Rustproof kraft paper adhesive tape as well as preparation method and application thereof

A kraft paper and tape technology, applied in the direction of adhesives, non-polymer adhesive additives, film/flake adhesives, etc., can solve the problems of pollution, solvent pollution, etc. Easy-to-remove effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 A kind of antirust kraft paper tape, its preparation method and application

[0041] An antirust kraft paper tape, which is composed of kraft paper and antirust glue, wherein the antirust glue is composed of the following raw materials:

[0042] Water-based pressure sensitive adhesive 75%, dimethylethanolamine 5%, rust inhibitor 20%.

[0043] As a limitation of the present invention,

[0044] Methyl methacrylate 50g, methacrylic acid 30g and ethyl acrylate 20g.

[0045] As a further limitation of the above-mentioned limitations, the preparation method of the water-based pressure-sensitive adhesive is carried out in the following order:

[0046] ① Cover the methyl methacrylate, seal it and heat it to 65°C, set aside;

[0047] ② Add methacrylic acid to methyl methacrylate in small amounts in batches and stir, and then add the next batch until the methacrylic acid is completely dissolved each time until it is completely dissolved to make solution a;

[004...

Embodiment 2-6

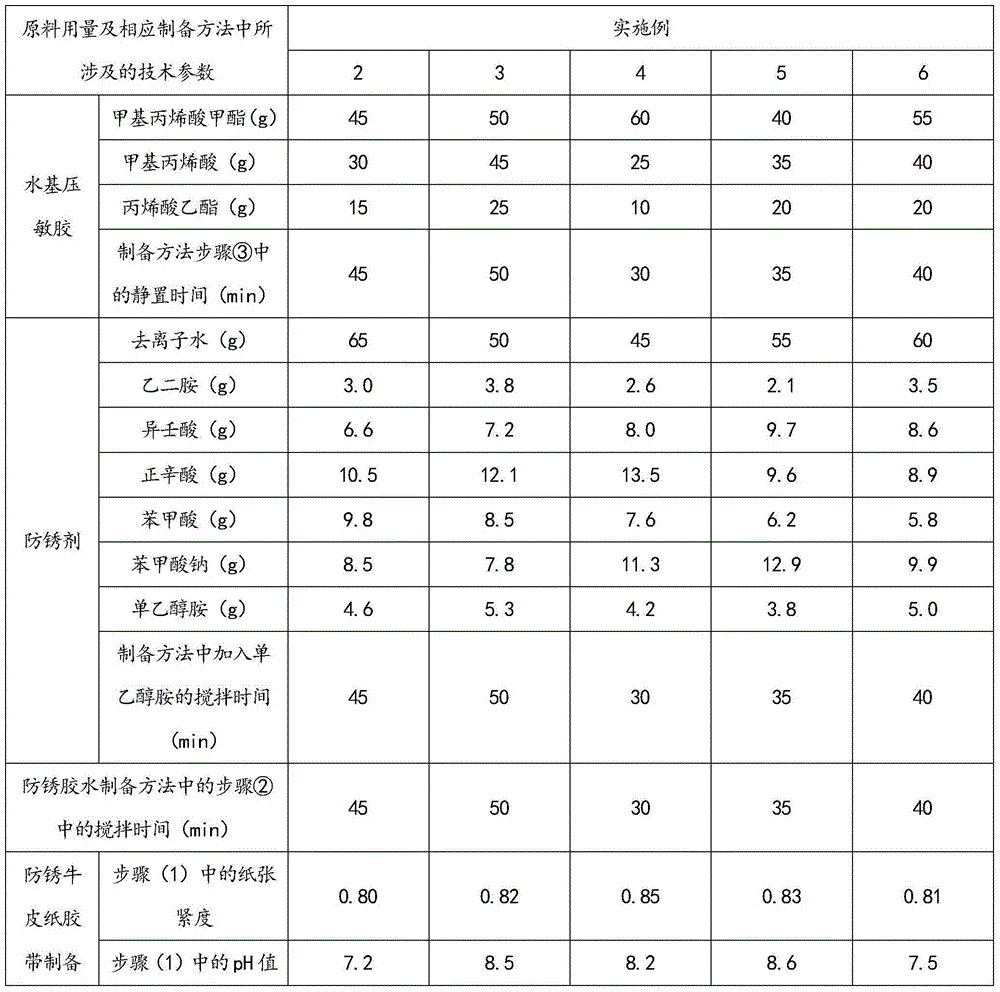

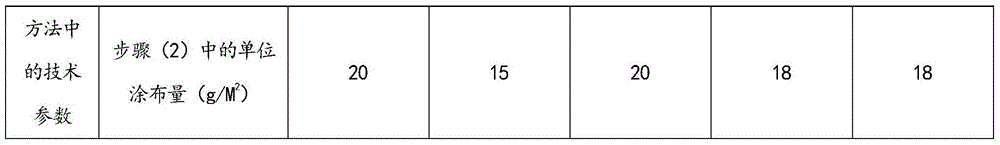

[0068] Embodiment 2-6 Anti-rust kraft paper tape and preparation method thereof

[0069] Embodiment 2-6 is a kind of antirust kraft paper adhesive tape and preparation method thereof respectively, and its raw material and preparation method are similar to embodiment 1, and the only difference is that the raw material consumption used and the technical parameter involved in the preparation method are different , as shown in the following table:

[0070]

[0071]

[0072] The anti-rust kraft paper tapes prepared in Examples 2-6 can be applied to the rust prevention of metals. The anti-rust agent in the anti-rust kraft paper tapes uses ethylenediamine as a gas-phase anti-corrosion inhibitor, and the gas-phase anti-rust is not only for metal contact The surface can play an effective anti-rust and anti-oxidation effect. For the distance of 10cm above and below the anti-rust paper tape, it is within the effective anti-rust protection range of vapor phase anti-rust. Therefore, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com