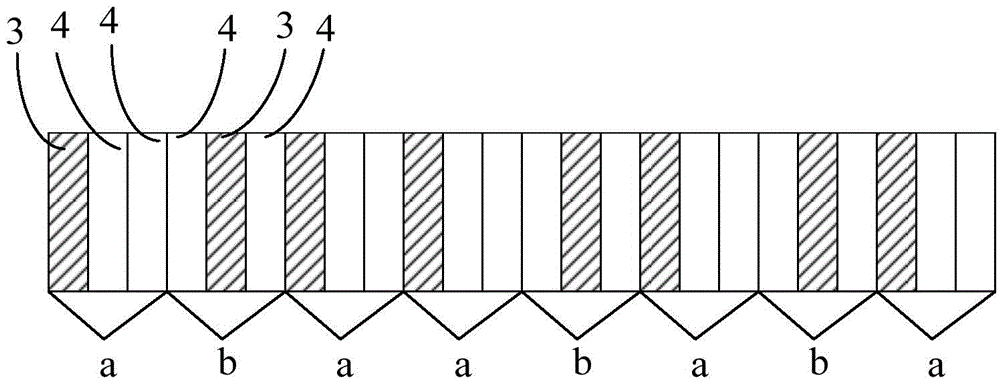

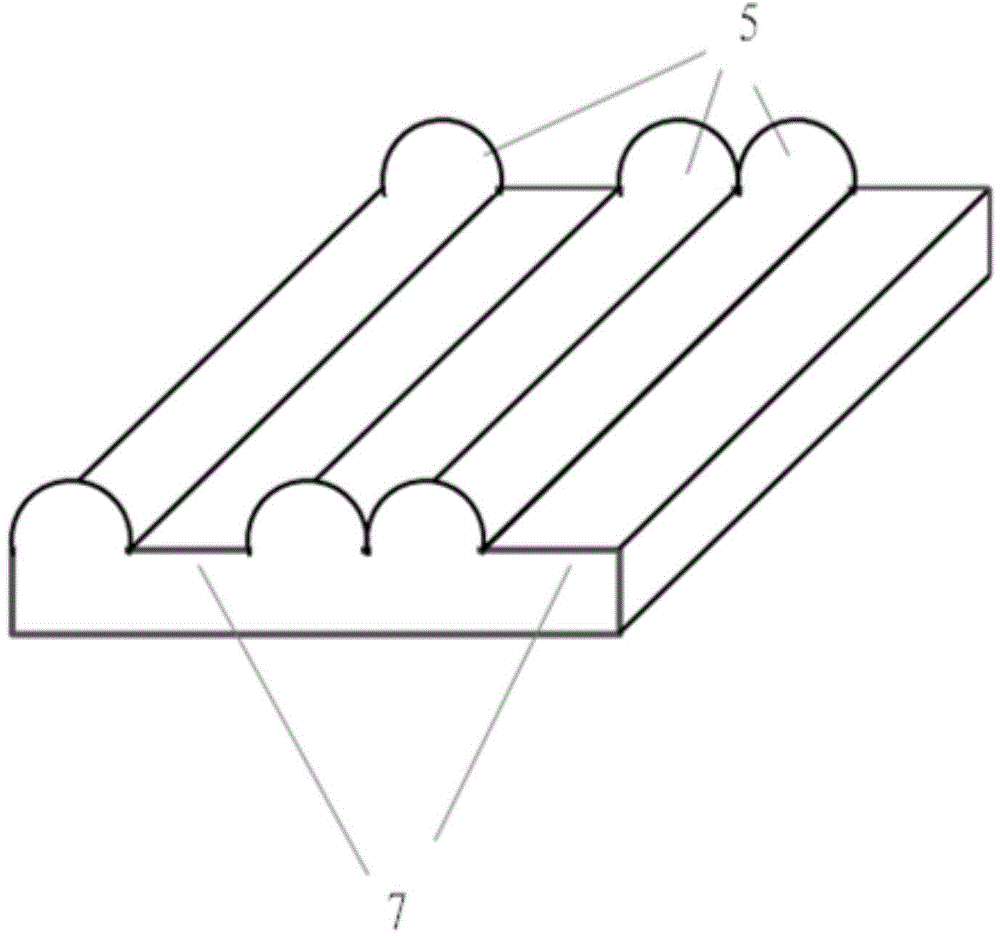

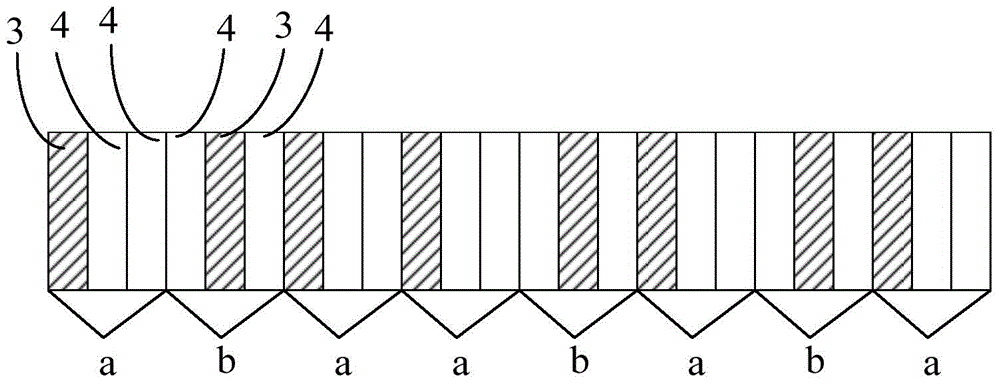

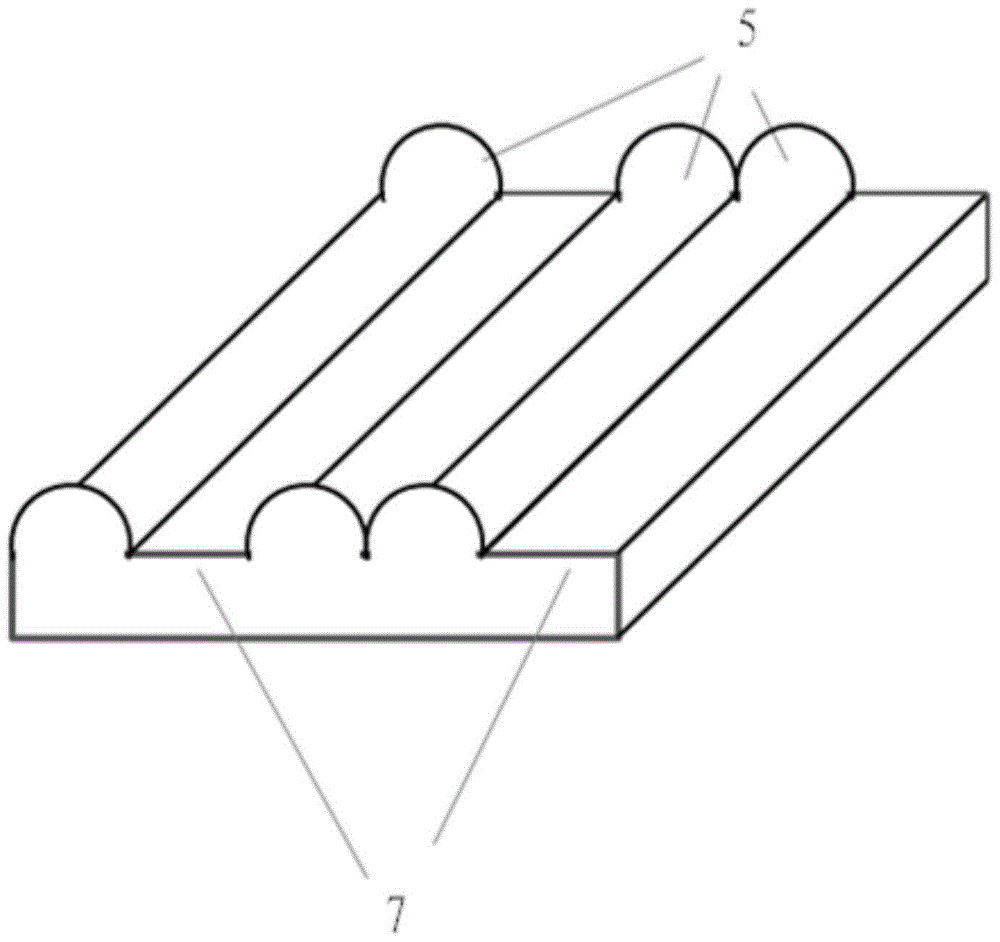

Three-dimensional breathable sheet and absorption product

PendingCN108095903AReduce surface residueImprove drynessAbsorbent padsBandagesBiomedical engineeringBonding strength

The invention discloses a three-dimensional breathable sheet and an absorption product. The absorption product comprises a surface layer and an absorption layer, wherein the surface layer is made of the three-dimensional breathable sheet. The three-dimensional breathable sheet comprises a surface sheet body and a bottom sheet body, wherein the surface sheet body is distributed in the middle of bottom sheet body, and the width of the surface sheet body is smaller than that of the bottom sheet body. The three-dimensional breathable sheet is provided with through holes penetrating the surface sheet body and the bottom sheet body and three-dimensional hollow protrusion areas formed by the surface sheet body and the bottom sheet body. The three-dimensional breathable sheet and the absorption product have the advantages that the surface sheet body is located in the middle of the absorption product, two sides, without the protrusion areas, of the bottom sheet body are adhered to the absorption layer of the absorption product, the liquid permeability and breathability of the surface layer are unaffected while the bonding strength between the surface layer and the absorption layer is increased favorably, the surface sheet body parts on two sides of the surface layer are omitted, the breathability of the absorption production is increased, and the production cost of the absorption product is lowered.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

Recovery preparation method of waste and old carbon fiber PA6 composite material

The invention relates to a recovery preparation method of a waste and old carbon fiber PA6 composite material. The method comprises the following steps of cutting the carbon fiber PA6 composite material into thin sheet blocks with the volume of 1 to 5.5 cm<3>; then, treating the surface of the obtained thin sheet block until carbon fiber is exposed; performing pretreatment on the thin sheet blocksto obtain the pretreated carbon fiber; adding the pretreated carbon fiber into liquid solvents; heating to 50 to 90 DEG C; adding catalysts into the treatment liquid to obtain a treatment solution; finally, adding the treatment solution into a reaction kettle; performing pressure reduction treatment on the treatment solution in the reaction kettle so that the liquid solvent becomes critical fluid; maintaining the condition time of the critical fluid to be 1 to 3 hours; finally obtaining solid, liquid and gas products; in the constant temperature and constant pressure states, discharging liquid and gas; collecting the solid products; then, cleaning and drying the solid products; finally obtaining the carbon fiber. The method has the advantages that no damage can be caused on the surface ofthe carbon fiber in the separation process of the carbon fiber, so that the mechanical property of the carbon fiber is ensured.

Owner:苏素珍

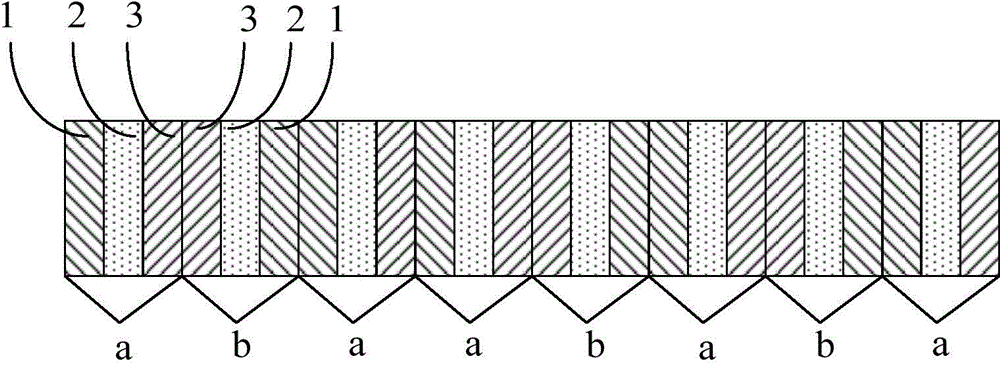

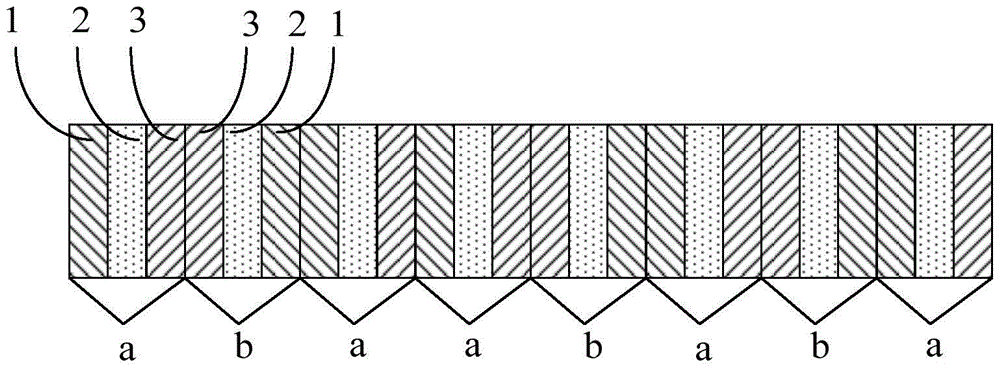

Display substrate, display device and manufacturing method of color film substrate

The invention relates to a display substrate, a display device and a manufacturing method of a color film substrate. The display substrate comprises at least two different types of pixel units, and the pixel units are arranged in a one-dimensional quasi crystal mode. The display substrate, the display device and the manufacturing method of the color film substrate have the advantages that the at least two types of pixel units on the display substrate are displayed in the one-dimensional quasi crystal mode, the fluid resistance on the surface of the display substrate is lowered, the surface energy is increased, and the surface residue of water stain is reduced.

Owner:BOE TECH GRP CO LTD +1

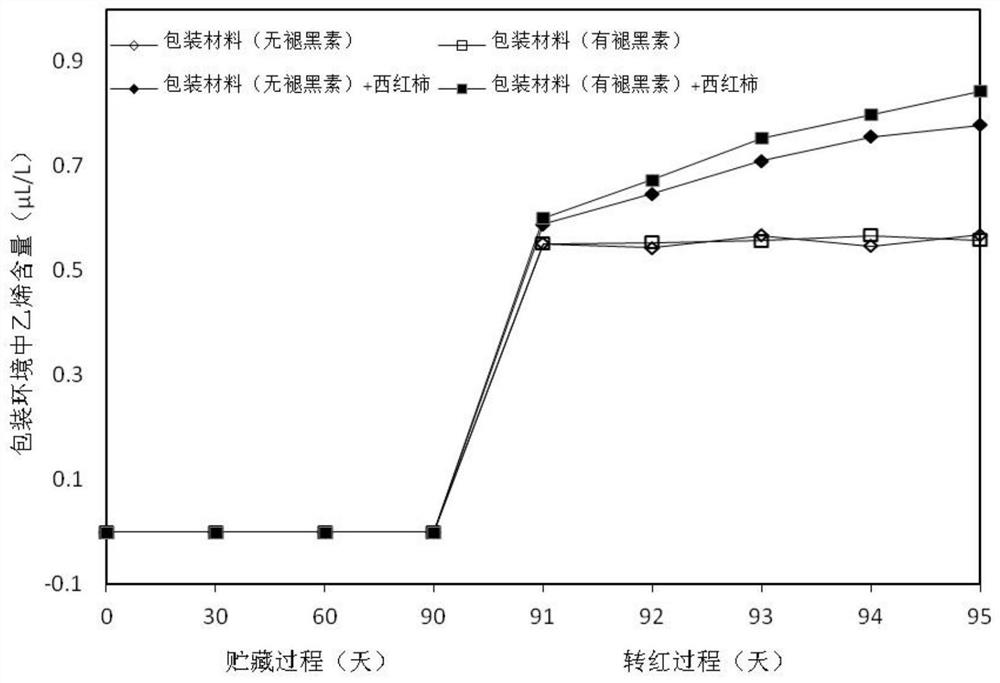

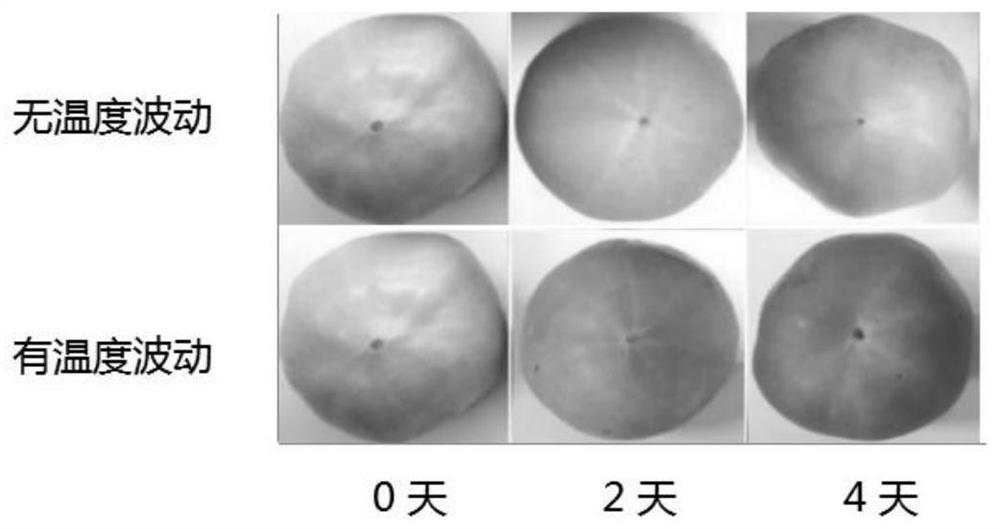

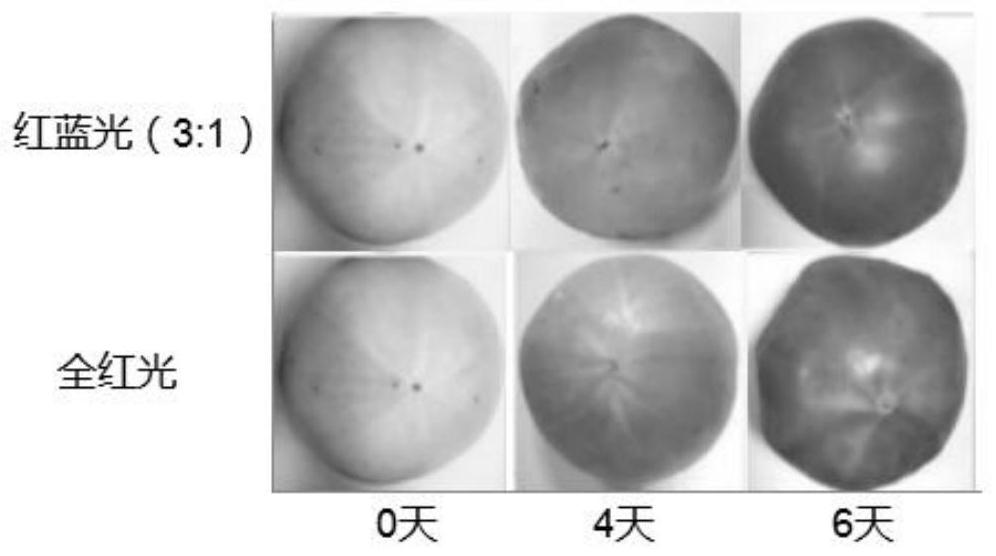

Fresh-keeping and rapid reddening method for green ripe tomatoes

InactiveCN112056387AGuaranteed qualityFacilitated releaseFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by heatingNutrientPoly ethylene

The invention relates to a fresh-keeping and rapid reddening method for green ripe tomatoes. Ethephon and low-density polyethylene are utilized to prepare a temperature-sensitive ethylene slow-releasepackaging material; ethylene is not released in a low-temperature storage stage; ethylene is slowly released in a high-temperature colour changing stage; meanwhile, melatonin in microcapsules can increase synthesis of endogenous ethylene of the tomatoes; therefore, the reddening speed of the tomatoes is increased; meanwhile, exogenous ethylene can be reasonably released through the slow-release material; the reddening uniformity and consistency of the tomatoes are improved; the tomatoes are not directly sprayed or soaked by ethylene; surface residues are reduced; in a colour changing period,semiconductor light source LED red and blue combined light is used for evenly irradiating the tomatoes; red light can promote synthesis of lycopene; blue light can promote the content of VC, total phenols, soluble solids and other nutrient substances and aroma components in the tomatoes; the red light and the blue light can cooperate with ethylene to promote colour changing of the tomatoes; and the eating quality and the nutritional value of the tomatoes after colour changing also can be improved.

Owner:大有作为(天津)冷链技术研究院

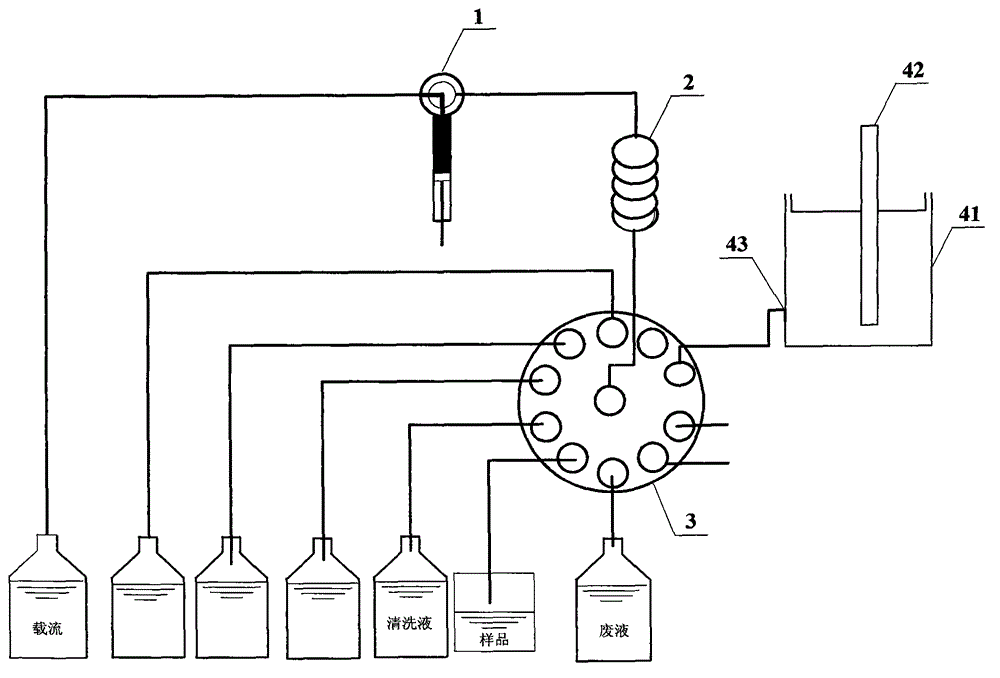

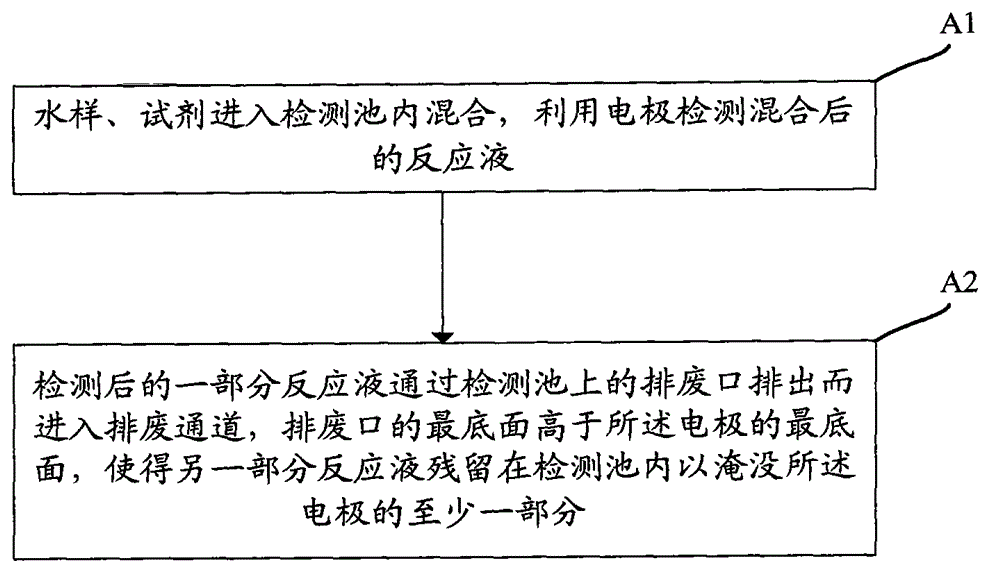

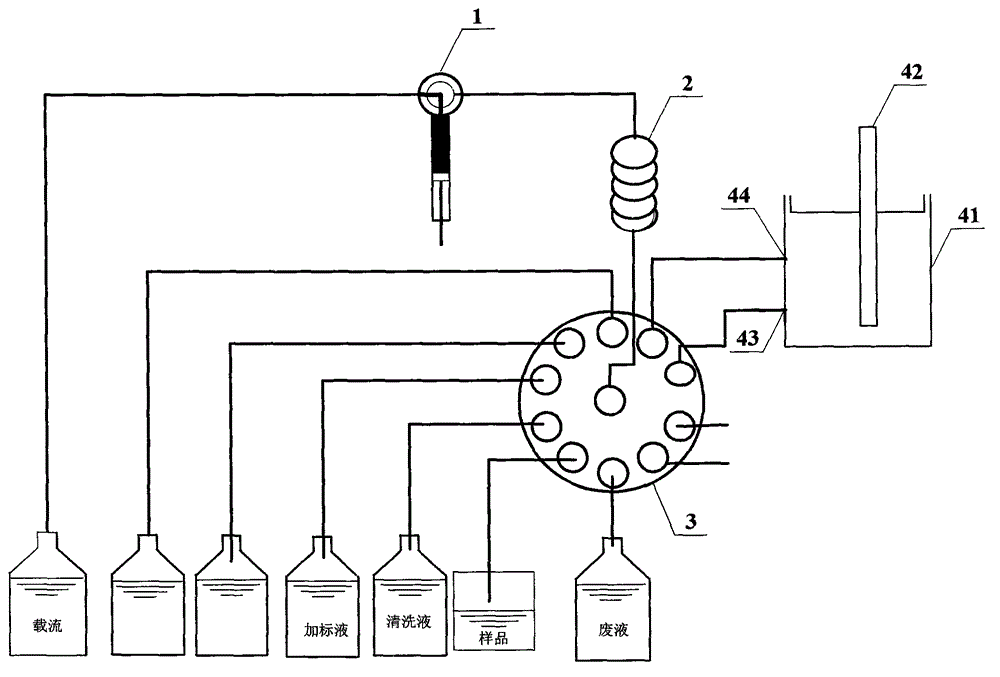

Water quality detection device and method

ActiveCN103105425BActivity unchangedExtended service lifeMaterial analysis by electric/magnetic meansWater qualityEngineering

The invention provides a water quality detection device. The water quality detection device comprises an electrode and a detection cell, as well as a liquid drain hole formed in the detection cell, and a liquid drain passage communicated with the liquid drain hole, wherein the lowermost surface of the liquid drain hole is higher than the lowermost surface of the electrode. The water quality detection device provided by the invention has the advantages of reliable and stable electrode, long work time, and so on.

Owner:FOCUSED PHOTONICS

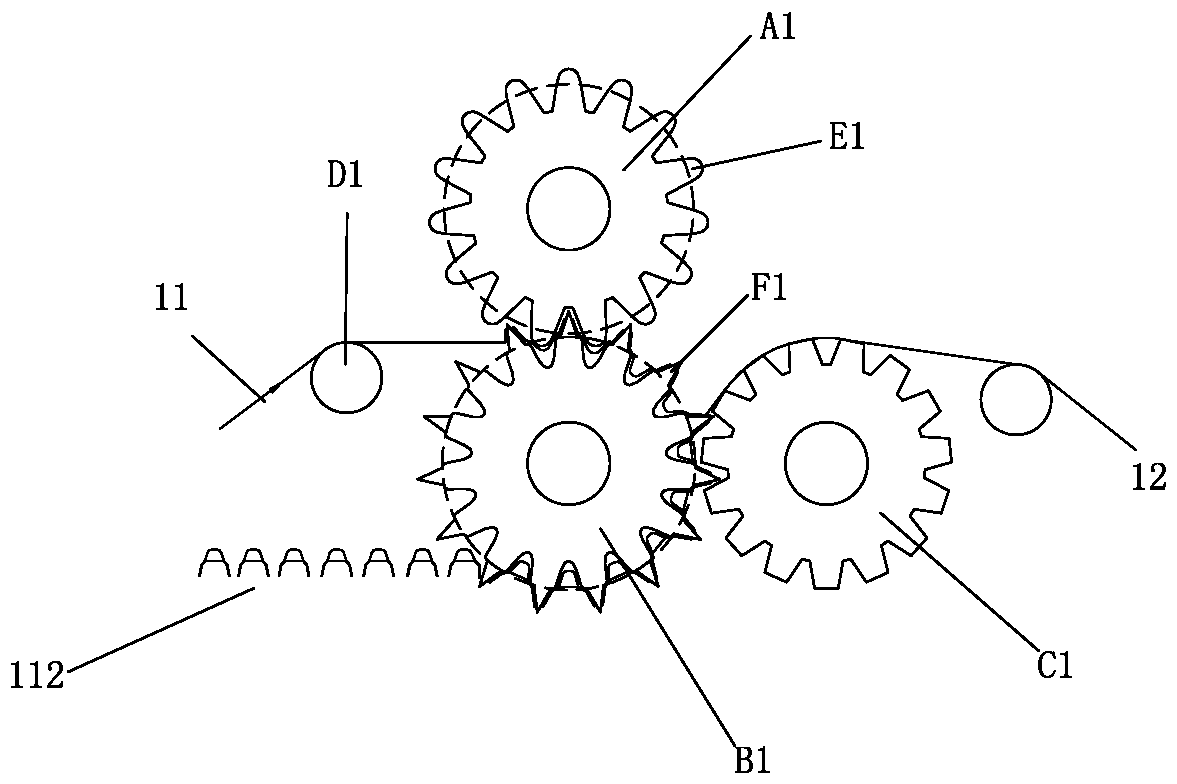

Gear precision grinding machining oil and preparation method thereof

InactiveCN113773893AReduce surface residueGuaranteed machining accuracyLubricant compositionAntioxidantMaterials science

The invention belongs to the technical field of grinding machining oil and relates to gear precision grinding oil and a preparation method thereof. The gear precision grinding machining oil comprises the following components of: secondary hydrogenation paraffin-based mineral oil, pentaerythritol oleate, high-base-number calcium sulfonate, sulfurized fatty acid ester, high-molecular polyisobutene and an antioxidant. The preparation method of the gear precision grinding machining oil comprises the following steps of: putting secondary hydrogenation paraffin-based mineral oil and an antioxidant into a container, heating the materials to 40-50 DEG C, and stirring the materials until the materials is transparent; stopping heating, adding sulfurized fatty acid ester and high-molecular polyisobutene into the container, and performing stirring until the mixture is transparent; adding pentaerythritol oleate and high-base-number calcium sulfonate into the container, and performing stirring until the mixture is transparent; and filtering the liquid in the container, and taking filtrate to obtain the gear precision grinding machining oil. The gear precision grinding machining oil is small in harm to the environment and human bodies, good in lubricating performance, high in rust resistance, corrosion resistance and the like, and capable of reducing the machining precision of workpieces.

Owner:AMER TECH CO LTD

Drug Foil Rolling Additive Composition

Owner:石家庄新泰特种油有限公司

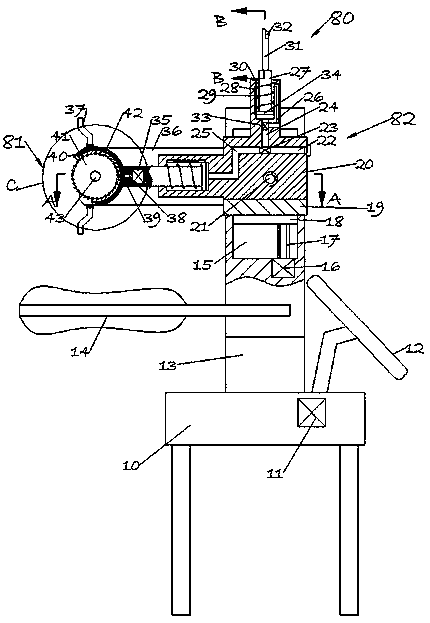

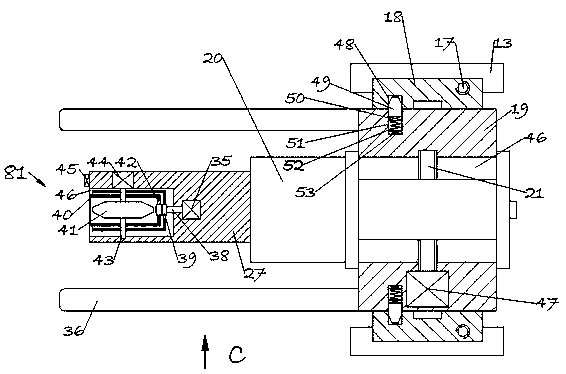

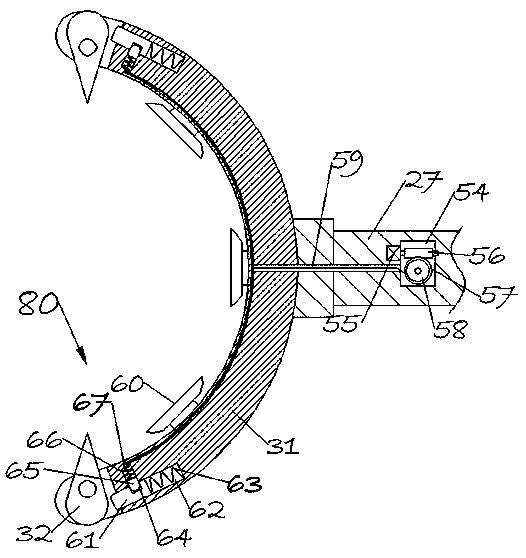

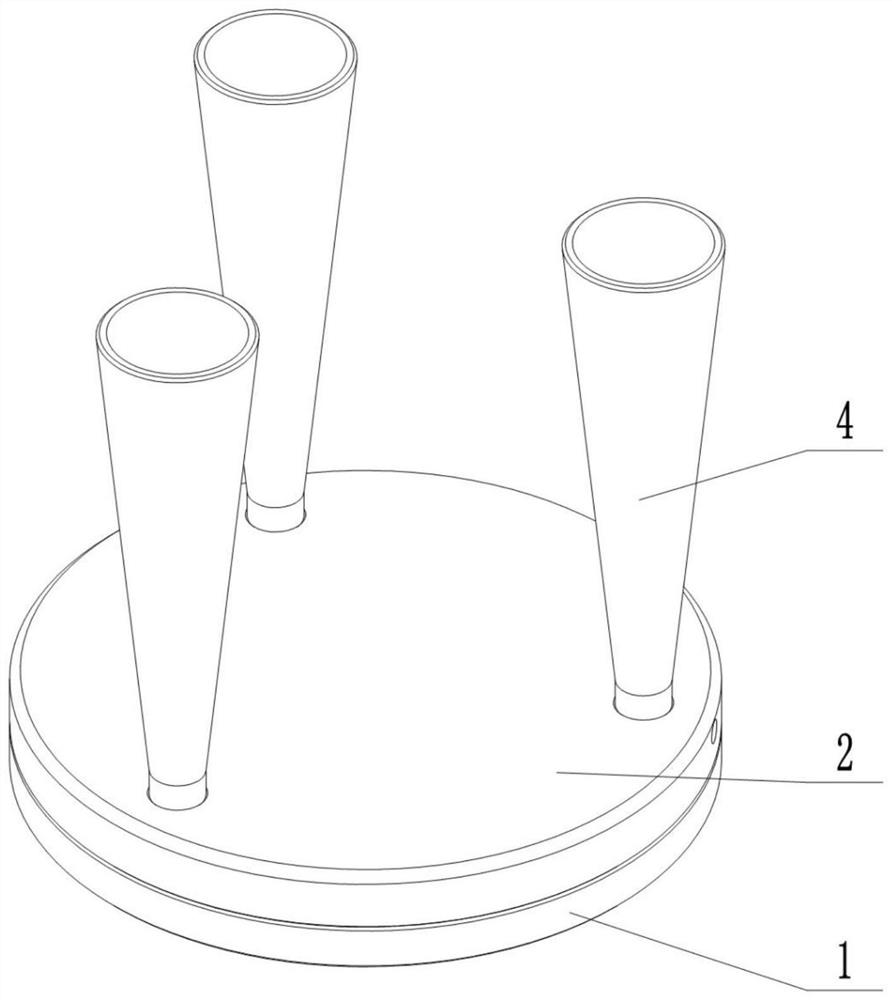

Installer-remover for orthodontics

InactiveCN110652366ASo as not to damageReduce surface residueOthrodonticsDentistryMechanical engineering

The invention discloses an installer-remover for orthodontics. The installer-remover comprises a base, wherein the base is arranged on the ground; vertical columns are symmetrically and fixedly mounted in the front and back of the top surface of the base; and lifting sliding blocks are mounted on the vertical columns in the front and back in a sliding manner. When a lifting motor is powered on, afirst threaded shaft is driven by the lifting motor to rotate, the first threaded shaft is rotated to drive the lifting sliding blocks to move up and down, and then the lifting sliding blocks can be adjusted in up and down directions; a rotating sliding block is capable of rotating for 90 degrees around the lifting sliding blocks, and then switching of mounting, dismounting and cutting can be implemented; a tooth socket mounted on the surface of a tooth is firstly cut, the tooth socket is not damaged, residues on the surface of the tooth can be reduced, and accurate positioning can be implemented through a monitor; and due to adoption of a protection shell, lips can be prevented from being cut when the tooth socket is cut, security of the mouth of a user can be protected, and the application range is wide.

Owner:宁波锐风医疗器械有限公司

Silicon wafer chemical and mechanical polishing composition with high stability

InactiveCN102093820BImprove stabilityNo condensationOther chemical processesPolishing compositions with abrasivesOrganic acidWafering

The invention discloses a silicon wafer chemical and mechanical polishing composition with high stability, belonging to the technical field of polishing compositions for roughlly polishing a semiconductor silicon substrate material. The polishing composition comprises the following components in percentage by weight: 0.5-50 percent of silicon dioxide abrasive particles, 0.01-10 percent of silicon-containing stabilizer, 0.01-20 percent of organic alkali corrosive, 0.01 -10 percent of organic acid chelating agent, 0.01-5.0 percent of other functional auxiliaries and the balance of deionized water. The polishing solution has a stabilization period of over 2 years, can perform repeated polishing or cyclic polishing, and has stable pH value and removal speed, wherein the number of cyclic polishing times can be up to 10. Meanwhile, the polishing composition has high silicon wafer removal rate up to over 1.0 mum / min, and the cyclic polishing removal rate in multiple times can be stable. The polishing solution is convenient to prepare and easy to use, has low cost, and is suitable for the rough polishing of silicon wafers of various types and sizes in the semiconductor industry.

Owner:TSINGHUA UNIV +2

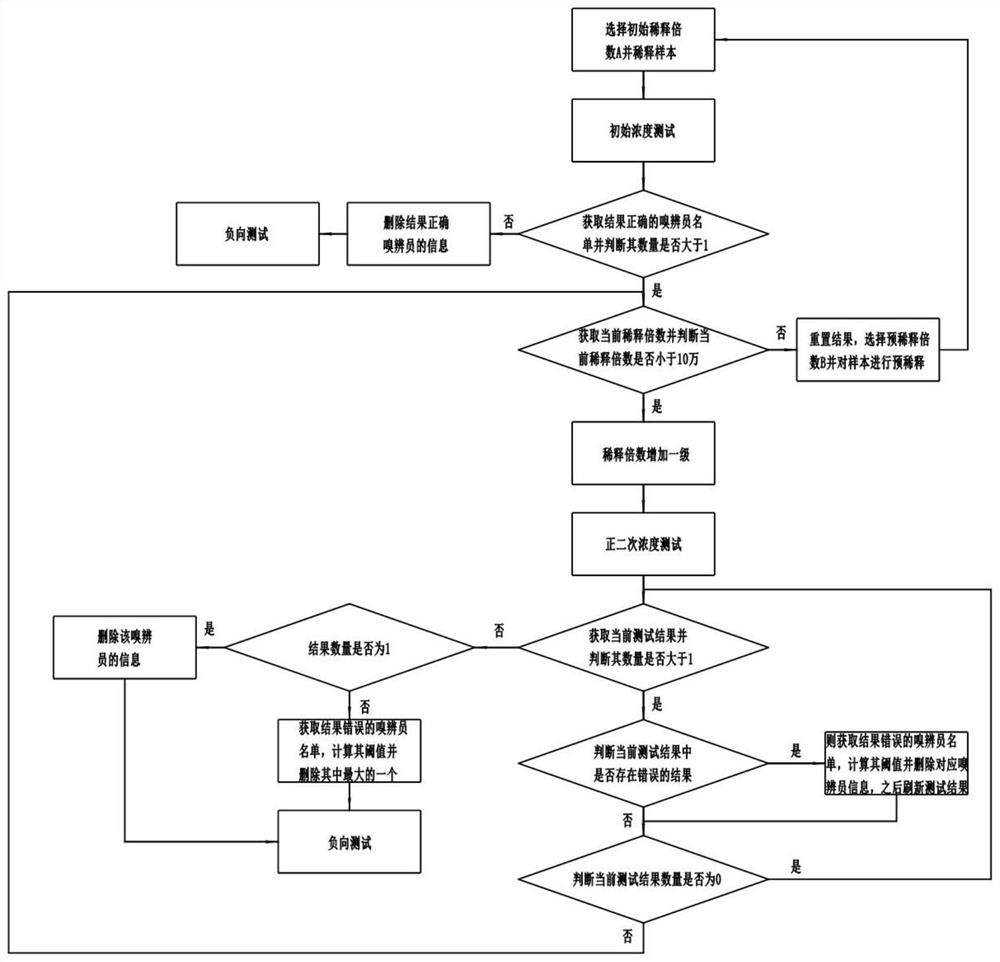

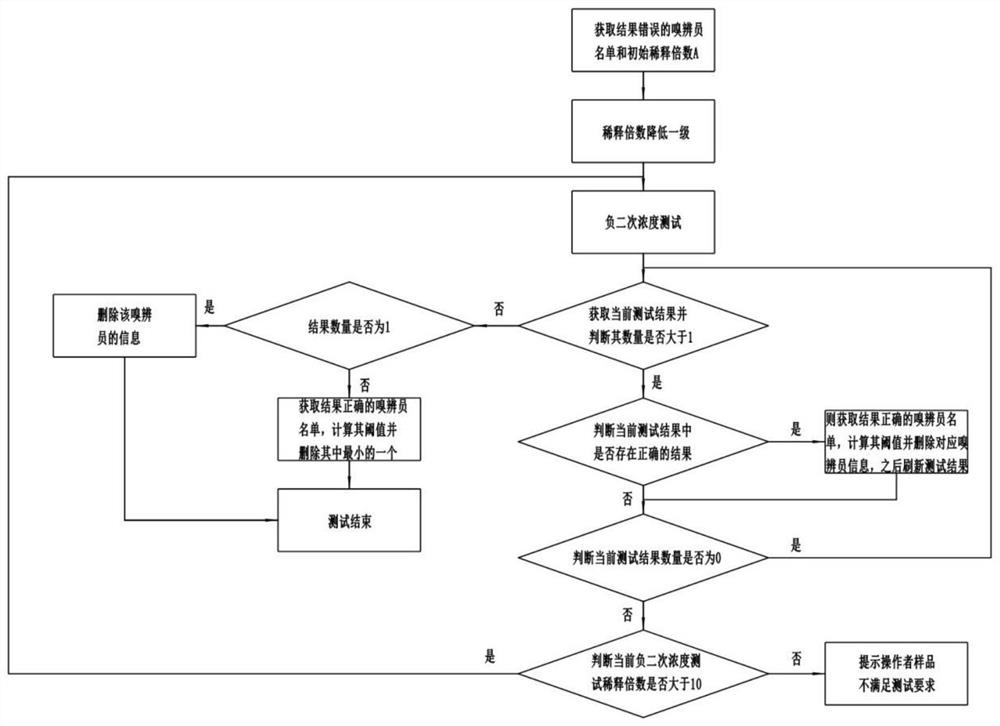

Rapid determination method for intelligent stink determinator and intelligent stink determinator

PendingCN113984953AImprove assay efficiencyHigh precisionMaterial analysisPattern recognitionSmell Perception

The invention provides a rapid determination method for an intelligent stink determinator and the intelligent stink determinator, and the method comprises the following specific steps: carrying out a forward test, setting an initial dilution multiple, starting the test, independently judging whether a result of each sniffing identification person is correct or not, if an answer is correct, increasing the dilution multiple, continuing sniffing identification until an error occurs, and then calculating a personal threshold value of the sniffing identification person; carrying out negative testing, if the answer is wrong, progressively decreasing the dilution multiple until the sniffing identification person obtains the correct answer, and then calculating the personal threshold value of the sniffing identification person; and carrying out concentration calculation: calculating an average threshold value and the odor concentration after all the sniffing identification persons finish sniffing identification. According to the method disclosed by the invention, the initial concentration test results of the sniffing identification persons under the initial dilution multiple do not need to be all correct, and the positive and negative tests are respectively carried out according to different results, so that the olfactory threshold of each multiple is quickly found, the adjustment and test frequency of the initial dilution multiple are reduced, and the gas concentration determination efficiency and accuracy are improved.

Owner:天津市生态环境科学研究院

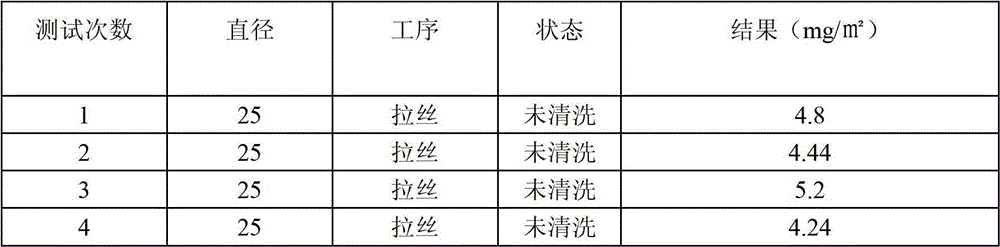

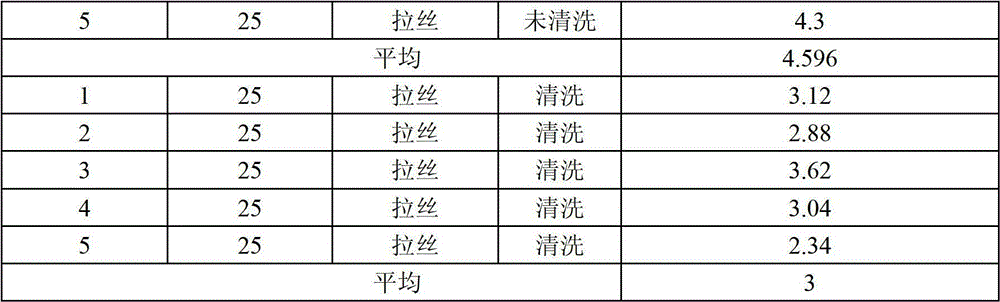

Gold bonding wire and preparation method thereof

ActiveCN102121077BHigh strengthImprove high temperature strengthSemiconductor/solid-state device detailsSolid-state devicesHigh pressure waterAlloy

The invention discloses a gold bonding wire which comprises the following components in percentage by weight: 0.0003-0.0008 percent of calcium, 0.002-0.004 percent of copper, 0.0005-0.0015 percent of germanium and the balance of gold, wherein the purity of the gold is larger than or equal to 99.99 weight percent. The invention also discloses a preparation method of the gold bonding wire. The method mainly comprises the following step of after a wire drawing step and before an annealing step: loading a gold wire obtained after wire drawing into a high-pressure water washing system for washing,wherein the water pressure of the washing system is 2-4kg, i.e. 0.2-0.4MPa, and the water temperature is 40-60 DEG C. The gold bonding wire has the advantages of high strength and low and long arc and can meet the high requirement on gold bonding wires of the semiconductor industry; and moreover, in the preparation process, lubricating agents on the surfaces of the gold bonding wires can be effectively washed, therefore, the use effect of a final product is guaranteed.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

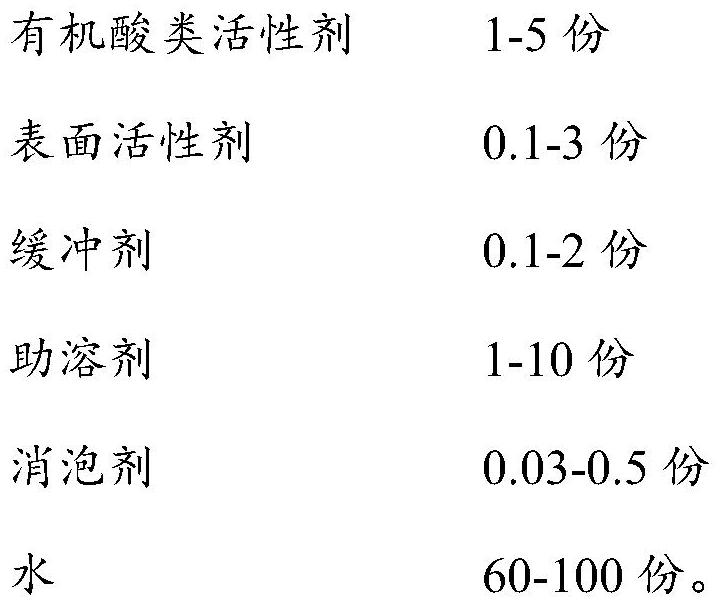

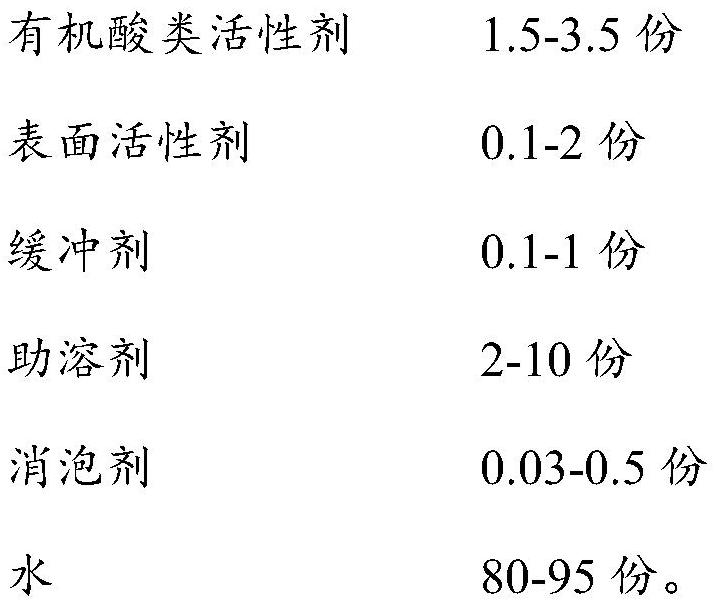

A kind of water-based flux and preparation method thereof

ActiveCN111843292BImprove wettabilityGood spreadabilityWelding/cutting media/materialsSoldering mediaOrganic acidActive agent

The invention belongs to the technical field of solder, and discloses a water-based flux and a preparation method thereof. The water-based flux comprises the following components: an organic acid activator, a surfactant, a buffer, a cosolvent, and a defoaming agent. and water; the surfactants include EO / PO block copolymers and polyoxyethylene ethers. The invention adopts EO / PO block copolymer and polyoxyethylene ether compound as surfactant, which improves the wettability and spreadability of lead-free solder, and can effectively prevent the re-oxidation of the surface during soldering; meanwhile, it has strong cleaning ability. ; Use water as the main solvent, which is environmentally safe, non-toxic, low VOC, not easy to burn, and does not need to be cleaned; the water-based flux has high insulation resistance, non-corrosiveness, strong bacteriostatic properties, and a mildew growth grade of zero. The preparation method has simple operation and high efficiency.

Owner:NANXIONG JINHONGTAI CHEM NEW MATERIAL

Water spray injection method of leveling liquid in cold milling wet leveling production

ActiveCN102319749BSolve the problem of residual smooth spotsReduce consumptionRolling equipment maintainenceWork treatment devicesSpray nozzleEngineering

The invention relates to a method for carrying out leveling production by adopting the water spray injection for replacing the ordinary leveling liquid spraying, which is applied to various cold milling leveling machine sets. A water spray injection method of leveling liquid in cold milling wet leveling production is characterized by comprising the following steps that: 1, a water spray injector is arranged at an inlet side of a wet leveling machine, a spray opening of the spray nozzle of the water spray injector faces a roller seam formed between a work roller and a support roller, and an air input end and a leveling liquid input end are arranged on the spray nozzle; 2, when the leveling milling of the wet leveling machine is started, the compressed air and the leveling liquid are input to the spray nozzle, a mixing valve is opened and regulated so that the flow rate of the leveling liquid flowing into each spray nozzle is 10 to 44.7 L / h, the flow rate of the air flowing into each spray nozzle is 5.2 to 13 m<3> / h, the leveling liquid and the compressed air are mixed at the spray nozzle part and are sprayed out at the spray opening of the spray nozzle in a gas spray mode, when the leveling milling is completed, the conveyance of the compressed air and the leveling liquid is stopped, and the mixing valve is closed. The problem of leveling spot residue caused by unclean blowing of the leveling liquid is solved by the method.

Owner:WISDRI ENG & RES INC LTD

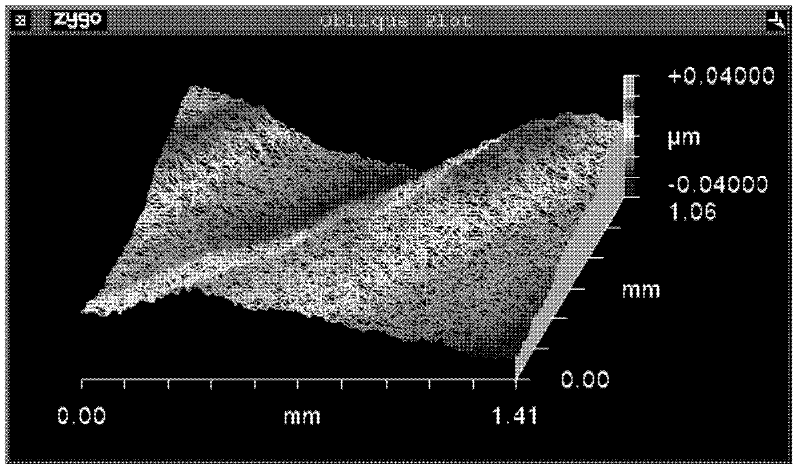

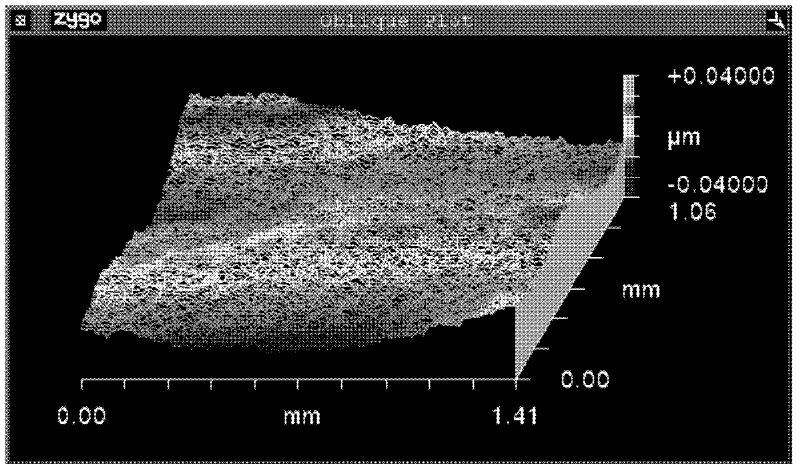

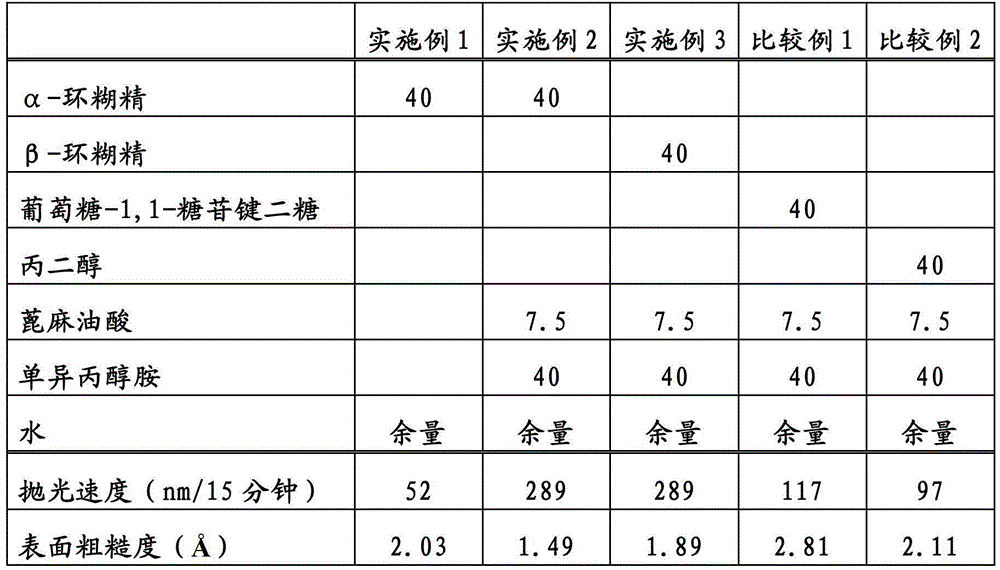

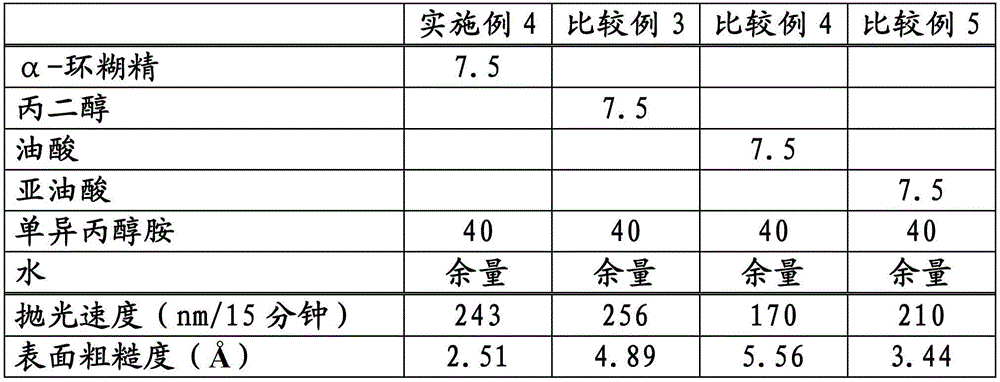

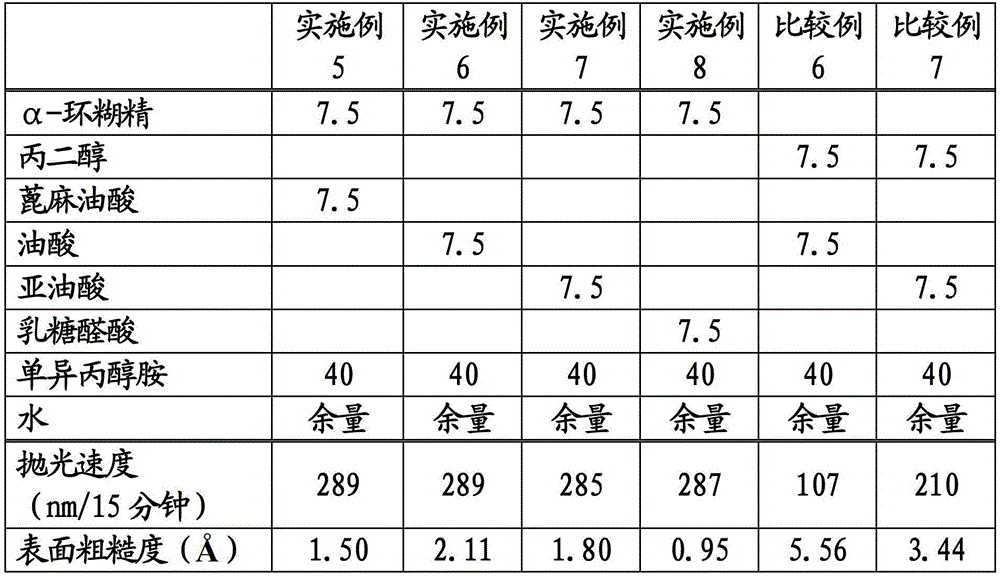

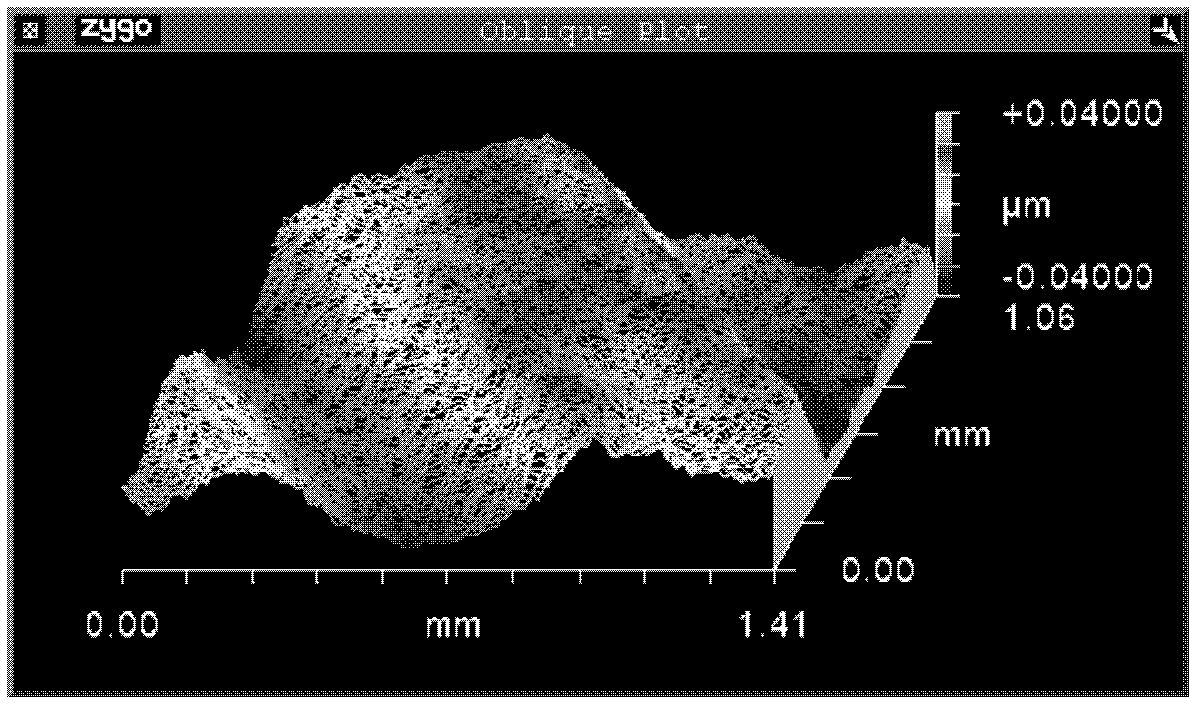

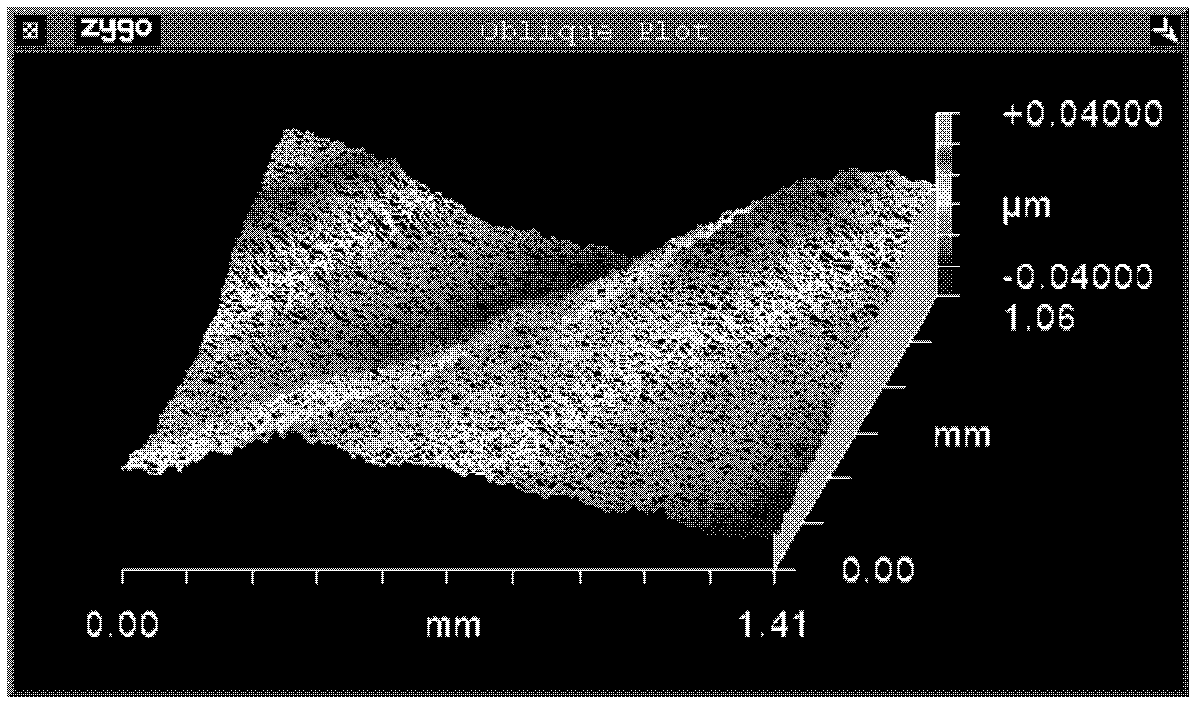

Lubricant composition for polishing glass substrates and polishing slurry

InactiveCN103154178BFast polishingFinishing surface roughness improvementProtective coatings for layersOther chemical processesCarboxylic acidSlurry

Provided are a lubricant composition for polishing glass substrates and a polishing slurry that contain components (A) and (B), and when necessary, components (C) and / or (D). (A) A cyclic oligosaccharide (B) Water (C) An alkanolamine (D) A C6-24 aliphatic carboxylic acid

Owner:MORESCO

A kind of environment-friendly superfine grinding oil and preparation method thereof

ActiveCN107338096BLow carbon residueHigh aniline pointLubricant compositionOil mistMaterials science

The invention relates to environmentally-friendly super-finishing grinding oil and a preparation method thereof. The environmentally-friendly super-finishing grinding oil is prepared from, by weight, 5.0%-10.0% of ester base oil, 3.0%-5.0% of an extreme-pressure and anti-wear agent, 0.5%-1.0% of an antioxygen, 0.05%-0.1% of a metal desactivation agent, 0.5%-1.0% of an oil mist inhibitor, 0.01%-0.05% of an anti-foaming agent and mineral base oil balance. The sum of the percentages of the above components is 100%. The environmentally-friendly super-finishing grinding oil has high lubrification, cooling, rust protection and corrosion protection performances; meanwhile, heavy metals, chlorine and low oil mist do not exist in the environmentally-friendly super-finishing grinding oil, so that the environmental-friendly super-finishing grinding oil is harmless to an operator and the environment.

Owner:辽宁海华科技股份有限公司

Water mist leveling system in cold-rolling wet leveling production

ActiveCN102284519BSolve the problem of residual smooth spotsReduce consumptionWork treatment devicesMetal rolling arrangementsStrip steelEngineering

Owner:WISDRI ENG & RES INC LTD

A method for manufacturing a display substrate, a display device, and a color filter substrate

The invention relates to a display substrate, a display device and a manufacturing method of a color film substrate. The display substrate comprises at least two different types of pixel units, and the pixel units are arranged in a one-dimensional quasi crystal mode. The display substrate, the display device and the manufacturing method of the color film substrate have the advantages that the at least two types of pixel units on the display substrate are displayed in the one-dimensional quasi crystal mode, the fluid resistance on the surface of the display substrate is lowered, the surface energy is increased, and the surface residue of water stain is reduced.

Owner:BOE TECH GRP CO LTD +1

A production method of aluminum alloy strip in 1100-h14 state for processing high-end cosmetic bottle caps

ActiveCN110102580BRaise the finishing temperatureImprove surface propertiesMetal rolling arrangementsProfile control devicePunchingHigh surface

The invention belongs to the technical field of aluminum alloy processing, and discloses a production method for a 1100-H14 state aluminum alloy strip for processing a high-end cosmetic bottle cap. The production method comprises the following steps of smelting, adopting of a semi-continuous-method casting ingot, homogenizing heat treatment, head cutting, tail cutting and face milling, hot rolling, primary cold rolling, primary intermediate annealing, secondary cold rolling, secondary intermediate annealing, third-time cold rolling until the finished product thickness is 0.7 mm or less, cleaning and tension correction. By means of the production method, the hot rolling and cold rolling processes are optimized, the rolling texture and the annealing texture after a heat treatment system andfinal cold rolling deformation are balanced, the rolled finished product thickness is less than 1 mm, meanwhile, the earing ratio after material punching is reduced, the high surface characteristics of the material after anodic oxidation and coloring are ensured, the color is uniform after oxidation and coloring, and the appearance is high in metal texture, and the using requirements of high-end cosmetic cover material substrates are met.

Owner:河南明晟新材料科技有限公司

A kind of preparation method of bonding alloy wire

InactiveCN106935523BLow costSphericalSolid-state devicesSemiconductor/solid-state device manufacturingVacuum packMegasonic cleaning

The invention discloses a method for preparing a bonded alloy wire, which comprises the following steps: (1) purchasing 99.995% silver and making it into a silver sheet; (2) making an intermediate alloy; (3) vertical melting; (4) wire drawing ; (5) intermediate annealing; (6) re-drawing (7) annealing; (8) coiling; (9) vacuum packaging. Compared with the prior art, the present invention has the following advantages: in this preparation method: (1) an intermediate annealing process is added to eliminate stress when the wire drawing reaches 70-100 μm, so that the wire drawing is smoother and the wire is not easy to break; (2) after the finished wire is annealed The surface treatment effectively prevents the bonding effect of self-diffusion between the bonded alloy wires and improves the product yield; effectively reduces the surface residue of the alloy wires and improves product quality. In the preparation method, the lubricating liquid on the surface of the alloy wire is effectively cleaned by using an ultrasonic cleaning system, thereby effectively reducing the surface residue of the alloy wire and improving product quality.

Owner:深圳金斯达应用材料有限公司

Copper chemical and mechanical polishing combination

InactiveCN102329572BReduce surface residueReduce surface corrosion defectsPolishing compositions with abrasivesSurface-active agentsCopper

The invention discloses a copper chemical and mechanical polishing combination, which belongs to the technical field of microelectronic auxiliary materials and ultra-precision machining processes. The copper chemical and mechanical polishing combination comprises abrasive particles, an oxidant, a complexing agent, a polishing accelerating agent and a pH regulator. The copper chemical and mechanical polishing combination is characterized by further comprising a long chain corrosion inhibitor and a surface active agent. By using the polishing combination provided by the invention, surface residues, particularly surface granular residues, can be obviously decreased; surface corrosion defects can be obviously decreased; a higher removal speed rate is obtained; and the polishing combination provided by the invention further has the advantages of simple process, cheap price, low cost and the like.

Owner:SHENZHEN LEAGUER MATERIAL +2

A method for producing low-acid consumption and corrosion-resistant products by substituting heat for cold products

ActiveCN103924254BHigh mechanical descaling efficiencyShort pickling timeWork treatment devicesMetal rolling arrangementsSurface roughnessBrush device

The invention relates to a low acid consumption anti-corrosion hot-replacing-cold product production method. The low acid consumption anti-corrosion hot-replacing-cold product production method comprises the following steps: uncoiling by adopting an uncoiler; breaking and stripping oxide on the surface of strip steel by adopting a temper mill; further breaking and stripping the oxide on the surface of the strip steel by adopting a multi-roll straighter; eliminating the oxide which falls off and is loose on the surface of the strip steel by adopting a brushing device; carrying out acid pickling and rinsing on the treated strip steel; then eliminating residue on the surface of the strip steel by adopting a mechanical way; carrying out surface roughness homogenization finishing on the strip steel; recoiling by adopting a recoiler. By virtue of the technical scheme, the low acid consumption anti-corrosion hot-replacing-cold product production method has the advantages that firstly more cracks and large gaps are formed in the oxide on the surface of the strip steel, so that acid pickling efficiency is high; secondly, eliminating part of oxide while breaking scale, so that acid picking reacting dose is reduced, and acid consumption is reduced; thirdly, added value of yield strength of the strip steel after processing is low; fourthly, a Luders strip is avoided from being formed on the surface of a common hot rolling product; fifthly, chlorine ion residue on the surface of a product is reduced, and corrosion resistance of the product is improved.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com