Lauric acid diethanolamide borate vapor phase antirust masterbatch and its preparation method and application

The technology of lauric acid diethanolamide borate and gas phase rust prevention is applied in the field of lauric acid diethanolamide borate gas phase rust prevention master batch and its preparation, which can solve the problems that have not been involved, and achieves environmental protection, safety, and safety in use. The effect of enhancing anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

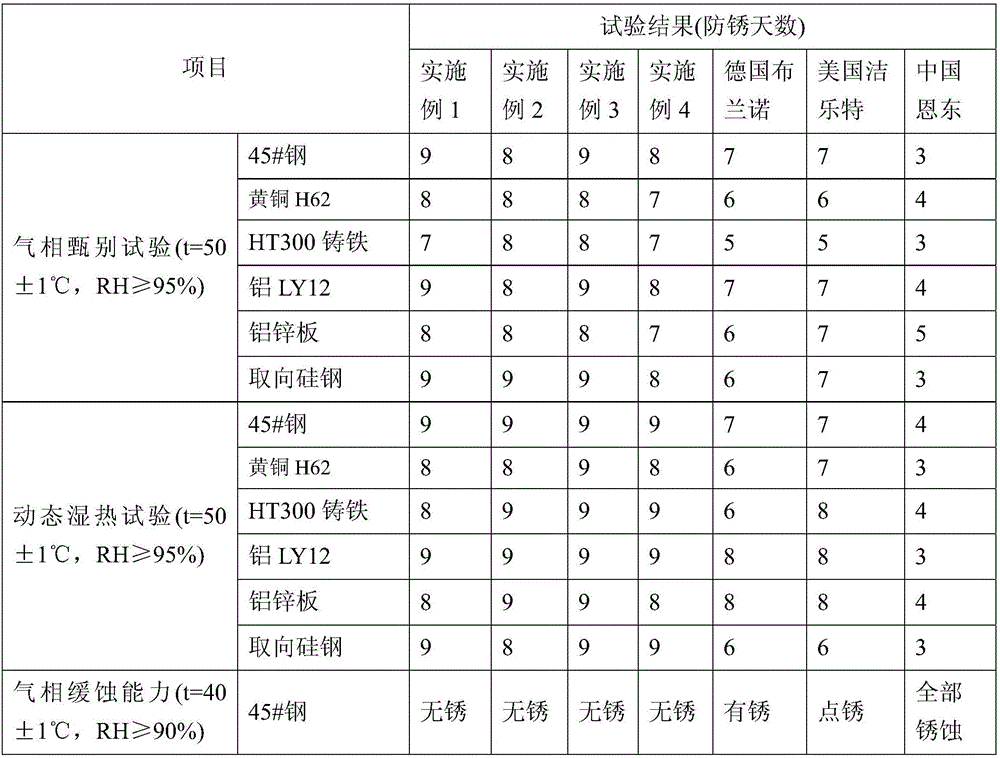

Examples

Embodiment 1

[0019] Lauric acid diethanolamide borate vapor phase anti-rust masterbatch a, wherein the mass percentage of each component is: 37% compound anti-rust agent, 48% carrier plastic and 15% auxiliary agent; the compound anti-rust The rust agent is composed of sodium benzoate, sodium sebacate, lauric acid diethanolamide borate, and hexamethylenetetramine in a mass ratio of 1:1.3:3:1. The diameter is 900-1100 mesh; the auxiliary agent is mixed with stearic acid amide, heavy calcium carbonate, sucrose fatty acid ester, and antioxidant 246 in a mass ratio of 1:5.5:3:1.

Embodiment 2

[0021] Lauric acid diethanolamide borate vapor phase antirust masterbatch b, wherein the mass percentage of each component is 38% compound antirust agent, 45% carrier plastic and 17% auxiliary agent; the compound antirust The antirust agent is mixed with sodium benzoate, sodium sebacate, lauric acid diethanolamide borate, and hexamethylenetetramine in a mass ratio of 1:1.3:3:1. The particle size of the compound antirust agent is 900-1100 mesh; the auxiliary agent is mixed with stearic acid amide, heavy calcium carbonate, sucrose fatty acid ester, and antioxidant 246 in a mass ratio of 1:5.5:3:1.

Embodiment 3

[0023] Lauric acid diethanolamide borate vapor phase anti-rust masterbatch c, wherein the mass percentage of each component is: 42% compound anti-rust agent, 44% carrier plastic and 14% auxiliary agent; the compound anti-rust The rust agent is composed of sodium benzoate, sodium sebacate, lauric acid diethanolamide borate, and hexamethylenetetramine in a mass ratio of 1:1.3:3:1. The diameter is 900-1100 mesh; the auxiliary agent is mixed with stearic acid amide, heavy calcium carbonate, sucrose fatty acid ester, and antioxidant 246 in a mass ratio of 1:5.5:3:1. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com