Water mist skin leveling system in cold rolling wet skin leveling production

A wet leveling and leveling technology, used in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of high power requirements of suction fans, unclean mist and dust extraction, affecting product quality, etc. The effect of power, saving consumption and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

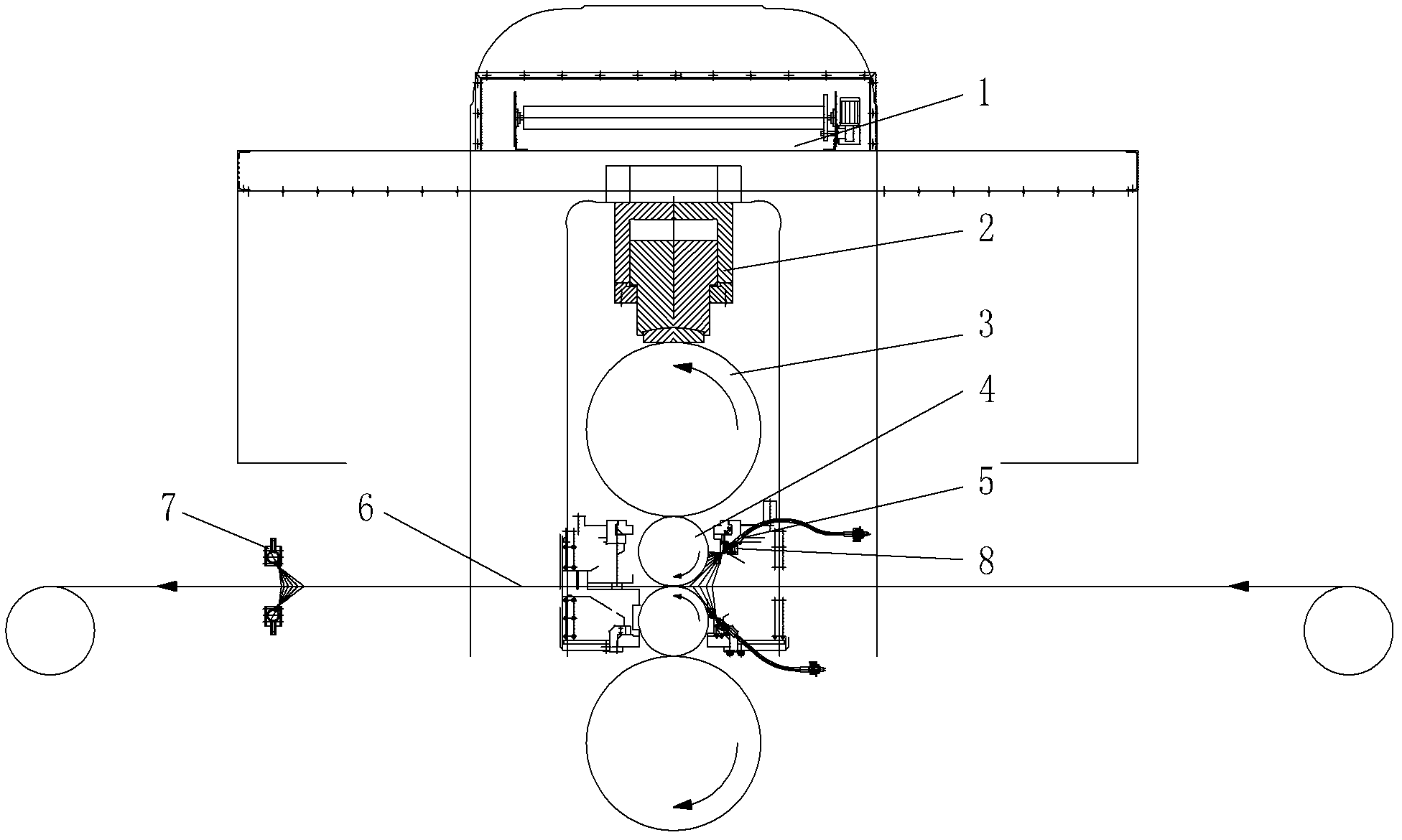

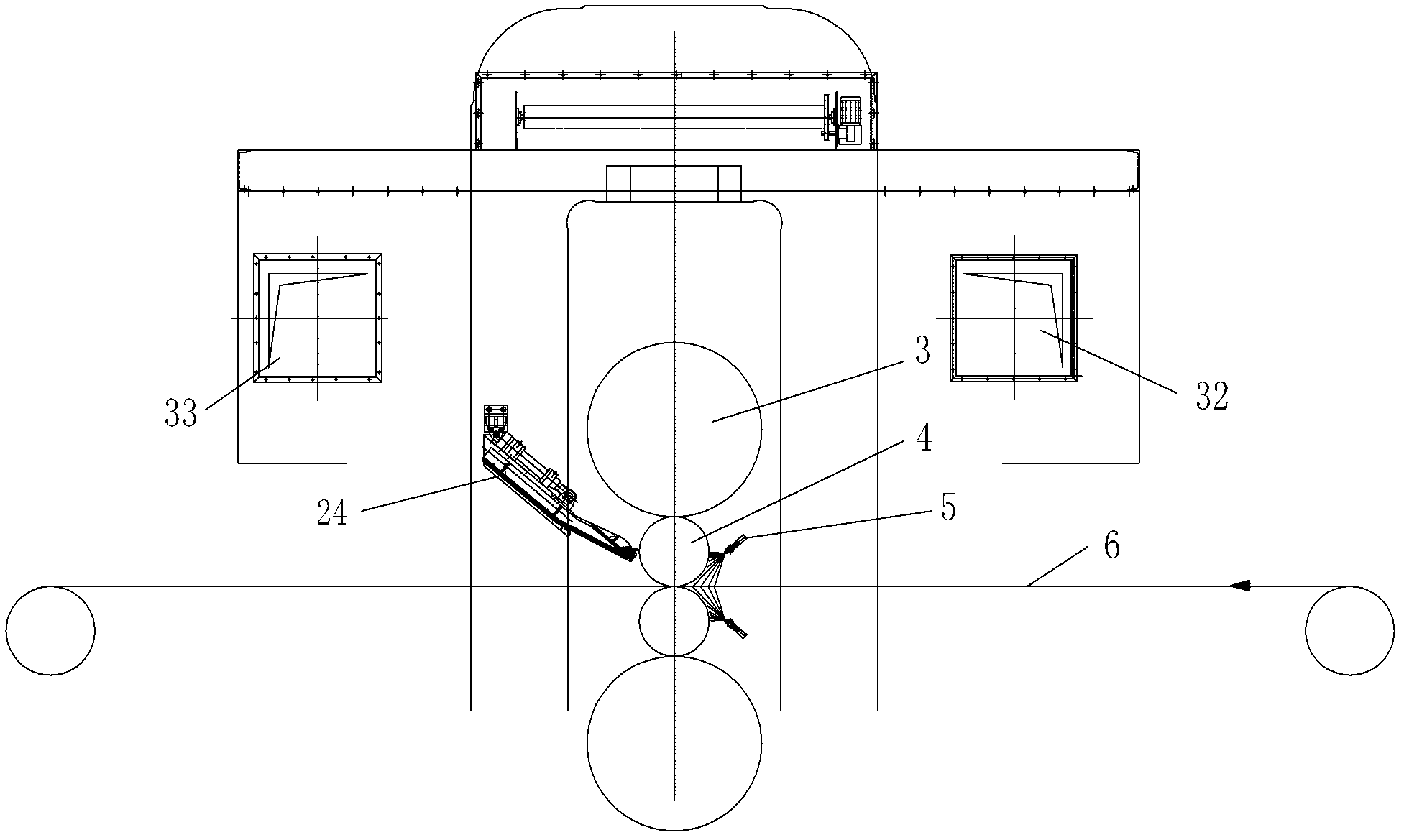

[0025] The water mist leveling system in cold rolling wet leveling production is composed of water mist leveling injection device and water mist leveling suction dust removal system.

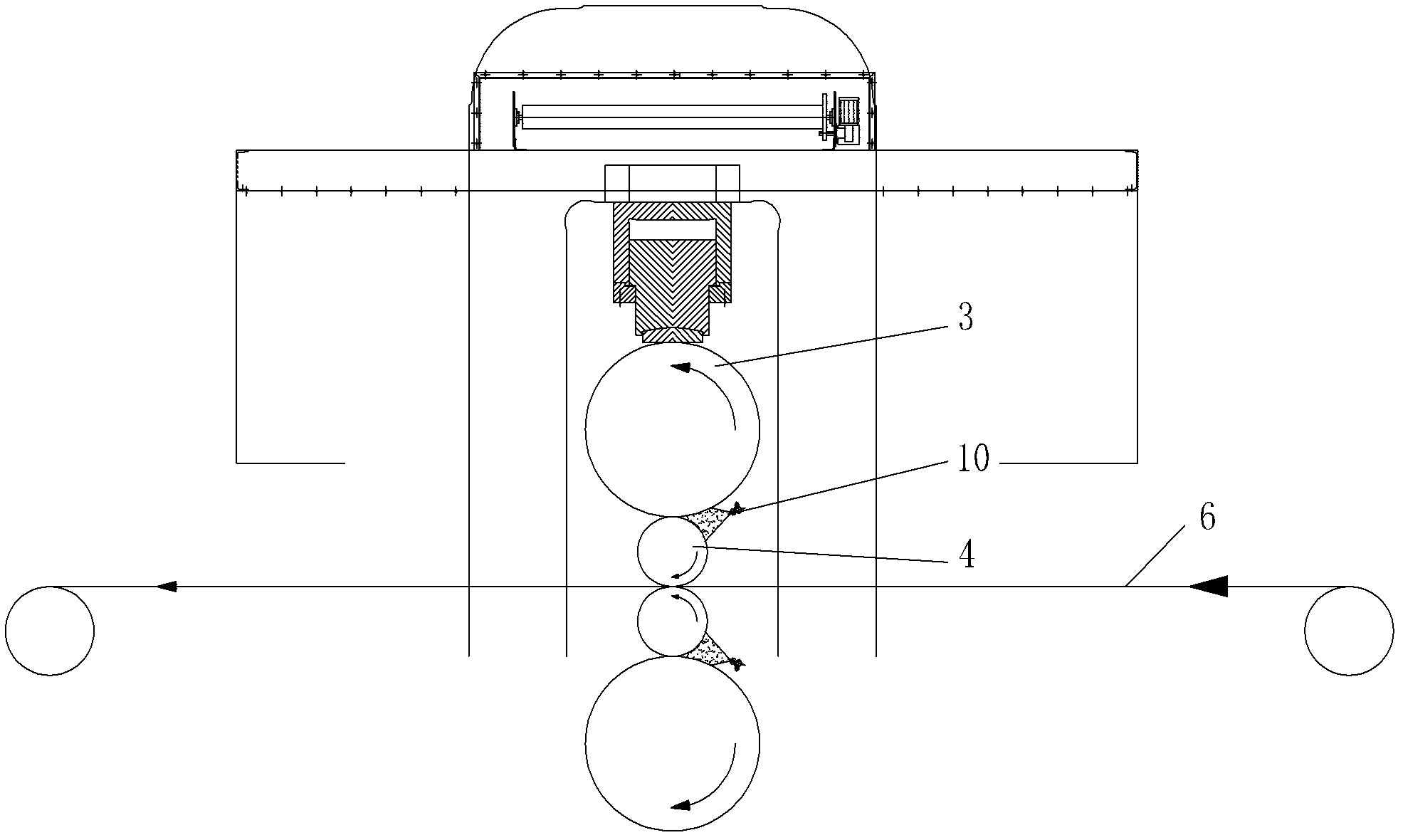

[0026] Such as image 3 As shown, the water mist leveling injection device comprises a water mist leveling spray beam 10, a telescopic mechanism, and a leveling mist spraying device; The connecting beam 15 is connected, and the two ends of the beam 15 are respectively fixed on the frame 16 of the wet tempering machine;

[0027] Such as Figure 4 , Figure 5 and Figure 6 As shown, the described leveling mist spraying device comprises nozzle 18, air main pipe 20, leveling liquid main pipe 21; Consistent), the air main pipe 20 and the leveling liquid main pipe 21 are all fixed on the water mist leveling spray beam 10, one end of the air main pipe 20 is closed, and the other end of the air main pipe 20 is connected with the air delivery hose 22 (the air delivery hose provides air source), one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com