Volatile corrosion inhibitor, and forming material and formed article using the same

A molding material and volatile technology, applied in the direction of coating, etc., can solve the problems of film or thin plate physical and appearance deterioration, anti-rust performance reduction, anti-rust effect can not be fully exerted, etc., to achieve superior anti-rust performance, thermal Stable performance, excellent anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

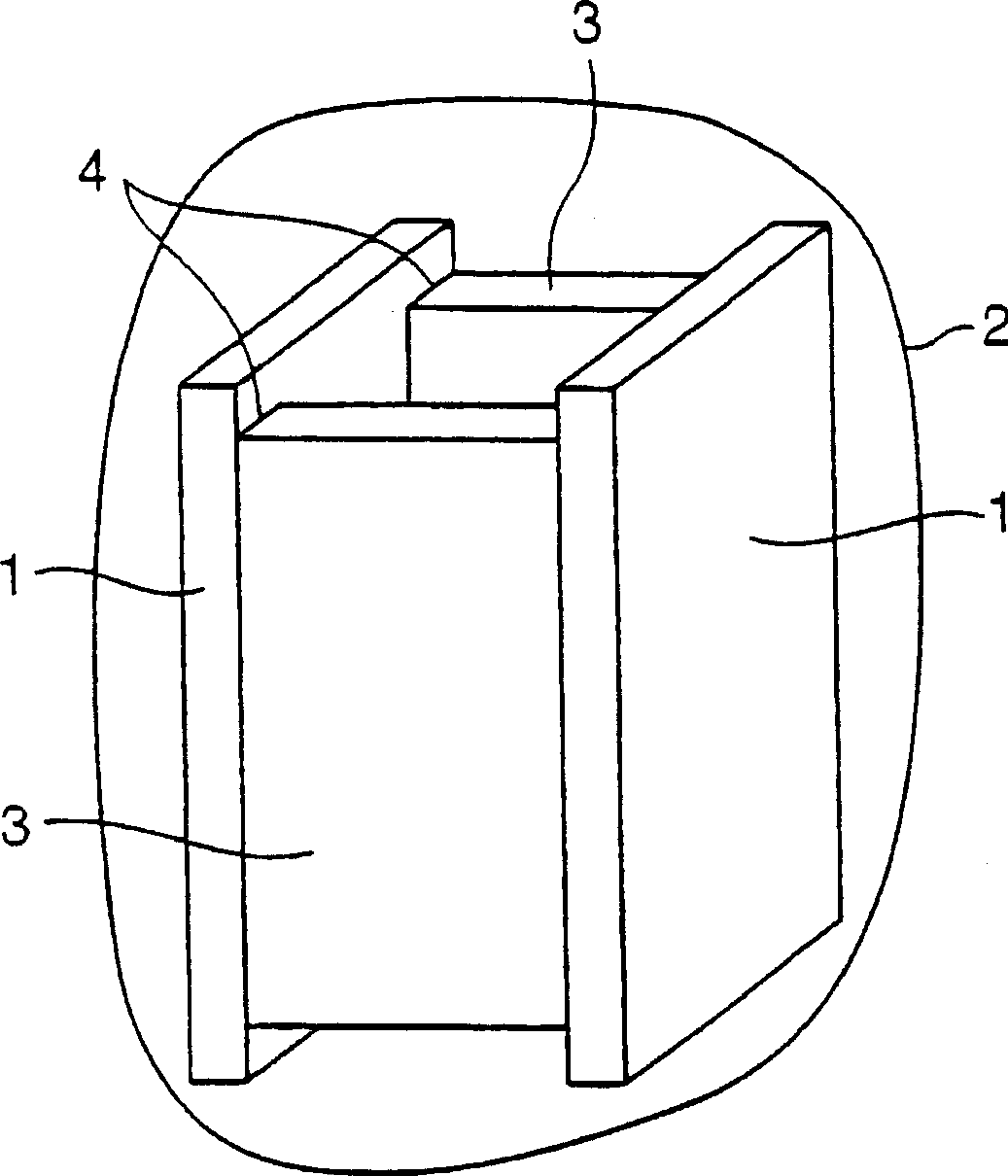

Image

Examples

Embodiment

[0040] The following examples are given to describe the present invention more specifically. The present invention is certainly not limited by the following examples, and can also be appropriately modified and implemented within the scope of the above and following purposes. These are all included in this document. within the technical scope of the invention.

[0041] In addition, the components used in the following examples and comparative examples are as follows:

[0042] Component (A): Sodium nitrite, trade name [Nitrite So-da] manufactured by Nissan Chemical Industry Co., Ltd.

[0043] Component (B): Sodium sebacate, trade name [SA-NA] manufactured by Toyokuni Oil Co., Ltd.

[0044] Component (C): Sodium benzoate, trade name [フミナ-ル] manufactured by Fushimi Pharmaceutical Co., Ltd.

[0045] Component (D): 2-Mercaptobenzothiazole (MBT), trade name [Sansera-M] manufactured by Sanshin Chemical Industry Co., Ltd.

[0046] Examples and Comparative Examples

[0047] As an em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com