Exhaust heat drying rotary kiln with induced draft fan convenient to disassemble

A technology of rotary kiln and induced draft fan, applied in the field of rotary kiln, can solve problems such as difficult disassembly, achieve rapid centrifugal separation, improve efficiency, and achieve remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

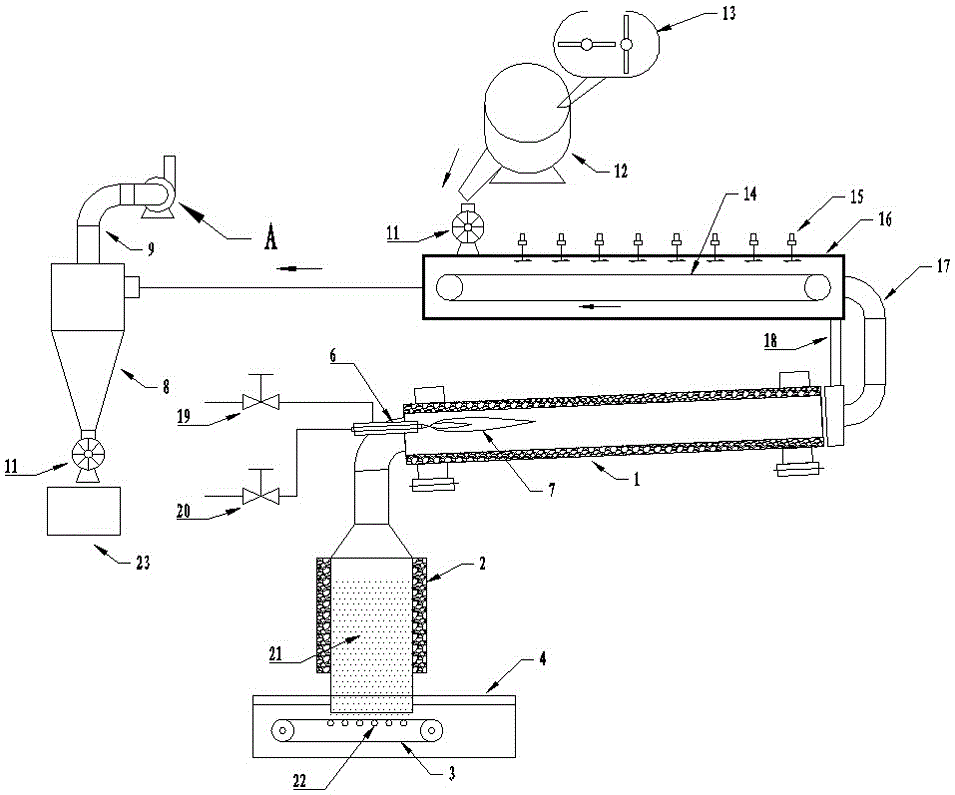

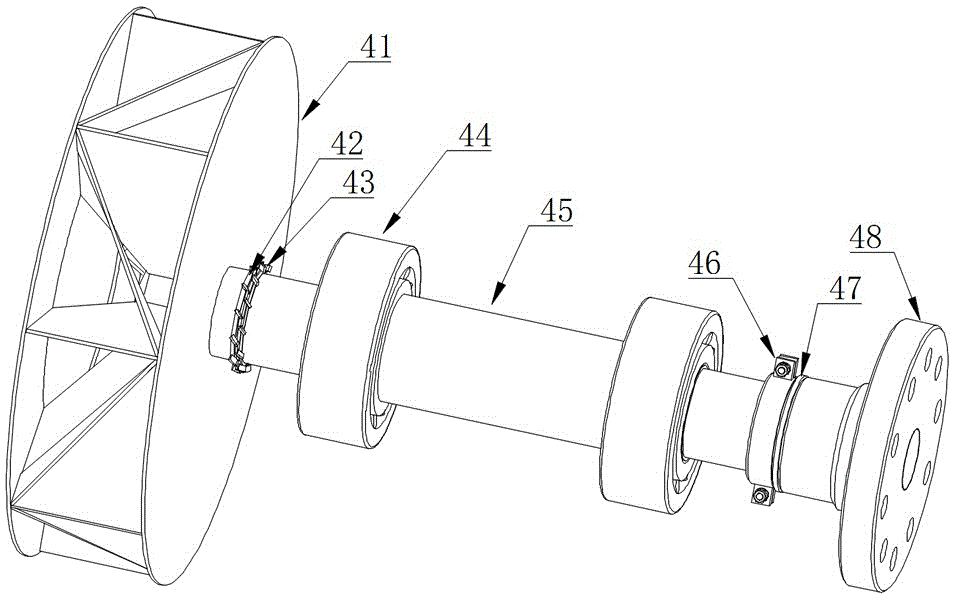

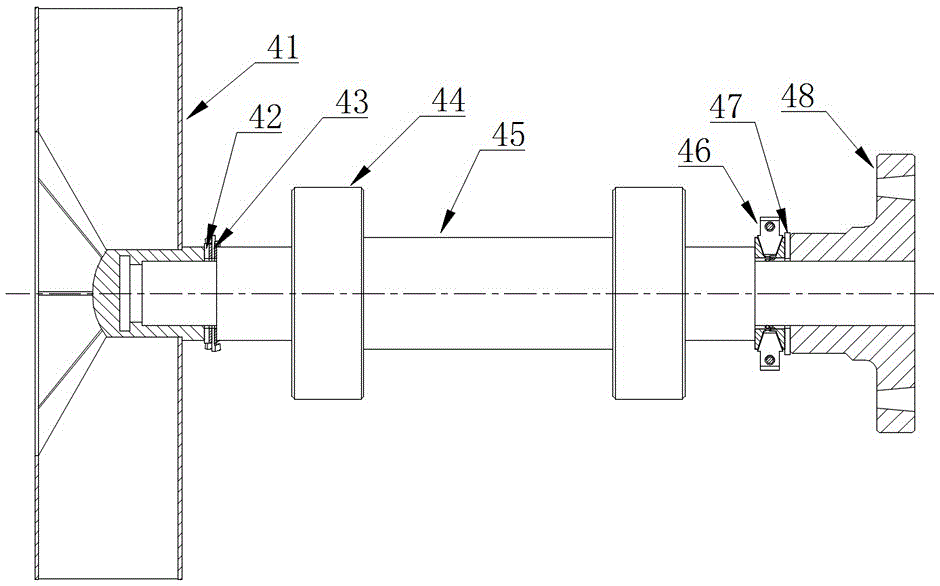

[0042] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0043] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 The exhaust heat drying rotary kiln shown by the induced draft fan is easy to disassemble, including the rotary kiln 1, which is arranged obliquely, and has a built-in burner 6. 17 two-way connection, the dryer 16 is provided with a conveyor belt 14 connected to the drop pipe 18, the other end of the dryer 16 is provided with an air lock 11; the rotary kiln 1 is provided with a raised refractory board 5; The dryer 16 is connected to the induced draft fan A through the cyclone dust collector 8, and the lower side of the cyclone dust collector 8 is connected to the air locker 11, and the lower side of the air locker 11 is provided with a dust collection bucket 23; the induced draft fan A includes a fan impeller 41, a bearing 44, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com