Copper chemical and mechanical polishing combination

A polishing composition and chemical-mechanical technology, applied to polishing compositions containing abrasives, etc., can solve problems such as micro-scratches, particle residues, and reduce removal rates, and achieve low cost, reduced surface residues, and cheap prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

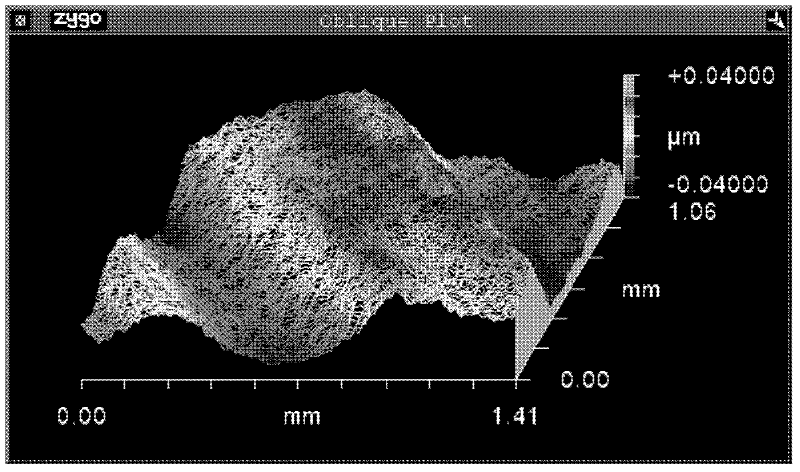

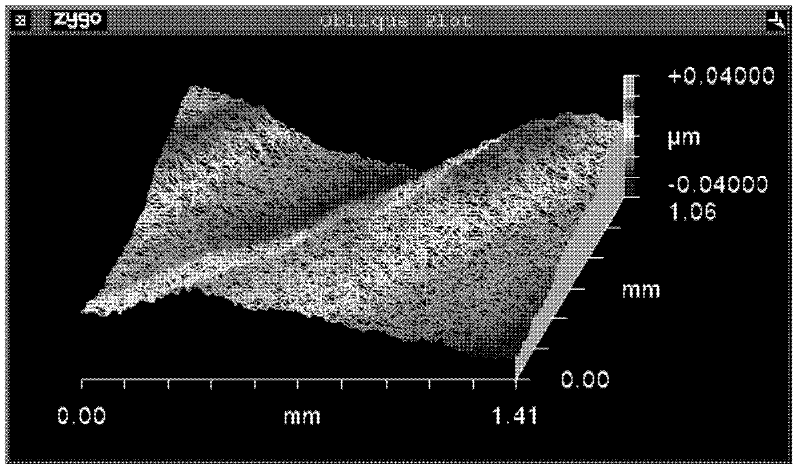

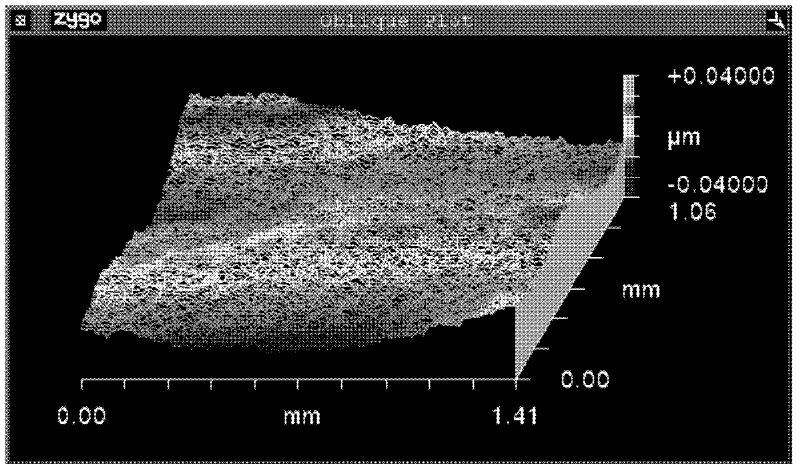

Image

Examples

Embodiment 1

[0041] Preparation of 700g polishing liquid: get 7g glycine, add deionized water under stirring, add 0.07g ammonium dodecylbenzotriazole sulfonate and 1.4g sodium fluoride simultaneously and stir until clarification, then add 14g silica sol (two The silicon oxide content is 30wt%, and the average particle size is 50nm) and 14g of urea hydrogen peroxide are stirred until uniform, the weight is determined to 700g with deionized water, and the pH value of the polishing solution is adjusted to 3.8 with phosphoric acid. Using the IC1000-XY / SUBA IV20 composite polishing pad of Rodel Company, through the CETR CP4 polishing tester, the polishing test was carried out under the conditions of polishing pressure 0.5psi, polishing relative motion speed 1m / s, and polishing liquid flow rate 70mL / min. By measuring the quality change of the wafer before and after polishing, and then considering the density and area of the wafer, the polishing rate of the embodiment is obtained, and the copper...

Embodiment 2

[0043] Preparation of 700g polishing liquid: get 7g serine, add deionized water under stirring, add 0.07g sodium dodecylbenzotriazole sulfonate and 1.4g potassium citrate simultaneously and stir until clarification, then add 14g silica sol (dioxide The silicon content is 30wt%, and the average particle diameter is 50nm) and 14g of urea hydrogen peroxide are stirred until uniform, the weight is determined to 700g with deionized water, and the pH value of the polishing solution is adjusted to 3.8 with phosphoric acid. Using the IC1000-XY / SUBA IV20 composite polishing pad of Rodel Company, through the CETR CP4 polishing tester, the polishing test was carried out under the conditions of polishing pressure 0.5psi, polishing relative motion speed 1m / s, and polishing liquid flow rate 70mL / min. By measuring the quality change of the wafer before and after polishing, and then considering the density and area of the wafer, the polishing rate of the embodiment is obtained, and the coppe...

Embodiment 3

[0045] Preparation of 700g polishing liquid: get 7g glutamic acid, add deionized water under stirring, add 0.28g fatty alcohol polyoxyethylene ether sodium sulfate and 1.4g sodium hydrogen phosphate simultaneously and stir until clarification, then add 14g silica sol (silicon dioxide Content 30wt%, average particle size is 50nm) and 14g of peracetic acid are stirred until uniform, weighed to 700g with deionized water, and the pH value of the polishing solution is adjusted to 3.8 with phosphoric acid. Using the IC1000-XY / SUBA IV20 composite polishing pad of Rodel Company, through the CETR CP4 polishing tester, the polishing test was carried out under the conditions of polishing pressure 0.5psi, polishing relative motion speed 1m / s, and polishing liquid flow rate 70mL / min. By measuring the quality change of the wafer before and after polishing, and then considering the density and area of the wafer, the polishing rate of the embodiment is obtained, and the copper surface roughn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com