Silicon wafer chemical and mechanical polishing composition with high stability

A technology of polishing composition and organosilicon compound, which is applied in the field of polishing composition, can solve the problems of difficult quantification and control of silica sol abrasive grain parameters, reduction of polishing removal rate, difficulty in measuring which is better, and achieves excellent practicability, The rate remains stable and the effect of less residue on the surface

Inactive Publication Date: 2011-06-15

TSINGHUA UNIV +2

View PDF2 Cites 39 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Under normal conditions, the parameters of silica sol abrasive grains are difficult to quantify and control, and each performance affects each other, so it is difficult to measure which is better; the use of surfactants and polymer dispersants can easily reduce the polishing removal rate and make the polishing efficiency low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

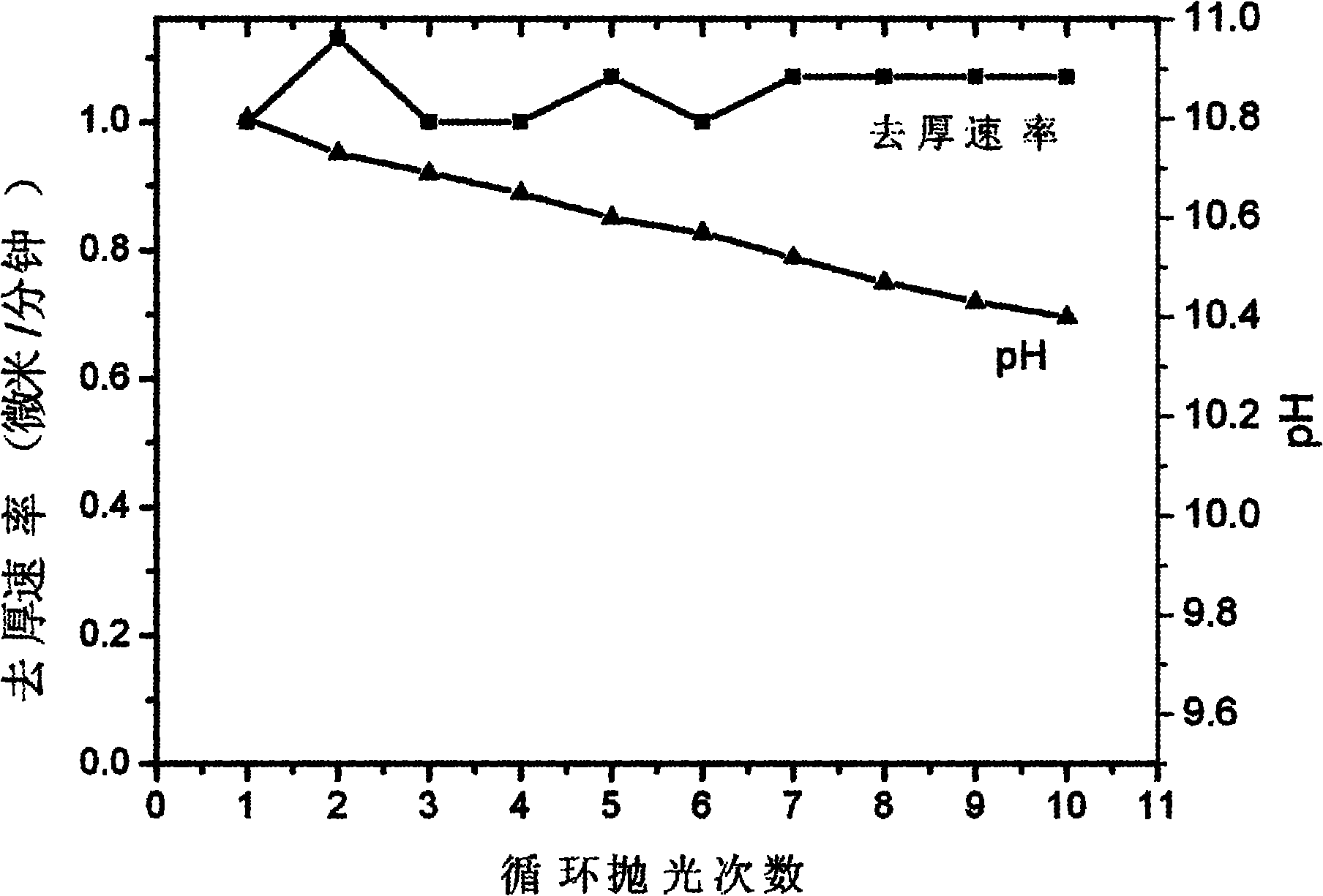

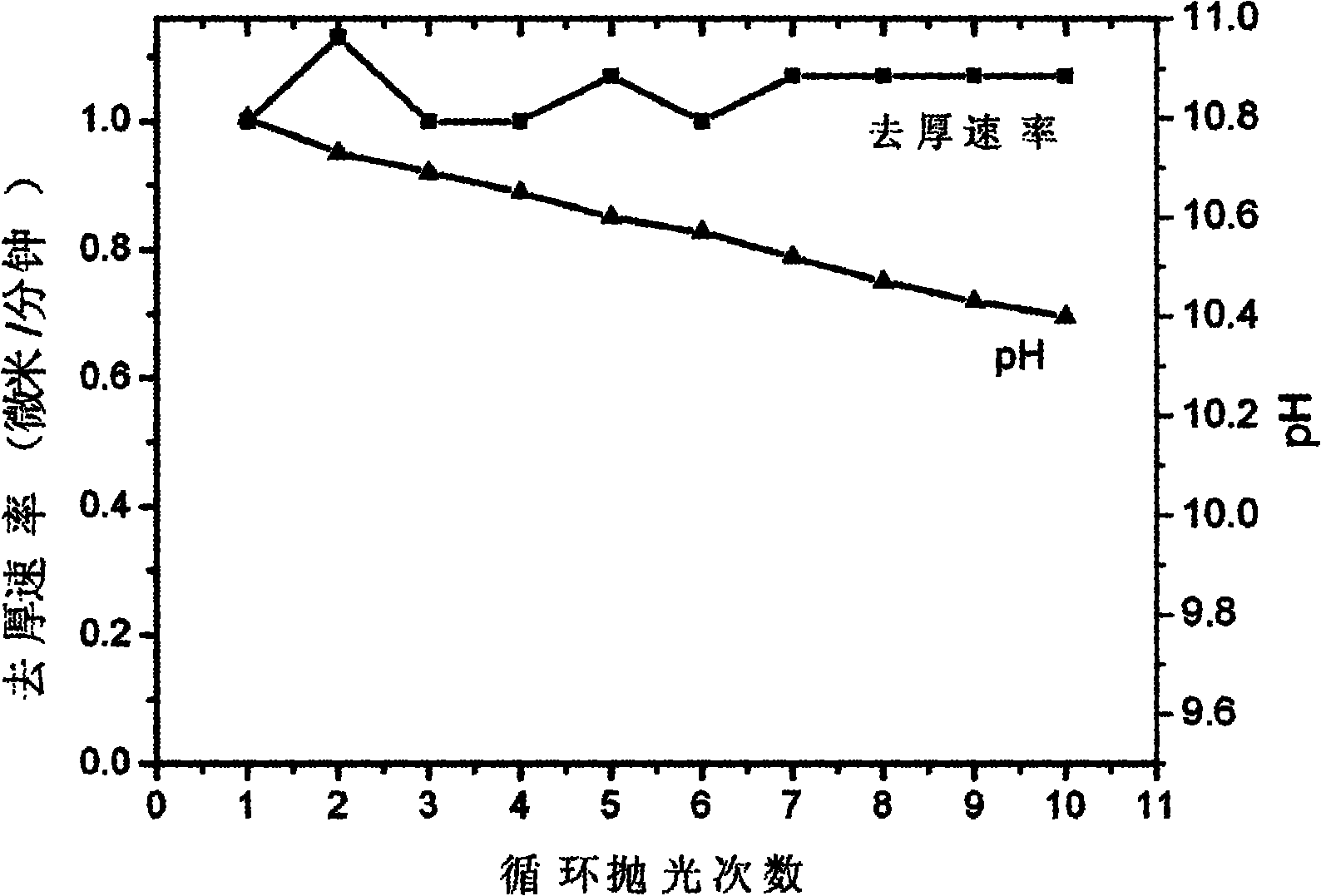

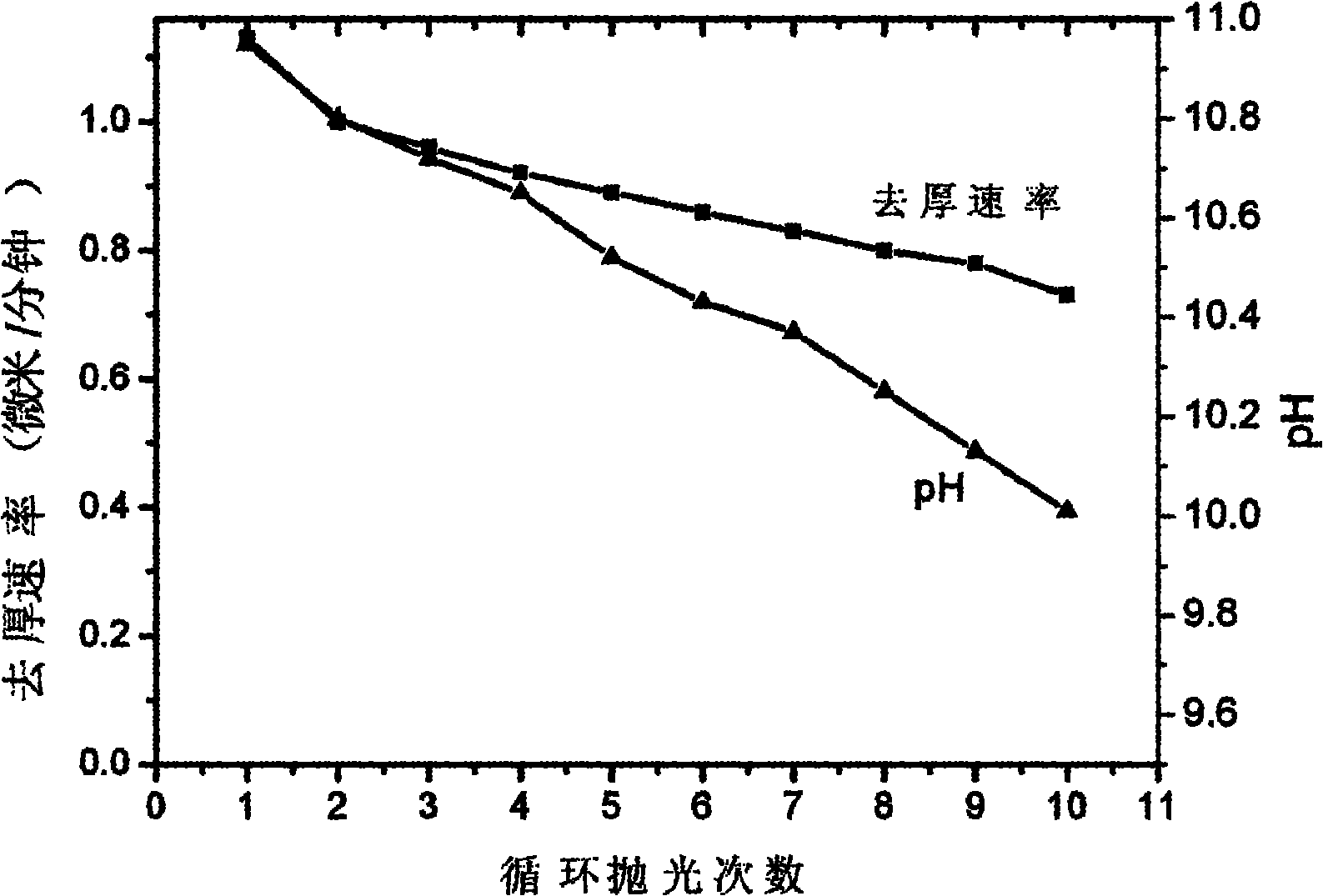

The invention discloses a silicon wafer chemical and mechanical polishing composition with high stability, belonging to the technical field of polishing compositions for roughlly polishing a semiconductor silicon substrate material. The polishing composition comprises the following components in percentage by weight: 0.5-50 percent of silicon dioxide abrasive particles, 0.01-10 percent of silicon-containing stabilizer, 0.01-20 percent of organic alkali corrosive, 0.01 -10 percent of organic acid chelating agent, 0.01-5.0 percent of other functional auxiliaries and the balance of deionized water. The polishing solution has a stabilization period of over 2 years, can perform repeated polishing or cyclic polishing, and has stable pH value and removal speed, wherein the number of cyclic polishing times can be up to 10. Meanwhile, the polishing composition has high silicon wafer removal rate up to over 1.0 mum / min, and the cyclic polishing removal rate in multiple times can be stable. The polishing solution is convenient to prepare and easy to use, has low cost, and is suitable for the rough polishing of silicon wafers of various types and sizes in the semiconductor industry.

Description

A kind of highly stable silicon wafer chemical mechanical polishing composition technical field The invention belongs to the technical field of polishing compositions used for rough polishing semiconductor silicon substrate materials, in particular to a high-stability silicon wafer chemical mechanical polishing composition. And it has the ability of multiple polishing and stable polishing removal. Background technique Polishing fluid for semiconductor silicon substrates is a key consumable in the front-end process of IC manufacturing industry, and an important supporting material for silicon single crystal polishing wafers. At present, the domestic polishing fluid is unstable in quality and key performance parameters are not up to standard. It is used for integrated circuits below 0.1 μm node Large-size single crystal polishing fluid basically relies on imports. According to the "Semiconductor Silicon Wafer Polishing Fluid Industry Research Report", it is estimated that b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09G1/02C09K3/14

Inventor 潘国顺李拓顾忠华雒建斌路新春刘岩

Owner TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com