Switch cabinet condensation prevention device

A technology for anti-condensation and switchgear, which is applied in the substation/power distribution device casing, anti-corrosion coating, coating, etc., can solve the problems of accelerated aging of equipment in the cabinet, achieve excellent mechanical properties and insulation properties, simple synthesis, and enhanced The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

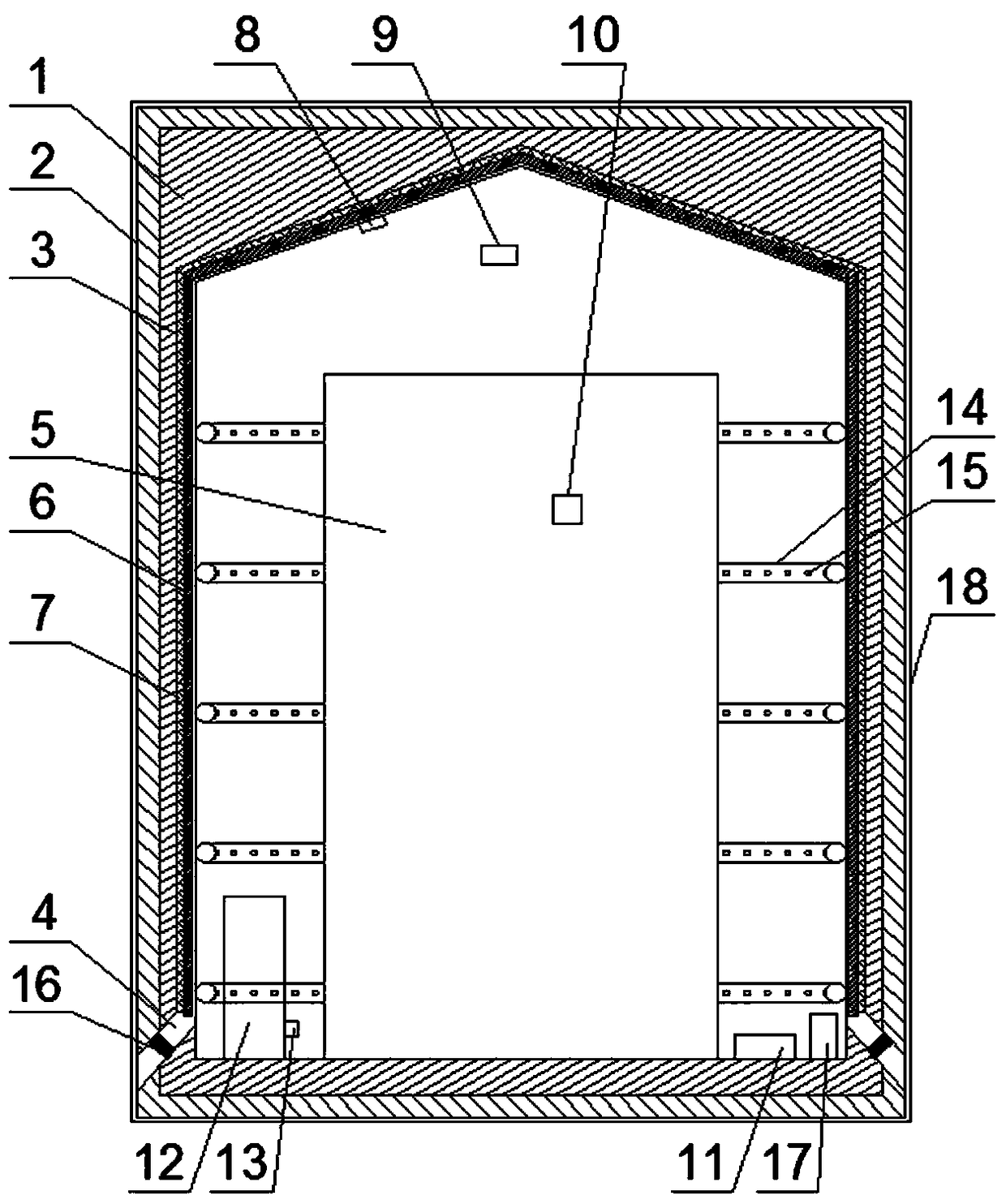

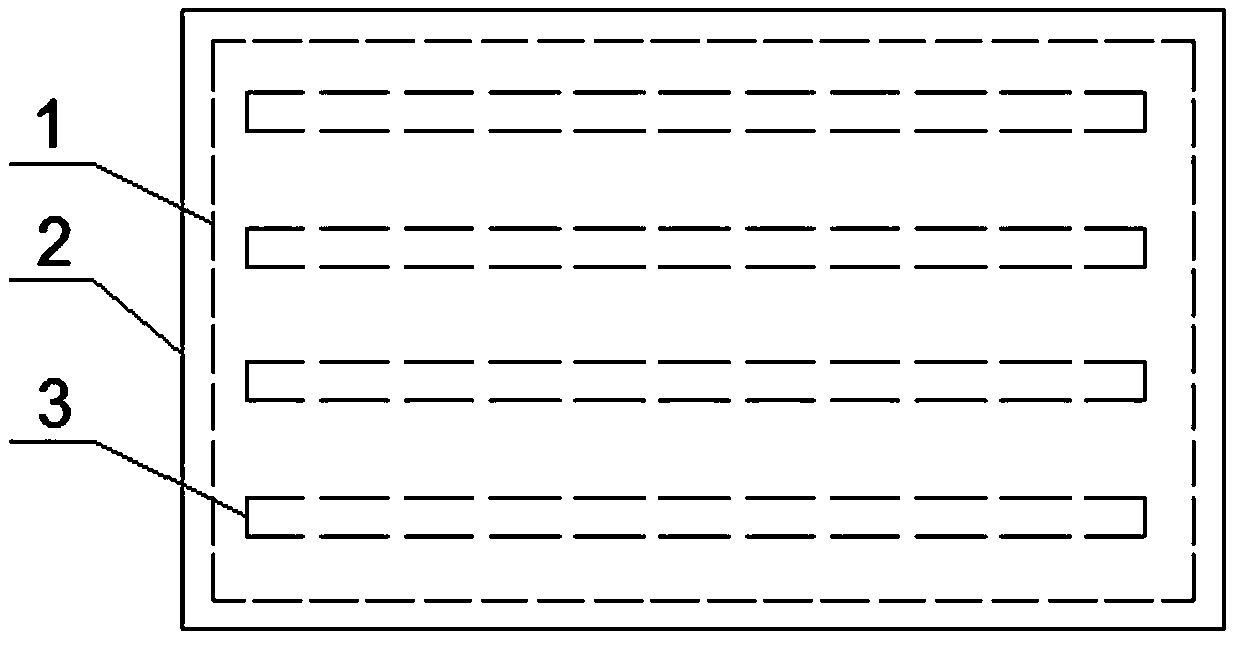

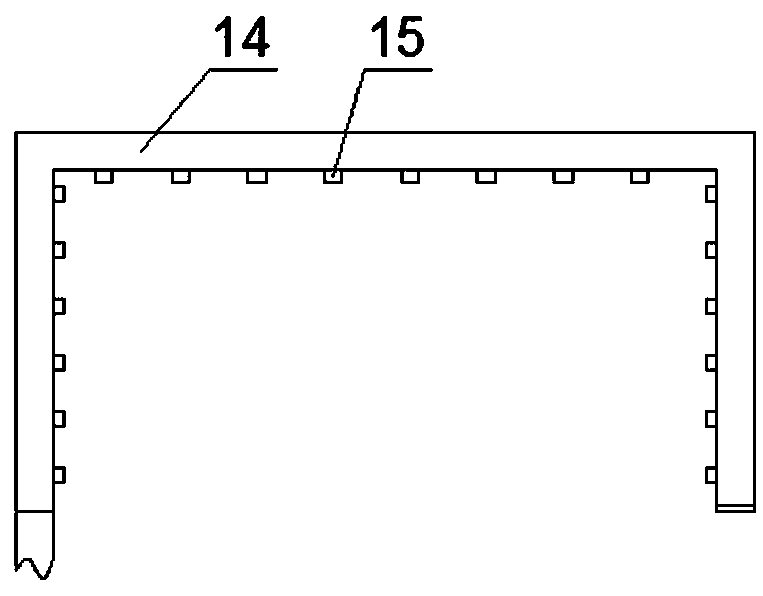

[0034] Such as figure 1 , figure 2 and image 3 As shown, a switch cabinet anti-condensation device includes a cabinet body 1, the outer surface of the cabinet body 1 is provided with an insulation layer 2, the inner top of the cabinet body 1 is tapered, and the inner wall of the cabinet body 1 is vertically A plurality of grooves 3 are provided in the vertical direction, and inclined drainage holes 4 are provided at the lower part of the cabinet body 1 corresponding to the two lower ends of the grooves 3, and the grooves 3 are provided with a The cold iron bars 6 that describe the surface temperature of the electrical equipment 5 in the cabinet 1, the two lower ends of the cold iron bars 6 are respectively located at the upper ends of the corresponding drain holes 4, the gap between the cold iron bars 6 and the groove 3 A semiconductor cooling chip 7 for cooling the cold iron bars 6 is arranged between them, a first temperature sensor 8 is arranged on the inner wall of the...

Embodiment 2

[0045] The difference from Example 1 is that the waterproof layer contains components and their contents: 16 parts by weight of polyaniline, 2.5 parts by weight of polymethyl methacrylate, 7 parts by weight of chloroform, N,N-di 42 parts by weight of methyl formamide, 16 parts by weight of sodium silicate, 2.8 parts by weight of sodium lauryl sulfate, 8 parts by weight of nano silicon dioxide, 6 parts by weight of sodium methyl silicate, tetrachloroterephthalic acid di 3.7 parts by weight of methyl ester, 8.9 parts by weight of cinnamaldehyde, 23 parts by weight of acetone, and 48 parts by weight of deionized water.

Embodiment 3

[0047] The difference from Example 1 is that the waterproof layer contains components and their contents: 17 parts by weight of polyaniline, 3 parts by weight of polymethyl methacrylate, 7.5 parts by weight of chloroform, N,N-di 44 parts by weight of methyl formamide, 16.5 parts by weight of sodium silicate, 3 parts by weight of sodium lauryl sulfate, 9 parts by weight of nano silicon dioxide, 6.1 parts by weight of calcium stearate, dimethyl tetrachloroterephthalate 3.9 parts by weight of ester, 9 parts by weight of polyaspartic acid, 24 parts by weight of acetone, and 50 parts by weight of deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com