A convenient quick-release hammer crushing system with silo and dust removal device

A dust removal device and hammer crushing technology, applied in the field of ore crushing and pulverization, can solve the problems of inconvenient disassembly, large dust, environmental impact, etc., and achieve the effects of quick and convenient disassembly, enhanced bearing capacity, and elimination of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

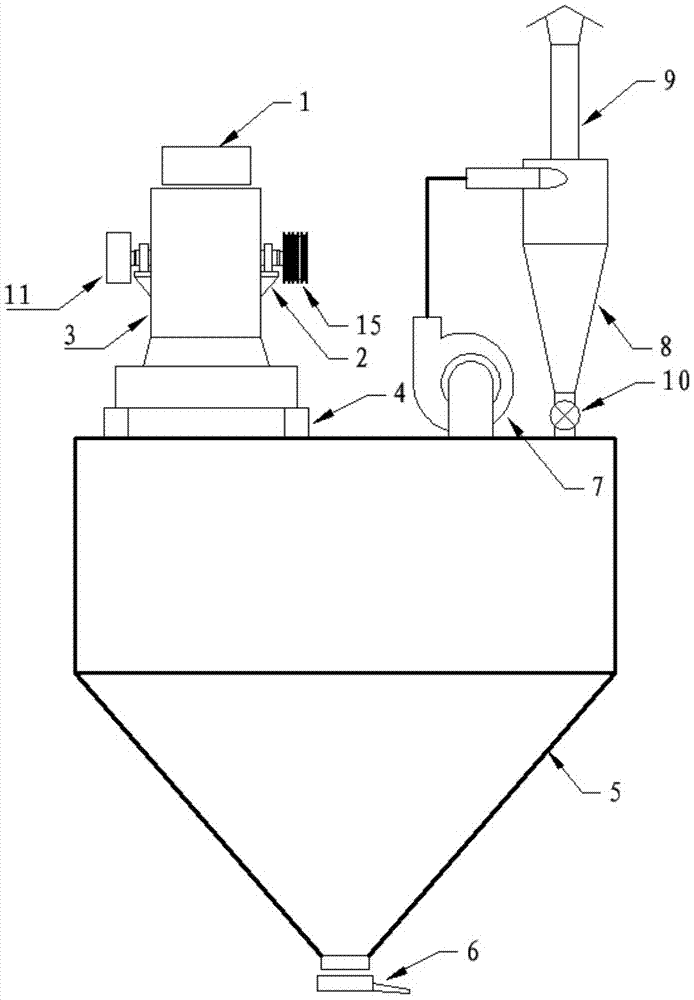

[0030] Such as Figure 1~2 As shown, a convenient quick-release hammer crushing system with a silo and a dust removal device includes a convenient quick-release hammer crusher, a hopper 5 arranged at the bottom of the convenient quick-release hammer crusher, and a dust removal device.

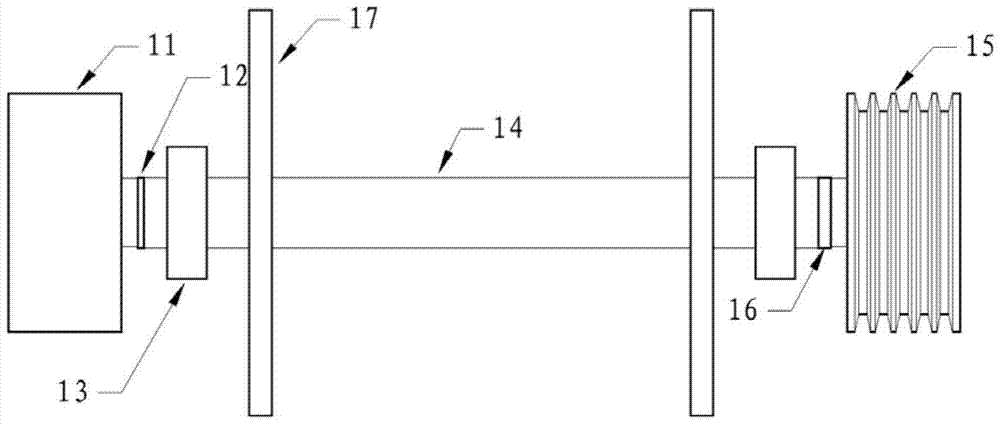

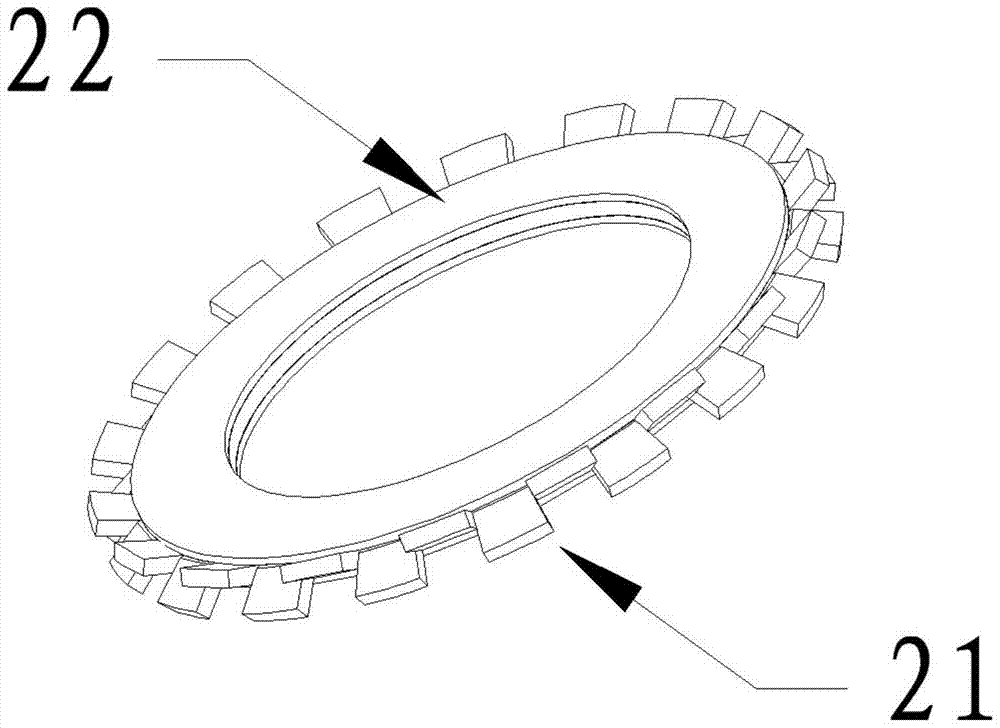

[0031] The convenient quick-release hammer crusher includes a feed port 1, a shock absorber 4, a body 3, and a flywheel 11 and a pulley 15 threadedly assembled with the hammer shaft 14 of the body 3, respectively. A copper-plastic composite pad 12 is provided between the flywheel 11 and the hammer shaft 14 , and a clamp assembly 16 is provided between the pulley 15 and the hammer shaft 14 . Wherein, hammer disc shaft 14 and flywheel 11 adopt counter-rotating thread to cooperate, and belt pulley 15 adopts positive-rotating thread to assemble.

[0032] The use of such pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com