A water-based anti-rust, degreasing and wax-removing cleaning agent and its preparation method and application

A cleaning agent, water-based technology, applied in the field of metal surface treatment, can solve the problems of accelerating the dissolution rate of wax, easy rusting of metal parts, increasing operating costs, etc., achieving good removal ability, surface tension reduction, critical micelles The effect of value drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

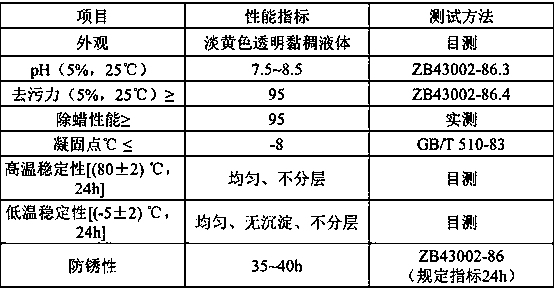

[0036] According to the formula in Table 1, the removal ability of alcohol amine type oleic acid soaps with different compositions to the polishing wax on the steel sheet surface was tested.

[0037] Table 1 The wax removal ability of alcohol amine type oleic acid soap

[0038]

[0039] As can be seen from Table 1, the compound whose molar ratio of oleic acid and diethanolamine is 1:2 has the best wax removal performance, so the diethanolamine oleic acid soap formed by this molar ratio is selected for use in the following examples.

Embodiment 2

[0041] A water-based metal anti-rust degreasing wax removal cleaning agent, which consists of the following formula by weight:

[0042] Polyacrylic acid or its copolymers, crotonic acid or its copolymers, acrylic acid maleic anhydride copolymer 18%,

[0043] Diethanolamine Oleic Soap 16%,

[0044] Alkanolamide Phosphate 6503 14%,

[0045] Dienyl succinimide T154 8%,

[0046] Sodium Tripolyphosphate 6%,

[0047] Anhydrous sodium metasilicate 2%,

[0048] Penetrant TA-2 7%,

[0049] Zinc Dialkyl Dithiophosphate 2%,

[0050] Macrogol 400 15%,

[0051] The balance is deionized water.

Embodiment 3

[0053] A water-based metal anti-rust degreasing wax removal cleaning agent, which consists of the following formula by weight:

[0054] Anionic carboxylic acid type macromolecule surfactant (identical to the components of Example 2) 16%,

[0055] Diethanolamine Oleic Soap 16%,

[0056] Alkanolamide Phosphate 6503 18%,

[0057] The addition of other components is identical with embodiment 2,

[0058] The balance is deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com