Phytic-acid type gas-phase antirust masterbatch, and preparation method and application thereof

A gas-phase rust prevention and masterbatch technology, applied in the field of phytic acid-type gas-phase rust-proof masterbatch and its preparation, can solve the problems that have not been involved, achieve the effects of environmental protection and safety, and enhance the performance of gas-phase rust prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

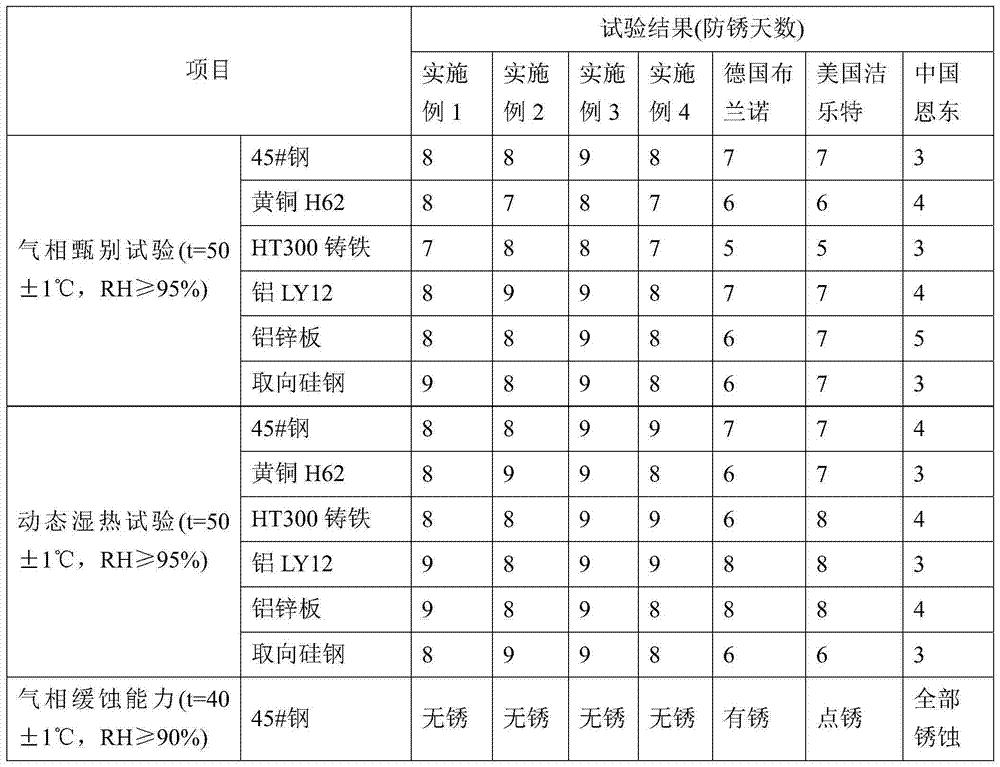

Examples

Embodiment 1

[0022] Phytic acid type gas-phase antirust masterbatch a, wherein the mass percent ratio of each component is: 36% compound antirust agent, 50% carrier plastic and 14% auxiliary agent; Described compound antirust agent is made of sodium benzoate , phytic acid, triethanolamine borate, and benzoic acid monoethanolamine are mixed in a mass ratio of 1:2.8:2.5:1.2, and the particle size of the compound antirust agent is 900-1100 mesh; the auxiliary agent is composed of Sodium silicate, silicon dioxide, stearic acid amide, and antioxidant 1076 are mixed in a mass ratio of 1:5.5:3:1.

Embodiment 2

[0024]Phytic acid type vapor phase antirust masterbatch b, wherein the mass percentage of each component is 40% compound antirust agent, 47% carrier plastic and 13% auxiliary agent; described compound antirust agent is composed of sodium benzoate, Phytic acid, triethanolamine borate, and benzoic acid monoethanolamine are mixed in a mass ratio of 1:2.8:2.5:1.2. The particle size of the compound antirust agent is 900-1100 mesh; the additive is made of silicon Sodium phosphate, silicon dioxide, stearic acid amide, and antioxidant 1076 are mixed in a mass ratio of 1:5.5:3:1.

Embodiment 3

[0026] Phytic acid type gas-phase anti-rust masterbatch c, wherein the mass percentage of each component is: 43% compound anti-rust agent, 45% carrier plastic and 12% auxiliary agent; the compound anti-rust agent is composed of sodium benzoate , phytic acid, triethanolamine borate, and benzoic acid monoethanolamine are mixed in a mass ratio of 1:2.8:2.5:1.2, and the particle size of the compound antirust agent is 900-1100 mesh; the auxiliary agent is composed of Sodium silicate, silicon dioxide, stearic acid amide, and antioxidant 1076 are mixed in a mass ratio of 1:5.5:3:1. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com