Water spray injection method of leveling liquid in cold milling wet leveling production

A technology of water mist spraying and leveling liquid, which is applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of leveling liquid residual leveling spots, etc., and achieve the effect of reducing surface residue, reducing pollution, and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

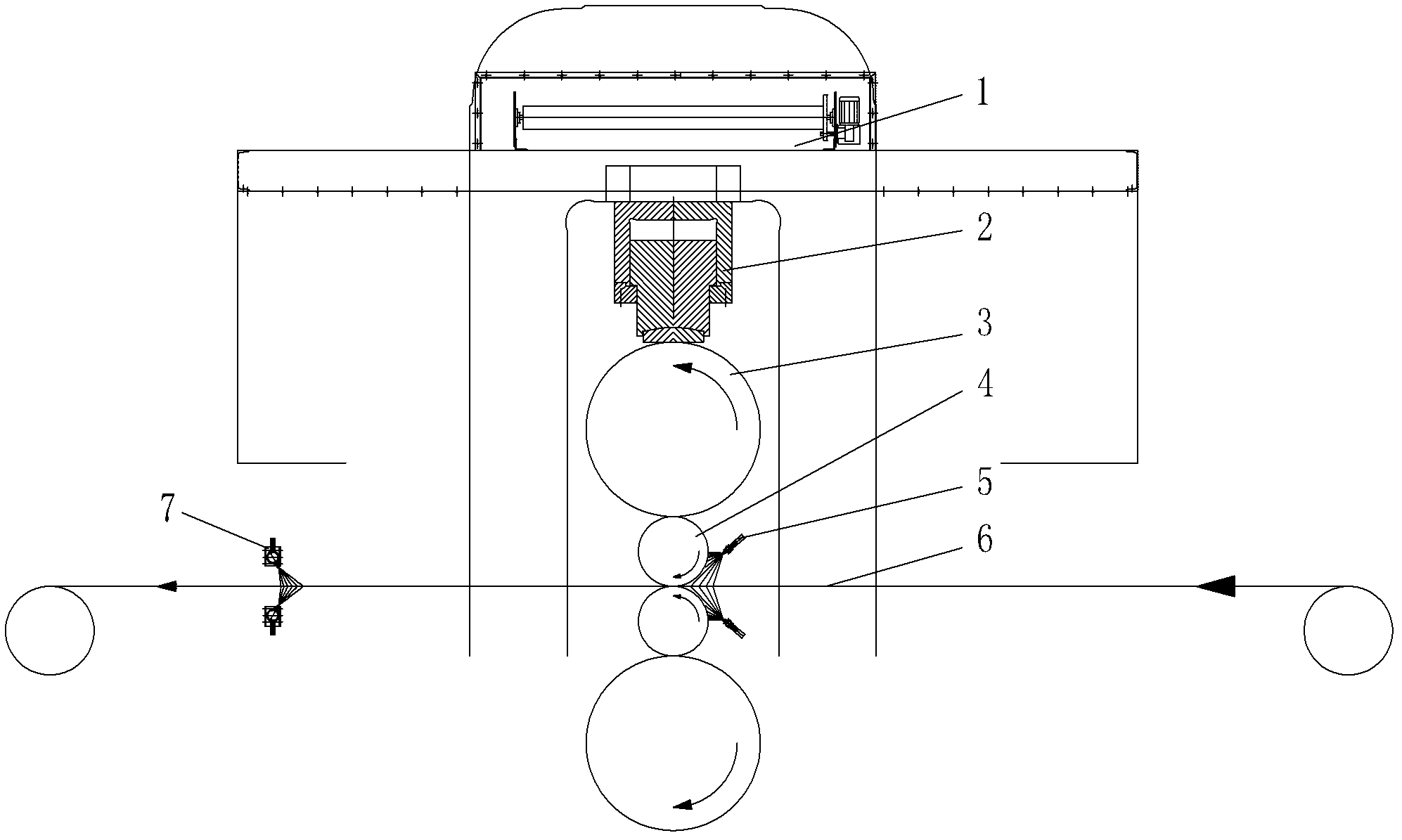

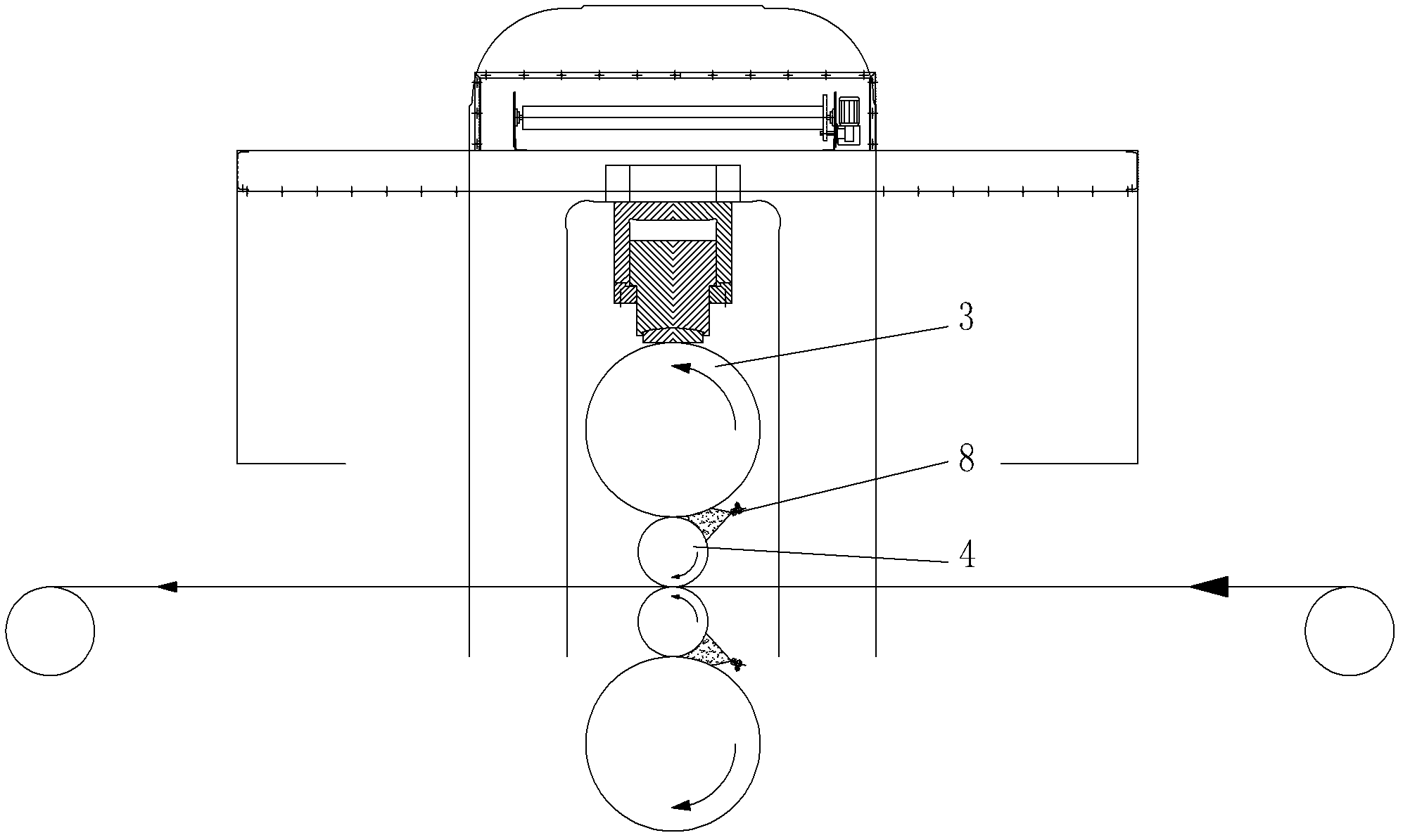

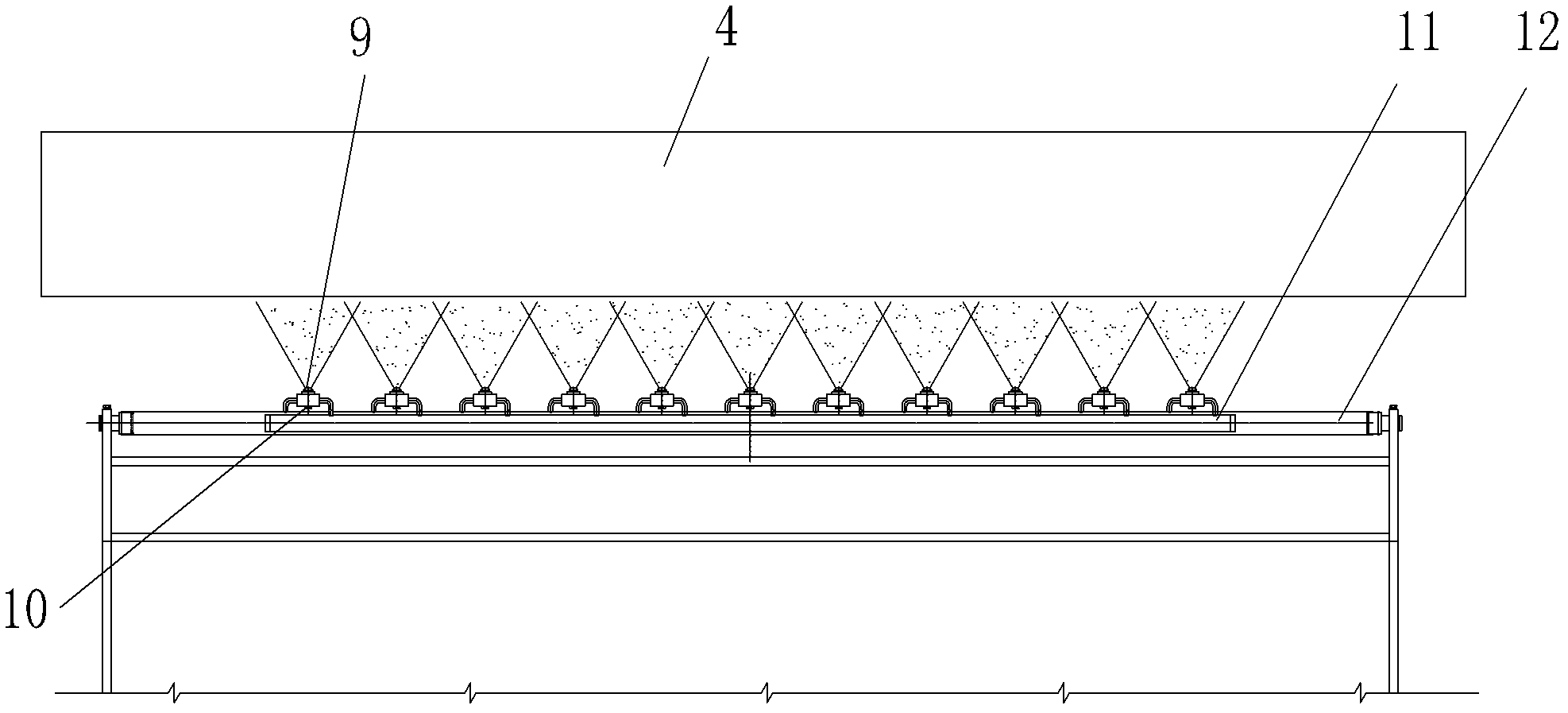

[0017] The water mist injection method of the leveling liquid in the wet leveling production of cold rolling, it comprises the following steps: 1) the water mist injection device (or claiming the aerosol injection device) is set at the entrance side of the wet leveler, the nozzle of the water mist injection device The nozzle faces the roll gap between the work roll and the back-up roll; the nozzle is equipped with an air input port and a leveling liquid input end, and a mixing valve for adjusting the air flow and the leveling liquid flow is installed on the nozzle;

[0018] 2) When the wet tempering mill starts rolling, input compressed air and leveling liquid to the nozzle, open and adjust the mixing valve, so that the flow rate of the leveling liquid flowing into each nozzle is 10-44.7L / h (the leveling liquid is the existing ), the air flow into each nozzle is 5.2 ~ 13m 3 / h, the leveling liquid and compressed air are mixed at the nozzle, and sprayed out as aerosol through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com