Patents

Literature

60results about How to "Solve the problem of continuous automatic locking and difficult disassembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot air type penetration reverse flow fluidization drying machine with tail heat utilization and inertial dust collecting functions

InactiveCN105783478AStrong extrusion rigidityEliminate fatigue fractureDrying solid materials with heatDrying gas arrangementsImpellerCyclone

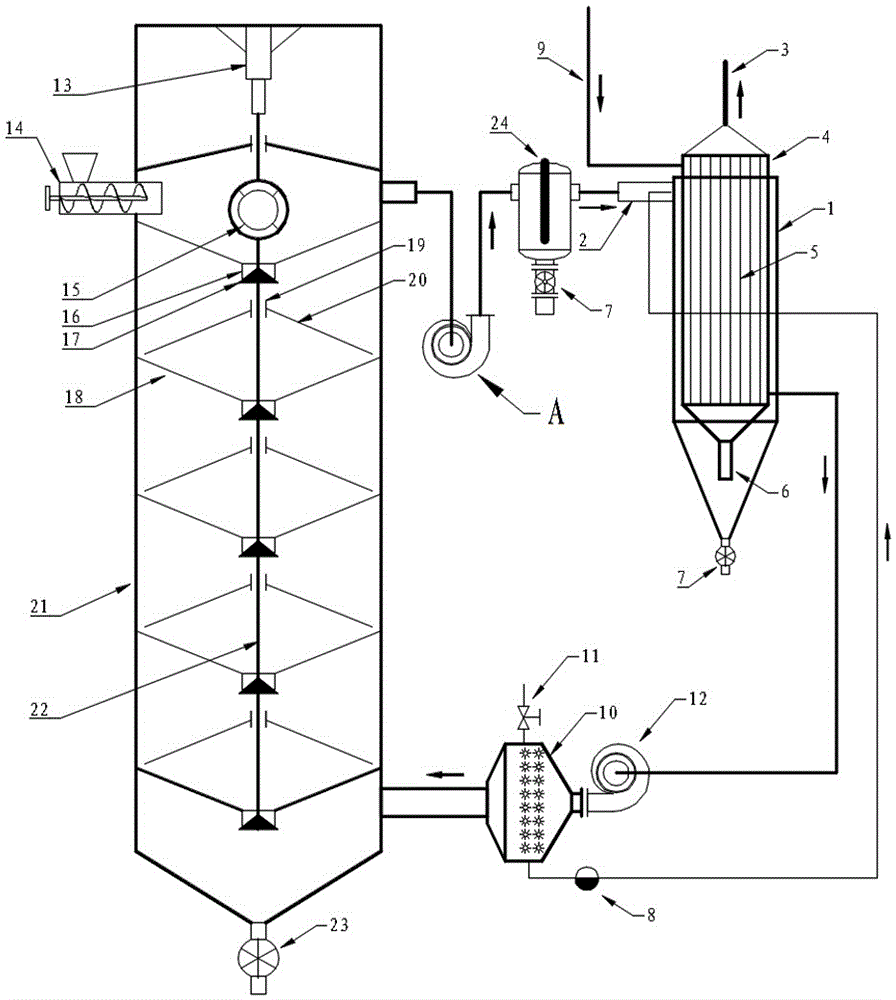

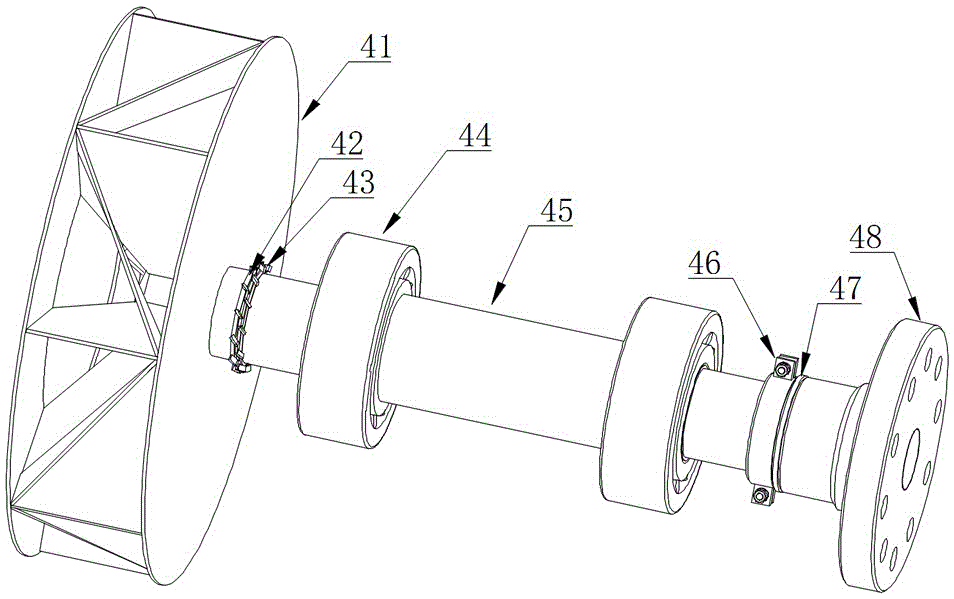

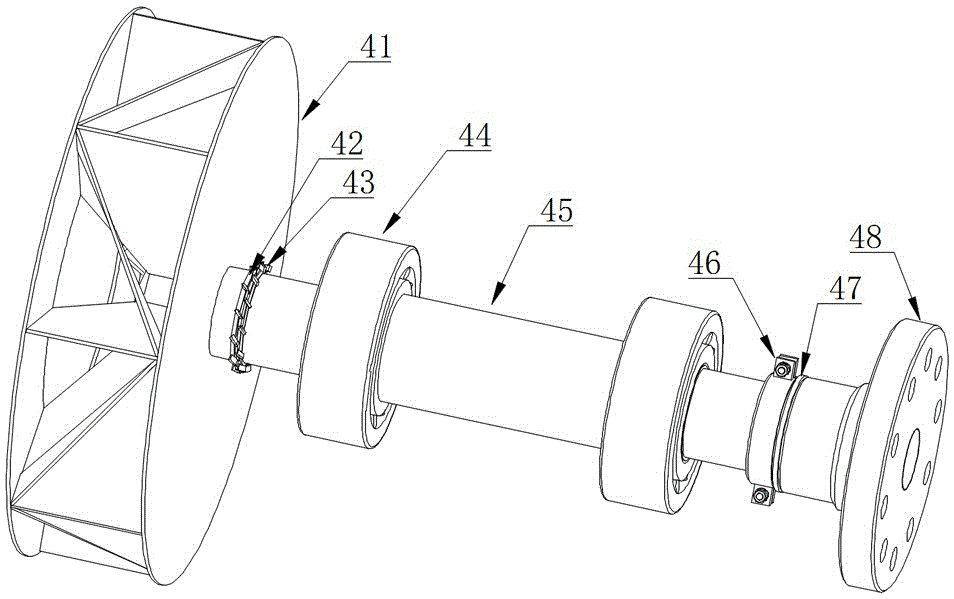

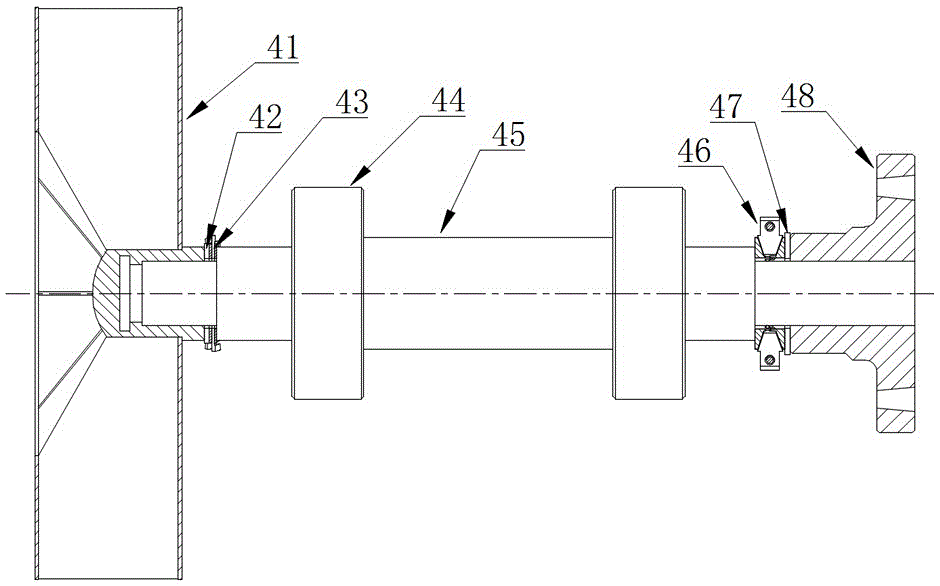

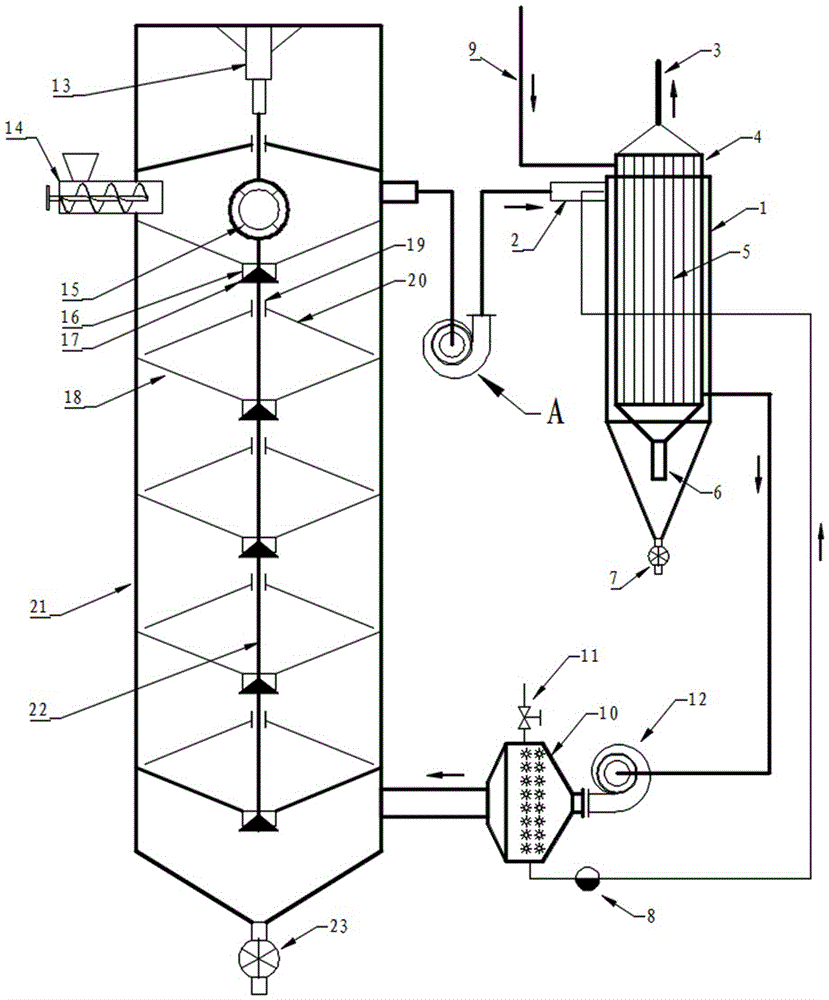

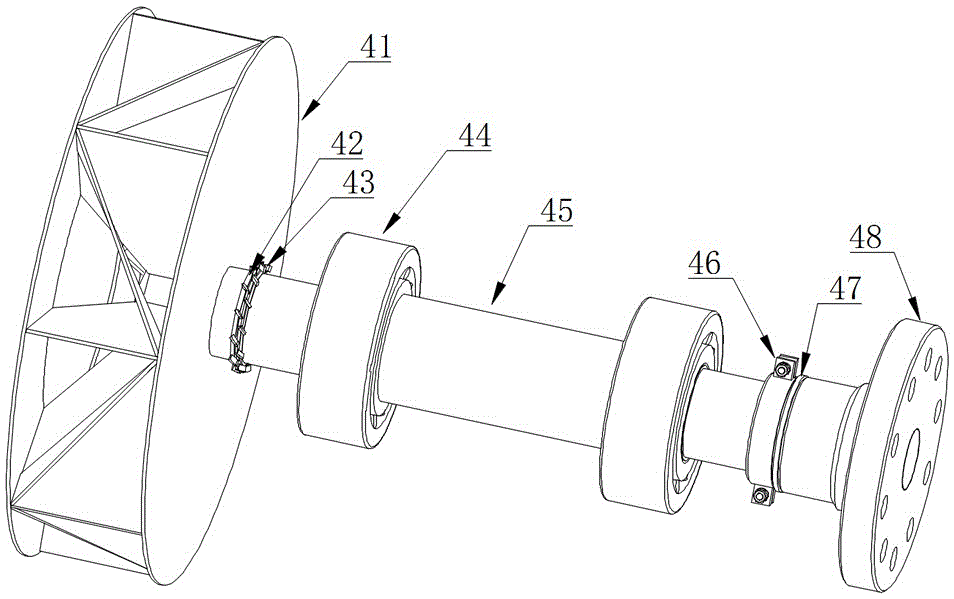

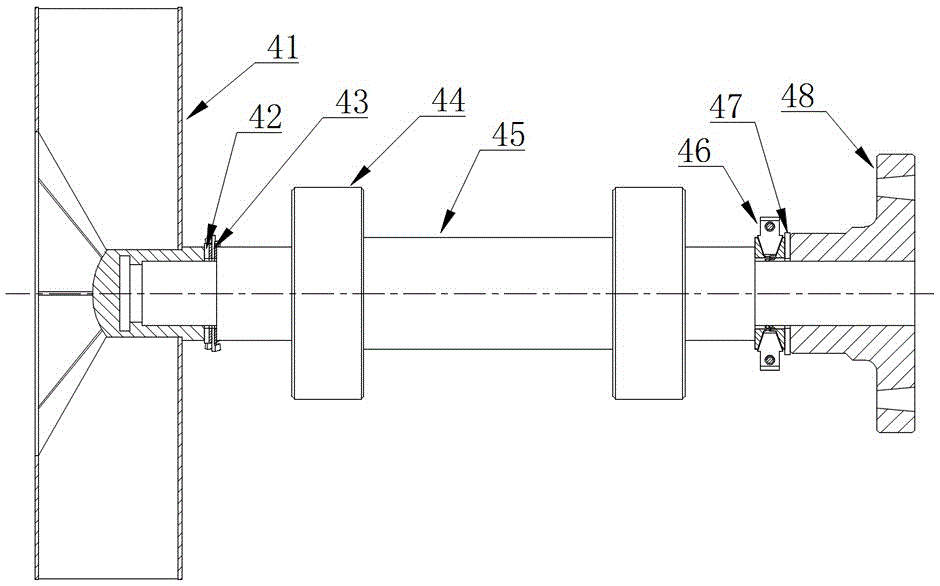

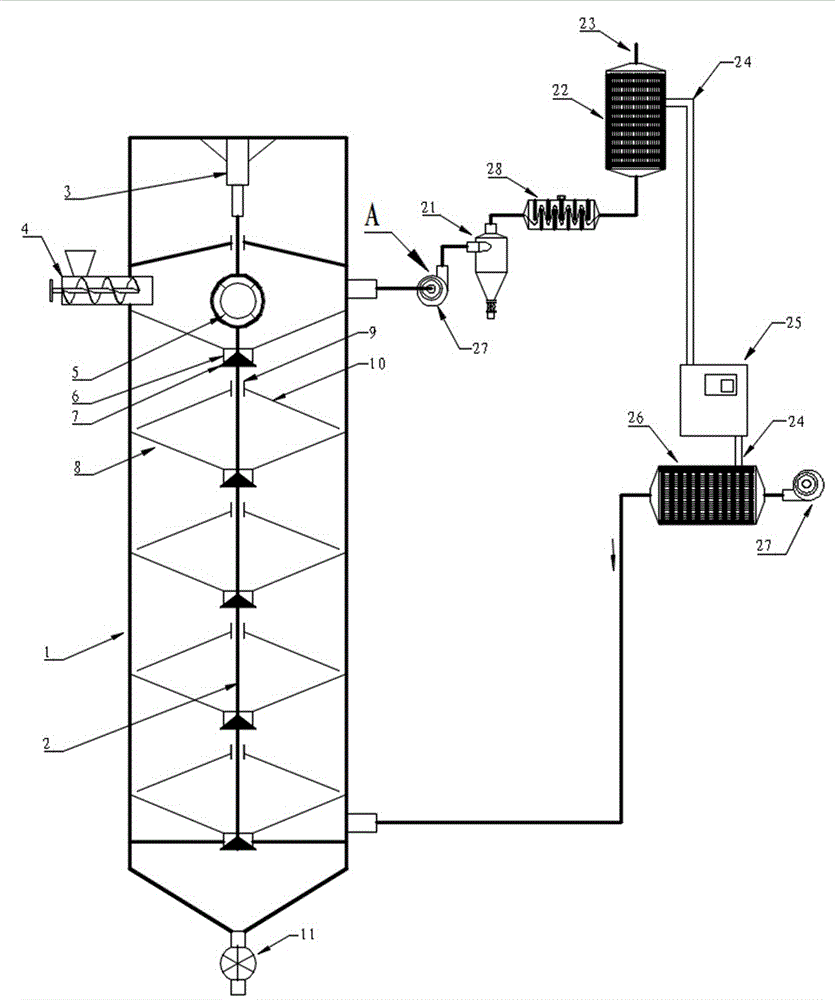

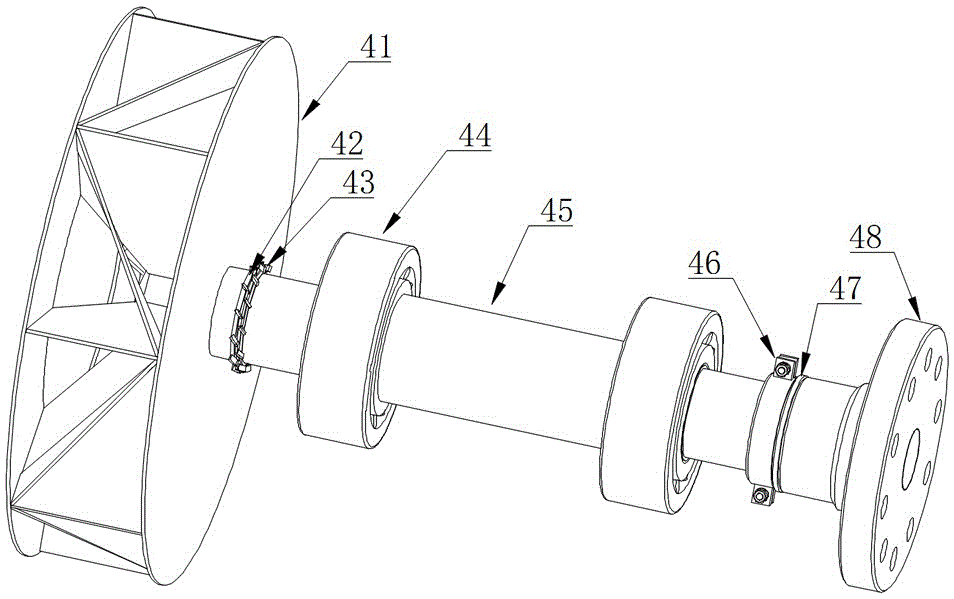

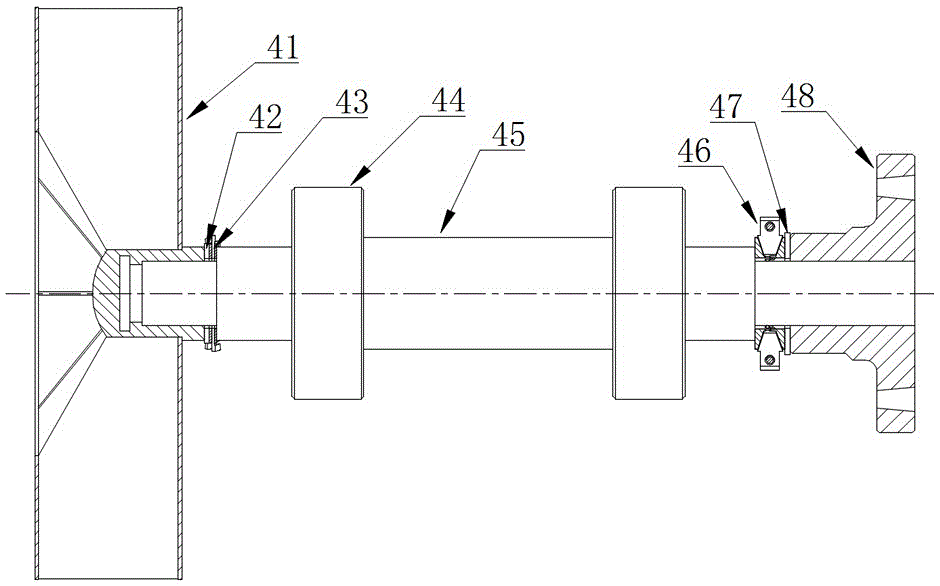

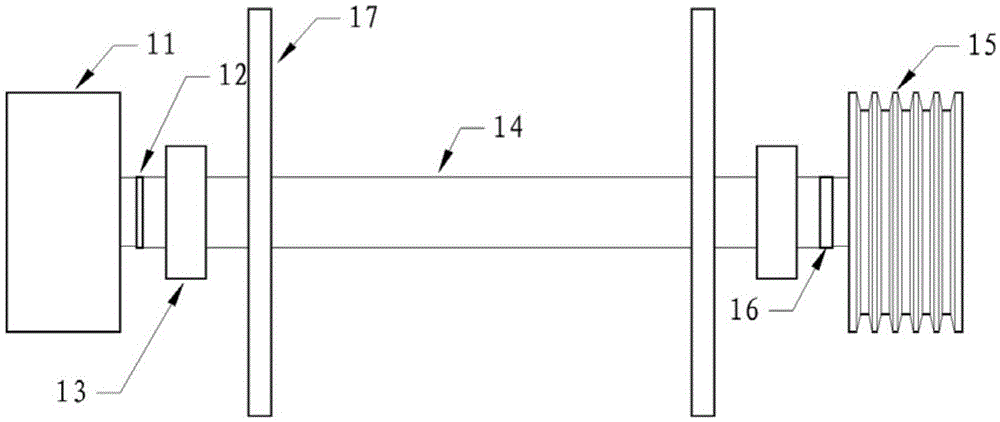

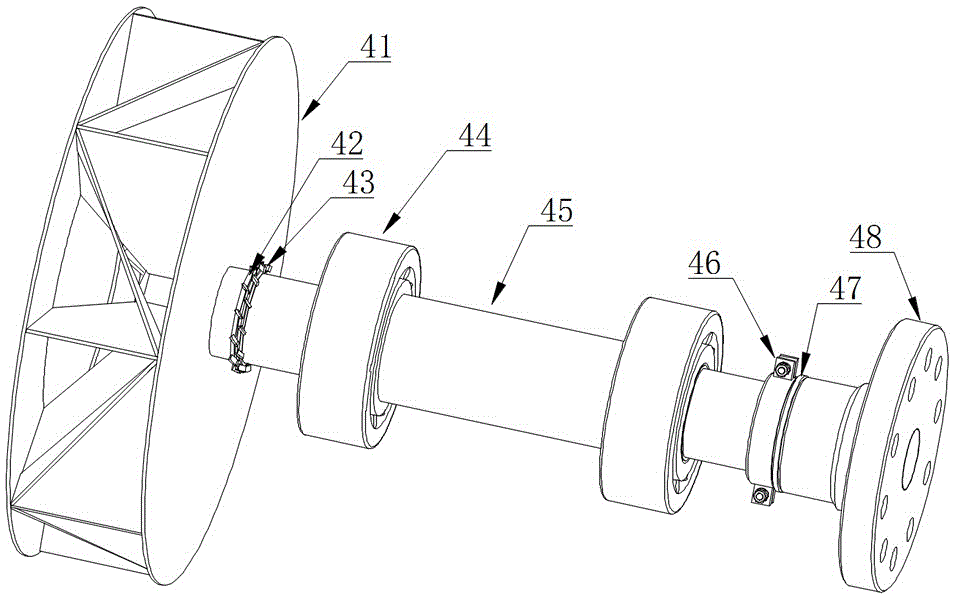

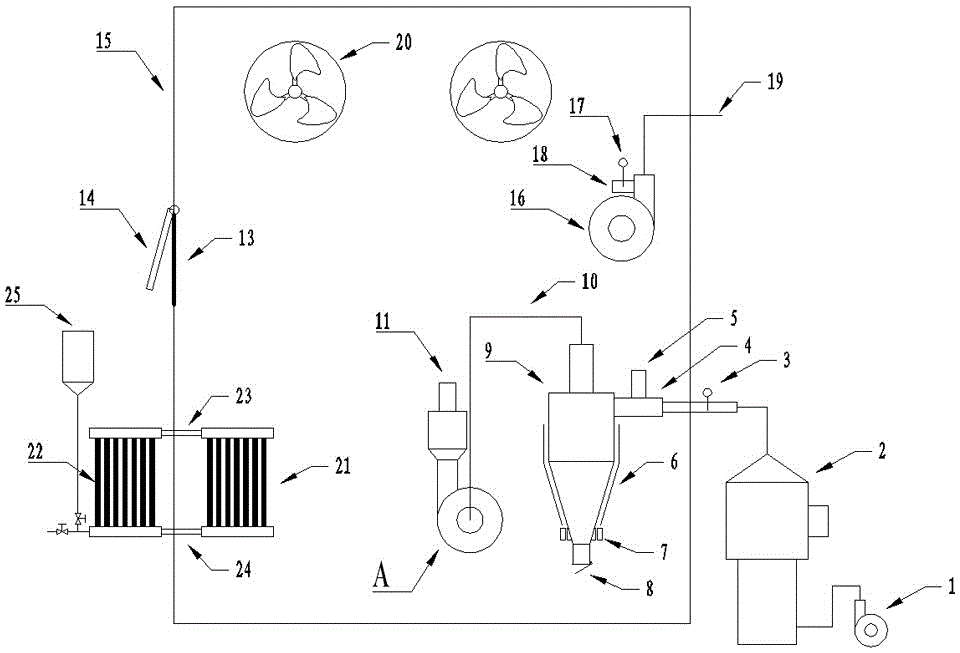

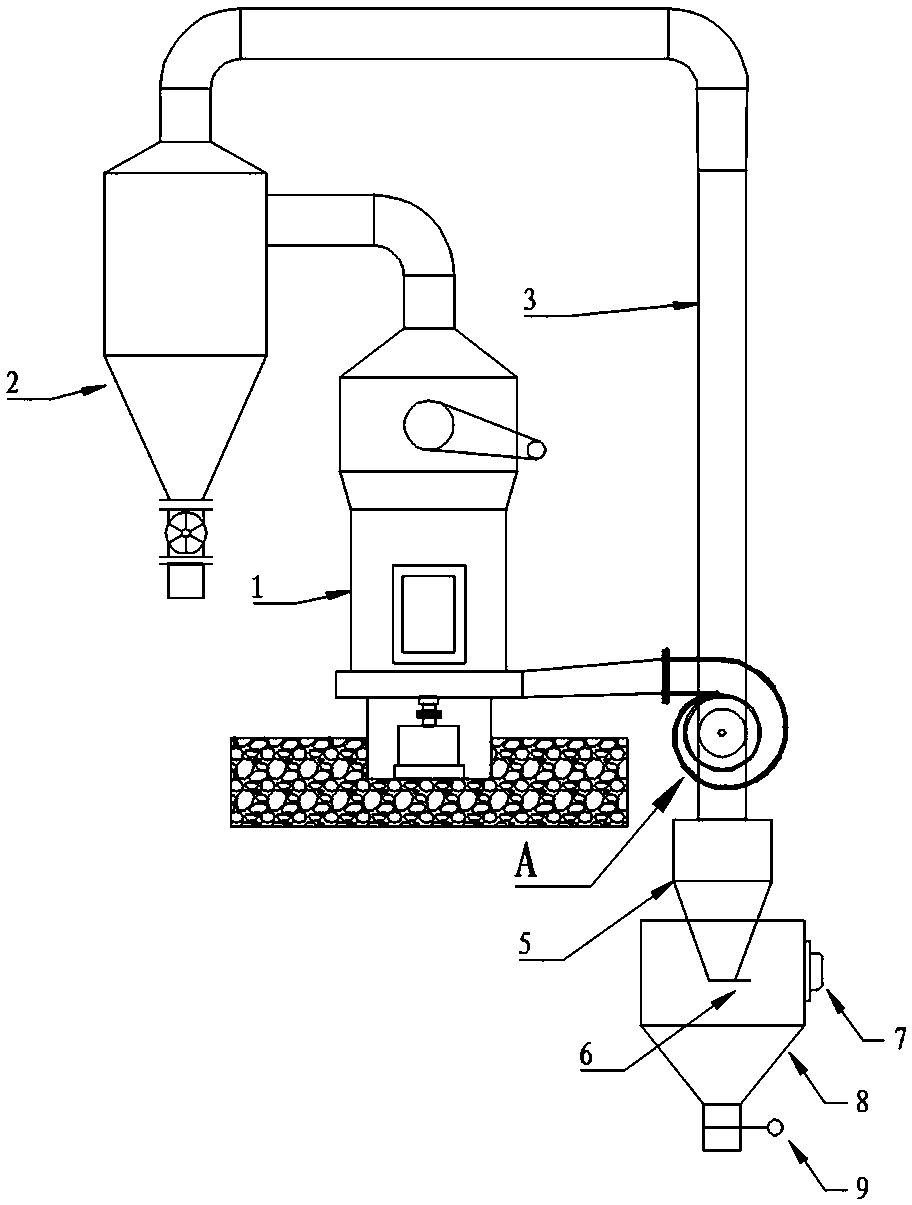

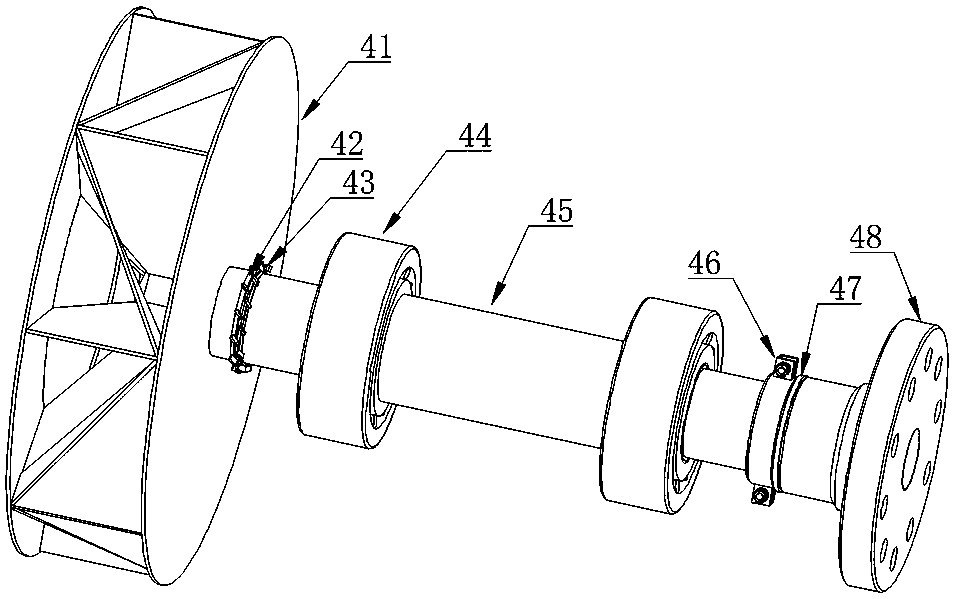

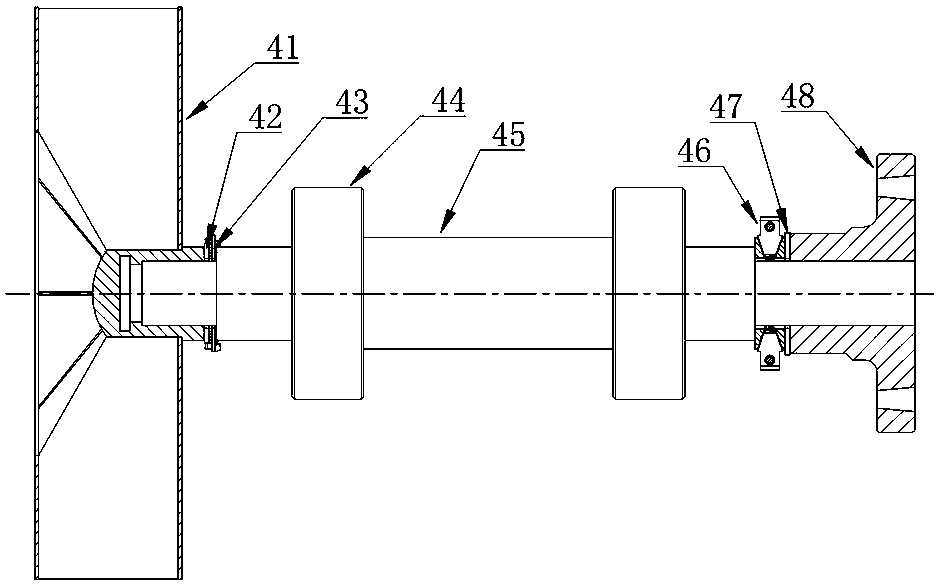

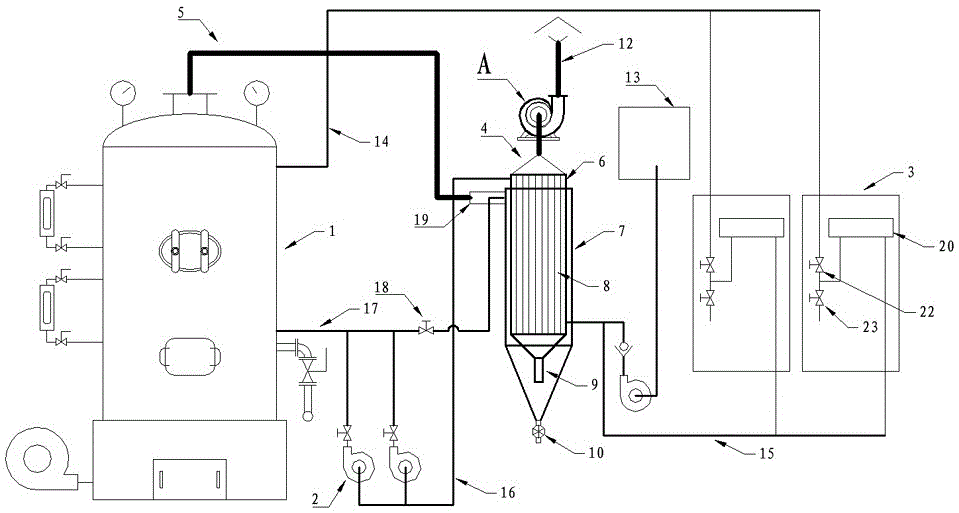

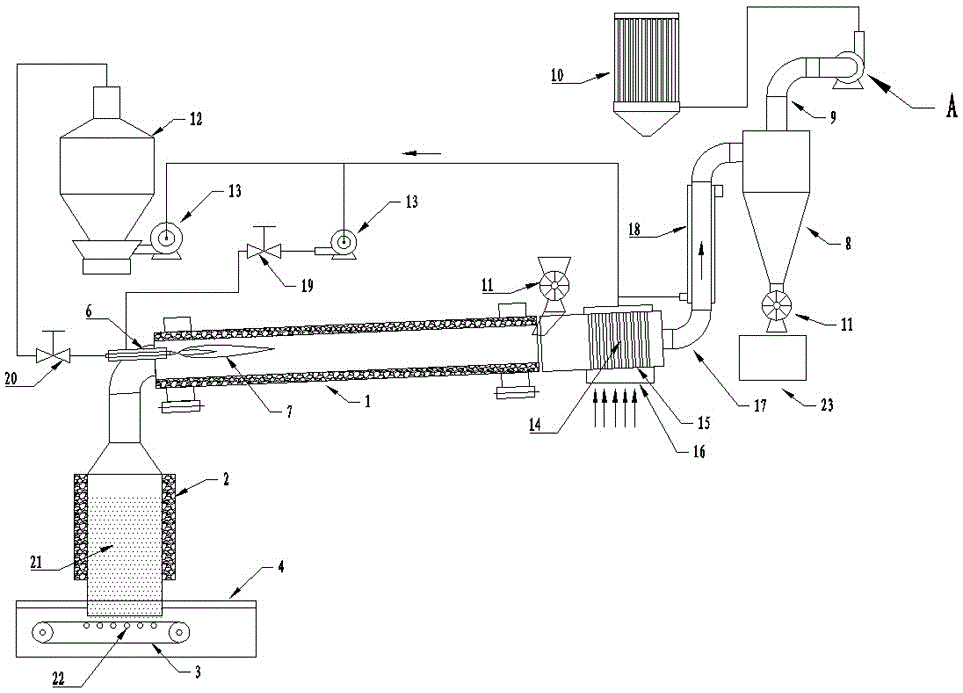

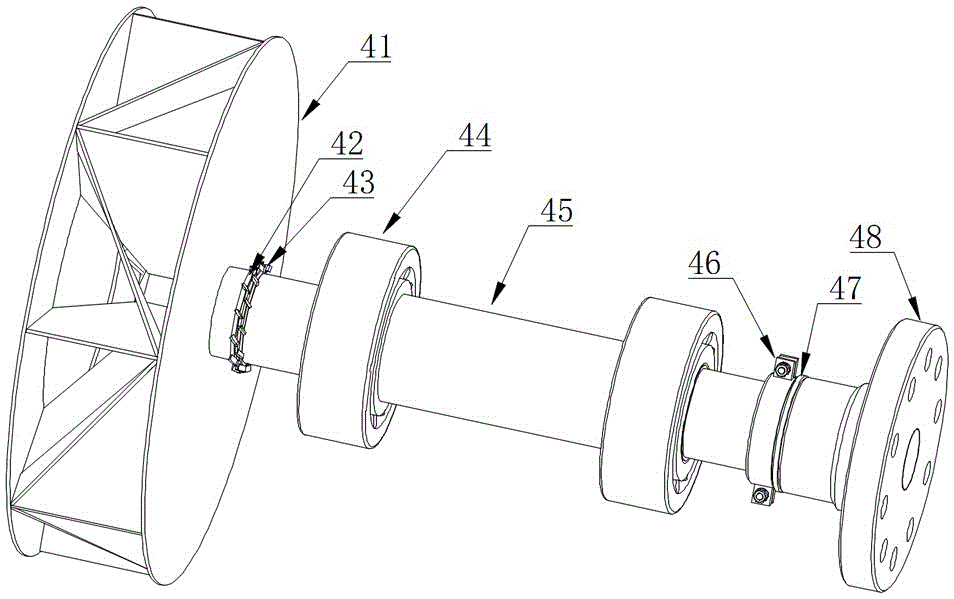

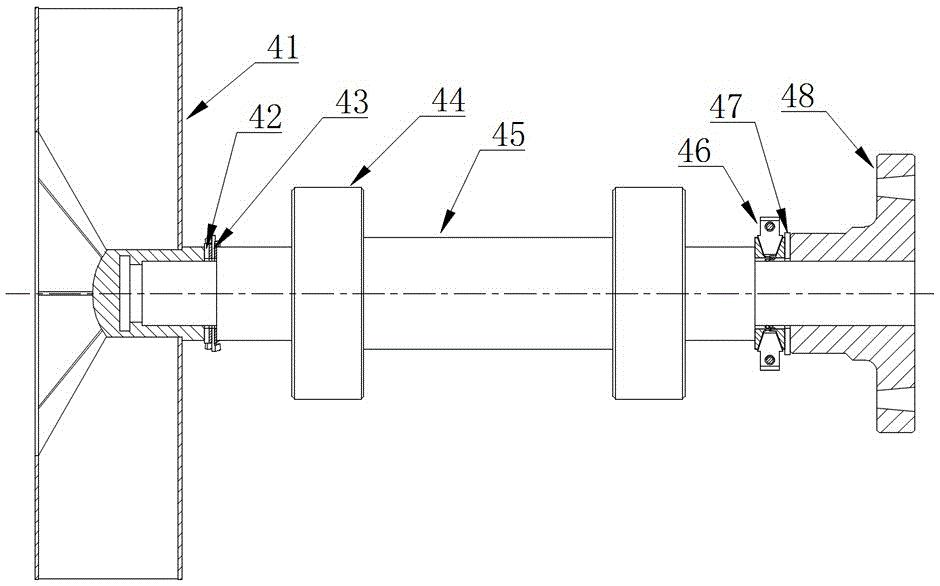

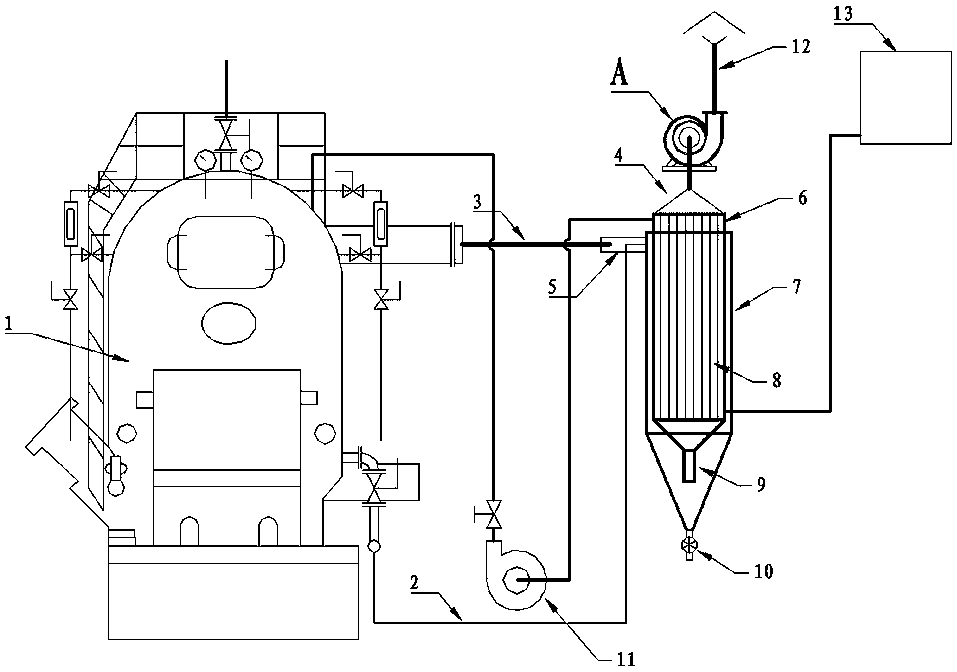

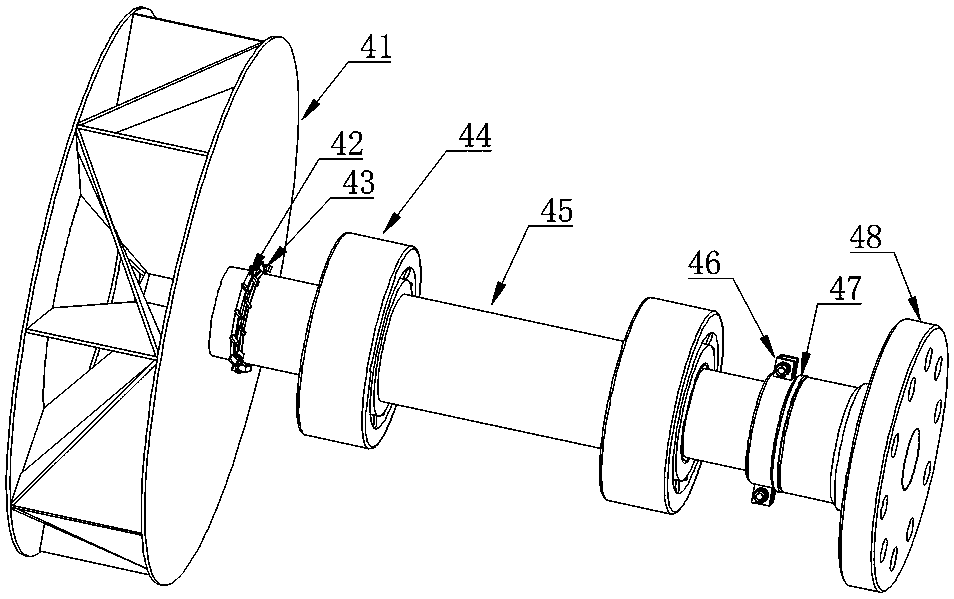

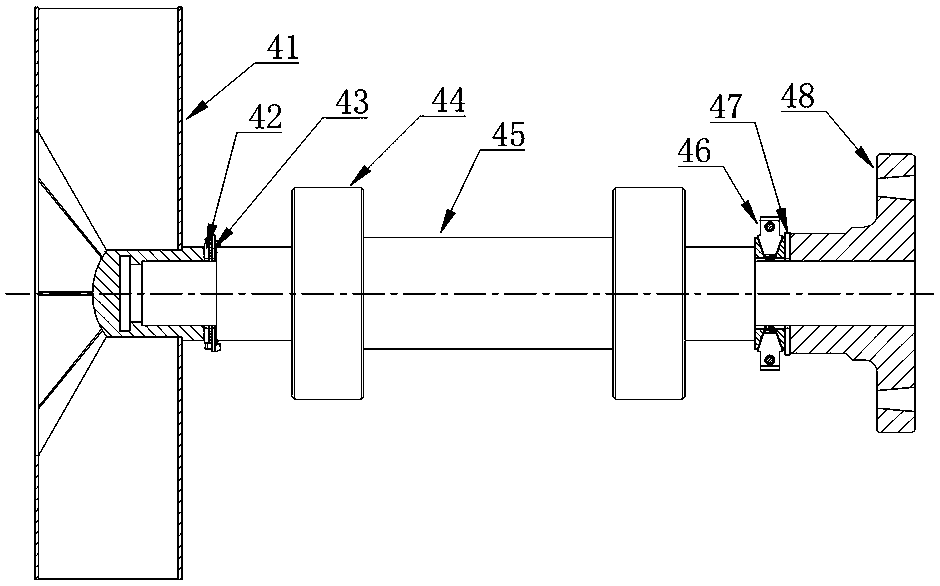

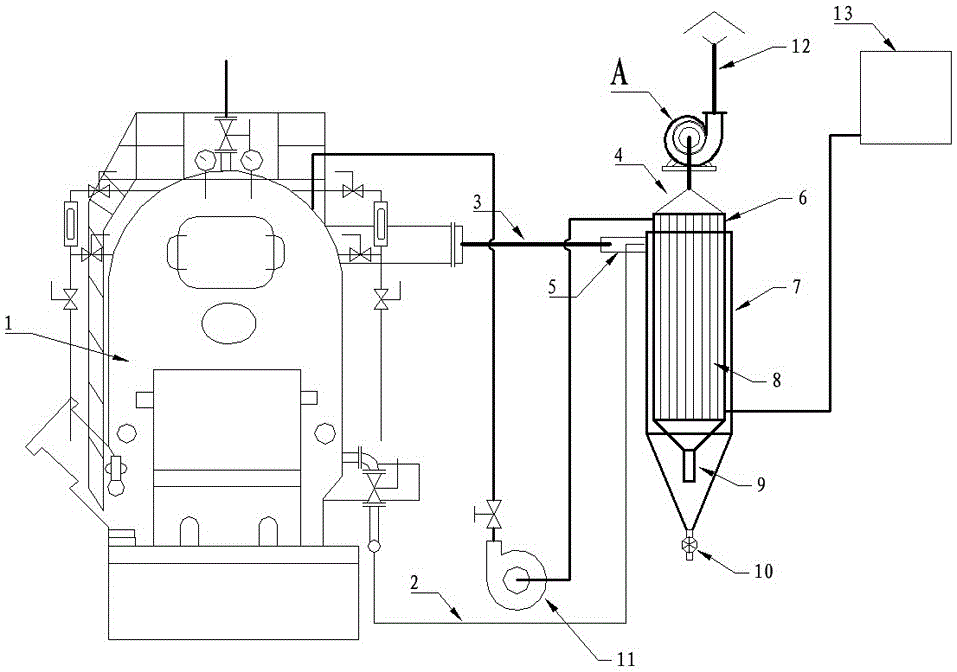

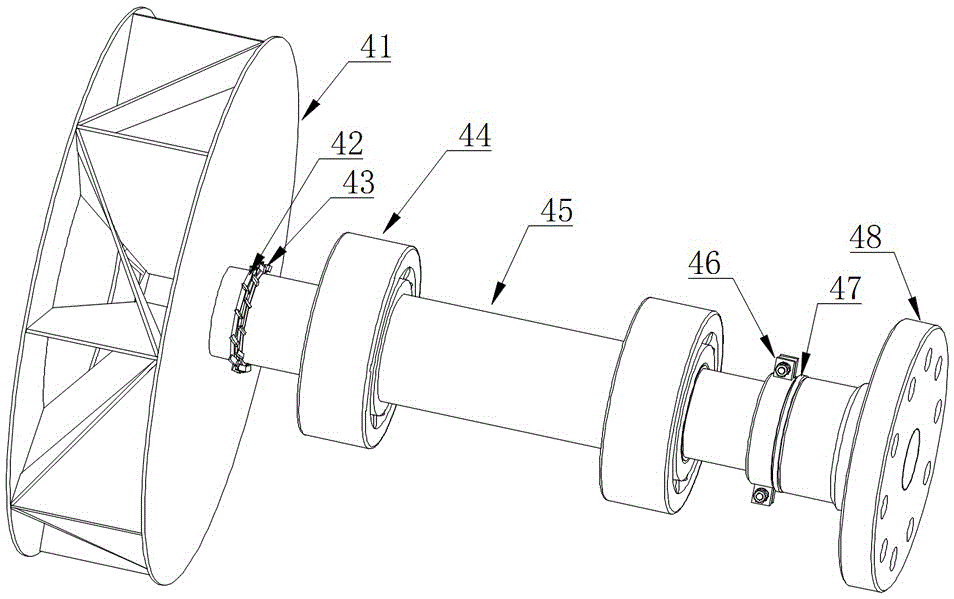

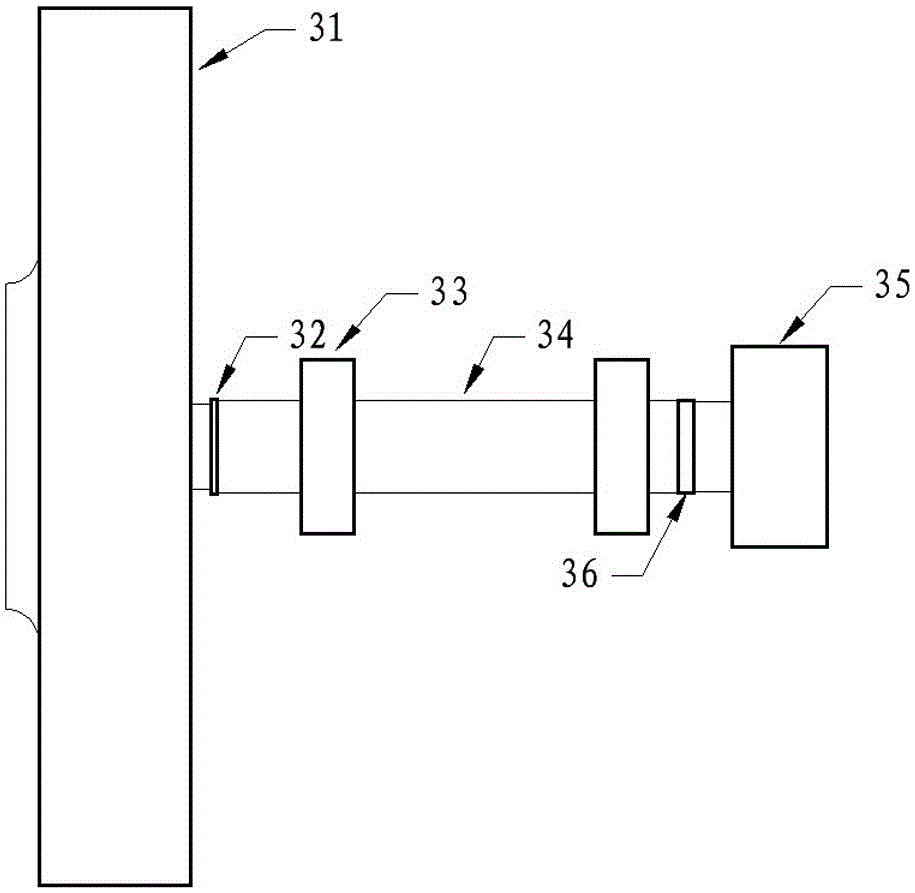

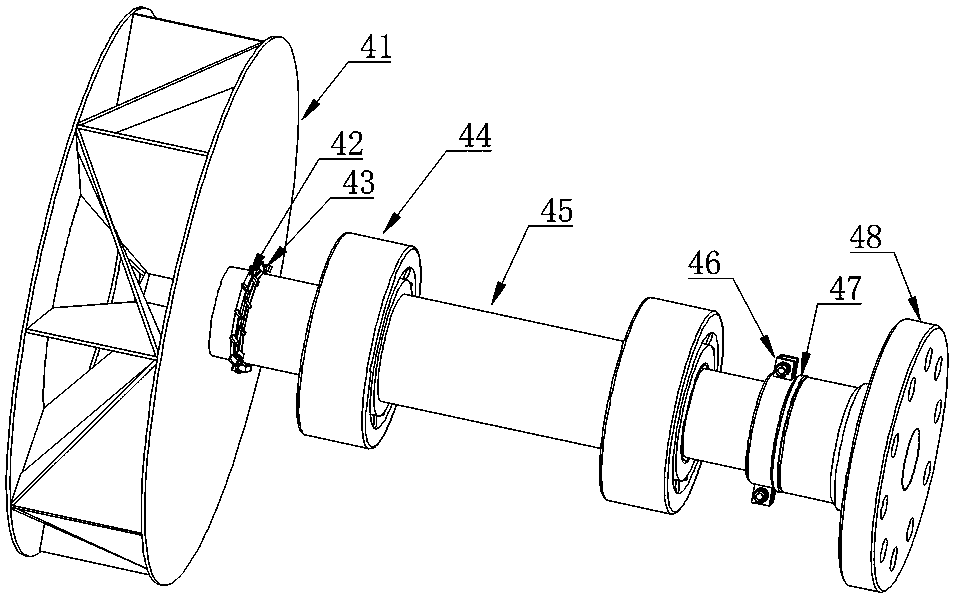

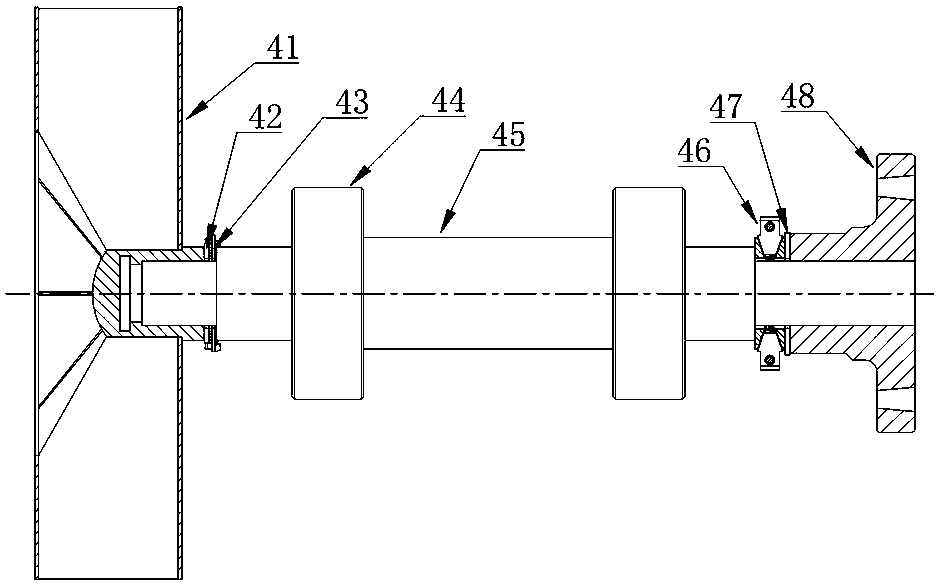

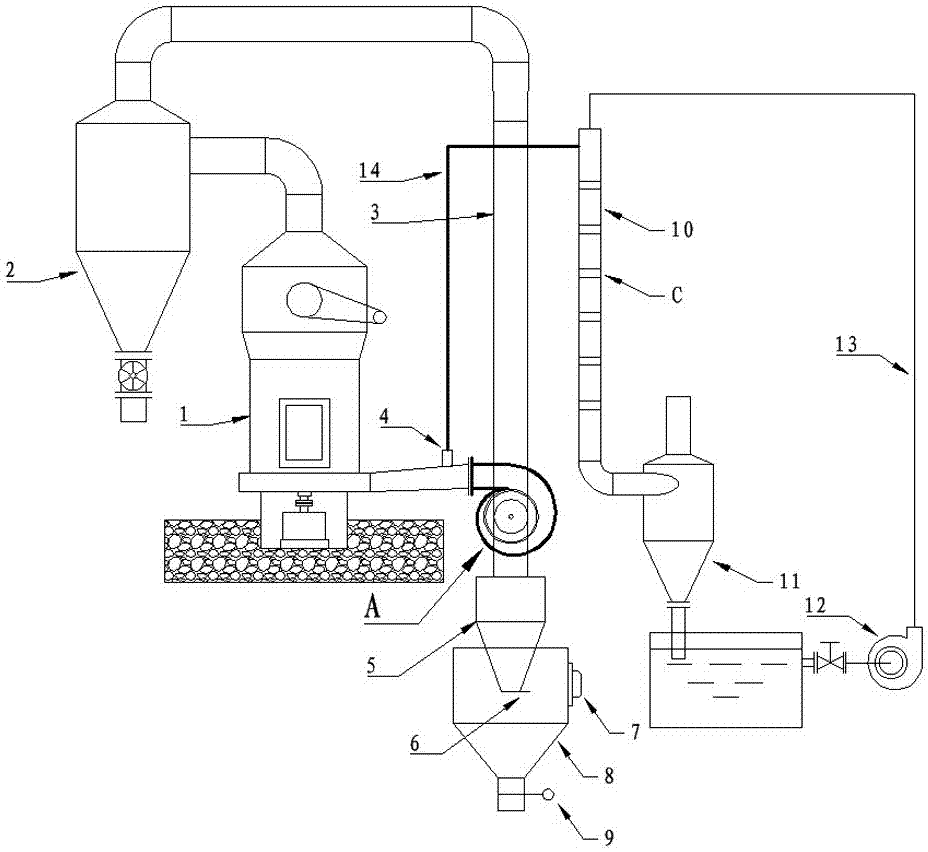

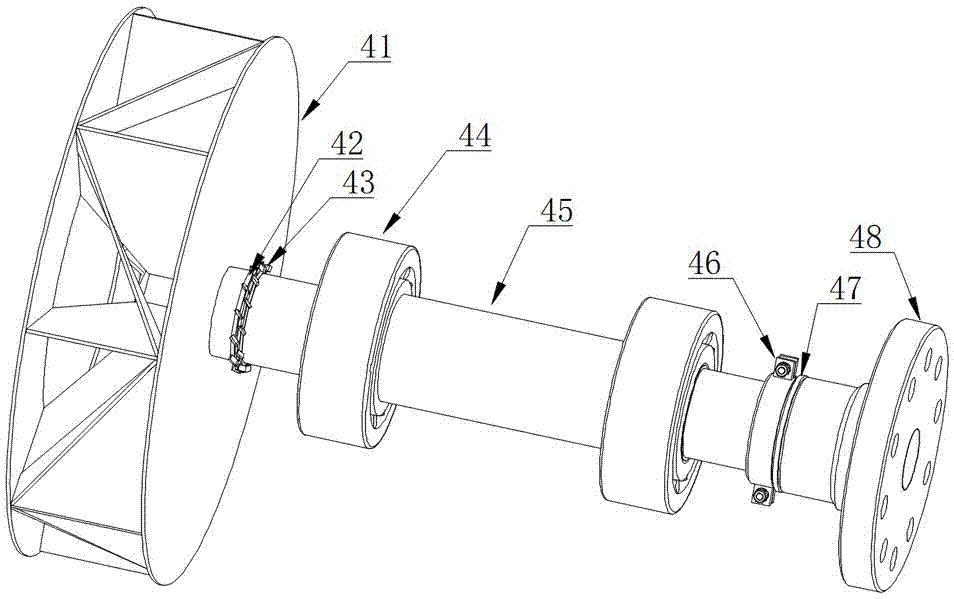

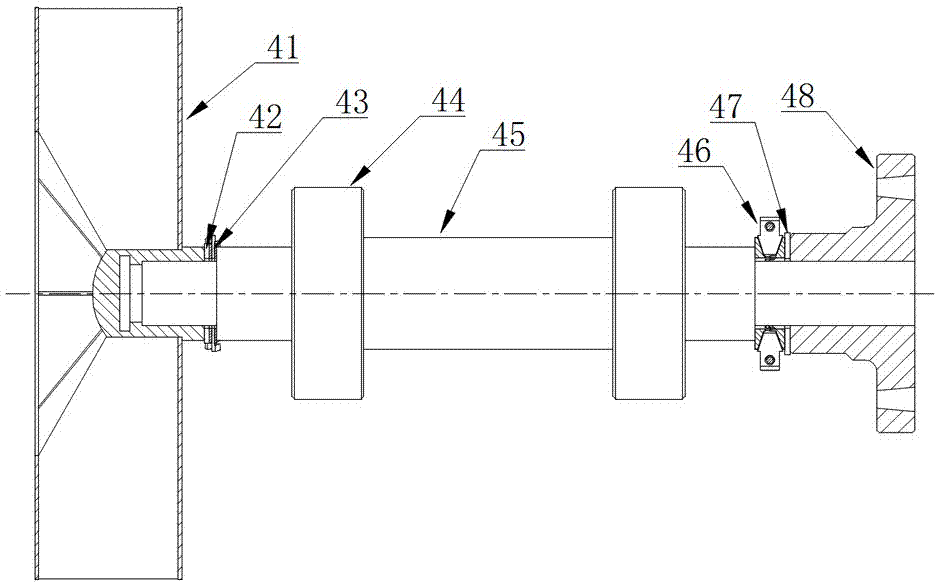

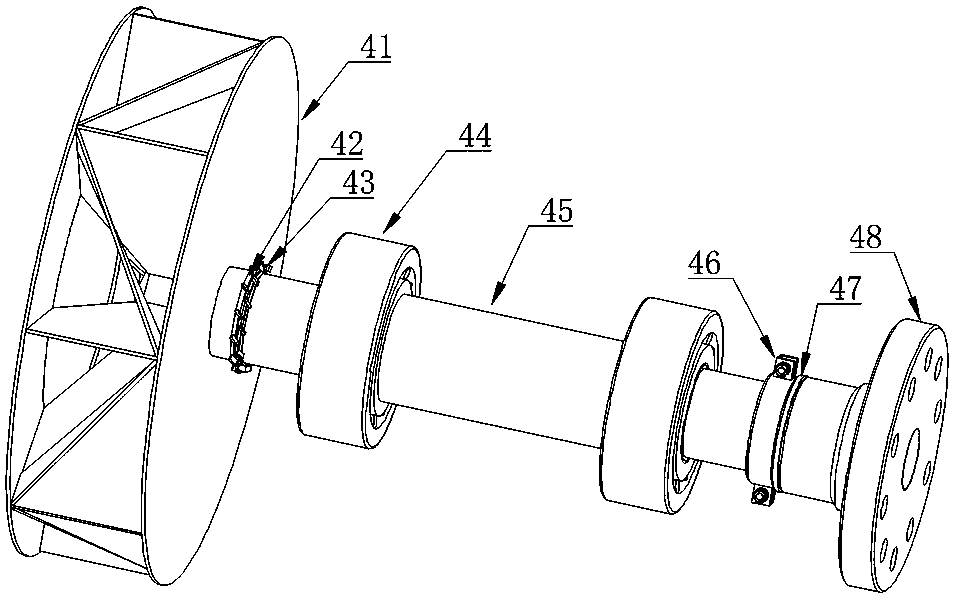

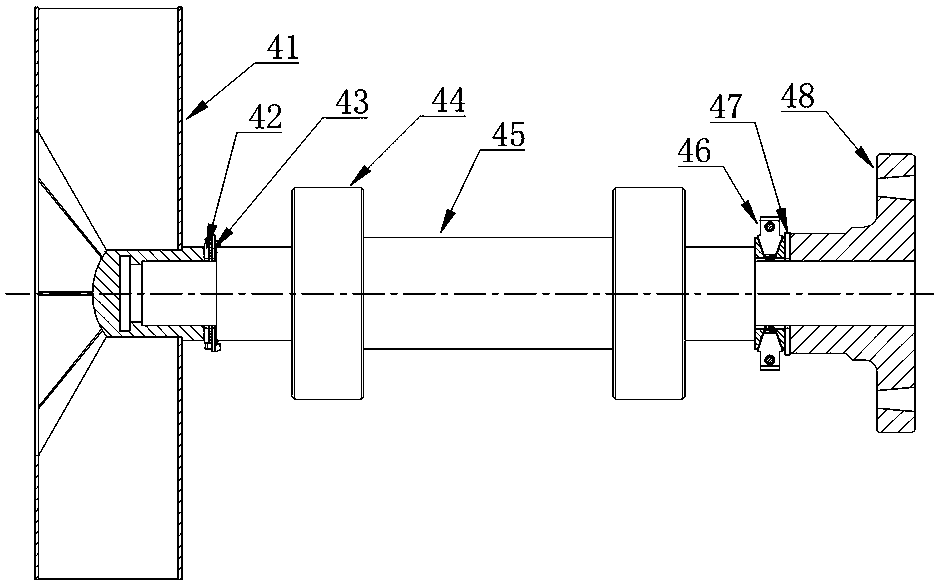

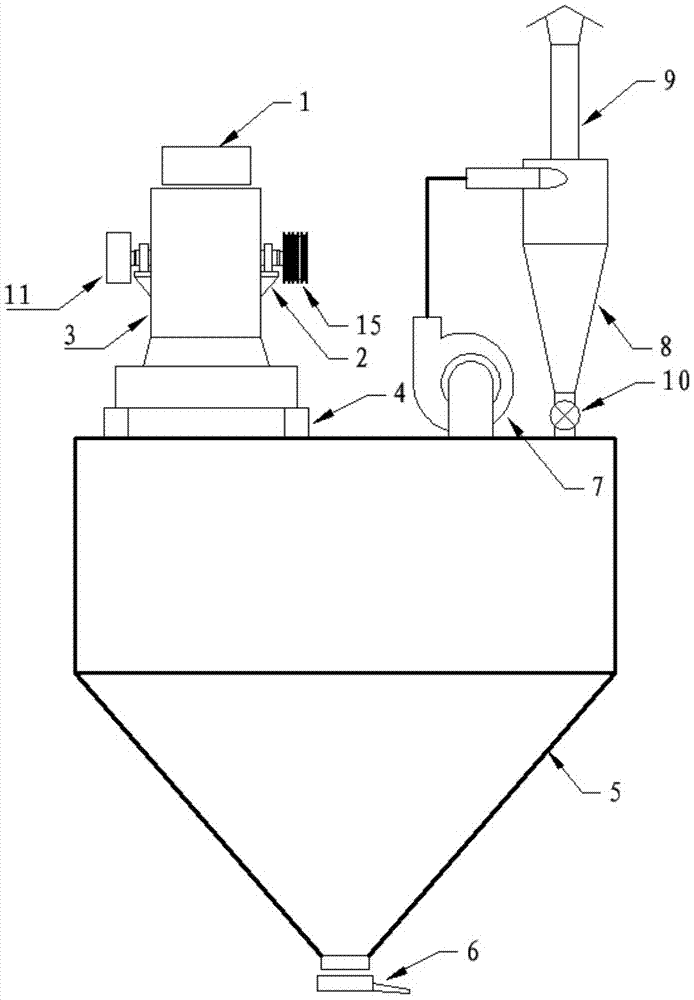

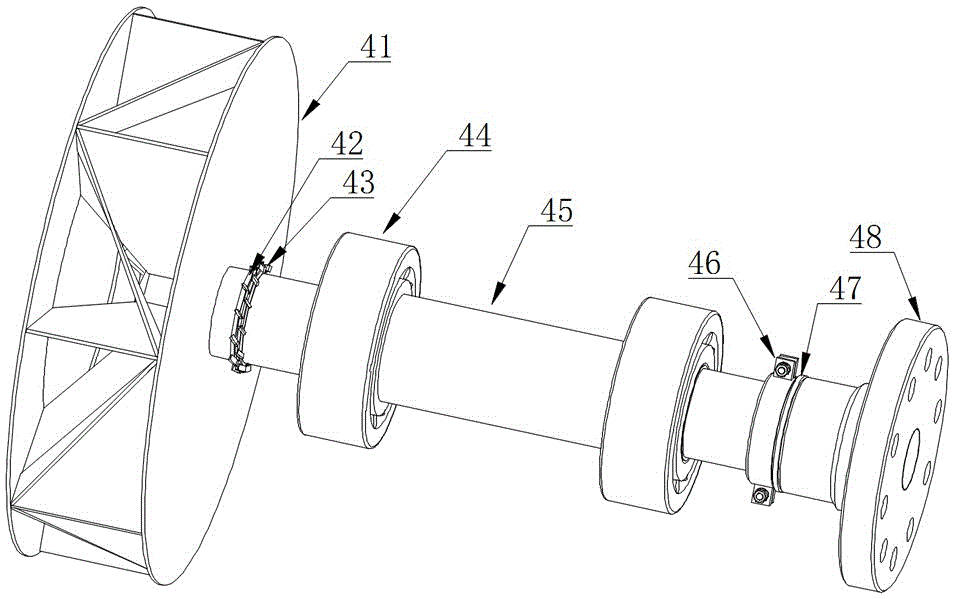

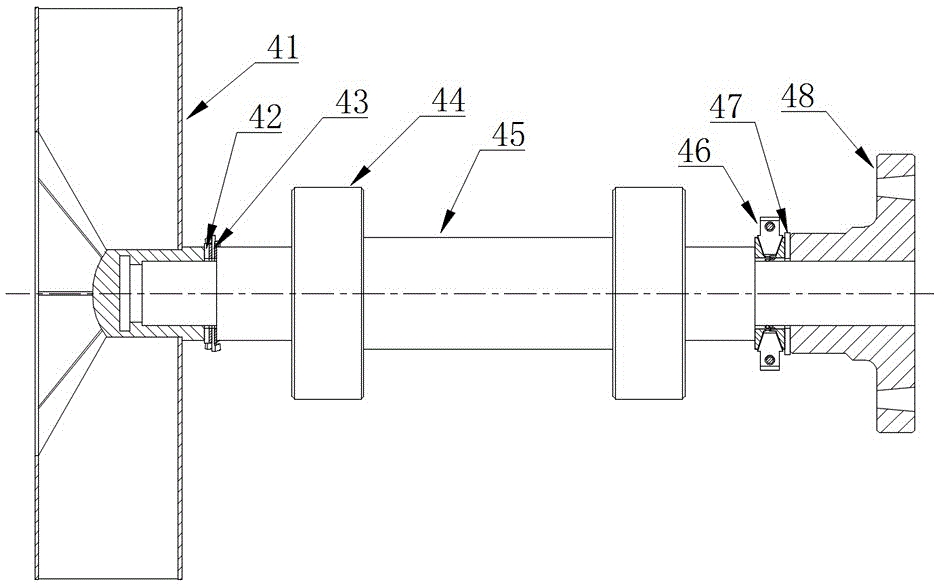

The invention discloses a hot air type penetration reverse flow fluidization drying machine with tail heat utilization and inertial dust collecting functions. The upper portion of a drying tower is connected with an induced draft fan. The induced draft fan is connected with an efficient cyclone dedusting tail heat recovery device in a tangential manner through an inertial dust collecting device and then performs evacuation, wherein the efficient cyclone dedusting tail heat recovery device is formed by overlaying a tube bank type heat exchanger and a cyclone dust collector. The air inlet end of a shell pass of the tube bank type heat exchanger is communicated with atmosphere, and the air outlet end is connected with the lower portion of the drying tower through an air blower and a steam fin heater; and blades of an impeller of the induced draft fan are arranged to be in a radiation shape and are in radial and central symmetry with respect to an impeller shaft, the dust can be cleared up in time through centrifugal force, and safety accidents are avoided. By the adoption of the hot air type penetration reverse flow fluidization drying machine, the drying efficiency is improved, and energy saving and emission reduction are achieved; and more importantly, the disassembly and assembly technology of the induced draft fan is improved greatly, so that pressure applied to the shaft shoulder end face of a screw by components similar to a nut component can be eliminated simply when the induced draft fan is disassembled, and the problem that the induced draft fan is locked continuously and automatically and cannot be disassembled easily under the load action due to threaded assembly is solved effectively; and the hot air type penetration reverse flow fluidization drying machine is especially suitable for convenient and fast disassembly of a large-scale fan which is locked in a threaded manner, and the effect is particularly obvious.

Owner:罗军

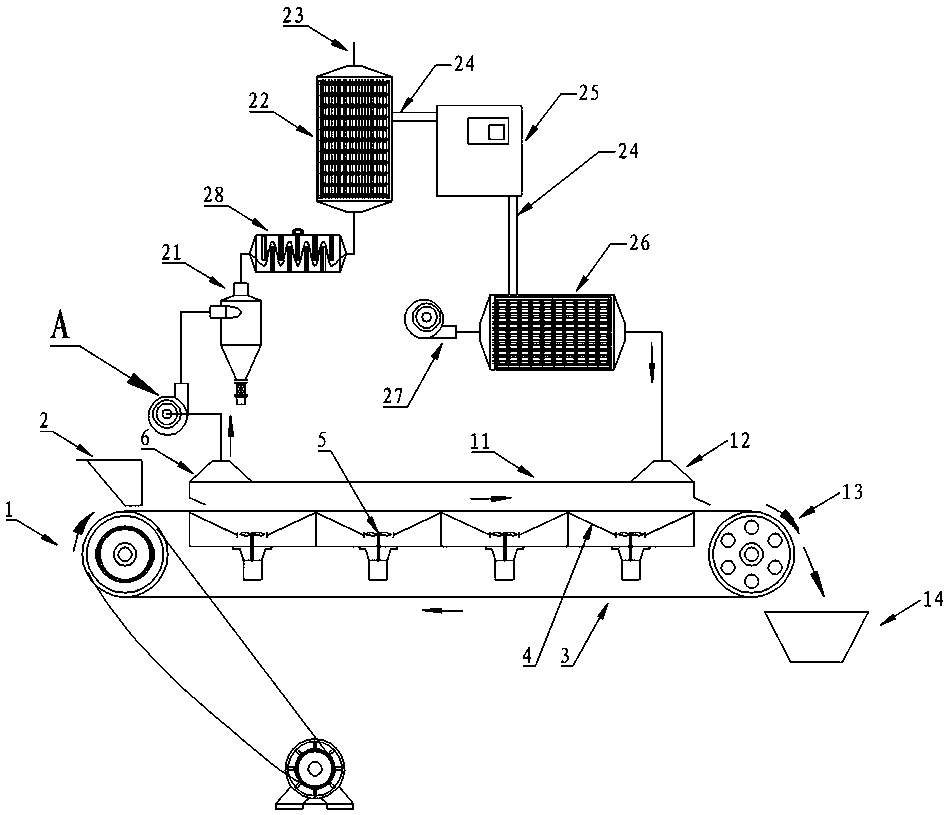

Heat pump type waste heat utilization inertial dust collection penetrating countercurrent drying machine

ActiveCN105674713AHigh extrusion rigidityStrong extrusion rigidityPump componentsDrying gas arrangementsImpellerEngineering

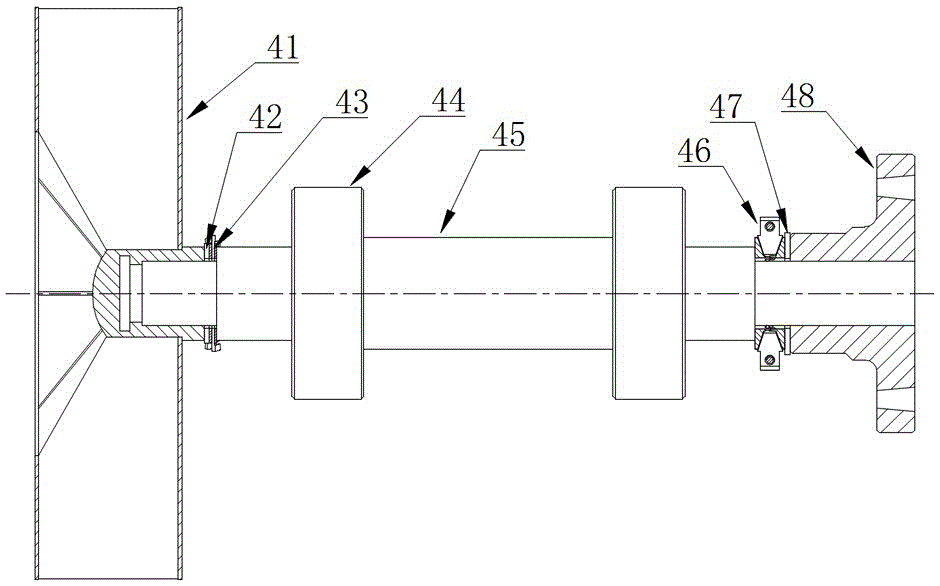

The invention discloses a heat pump type waste heat utilization inertial dust collection penetrating countercurrent drying machine. An exhaust hood of the drying machine is connected with an induced draught fan. The induced draught fan is evacuated after being connected with an evaporator of a heat pump system through a cyclone dust collector and a repeated back-turning baffle type inertial dust collector. The evaporator of the heat pump system is connected with a main machine through a refrigerant pipe. The main machine is connected with a condenser through a refrigerant pipe. The air outlet end of an air blower is connected in an air inlet hood through the condenser. Blades of an impeller of the induced draught fan are arranged to be in a radial shape and centrosymmetric about an impeller shaft in the radial direction, dust can be removed in time under the effect of centrifugal force, and safety accidents are avoided. The drying efficiency is improved, energy conservation and emission reduction are achieved, more importantly, a demounting and mounting technology of the induced draught fan is transformed to a great extent, when the induced draught fan is demounted, the pressure applied to the end face of a screw shaft shoulder by nut-like parts can be simply eliminated, the problem that the induced draught fan assembled in a threaded manner is automatically locked continuously under the effect of loads and cannot be easily demounted is effectively solved, the heat pump type waste heat utilization inertial dust collection penetrating countercurrent drying machine is particularly suitable for convenient demounting of large draught fans which are locked in a threaded manner, and effects are particularly obvious.

Owner:四川良仕农业科技有限公司

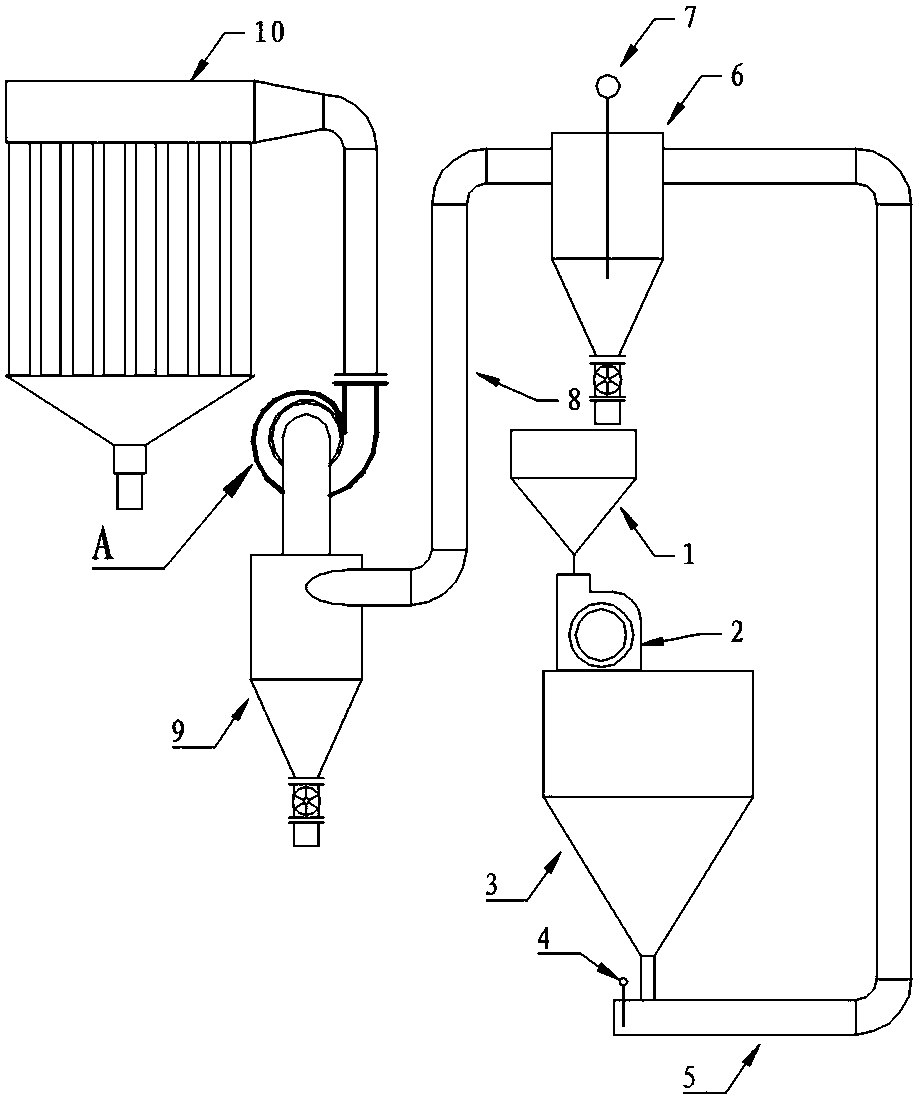

Tail heat utilized hot-air type penetration countercurrent fluidized drying machine

ActiveCN105758151AStrong extrusion rigidityEliminate fatigue fractureDrying gas arrangementsDrying solid materialsImpellerAtmosphere

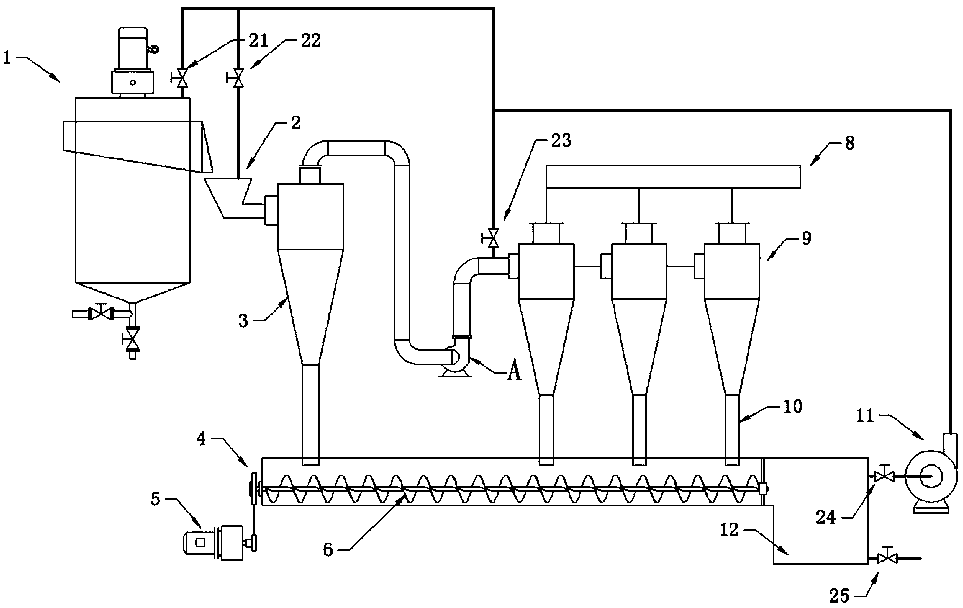

The invention discloses a tail heat utilized hot-air type penetration countercurrent fluidized drying machine. A draught fan is connected to the upper part of a drying tower; the draught fan is tangentially connected with a cyclone dust removal tail heat efficient recoverer which is formed by a tube type heat exchanger and a cyclone dust collector which are overlapped, and is evacuated; the shell pass air inlet end of the tube type heat exchanger is communicated with the atmosphere; the air outlet of the tube type heat exchanger is connected to the lower part of the drying tower through an air blower and a steam fin heater; blades of the draught fan impeller are arranged in a radiation manner that impeller shafts are in radial and central symmetry; dust can be collected by virtue of centrifugal force in time, and thus security accidents can be avoided. By adopting the tail heat utilized hot-air type penetration countercurrent fluidized drying machine, the drying efficiency is improved, the purposes of energy conservation and emission reduction are achieved, more importantly, the assembling and disassembling technique of the draught fan is greatly improved, pressure caused by components such as a screw nut to the shoulder end surface of a screw shaft can be easily eliminated when the draught fan is assembled and disassembled, the problem that the draught fan is continuously automatically locked and is not easy to disassemble under the action of load in threaded assembling can be effectively solved, and the tail heat utilized hot-air type penetration countercurrent fluidized drying machine is particularly applicable to convenient and rapid disassembling after a large-size draught fan is in threaded locking and is particularly remarkable in effect.

Owner:安徽上元家居材料股份有限公司

Heat pump type tail heat recycling inertial dust collection penetrating countercurrent fluidization drying machine

InactiveCN105698513AStrong extrusion rigidityEliminate fatigue fractureHeat pumpsDrying solid materials with heatImpellerEvaporator

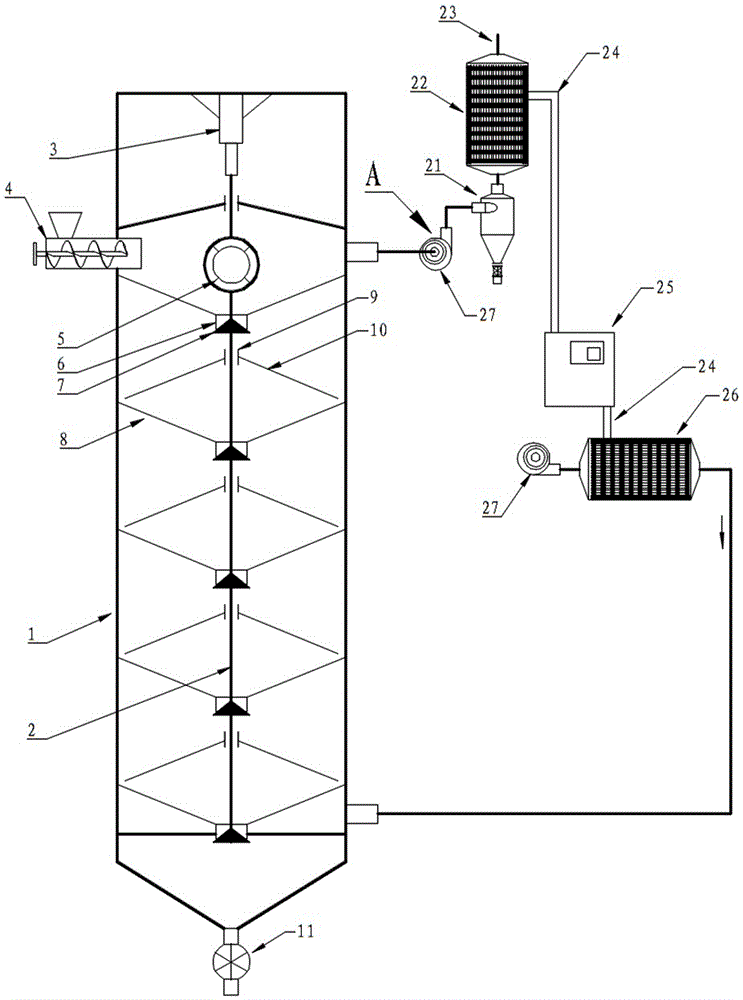

The invention discloses a heat pump type tail heat recycling inertial dust collection penetrating countercurrent fluidization drying machine. A material seal spiral feeder is arranged on the upper portion of a drying tower, and a closed-air aspirator discharging machine is arranged at the bottom of the drying tower; an induced draft fan is connected to the upper portion of the drying tower, and is connected with an evaporator of a heat pump system through a cyclone dust collector and a repeated reciprocating type inertial dust collector and then is subject to venting; the air outlet end of an air blower is connected with the lower portion of the drying tower through a condenser; blades of an induced draft fan impeller are arranged to be in a radiation shape in impeller shaft radial and central symmetry, centrifugal force can be used for cleaning up dust in time, and safety accidents are avoided; and according to the drying machine, the drying efficiency is improved, energy saving and emission reduction are achieved, more importantly, the dismounting and mounting technology of the induced draft fan is greatly changed, and therefore during dismounting, the pressure of similar nut components on the end face of a screw shaft shoulder can be simply eliminated; and the problem that according to the induced draft fan thread assembly, automatic locking is continuously carried out under the load effect, and dismounting is not likely to be achieved is effectively solved, and the drying machine is particularly suitable for portable dismounting of a large-scale fan obtained after thread locking, and the effect is particularly obvious.

Owner:山东启邦博冠科技发展有限公司

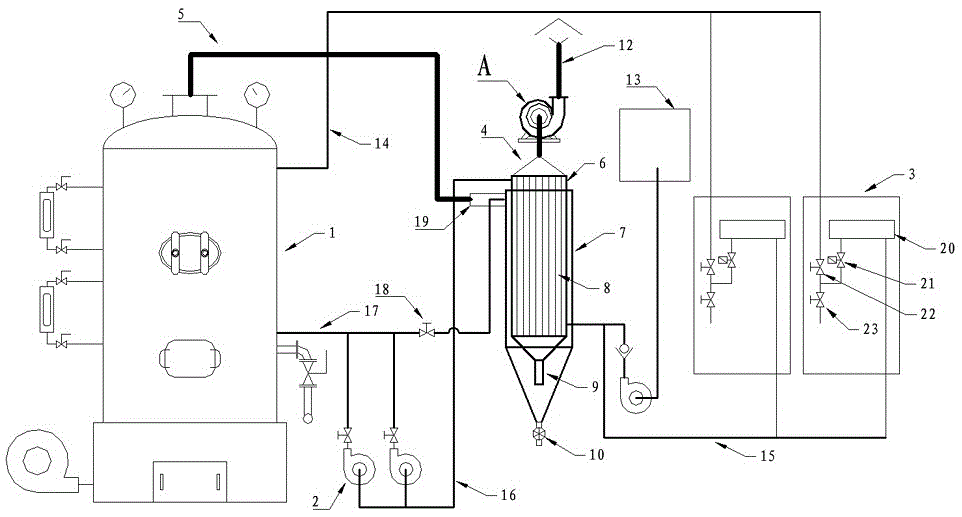

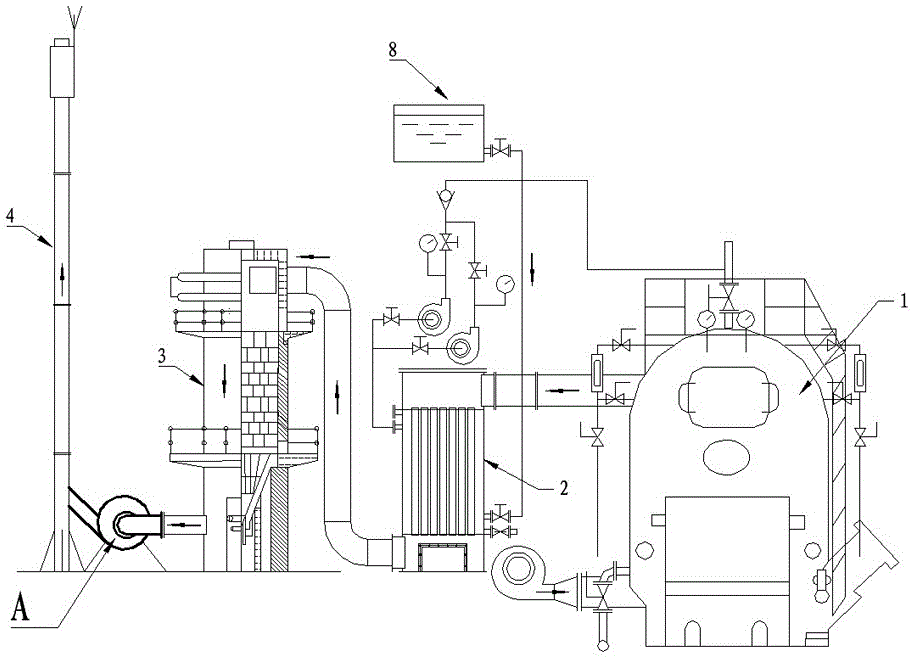

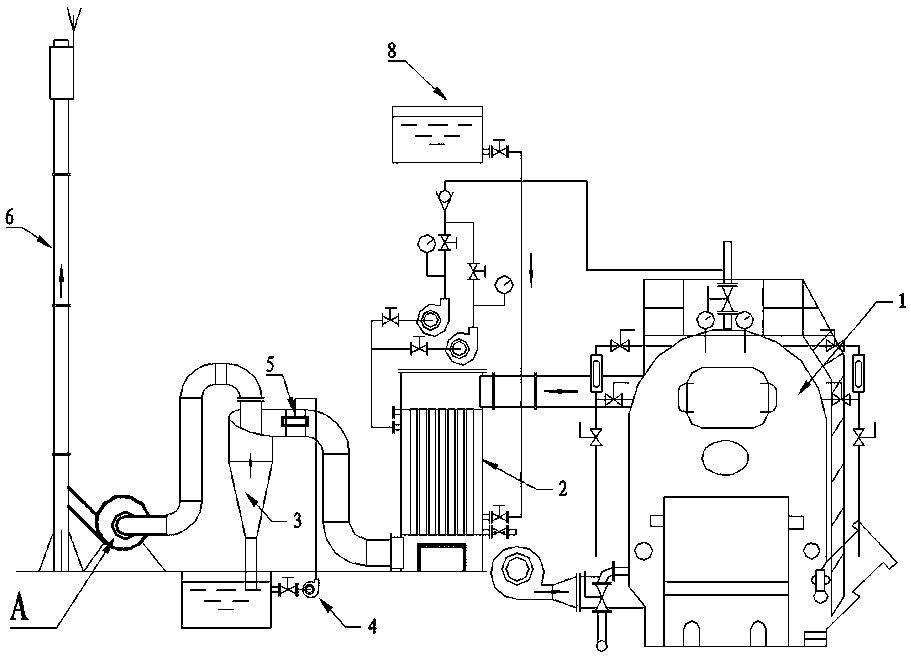

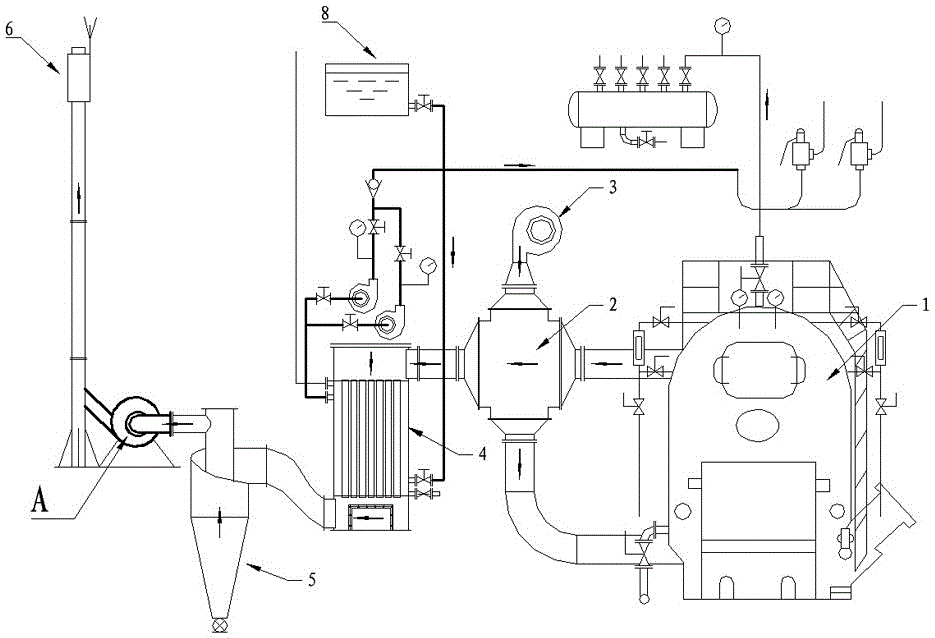

Heat supply system of biomass boiler

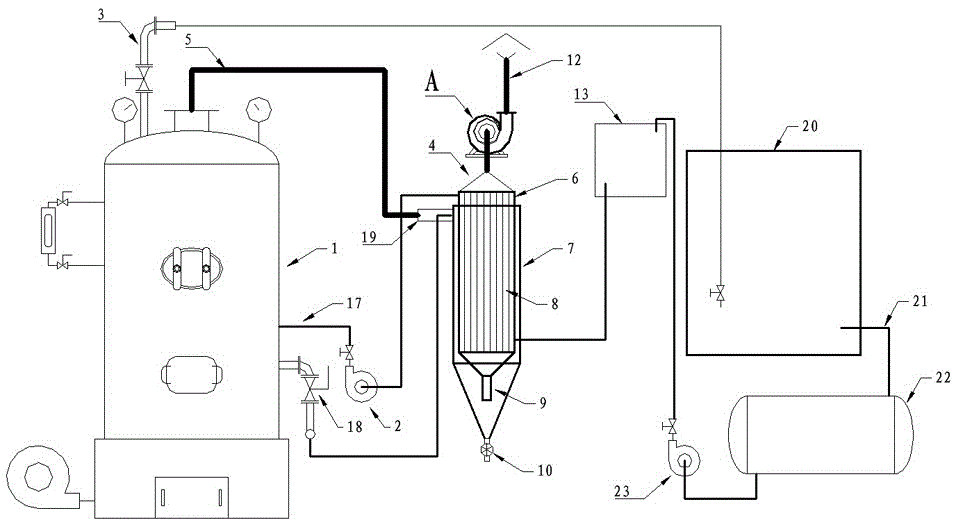

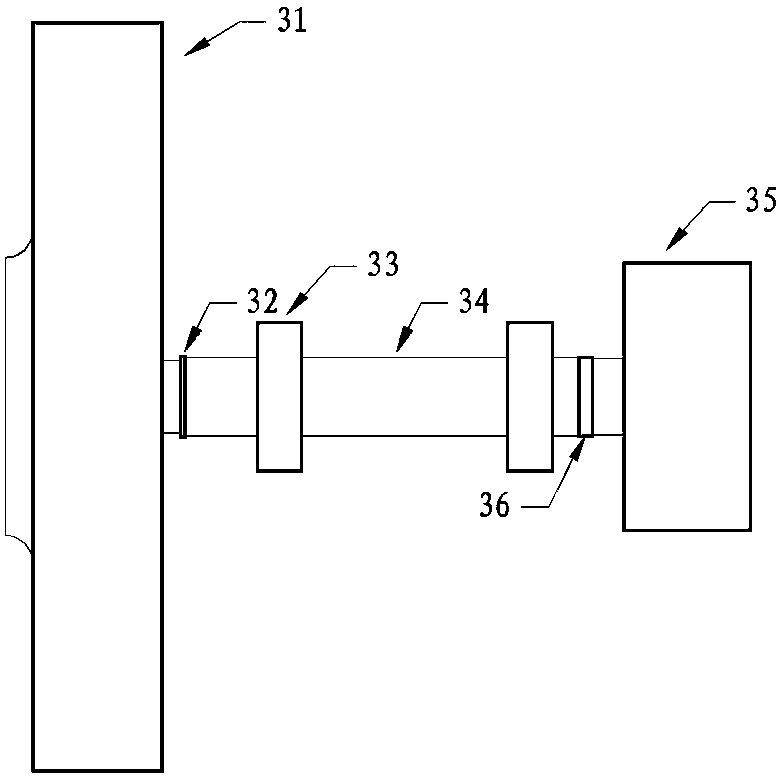

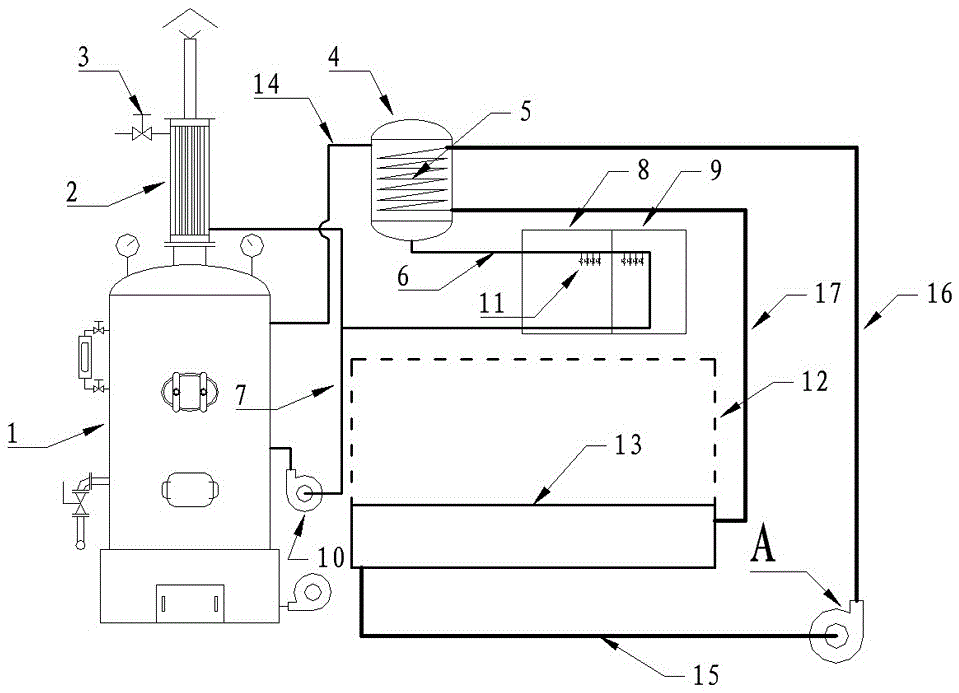

InactiveCN105650850ARemove tensionEasy to disassembleWater heatersDraught inductionSolenoid valveBathing

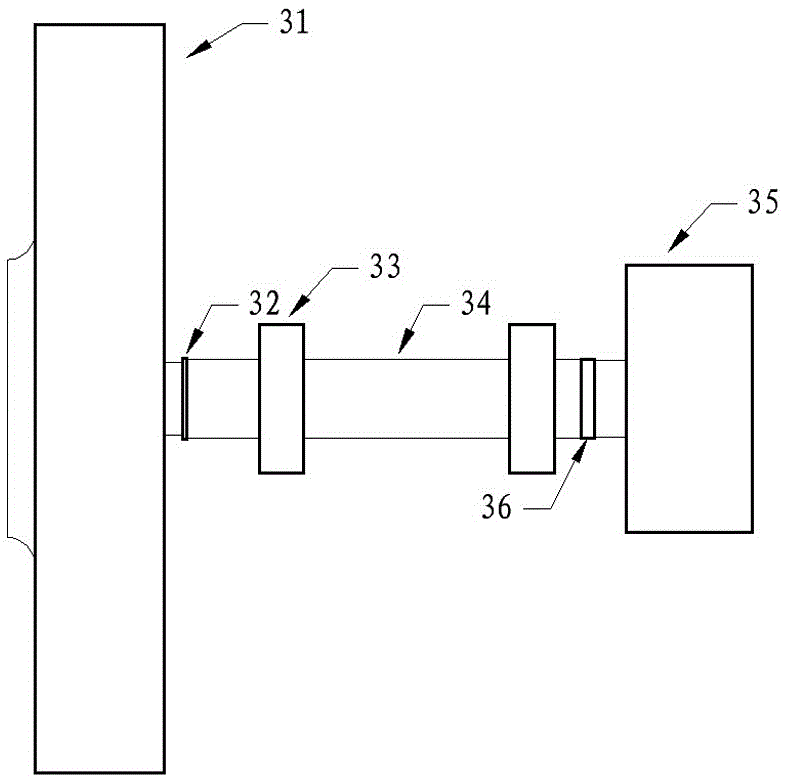

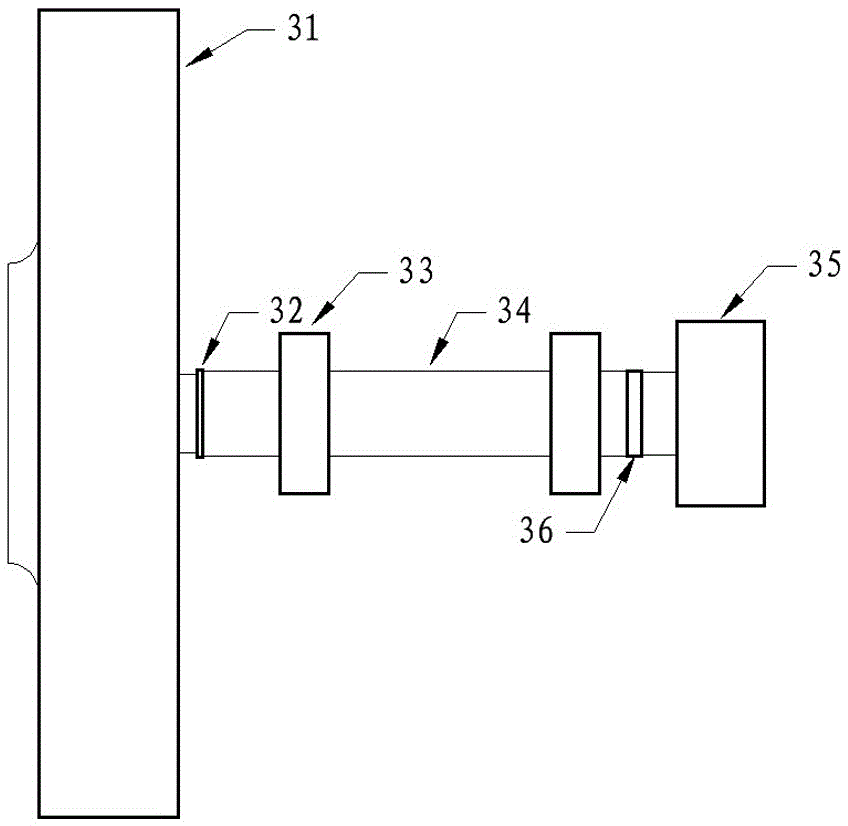

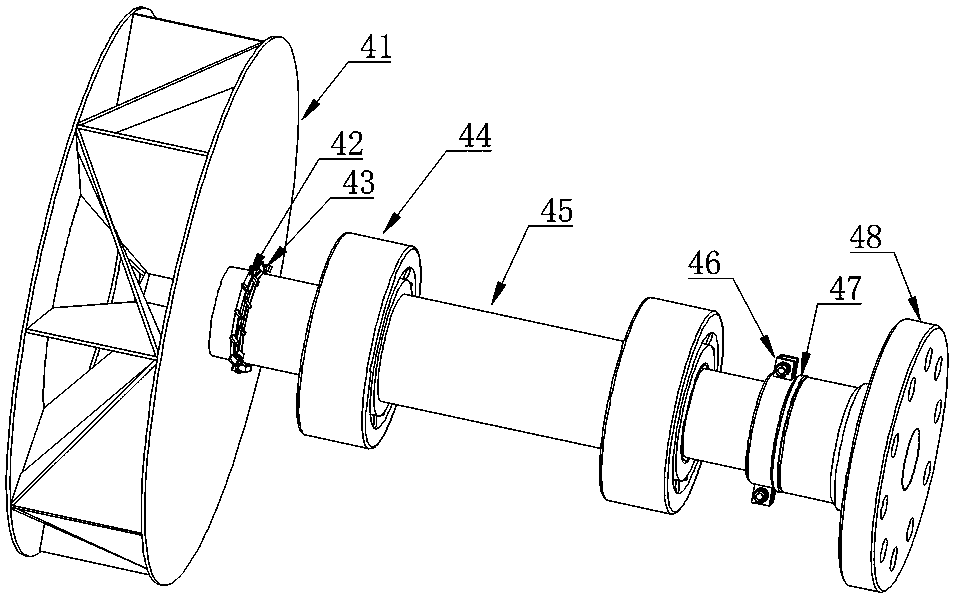

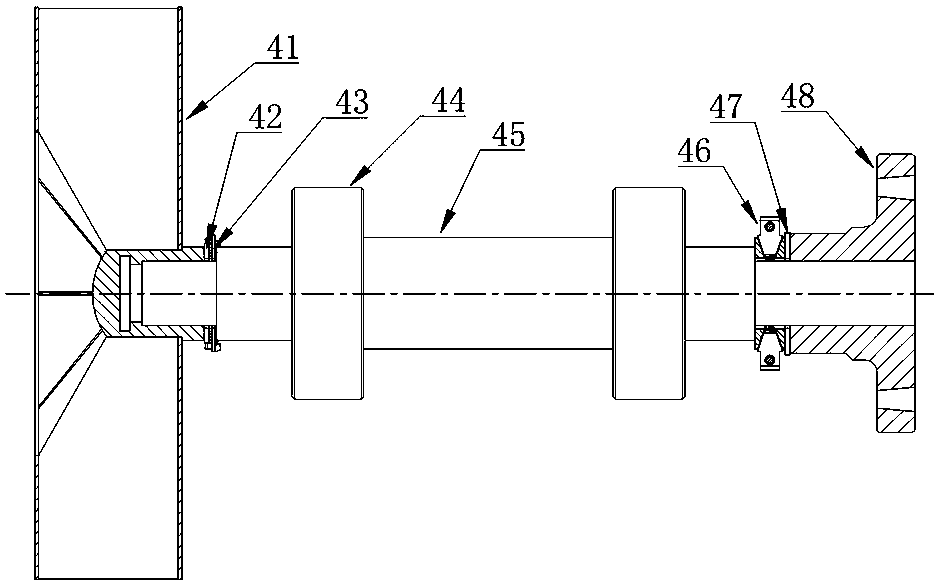

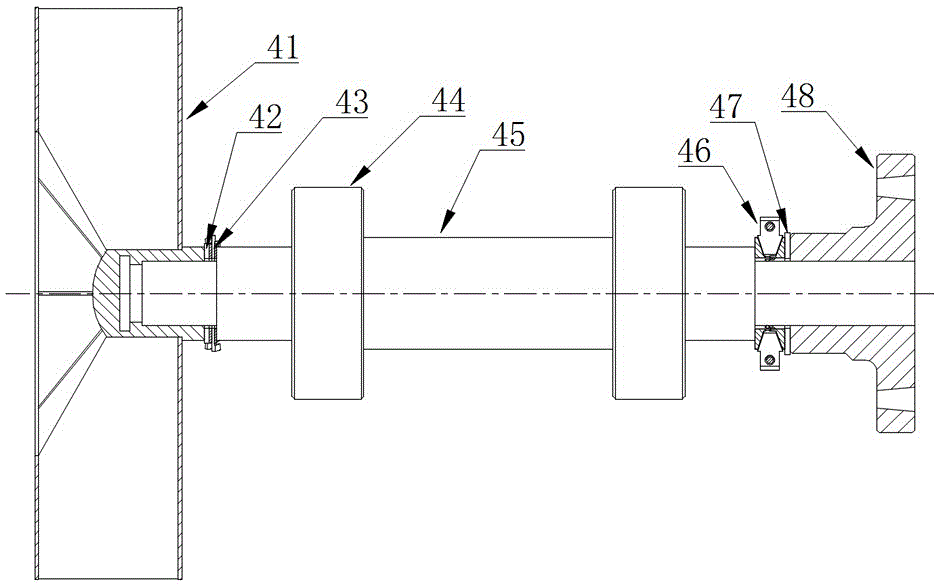

The invention discloses a heat supply system of a biomass boiler. A high-position soft water pool supplies water to the boiler, a boiler body is provided with a hot water outlet pipe connected to rooms, and a high-temperature tail gas pipe of the boiler body is connected to an air induction fan; valves are arranged in the rooms for controlling hot water bathing, solenoid valves are additionally arranged and are linked to fan coils for working, and a water return pipe gathers flow and returns; a coupling and a fan shaft of the air induction fan are assembled in a threaded mode, a fan impeller and the fan shaft of the air induction fan are assembled in a threaded mode, and the thread rotation direction is the automatic locking direction along with working and bearing; the fan impeller is in threaded and rigid connection with the fan shaft after pressing a copper-lead torsion composite pad; the coupling and the other end of the fan shaft are connected rigidly through a clamp part. According to the system, heat recovery and purification treatment of tail gas of the boiler are realized, the disassembly and assembly technology of the air induction fan of the boiler is greatly modified, the problems that the air induction fan of the boiler is continuously and automatically locked and is difficult to disassemble under the loading effect due to threaded assembly can be effectively solved, and large boiler fans can be disassembled conveniently and quickly after being locked in a threaded mode.

Owner:JISHOU UNIVERSITY

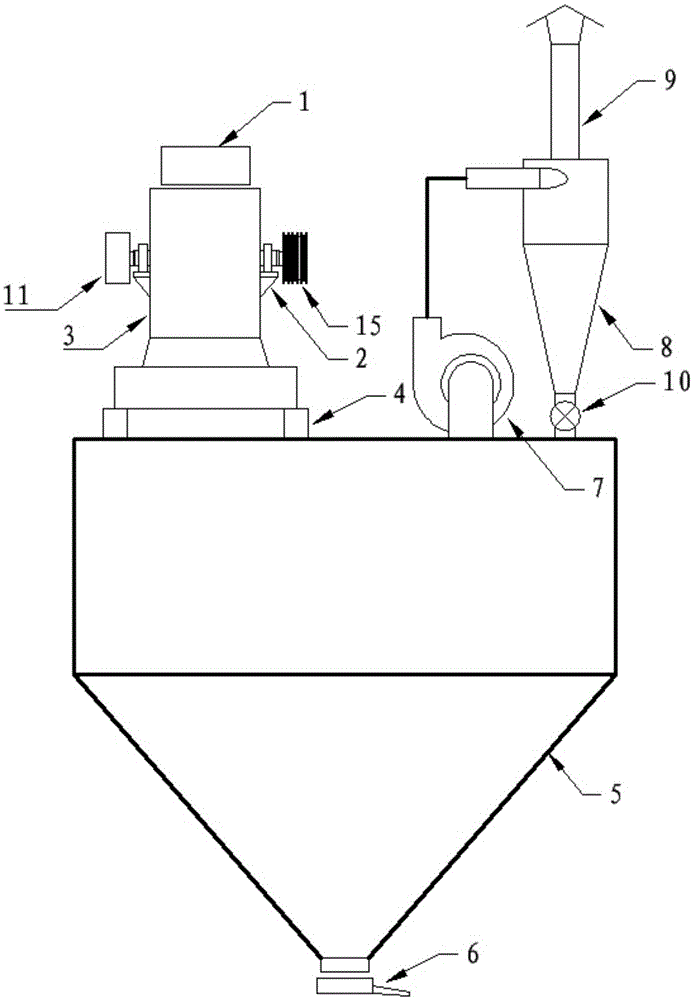

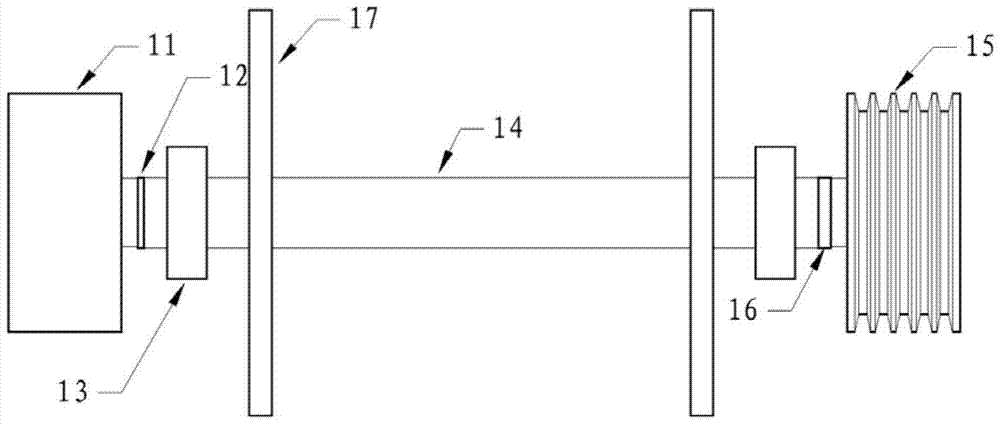

Convenient and quick-dismounted hammer crushing system with bin and dust removing device

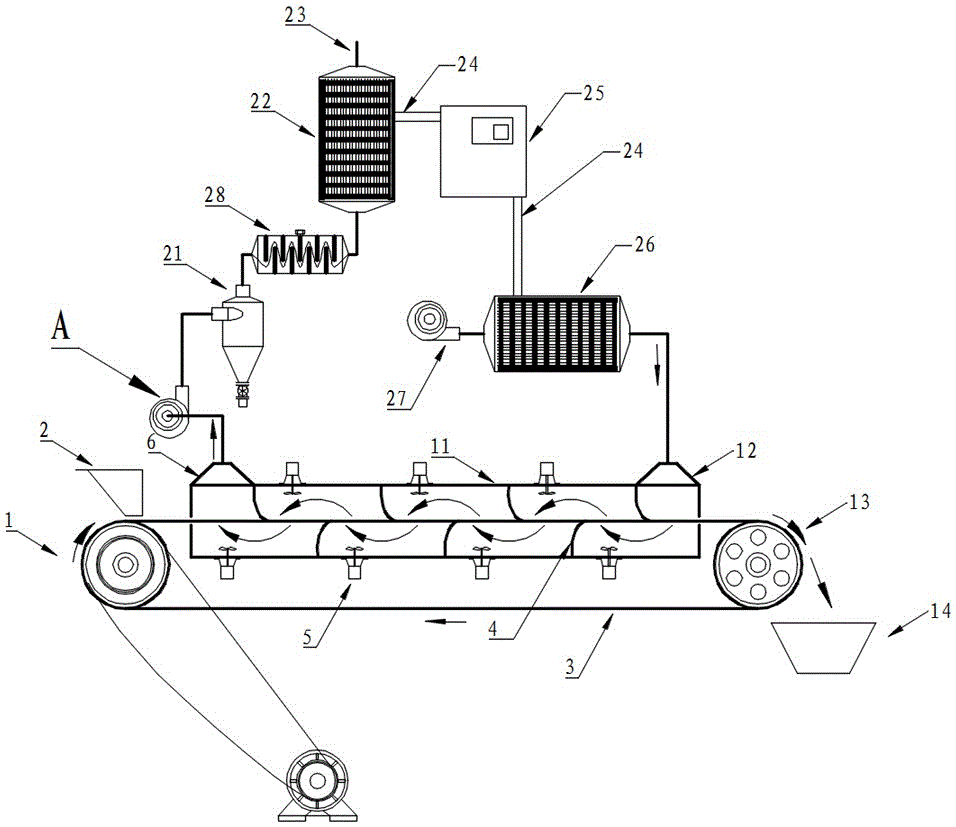

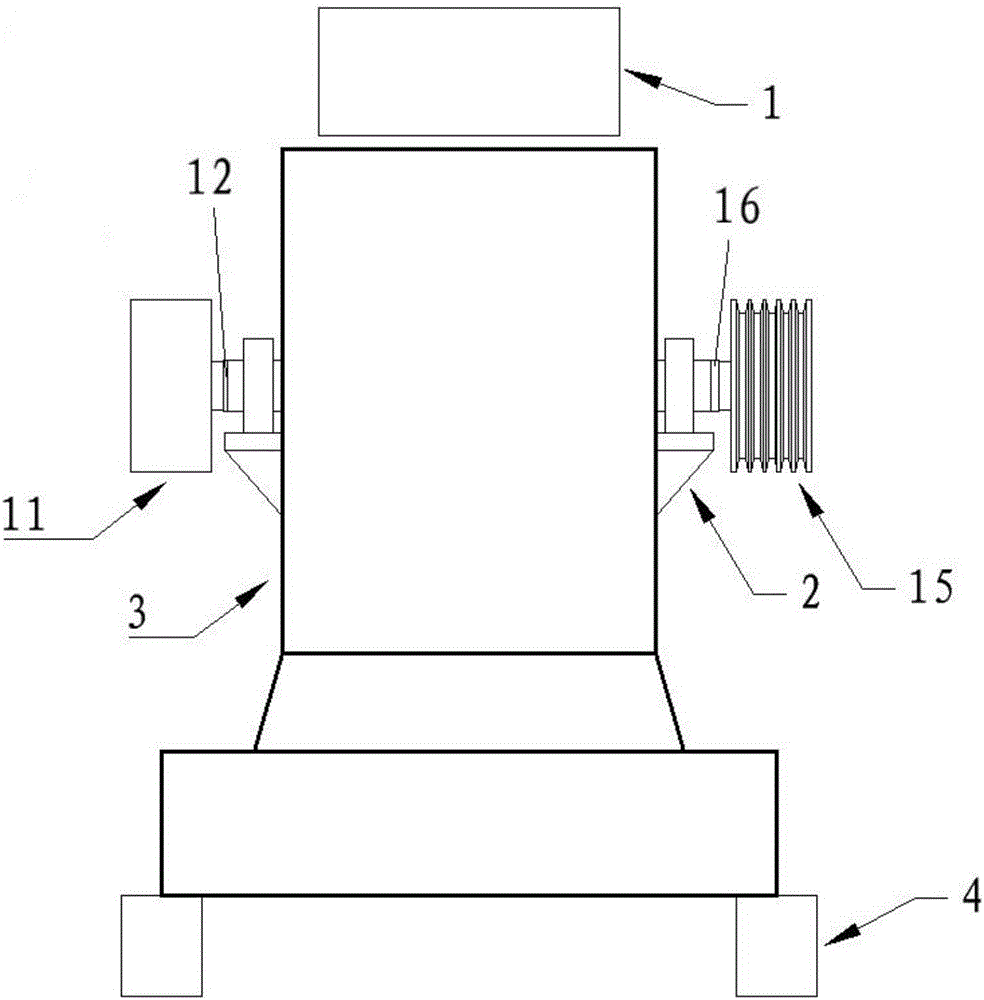

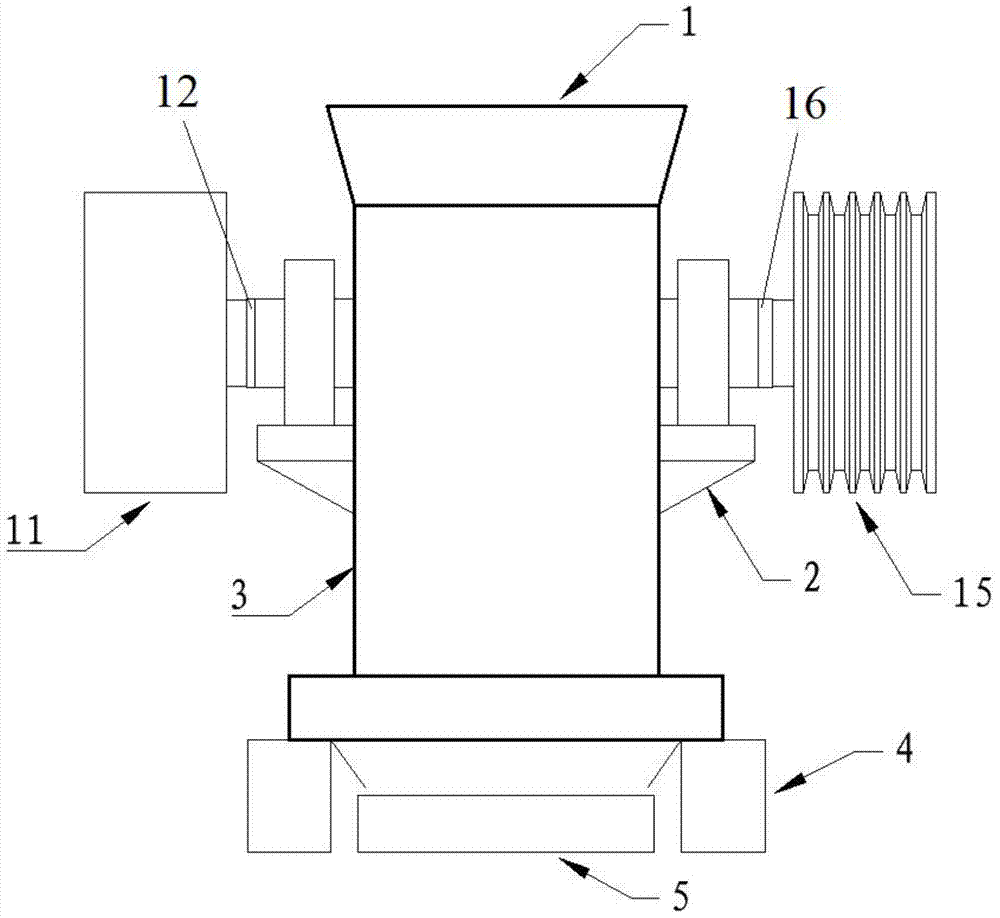

ActiveCN105665072ASolve the problem of continuous automatic locking and difficult disassemblySolve the problem that automatic locking is not easy to disassembleDirt cleaningGrain treatmentsCrusherFlywheel

The invention discloses a convenient and quick-dismounted hammer crushing system with a bin and a dust removing device. The system comprises a convenient and quick-dismounted hammer crusher, the bin (5) arranged at the bottom of the convenient and quick-dismounted hammer crusher, and the dust removing device; and the convenient and quick-dismounted hammer crusher includes a machine body (3), a flywheel (11) in reverse thread assembly with a hammer disc shaft (14) of the machine body (3), and a belt wheel (15) in forward thread assembly with the hammer disc shaft (14) of the machine body (3). The convenient and quick-dismounted hammer crushing system can effectively solve the problem of difficult disassembly of the thread assembly of the hammer crusher caused by continuously automatic locking under the load effect, can realize the disassembly convenience, and realizes the dustless crushing work.

Owner:广西宾阳力拓新型建材有限公司

Heat pump type penetrating and inverse-flow fluidized drying machine with exhaust heat recovery function

ActiveCN105674717AStrong extrusion rigidityEliminate fatigue fracturePump componentsDrying gas arrangementsImpellerEvaporator

The invention discloses a heat pump type penetrating and inverse-flow fluidized drying machine with the exhaust heat recovery function. A material seal screw feeder is arranged on the upper portion of a drying tower, and a closed-air aspirator discharging machine is arranged at the bottom of the drying tower. The upper portion of the drying tower is connected with an induced draft fan. The induced draft fan is connected with an evaporator of a heat pump system through a cyclone dedusting device for evacuation. The air outflow end of an air blower is connected with the lower portion of the drying tower through a condenser. Blades of an impeller of the induced draft fan are arranged symmetrical about the center of an impeller shaft in the radial direction in a radial manner, dust can be cleared up in time through centrifugal force, and safety accidents are avoided. By the adoption of the heat pump type penetrating and inverse-flow fluidized drying machine with the exhaust heat recovery function, drying efficiency is improved, and energy saving and emission reduction are achieved; and more importantly, the disassembly technology of the induced draft fan is improved greatly, so that pressure applied to the shaft shoulder end face of a screw by components similar to a nut component can be eliminated easily when the induced draft fan is disassembled, and the problem that the induced draft fan is locked continuously and automatically and cannot be disassembled easily under the load action due to threaded assembly is solved effectively; and the heat pump type penetrating and inverse-flow fluidized drying machine with the exhaust heat recovery function is especially suitable for convenient and fast disassembly of a large-scale fan which is locked in a threaded manner, and the effect is especially remarkable.

Owner:河南星光机械制造有限公司 +1

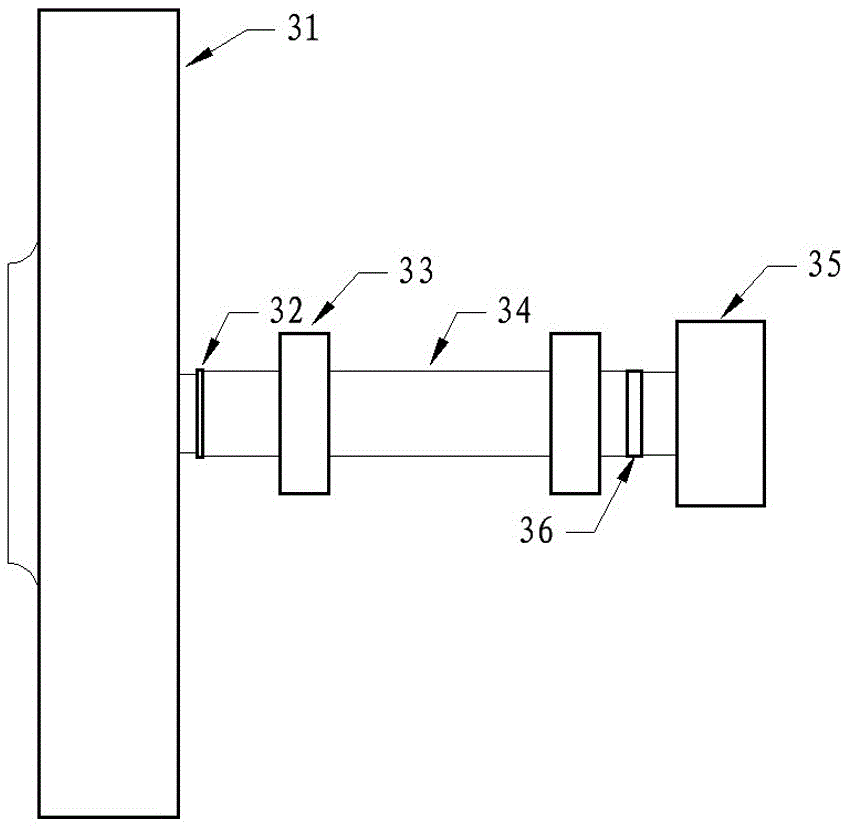

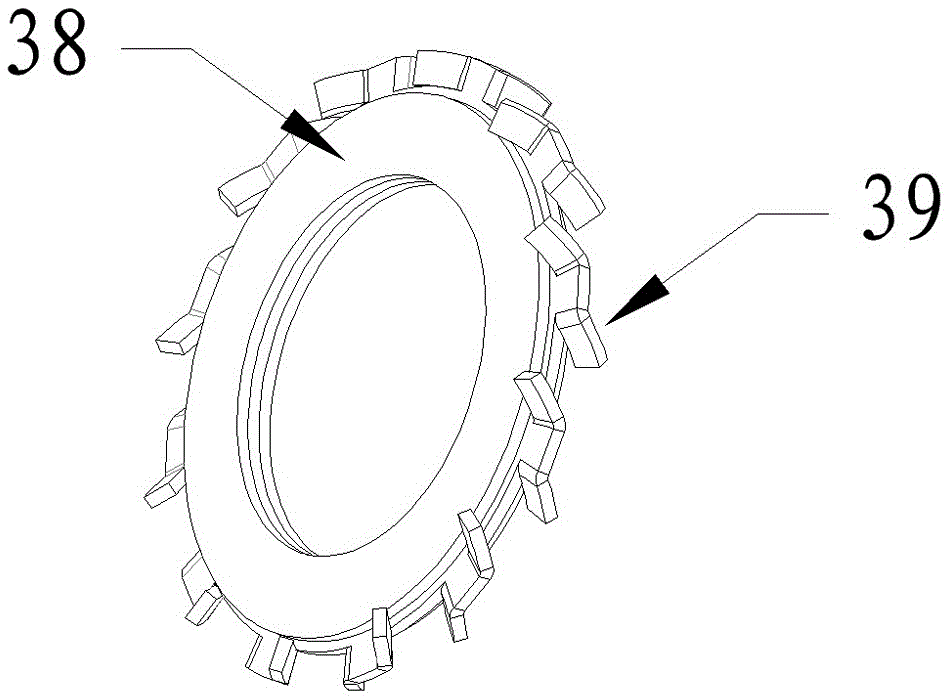

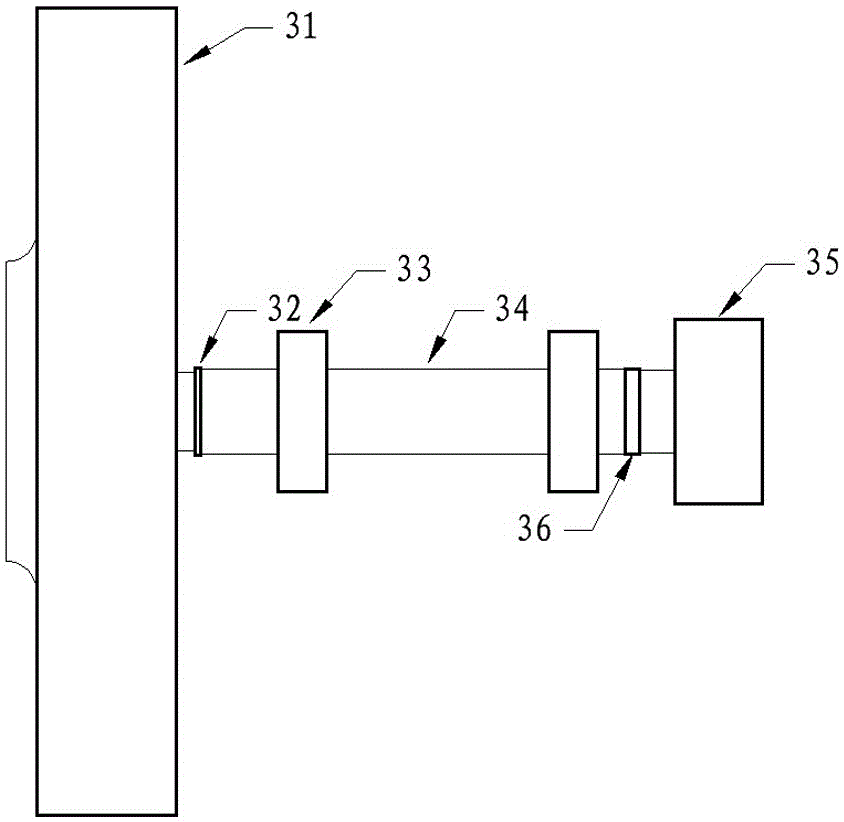

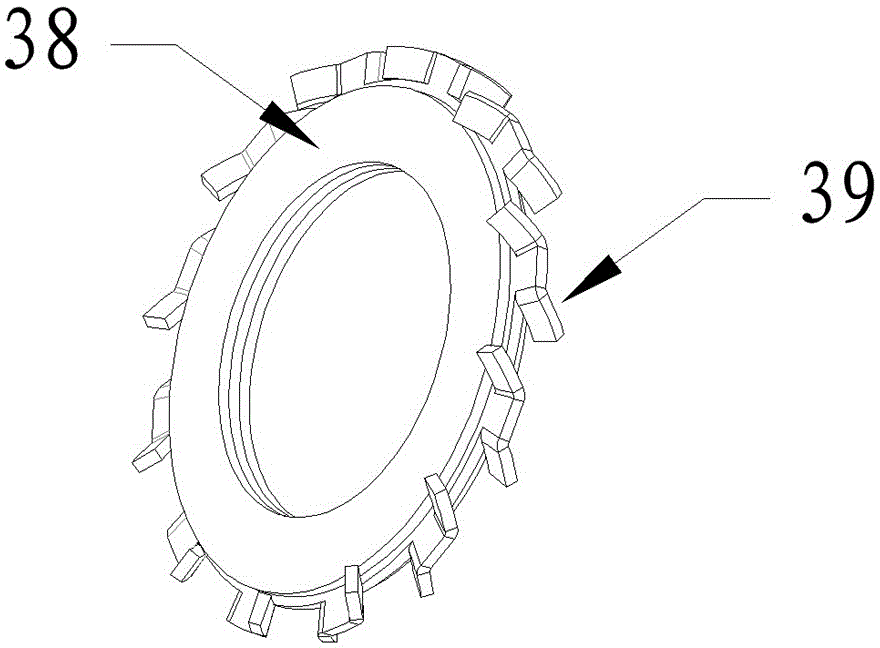

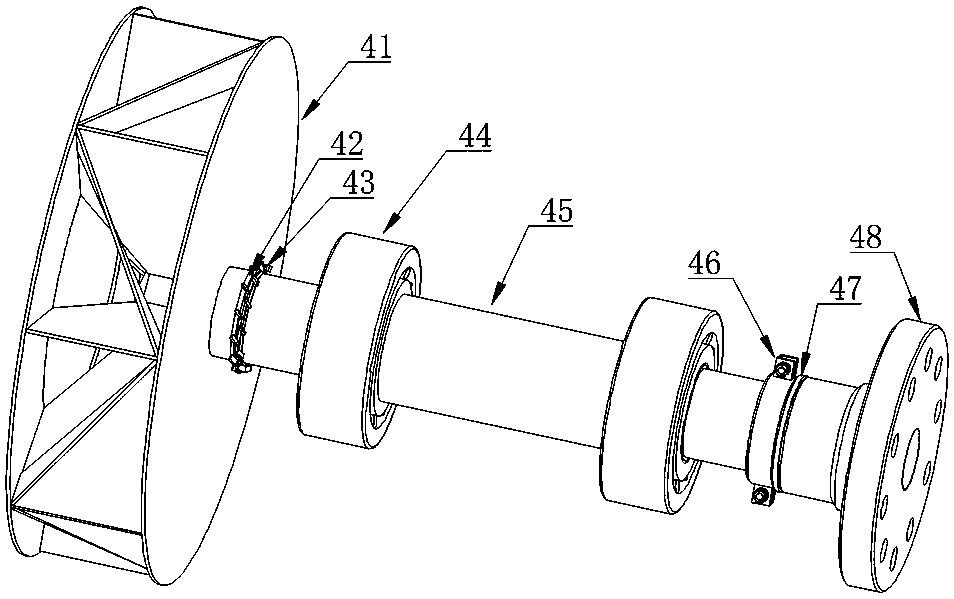

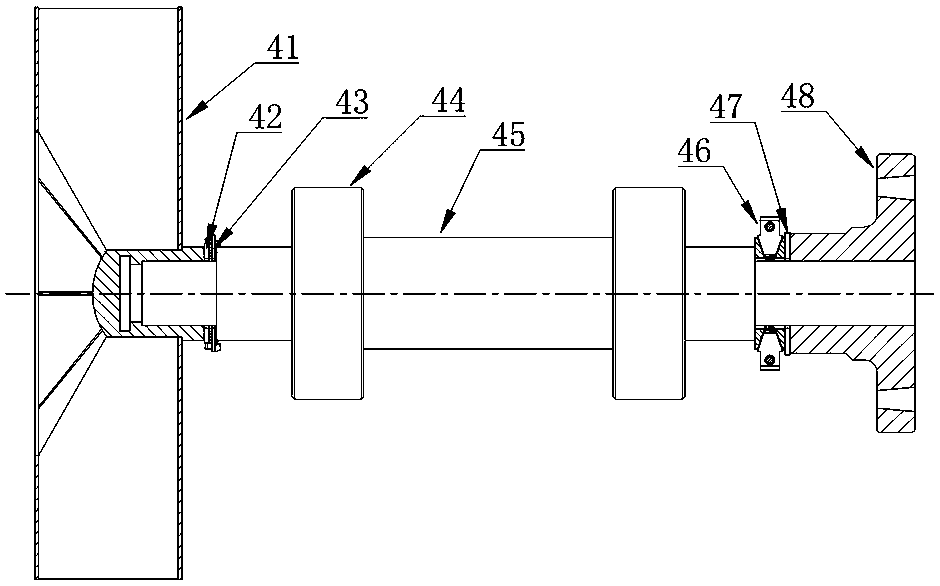

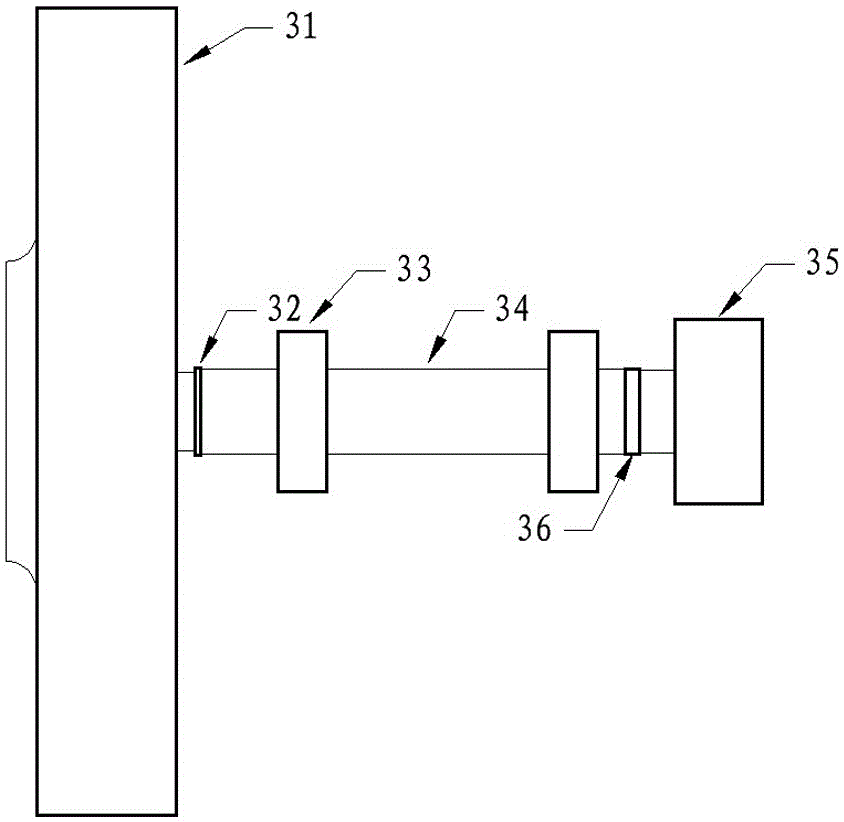

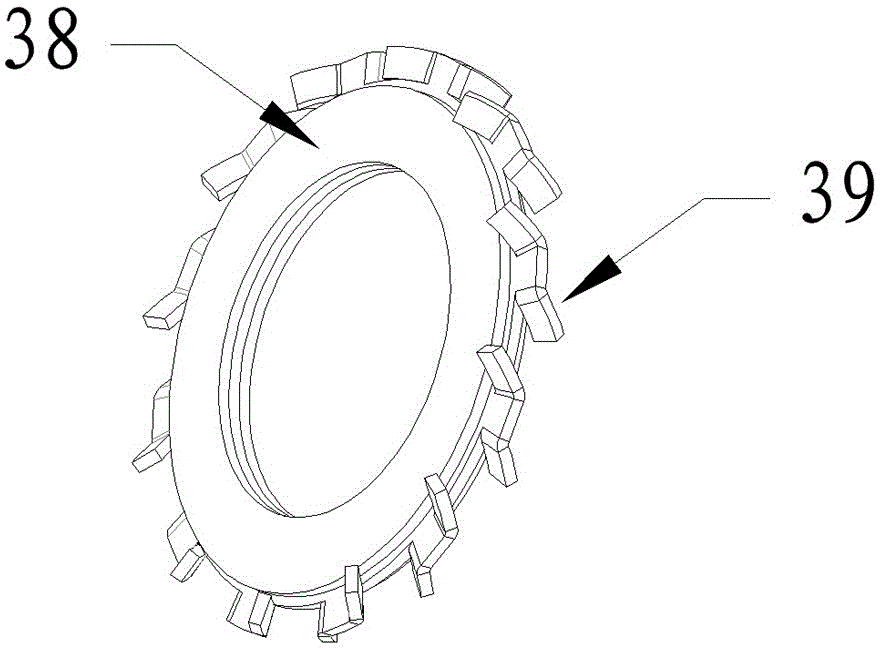

Hammer type crushing machine convenient and quick to disassemble

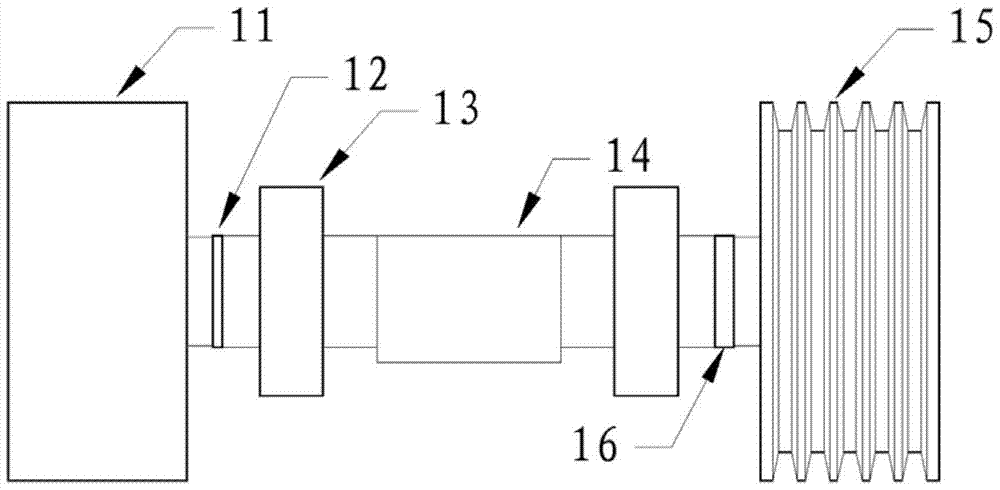

InactiveCN105689062ASolve the problem of continuous automatic locking and difficult disassemblySolve the problem that automatic locking is not easy to disassembleGrain treatmentsEngineeringFlywheel

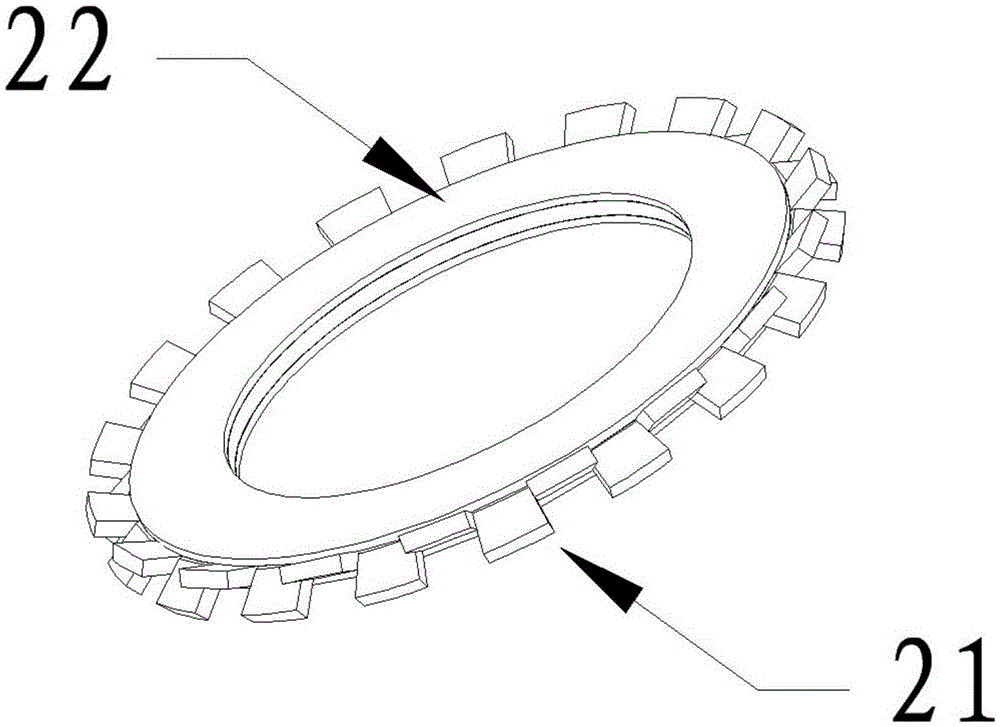

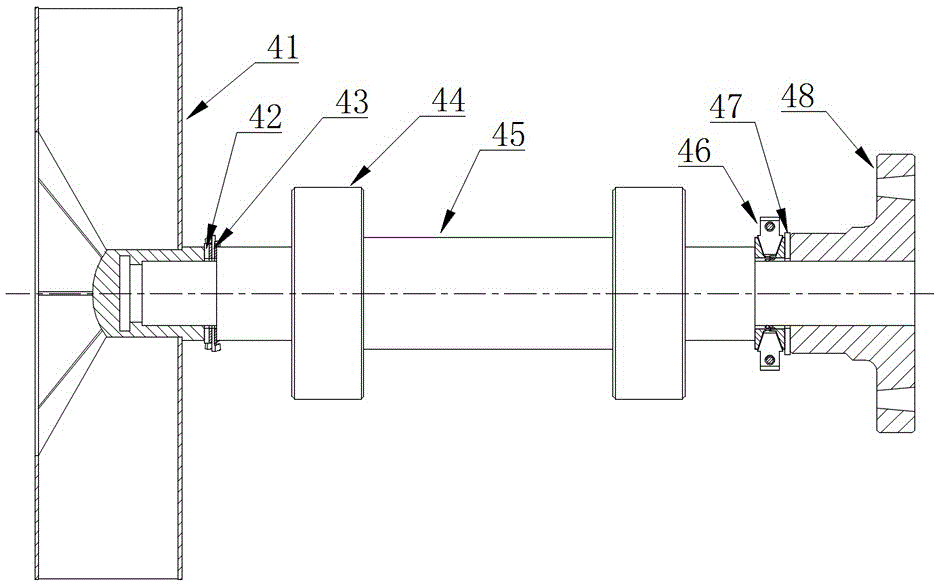

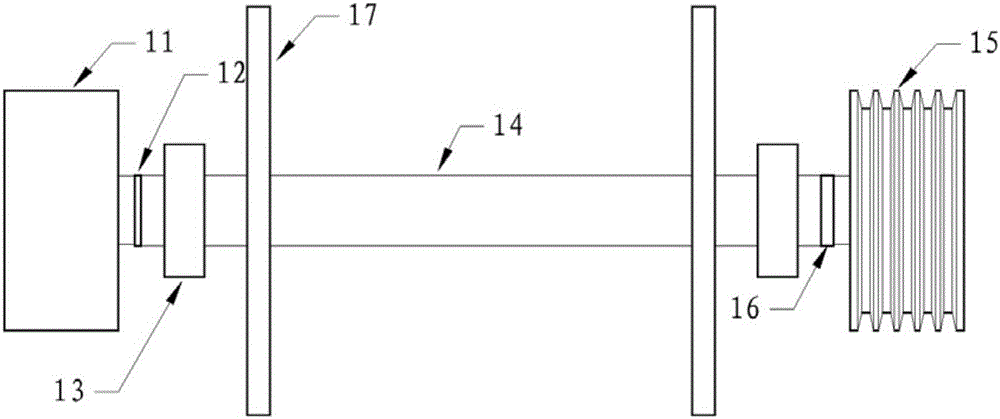

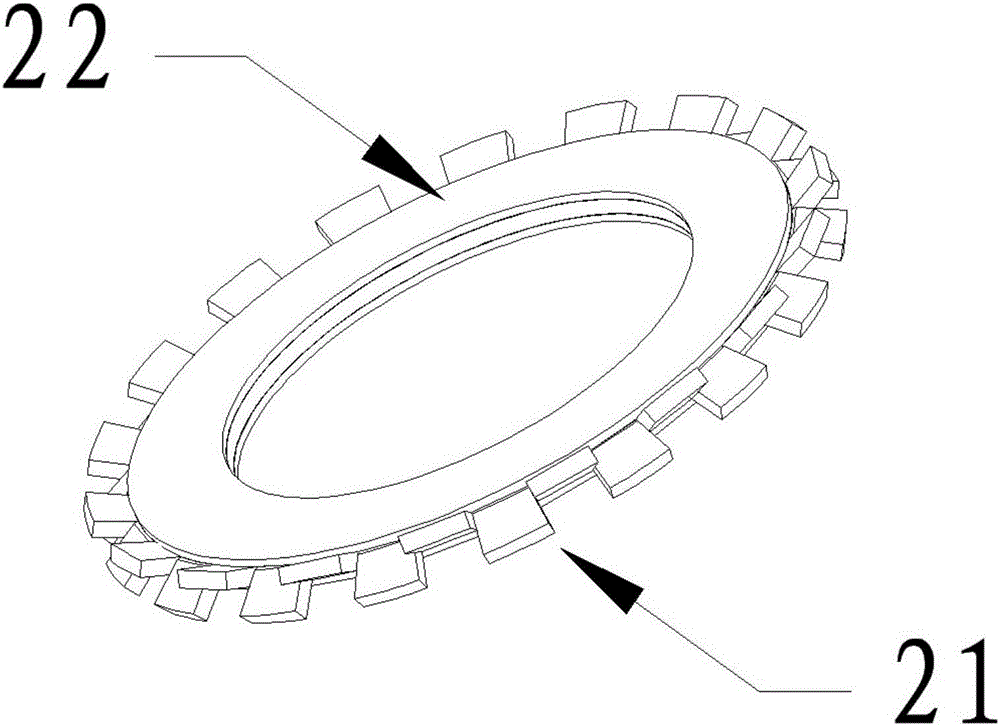

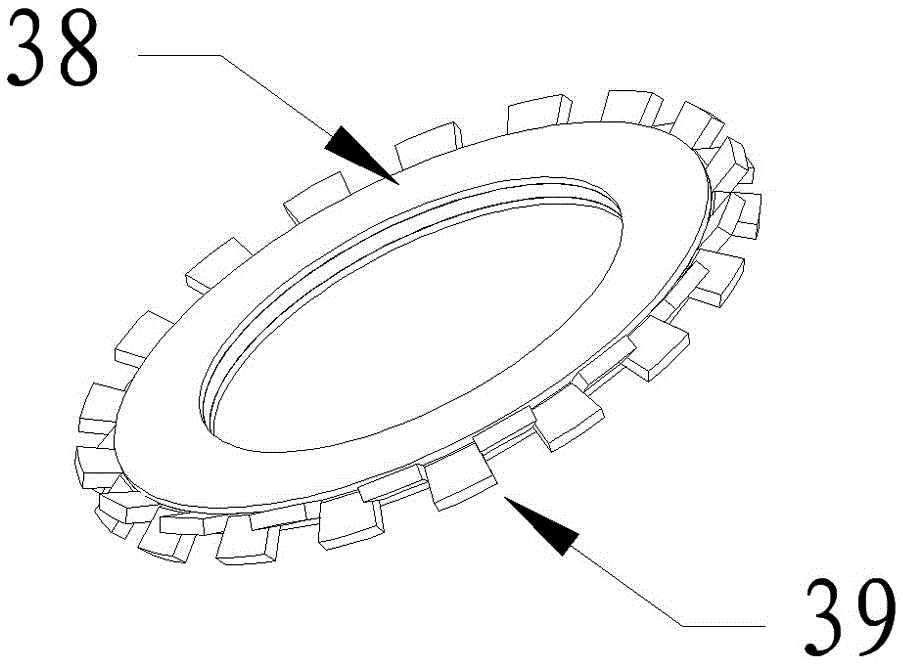

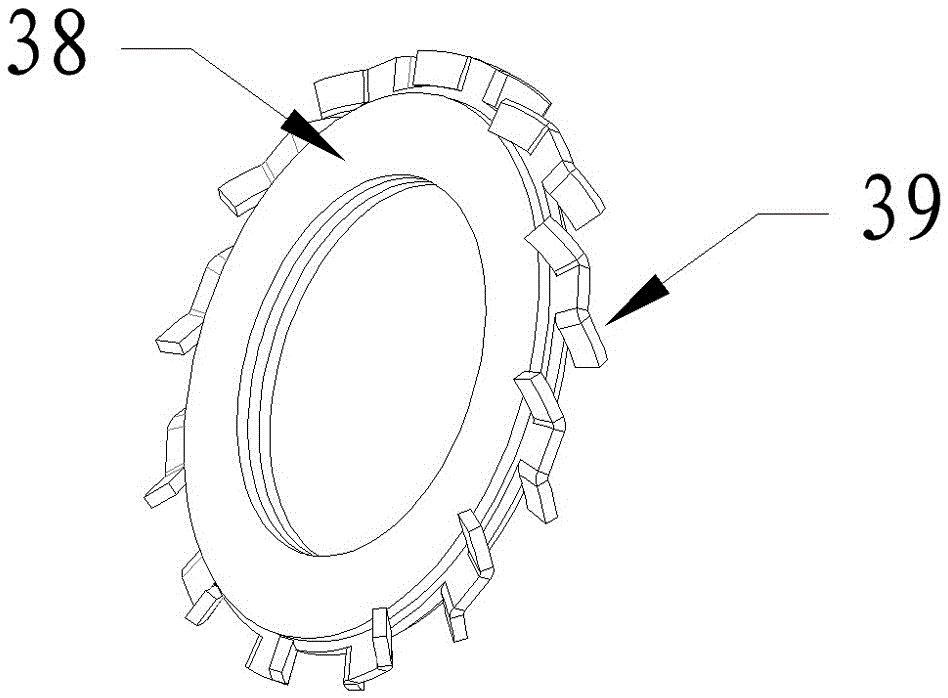

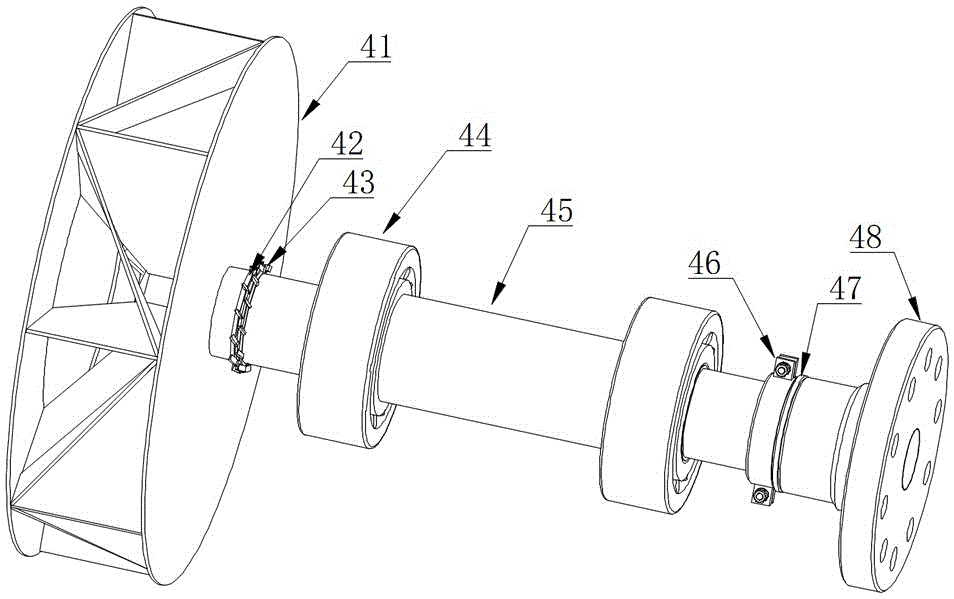

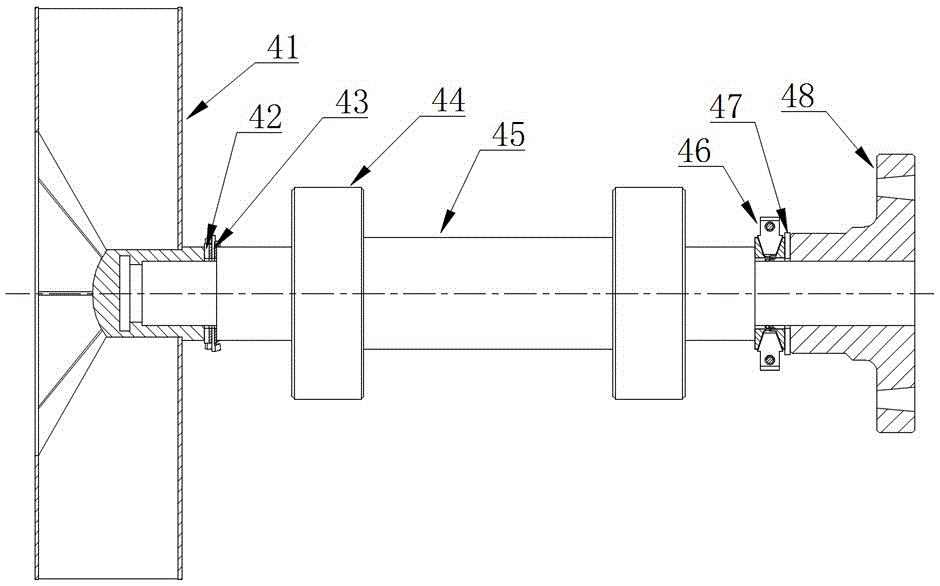

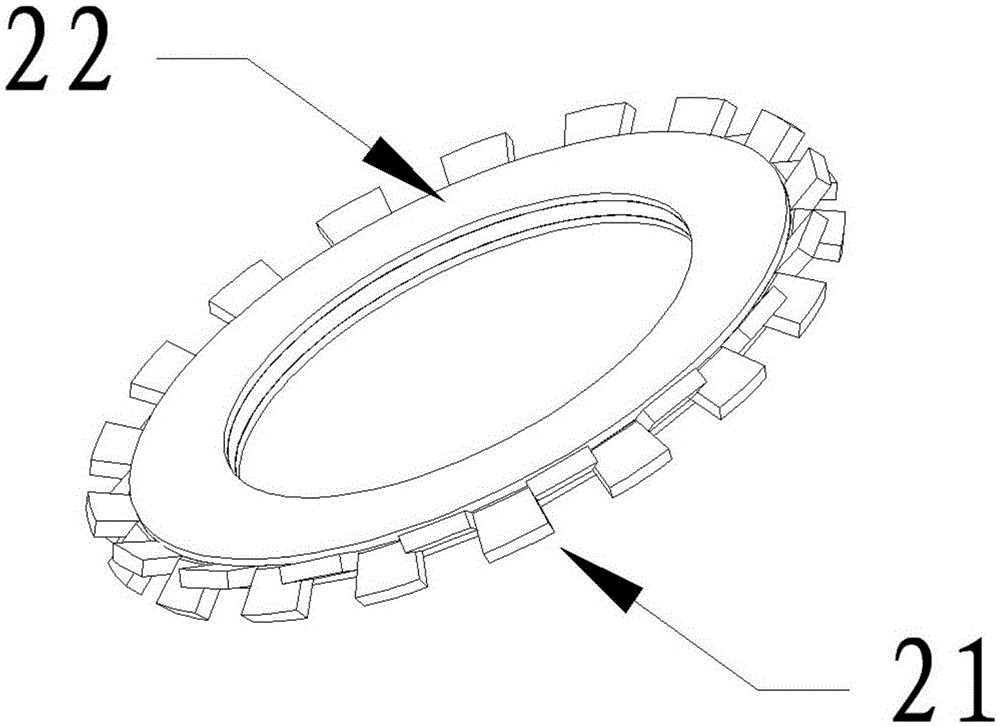

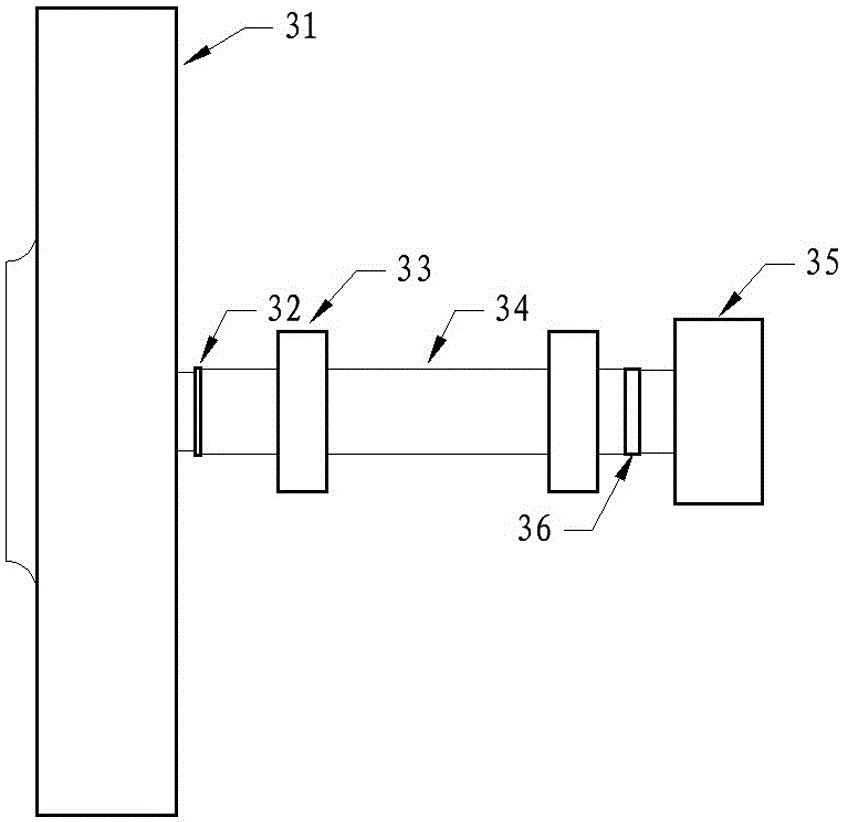

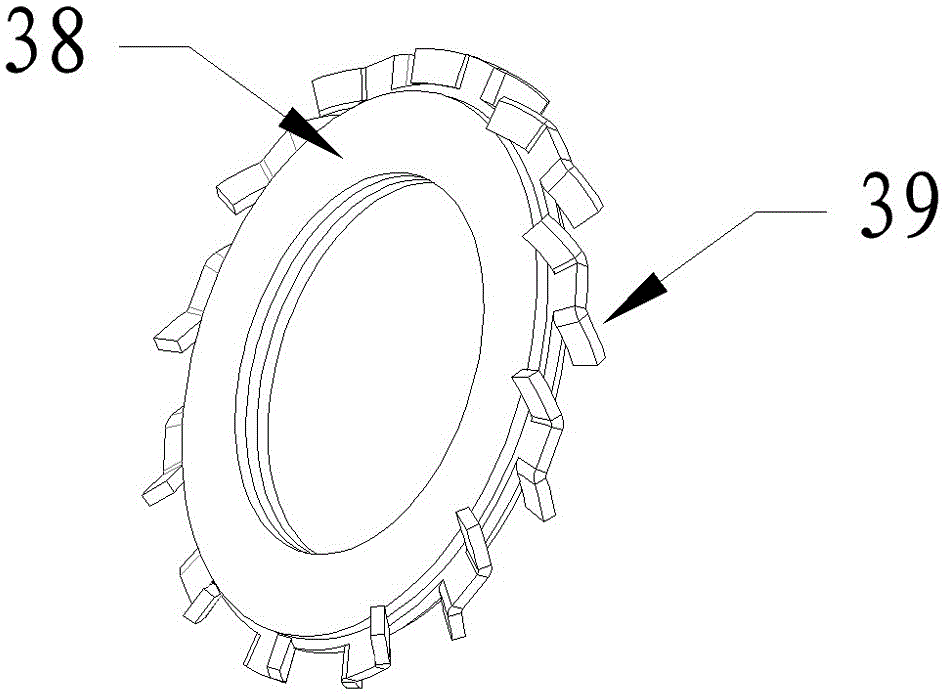

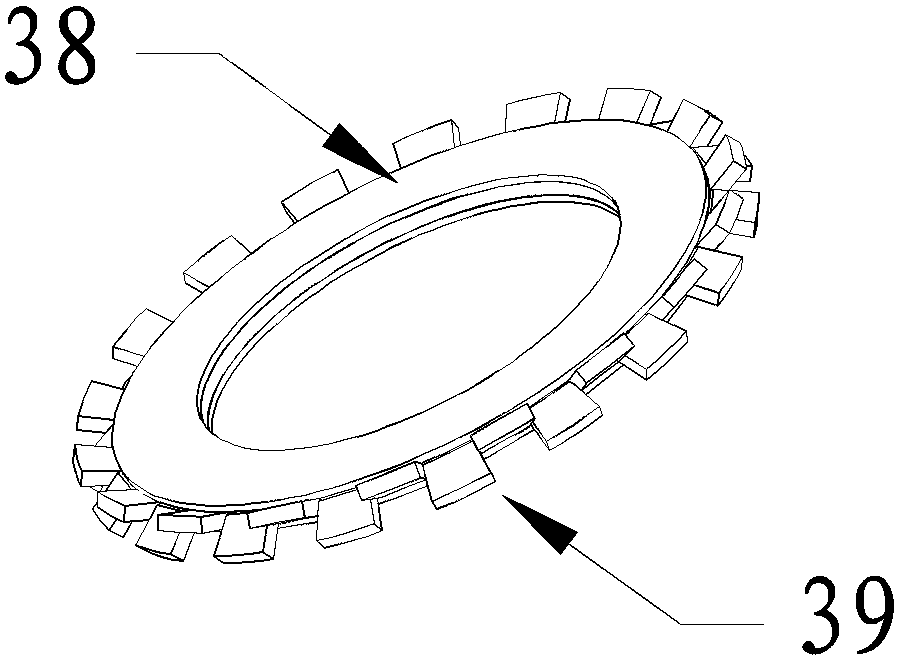

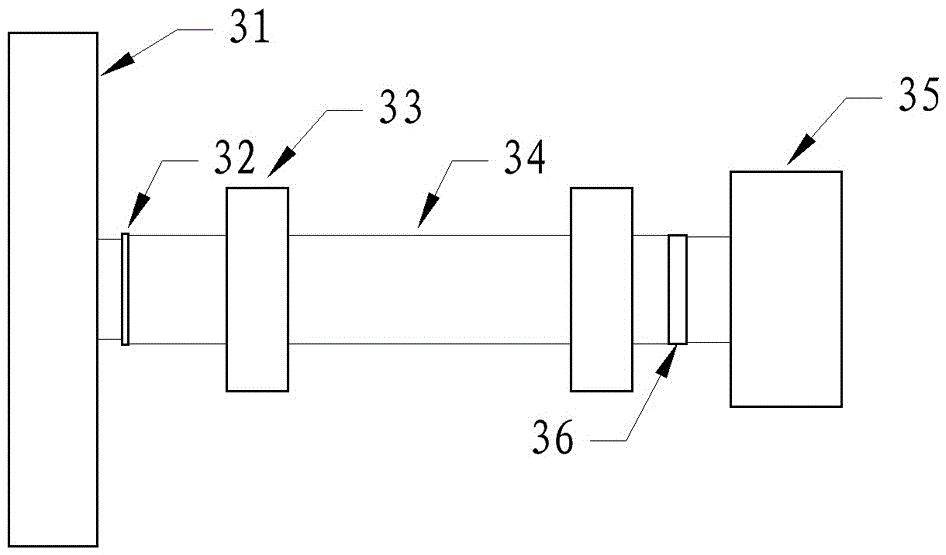

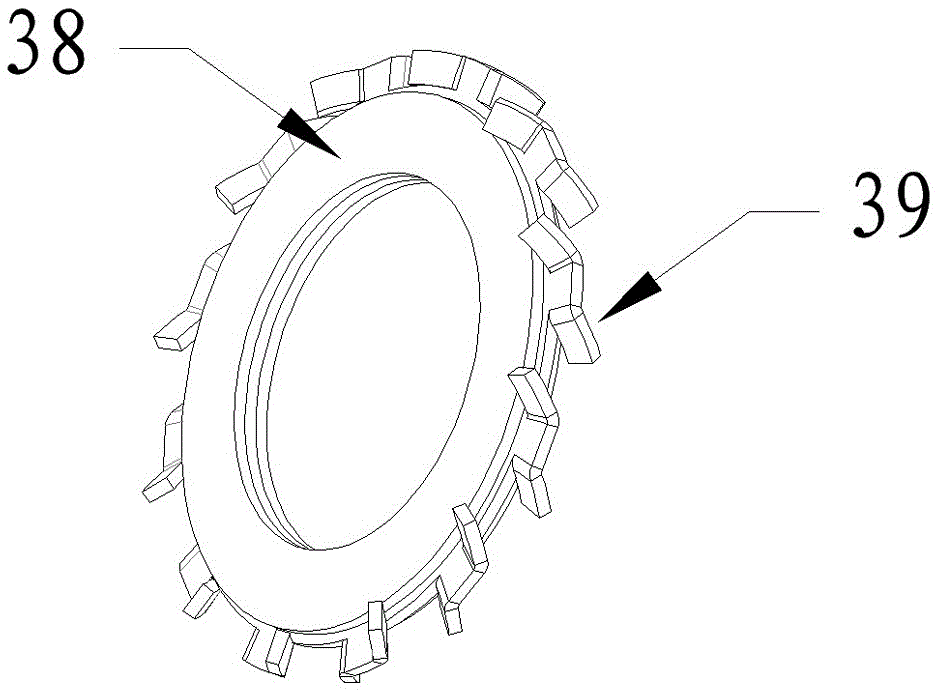

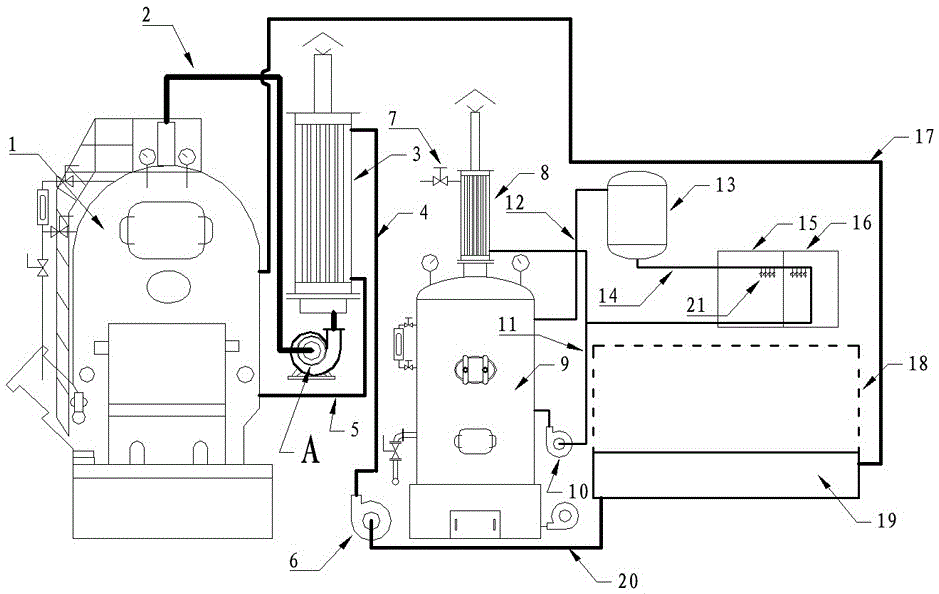

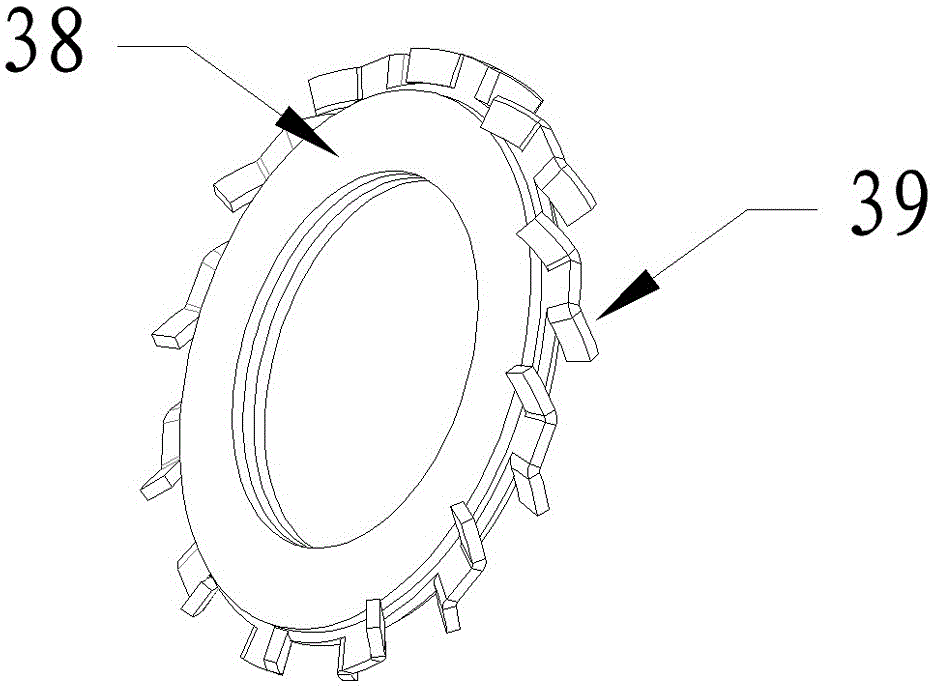

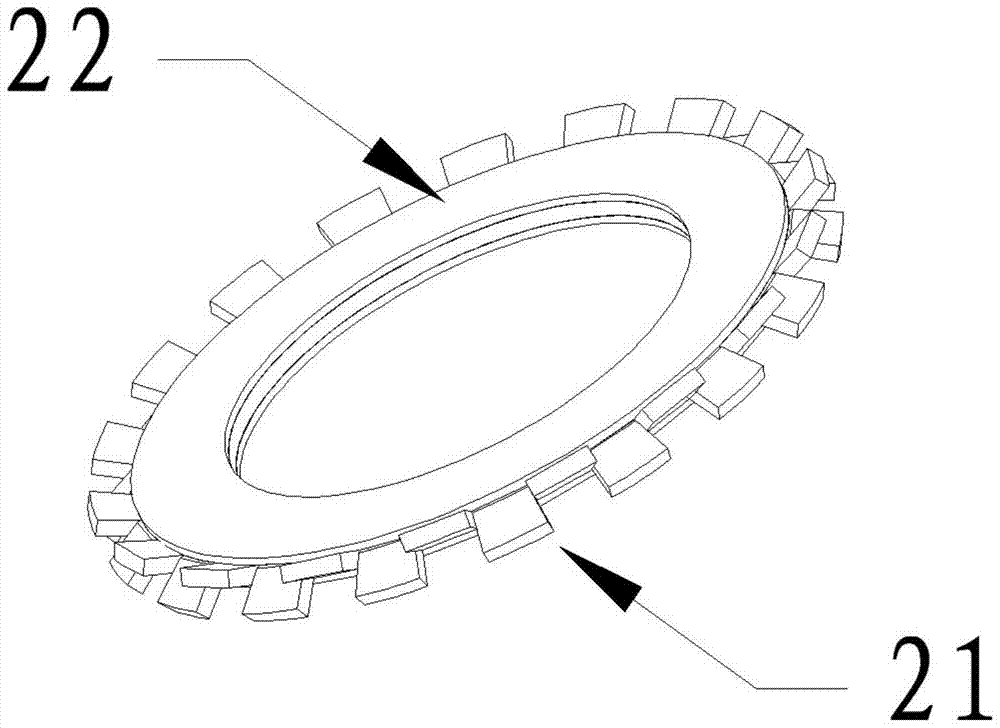

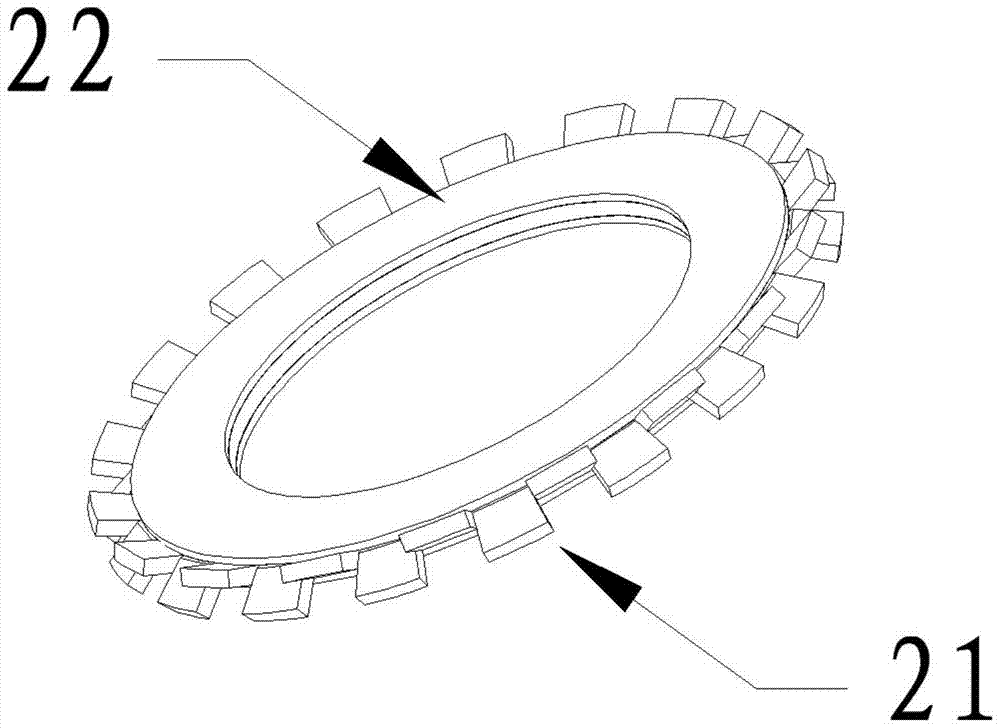

The invention discloses a hammer type crushing machine convenient and quick to disassemble. The hammer type crushing machine comprises a machine body (3), a flywheel (11) and a belt pulley (15), wherein the flywheel (11) and the belt pulley (15) are in right-and-left threaded assembly with a hammer disc shaft (14) of the machine body (3); a copper-plastic composite pad (12) is arranged between the flywheel (11) and the hammer disc shaft (14); the copper-plastic composite pad (12) comprises a copper pad (21) and fusible plastic gaskets (22) arranged on two sides of the copper pad (21); a clamp hoop assembly (16) is arranged between the belt pulley (15) and the hammer disc shaft (14); the clamp hoop assembly (16) comprises a plurality of clamp hoop bodies (31), clamp hoop pads (33) mounted in fit with the clamp hoop bodies (31) and connection parts used for fixing the clamp hoop bodies (31); the sections of the clamp hoop bodies (31) are wedge-shaped and are mounted in fit with similarly wedge-shaped clamping slots of the clamp hoop pads (33). Through the hammer type crushing machine, the problem that the hammer type crushing machine thread assembly is continuously and automatically locked under the action of load and is not easy to disassemble can be effectively solved; and the hammer type crushing machine is convenient to disassemble.

Owner:江华瑶族自治县金牛开发建设有限公司

Granite wet dust collection type energy-saving coal-fired boiler

ActiveCN105698153AImproved disassembly technologyGood effectPump componentsPump installationsImpellerCopper

The invention discloses a granite wet dust collection type energy-saving coal-fired boiler. A high-temperature exhaust pipe of a boiler body is connected with an induced draft fan through a water-preheating shell-and-tube heat exchanger tube pass and a granite wet dust collector. A high-position soft water pond is preheated by a water-preheating shell-and-tube heat exchanger shell pass and then supplies water to the boiler through a high-pressure pump system. A coupling and a fan shaft of the induced draft fan are assembled in a threaded mode, a fan impeller and the fan shaft of the induced draft fan are also assembled in a threaded mode, and the thread turning direction is the direction for automatic locking along with work and loads. The fan impeller presses a copper-lead torsional composite gasket and then is connected with the fan shaft in a threaded rigid connection mode, and a hoop part enables the coupling and the other end of the fan shaft to be connected in a rigid connection mode. According to the granite wet dust collection type energy-saving coal-fired boiler, heat recovery and purification treatment of boiler exhaust are achieved, more importantly, the disassembling technology of the boiler induced draft fan is greatly improved, the problem that an existing boiler induced draft fan is assembled in a threaded mode, is automatically locked continuously under the action of loads and is not easy to disassemble can be effectively solved, and fans of large boilers can be conveniently disassembled after threaded locking.

Owner:YANGZHOUSR BOILER

Cyclone wet dust collection type energy-saving coal-fired boiler

ActiveCN105650659AAchieve heat recoveryAchieving processing powerCombustion technology mitigationFeed-water heatersCycloneEngineering

The invention discloses a cyclone wet dust collection type energy-saving coal-fired boiler. A high-temperature tail gas tube of a boiler body is connected to an air induction fan through the tube side of a water preheating tubular heat exchanger and a cyclone dust collector; water in a sewage pool below the cyclone dust collector is connected to a spraying plate in the cyclone dust collector through a spraying pump; a high-position soft water pool supplies water to the boiler after being preheated by the shell side of the water preheating tubular heat exchanger; threaded assembly with the automatic locking effect is adopted between a belt pulley and a fan shaft of the air induction fan and between a fan impeller and the fan shaft of the air induction fan; the fan impeller is in threaded and rigid connection with the fan shaft after pressing a copper-plastic reversed composite pad; the belt pulley and the other end of the fan shaft are connected rigidly through a clamp part. According to the boiler, heat recovery and purification treatment of tail gas of the boiler are realized, the disassembly and assembly technology of the air induction fan of the boiler is greatly modified, the problems that the air induction fan of the boiler is continuously and automatically locked and is difficult to disassemble under the loading effect due to threaded assembly can be effectively solved, and large boiler fans can be disassembled conveniently and quickly after being locked in a threaded mode.

Owner:长沙天宁热电有限公司

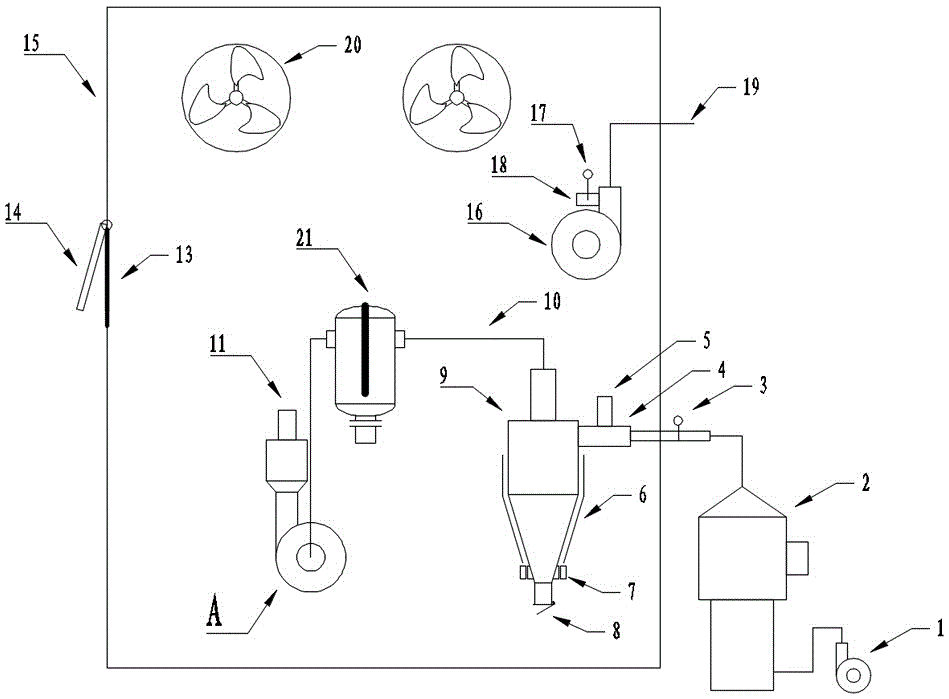

Biomass boiler drying system

ActiveCN105605912AAchieve heat recoveryAchieving processing powerBoiler cleaning apparatusSteam boilersCycloneImpeller

The invention discloses a biomass boiler drying system. A high-temperature tail gas pipe is connected with an interlayer of a tubular heat exchanger and an interlayer of a cyclone in a tangential mode, after cyclone dedusting is conducted, dust is discharged out of a cone base through an air-lock device, and tail gas penetrates through a tube nest after being evenly dispersed and is discharged out through an upper conical hopper by means of a draught fan; a drying room is provided with a condensate water backflow pipe to recycle condensate water; a coupling of the draught fan, a fan shaft and a fan impeller are all assembled in a threaded mode, and the thread screw direction means the automatic locking direction along with work and the load; the fan impeller is in threaded rigid connection with the fan shaft after pressing a copper lead twisting composite pad; the coupling and the other end of the fan shaft are also in rigid connection through a clamp part. By means of the biomass boiler drying system, heat recovery and purification treatment of boiler tail gas are achieved, most importantly, the disassembling and assembling technology of a boiler draught fan is greatly improved, the problem that the boiler draught fan is automatically locked continuously under the action of the load and not easy to detach in the screw assembling process can be effectively solved, and the biomass boiler drying system is particularly suitable for fast and convenient detachment of a large boiler draught fan which is locked in a threaded mode.

Owner:安徽中节节能环保科技股份有限公司

Healthy dampness removing type smoked and roasted product smoking and roasting device convenient for induced draft fan disassembly

InactiveCN105767120ADoes not affect dynamicDoes not affect balanceMeat/fish preservationPump componentsImpellerWater storage tank

The invention discloses a healthy dampness removing type smoked and roasted product smoking and roasting device convenient for induced draft fan disassembly. Fins are arranged at both inside and outside of a smoking chamber wall body and connected to a water storage tank via an upper connecting pipe and a lower connecting pipe; a smoke producing pipeline of a smoke producing stove passes the wall body and is connected to an air inlet pipe of a cyclone separator, the cyclone separator is connected to an induced draft fan via a pipeline, and an air outlet of the induced draft fan is arranged inside the wall body; a flashboard is arranged on the smoke producing pipeline of the smoke producing stove; a light-weight valve is arranged at the bottom of the cyclone separator, and a heat radiator and a vibrator are arranged on the surface of the cyclone separator; and an impeller of the induced draft fan can use a centrifugal force to timely clean dust. The smoking and roasting device can realize green and energy-efficient smoking and roasting and more importantly greatly improve the disassembly and assembly technologies of the induced draft fan, so that during the disassembly, the device can simply eliminate similar pressures of blind nut parts for shoulder end surfaces of screw shafts, effectively solves the problem that the screw assembly of the induced draft fan is continuously automatically locked and not easy for disassembly under a loading effect, and is especially suitable for and has a particularly significant effect for a convenient disassembly after thread locking of large-sized fans.

Owner:JISHOU UNIVERSITY

A simple Raymond mill device that is easy to disassemble the fan

ActiveCN105665080BHigh extrusion rigidityStrong extrusion rigidityUsing liquid separation agentGrain treatmentsImpellerCyclone

The invention discloses a simple Raymond mill device with a fan convenient to disassemble. The fan, a Raymond mill, a cyclone separating and discharging device and an air return duct form an air-flow-circulating ground-powder discharging system. An isolating temporary storage barrel is arranged at an inlet, connected with the air return duct, of the fan. A gravity material door is arranged on the isolating temporary storage barrel. A temporary powder storage barrel is arranged below the gravity material door. A valve and a discharging gate are arranged on the temporary powder storage barrel. Blades of an impeller of the induced draft fan are arranged symmetrical about the center of an impeller shaft in the radial direction in a radial manner, dust can be cleared up in time through centrifugal force, and safety accidents are avoided. The simple Raymond mill device is simple in structure, and more importantly, the disassembly technology of the induced draft fan is improved greatly, so that pressure applied to the shaft shoulder end face of a screw by components similar to a nut component can be eliminated easily when the induced draft fan is disassembled, and the problem that the induced draft fan is locked continuously and automatically and cannot be disassembled easily under the load action due to threaded assembly is solved effectively; and the simple Raymond mill device is especially suitable for convenient and fast disassembly of the large-scale fan which is locked in a threaded manner, and the effect is especially remarkable.

Owner:HENAN TIANXIANG NEW MATERIALS

Tail heat utilization sieve hole flap dryer

ActiveCN105716402BHigh extrusion rigidityStrong extrusion rigidityPump componentsDrying gas arrangementsEngineeringCentrifugal force

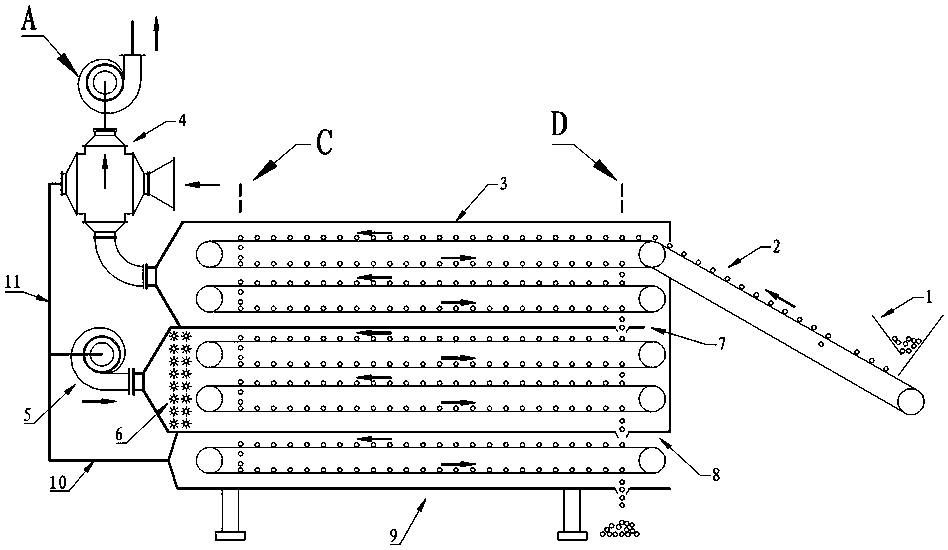

The invention discloses a tail heat utilization sieve mesh turning-plate type drier. A drier box body is provided with a structure of sieve mesh turning-plate type conveying from top to bottom and is divided into an upper drying area, a middle drying area and a lower drying area by a middle baffle and a lower baffle. The upper drying area is connected with an induced draft fan through an air heat exchanger and then is drained; the air outlet end of the upper drying area is connected with an air inlet of an air blower through an air pipe; and an air outlet of the air blower is connected with a steam fin heater in the middle drying area. Blades of an impeller of the induced draft fan are arranged in a radiated mode with an impeller shaft being in radial symmetry and central symmetry, dust is cleaned up in time by centrifugal force, and safety accidents are avoided. The tail heat utilization sieve mesh turning-plate type drier improves the drying efficiency and achieves energy saving and emission reduction; more importantly, the disassembling technology of the induced draft fan is greatly improved, and the induced draft fan can simply eliminate the pressure of nut-like parts to the shaft shoulder end faces of screw rods when being disassembled, so that the problem that due to the threaded assembly mode, the induced draft fan is continuously and automatically locked under the load action and is not likely to be disassembled is effectively solved; and the tail heat utilization sieve mesh turning-plate type drier is particularly suitable for convenient disassembling of large draft fans after threaded locking, and the effect is very obvious.

Owner:武汉新实诚诺资源开发有限公司

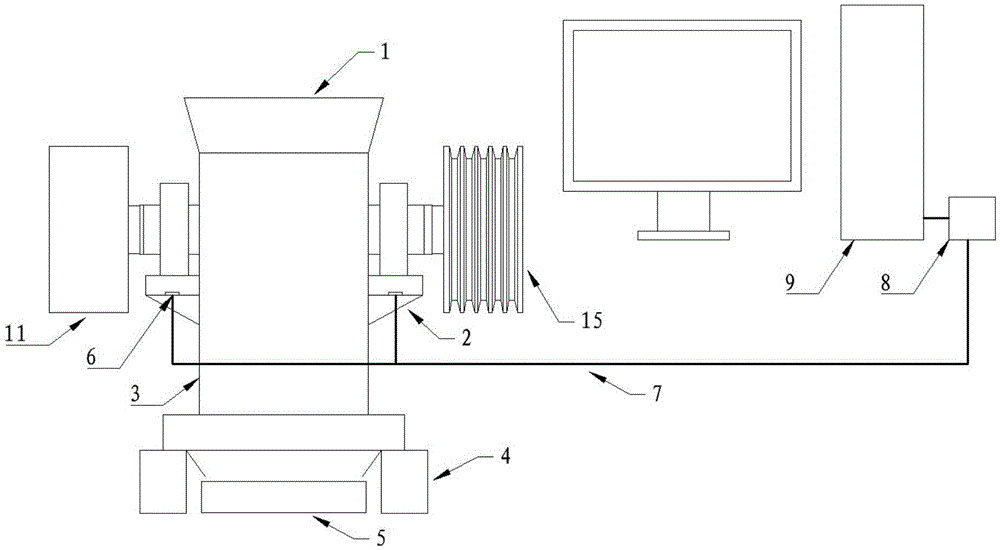

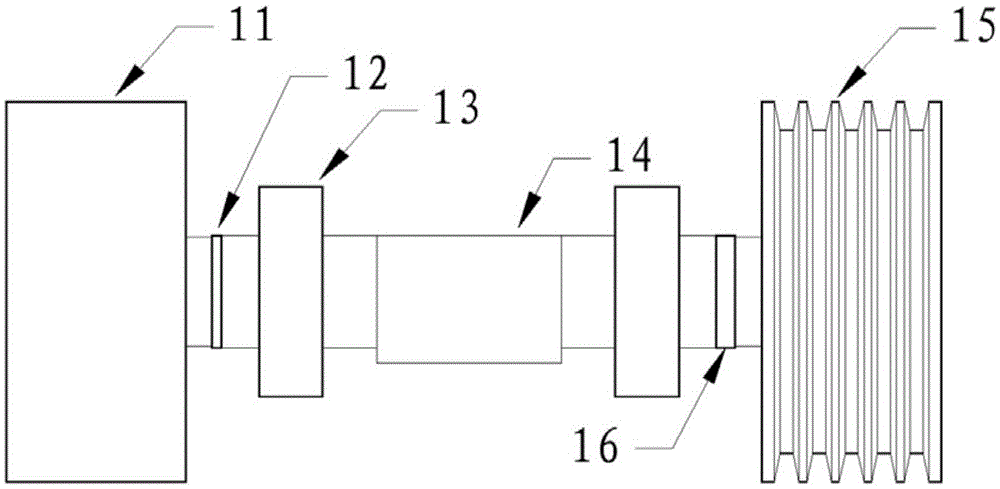

Miniature jaw crusher with monitor

The invention discloses a miniature jaw crusher. The miniature jaw crusher comprises a miniature jaw crusher body and a monitoring system, wherein the miniature jaw crusher body comprises a machine body (3), a flywheel (11) and a belt pulley (15); the flywheel (11) and the belt pulley (15) are assembled with a camshaft (14) of the machine body (3) in a normally and reversely threaded manner; the monitoring system comprises a strain sensor (6) arranged on a bearing block (2) of the machine body (3); and the strain sensor (6) is connected with a signal processor (8) through a signal line (7), carries out processing and controlling through a computer (9). By the miniature jaw crusher, the problem that threaded assembly of the jaw crusher is locked automatically and continuously and is not easy to detach can be solved effectively, the jaw crusher can be detached conveniently, meanwhile, impact load in a crushing operation process can be monitored indirectly, particularly, the miniature jaw crusher can be detached conveniently after components of the miniature jaw crusher are locked in a threaded manner, and working condition maintenance of the miniature jaw crusher can also be implemented.

Owner:江苏佳华机械科技有限公司

Exhaust heat recovery and dust removal integrated biomass boiler heating system

InactiveCN105716271ARemove tensionEasy to disassemblePump componentsWater heatersEngineeringExhaust pipe

The invention discloses an exhaust heat recovery and dust removal integrated biomass boiler heating system. A high-position soft water tank is used for supplying water for a boiler; a boiler main body is provided with a hot water outlet pipe connected with rooms; a high-temperature exhaust pipe of the boiler main body is connected with an induced-draft fan; valves are arranged in each room to control hot water for use during a bath, and an electromagnetic valve is added and is linked with fan coils to work; a water return pipe is used for converging flow and returning water; a thread assembly is adopted by each of a coupling, a fan shaft and a fan impeller of the induced-draft fan; a helical direction of threads is a direction of automatic locking along with working and bearing; after tightly compressing a copper and lead torsion composite gasket, the fan impeller is in threaded rigid connection with the fan shaft; and the coupling and the other end of the fan shaft are enabled to be also in rigid connection by a hoop part. According to the exhaust heat recovery and dust removal integrated biomass boiler heating system disclosed by the invention, heat recovery and purification treatment on boiler exhaust are realized, and more importantly, a problem that the thread assembly of the induced-draft fan of a boiler is not easy to disassemble due to the fact that the thread assembly automatically locks continuously under load action can be effectively solved, and the exhaust heat recovery and dust removal integrated biomass boiler heating system is especially suitable for conveniently disassembling a large boiler fan under thread locking.

Owner:JISHOU UNIVERSITY

Cyclone wet dust removal type energy-saving coal-fired boiler

ActiveCN105650659BAchieve heat recoveryAchieving processing powerCombustion technology mitigationFeed-water heatersCycloneEngineering

Owner:长沙天宁热电有限公司

The induced draft fan is easy to dismantle the suction type Chinese herbal medicine pulverizer

ActiveCN105709913BRemove tensionEasy to disassembleCombination devicesGrain treatmentsImpellerAir volume

The invention discloses an induced-draft traditional Chinese medicinal material pulverizer with a convenient-to-disassemble induced draft fan. The induced-draft traditional Chinese medicinal material pulverizer comprises a pulverizer body and the induced draft fan, wherein the material falling end of the pulverizer body is connected with the induced draft fan by a material storage box, exhaust tubes and a cyclone separator, and a ventilation door used for adjusting air volume is arranged one exhaust tube, a pull-back separator is arranged on the exhaust tube, the material falling end of the pull-back separator is connected with a feed hopper, and the feed hopper is connected with the pulverizer body; and an impeller of the induced draft fan can promptly clean dust by use of the centrifugal force. The induced-draft traditional Chinese medicinal material pulverizer not only can complete returning and secondary crushing of coarse particles in one step to realize qualified material output, and more importantly, the assembly and disassembly technology of the induced draft fan is greatly improved to ensure that pressure exerted on the end surface of a screw shaft shoulder by similar nut parts is simply eliminated during disassembly of the induced draft fan, so that the problem that the induced draft fan in screw assembly is continually and automatically locked under the load action and therefore is difficult to disassemble is solved. The improved assembly and disassembly technology is particularly suitable for convenient disassembly of a large-scale fan in screw-threaded coupling, and the effect is particularly remarkable.

Owner:山西天生制药有限责任公司

Hot water auxiliary system for natatorium

The invention discloses a hot water auxiliary system for a natatorium. A tail gas tube of a boiler body is emptied through a chimney after being subjected to heat exchange through a tubular heat exchanger, the upper part of the shell side of the tubular heat exchanger is connected to a water supplementation control valve, and the lower part of the shell side feeds water to a boiler through a tube; hot water of the boiler is supplied to bathing through a hot water storage tank, water return tubes enter the boiler after being merged, and therefore heating circulation is realized; water in a swimming pool is conveyed into a coil tube in the hot water storage tank by a circulating water pump and exchanges heat with the hot bathing water, and the heated warm water returns to the swimming pool; a coupling and a water pump shaft of the circulating water pump are assembled in a threaded mode, a water pump impeller and the water pump shaft of the circulating water pump are assembled in a threaded mode, the thread rotation direction is the automatic locking direction along with working and bearing, and rigid connection is realized. According to the system, the single boiler is used for supplying heat to the bathing water and the pool water simultaneously in a constant-temperature mode, the disassembly and assembly technology of the water pump is greatly modified, the problems that the water pump is continuously and automatically locked and is difficult to disassemble under the loading effect due to threaded assembly can be effectively solved, and large water pumps can be disassembled conveniently and quickly after being locked in a threaded mode.

Owner:JISHOU UNIVERSITY

Bag filter-type manganese processing rotary kiln system with highly demountable induced draft fan

InactiveCN105783505AHigh extrusion rigidityStrong extrusion rigidityPump componentsRotary drum furnacesManganeseEngineering

The invention discloses a bag filter-type manganese processing rotary kiln system with a highly demountable induced draft fan. The bag filter-type manganese processing rotary kiln system adopts the structure that an air-lock valve used for feeding is arranged at the high end of a rotary kiln; the high end of the rotary kiln is connected with a cyclone dust extractor, an induced draft fan and a bag-type dust remover via a fin section and air pipes; fins are arranged in the fin section; a hood cylinder is arranged outside the fin section; a sleeve-type air heat exchanger is arranged outside an air pipe; the hood cylinder is communicated with a lower pumping hole in the air heat exchanger, and then divided into two paths for supplying preheated air; and the blades of the impeller of the induced draft fan are arranged in a radiation shaped and are in radial and central symmetry with respect to an impeller shaft, so that dust can be cleaned promptly via centrifugal force, and safety accidents can be avoided. The bag filter-type manganese processing rotary kiln system not only is high in heat efficiency, but also has the advantages that the demounting technology of the induced draft fan is greatly improved; pressure of a nut-like component on a shaft shoulder end surface of a screw can be eliminated simply during demounting, the problem that a threaded assembly of the induced draft fan is automatically screwed continuously under the action of a load to be difficult to demount can be solved effectively; the suitability for convenient demounting of a large-scale induced draft fan after thread screwing is high; and the effect is remarkable.

Owner:涡阳县华夏气体有限公司

Tail heat recovery and dust removal integrated coal-fired boiler with induced draft fan for easy disassembly

ActiveCN105757704BHigh extrusion rigidityStrong extrusion rigidityPump componentsPumpsCyclonic spray scrubberExhaust pipe

Owner:安徽星洁环保科技有限公司

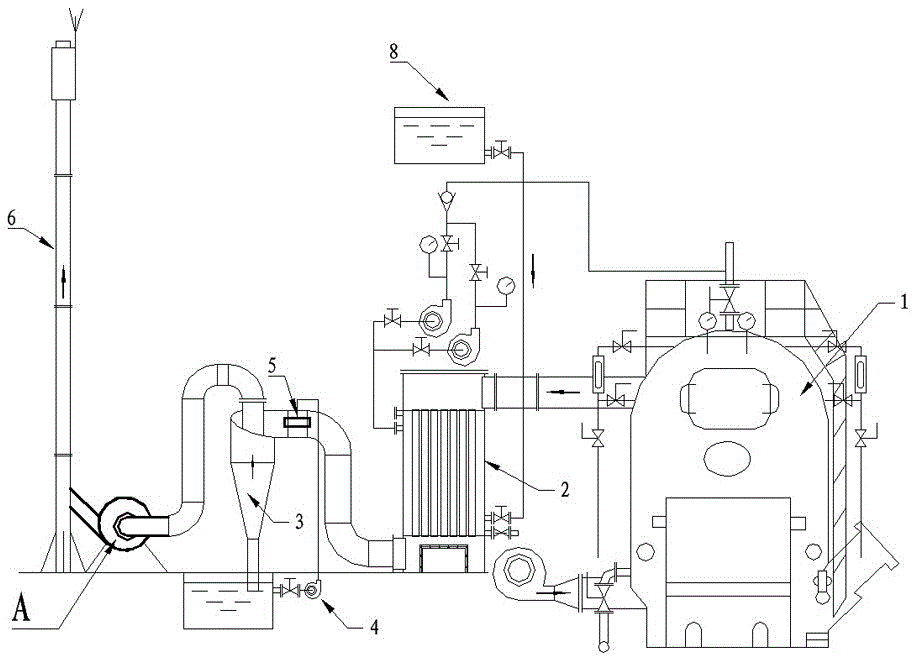

Residual heat recycling and dust removal integrated coal-fired boiler with conveniently detachable draught fan

ActiveCN105757704ADoes not affect dynamicDoes not affect balancePump componentsPumpsCyclonic spray scrubberExhaust pipe

The invention discloses a residual heat recycling and dust removal integrated coal-fired boiler with a conveniently detachable draught fan. A cyclone dust removal residual heat efficiency recycling device is formed by overlapping a tubular heat exchanger and a cyclone dust remover; a boiler exhaust pipe is connected with the cyclone dust remover in a tangential direction; after cyclone dust removal is carried out, ash is discharged from a cone bottom through an air closing device; exhaust is connected with a cone body through a rotational flow ascending pipe, is uniformly dispersed and then penetrates through tubes; after being concentrated through an upper conical hopper, the exhaust is discharged by the draught fan through an exhausting pipe; a high-level water tank is connected with the lower part of a shell side of the tubular heat exchanger; and an impeller of the draught fan can be used for cleaning the ash in real time through a centrifugal force. The residual heat recycling and dust removal integrated coal-fired boiler realizes integrated type residual heat recycling and dust removal; more importantly, a dismounting technology of the draught fan is greatly improved, and pressure on the end face of a screw shaft shoulder of a screw cap part can be simply eliminated in a dismounting process, so that the problem that thread assembling of the draught fan is continuously automatically locked under the action of a load and thus detachment is not easy is effectively solved; and therefore, the technical scheme is particularly suitable for conveniently detaching a large-size draught fan locked through a thread and the effect is particularly remarkable.

Owner:安徽星洁环保科技有限公司

Double-temperature hot water system for natatorium

The invention discloses a double-temperature hot water system for a natatorium. A tail gas tube of a fire grate biomass boiler is emptied after being connected with a tubular heat exchanger through an induced draft fan; the fire grate biomass boiler carries out constant temperature keeping and heating on pool water; a fixed bed biomass boiler supplies bathing hot water; a coupling of the induced draft fan is in threaded assembly with both a fan shaft and a fan impeller; the thread turning direction is in a working and bearing automatic locking direction; the fan impeller forms threaded rigid connection with the fan shaft after compacting a copper-lead torsion compound pad; and the coupling also forms threaded rigid connection with the other end of the fan shaft through a hoop part. The double-temperature hot water system for the natatorium supplies double-temperature hot water, recovers tail heat of the boiler, more importantly transforms the disassembly and assembly technology of the induced draft fan of the boiler dramatically, can efficiently solve the problem of difficulty in disassembly as threaded assembly of the induced draft fan of the boiler is continuously automatically locked under the loading action and is particularly suitable for convenient and rapid disassembly of a fan of a large boiler after being in threaded locking.

Owner:JISHOU UNIVERSITY

Cyclone Mineral Flotation Defoamer with Induced Fan for Easy Disassembly

ActiveCN105597947BHigh extrusion rigidityStrong extrusion rigidityVortex flow apparatusFlotationCycloneImpeller

The invention discloses a cyclone type mineral flotation and defoaming device with an induced draft fan convenient to disassemble. The cyclone type mineral flotation and defoaming device is characterized in that a flotation machine is connected with a foam feeding hopper, the foam feeding hopper is connected with the induced draft fan by a primary cyclone separator, secondary cyclone separators are connected with the induced draft fan, an exhaust pipe is connected to the tops of the secondary cyclone separators, discharge pipes at the bottoms of the primary cyclone separator and the secondary cyclone separators are connected with a spiral conveyor, and a discharge outlet of the spiral conveyor is connected with a sedimentation tank; an impeller of the induced draft fan can timely clean dust by the aid of centrifugal force. The cyclone type mineral flotation and defoaming device has the advantages that emission and water consumption can be reduced, chemicals can be saved, the cyclone type mineral flotation and defoaming device is high in defoaming speed, more importantly, disassembling technologies for the induced draft fan are changed to a great extent, accordingly, pressures of components similar to nuts on the end surfaces of shaft shoulders of screws can be easily eliminated when the induced draft fan is disassembled, the problem that an existing induced draft fan assembled in a threaded manner is continuously automatically locked under the effects of load and is difficult to detach can be effectively solved, the cyclone type mineral flotation and defoaming device is particularly applicable to conveniently and quickly detaching large fans after the large fans are locked in a threaded manner, and particularly obvious effects can be realized.

Owner:SUZHOU KANGDUN ENVIRONMENTAL PROTECTION TECH CO LTD

The fan is easy to disassemble the Raymond mill device

InactiveCN105521855BHigh extrusion rigidityStrong extrusion rigidityHuman health protectionUsing liquid separation agentCycloneImpeller

The invention discloses a Raymond mill device with a convenient-to-disassemble fan. The fan, a Raymond mill, a cyclone separation discharger and a return air pipe form an airflow circulating milling discharging system, a pressure-equalizing exhausting branched pipe is connected with the upper end of a cyclone pipe, multiple cyclone separators are arranged in the cyclone pipe, the lower end of the cyclone pipe is tangentially connected with the cyclone separation discharger, the cyclone separation discharger discharges purified air and immerses below liquid level of a circulating water pool which is connected with the upper end of the cyclone pipe, blades of an induced draft fan impeller are arranged radially in a manner than the impeller is in axial, radial and central symmetry, and centrifugal force can be utilized to timely clean dust to avoid safety accidents. The Raymond mill device is less prone to causing mineral powder dust leakage, disassembling and assembling technology of an induced draft fan is improved substantially, pressure applied on screw shaft shoulder end faces by nut parts can be eliminated simply during disassembling of the fan, and the problem that the induced draft fan which is in threaded assembly constantly locks automatically and is difficult to disassemble under load action is solved effectively. The Raymond mill device is especially suitable for and has particularly remarkable effect on convenient and quick disassembling of large fans after being locked in a threaded manner.

Owner:盐城阳鑫新能源有限公司

A heat pump tail heat utilization inertia dedusting countercurrent dryer

ActiveCN105674715BHigh extrusion rigidityStrong extrusion rigidityPump componentsDrying gas arrangementsCycloneImpeller

The invention discloses a heat pump type reverse flow drying machine with the exhaust heat utilization and inertial dedusting functions. A draught hood of the drying machine is connected with an induced draft fan. The induced draft fan is connected with an evaporator of a heat pump system through a cyclone dedusting device and an inertial dedusting device for evacuation. The evaporator of the heat pump system is connected with a main machine through a refrigerant pipe. The main machine is connected with a condenser through the refrigerant pipe. The air outflow end of an air blower is connected with an air inflow hood through the condenser. Blades of an impeller of the induced draft fan are arranged symmetrical about the center of an impeller shaft in the radial direction in a radial manner, the dust can be cleared up in time through centrifugal force, and safety accidents are avoided. By the adoption of the heat pump type reverse flow drying machine with the exhaust heat utilization and inertial dedusting functions, drying efficiency is improved, and energy saving and emission reduction are achieved; and more importantly, the disassembly technology of the induced draft fan is improved greatly, so that pressure applied to the shaft shoulder end face of a screw by components similar to a nut component can be eliminated easily when the induced draft fan is disassembled, and the problem that the induced draft fan is locked continuously and automatically and cannot be disassembled easily under the load action due to threaded assembly is solved effectively; and the heat pump type reverse flow drying machine with the exhaust heat utilization and inertial dedusting functions is especially suitable for convenient and fast disassembly of a large-scale fan which is locked in a threaded manner, and the effect is especially remarkable.

Owner:安徽中节节能环保科技股份有限公司

A convenient quick-release hammer crushing system with silo and dust removal device

ActiveCN105665072BSolve the problem of continuous automatic locking and difficult disassemblySolve the problem that automatic locking is not easy to disassembleDirt cleaningGrain treatmentsFlywheelCrusher

The invention discloses a convenient and quick-dismounted hammer crushing system with a bin and a dust removing device. The system comprises a convenient and quick-dismounted hammer crusher, the bin (5) arranged at the bottom of the convenient and quick-dismounted hammer crusher, and the dust removing device; and the convenient and quick-dismounted hammer crusher includes a machine body (3), a flywheel (11) in reverse thread assembly with a hammer disc shaft (14) of the machine body (3), and a belt wheel (15) in forward thread assembly with the hammer disc shaft (14) of the machine body (3). The convenient and quick-dismounted hammer crushing system can effectively solve the problem of difficult disassembly of the thread assembly of the hammer crusher caused by continuously automatic locking under the load effect, can realize the disassembly convenience, and realizes the dustless crushing work.

Owner:广西宾阳力拓新型建材有限公司

Mini Jaw Crusher

ActiveCN105536917BSolve the problem of continuous automatic locking and difficult disassemblyEasy to disassembleGrain treatmentsEngineeringFlywheel

The invention discloses a micro jaw crusher which comprises a crusher body (3), a flywheel (11) and a belt pulley (15), wherein the flywheel (11) and the belt pulley (15) are in positive screw assembling and negative screw assembling with a camshaft (14) of the crusher body (3) respectively; a copper-plastic composite cushion (12) is arranged between the flywheel (11) and the camshaft (14), and comprises a copper cushion (21) and fusible plastic washers (22) arranged at the two sides of the copper cushion (21); a hoop assembly (16) is arranged between the belt pulley (15) and the camshaft (14), and comprises a plurality of hoop bodies (31), hoop cushions (33) in fit assembling with the hoop bodies (31), and connecting pieces for fixing the hoop bodies (31); the cross sections of the hoop bodies (31) are wedge-shaped; and the hoop bodies (31) are in fit assembling with wedge-shaped clamping grooves of the hoop cushions (33). According to the micro jaw crusher, the problem that the disassembling is difficult due to the fact that continuous automatic locking occurs under loading action by adopting the screw assembling of the conventional jaw crusher can be solved effectively, and convenient and quick disassembling can be realized.

Owner:江苏佳华机械科技有限公司

Two-stage heat recovery type cyclone dust removal coal-fired boiler

InactiveCN105757709AImproved disassembly technologySolve the problem of continuous automatic locking and difficult disassemblyIndirect carbon-dioxide mitigationDraught inductionCycloneSoft water

The invention discloses a two-stage heat recovery type cyclone dust removal coal-fired boiler.A high-temperature tail gas tube of a boiler body is connected with an induced draft fan through an air preheating plate type heat exchanger, a water preheating shell-and-tube heat exchanger tube pass and a cyclone dust collector.A high-position soft water pond is preheated through a water preheating shell-and-tube heat exchanger shell pass and then supplies water to the boiler through a high-pressure pump system.A coupler and a fan shaft, and fan impellers and the fan shaft of the induced draft fan are assembled through threads, and the thread screwing direction is the same as the automatic locking direction of working and bearing.After the fan impellers compress a copper-lead torsion composite gasket, thread rigid connection is formed by the fan shaft.By means of clamping parts, the coupler and the other end of the fan shaft form rigid connection.By means of the two-stage heat recovery type cyclone dust removal coal-fired boiler, two-stage heat recovery and purification treatment of boiler tail gases are achieved, more importantly, the dismounting technology of the boiler induced draft fan is greatly improved, the problem that the boiler draft fan continuously and automatically locks under the load action and is not easy to dismount due to thread assembling can be effectively solved, and the two-stage heat recovery type cyclone dust removal coal-fired boiler is especially suitable for convenient dismounting after thread locking of large boiler draft fans.

Owner:南京浦口科创投资集团有限公司

Green inertial dust catching preserved product smoking and roasting device with convenient-to-disassemble induced draft fan

InactiveCN105724551AEasy maintenanceHigh extrusion rigidityMeat/fish preservationFood processingImpellerCentrifugal force

The invention discloses a green inertial dust catching preserved product smoking and roasting device with a convenient-to-disassemble induced draft fan. A smoke generation pipeline of a smoke generation furnace penetrates through a wall body to be connected with an air inlet pipe of a cyclone separator, the cyclone separator is connected with the induced draft fan through a pipeline and an inertial dust catcher, and an air outlet of the induced draft fan is arranged in the wall body; a wedge disc is arranged on the smoke generation pipeline of the smoke generation furnace; a light valve is arranged at the bottom of the cyclone separator, and a heat radiator and a vibrator are arranged on the surface of the cyclone separator; blades of an impeller of the induced draft fan are radially arranged symmetrically about the radial direction and center of an impeller shaft, and dust can be timely cleaned by virtue of centrifugal force. According to the device, green and energy-saving smoking and roasting can be implemented; more importantly, an assembling and disassembling technology for the induced draft fan is greatly changed, so that the pressure of parts such as screw caps on the end surfaces of a screw shaft shoulder can be simply eliminated during disassembling, the problem of high disassembling difficulty caused by continuous automatic locking under the action of a load in case of threaded assembling of the induced draft fan is effectively solved, and the device is particularly suitable for convenient disassembling of a large-sized fan after threaded locking, and has particularly remarkable effects.

Owner:JISHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com