Cyclone Mineral Flotation Defoamer with Induced Fan for Easy Disassembly

A technology of mineral flotation and induced draft fan, applied in cyclone devices, flotation, solid separation, etc., can solve problems such as difficulty in disassembly, and achieve the effect of eliminating fatigue fracture, saving materials, and facilitating lightweight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Now in conjunction with accompanying drawing, the present invention is described in further detail.

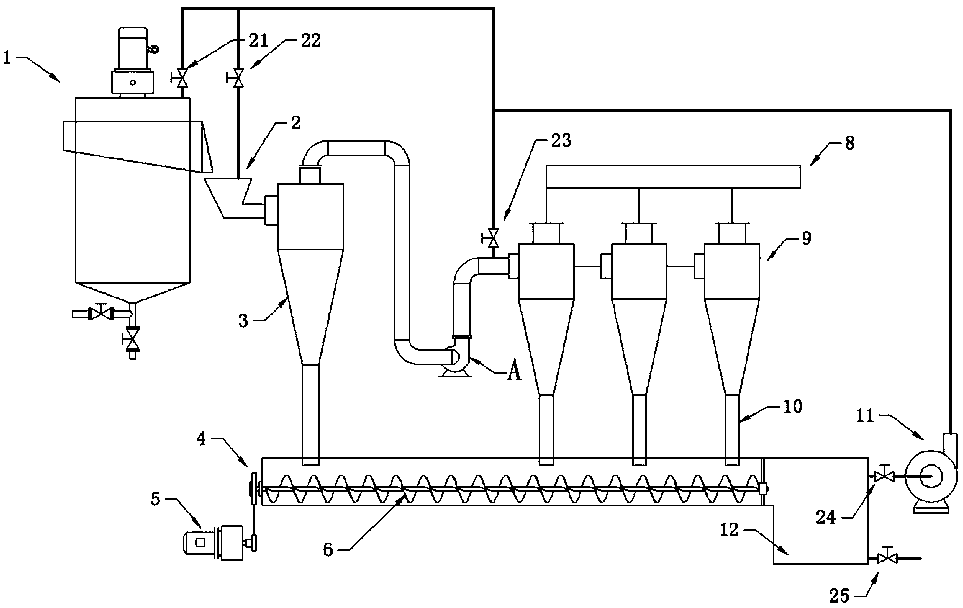

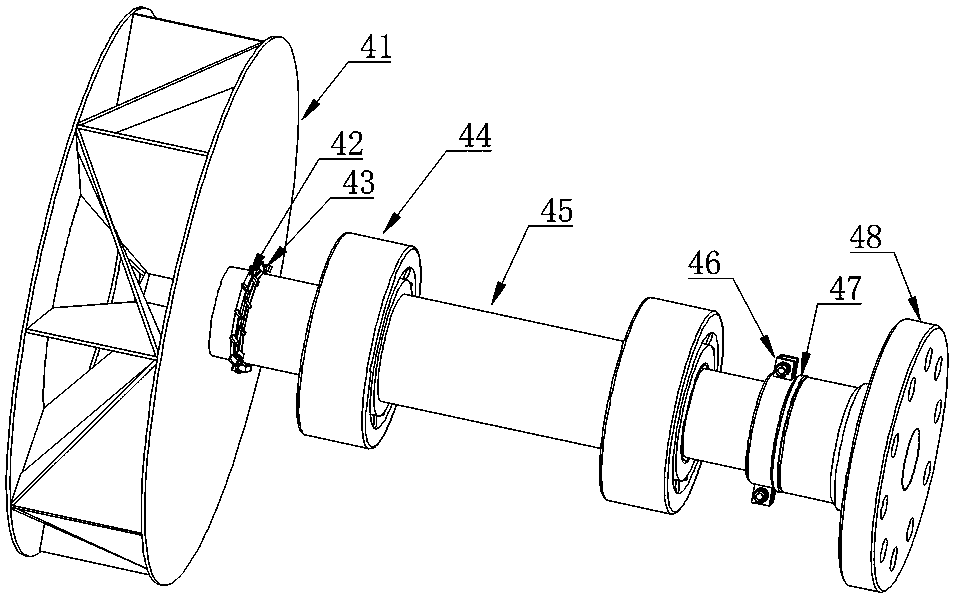

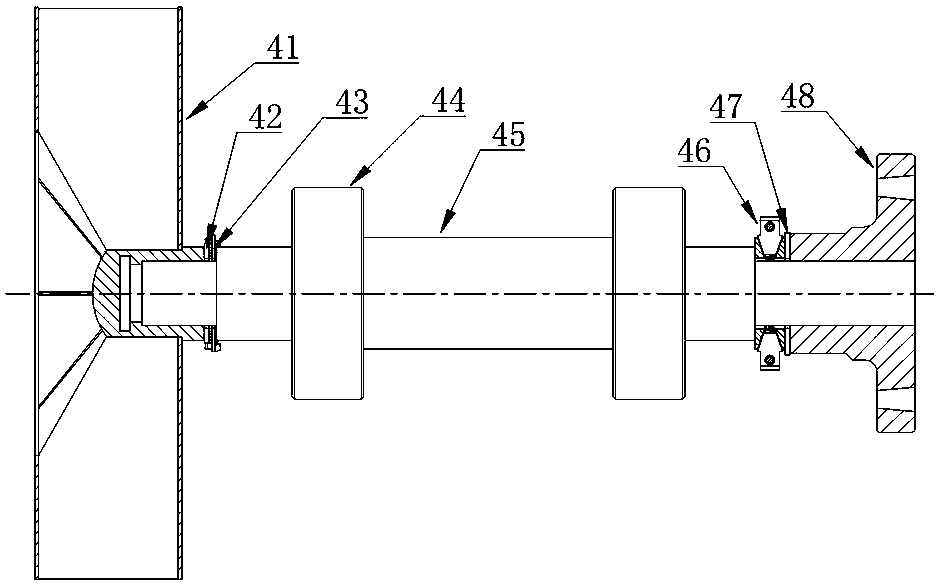

[0041] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 The cyclone-type mineral flotation defoaming device shown is easy to dismantle by induced draft fan, including flotation machine 1, foam inlet hopper 2, primary cyclone separator 3, induced draft fan A, secondary cyclone separator 9, and exhaust pipe 8 , screw conveyor 6 and settling tank 12, the flotation machine 1 is connected into the foam hopper 2, the foam hopper 2 is connected to the induced draft fan A through the primary cyclone separator 3, the induced draft fan A is connected to the secondary cyclone separator 9, and the secondary cyclone The top of the separator 9 is connected to the exhaust pipe 8, and the discharge pipe 10 at the bottom of the primary cyclone separator 3 and the secondary cyclone separator 9 is connected to the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com