Lubricant composition for polishing glass substrates and polishing slurry

A glass substrate and slurry technology, applied in chemical instruments and methods, magnetic recording, instruments, etc., can solve the problems of low surface roughness, inability to obtain, and insufficient polishing speed in finishing, and reduce surface residues , The effect of improving the polishing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8 and comparative example 1~8

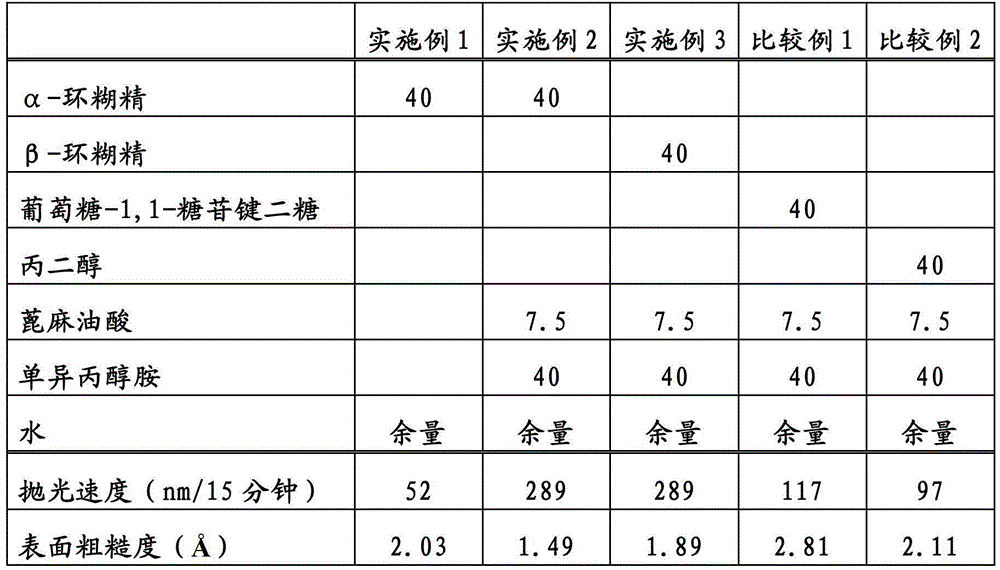

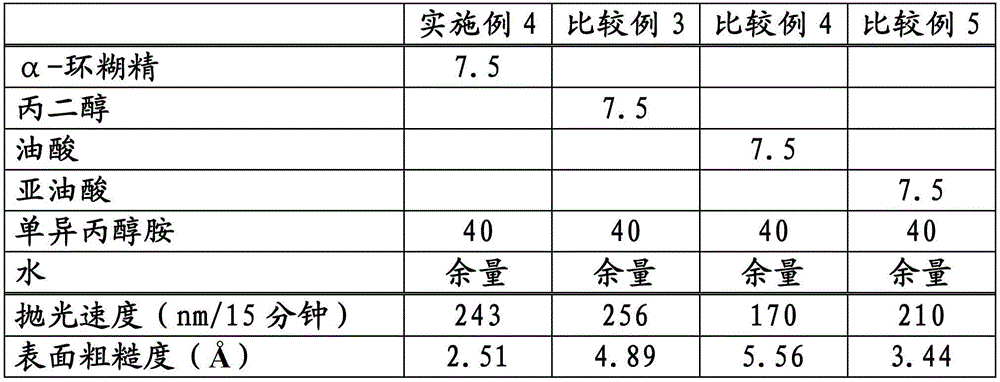

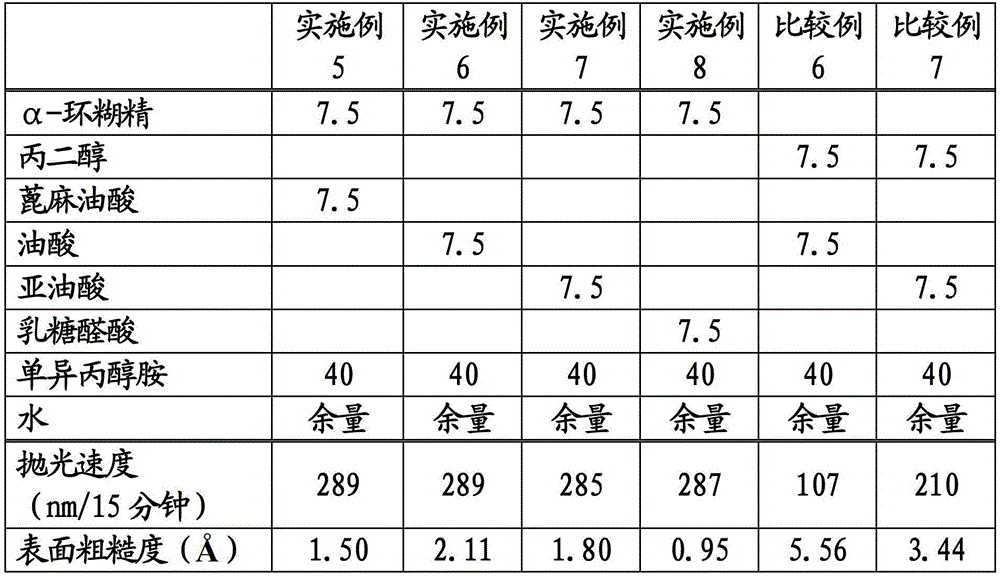

[0062] The components shown in the following Tables 1 to 4 were mixed (values are % by weight) to prepare a lubricant for hard disk glass substrates. As water, purified water was used. The ricinoleic acid in Comparative Example 2 is a carboxylic acid with 16 to 40 carbon atoms used in JP-A-2004-306248 (Patent Document 2); ) is a fatty acid with 10 to 22 carbon atoms. In addition, in Comparative Example 1, glucose 1,1-glycosidic disaccharide was used as sugars other than cyclodextrin.

[0063] A polishing slurry for hard disk glass substrates was prepared by diluting 17.5 g of the lubricating composition with 321.5 g of pure water, adding diamond concentration: 1.5% by weight and average particle size: 30 nm [by dynamic light scattering method (Otsuka Electronics Co., Ltd. Company DLS-6000HL) measured] diamond slurry 10.9 g to obtain a polishing slurry having a diamond abrasive grain content of 0.05% by weight. Polishing evaluation of hard disk glass substrates was perform...

Embodiment 9~12 and comparative example 9~16

[0078] Except having mixed the components shown in following Tables 5-6 (value is weight%), and prepared the lubricating liquid for glass substrates, it carried out similarly to Example 1, and prepared the polishing slurry. Using this polishing slurry, polishing evaluation was performed using various glass substrates having different components, and the results are shown in Tables 5-6.

[0079] [table 5]

[0080]

[0081] [Table 6]

[0082]

[0083] Glass substrate A: with silicic acid (SiO 2 ) as the main component, and a glass substrate with sodium oxide, aluminum oxide, and potassium oxide as subcomponents.

[0084] Glass substrate B: with silicic acid (SiO 2 ) as the main component, with sodium oxide, aluminum oxide, potassium oxide, P 2 o 5 Subcomponent glass substrate.

[0085] Glass substrate C: with silicic acid (SiO 2 ) is a glass substrate whose main component is aluminum oxide and potassium oxide.

[0086] Glass substrate D: with silicic acid (SiO 2 )...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com