Patents

Literature

37results about How to "High extrusion rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot air type penetration reverse flow fluidization drying machine with tail heat utilization and inertial dust collecting functions

InactiveCN105783478AStrong extrusion rigidityEliminate fatigue fractureDrying solid materials with heatDrying gas arrangementsImpellerCyclone

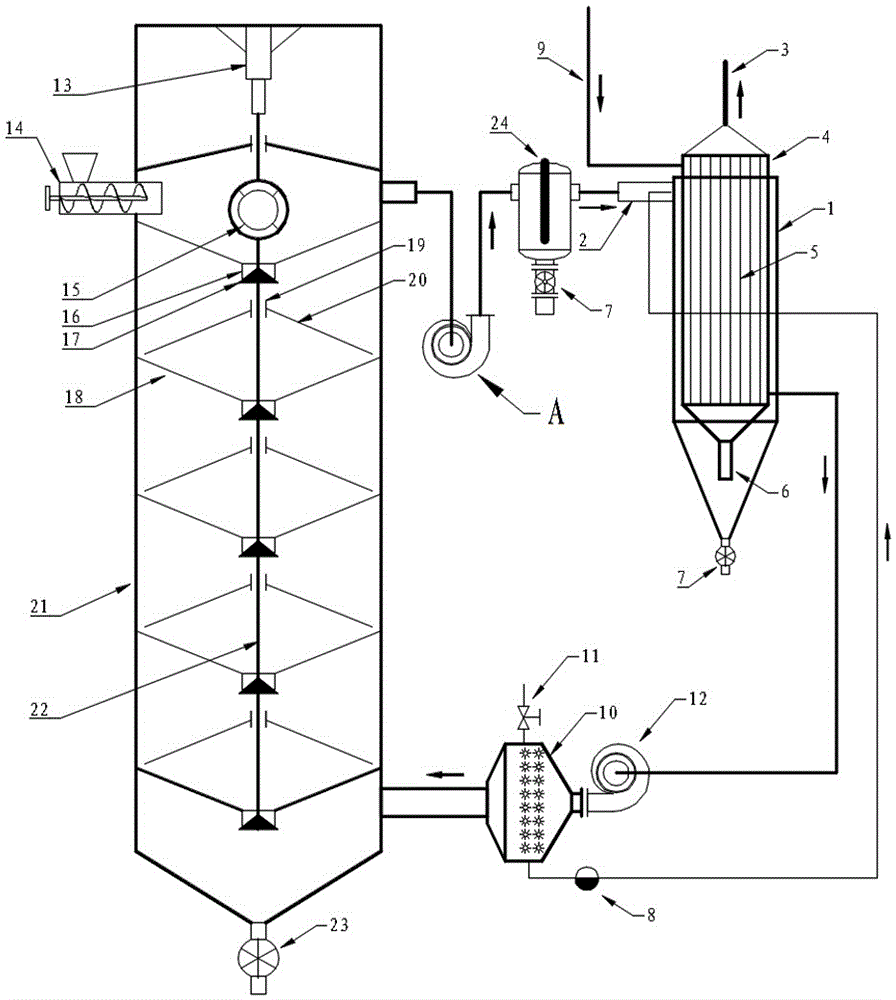

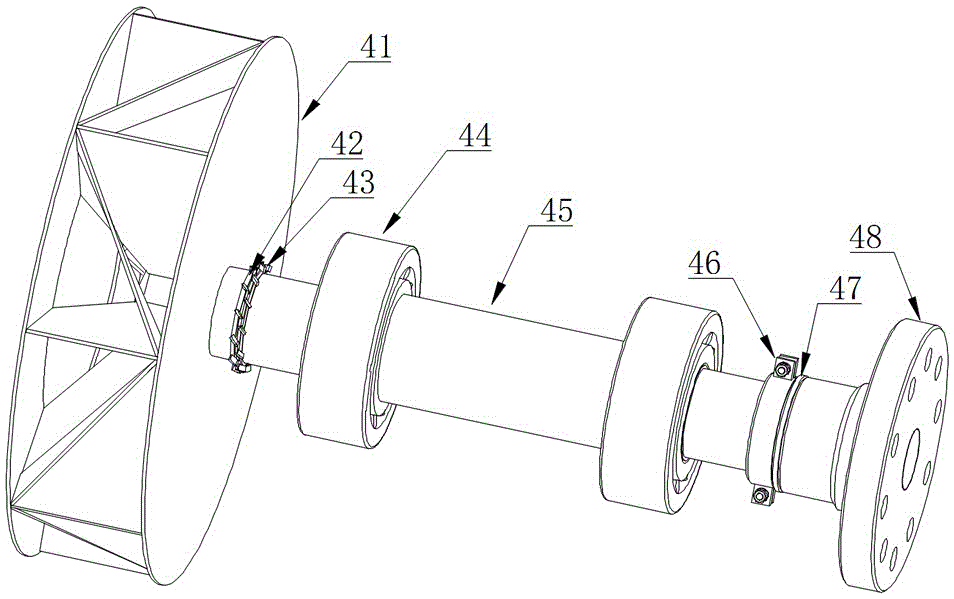

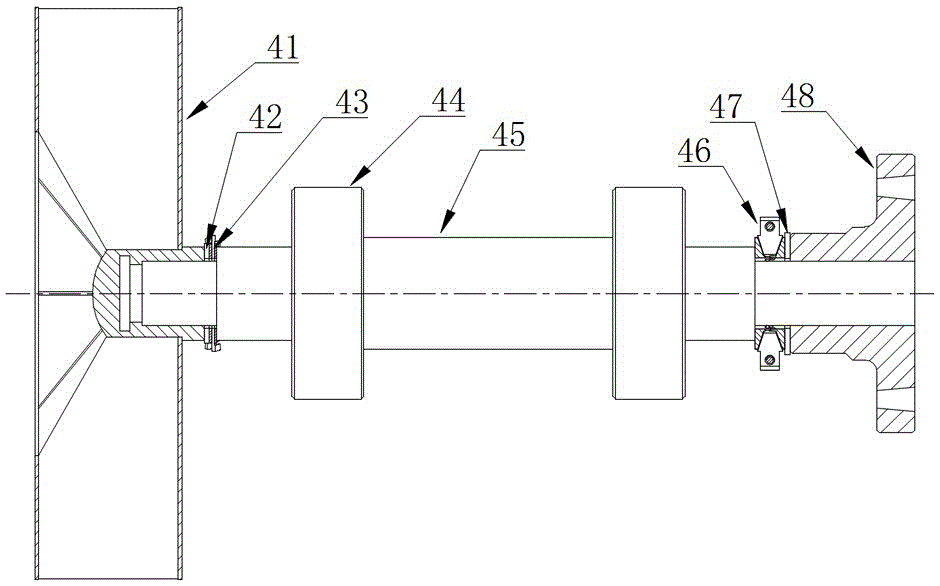

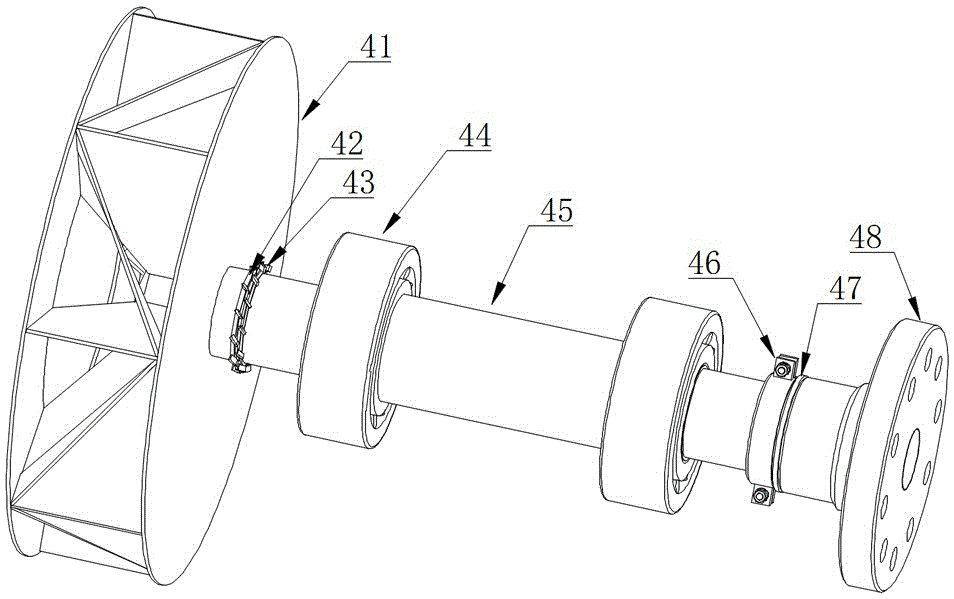

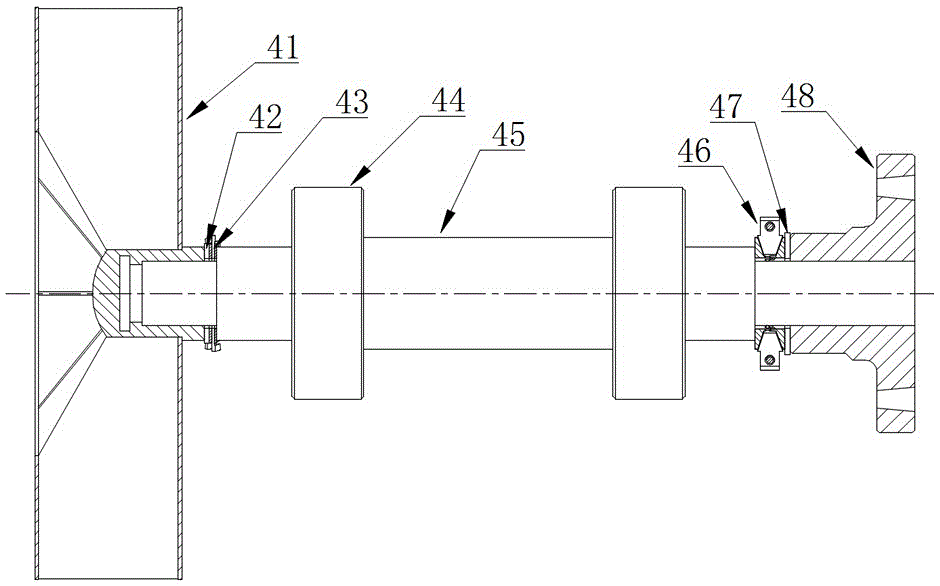

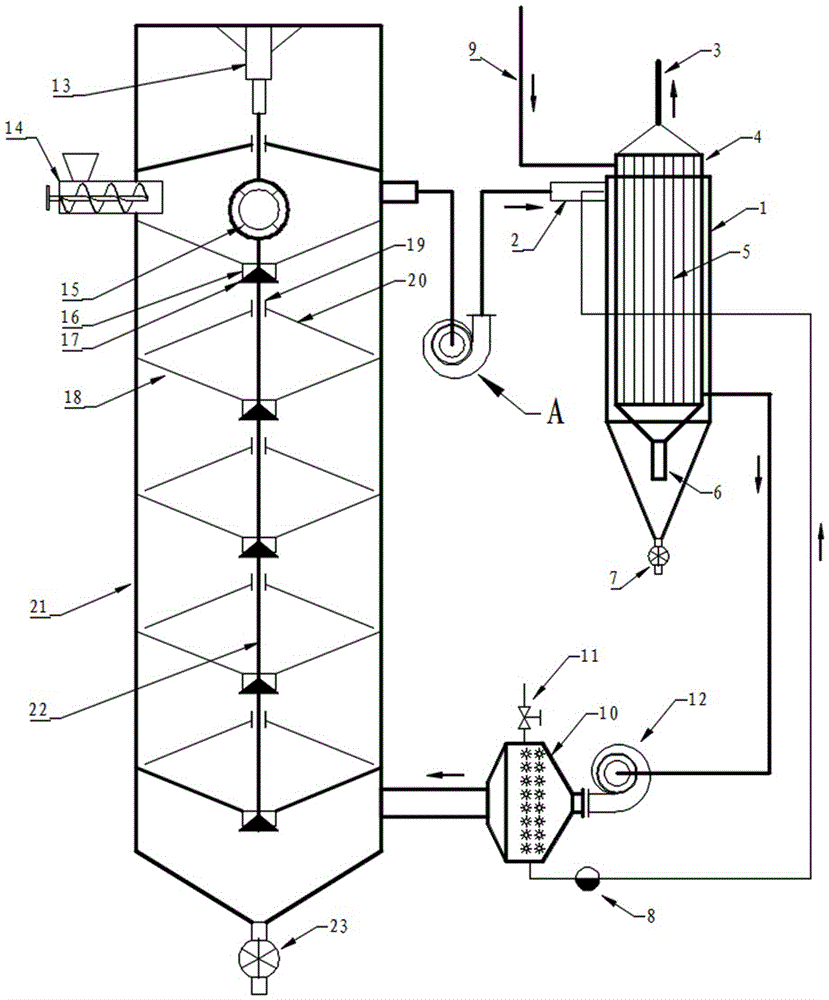

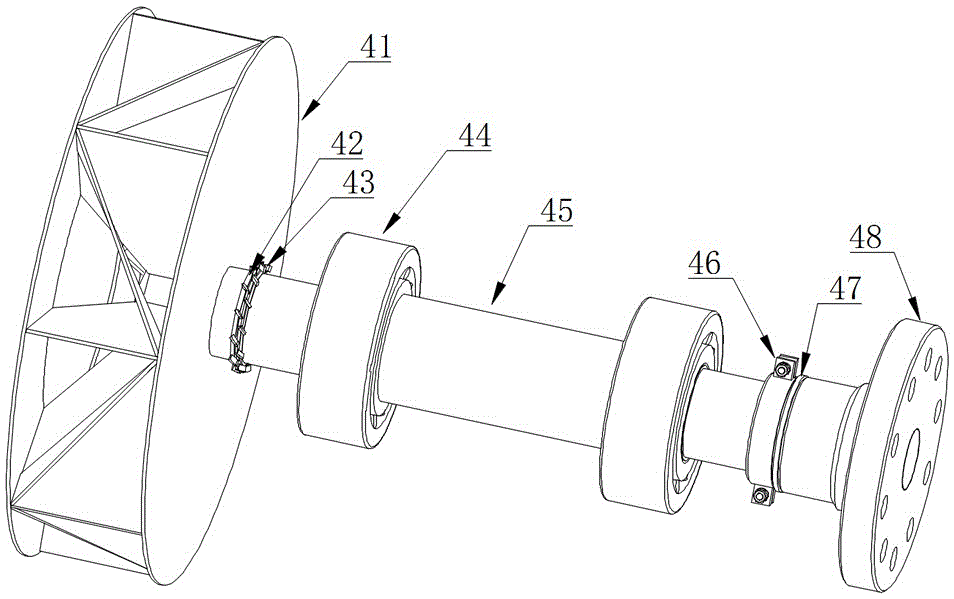

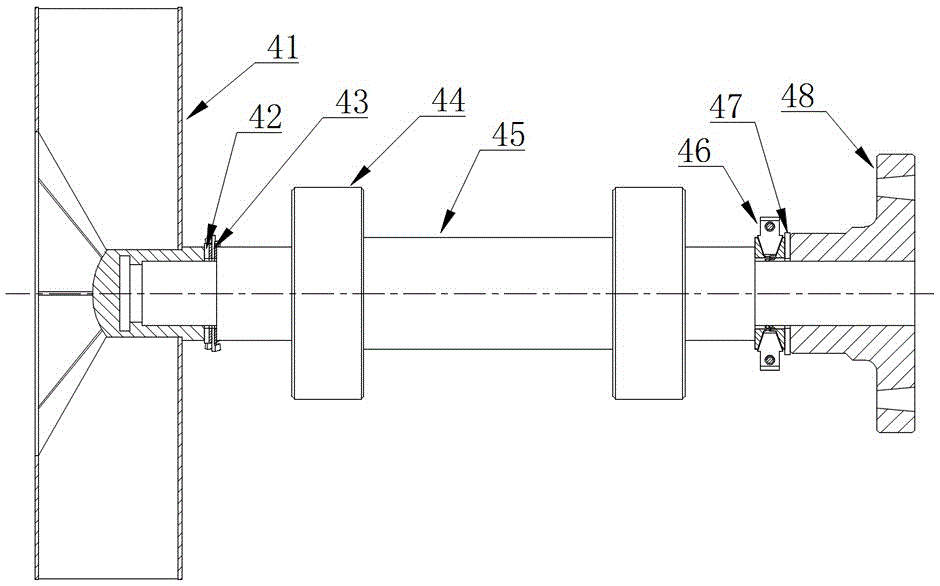

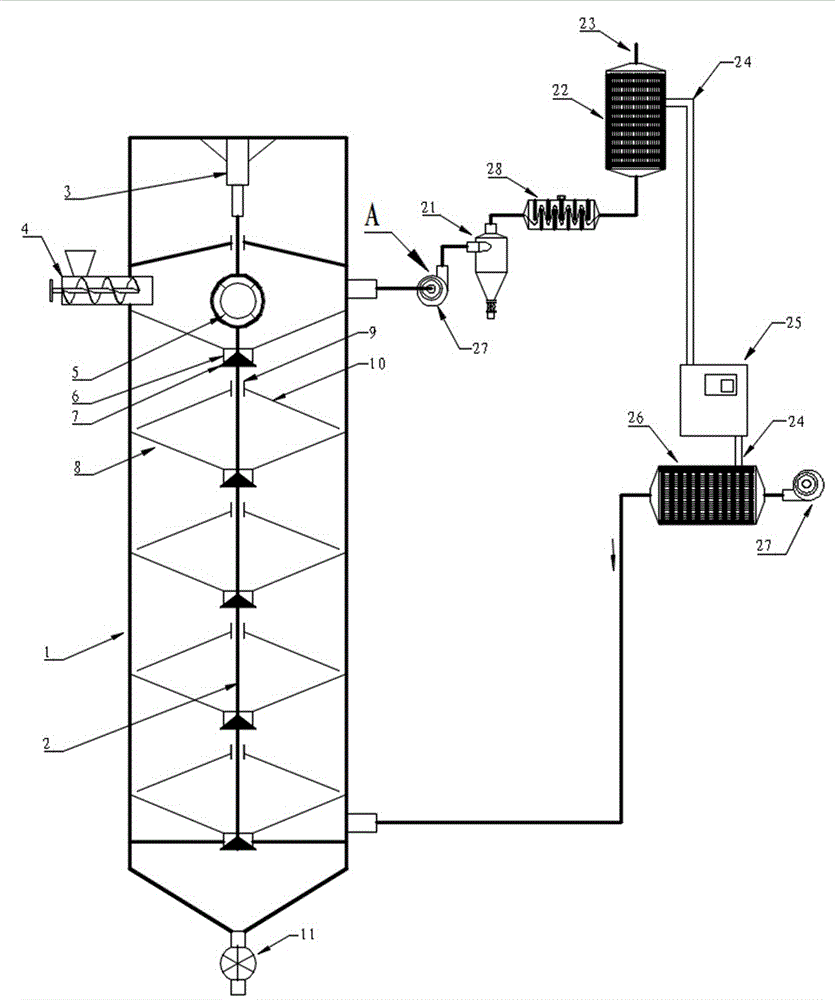

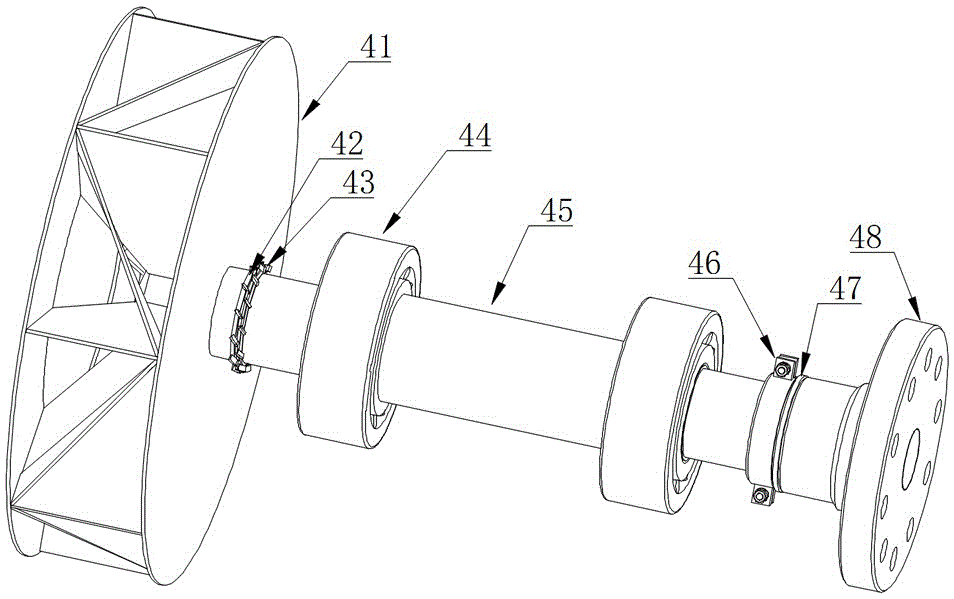

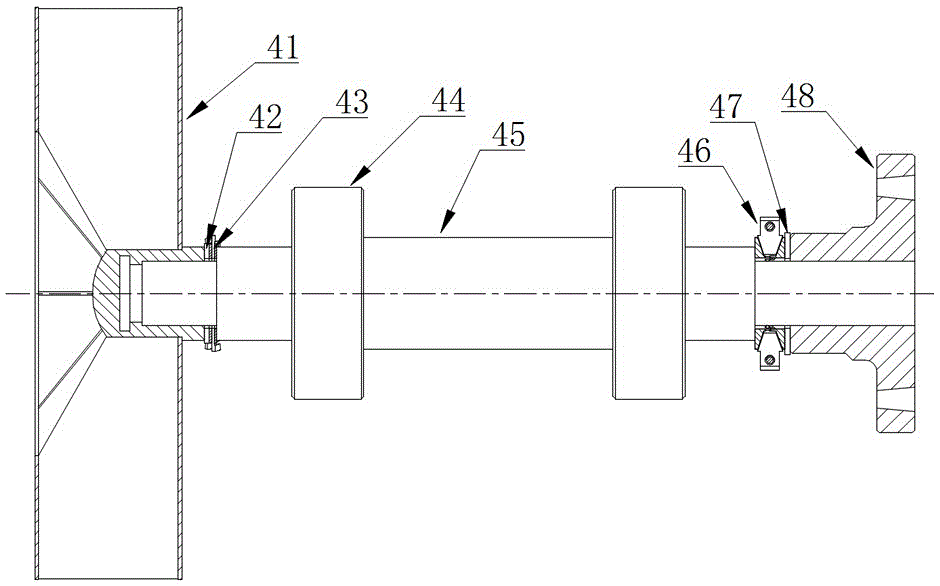

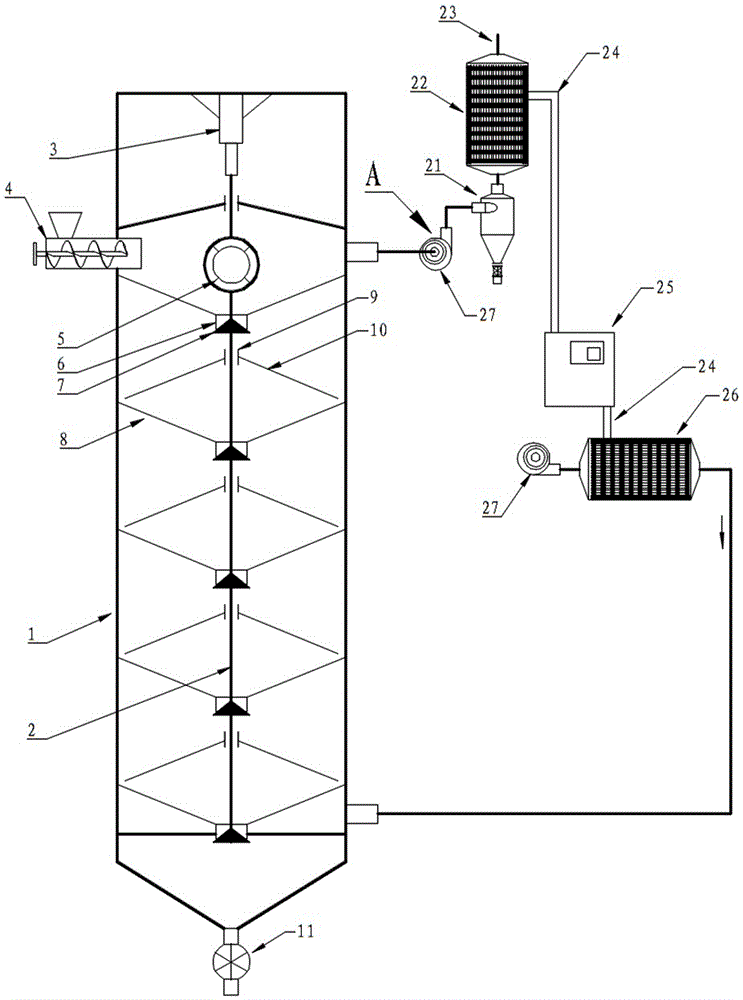

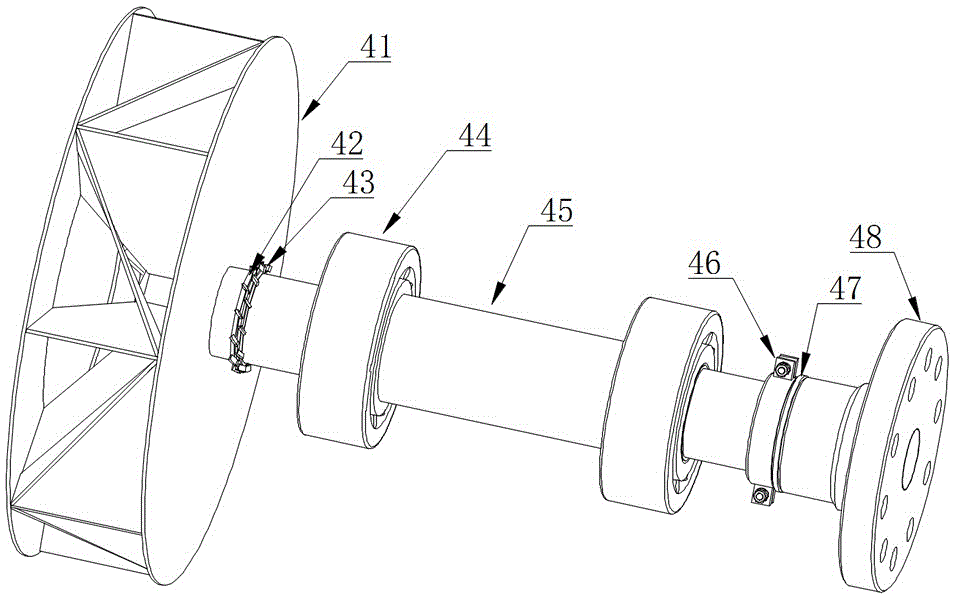

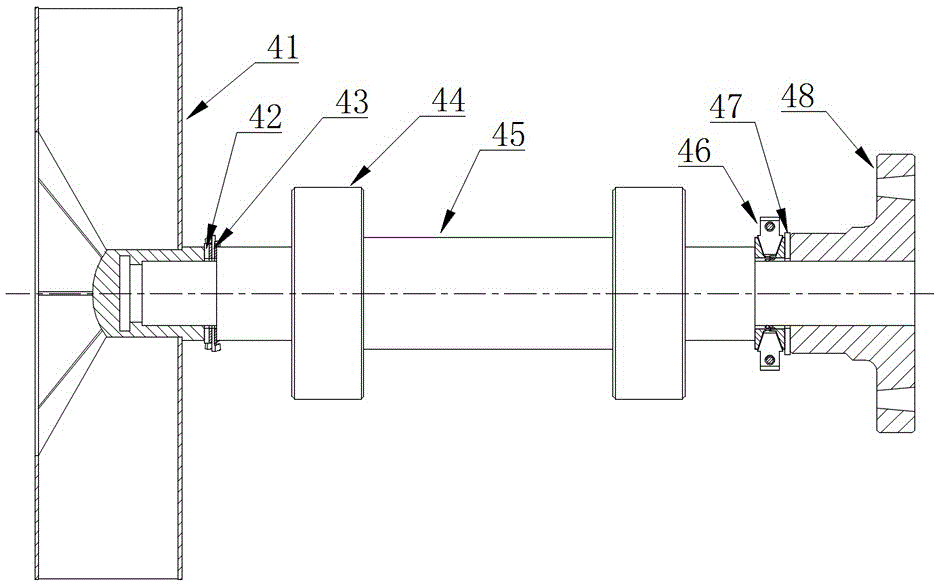

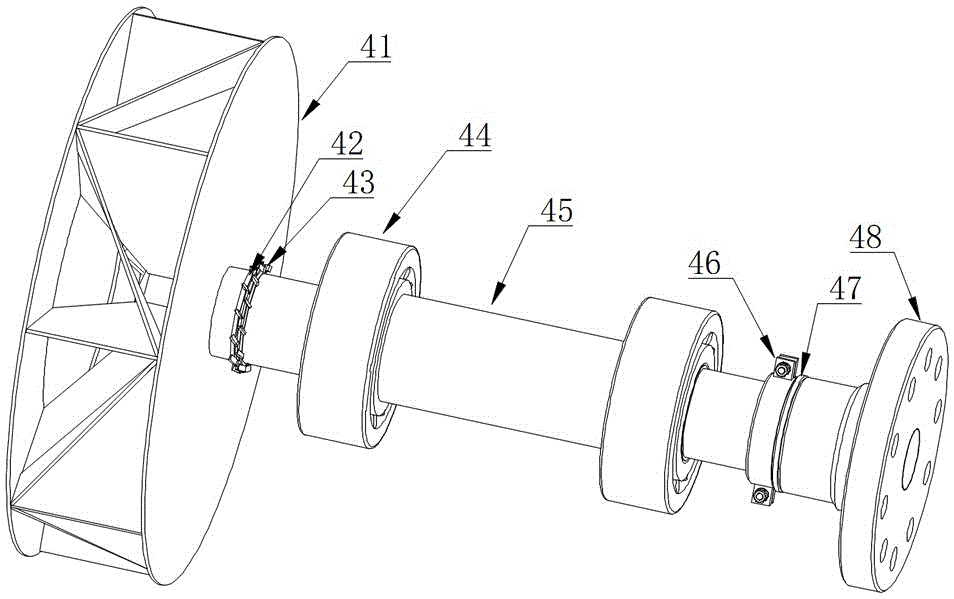

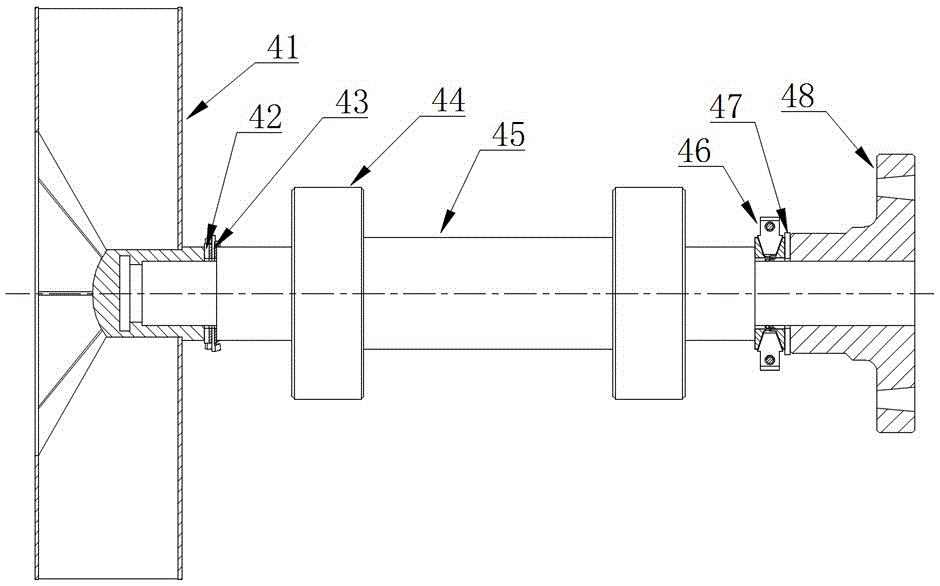

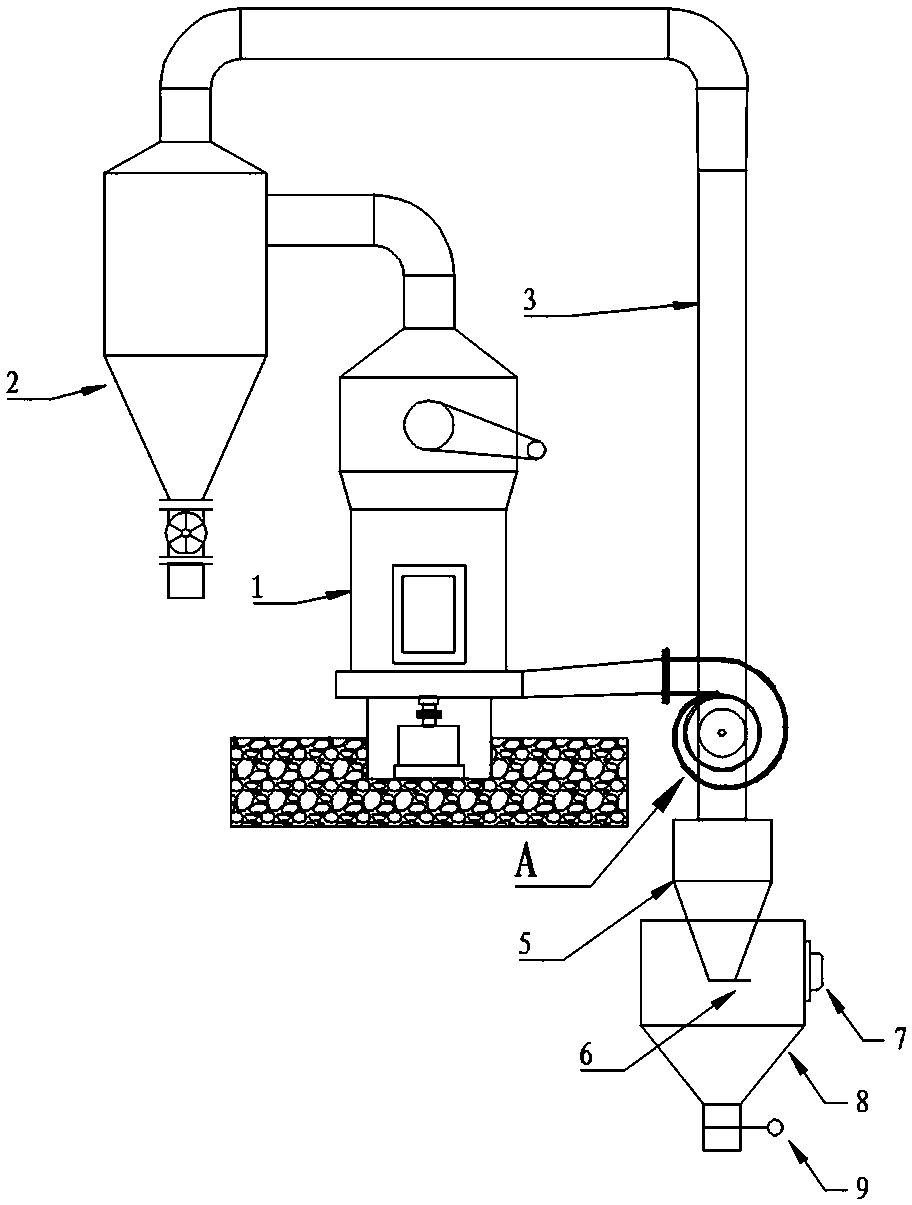

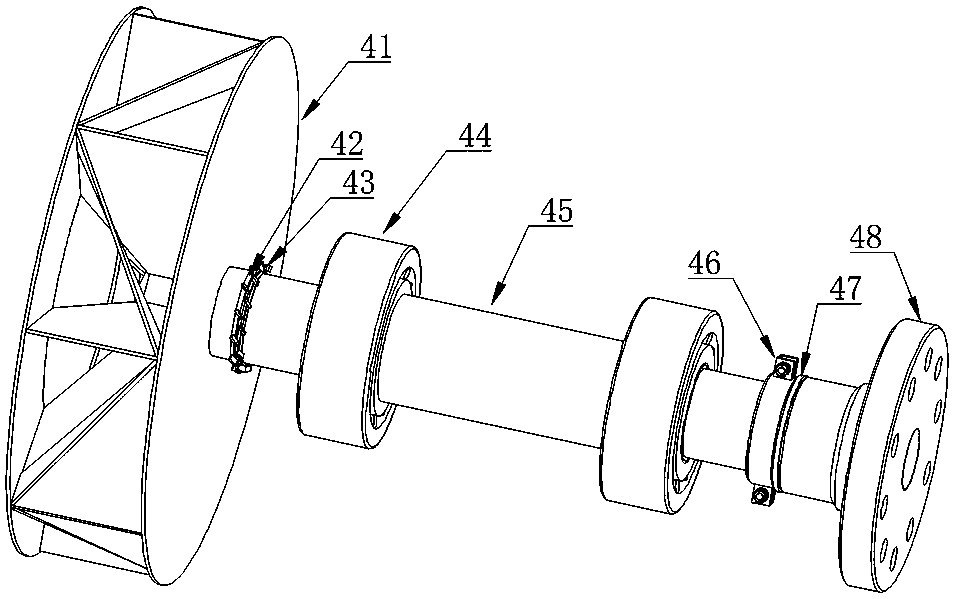

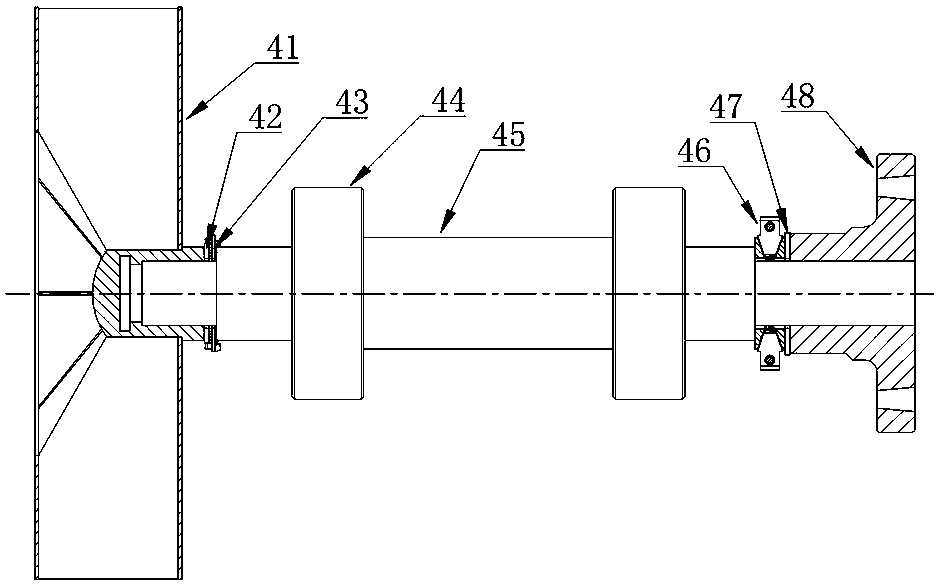

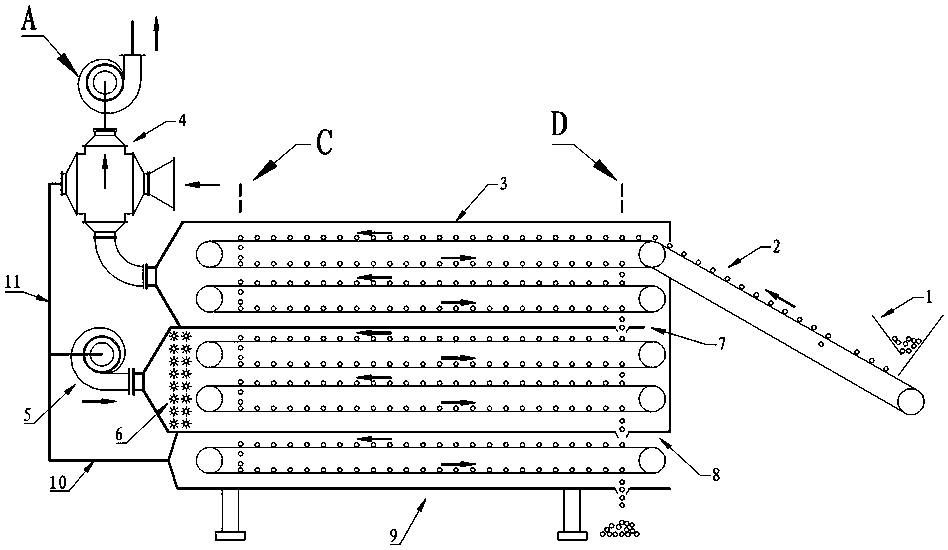

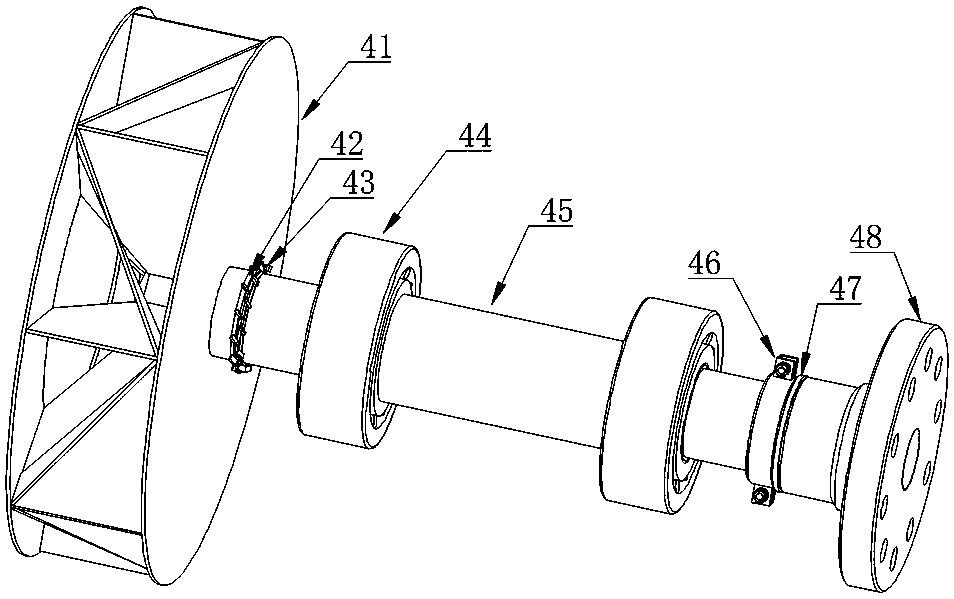

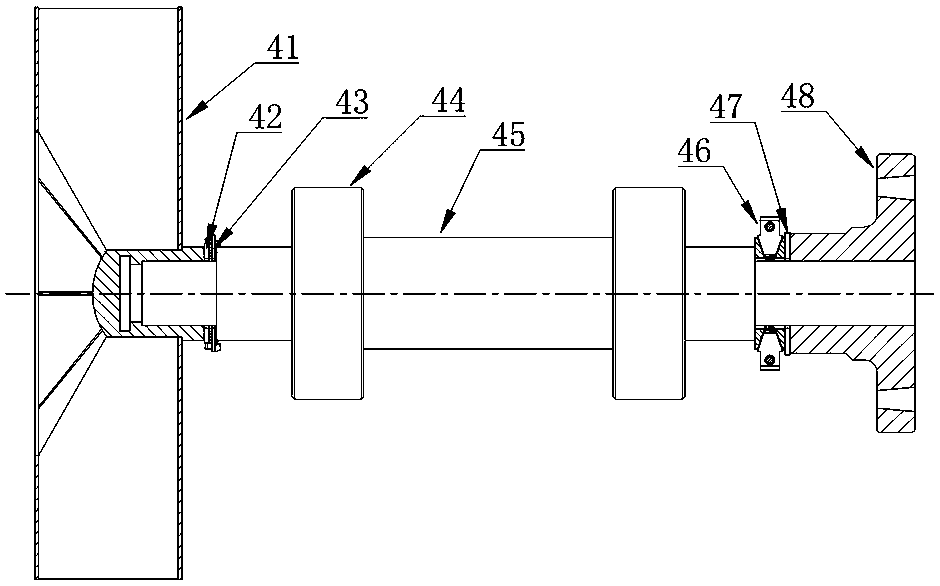

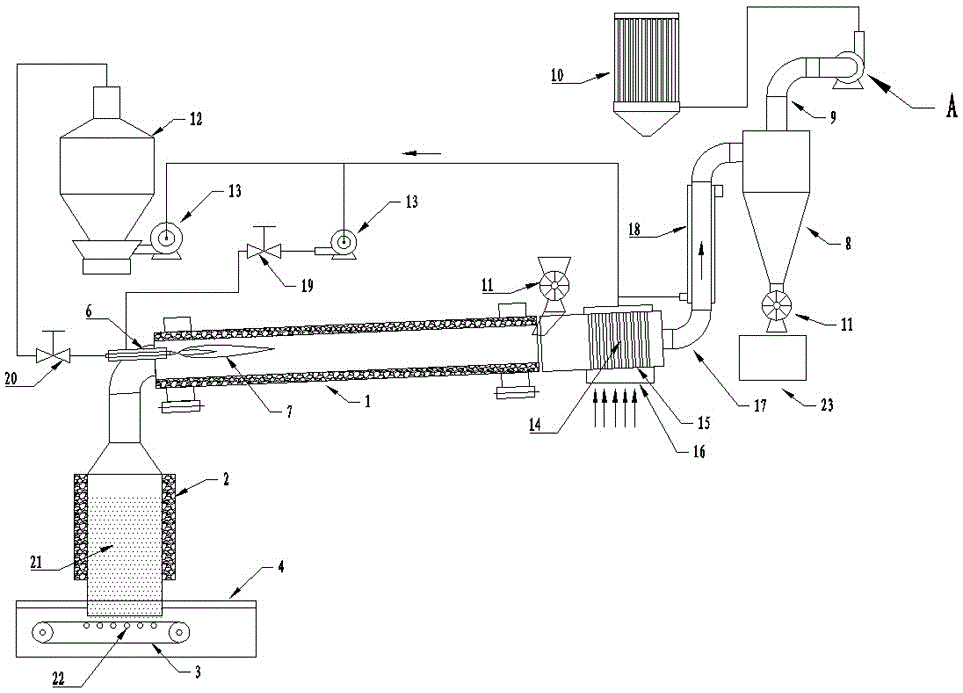

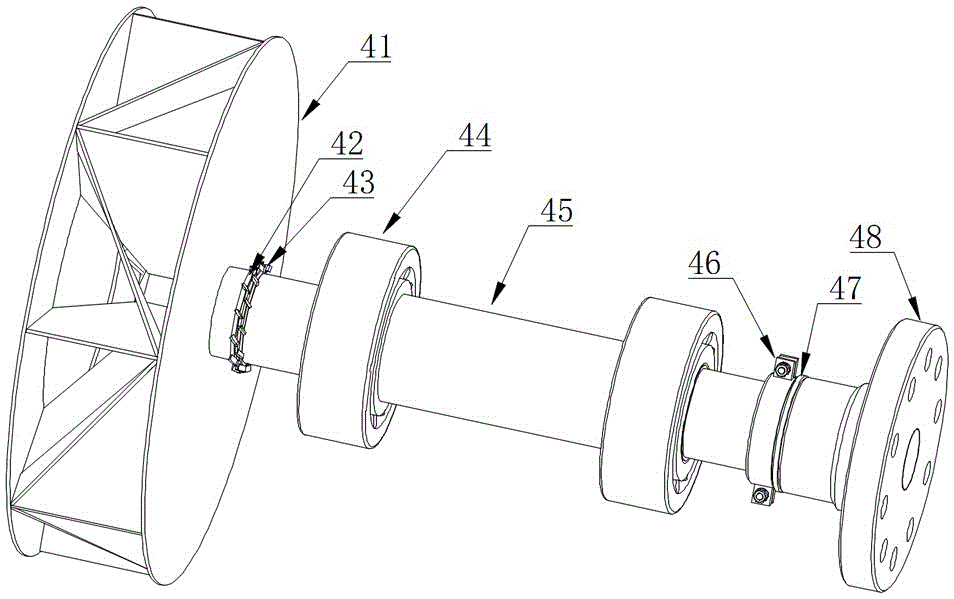

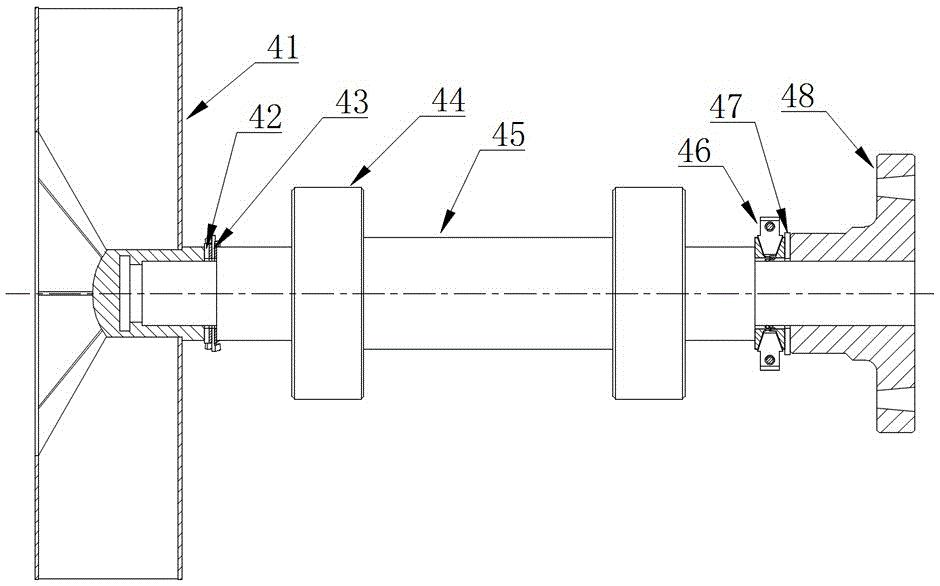

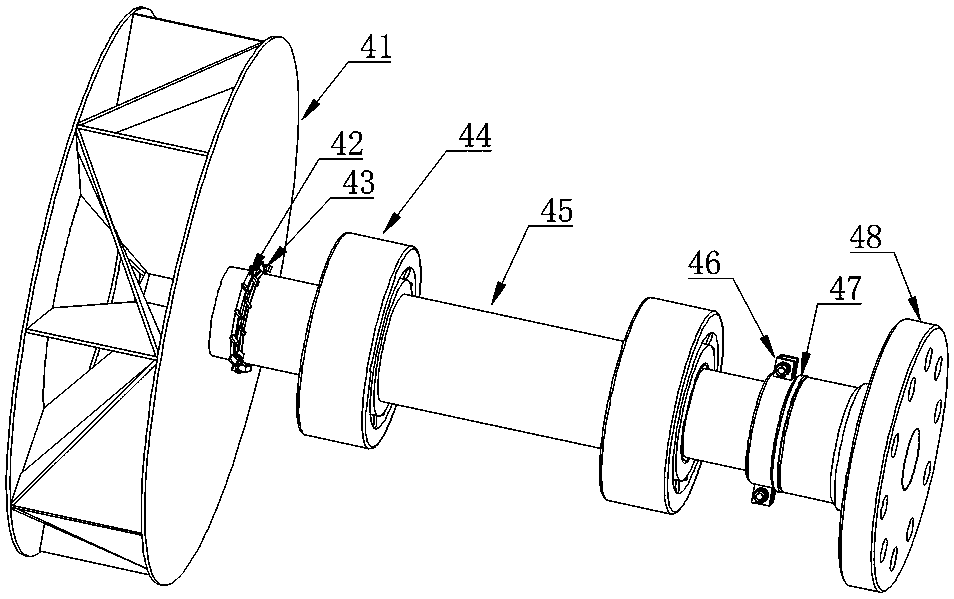

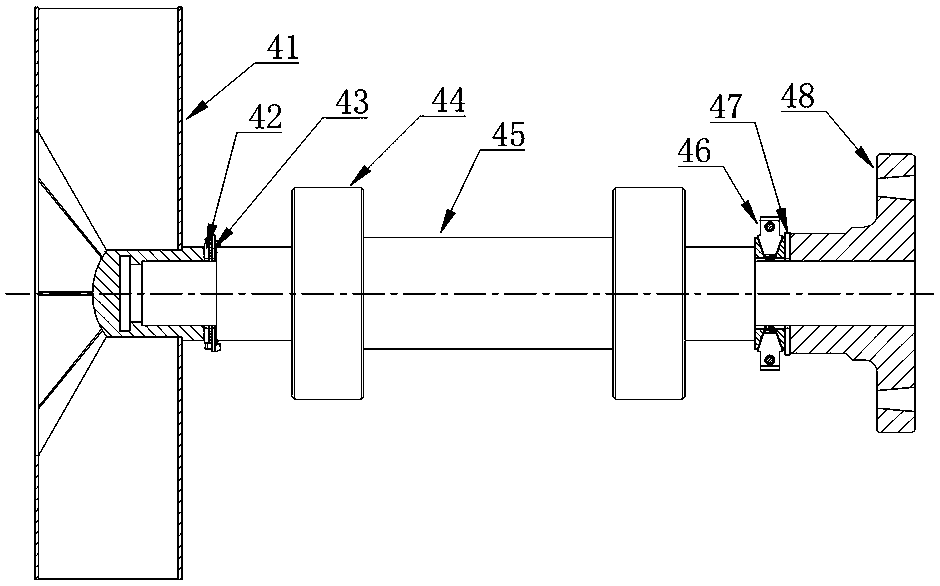

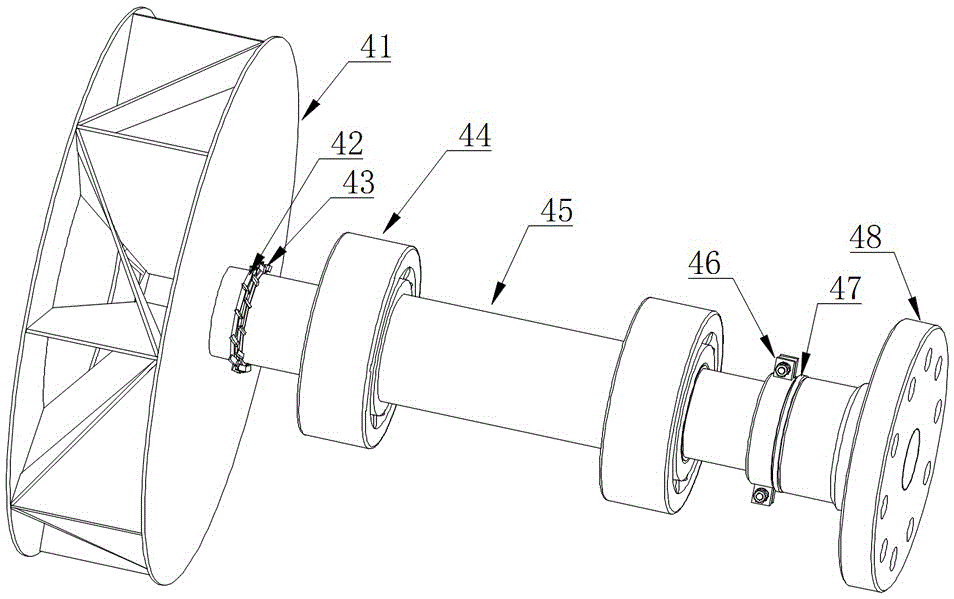

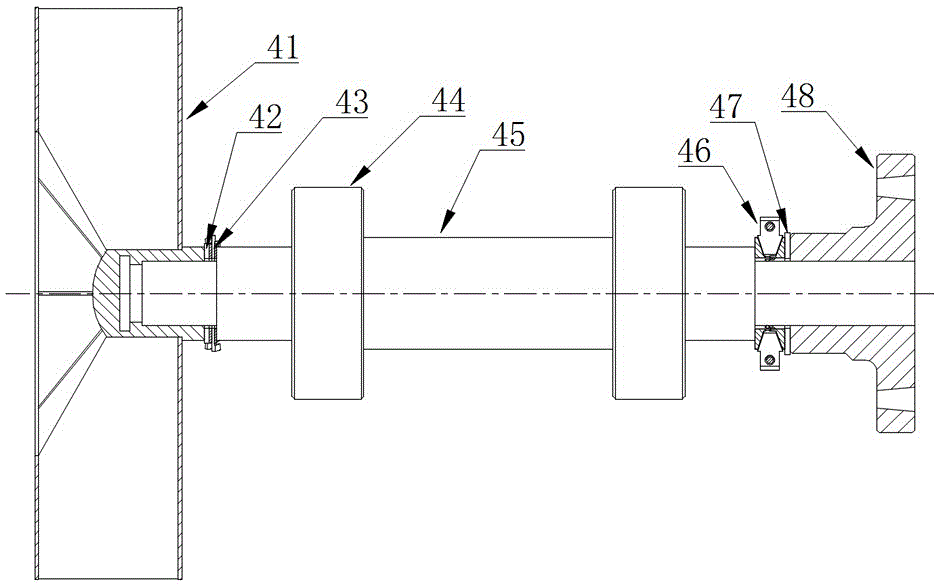

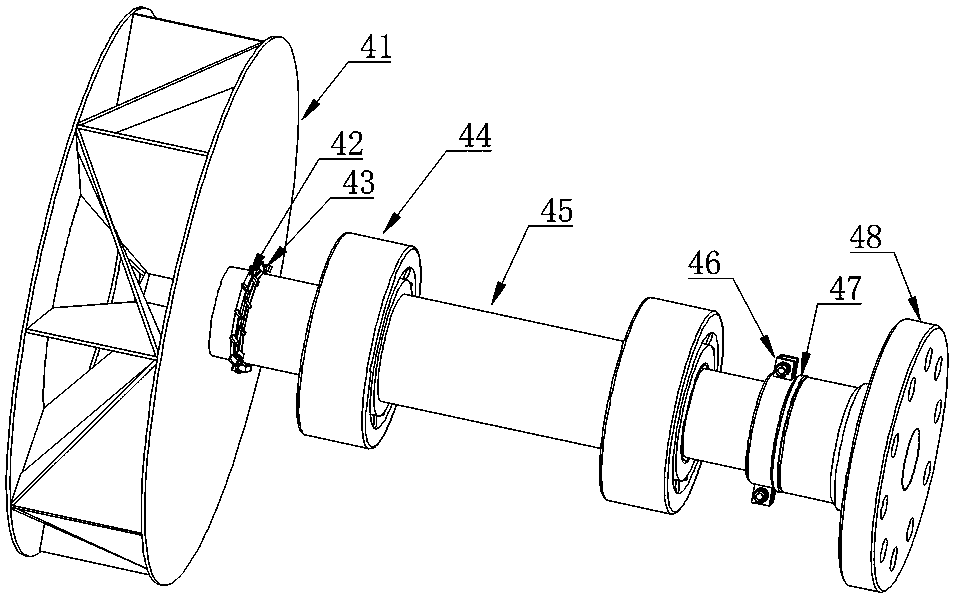

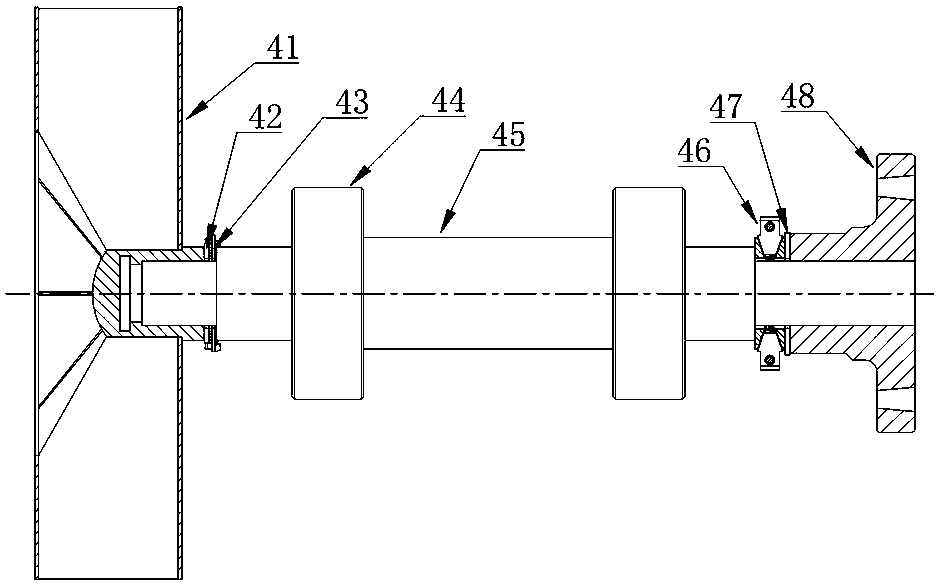

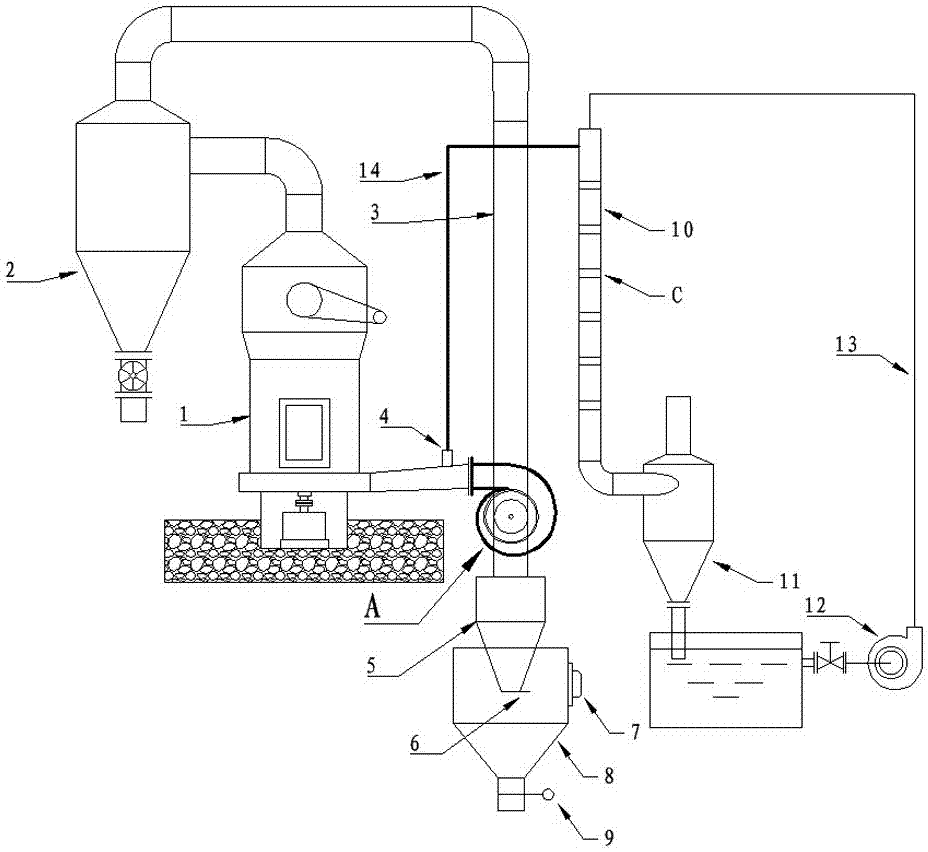

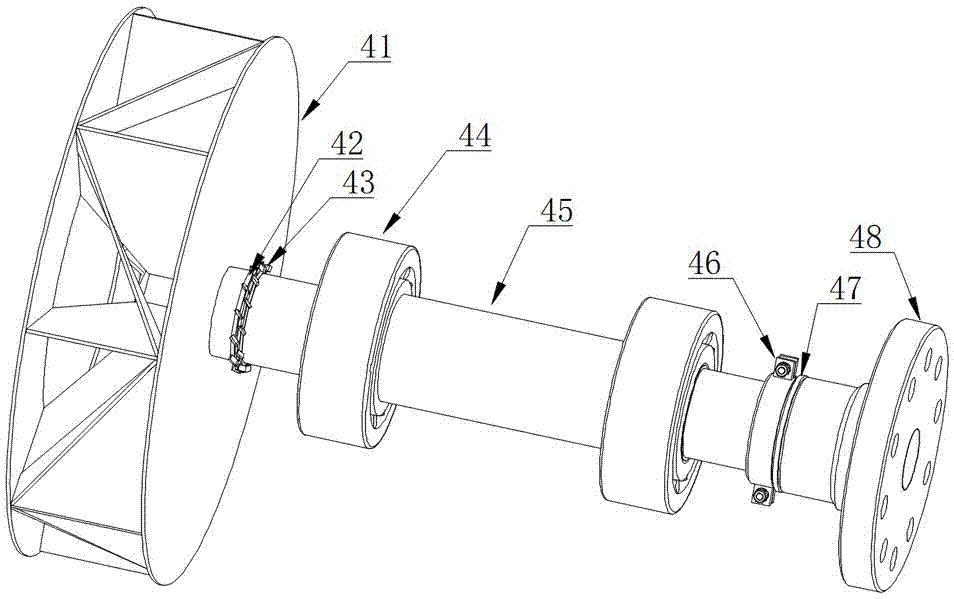

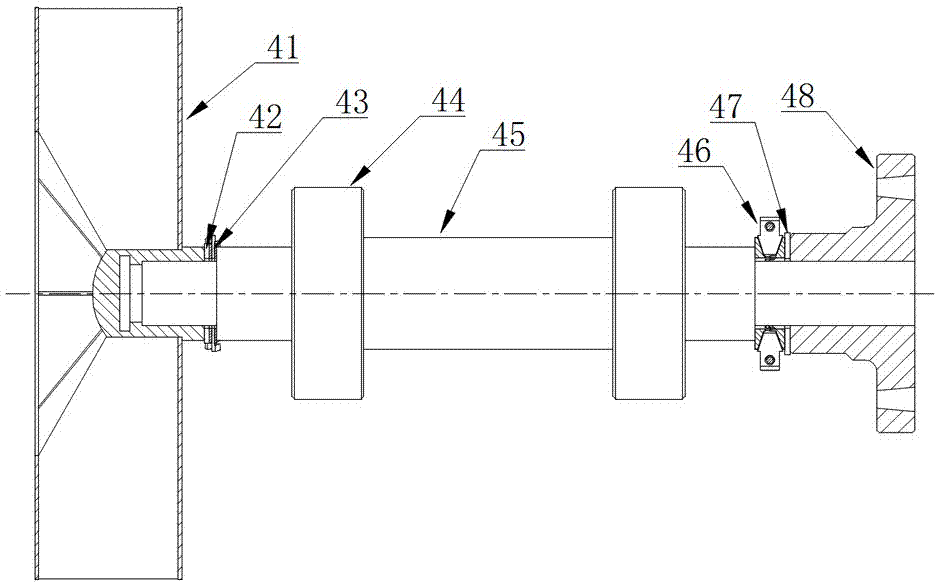

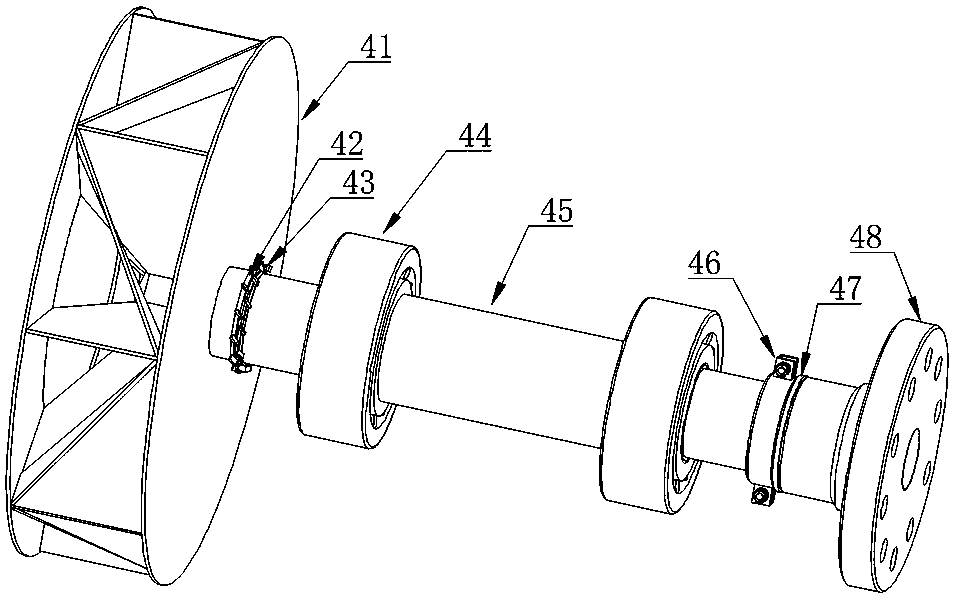

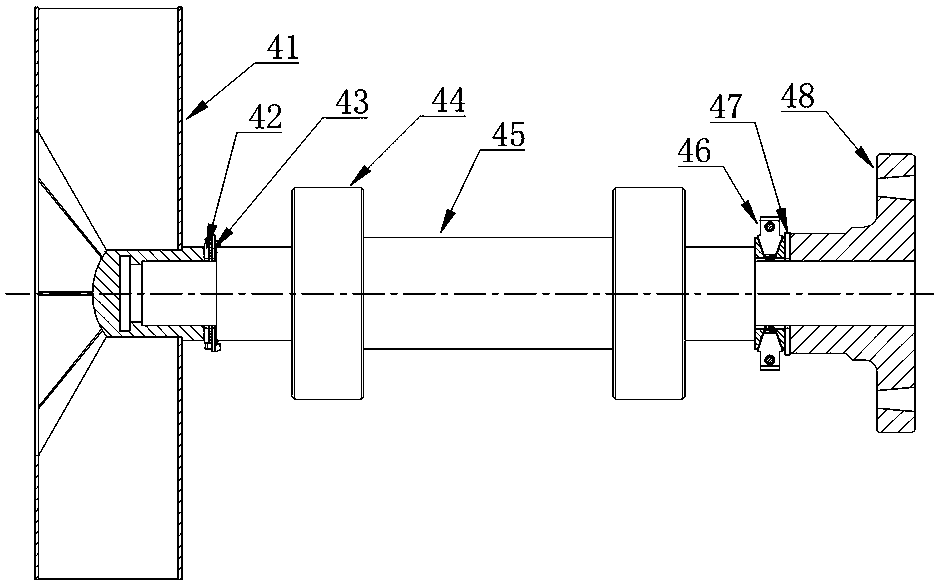

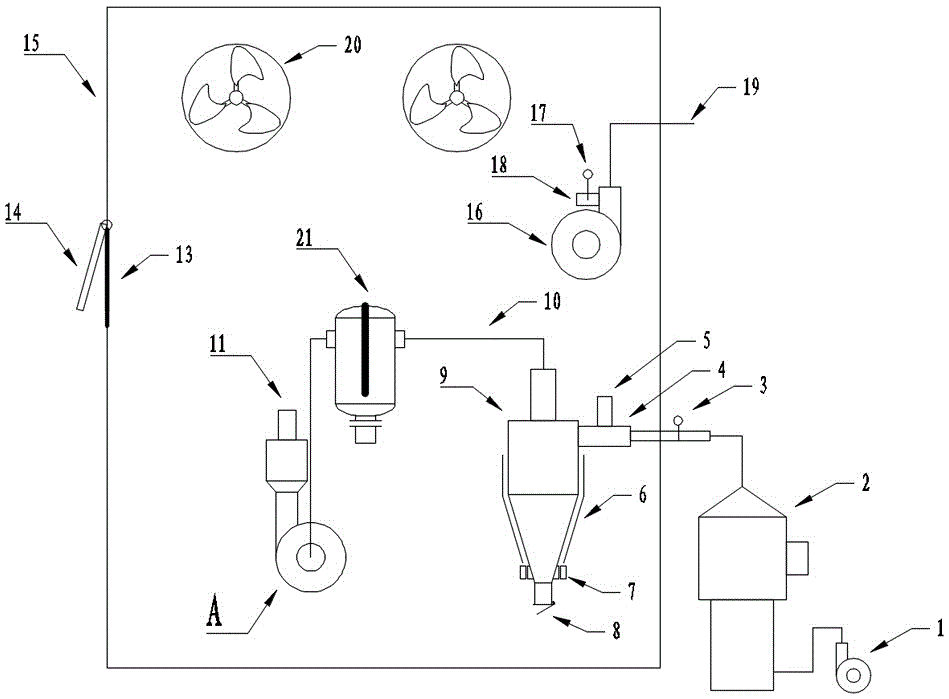

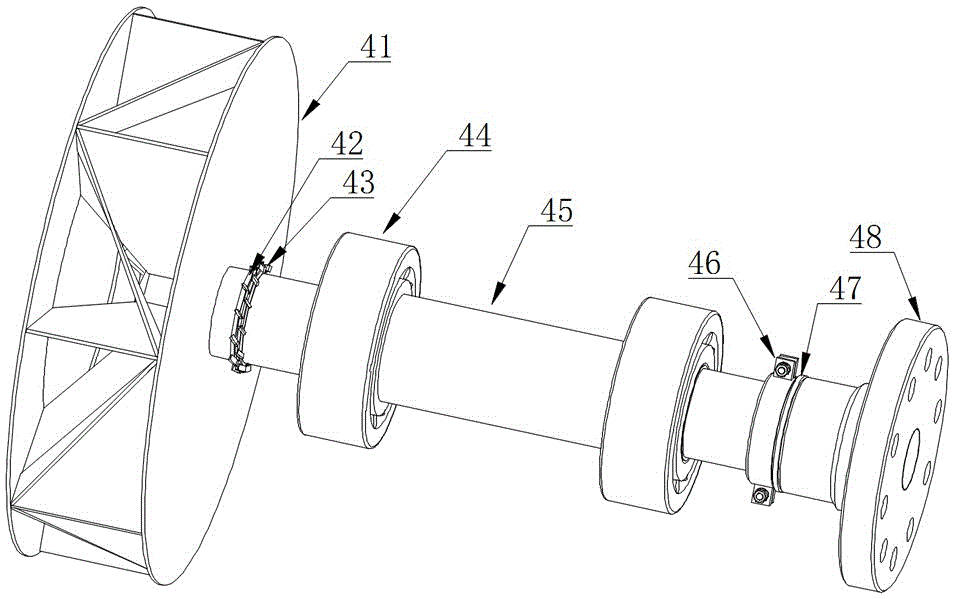

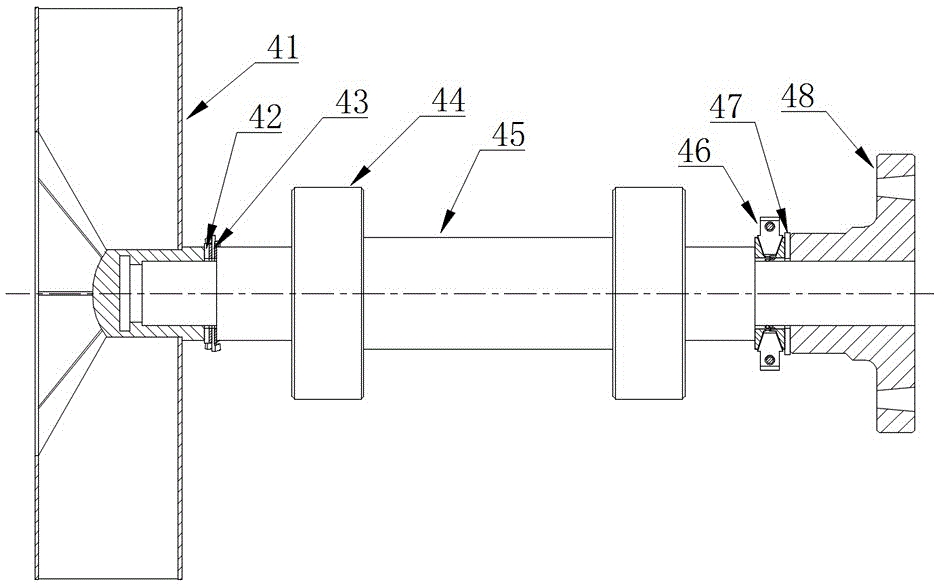

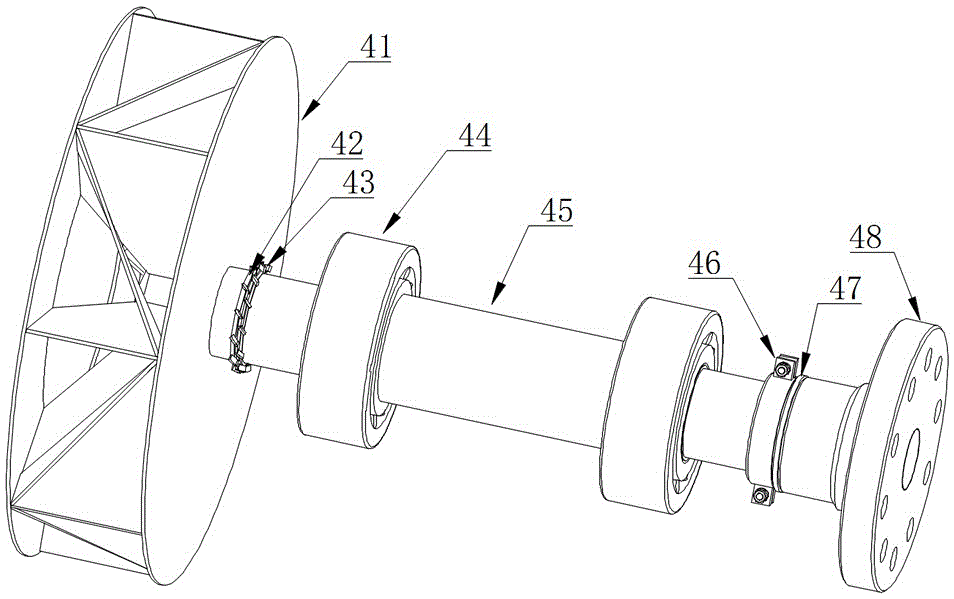

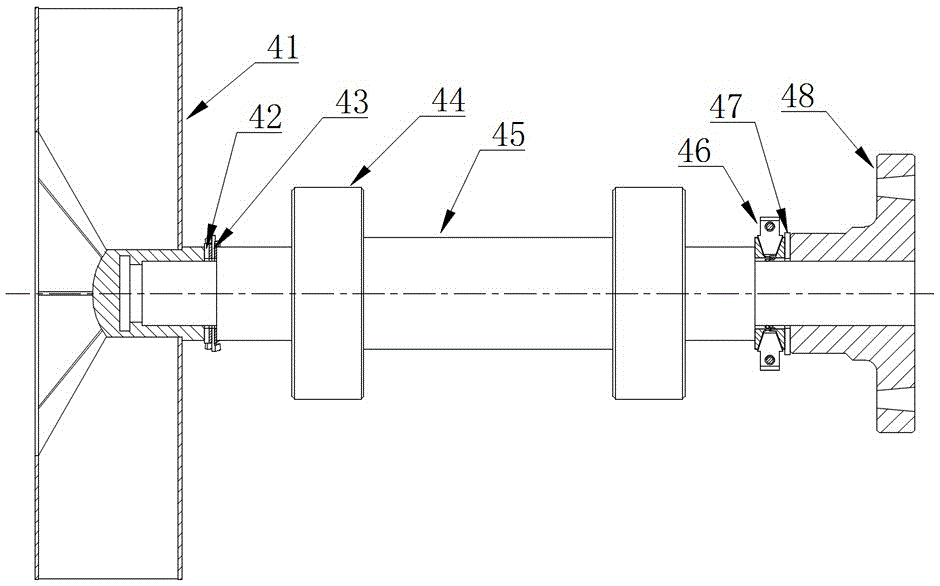

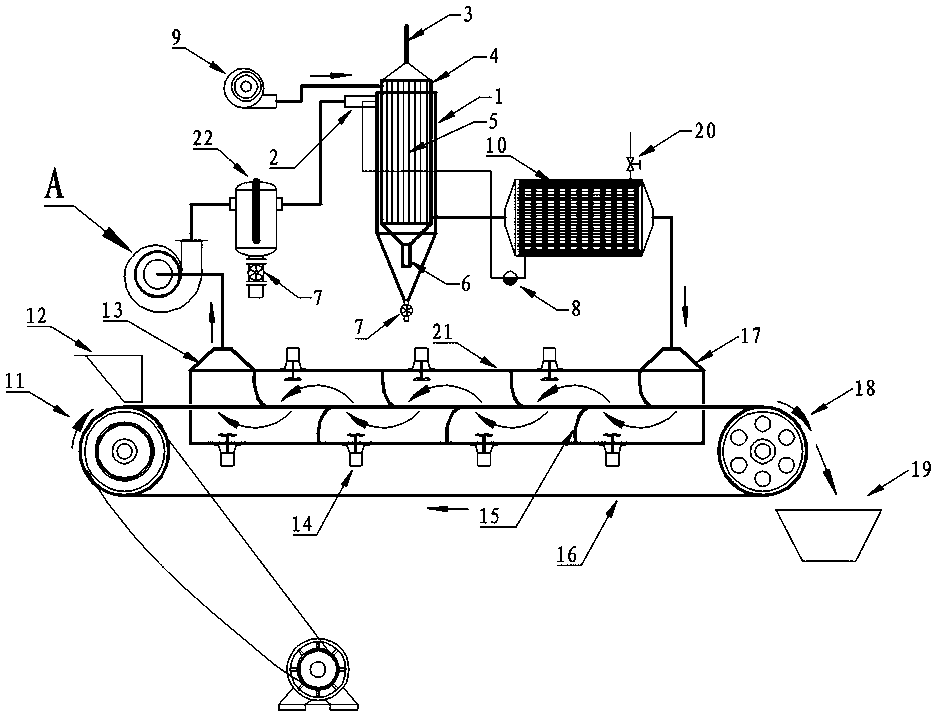

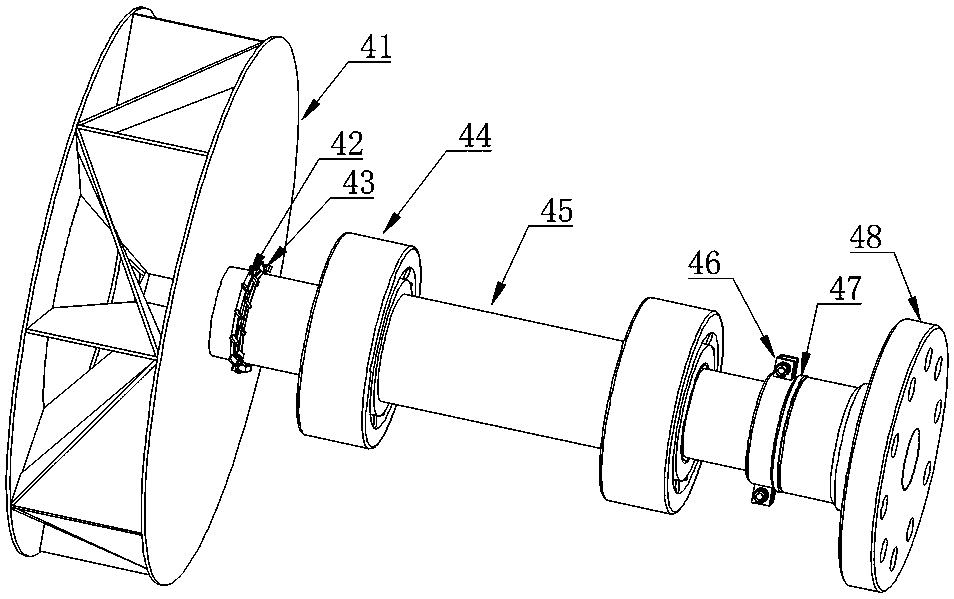

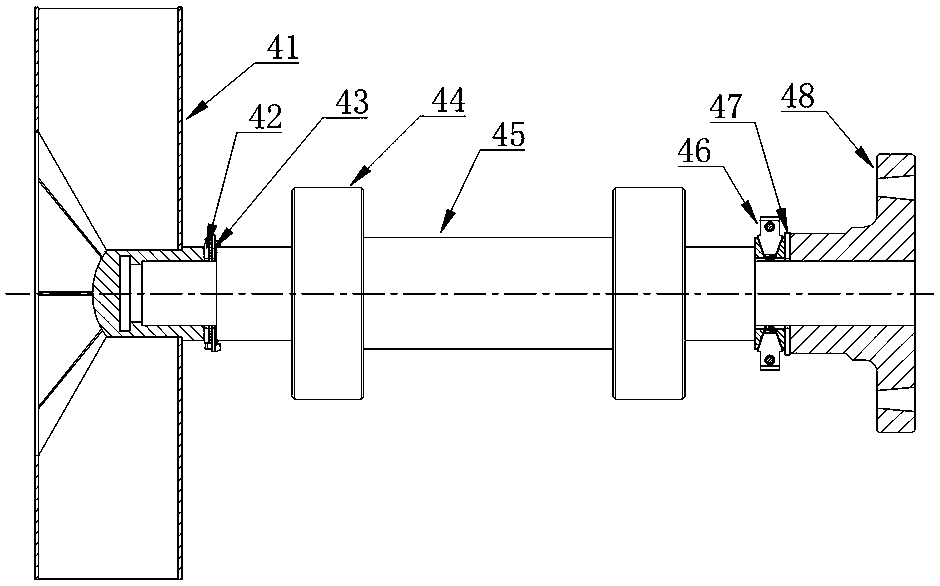

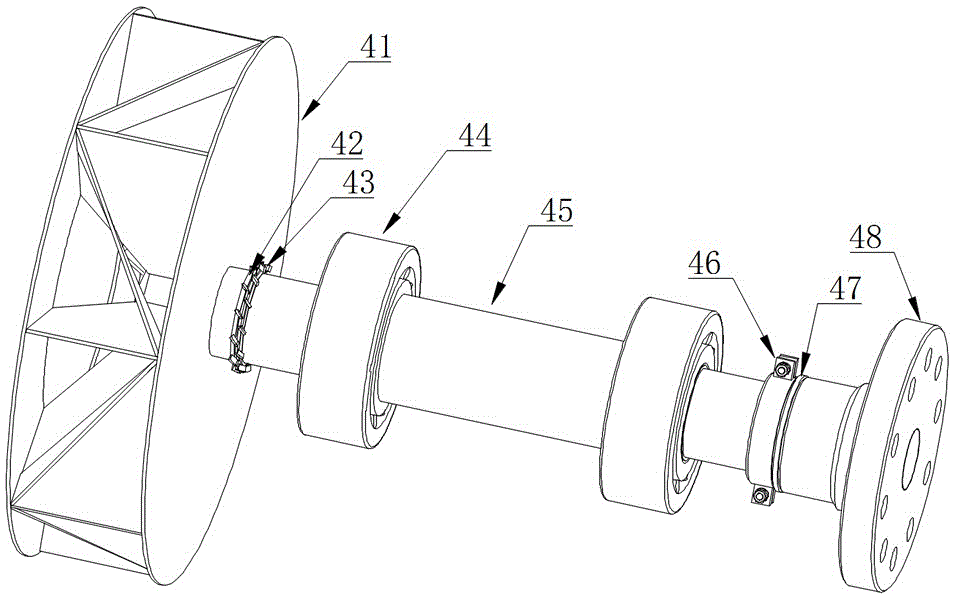

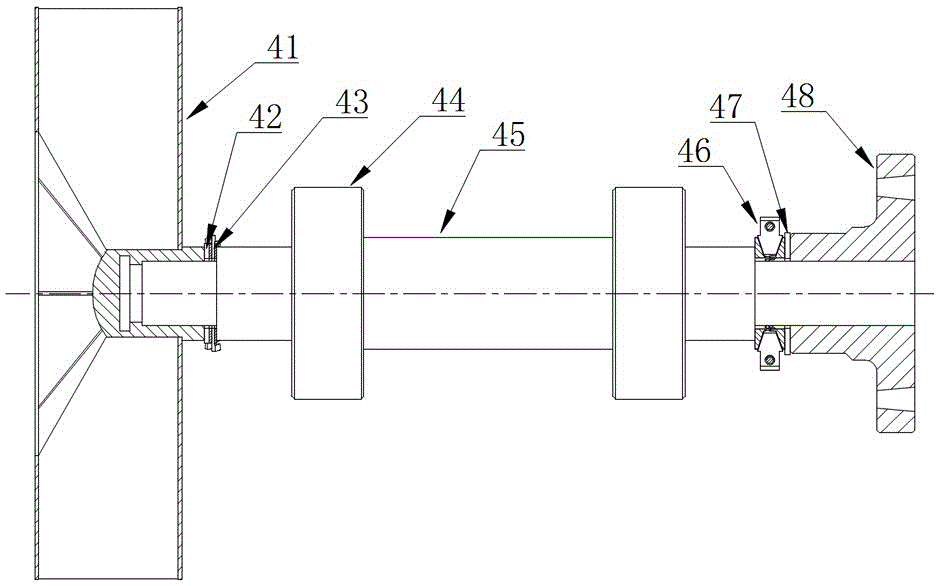

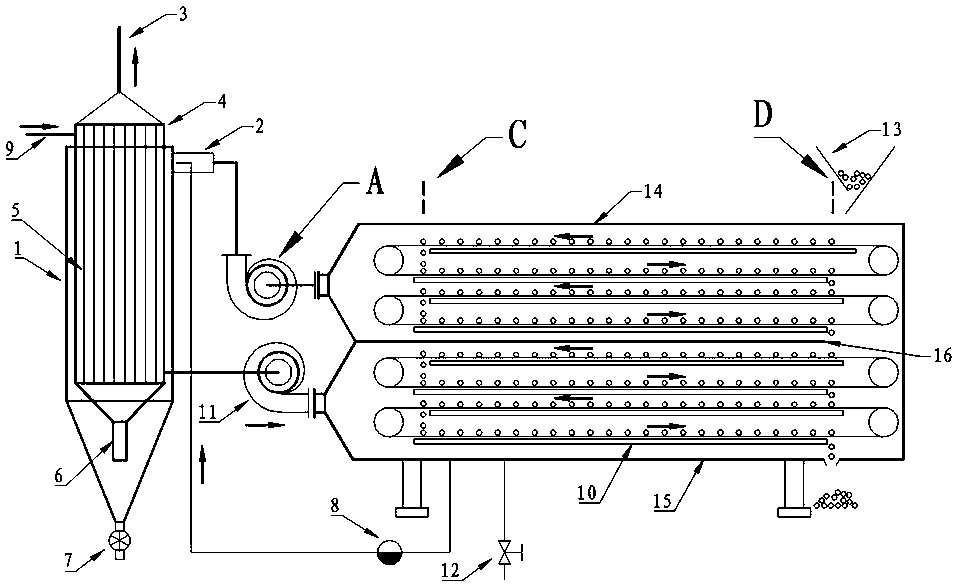

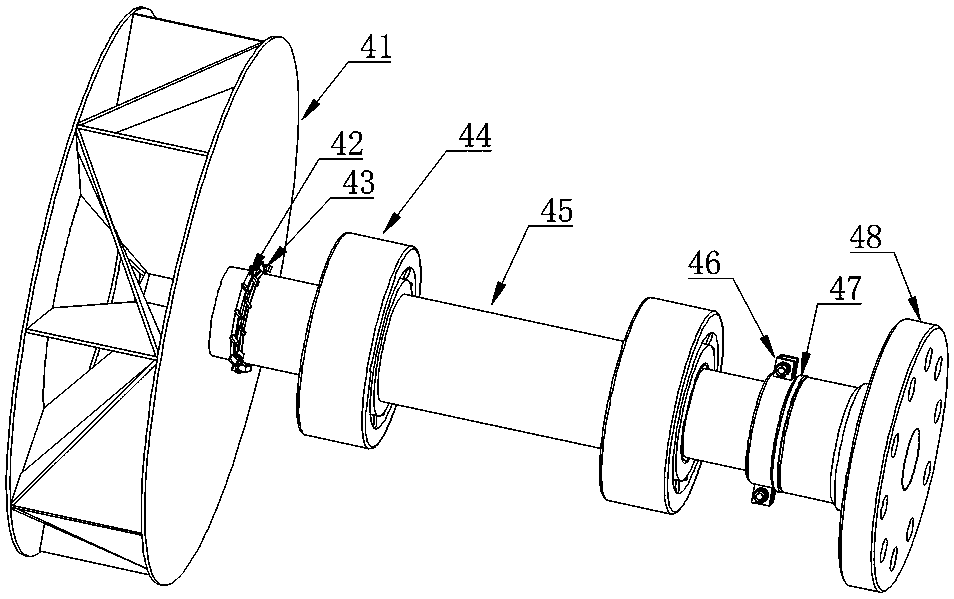

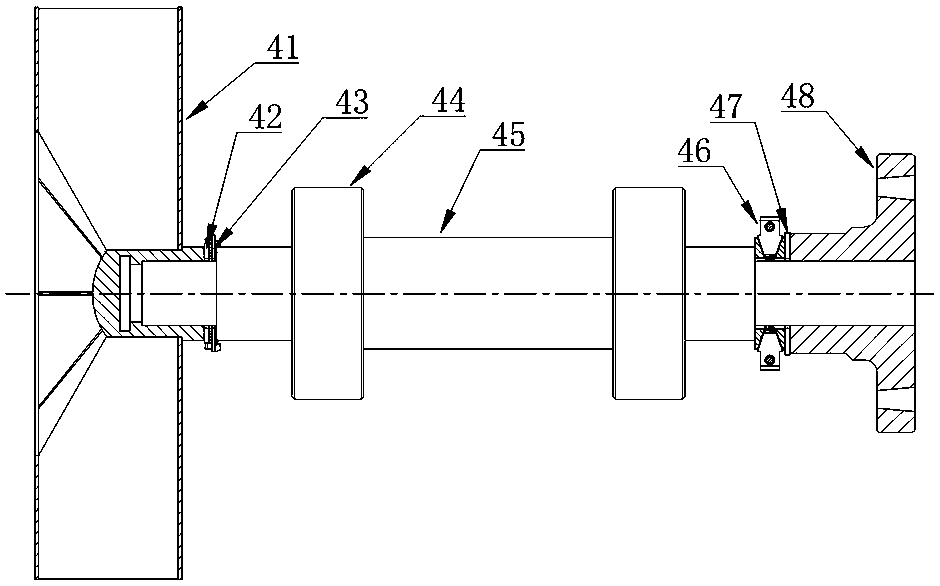

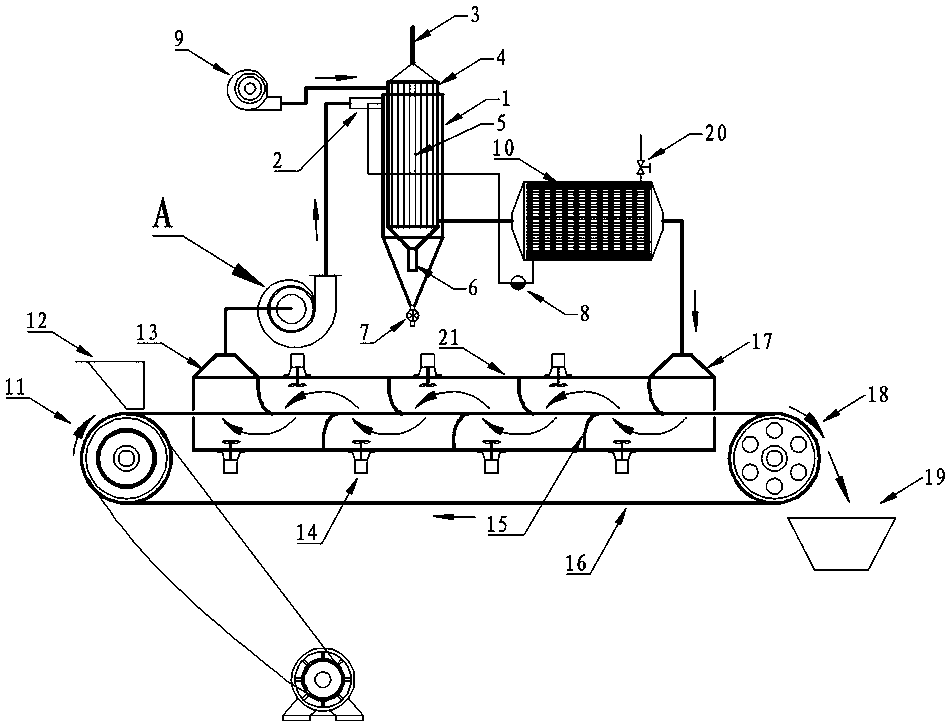

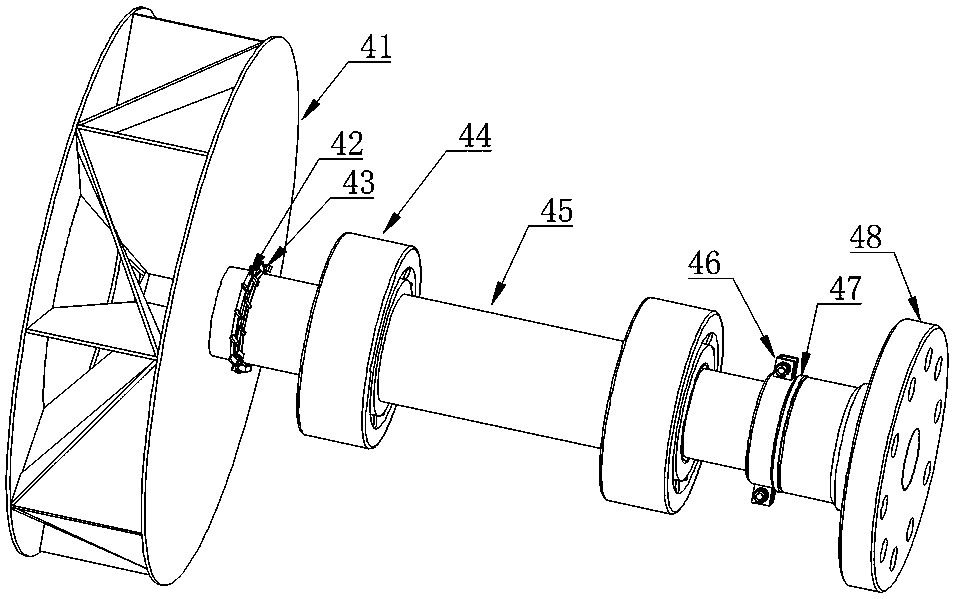

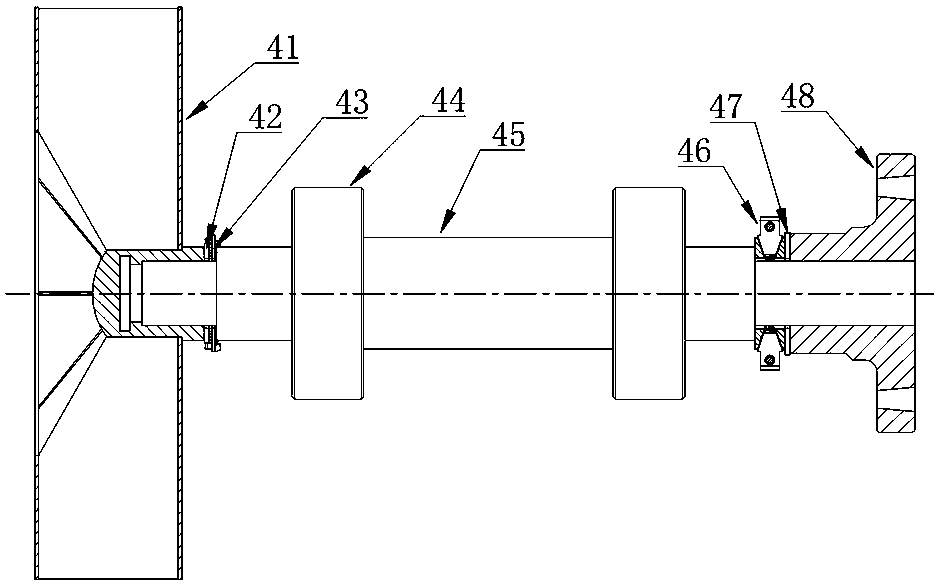

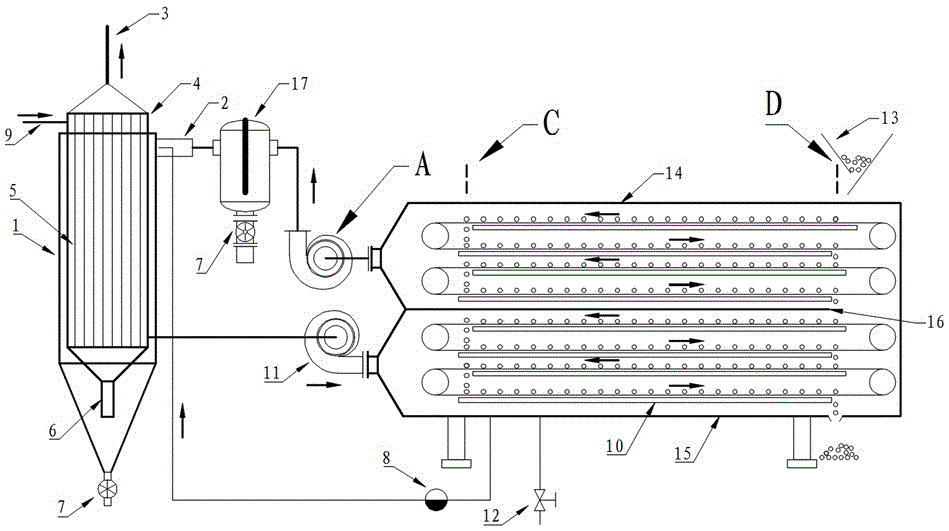

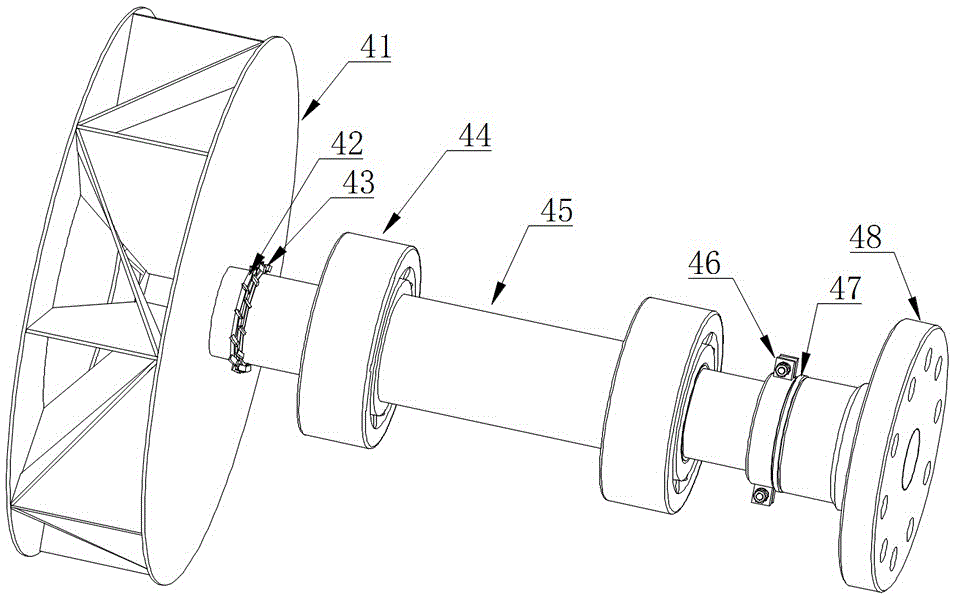

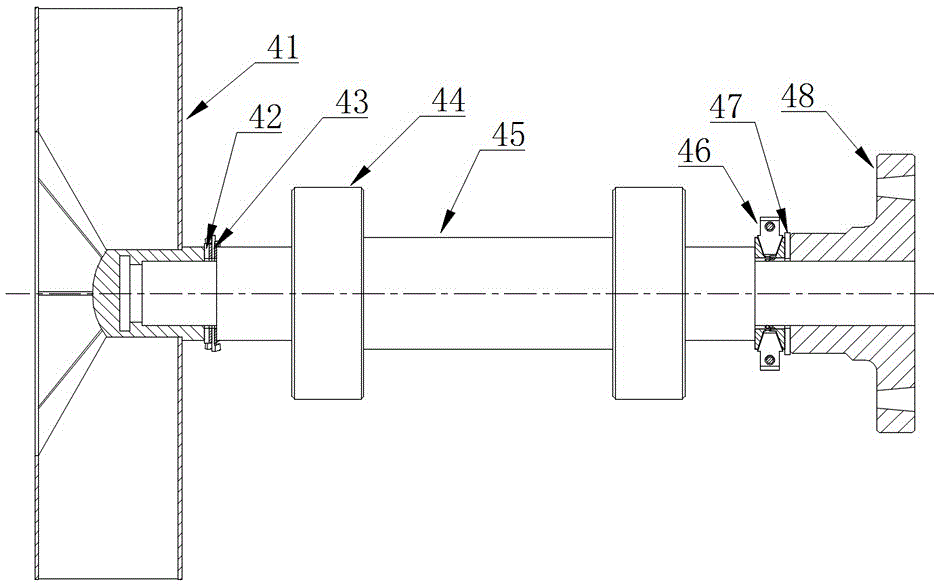

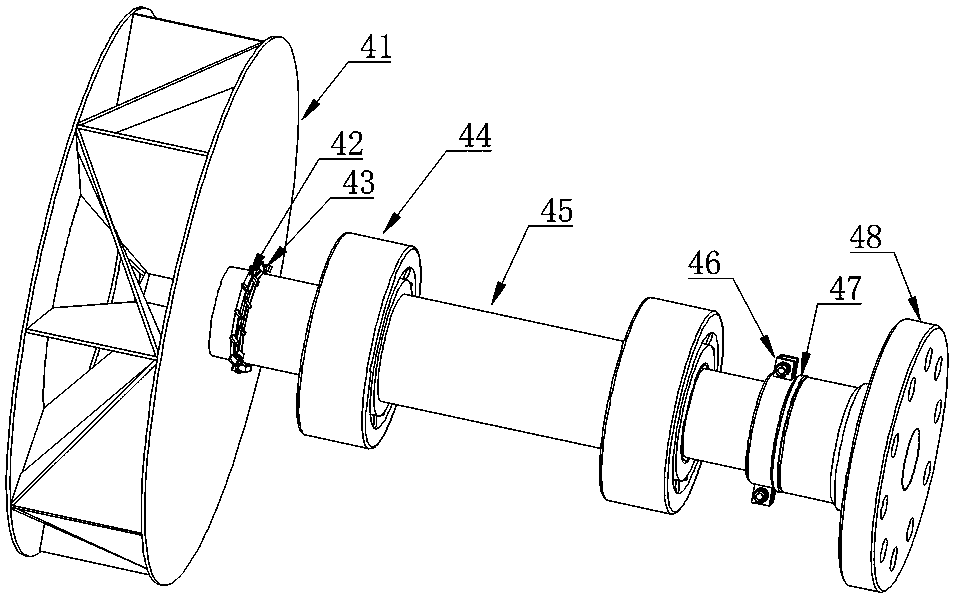

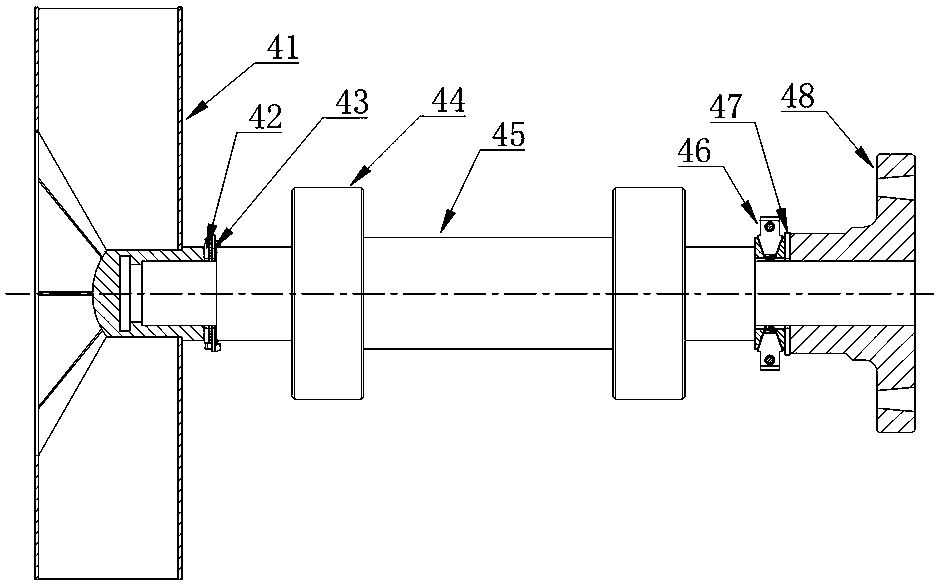

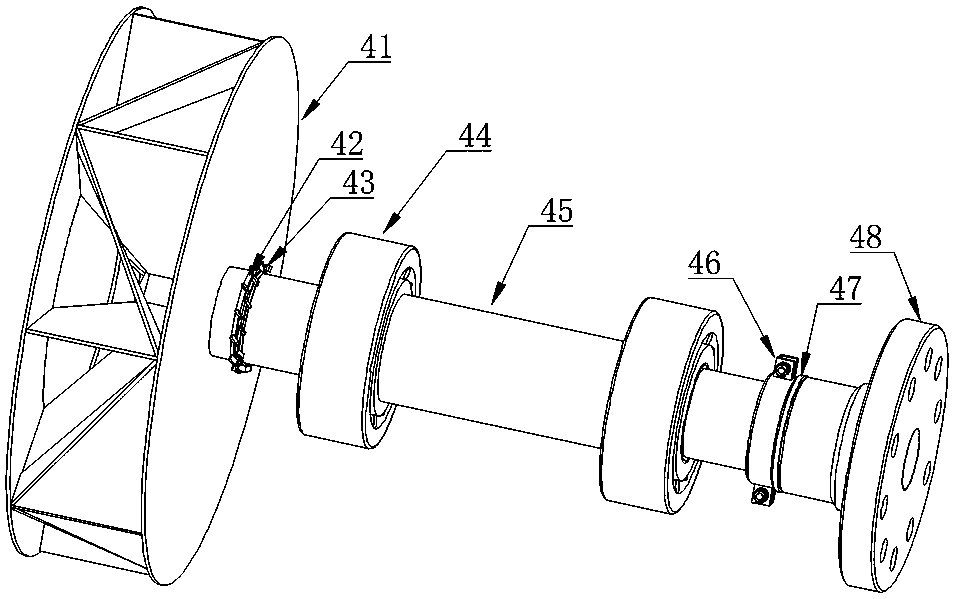

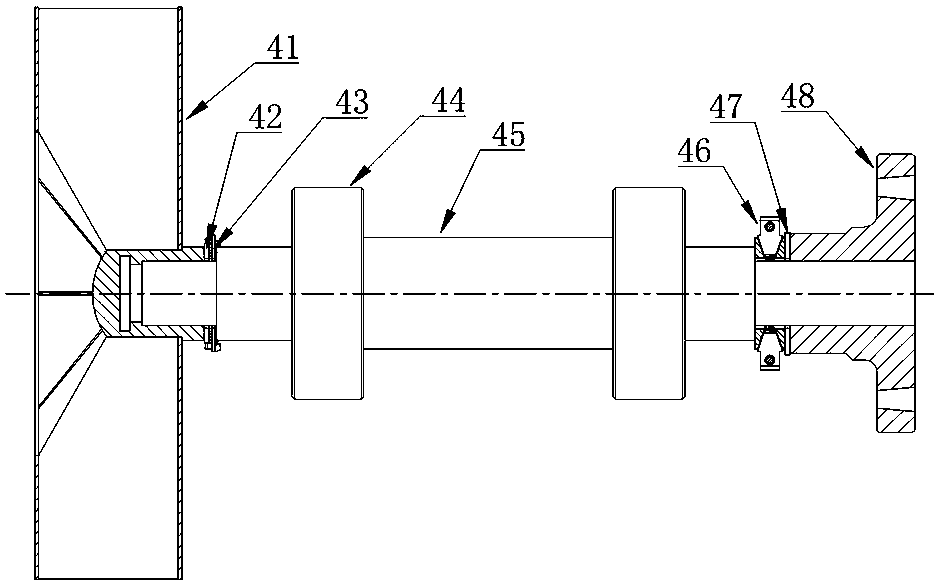

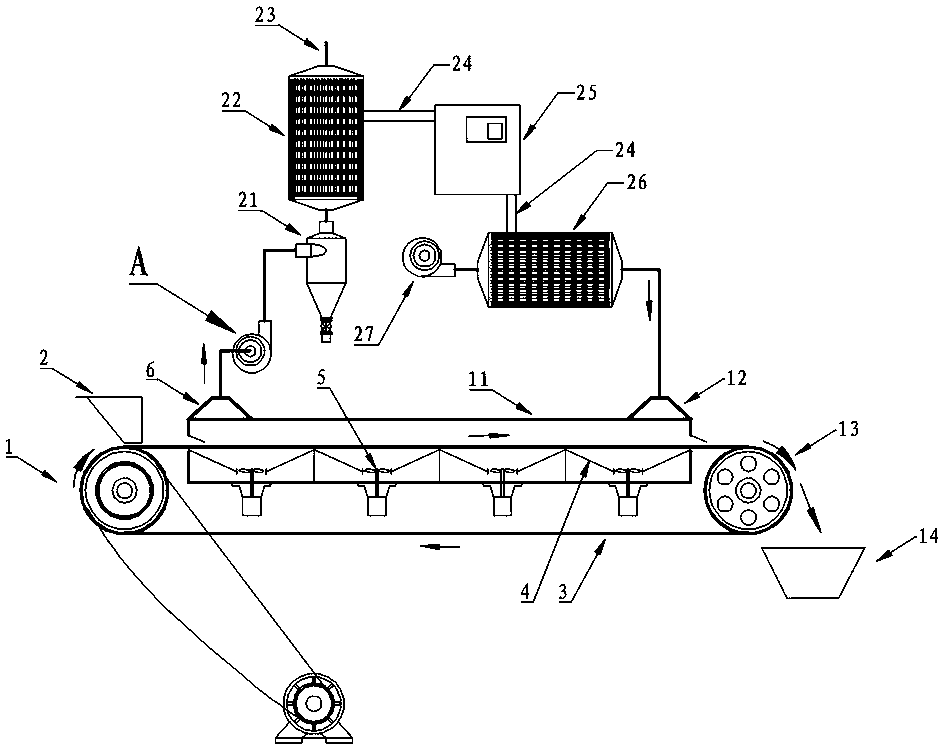

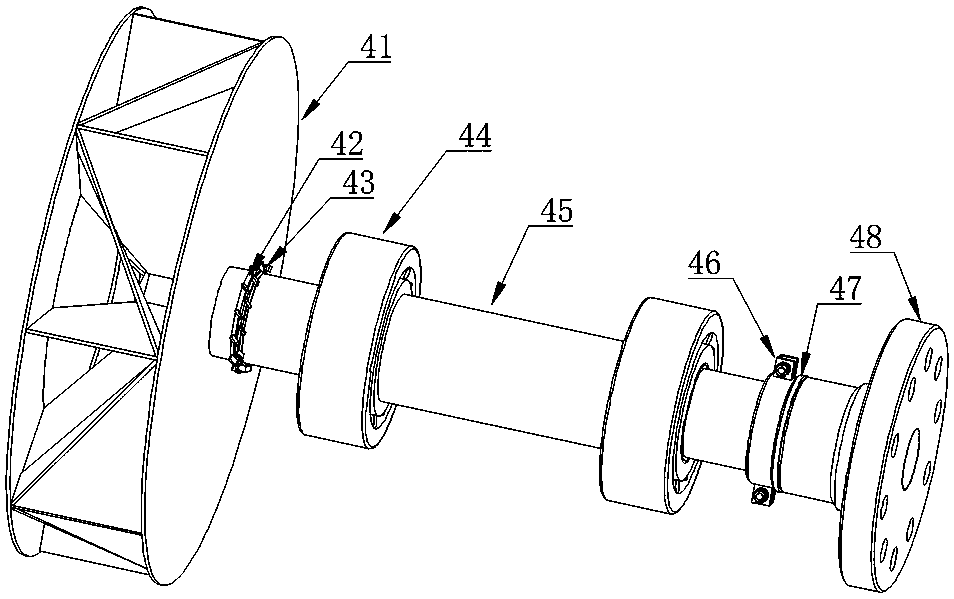

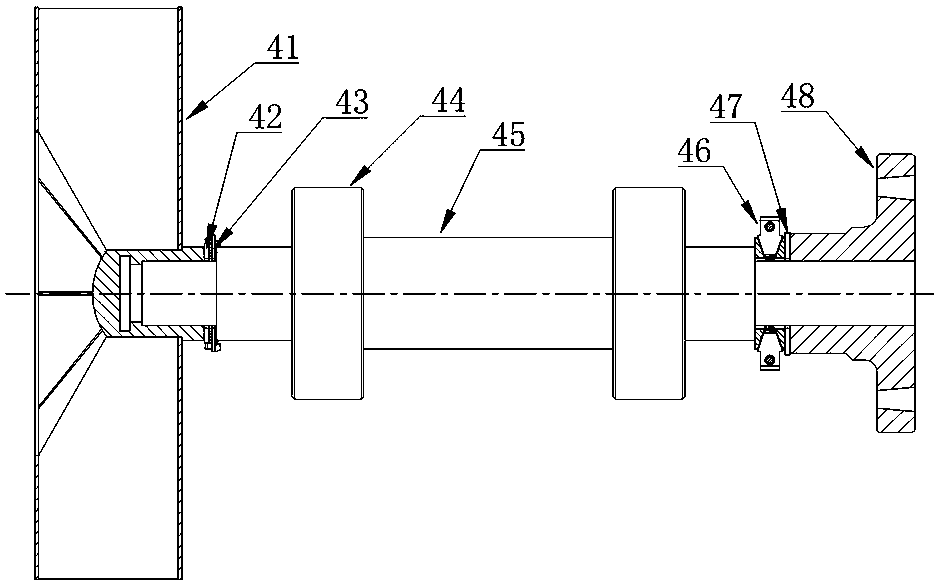

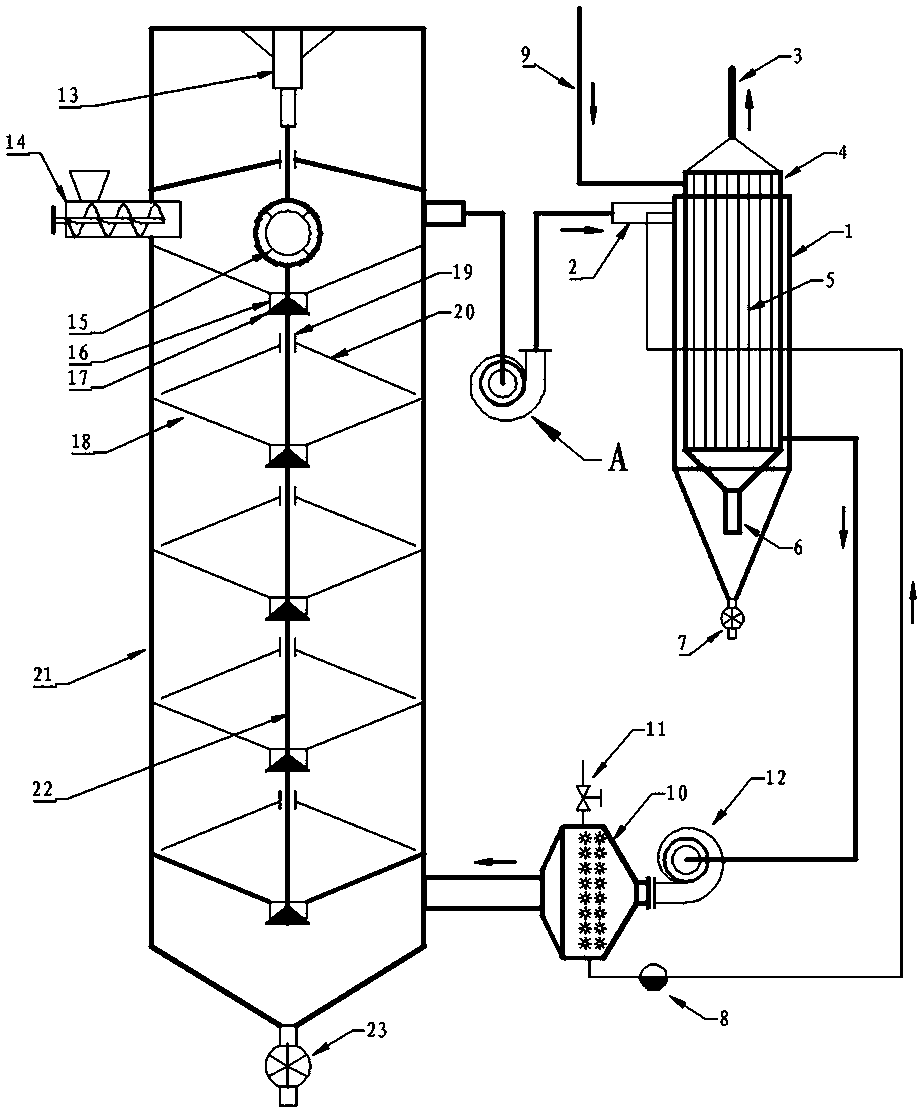

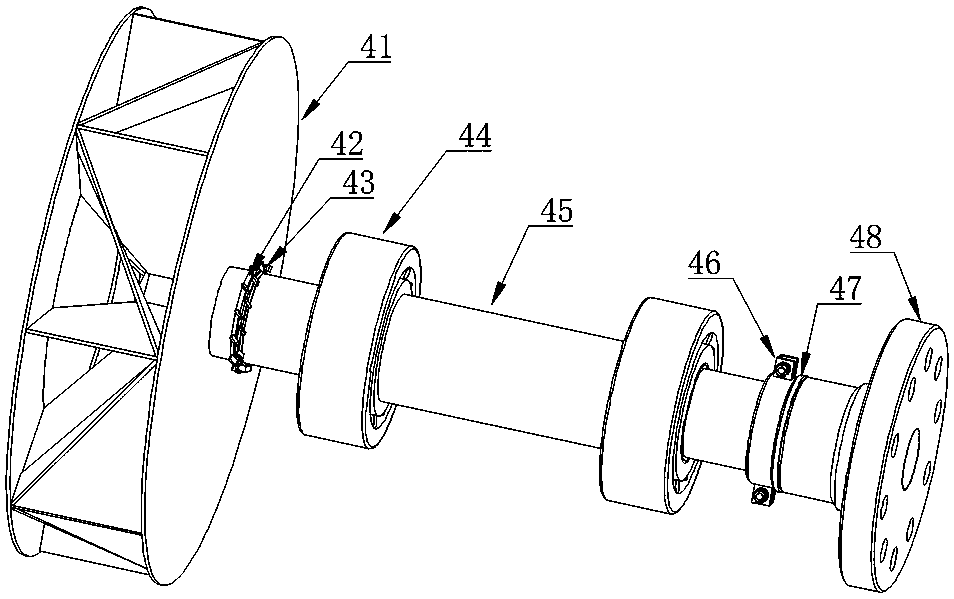

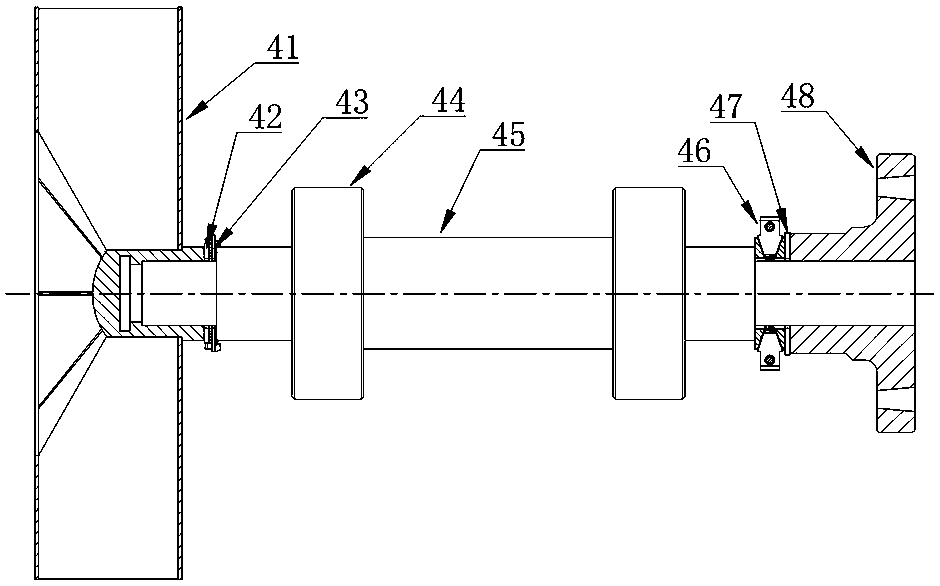

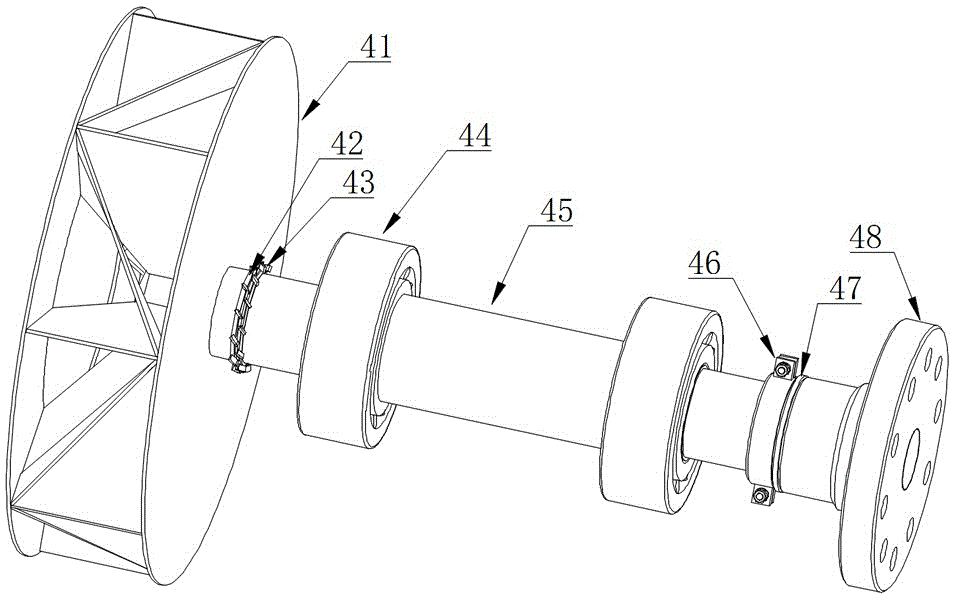

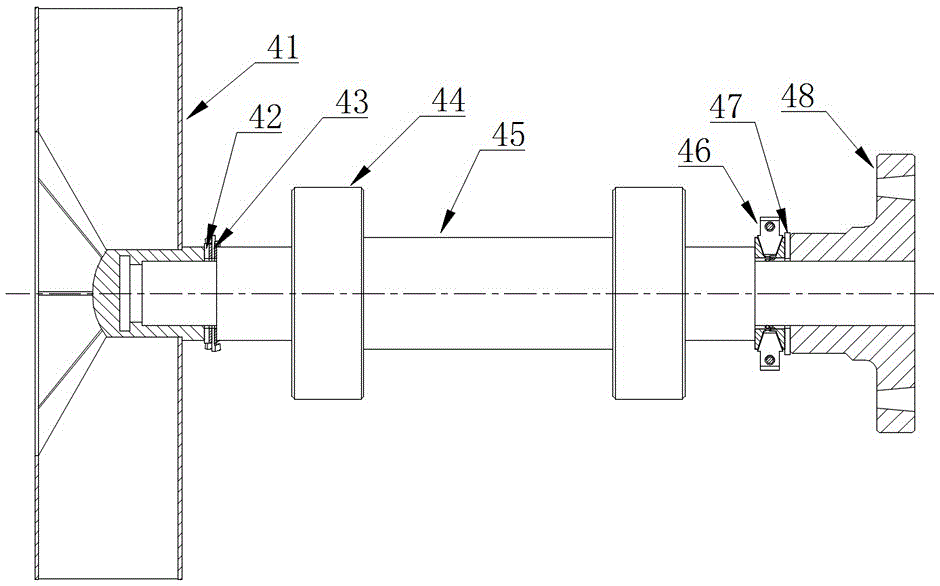

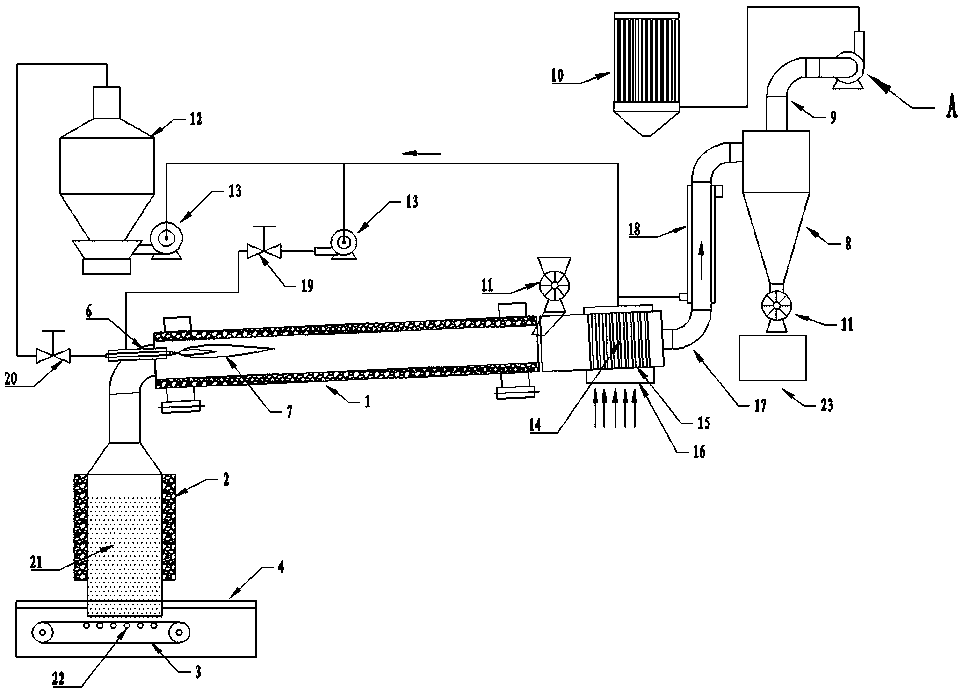

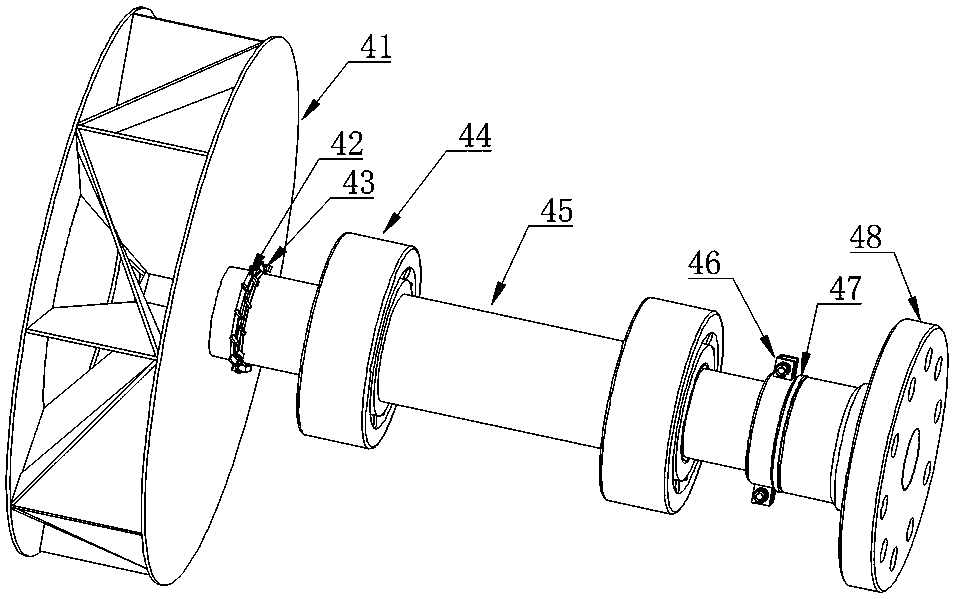

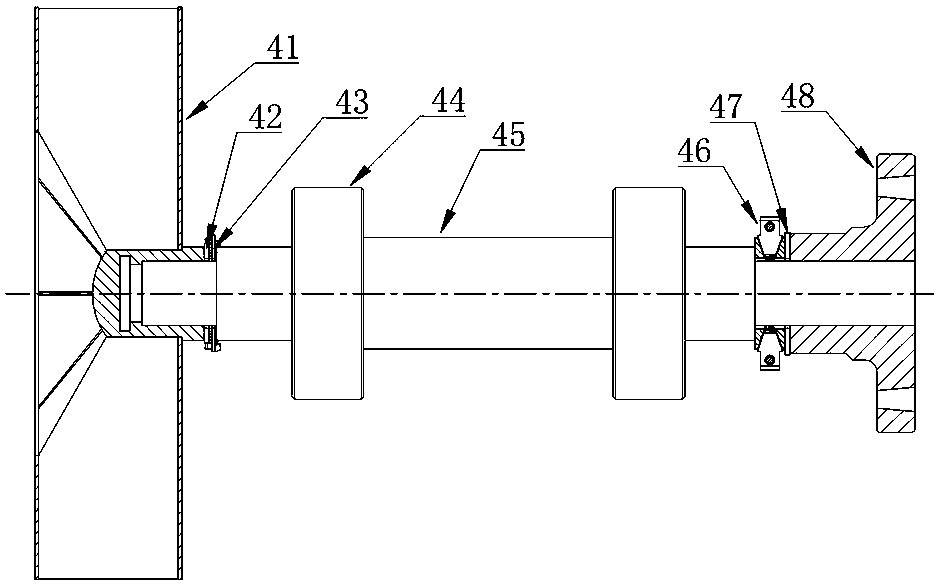

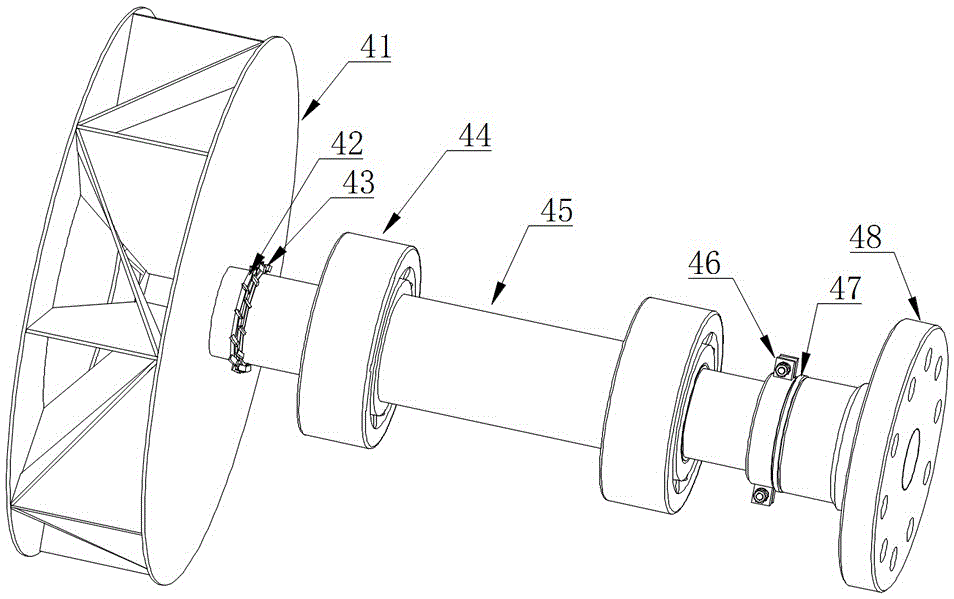

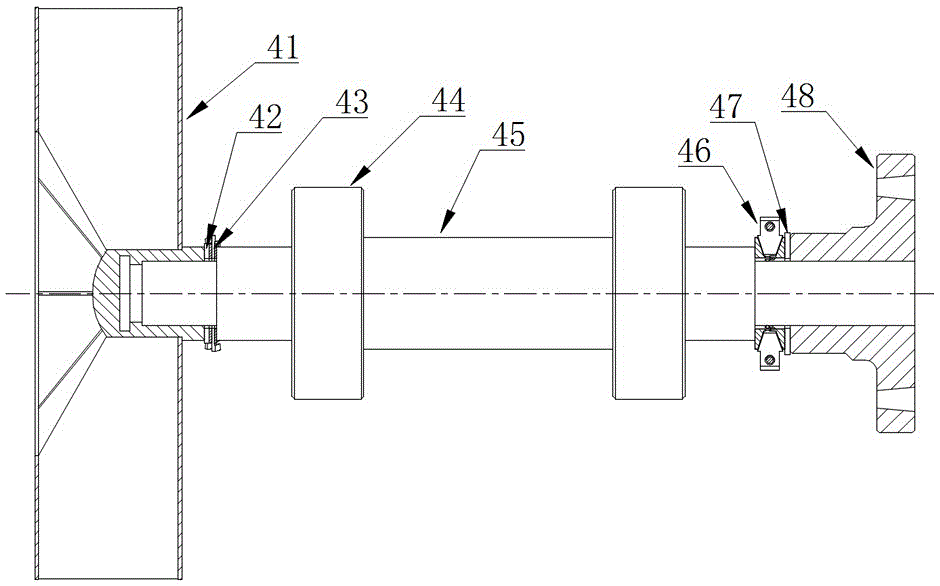

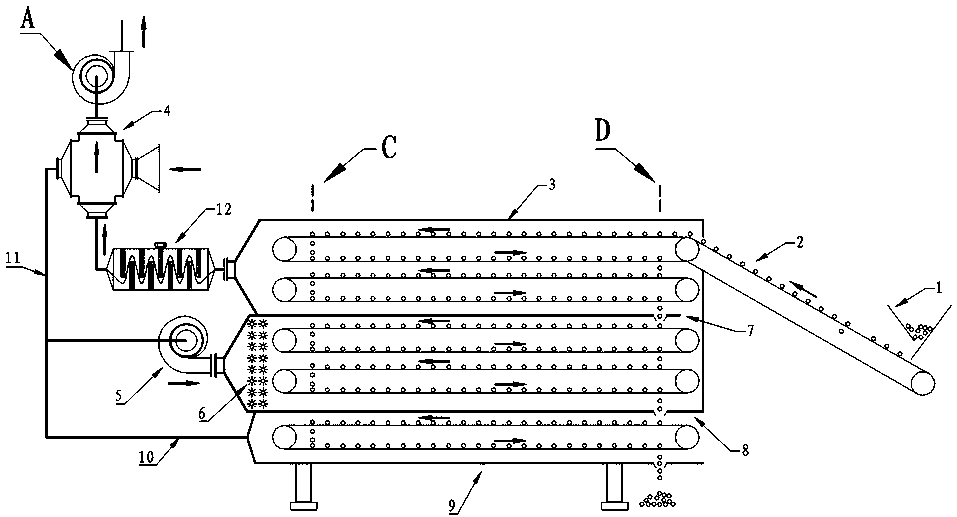

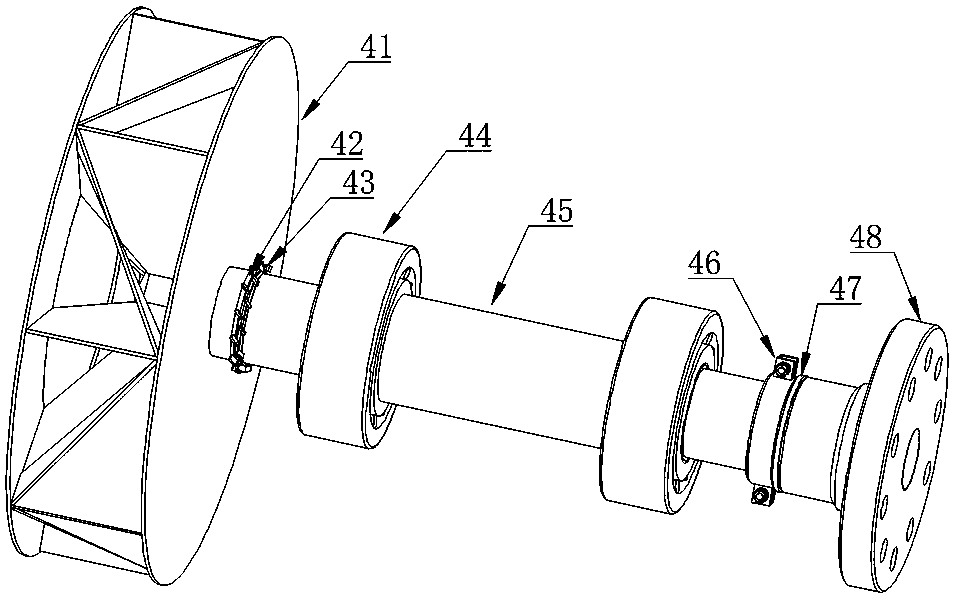

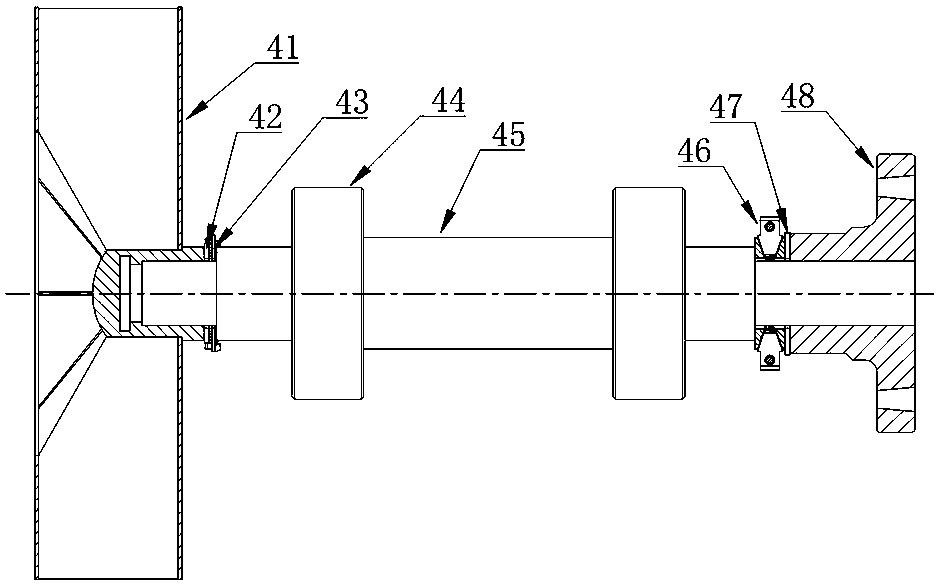

The invention discloses a hot air type penetration reverse flow fluidization drying machine with tail heat utilization and inertial dust collecting functions. The upper portion of a drying tower is connected with an induced draft fan. The induced draft fan is connected with an efficient cyclone dedusting tail heat recovery device in a tangential manner through an inertial dust collecting device and then performs evacuation, wherein the efficient cyclone dedusting tail heat recovery device is formed by overlaying a tube bank type heat exchanger and a cyclone dust collector. The air inlet end of a shell pass of the tube bank type heat exchanger is communicated with atmosphere, and the air outlet end is connected with the lower portion of the drying tower through an air blower and a steam fin heater; and blades of an impeller of the induced draft fan are arranged to be in a radiation shape and are in radial and central symmetry with respect to an impeller shaft, the dust can be cleared up in time through centrifugal force, and safety accidents are avoided. By the adoption of the hot air type penetration reverse flow fluidization drying machine, the drying efficiency is improved, and energy saving and emission reduction are achieved; and more importantly, the disassembly and assembly technology of the induced draft fan is improved greatly, so that pressure applied to the shaft shoulder end face of a screw by components similar to a nut component can be eliminated simply when the induced draft fan is disassembled, and the problem that the induced draft fan is locked continuously and automatically and cannot be disassembled easily under the load action due to threaded assembly is solved effectively; and the hot air type penetration reverse flow fluidization drying machine is especially suitable for convenient and fast disassembly of a large-scale fan which is locked in a threaded manner, and the effect is particularly obvious.

Owner:罗军

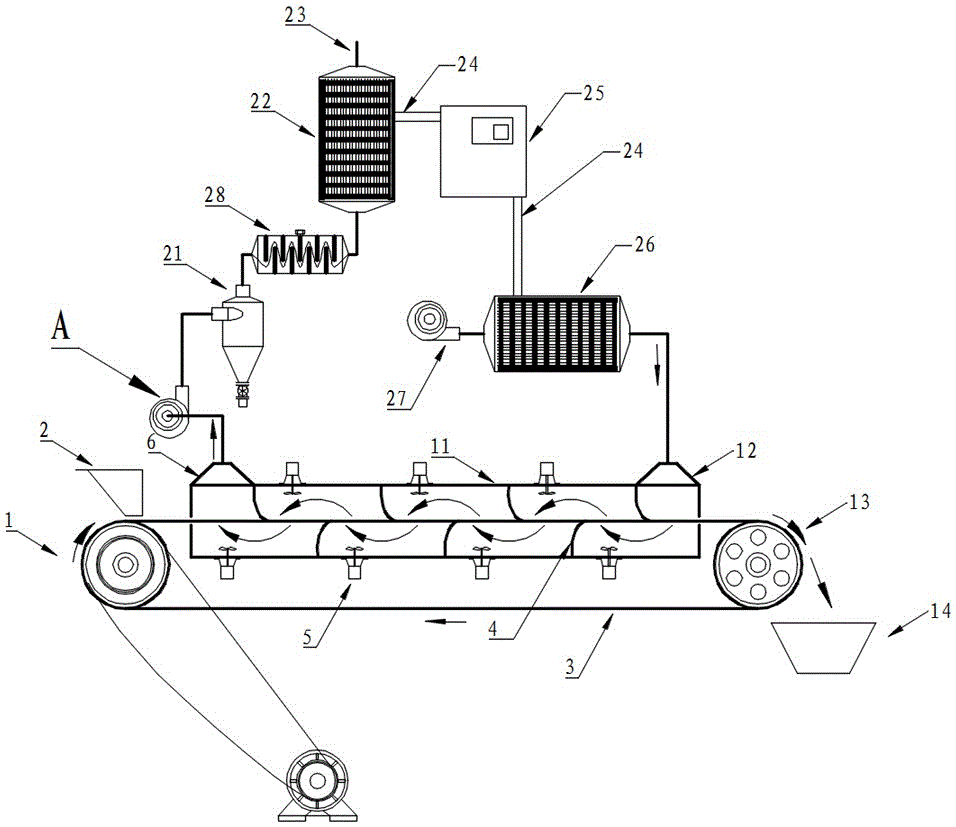

Heat pump type waste heat utilization inertial dust collection penetrating countercurrent drying machine

ActiveCN105674713AHigh extrusion rigidityStrong extrusion rigidityPump componentsDrying gas arrangementsImpellerEngineering

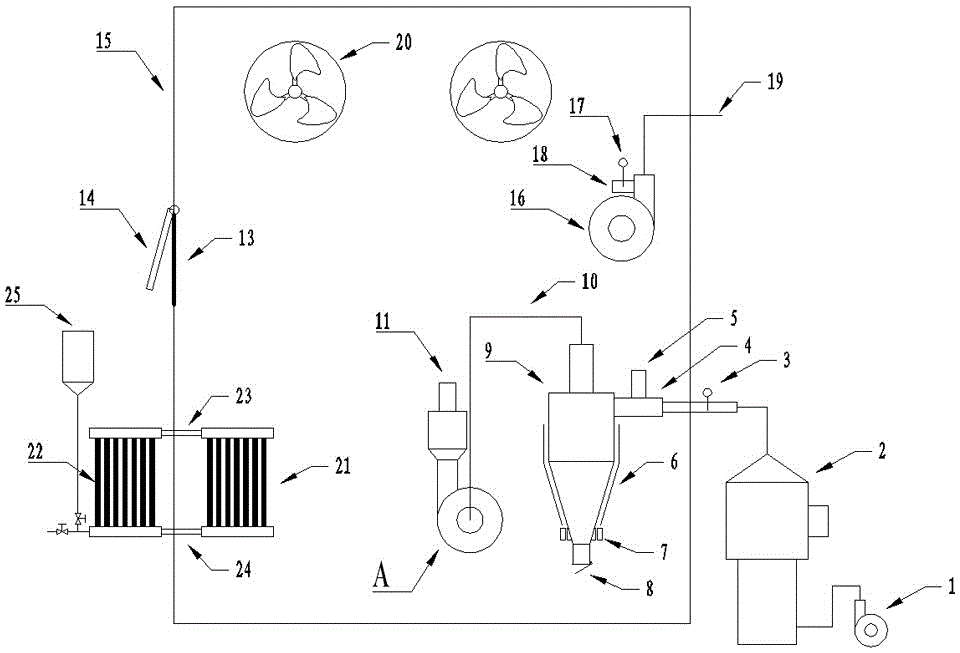

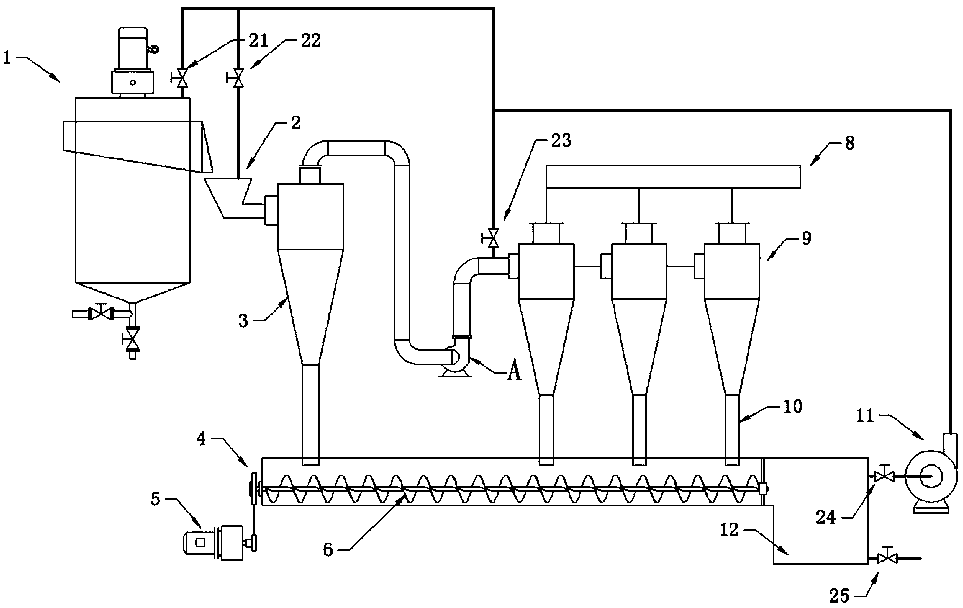

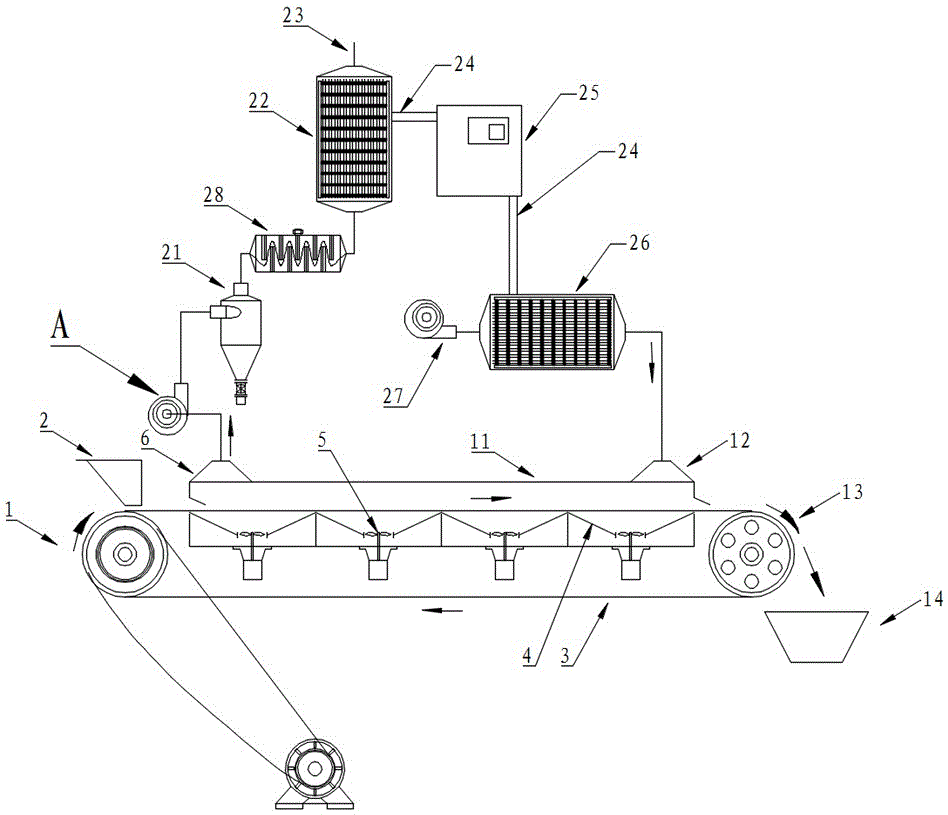

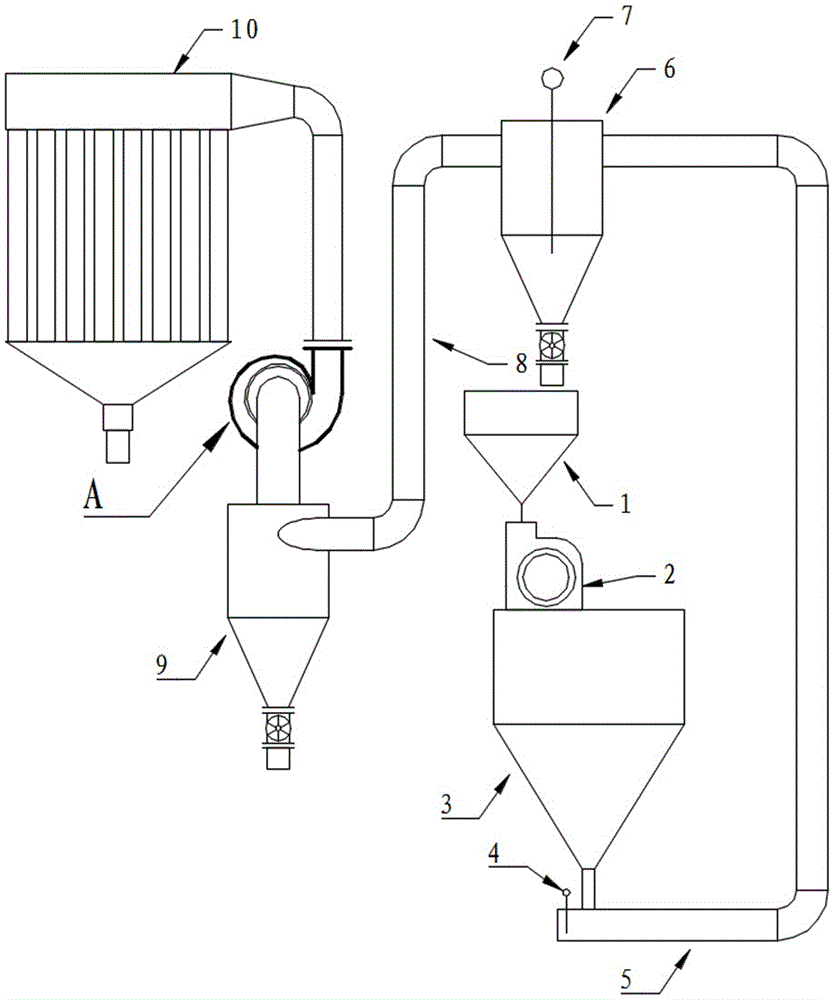

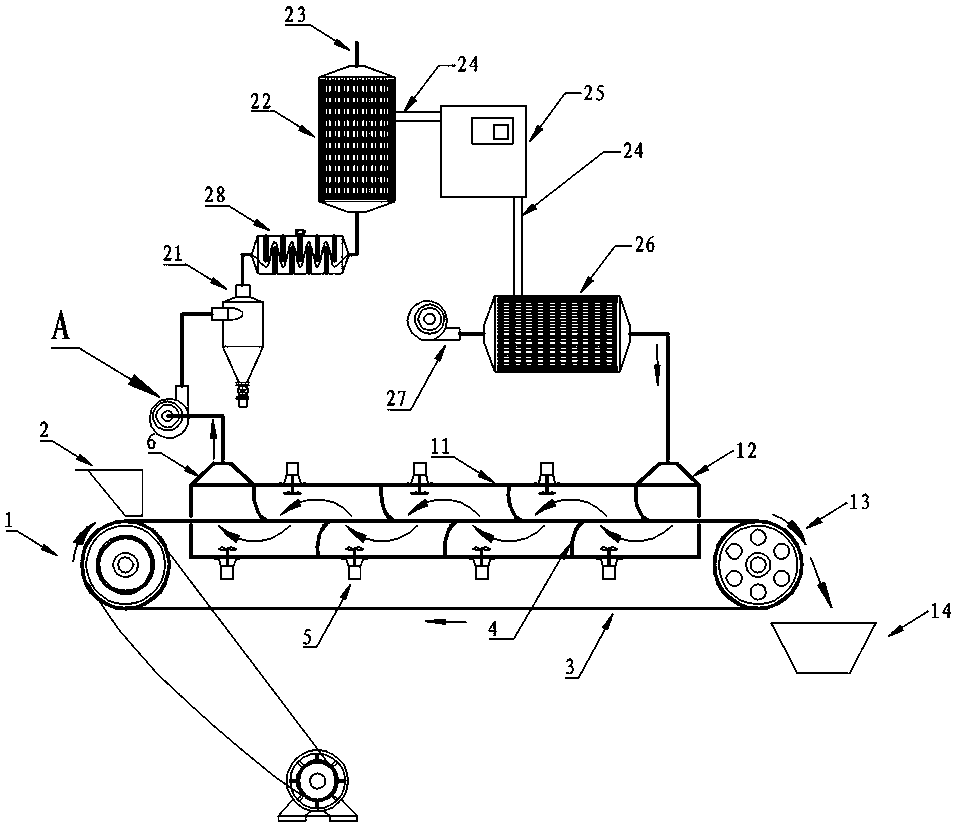

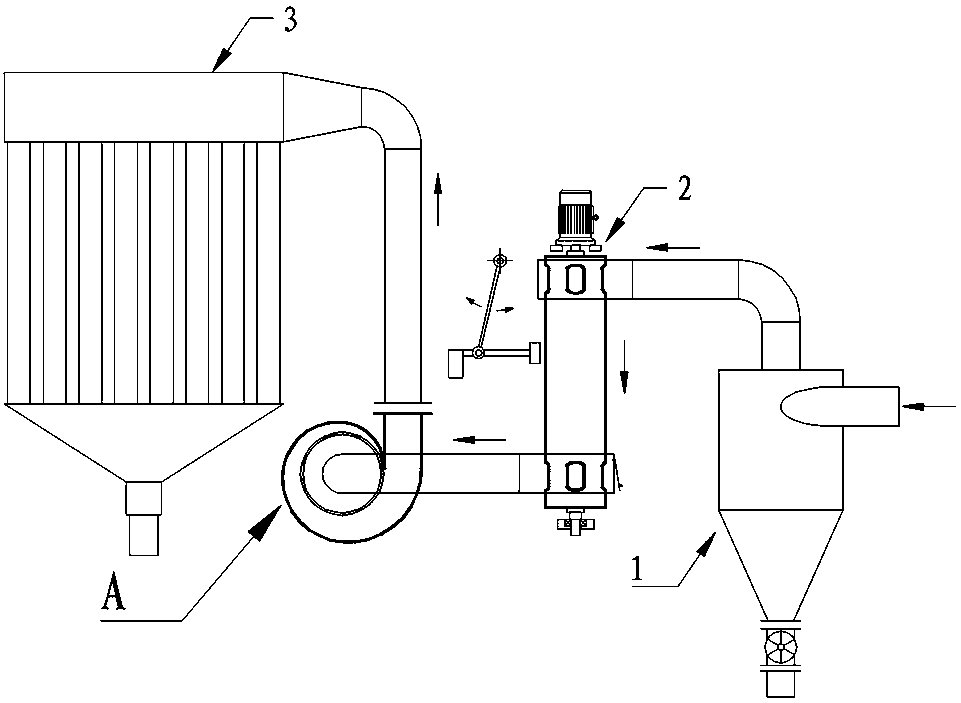

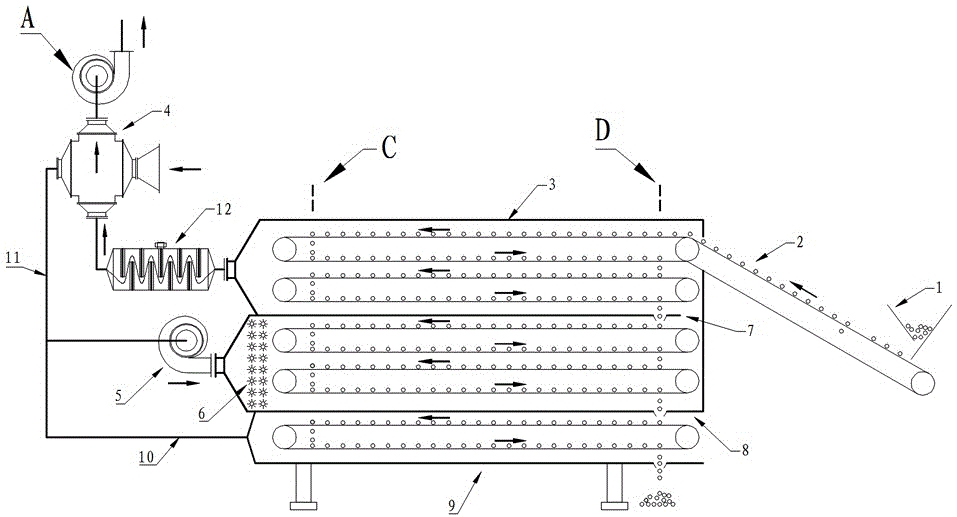

The invention discloses a heat pump type waste heat utilization inertial dust collection penetrating countercurrent drying machine. An exhaust hood of the drying machine is connected with an induced draught fan. The induced draught fan is evacuated after being connected with an evaporator of a heat pump system through a cyclone dust collector and a repeated back-turning baffle type inertial dust collector. The evaporator of the heat pump system is connected with a main machine through a refrigerant pipe. The main machine is connected with a condenser through a refrigerant pipe. The air outlet end of an air blower is connected in an air inlet hood through the condenser. Blades of an impeller of the induced draught fan are arranged to be in a radial shape and centrosymmetric about an impeller shaft in the radial direction, dust can be removed in time under the effect of centrifugal force, and safety accidents are avoided. The drying efficiency is improved, energy conservation and emission reduction are achieved, more importantly, a demounting and mounting technology of the induced draught fan is transformed to a great extent, when the induced draught fan is demounted, the pressure applied to the end face of a screw shaft shoulder by nut-like parts can be simply eliminated, the problem that the induced draught fan assembled in a threaded manner is automatically locked continuously under the effect of loads and cannot be easily demounted is effectively solved, the heat pump type waste heat utilization inertial dust collection penetrating countercurrent drying machine is particularly suitable for convenient demounting of large draught fans which are locked in a threaded manner, and effects are particularly obvious.

Owner:四川良仕农业科技有限公司

Tail heat utilized hot-air type penetration countercurrent fluidized drying machine

ActiveCN105758151AStrong extrusion rigidityEliminate fatigue fractureDrying gas arrangementsDrying solid materialsImpellerAtmosphere

The invention discloses a tail heat utilized hot-air type penetration countercurrent fluidized drying machine. A draught fan is connected to the upper part of a drying tower; the draught fan is tangentially connected with a cyclone dust removal tail heat efficient recoverer which is formed by a tube type heat exchanger and a cyclone dust collector which are overlapped, and is evacuated; the shell pass air inlet end of the tube type heat exchanger is communicated with the atmosphere; the air outlet of the tube type heat exchanger is connected to the lower part of the drying tower through an air blower and a steam fin heater; blades of the draught fan impeller are arranged in a radiation manner that impeller shafts are in radial and central symmetry; dust can be collected by virtue of centrifugal force in time, and thus security accidents can be avoided. By adopting the tail heat utilized hot-air type penetration countercurrent fluidized drying machine, the drying efficiency is improved, the purposes of energy conservation and emission reduction are achieved, more importantly, the assembling and disassembling technique of the draught fan is greatly improved, pressure caused by components such as a screw nut to the shoulder end surface of a screw shaft can be easily eliminated when the draught fan is assembled and disassembled, the problem that the draught fan is continuously automatically locked and is not easy to disassemble under the action of load in threaded assembling can be effectively solved, and the tail heat utilized hot-air type penetration countercurrent fluidized drying machine is particularly applicable to convenient and rapid disassembling after a large-size draught fan is in threaded locking and is particularly remarkable in effect.

Owner:安徽上元家居材料股份有限公司

Heat pump type tail heat recycling inertial dust collection penetrating countercurrent fluidization drying machine

InactiveCN105698513AStrong extrusion rigidityEliminate fatigue fractureHeat pumpsDrying solid materials with heatImpellerEvaporator

The invention discloses a heat pump type tail heat recycling inertial dust collection penetrating countercurrent fluidization drying machine. A material seal spiral feeder is arranged on the upper portion of a drying tower, and a closed-air aspirator discharging machine is arranged at the bottom of the drying tower; an induced draft fan is connected to the upper portion of the drying tower, and is connected with an evaporator of a heat pump system through a cyclone dust collector and a repeated reciprocating type inertial dust collector and then is subject to venting; the air outlet end of an air blower is connected with the lower portion of the drying tower through a condenser; blades of an induced draft fan impeller are arranged to be in a radiation shape in impeller shaft radial and central symmetry, centrifugal force can be used for cleaning up dust in time, and safety accidents are avoided; and according to the drying machine, the drying efficiency is improved, energy saving and emission reduction are achieved, more importantly, the dismounting and mounting technology of the induced draft fan is greatly changed, and therefore during dismounting, the pressure of similar nut components on the end face of a screw shaft shoulder can be simply eliminated; and the problem that according to the induced draft fan thread assembly, automatic locking is continuously carried out under the load effect, and dismounting is not likely to be achieved is effectively solved, and the drying machine is particularly suitable for portable dismounting of a large-scale fan obtained after thread locking, and the effect is particularly obvious.

Owner:山东启邦博冠科技发展有限公司

Heat pump type penetrating and inverse-flow fluidized drying machine with exhaust heat recovery function

ActiveCN105674717AStrong extrusion rigidityEliminate fatigue fracturePump componentsDrying gas arrangementsImpellerEvaporator

The invention discloses a heat pump type penetrating and inverse-flow fluidized drying machine with the exhaust heat recovery function. A material seal screw feeder is arranged on the upper portion of a drying tower, and a closed-air aspirator discharging machine is arranged at the bottom of the drying tower. The upper portion of the drying tower is connected with an induced draft fan. The induced draft fan is connected with an evaporator of a heat pump system through a cyclone dedusting device for evacuation. The air outflow end of an air blower is connected with the lower portion of the drying tower through a condenser. Blades of an impeller of the induced draft fan are arranged symmetrical about the center of an impeller shaft in the radial direction in a radial manner, dust can be cleared up in time through centrifugal force, and safety accidents are avoided. By the adoption of the heat pump type penetrating and inverse-flow fluidized drying machine with the exhaust heat recovery function, drying efficiency is improved, and energy saving and emission reduction are achieved; and more importantly, the disassembly technology of the induced draft fan is improved greatly, so that pressure applied to the shaft shoulder end face of a screw by components similar to a nut component can be eliminated easily when the induced draft fan is disassembled, and the problem that the induced draft fan is locked continuously and automatically and cannot be disassembled easily under the load action due to threaded assembly is solved effectively; and the heat pump type penetrating and inverse-flow fluidized drying machine with the exhaust heat recovery function is especially suitable for convenient and fast disassembly of a large-scale fan which is locked in a threaded manner, and the effect is especially remarkable.

Owner:河南星光机械制造有限公司 +1

Healthy dampness removing type smoked and roasted product smoking and roasting device convenient for induced draft fan disassembly

InactiveCN105767120ADoes not affect dynamicDoes not affect balanceMeat/fish preservationPump componentsImpellerWater storage tank

The invention discloses a healthy dampness removing type smoked and roasted product smoking and roasting device convenient for induced draft fan disassembly. Fins are arranged at both inside and outside of a smoking chamber wall body and connected to a water storage tank via an upper connecting pipe and a lower connecting pipe; a smoke producing pipeline of a smoke producing stove passes the wall body and is connected to an air inlet pipe of a cyclone separator, the cyclone separator is connected to an induced draft fan via a pipeline, and an air outlet of the induced draft fan is arranged inside the wall body; a flashboard is arranged on the smoke producing pipeline of the smoke producing stove; a light-weight valve is arranged at the bottom of the cyclone separator, and a heat radiator and a vibrator are arranged on the surface of the cyclone separator; and an impeller of the induced draft fan can use a centrifugal force to timely clean dust. The smoking and roasting device can realize green and energy-efficient smoking and roasting and more importantly greatly improve the disassembly and assembly technologies of the induced draft fan, so that during the disassembly, the device can simply eliminate similar pressures of blind nut parts for shoulder end surfaces of screw shafts, effectively solves the problem that the screw assembly of the induced draft fan is continuously automatically locked and not easy for disassembly under a loading effect, and is especially suitable for and has a particularly significant effect for a convenient disassembly after thread locking of large-sized fans.

Owner:JISHOU UNIVERSITY

A simple Raymond mill device that is easy to disassemble the fan

ActiveCN105665080BHigh extrusion rigidityStrong extrusion rigidityUsing liquid separation agentGrain treatmentsImpellerCyclone

The invention discloses a simple Raymond mill device with a fan convenient to disassemble. The fan, a Raymond mill, a cyclone separating and discharging device and an air return duct form an air-flow-circulating ground-powder discharging system. An isolating temporary storage barrel is arranged at an inlet, connected with the air return duct, of the fan. A gravity material door is arranged on the isolating temporary storage barrel. A temporary powder storage barrel is arranged below the gravity material door. A valve and a discharging gate are arranged on the temporary powder storage barrel. Blades of an impeller of the induced draft fan are arranged symmetrical about the center of an impeller shaft in the radial direction in a radial manner, dust can be cleared up in time through centrifugal force, and safety accidents are avoided. The simple Raymond mill device is simple in structure, and more importantly, the disassembly technology of the induced draft fan is improved greatly, so that pressure applied to the shaft shoulder end face of a screw by components similar to a nut component can be eliminated easily when the induced draft fan is disassembled, and the problem that the induced draft fan is locked continuously and automatically and cannot be disassembled easily under the load action due to threaded assembly is solved effectively; and the simple Raymond mill device is especially suitable for convenient and fast disassembly of the large-scale fan which is locked in a threaded manner, and the effect is especially remarkable.

Owner:HENAN TIANXIANG NEW MATERIALS

Tail heat utilization sieve hole flap dryer

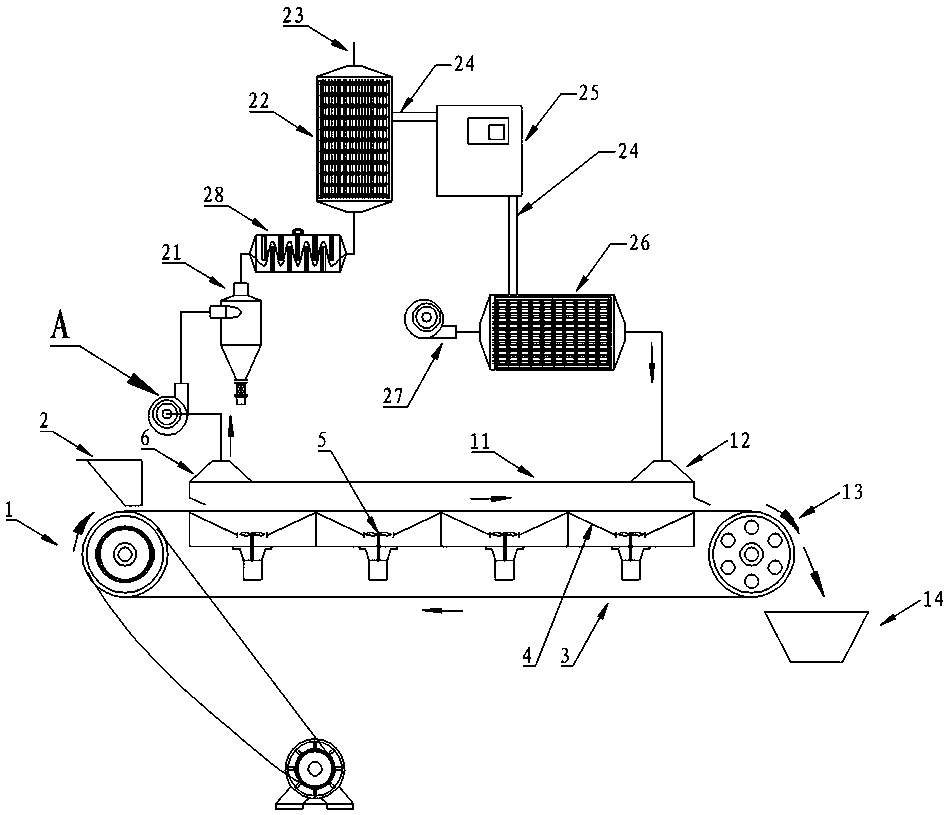

ActiveCN105716402BHigh extrusion rigidityStrong extrusion rigidityPump componentsDrying gas arrangementsEngineeringCentrifugal force

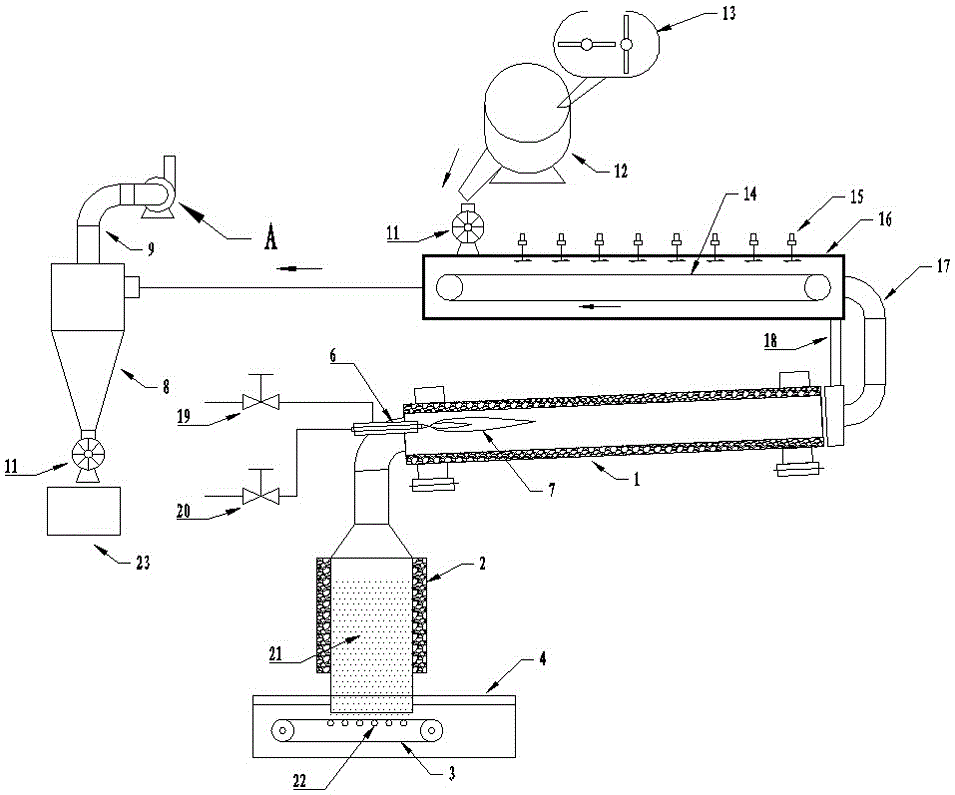

The invention discloses a tail heat utilization sieve mesh turning-plate type drier. A drier box body is provided with a structure of sieve mesh turning-plate type conveying from top to bottom and is divided into an upper drying area, a middle drying area and a lower drying area by a middle baffle and a lower baffle. The upper drying area is connected with an induced draft fan through an air heat exchanger and then is drained; the air outlet end of the upper drying area is connected with an air inlet of an air blower through an air pipe; and an air outlet of the air blower is connected with a steam fin heater in the middle drying area. Blades of an impeller of the induced draft fan are arranged in a radiated mode with an impeller shaft being in radial symmetry and central symmetry, dust is cleaned up in time by centrifugal force, and safety accidents are avoided. The tail heat utilization sieve mesh turning-plate type drier improves the drying efficiency and achieves energy saving and emission reduction; more importantly, the disassembling technology of the induced draft fan is greatly improved, and the induced draft fan can simply eliminate the pressure of nut-like parts to the shaft shoulder end faces of screw rods when being disassembled, so that the problem that due to the threaded assembly mode, the induced draft fan is continuously and automatically locked under the load action and is not likely to be disassembled is effectively solved; and the tail heat utilization sieve mesh turning-plate type drier is particularly suitable for convenient disassembling of large draft fans after threaded locking, and the effect is very obvious.

Owner:武汉新实诚诺资源开发有限公司

Bag filter-type manganese processing rotary kiln system with highly demountable induced draft fan

InactiveCN105783505AHigh extrusion rigidityStrong extrusion rigidityPump componentsRotary drum furnacesManganeseEngineering

The invention discloses a bag filter-type manganese processing rotary kiln system with a highly demountable induced draft fan. The bag filter-type manganese processing rotary kiln system adopts the structure that an air-lock valve used for feeding is arranged at the high end of a rotary kiln; the high end of the rotary kiln is connected with a cyclone dust extractor, an induced draft fan and a bag-type dust remover via a fin section and air pipes; fins are arranged in the fin section; a hood cylinder is arranged outside the fin section; a sleeve-type air heat exchanger is arranged outside an air pipe; the hood cylinder is communicated with a lower pumping hole in the air heat exchanger, and then divided into two paths for supplying preheated air; and the blades of the impeller of the induced draft fan are arranged in a radiation shaped and are in radial and central symmetry with respect to an impeller shaft, so that dust can be cleaned promptly via centrifugal force, and safety accidents can be avoided. The bag filter-type manganese processing rotary kiln system not only is high in heat efficiency, but also has the advantages that the demounting technology of the induced draft fan is greatly improved; pressure of a nut-like component on a shaft shoulder end surface of a screw can be eliminated simply during demounting, the problem that a threaded assembly of the induced draft fan is automatically screwed continuously under the action of a load to be difficult to demount can be solved effectively; the suitability for convenient demounting of a large-scale induced draft fan after thread screwing is high; and the effect is remarkable.

Owner:涡阳县华夏气体有限公司

Tail heat recovery and dust removal integrated coal-fired boiler with induced draft fan for easy disassembly

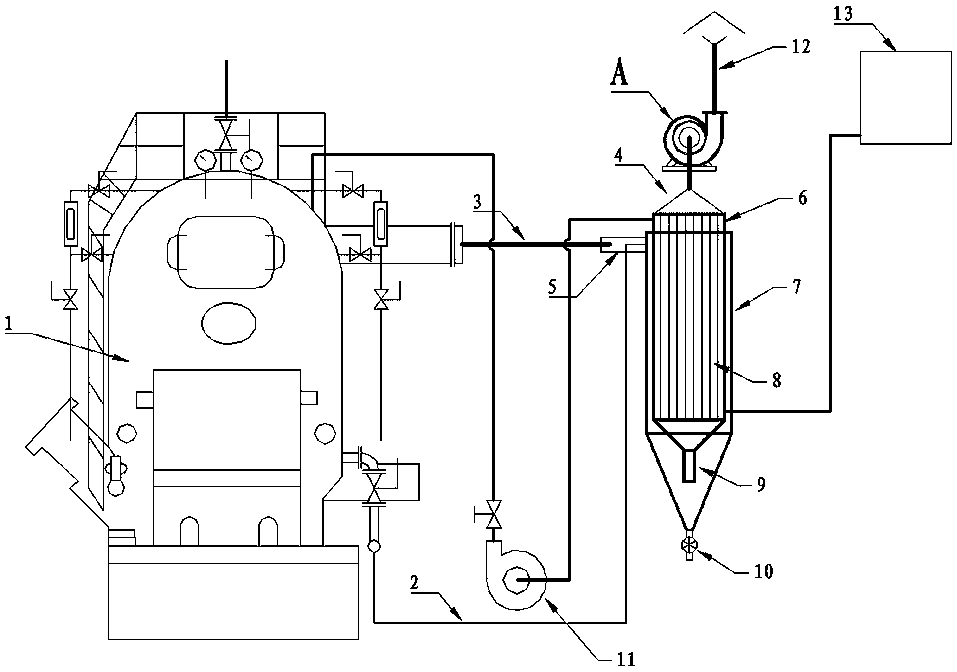

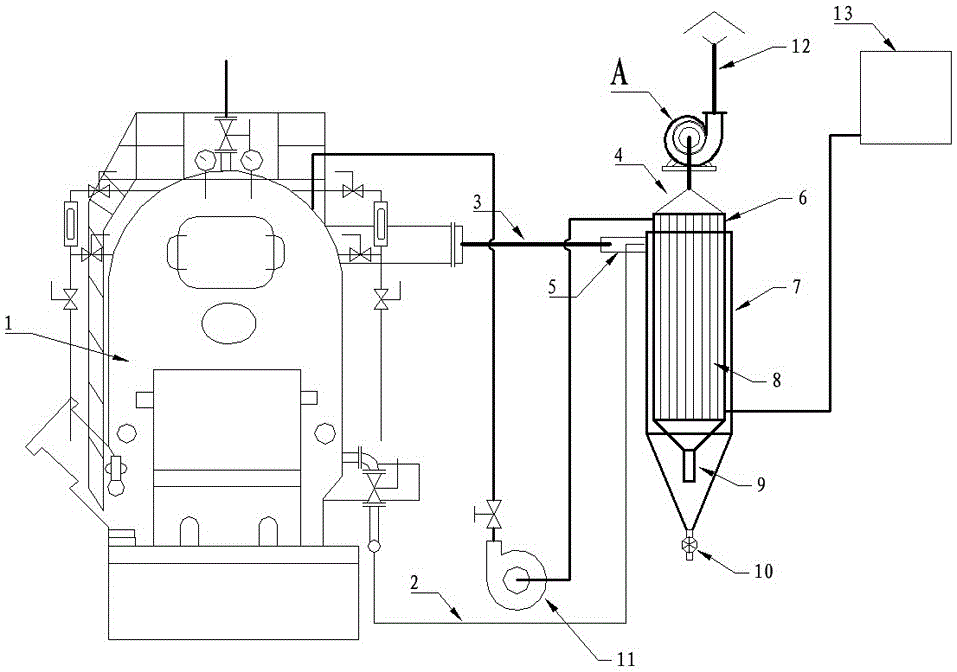

ActiveCN105757704BHigh extrusion rigidityStrong extrusion rigidityPump componentsPumpsCyclonic spray scrubberExhaust pipe

Owner:安徽星洁环保科技有限公司

Residual heat recycling and dust removal integrated coal-fired boiler with conveniently detachable draught fan

ActiveCN105757704ADoes not affect dynamicDoes not affect balancePump componentsPumpsCyclonic spray scrubberExhaust pipe

The invention discloses a residual heat recycling and dust removal integrated coal-fired boiler with a conveniently detachable draught fan. A cyclone dust removal residual heat efficiency recycling device is formed by overlapping a tubular heat exchanger and a cyclone dust remover; a boiler exhaust pipe is connected with the cyclone dust remover in a tangential direction; after cyclone dust removal is carried out, ash is discharged from a cone bottom through an air closing device; exhaust is connected with a cone body through a rotational flow ascending pipe, is uniformly dispersed and then penetrates through tubes; after being concentrated through an upper conical hopper, the exhaust is discharged by the draught fan through an exhausting pipe; a high-level water tank is connected with the lower part of a shell side of the tubular heat exchanger; and an impeller of the draught fan can be used for cleaning the ash in real time through a centrifugal force. The residual heat recycling and dust removal integrated coal-fired boiler realizes integrated type residual heat recycling and dust removal; more importantly, a dismounting technology of the draught fan is greatly improved, and pressure on the end face of a screw shaft shoulder of a screw cap part can be simply eliminated in a dismounting process, so that the problem that thread assembling of the draught fan is continuously automatically locked under the action of a load and thus detachment is not easy is effectively solved; and therefore, the technical scheme is particularly suitable for conveniently detaching a large-size draught fan locked through a thread and the effect is particularly remarkable.

Owner:安徽星洁环保科技有限公司

Cyclone Mineral Flotation Defoamer with Induced Fan for Easy Disassembly

ActiveCN105597947BHigh extrusion rigidityStrong extrusion rigidityVortex flow apparatusFlotationCycloneImpeller

The invention discloses a cyclone type mineral flotation and defoaming device with an induced draft fan convenient to disassemble. The cyclone type mineral flotation and defoaming device is characterized in that a flotation machine is connected with a foam feeding hopper, the foam feeding hopper is connected with the induced draft fan by a primary cyclone separator, secondary cyclone separators are connected with the induced draft fan, an exhaust pipe is connected to the tops of the secondary cyclone separators, discharge pipes at the bottoms of the primary cyclone separator and the secondary cyclone separators are connected with a spiral conveyor, and a discharge outlet of the spiral conveyor is connected with a sedimentation tank; an impeller of the induced draft fan can timely clean dust by the aid of centrifugal force. The cyclone type mineral flotation and defoaming device has the advantages that emission and water consumption can be reduced, chemicals can be saved, the cyclone type mineral flotation and defoaming device is high in defoaming speed, more importantly, disassembling technologies for the induced draft fan are changed to a great extent, accordingly, pressures of components similar to nuts on the end surfaces of shaft shoulders of screws can be easily eliminated when the induced draft fan is disassembled, the problem that an existing induced draft fan assembled in a threaded manner is continuously automatically locked under the effects of load and is difficult to detach can be effectively solved, the cyclone type mineral flotation and defoaming device is particularly applicable to conveniently and quickly detaching large fans after the large fans are locked in a threaded manner, and particularly obvious effects can be realized.

Owner:SUZHOU KANGDUN ENVIRONMENTAL PROTECTION TECH CO LTD

The fan is easy to disassemble the Raymond mill device

InactiveCN105521855BHigh extrusion rigidityStrong extrusion rigidityHuman health protectionUsing liquid separation agentCycloneImpeller

The invention discloses a Raymond mill device with a convenient-to-disassemble fan. The fan, a Raymond mill, a cyclone separation discharger and a return air pipe form an airflow circulating milling discharging system, a pressure-equalizing exhausting branched pipe is connected with the upper end of a cyclone pipe, multiple cyclone separators are arranged in the cyclone pipe, the lower end of the cyclone pipe is tangentially connected with the cyclone separation discharger, the cyclone separation discharger discharges purified air and immerses below liquid level of a circulating water pool which is connected with the upper end of the cyclone pipe, blades of an induced draft fan impeller are arranged radially in a manner than the impeller is in axial, radial and central symmetry, and centrifugal force can be utilized to timely clean dust to avoid safety accidents. The Raymond mill device is less prone to causing mineral powder dust leakage, disassembling and assembling technology of an induced draft fan is improved substantially, pressure applied on screw shaft shoulder end faces by nut parts can be eliminated simply during disassembling of the fan, and the problem that the induced draft fan which is in threaded assembly constantly locks automatically and is difficult to disassemble under load action is solved effectively. The Raymond mill device is especially suitable for and has particularly remarkable effect on convenient and quick disassembling of large fans after being locked in a threaded manner.

Owner:盐城阳鑫新能源有限公司

A heat pump tail heat utilization inertia dedusting countercurrent dryer

ActiveCN105674715BHigh extrusion rigidityStrong extrusion rigidityPump componentsDrying gas arrangementsCycloneImpeller

The invention discloses a heat pump type reverse flow drying machine with the exhaust heat utilization and inertial dedusting functions. A draught hood of the drying machine is connected with an induced draft fan. The induced draft fan is connected with an evaporator of a heat pump system through a cyclone dedusting device and an inertial dedusting device for evacuation. The evaporator of the heat pump system is connected with a main machine through a refrigerant pipe. The main machine is connected with a condenser through the refrigerant pipe. The air outflow end of an air blower is connected with an air inflow hood through the condenser. Blades of an impeller of the induced draft fan are arranged symmetrical about the center of an impeller shaft in the radial direction in a radial manner, the dust can be cleared up in time through centrifugal force, and safety accidents are avoided. By the adoption of the heat pump type reverse flow drying machine with the exhaust heat utilization and inertial dedusting functions, drying efficiency is improved, and energy saving and emission reduction are achieved; and more importantly, the disassembly technology of the induced draft fan is improved greatly, so that pressure applied to the shaft shoulder end face of a screw by components similar to a nut component can be eliminated easily when the induced draft fan is disassembled, and the problem that the induced draft fan is locked continuously and automatically and cannot be disassembled easily under the load action due to threaded assembly is solved effectively; and the heat pump type reverse flow drying machine with the exhaust heat utilization and inertial dedusting functions is especially suitable for convenient and fast disassembly of a large-scale fan which is locked in a threaded manner, and the effect is especially remarkable.

Owner:安徽中节节能环保科技股份有限公司

Green inertial dust catching preserved product smoking and roasting device with convenient-to-disassemble induced draft fan

InactiveCN105724551AEasy maintenanceHigh extrusion rigidityMeat/fish preservationFood processingImpellerCentrifugal force

The invention discloses a green inertial dust catching preserved product smoking and roasting device with a convenient-to-disassemble induced draft fan. A smoke generation pipeline of a smoke generation furnace penetrates through a wall body to be connected with an air inlet pipe of a cyclone separator, the cyclone separator is connected with the induced draft fan through a pipeline and an inertial dust catcher, and an air outlet of the induced draft fan is arranged in the wall body; a wedge disc is arranged on the smoke generation pipeline of the smoke generation furnace; a light valve is arranged at the bottom of the cyclone separator, and a heat radiator and a vibrator are arranged on the surface of the cyclone separator; blades of an impeller of the induced draft fan are radially arranged symmetrically about the radial direction and center of an impeller shaft, and dust can be timely cleaned by virtue of centrifugal force. According to the device, green and energy-saving smoking and roasting can be implemented; more importantly, an assembling and disassembling technology for the induced draft fan is greatly changed, so that the pressure of parts such as screw caps on the end surfaces of a screw shaft shoulder can be simply eliminated during disassembling, the problem of high disassembling difficulty caused by continuous automatic locking under the action of a load in case of threaded assembling of the induced draft fan is effectively solved, and the device is particularly suitable for convenient disassembling of a large-sized fan after threaded locking, and has particularly remarkable effects.

Owner:JISHOU UNIVERSITY

Heat pump type reverse flow drying machine with exhaust heat utilization and inertial dedusting functions

ActiveCN105674715AHigh extrusion rigidityStrong extrusion rigidityPump componentsDrying gas arrangementsCycloneImpeller

The invention discloses a heat pump type reverse flow drying machine with the exhaust heat utilization and inertial dedusting functions. A draught hood of the drying machine is connected with an induced draft fan. The induced draft fan is connected with an evaporator of a heat pump system through a cyclone dedusting device and an inertial dedusting device for evacuation. The evaporator of the heat pump system is connected with a main machine through a refrigerant pipe. The main machine is connected with a condenser through the refrigerant pipe. The air outflow end of an air blower is connected with an air inflow hood through the condenser. Blades of an impeller of the induced draft fan are arranged symmetrical about the center of an impeller shaft in the radial direction in a radial manner, the dust can be cleared up in time through centrifugal force, and safety accidents are avoided. By the adoption of the heat pump type reverse flow drying machine with the exhaust heat utilization and inertial dedusting functions, drying efficiency is improved, and energy saving and emission reduction are achieved; and more importantly, the disassembly technology of the induced draft fan is improved greatly, so that pressure applied to the shaft shoulder end face of a screw by components similar to a nut component can be eliminated easily when the induced draft fan is disassembled, and the problem that the induced draft fan is locked continuously and automatically and cannot be disassembled easily under the load action due to threaded assembly is solved effectively; and the heat pump type reverse flow drying machine with the exhaust heat utilization and inertial dedusting functions is especially suitable for convenient and fast disassembly of a large-scale fan which is locked in a threaded manner, and the effect is especially remarkable.

Owner:安徽中节节能环保科技股份有限公司

A Tail Heat Utilizing Inertial Dust Capture Hot Air Penetration Counterflow Dryer

ActiveCN105651029BHigh extrusion rigidityStrong extrusion rigidityPump componentsDrying gas arrangementsWhirlwindAir blower

The invention discloses a hot-air penetration and reversed-current drying machine for tail heat utilization and inertial dust catching. According to the invention, an air draft hood of a drying machine box body is connected with an induced draft fan, and the induced draft fan is tangentially connected with a cyclone dust removal and efficient tail heat recovery device which is formed by superposing a tubular heat exchanger and a cyclone dust remover via an inertial dust catcher, and then is emptied; a shell-pass intake end of the tubular heat exchanger is connected with an air blower, and an exhaust end is connected with an air intake hood via a steam finned heater; and blades of an induced draft fan impeller are arranged to be in a radial shape with impeller-shaft radial and central symmetry, and ash can be timely cleaned by virtue of a centrifugal force, thus security incidents are avoided. According to the invention, drying efficiency is improved, and energy conservation and emission reduction are realized; and more importantly, a detachment technology for the induced draft fan is greatly improved, and a pressure of components such as a nut on the end surface of a shaft shoulder of a screw during detachment for the induced draft fan can be simply eliminated, thus the problem is effectively solved that the induced draft fan is not easy to detach due to continuously automatic locking in thread assembly for the induced draft fan under the action of a load. The hot-air penetration and reversed-current drying machine for tail heat utilization and inertial dust catching is especially suitable for convenient detachment for a large fan after thread locking, and has a particularly remarkable effect.

Owner:HUNAN NONGYOU MACHINERY GRP

Induced-draft traditional Chinese medicinal material pulverizer with convenient-to-disassemble induced draft fan

ActiveCN105709913ADoes not affect dynamicDoes not affect balanceCombination devicesGrain treatmentsImpellerAir volume

The invention discloses an induced-draft traditional Chinese medicinal material pulverizer with a convenient-to-disassemble induced draft fan. The induced-draft traditional Chinese medicinal material pulverizer comprises a pulverizer body and the induced draft fan, wherein the material falling end of the pulverizer body is connected with the induced draft fan by a material storage box, exhaust tubes and a cyclone separator, and a ventilation door used for adjusting air volume is arranged one exhaust tube, a pull-back separator is arranged on the exhaust tube, the material falling end of the pull-back separator is connected with a feed hopper, and the feed hopper is connected with the pulverizer body; and an impeller of the induced draft fan can promptly clean dust by use of the centrifugal force. The induced-draft traditional Chinese medicinal material pulverizer not only can complete returning and secondary crushing of coarse particles in one step to realize qualified material output, and more importantly, the assembly and disassembly technology of the induced draft fan is greatly improved to ensure that pressure exerted on the end surface of a screw shaft shoulder by similar nut parts is simply eliminated during disassembly of the induced draft fan, so that the problem that the induced draft fan in screw assembly is continually and automatically locked under the load action and therefore is difficult to disassemble is solved. The improved assembly and disassembly technology is particularly suitable for convenient disassembly of a large-scale fan in screw-threaded coupling, and the effect is particularly remarkable.

Owner:山西天生制药有限责任公司

Rotating drum dust removal and air suction type traditional Chinese medicinal material smashing machine with induced draft fan convenient to disassemble

ActiveCN105689100ADoes not affect dynamicDoes not affect balancePump componentsGrain treatmentsImpellerAir volume

The invention discloses a rotating drum dust removal and air suction type traditional Chinese medicinal material smashing machine with an induced draft fan convenient to disassemble. The smashing machine comprises a smashing machine body and the induced draft fan. The material falling end of the smashing machine body is connected with the induced draft fan through a material storage box, an air suction pipe, a cyclone separator and a rotating drum type dust removal machine; an air outlet of the induced draft fan is connected with a cloth bag dust collector; and the air suction pipe is provided with an air door for adjusting the air volume. An impeller of the induced draft fan can clear away dust in time through centrifugal force. Coarse particle returning and secondary smashing are completed by the smashing machine through one step, qualified output of materials is achieved, more importantly, the disassembly and assembly technology of the induced draft fan is substantially improved, pressure of parts similar to nut parts on the shaft shoulder end face of a screw can be easily eliminated in the disassembly process of the induced draft fan, the problem that disassembly is difficult because a thread assembly of the induced draft fan is continuously locked automatically is effectively solved, the disassembly technology is particularly for convenient and fast disassembly of threads of large draught fans after the threads are locked, and the effect is particularly remarkable.

Owner:安徽济人药业股份有限公司

Tail heat recovery steam plate dryer

ActiveCN105806068BHigh extrusion rigidityStrong extrusion rigidityPump componentsDrying gas arrangementsImpellerCyclone

Owner:JIANGSU ZHONGLI PETROCHEM EQUIP

A tail heat utilization hot air penetrating countercurrent dryer

ActiveCN105651028BHigh extrusion rigidityStrong extrusion rigidityPump componentsDrying gas arrangementsImpellerReverse current

The invention discloses a hot-air penetration and reversed-current drying machine for tail heat utilization. According to the invention, an air draft hood of a drying machine box body is connected with an induced draft fan, and the induced draft fan is tangentially connected with a cyclone dust removal and efficient tail heat recovery device which is formed by superposing a tubular heat exchanger and a cyclone dust remover, and then is emptied; a shell-pass intake end of the tubular heat exchanger is connected with an air blower, and an exhaust end is connected with an air intake hood via a steam finned heater; and blades of an induced draft fan impeller are arranged to be in a radial shape with impeller-shaft radial and central symmetry, and ash can be timely cleaned by virtue of a centrifugal force, thus security incidents are avoided. According to the invention, drying efficiency is improved, and energy conservation and emission reduction are realized; and more importantly, a detachment technology for the induced draft fan is greatly improved, and a pressure of components such as a nut on the end surface of a shaft shoulder of a screw during detachment for the induced draft fan can be simply eliminated, thus the problem is effectively solved that the induced draft fan is not easy to detach due to continuously automatic locking in thread assembly for the induced draft fan under the action of a load. The hot-air penetration and reversed-current drying machine for tail heat utilization is especially suitable for convenient detachment for a large fan after thread locking, and has a particularly remarkable effect.

Owner:江西高胜动物保健品有限公司

Exhaust heat recovery type steam slab drying machine with inertial dust collecting function

ActiveCN105674714AHigh extrusion rigidityStrong extrusion rigidityDrying gas arrangementsDrying machines with progressive movementsCycloneImpeller

The invention discloses an exhaust heat recovery type steam slab drying machine with the inertial dust collecting function. An upper drying region of the drying machine is connected with an efficient cyclone dedusting exhaust heat recovery device in a tangential manner through an induced draft fan and an inertial dust collecting device, wherein the efficient cyclone dedusting exhaust heat recovery device is formed by stacking a tube bank type heat exchanger and a cyclone dust collector. Dust is discharged through a closed-air aspirator at the cone bottom after rotational flow dedusting. Exhaust communicates with a cone through a rotational flow ascending pipe, penetrates a tube bank after being evenly dispersed and is concentrated by a conical hopper on the upper portion and then exhausted through an exhaust pipe. Blades of an impeller of the induced draft fan are arranged symmetrical about the center of an impeller shaft in the radial direction in a radial manner, and the dust can be cleared up in time through centrifugal force. By the adoption of the exhaust heat recovery type steam slab drying machine with the inertial dust collecting function, drying efficiency is improved, and energy saving and emission reduction are achieved; and more importantly, the disassembly technology of the induced draft fan is improved greatly, so that pressure applied to the shaft shoulder end face of a screw by components similar to a nut component can be eliminated easily when the induced draft fan is disassembled, and the problem that the induced draft fan is locked continuously and automatically and cannot be disassembled easily under the load action due to threaded assembly is solved effectively; and the exhaust heat recovery type steam slab drying machine with the inertial dust collecting function is especially suitable for convenient and fast disassembly of a large-scale fan which is locked in a threaded manner.

Owner:安徽上元家居材料股份有限公司

Heat pump tail heat utilizes inertial dust removal to penetrate countercurrent dryer

ActiveCN105674713BHigh extrusion rigidityStrong extrusion rigidityPump componentsDrying gas arrangementsImpellerEngineering

The invention discloses a heat pump type waste heat utilization inertial dust collection penetrating countercurrent drying machine. An exhaust hood of the drying machine is connected with an induced draught fan. The induced draught fan is evacuated after being connected with an evaporator of a heat pump system through a cyclone dust collector and a repeated back-turning baffle type inertial dust collector. The evaporator of the heat pump system is connected with a main machine through a refrigerant pipe. The main machine is connected with a condenser through a refrigerant pipe. The air outlet end of an air blower is connected in an air inlet hood through the condenser. Blades of an impeller of the induced draught fan are arranged to be in a radial shape and centrosymmetric about an impeller shaft in the radial direction, dust can be removed in time under the effect of centrifugal force, and safety accidents are avoided. The drying efficiency is improved, energy conservation and emission reduction are achieved, more importantly, a demounting and mounting technology of the induced draught fan is transformed to a great extent, when the induced draught fan is demounted, the pressure applied to the end face of a screw shaft shoulder by nut-like parts can be simply eliminated, the problem that the induced draught fan assembled in a threaded manner is automatically locked continuously under the effect of loads and cannot be easily demounted is effectively solved, the heat pump type waste heat utilization inertial dust collection penetrating countercurrent drying machine is particularly suitable for convenient demounting of large draught fans which are locked in a threaded manner, and effects are particularly obvious.

Owner:四川良仕农业科技有限公司

Drum type dust removal device for easy disassembly of induced draft fan

The invention discloses a drum-type dedusting device which can be easily disassembled by an induced draft fan. The drum has a cylindrical structure, and the cylinder is incompletely separated by several partitions; the drum is connected with a motor and can rotate with the motor at high speed; The upper and lower ends of the drum have openings, the upper air collection box is connected to the air inlet, the lower air collection box is connected to the induced draft fan, and the air outlet of the induced draft fan is connected to the bag filter; the lower air collection box is equipped with a dust removal door for easy dust removal ; The impeller of the induced draft fan can use the centrifugal force to clean up the dust in time. The invention not only has simple structure and good dust removal effect, but more importantly, it greatly improves the disassembly and assembly technology of the induced draft fan, so that it can simply eliminate the pressure on the end surface of the screw shaft shoulder by similar nut parts during disassembly, and effectively solve the problem of the induced draft fan. The problem that the threaded assembly is continuously and automatically locked under load and difficult to disassemble is especially suitable for the convenient disassembly of large fans after the thread is locked, and the effect is particularly remarkable.

Owner:湖南美林住宅工业有限公司

A heat pump tail heat utilization countercurrent dryer

ActiveCN105651030BHigh extrusion rigidityStrong extrusion rigidityPump componentsDrying gas arrangementsImpellerReverse current

The invention discloses a heat-pump reversed-current drying machine for tail heat utilization. According to the invention, an air draft hood of the drying machine is connected with an induced draft fan, and the induced draft fan is connected with an evaporator of a heat pump system via a cyclone dust remover, and then is emptied; the evaporator of the heat pump system is connected with a host via a refrigerant tube, and the host is connected with a condenser via the refrigerant tube; an exhaust end of an air blower is connected with an air intake hood via the condenser; and blades of an induced draft fan impeller are arranged to be in a radial shape with impeller-shaft radial and central symmetry, and ash can be timely cleaned by virtue of a centrifugal force, thus security incidents are avoided. According to the invention, drying efficiency is improved, and energy conservation and emission reduction are realized; and more importantly, a detachment technology for the induced draft fan is greatly improved, and a pressure of components such as a nut on the end surface of a shaft shoulder of a screw during detachment for the induced draft fan can be simply eliminated, thus the problem is effectively solved that the induced draft fan is not easy to detach due to continuously automatic locking in thread assembly for the induced draft fan under the action of a load. The heat-pump reversed-current drying machine for tail heat utilization is especially suitable for convenient detachment for a large fan after thread locking, and has a particularly remarkable effect.

Owner:NANTONG PRATT MACHINERY

A tail heat utilization hot air penetrating countercurrent fluidized dryer

ActiveCN105758151BHigh extrusion rigidityStrong extrusion rigidityDrying gas arrangementsDrying solid materialsEngineeringAir blower

The invention discloses a tail heat utilized hot-air type penetration countercurrent fluidized drying machine. A draught fan is connected to the upper part of a drying tower; the draught fan is tangentially connected with a cyclone dust removal tail heat efficient recoverer which is formed by a tube type heat exchanger and a cyclone dust collector which are overlapped, and is evacuated; the shell pass air inlet end of the tube type heat exchanger is communicated with the atmosphere; the air outlet of the tube type heat exchanger is connected to the lower part of the drying tower through an air blower and a steam fin heater; blades of the draught fan impeller are arranged in a radiation manner that impeller shafts are in radial and central symmetry; dust can be collected by virtue of centrifugal force in time, and thus security accidents can be avoided. By adopting the tail heat utilized hot-air type penetration countercurrent fluidized drying machine, the drying efficiency is improved, the purposes of energy conservation and emission reduction are achieved, more importantly, the assembling and disassembling technique of the draught fan is greatly improved, pressure caused by components such as a screw nut to the shoulder end surface of a screw shaft can be easily eliminated when the draught fan is assembled and disassembled, the problem that the draught fan is continuously automatically locked and is not easy to disassemble under the action of load in threaded assembling can be effectively solved, and the tail heat utilized hot-air type penetration countercurrent fluidized drying machine is particularly applicable to convenient and rapid disassembling after a large-size draught fan is in threaded locking and is particularly remarkable in effect.

Owner:安徽上元家居材料股份有限公司

Exhaust heat drying rotary kiln with induced draft fan convenient to disassemble

PendingCN105673568AFacilitate material turnoverIncrease the flame heating areaPump componentsDrying solid materialsImpellerEngineering

The invention discloses an exhaust heat drying rotary kiln with an induced draft fan convenient to disassemble. The rotary kiln is obliquely arranged and internally provided with a combustor. The high end of the rotary kiln is bidirectionally connected with one end of a drying machine through a discharging pipe and an air pipe. A conveyor belt is arranged in the drying machine and connected with the discharging pipe. A closed-air aspirator is arranged at the other end of the drying machining. A protruding refractory slab is arranged in the rotary kiln. The drying machine is connected with the induced draft fan through a cyclone dust collector. The closed-air aspirator is connected with the portion below the cyclone dust collector. A dust collection cylinder is arranged below the closed-air aspirator. Dust can be cleaned in time through an impeller of the induced draft fan under the centrifugal force action. By the adoption of the exhaust heat drying rotary kiln with the induced draft fan convenient to disassemble, thermal efficiency is high; besides, the disassembly technology of the induced draft fan is improved greatly, so that pressure applied to the shaft shoulder end face of a screw by components similar to a nut component can be eliminated easily when the induced draft fan is disassembled, and the problem that the induced draft fan is locked continuously and automatically and cannot be disassembled easily under the load action due to threaded assembly is solved effectively; and the exhaust heat drying rotary kiln is especially suitable for convenient and fast disassembly of a large-scale fan which is locked in a threaded manner, and the effect is especially remarkable.

Owner:JISHOU UNIVERSITY

Manganese processing rotary kiln system with bag dust removal type for easy disassembly of induced draft fan

InactiveCN105783505BHigh extrusion rigidityStrong extrusion rigidityPump componentsRotary drum furnacesImpellerBaghouse

The invention discloses a bag filter-type manganese processing rotary kiln system with a highly demountable induced draft fan. The bag filter-type manganese processing rotary kiln system adopts the structure that an air-lock valve used for feeding is arranged at the high end of a rotary kiln; the high end of the rotary kiln is connected with a cyclone dust extractor, an induced draft fan and a bag-type dust remover via a fin section and air pipes; fins are arranged in the fin section; a hood cylinder is arranged outside the fin section; a sleeve-type air heat exchanger is arranged outside an air pipe; the hood cylinder is communicated with a lower pumping hole in the air heat exchanger, and then divided into two paths for supplying preheated air; and the blades of the impeller of the induced draft fan are arranged in a radiation shaped and are in radial and central symmetry with respect to an impeller shaft, so that dust can be cleaned promptly via centrifugal force, and safety accidents can be avoided. The bag filter-type manganese processing rotary kiln system not only is high in heat efficiency, but also has the advantages that the demounting technology of the induced draft fan is greatly improved; pressure of a nut-like component on a shaft shoulder end surface of a screw can be eliminated simply during demounting, the problem that a threaded assembly of the induced draft fan is automatically screwed continuously under the action of a load to be difficult to demount can be solved effectively; the suitability for convenient demounting of a large-scale induced draft fan after thread screwing is high; and the effect is remarkable.

Owner:涡阳县华夏气体有限公司

Tail heat utilization inertial dust collection screen hole plate turnover type drying machine

ActiveCN105698511ADoes not affect dynamicDoes not affect balanceDrying gas arrangementsDrying machines with progressive movementsImpellerPulp and paper industry

The invention discloses a tail heat utilization inertial dust collection screen hole plate turnover type drying machine. A drying machine box body is provided with a screen hole plate turnover type conveying part from top to bottom and is provided with a middle partition plate and a lower partition plate, and the drying machine box body is divided into an upper drying area, a middle drying area and a lower drying area through the middle partition plate and the lower partition plate; the upper drying area is connected with an induced draft fan through an inertial dust collection device and an air heat exchanger to be subject to venting, the air outlet end is connected with an air blower air inlet, and an air blower air outlet is connected with a steam fin heater in the middle drying area; blades of an induced draft fan impeller are arranged to be in a radiation shape in impeller shaft radial and central symmetry, centrifugal force can be used for cleaning up dust in time, and safety accidents are avoided; and according to the drying machine, the drying efficiency is improved, energy saving and emission reduction are achieved, more importantly, the dismounting and mounting technology of the induced draft fan is greatly changed, and therefore during dismounting, the pressure of similar nut components on the end face of a screw shaft shoulder can be simply eliminated; and the problem that according to the induced draft fan thread assembly, automatic locking is continuously carried out under the load effect, and dismounting is not likely to be achieved is effectively solved, and the drying machine is particularly suitable for portable dismounting of a large-scale fan obtained after thread locking, and the effect is particularly obvious.

Owner:安徽中节节能环保科技股份有限公司

Tail heat utilizes inertial dust removal sieve hole flap dryer

ActiveCN105698511BHigh extrusion rigidityStrong extrusion rigidityDrying gas arrangementsDrying machines with progressive movementsImpellerPulp and paper industry

The invention discloses a tail heat utilization inertial dust collection screen hole plate turnover type drying machine. A drying machine box body is provided with a screen hole plate turnover type conveying part from top to bottom and is provided with a middle partition plate and a lower partition plate, and the drying machine box body is divided into an upper drying area, a middle drying area and a lower drying area through the middle partition plate and the lower partition plate; the upper drying area is connected with an induced draft fan through an inertial dust collection device and an air heat exchanger to be subject to venting, the air outlet end is connected with an air blower air inlet, and an air blower air outlet is connected with a steam fin heater in the middle drying area; blades of an induced draft fan impeller are arranged to be in a radiation shape in impeller shaft radial and central symmetry, centrifugal force can be used for cleaning up dust in time, and safety accidents are avoided; and according to the drying machine, the drying efficiency is improved, energy saving and emission reduction are achieved, more importantly, the dismounting and mounting technology of the induced draft fan is greatly changed, and therefore during dismounting, the pressure of similar nut components on the end face of a screw shaft shoulder can be simply eliminated; and the problem that according to the induced draft fan thread assembly, automatic locking is continuously carried out under the load effect, and dismounting is not likely to be achieved is effectively solved, and the drying machine is particularly suitable for portable dismounting of a large-scale fan obtained after thread locking, and the effect is particularly obvious.

Owner:安徽中节节能环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com