Three-dimensional breathable sheet and absorption product

A technology for absorbent products and sheets, applied in absorbent pads, medical science, bandages, etc., can solve the problems of increasing the manufacturing cost of surface materials, hindering the penetration of excreta, reducing air permeability, etc., to reduce surface residue and improve dryness , Improve the effect of air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

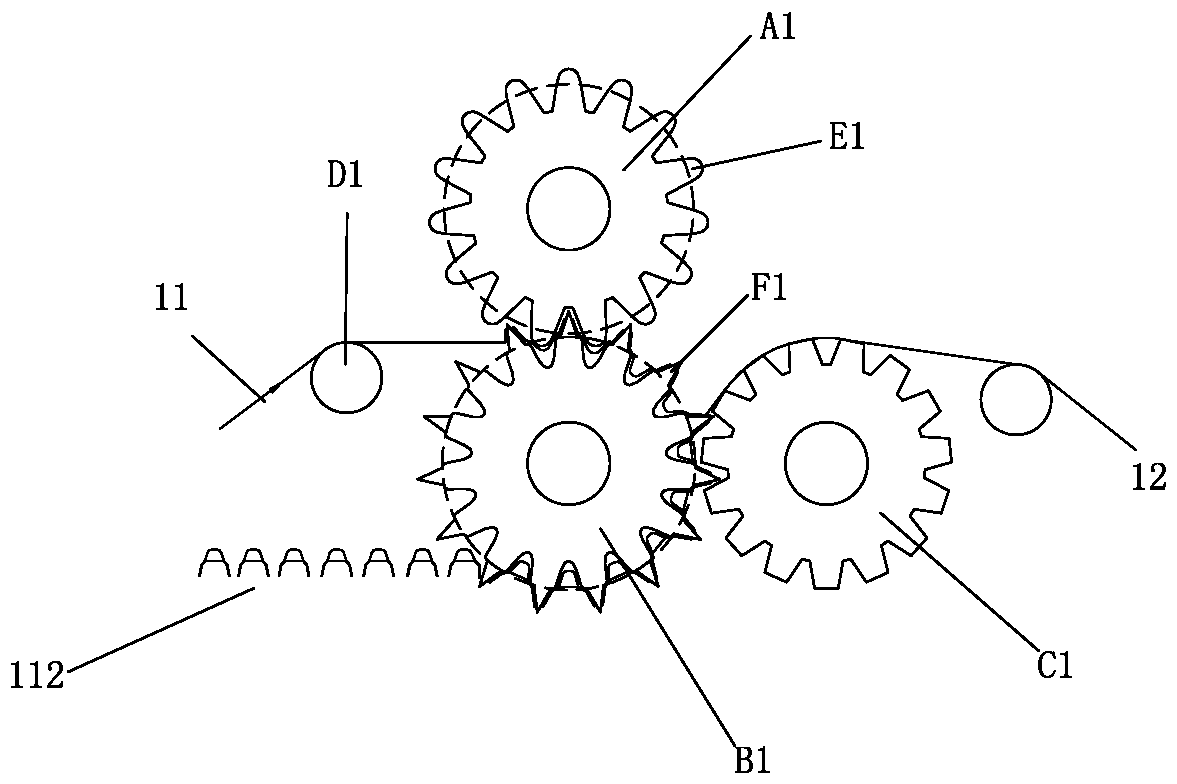

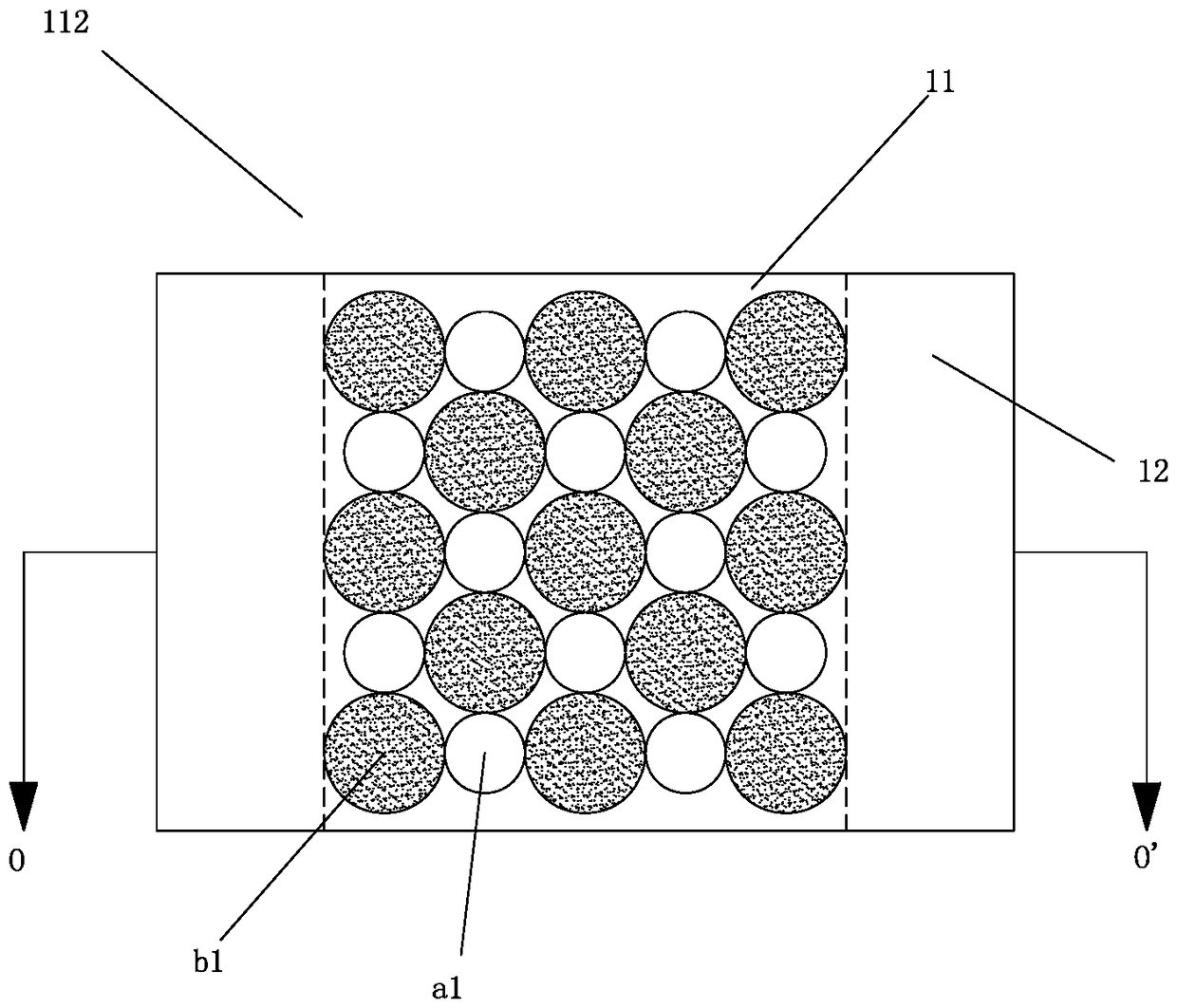

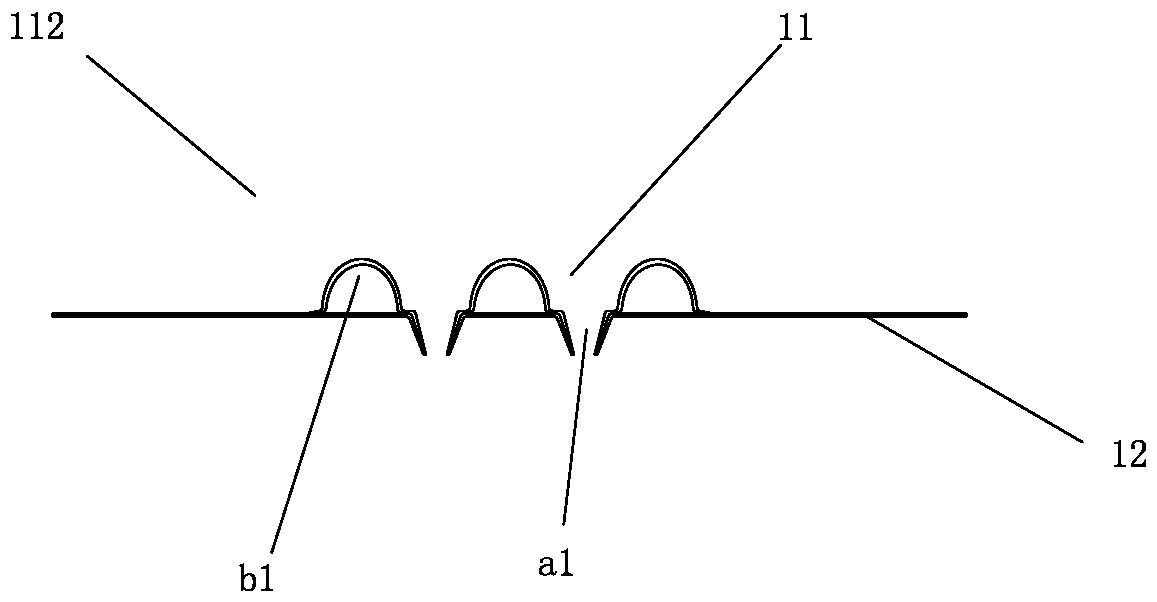

[0029] like Figure 1a , Figure 1b and Figure 1c As shown, the surface sheets 11 of several hydrophilic air-through nonwoven fabrics are evenly distributed in the axial direction of the guide roller D1, embossed and punched through the intermeshing convex roller A1 and needle roller B1, and passed through the convex roller A1. The protrusion E1 of the needle roller B1 and the perforated needle F1 on the needle roller B1 make the surface sheet 11 have raised areas and through holes, and then the surface sheet 11 pierced by the perforated needle F1 on the needle roller B1 is closely attached Attached to the needle roller B1, when it enters between the needle roller B1 and the concave roller C1 meshed with the needle roller B1, it will be re-opened and compounded with the bottom sheet 12 of the hydrophilic air-through non-woven fabric, and finally divided according to the required size. Cutting, the surface sheet 11 and the bottom sheet 12 are compounded by thermal bonding to ...

Embodiment 2

[0033] like Figure 2a , Figure 2b and Figure 2c As shown, the surface sheets 21 of several hydrophilic spunbonded nonwoven fabrics are evenly distributed in the axial direction of the guide roller D2, embossed and punched through the intermeshed convex roller A2 and needle roller B2, and passed through the convex roller A2 The protrusions E2 on the needle roller B2 and the perforated needles F21 and F22 on the needle roller B2 make the surface sheet 21 have raised areas and through holes, and then the surface after being pierced by the perforated needles F21 on the needle roller B2 The sheet 21 is closely attached to the needle roller B2, and when it enters between the needle roller B2 and the concave roller C2 meshed with the needle roller B2, it is perforated and compounded with the bottom sheet 22 of the hydrophilic hot-air nonwoven fabric, Finally, it is cut according to the required size, and the bottom sheet 22 is sprayed by the glue machine G2 before entering betwe...

Embodiment 3

[0037] like Figure 3a , Figure 3b and Figure 3c As shown, the surface sheets 31 of several hydrophobic hot-air nonwoven fabrics are evenly distributed in the axial direction of the guide roller D3, embossed and punched through the intermeshed convex roller A3 and needle roller B3, and passed through the convex roller A3. The protrusion E3 and the perforated needle F3 on the needle roller B3 make the surface sheet 31 have raised areas and through holes, and then the surface sheet 31 after being pierced by the perforated needle F3 on the needle roller B3 is closely attached On the needle roller B3, when it enters between the needle roller B3 and the concave roller C3 meshed with the needle roller B3, it is re-opened and compounded with the bottom sheet 32 of the hydrophilic air-through non-woven fabric, and finally cut according to the required size , the surface sheet 31 and the bottom sheet 32 are thermally combined to form a hollow three-dimensional raised area b3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com