Patents

Literature

111results about How to "Facilitate lightweight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

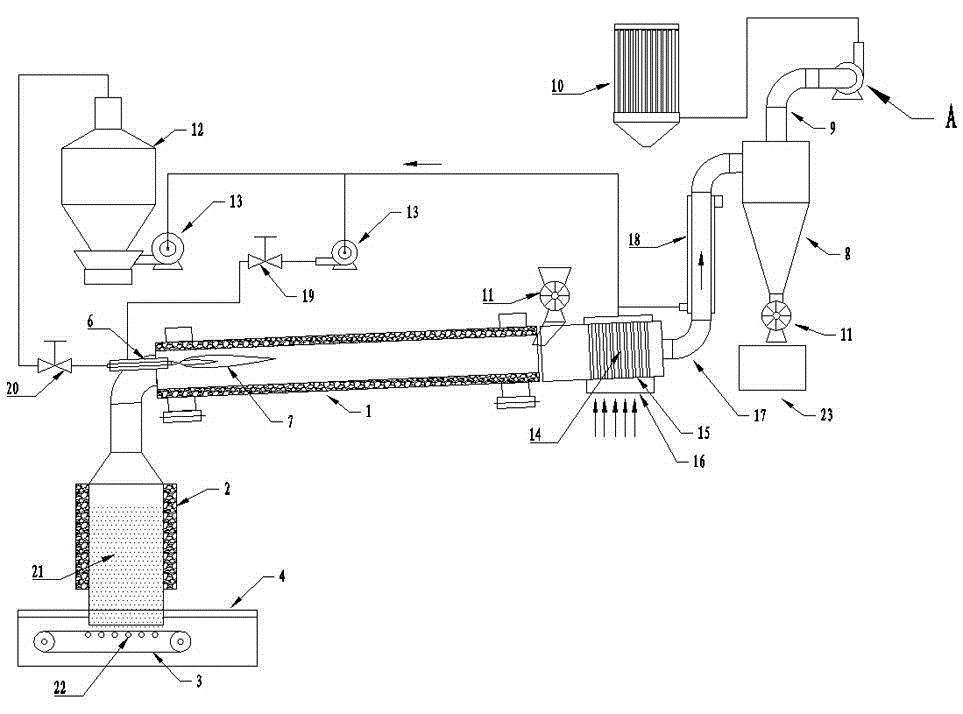

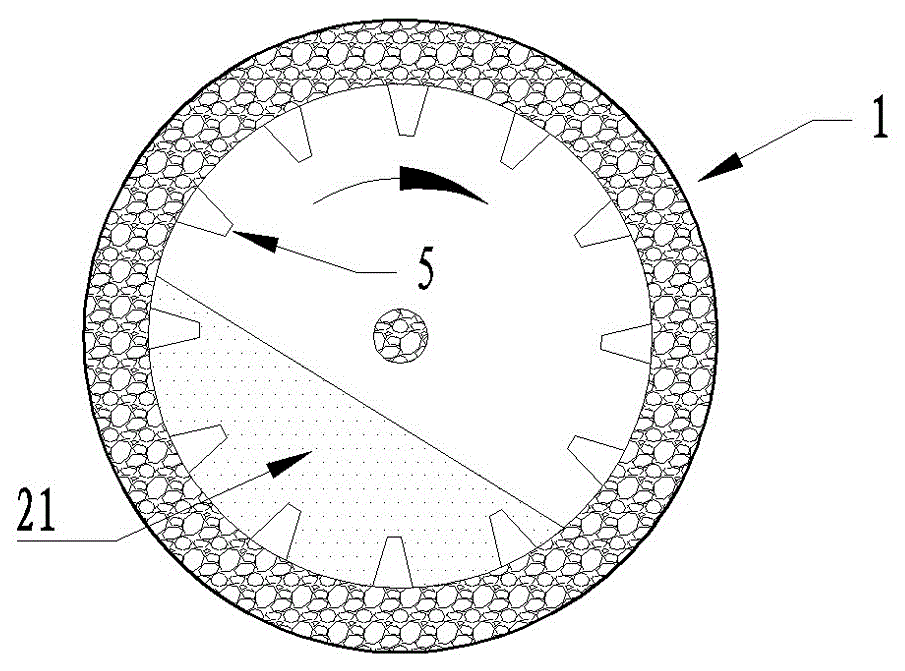

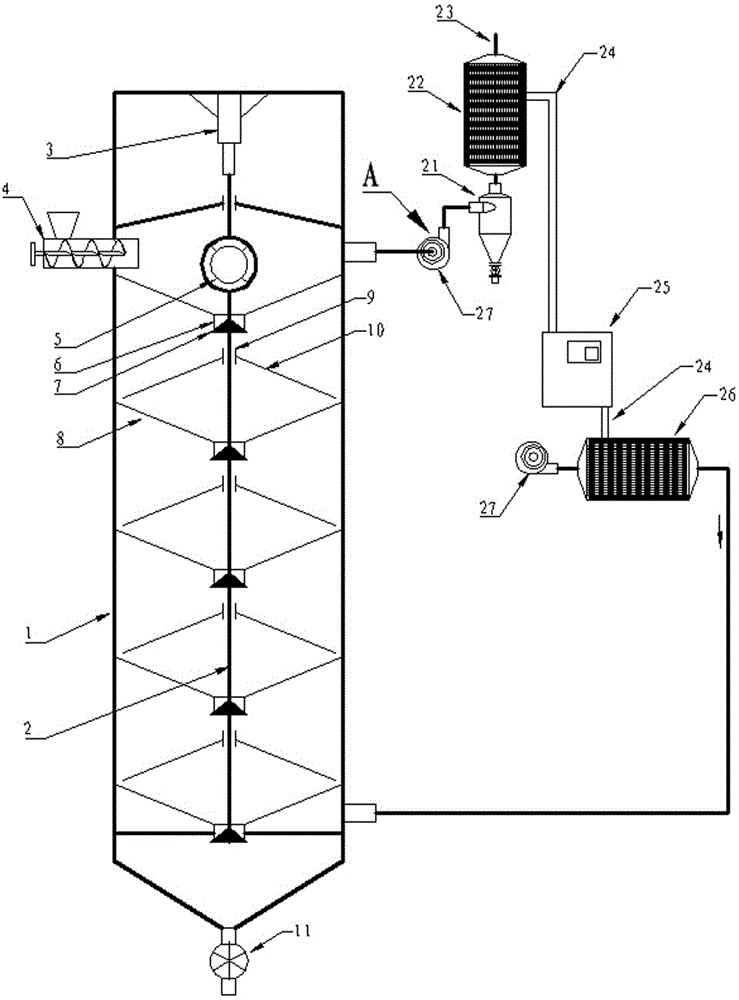

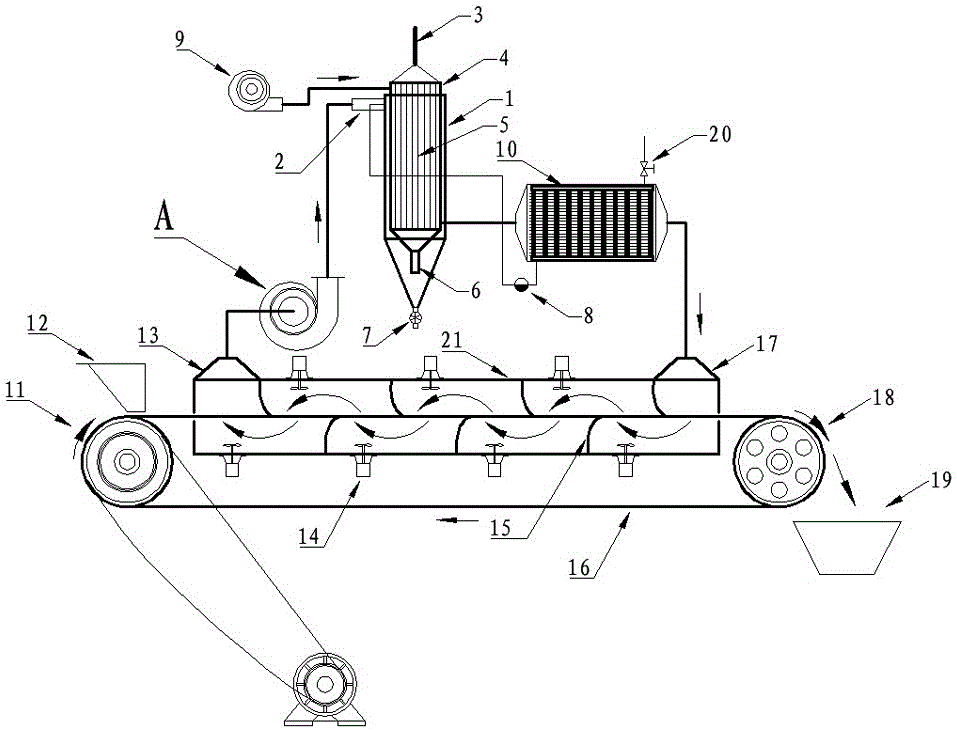

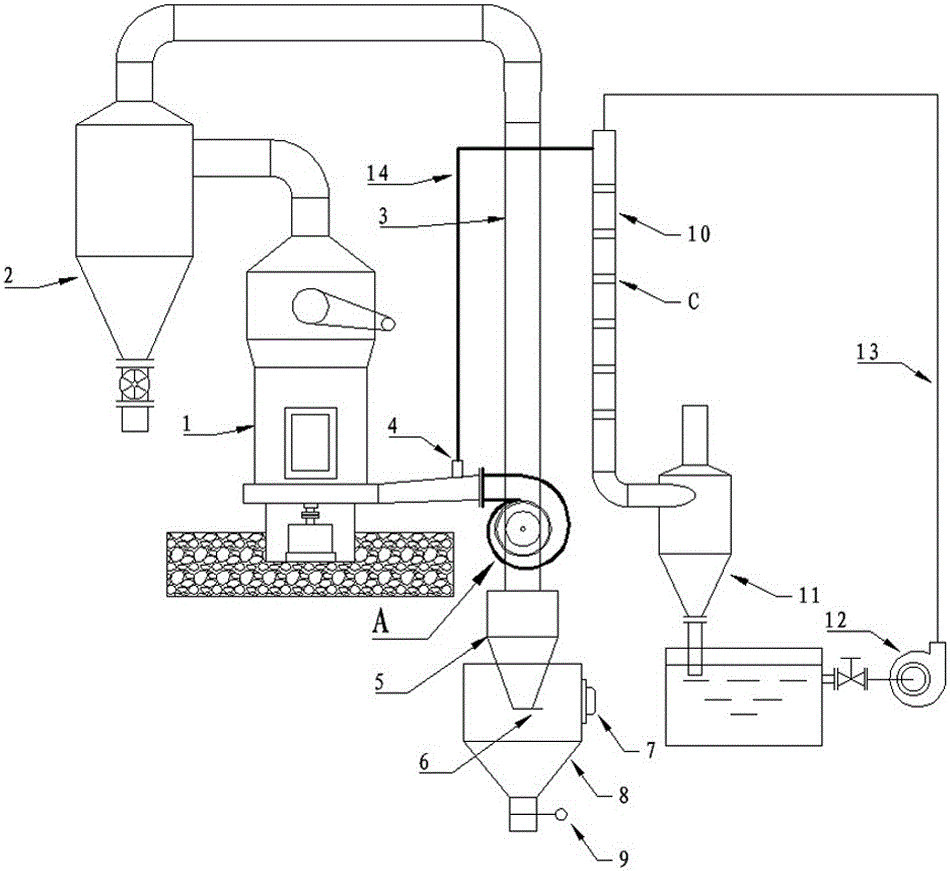

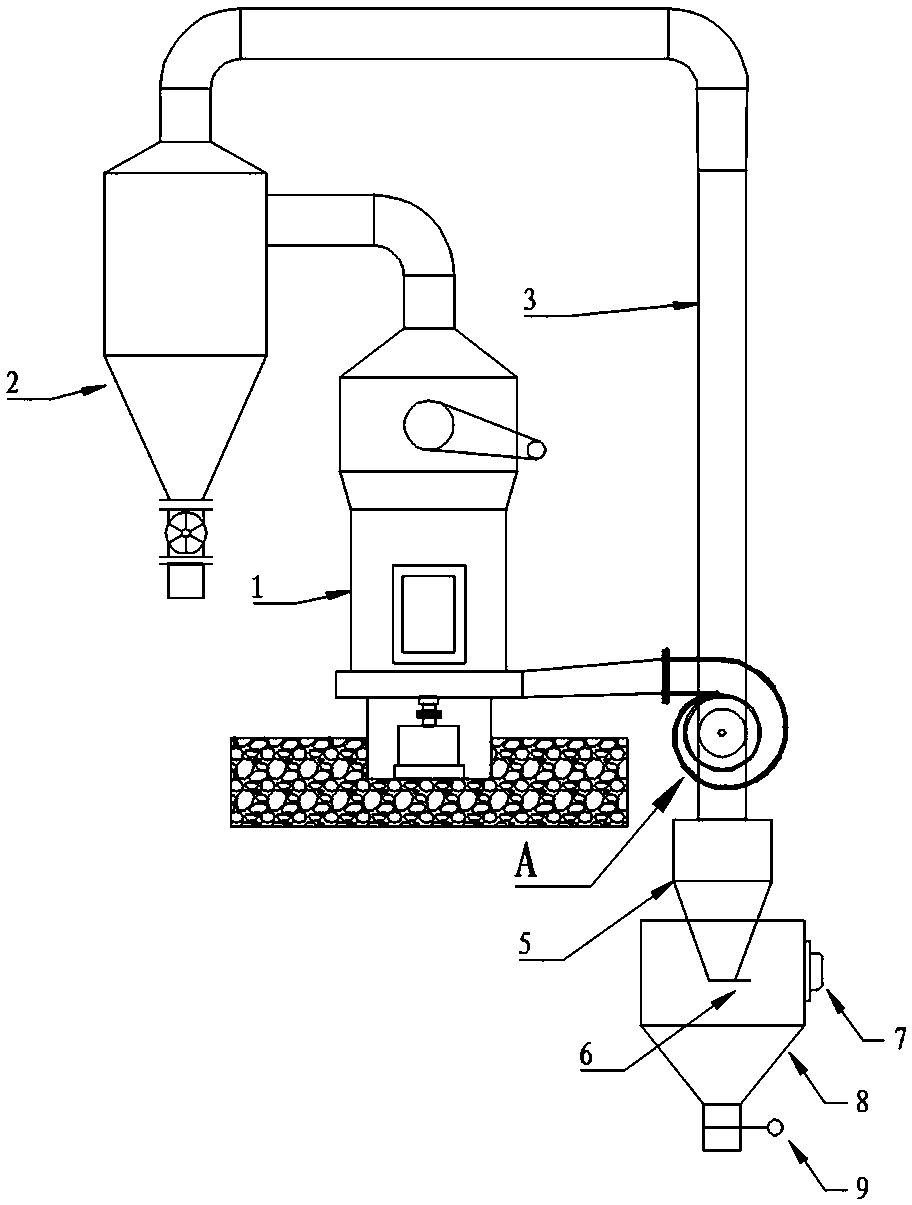

Air suction type grinder for polygonum cuspidatum

InactiveCN105013592AImprove rigidityImprove carrying capacityPump componentsVortex flow apparatusAir volumeInvolute

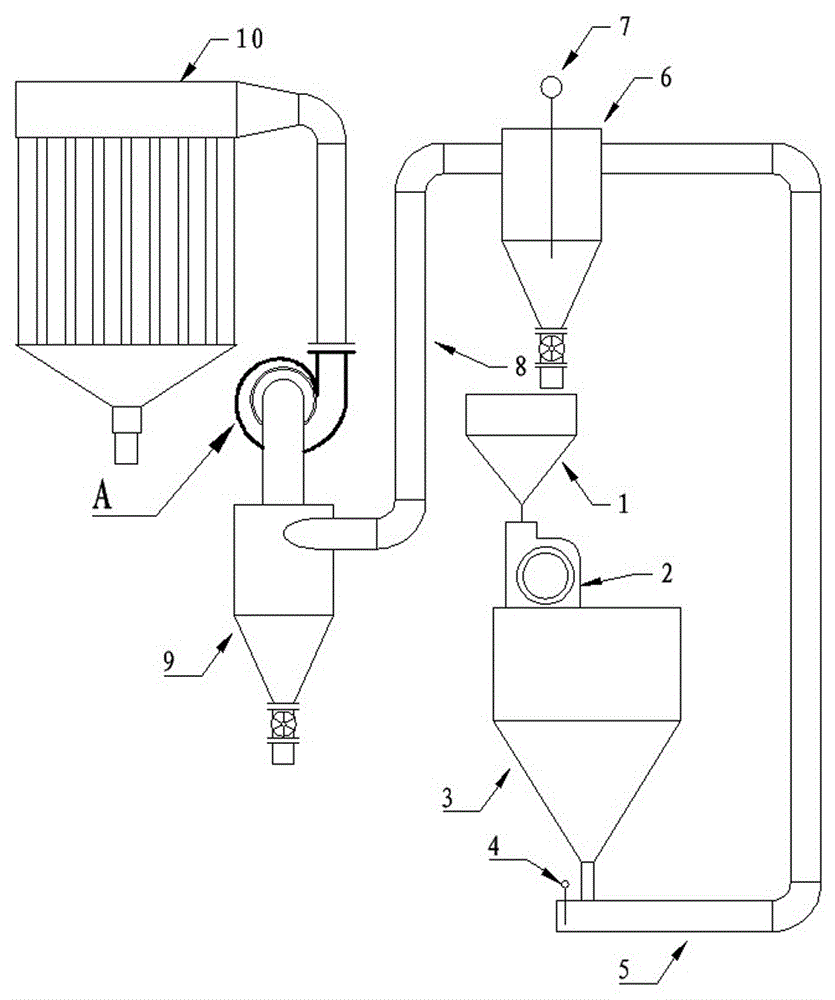

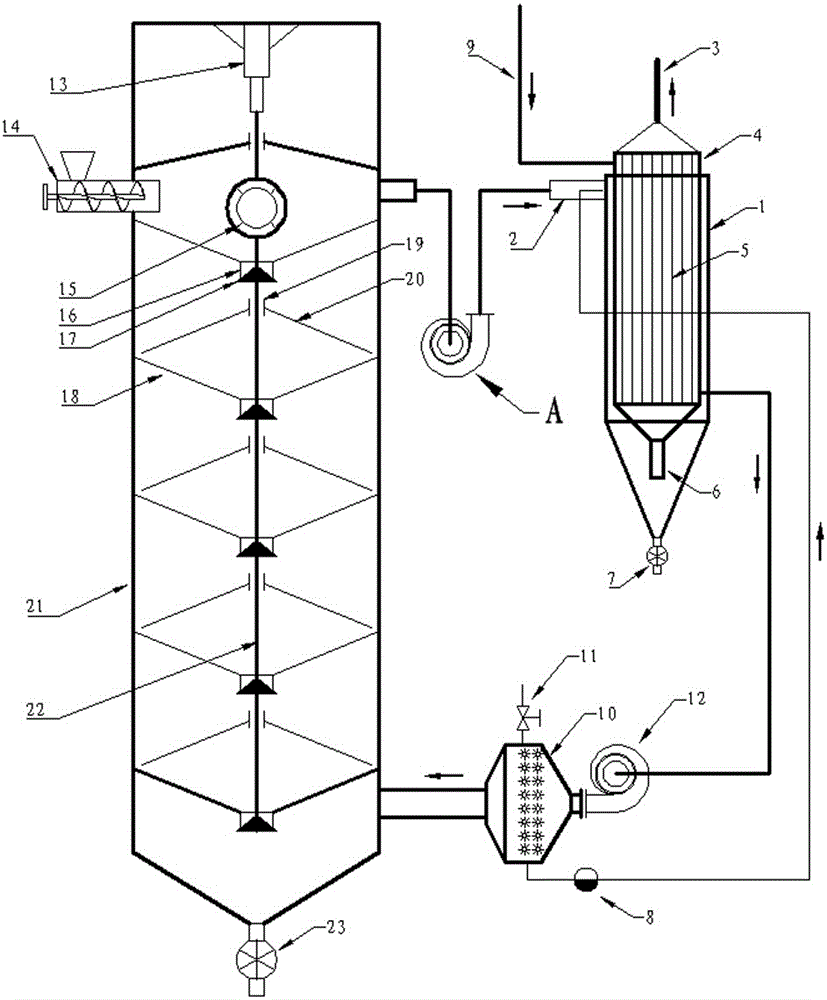

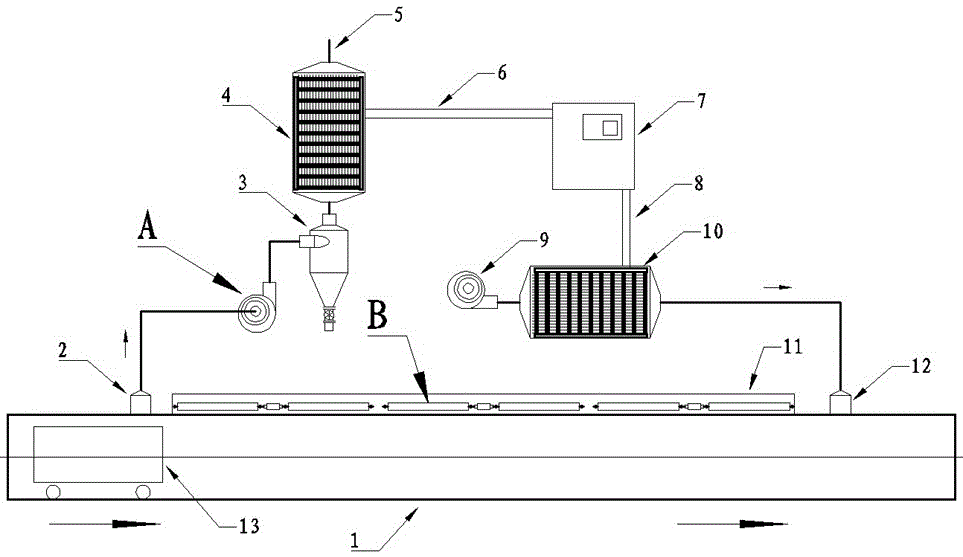

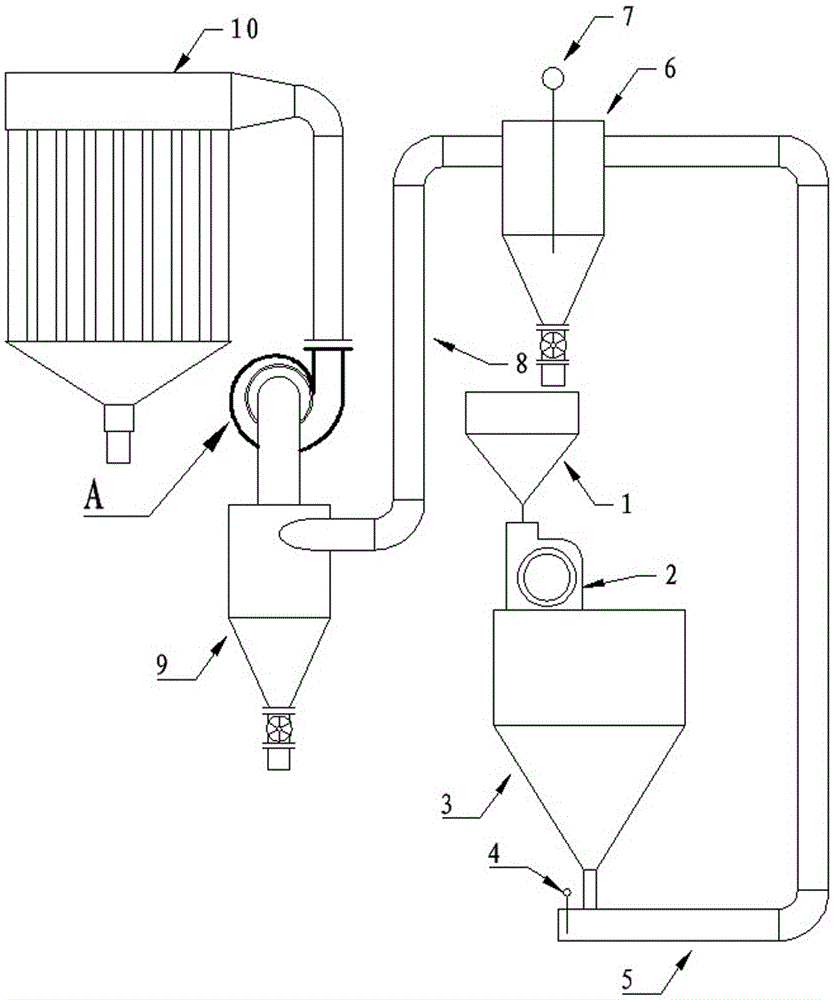

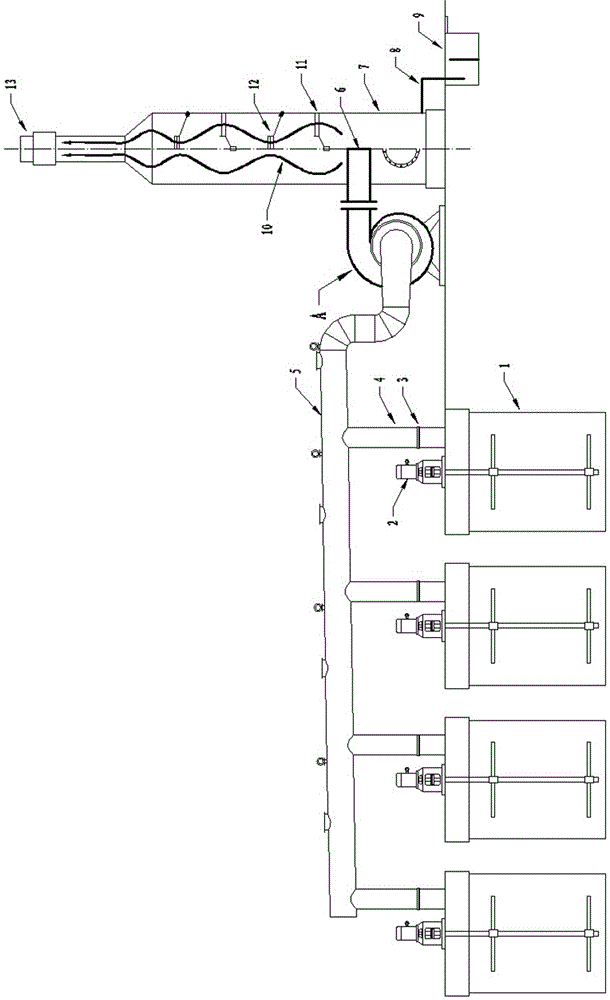

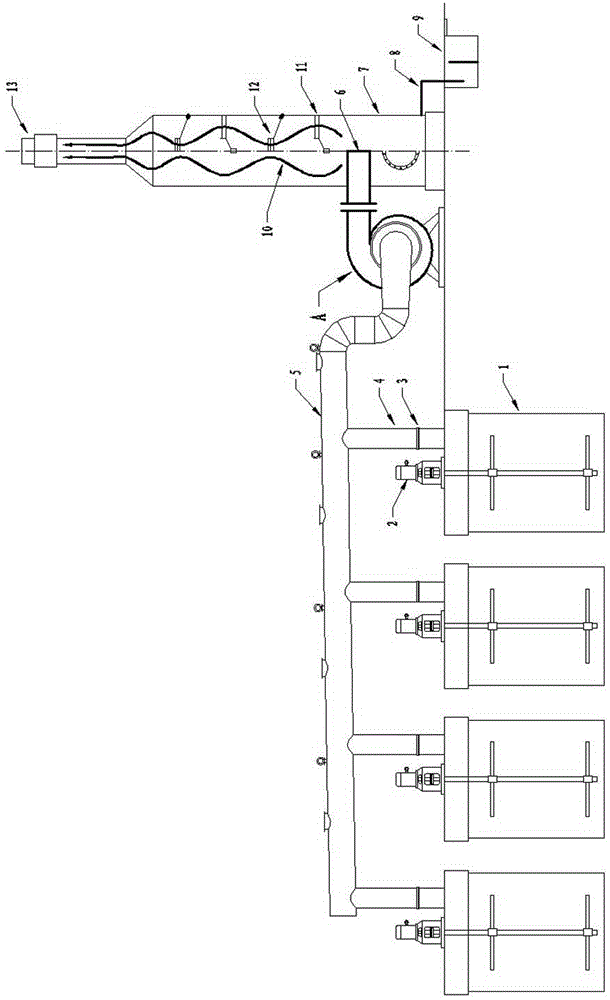

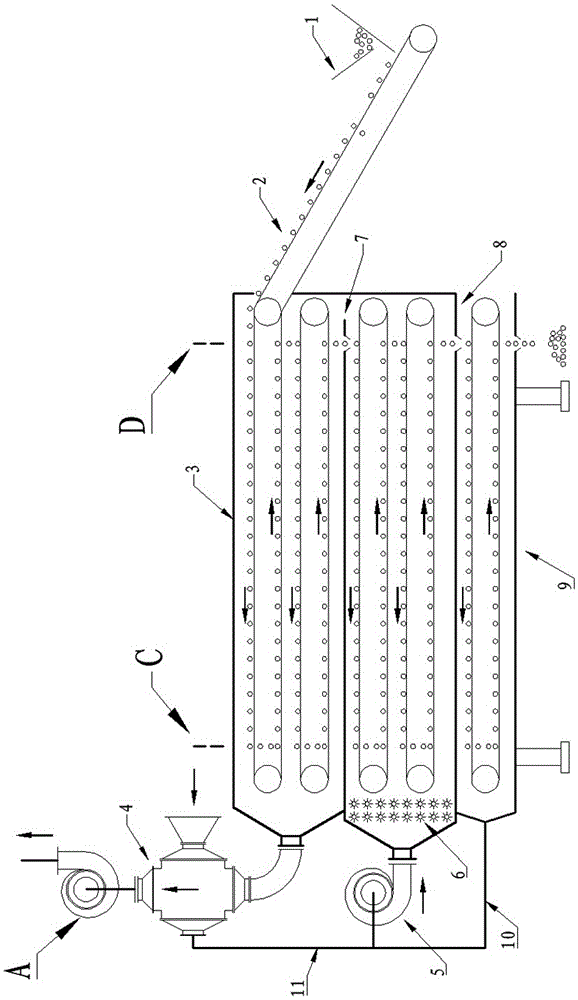

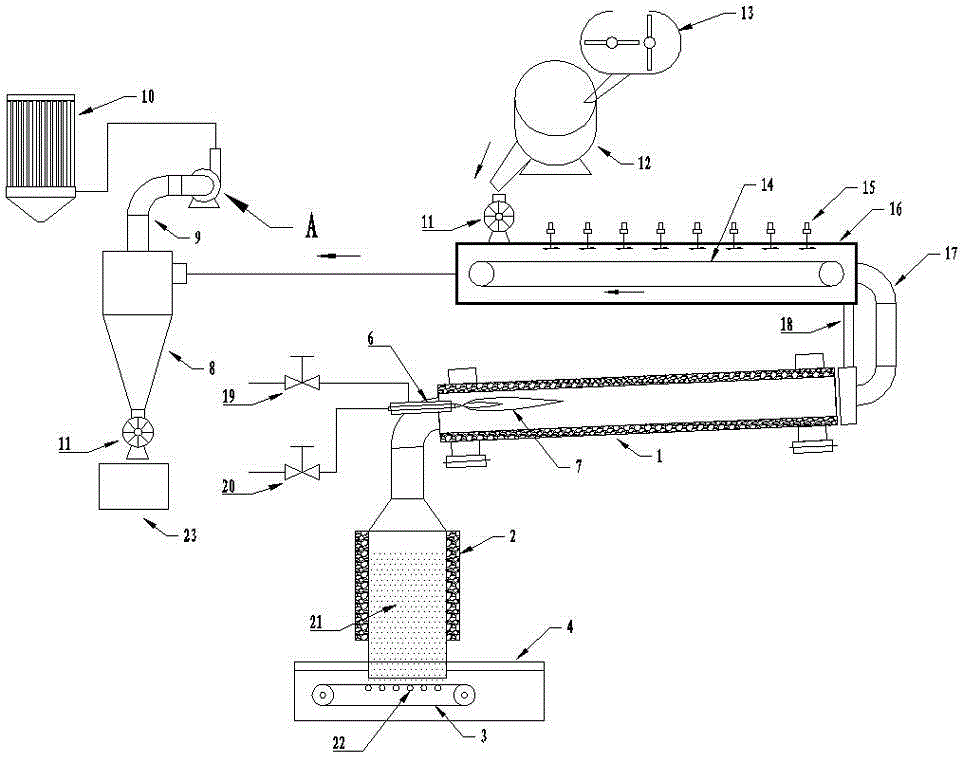

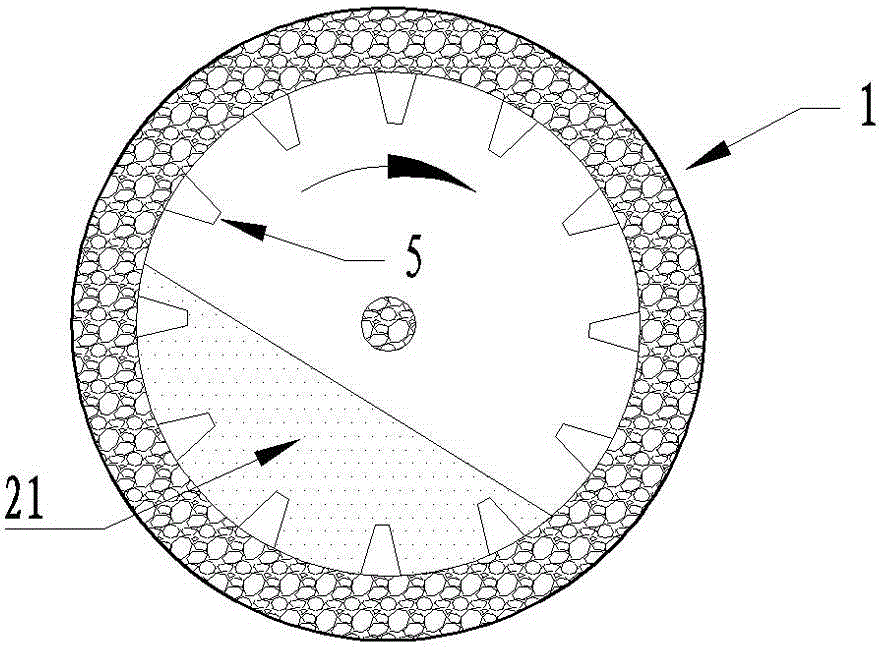

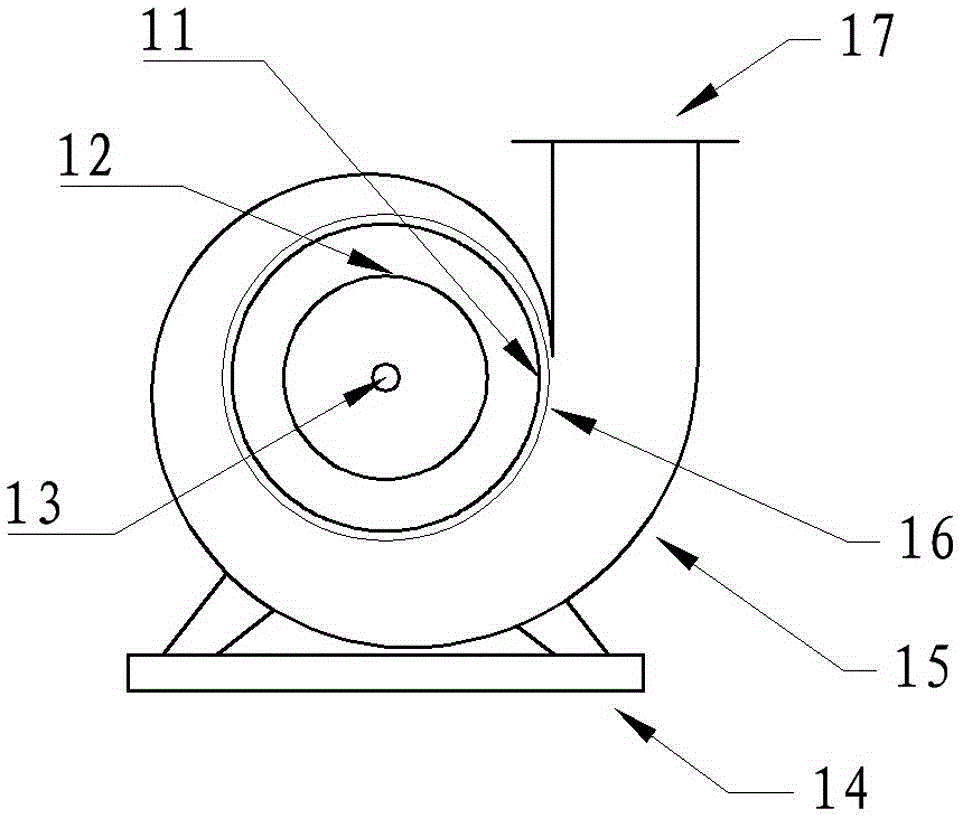

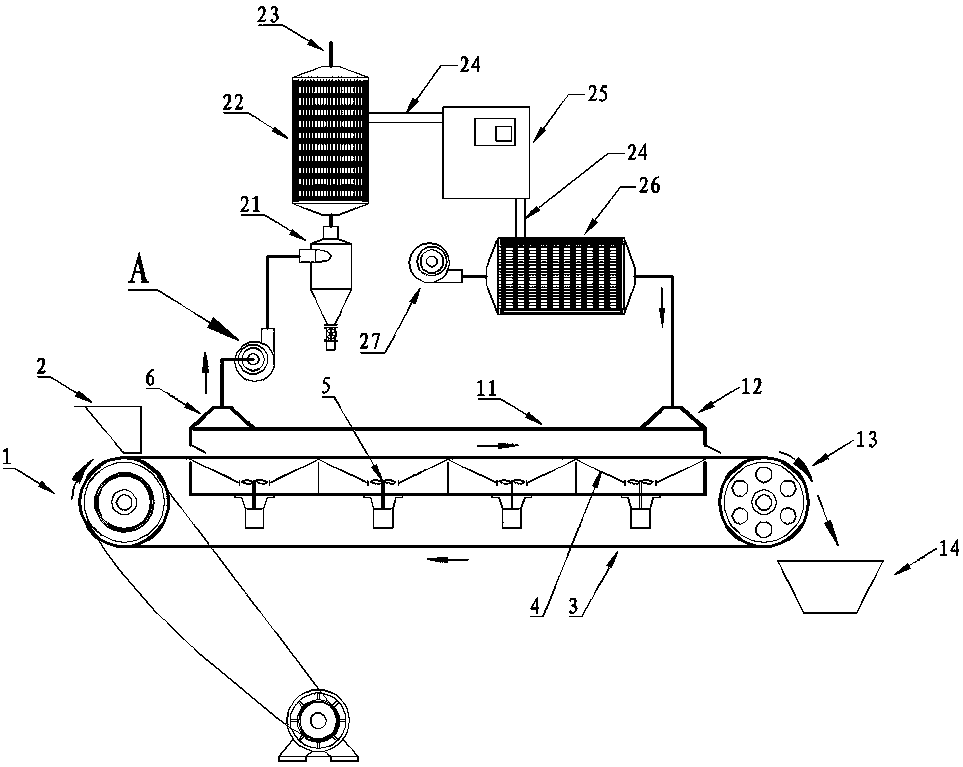

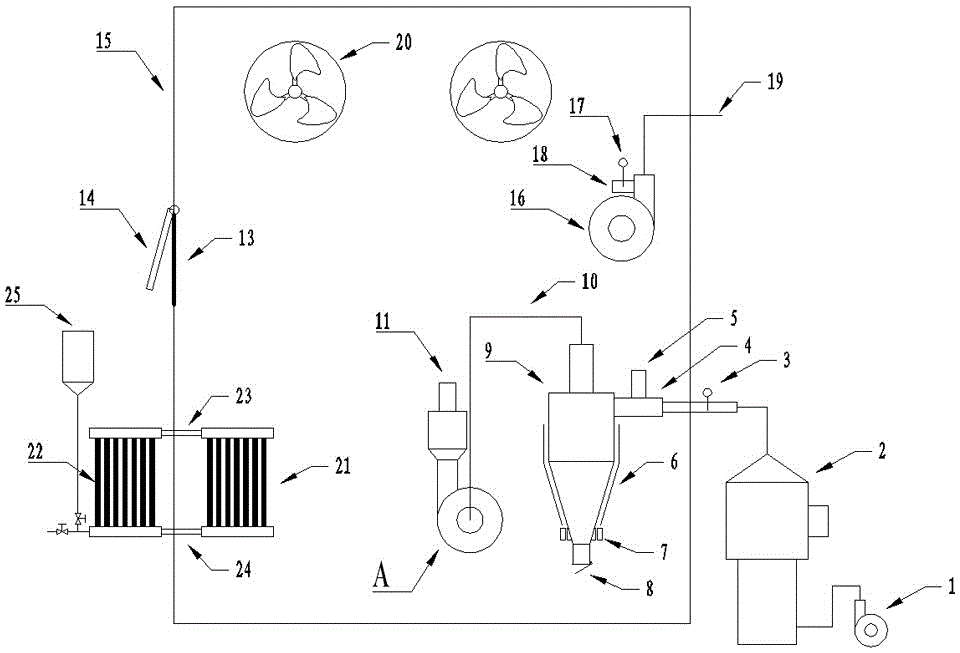

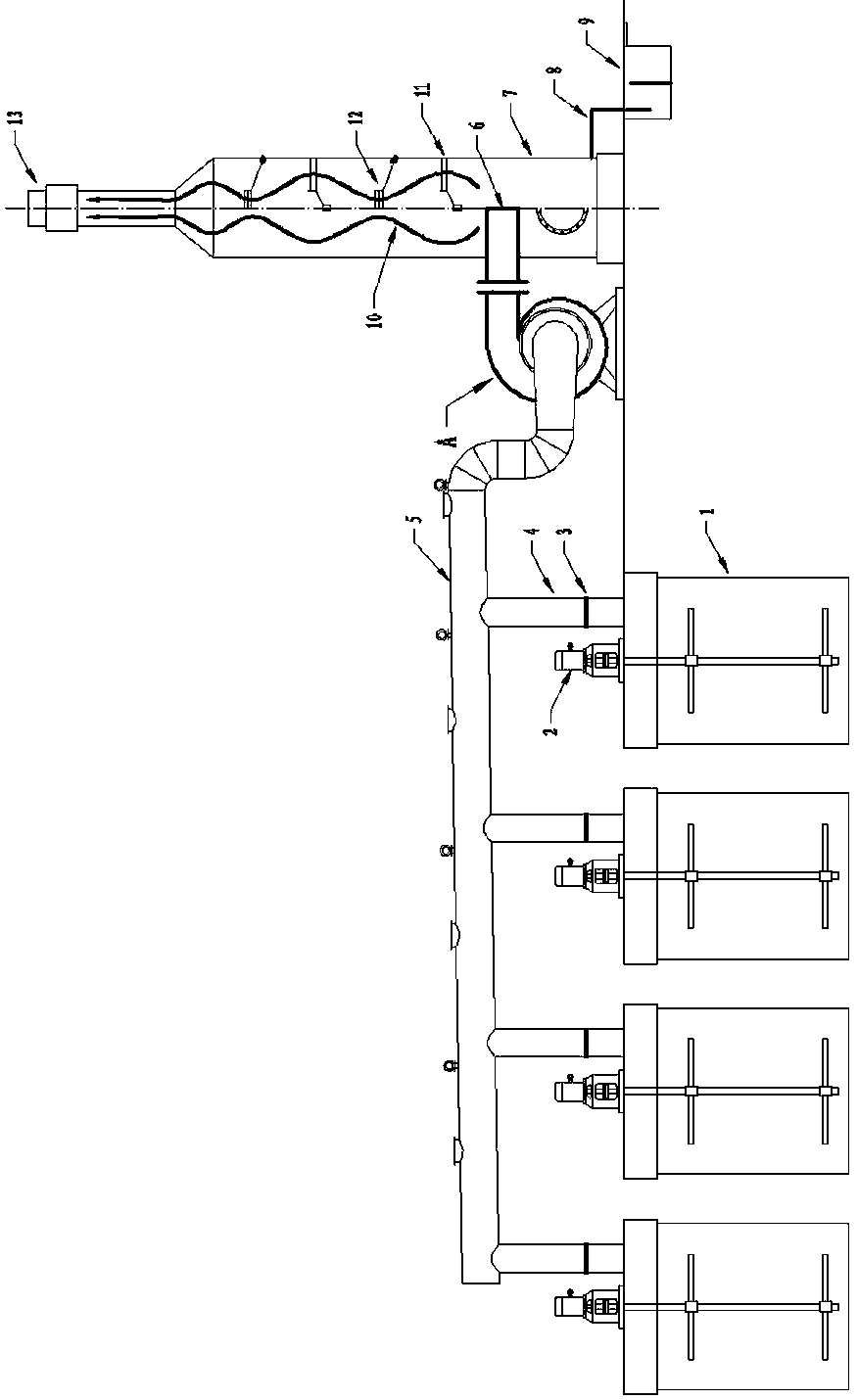

The invention discloses an air suction type grinder for polygonum cuspidatum. The air suction type grinder for the polygonum cuspidatum comprises a grinder body and an induced draft fan, wherein the discharging end of the grinder body is connected with the induced draft fan through a material storage case, air suction pipes and a cyclone separator; a ventilation door used for adjusting air volume is arranged on one of the air suction pipes; an impeller of the induced draft fan is of a structure with blades in a hollow wedge shape and a backboard in a dish shape; and the shape contour line of the induced draft fan is an involute. By means of the air suction type grinder for the polygonum cuspidatum, sorting of particles and cooling and temperature drop of the material are achieved in the pneumatic transmission process; the return and secondary grinding of the coarse particles are completed in one step, the qualified output of the material is achieved, and meanwhile dust capture is achieved; the timely and smooth discharging of the grinder is guaranteed by an air suction system, the material is prevented from being excessively ground, and electric power is saved; by means of the structure with the blades in the hollow wedge shape and the backboard in a dish shape, the real-time cleaning of dust on the impeller of the induced draft fan and the increase of the strength of the impeller of the draught fan are achieved; the stability is improved, and safety accidents caused by dust accumulation are effectively eradicated; and the application prospect is wide.

Owner:JISHOU UNIVERSITY

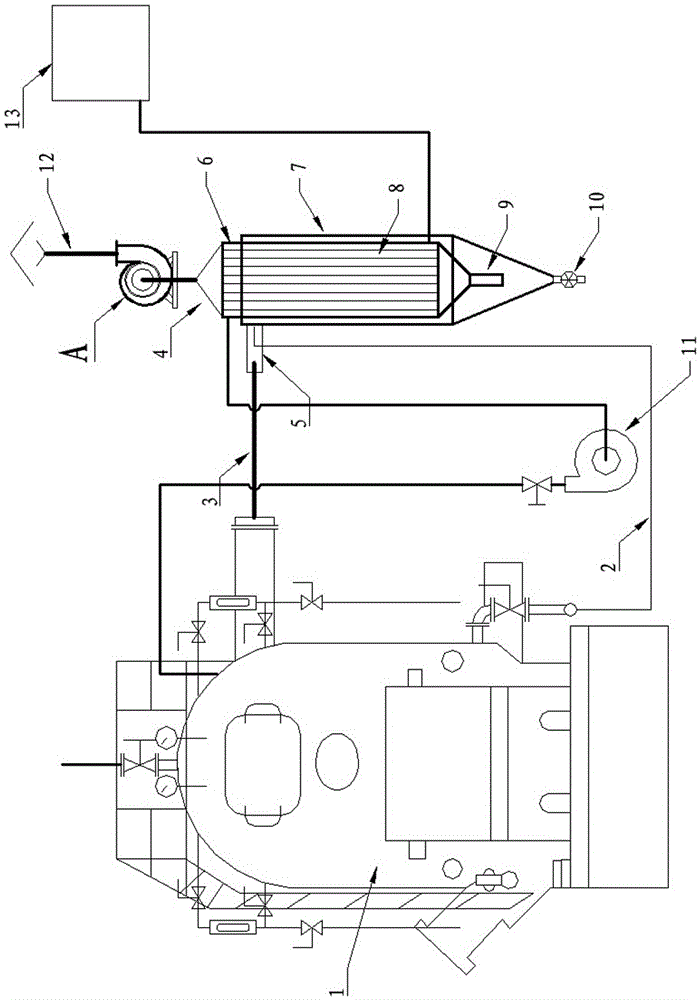

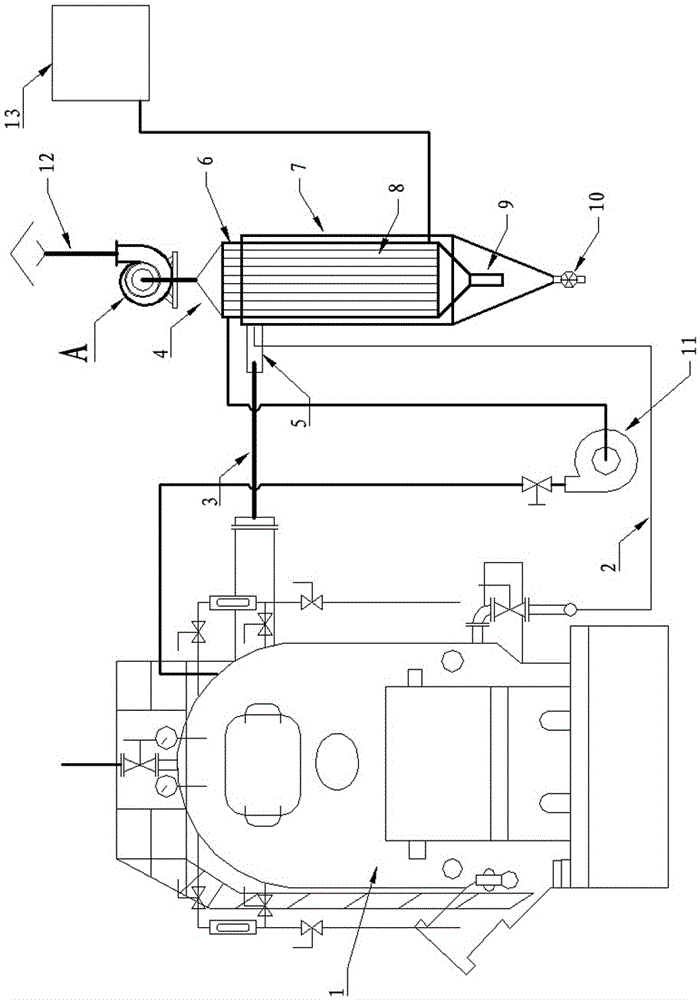

Tail heat utilization and dust removal integrated coil-fired boiler

InactiveCN105020728ADoes not affect dynamicDoes not affect balancePump componentsLighting and heating apparatusImpellerUltimate tensile strength

The invention discloses a tail heat utilization and dust removal integrated coil-fired boiler. A boiler tail gas pipe is connected with a cyclone dust remover in the tangent direction. Dust is discharged through an air-lock valve at the cone bottom after dust removal is conducted through rotational flow. Tail gas is connected with a cone through a rotational flow ascending pipe and penetrates a tube nest after being uniformly scattered. The tail gas is discharged through a discharge pipe by means of an induced draught fan after being concentrated through a conical hopper on the upper portion. An impeller of the induced draught fan is of a structure that blades are in a hollow wedge shape. The appearance contour line of the induced draught fan is an involute. According to the tail heat utilization and dust removal integrated coil-fired boiler, boiler tail heat utilization and dust removal are innovatively integrated, an efficient cyclone dust removal tail heat utilization device is designed, and therefore tail heat utilization and dust removal are completed in one step, the device input is reduced, and the work efficiency is improved; the blades are in the hollow wedge shape, and therefore dust on the impeller of the induced draught fan is removed in real time, the strength of the impeller of the draught fan is increased, stability is enhanced, accidents caused by dust accumulation are effectively eradicated, and application prospects are wide.

Owner:JISHOU UNIVERSITY

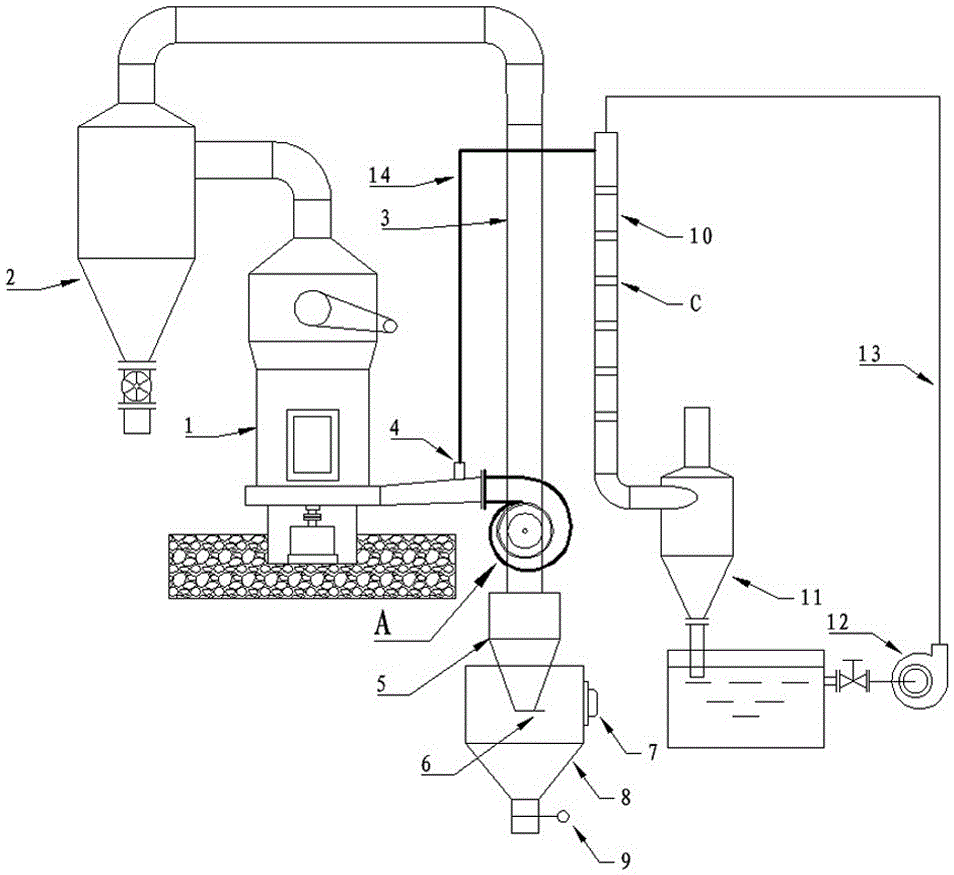

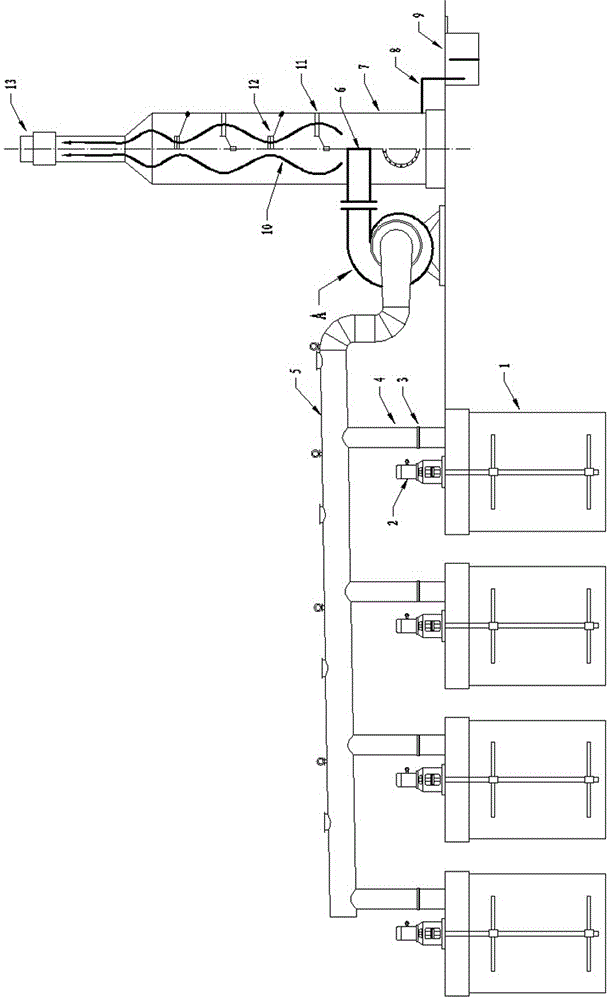

Raymond mill system with draught fan free of dust retention

The invention discloses a Raymond mill system with a draught fan free of dust retention. An air current circulation milling discharging system is formed by the draught fan, a Raymond mill, a cyclone separation discharging device and an air return duct; a pressure-equalizing exhaust branch pipe is connected with the upper end of a cyclone pipe, multiple cyclones are arranged in the cyclone pipe, the lower end of the cyclone pipe is connected with a cyclone separator in the tangent direction, and a lower pipe orifice of the cyclone separator immerges into a circulation water tank which is connected with the upper end of the cyclone pipe; and an impeller of the draught fan is of a structure that blades are in a hollow and wedged shape and the backing plate is in a disc shape, and the contour line of the appearance of the draught fan is an evolvent. According to the Raymond mill system with the draught fan free of the dust retention, due to the fact that the cyclone pipe and the cyclones are arranged, low-resistance pressure-equalizing exhaust is achieved, and dust overflow caused by positive pressure of the system is eliminated; by means of the circulation water tank, wet-method high-efficiency dust removal and mineral powder recycling are achieved; and by means of the structure that the blades are in the hollow and wedged shape and the backing plate is in the disc shape, real-time cleaning of the dust on an impeller of the draught fan is achieved, the impeller strength of the draught fan is increased, the stability is enhanced, safety accidents caused by dust accumulation is effectively eradicated, and the application prospect is wide.

Owner:JISHOU UNIVERSITY

Manganese processing rotary kiln system with gas furnace supplying heat and draught fan being free of dust accumulation

ActiveCN105066684AEasy flipIncrease the heating areaPump componentsRotary drum furnacesCombustorManganese

The invention discloses a manganese processing rotary kiln system with a gas furnace supplying heat and a draught fan being free of dust accumulation. A rotary kiln is arranged in an inclined mode. A combustor is arranged in the rotary kiln and connected with an air control valve and a gas control valve. An air lock is arranged at the higher end of the rotary kiln for feeding and connected with a dust remover through a fin section and an air pipe. A cover cylinder is arranged outside the fin section, a sleeve type air heat exchanger is arranged outside the air pipe, and the cover cylinder is connected with the gas control valve and the air control valve after being joined with a lower air suction port of the air heat exchanger. The draught fan is of a structure with blades being in a reverse drop shape and a back plate being in a butterfly shape. A convex refractory plate is arranged in the rotary kiln. Through the convex refractory plate, the heat transfer area of the rotary kiln is increased, material stirring is promoted, and heat efficiency is easily improved; through the fin section and the air heat exchanger, tail heat is utilized, and combustion is facilitated; through shock chilling liquid, the environmental protection pressure of production liquid expansion is effectively relieved; because the draught fan is free of dust accumulation, safety accidents are effectively eradicated. The manganese processing rotary kiln system is especially suitable for manganese ore firing processing and has broad application prospects.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

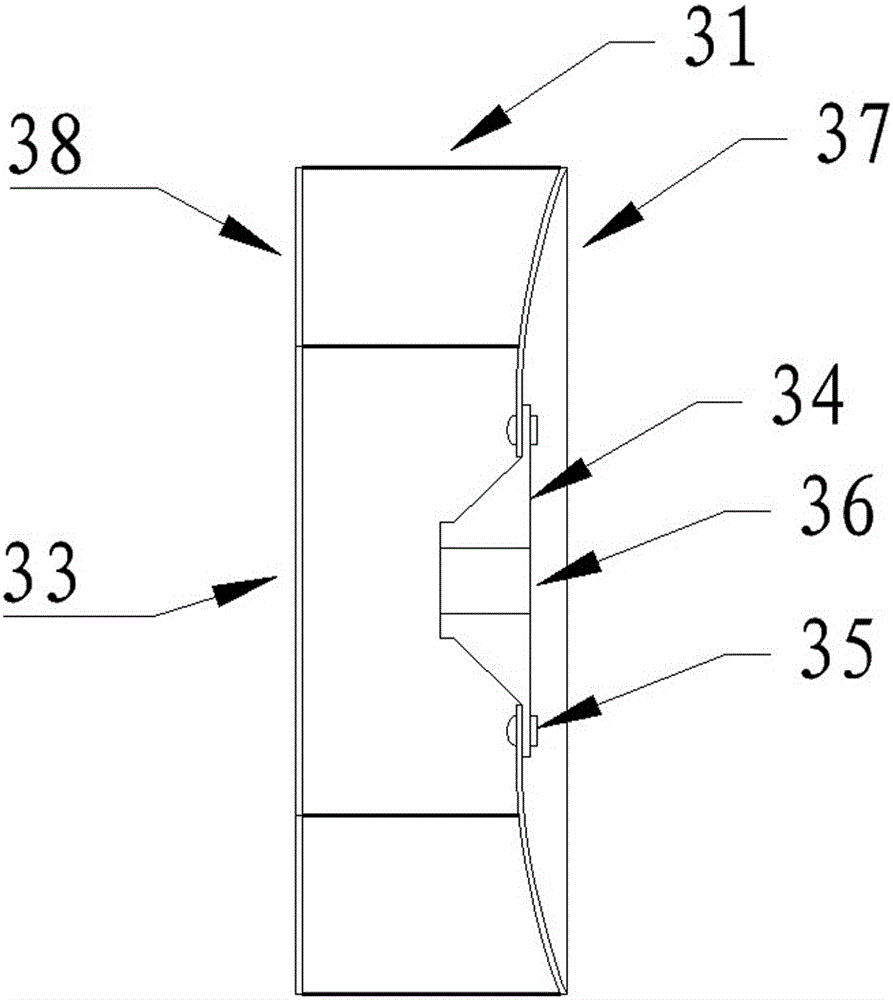

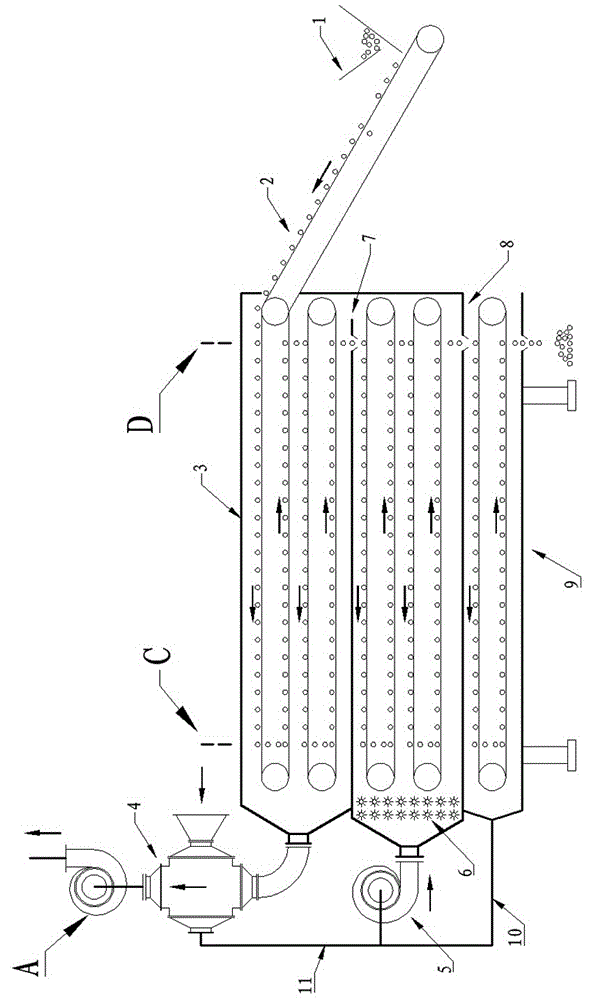

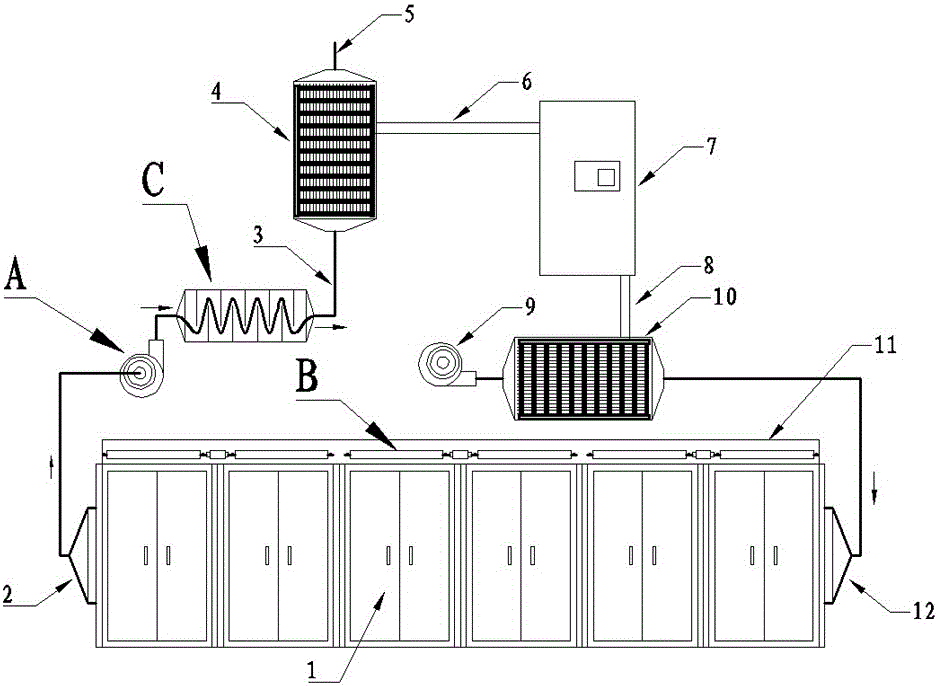

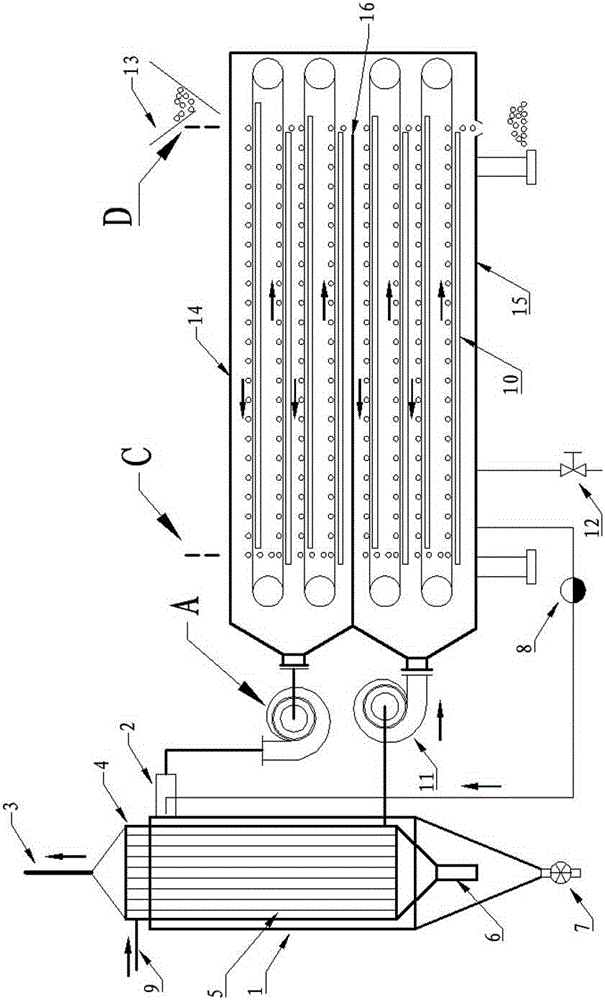

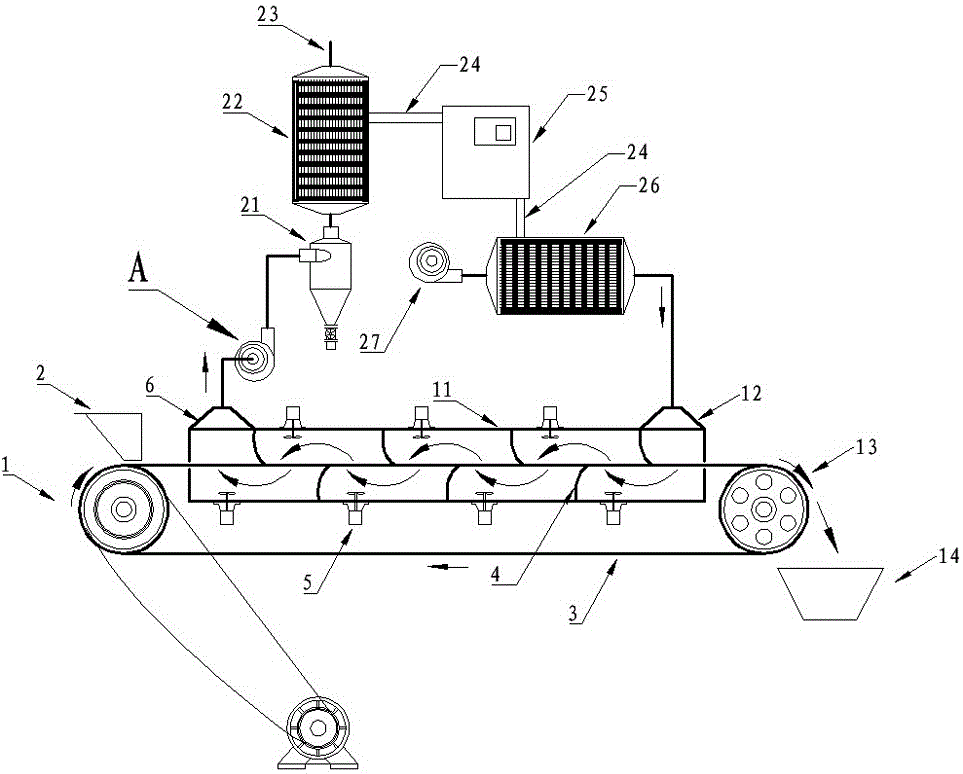

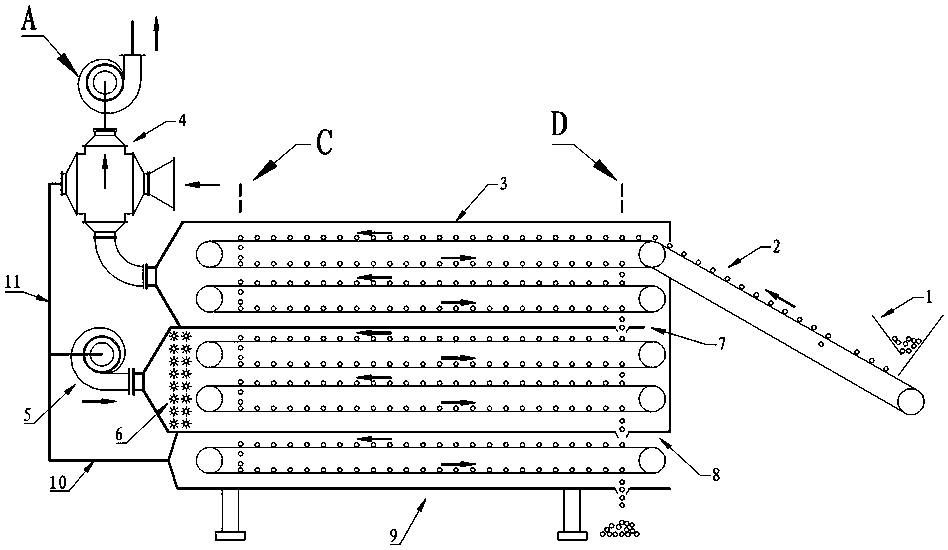

Hot-air drying machine capable of utilizing waste heat and achieving penetrating countercurrent fluidization

ActiveCN105020984ADoes not affect dynamicDoes not affect balanceDrying solid materials with heatHearth type furnacesAir blowerCyclonic spray scrubber

The invention discloses a hot-air drying machine capable of utilizing waste heat and achieving penetrating countercurrent fluidization. The upper portion of a drying tower is connected with an induced draft fan, and the induced draft fan is connected with a cyclone dust removing waste heat efficient recoverer formed by a tube-type heat exchanger and a cyclone dust collector in an overlapped manner in the tangent direction and then is emptied; the air inlet end of the shell side of the tube-type heat exchanger is communicated with the atmosphere, and the air outlet end of the shell side of the tube-type heat exchanger is connected with the lower portion of the drying tower through an air blower and a steam finned heater; and an impeller of the induced draft fan is of a structure that blades are in a hollow and wedged shape and the backing plate is in a disc shape, and the contour line of the appearance of the induced draft fan is an evolvent. According to the hot-air drying machine capable of utilizing the waste heat and achieving the penetrating countercurrent fluidization, creative integration is conducted on waste heat utilization and dust removal, the cyclone dust removing waste heat efficient recoverer is designed out, the equipment input is reduced, and the work efficiency is improved; and due to the fact that sieve mesh cone covers, sieve mesh cone discs, discharging tubes, a stretching vibration transmission shaft and conical plugs are arranged, penetrating, countercurrent, boiling and fluidization drying of materials are exquisitely and perfectly achieved, more energy is saved, the drying quality is higher, the power consumption of the induced draft fan is lower, and the application prospect is wider.

Owner:重庆信奇建材机械制造有限公司

Heat pump type waste heat utilization inertial dust collection penetrating countercurrent drying machine

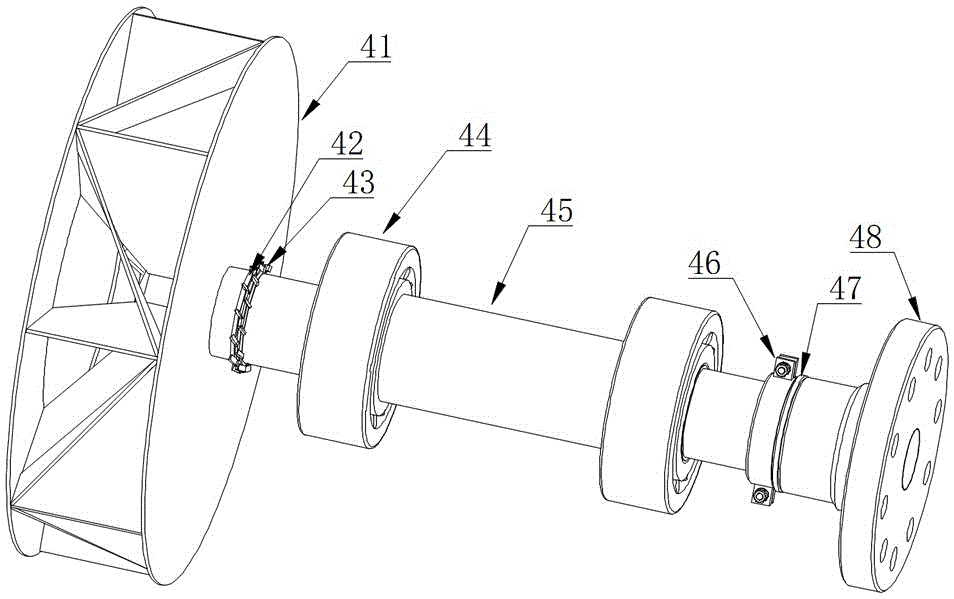

ActiveCN105674713AHigh extrusion rigidityStrong extrusion rigidityPump componentsDrying gas arrangementsImpellerEngineering

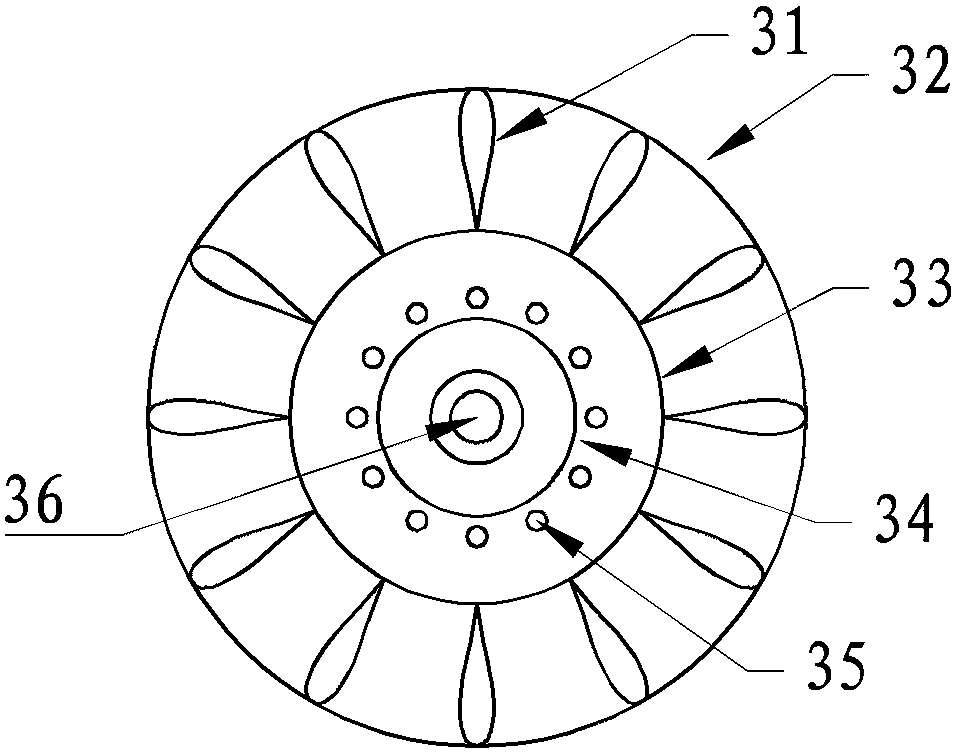

The invention discloses a heat pump type waste heat utilization inertial dust collection penetrating countercurrent drying machine. An exhaust hood of the drying machine is connected with an induced draught fan. The induced draught fan is evacuated after being connected with an evaporator of a heat pump system through a cyclone dust collector and a repeated back-turning baffle type inertial dust collector. The evaporator of the heat pump system is connected with a main machine through a refrigerant pipe. The main machine is connected with a condenser through a refrigerant pipe. The air outlet end of an air blower is connected in an air inlet hood through the condenser. Blades of an impeller of the induced draught fan are arranged to be in a radial shape and centrosymmetric about an impeller shaft in the radial direction, dust can be removed in time under the effect of centrifugal force, and safety accidents are avoided. The drying efficiency is improved, energy conservation and emission reduction are achieved, more importantly, a demounting and mounting technology of the induced draught fan is transformed to a great extent, when the induced draught fan is demounted, the pressure applied to the end face of a screw shaft shoulder by nut-like parts can be simply eliminated, the problem that the induced draught fan assembled in a threaded manner is automatically locked continuously under the effect of loads and cannot be easily demounted is effectively solved, the heat pump type waste heat utilization inertial dust collection penetrating countercurrent drying machine is particularly suitable for convenient demounting of large draught fans which are locked in a threaded manner, and effects are particularly obvious.

Owner:四川良仕农业科技有限公司

Cyclone dust removal heat pump type tunnel drying device

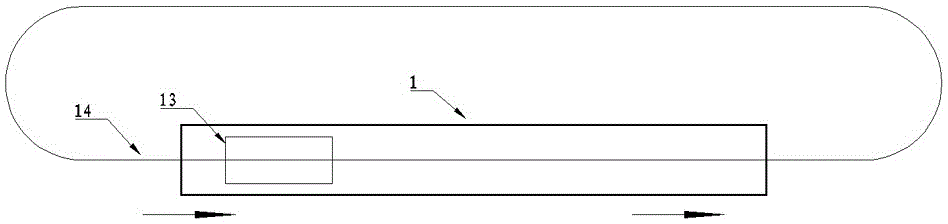

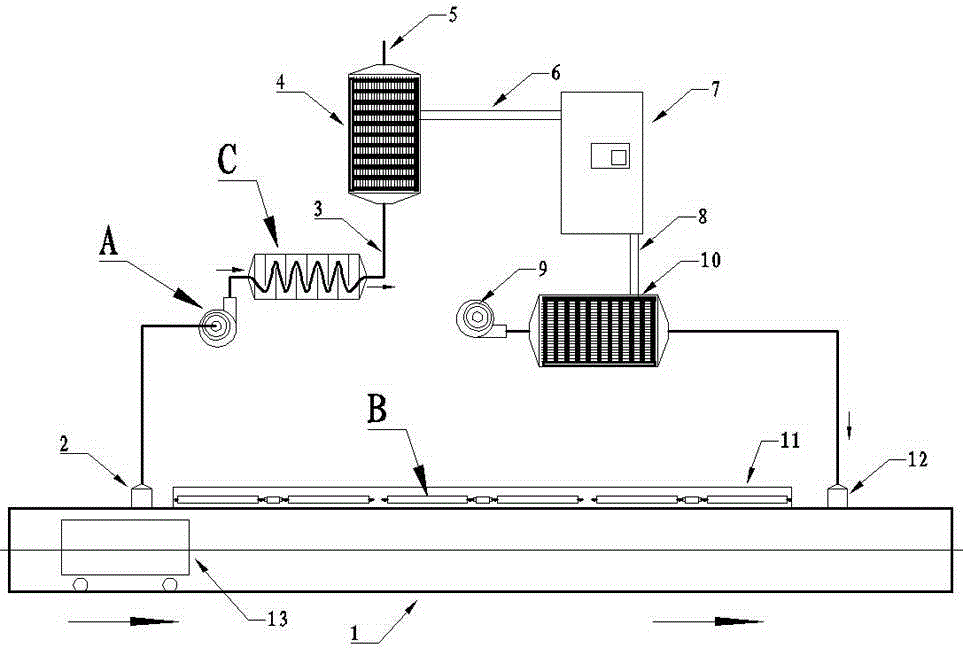

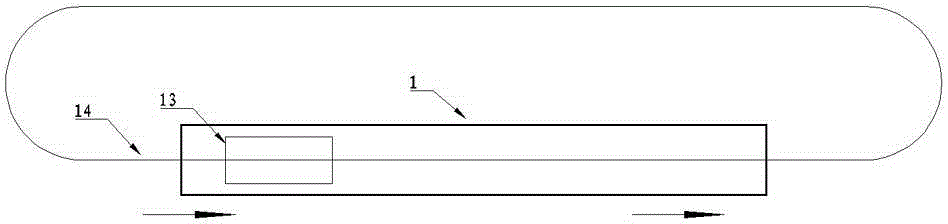

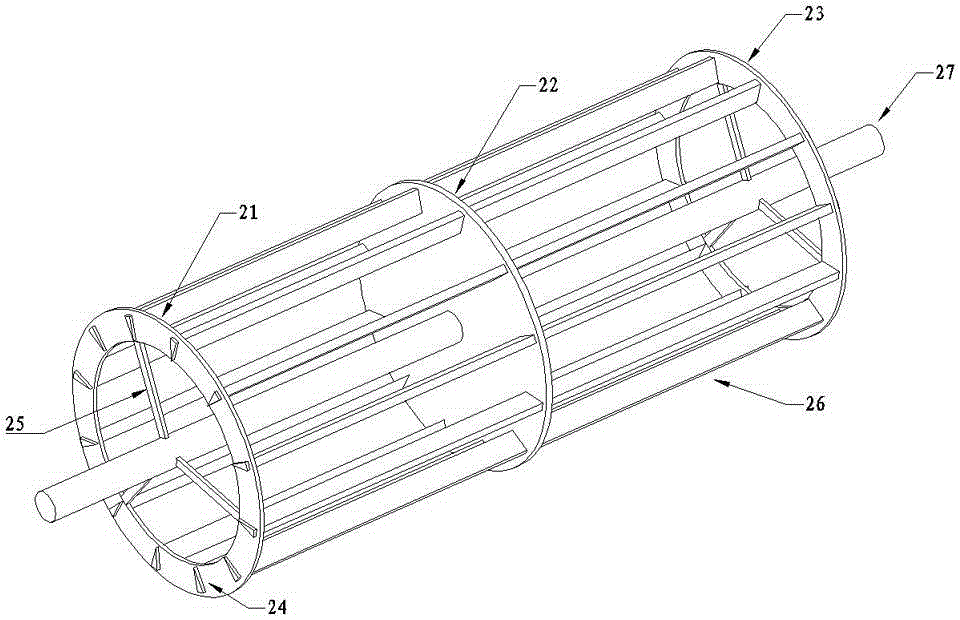

ActiveCN105066629AHigh wind resistance bendingHigh strengthDrying gas arrangementsDrying machines with progressive movementsImpellerCyclone

The invention discloses a cyclone dust removal heat pump type tunnel drying device. A trolley is arranged on a track path of a tunnel, an internal recycling long-shaft fan is arranged in the tunnel, the long-shaft fan comprises a long shaft and blades which are all shaped like a long stripe, and the cross section of each blade is a shaped like a hollow reversed water drop symmetrical to the radial direction and the center of an impeller shaft; the two ends of each blade are inserted into end plates respectively, and the long shaft is connected and fixed with the end plates through spokes; the two ends of the closed type tunnel are provided with an air draft hood and an air intake hood respectively, the air draft hood is connected with a draft fan, and the draft fan is connected with an evaporator through a cyclone dust collector for emptying; the evaporator of a heat pump system is connected with a main machine which is connected with a condenser; an air outlet end of an air blower is connected into an air hood through the condenser; the draft fan and the long-shaft fan impellers are both designed to be of a hollow symmetrical structure, dirt retention does not exist, and lightness, firmness and durability are achieved. According to the cyclone dust removal heat pump type tunnel drying device, heat pump cross flow drying and tail heat recovery are suitable for being adopted by a low-temperature drying system, destroy to heat sensitive components can be prevented, and the system can complete drying, dust removing and heat recovery efficiently with low energy.

Owner:倡创(上海)咨询管理事务所

Heat pump type tail heat recovery and penetrating counterflow fluidized drying machine

ActiveCN105066653AImprove rigidityImprove carrying capacityDrying solid materials with heatPump componentsDrop-shapedAir blower

The invention discloses a heat pump type tail heat recovery and penetrating counterflow fluidized drying machine. A material seal spiral feeding machine is arranged on the upper portion of a drying tower, and an air-lock valve discharging machine is arranged at the bottom of the drying tower. The upper portion of the drying tower is connected with an inducted draft fan, and the induced draft fan is connected with an evaporator of a heat pump system through a cyclone dust collector, and then evacuation is carried out. The evaporator of the heat pump system is connected with a main engine through a refrigerant pipe, and the main engine is connected with a condenser through a refrigerant pipe. The air outlet end of an air blower is connected with the lower portion of the drying tower through the condenser. An impeller of the induced draft fan is provided with a structure with hollow inverted-drop-shaped blades and a dish-shaped back plate. The contour line of the appearance of the induced draft fan is an involute. Screen mesh cone covers, screen mesh cone discs, a blanking tube, a telescopic vibration transmission shaft and a conical plug are arranged, so that penetrating, counterflow, boiling and fluidized drying on materials are achieved ingeniously and perfectly, and a classic boiling counterflow drying mode is thoroughly exceeded; and more energy is achieved, the drying quality is higher, the power consumption of the fan is lower. The heat pump type tail heat recovery and penetrating counterflow fluidized drying machine is especially suitable for recovery of heat of low-temperature tail gas.

Owner:JIANGSU XUEMEI REFRIGERATION EQUIP

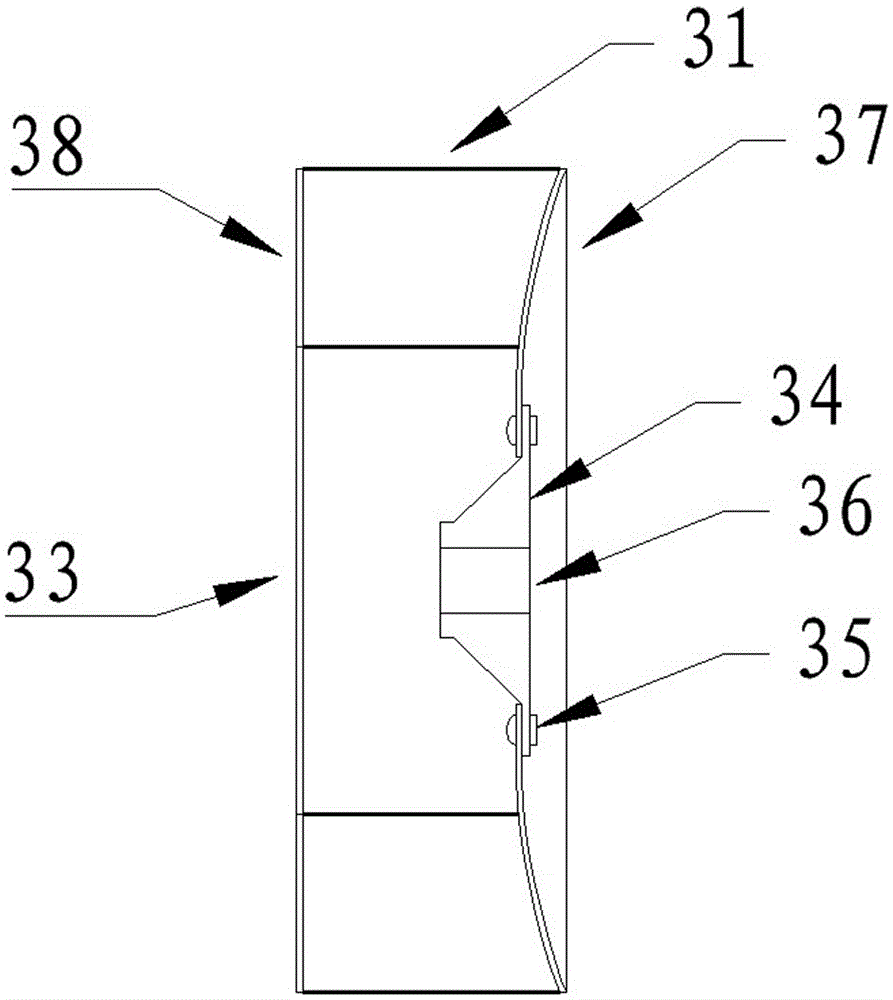

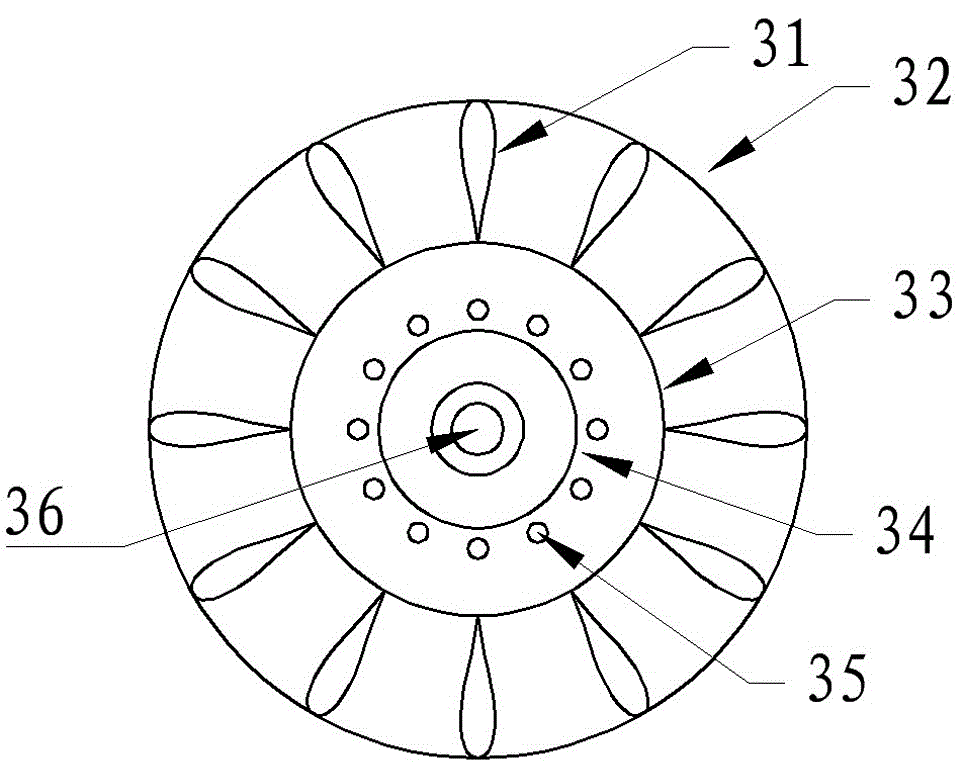

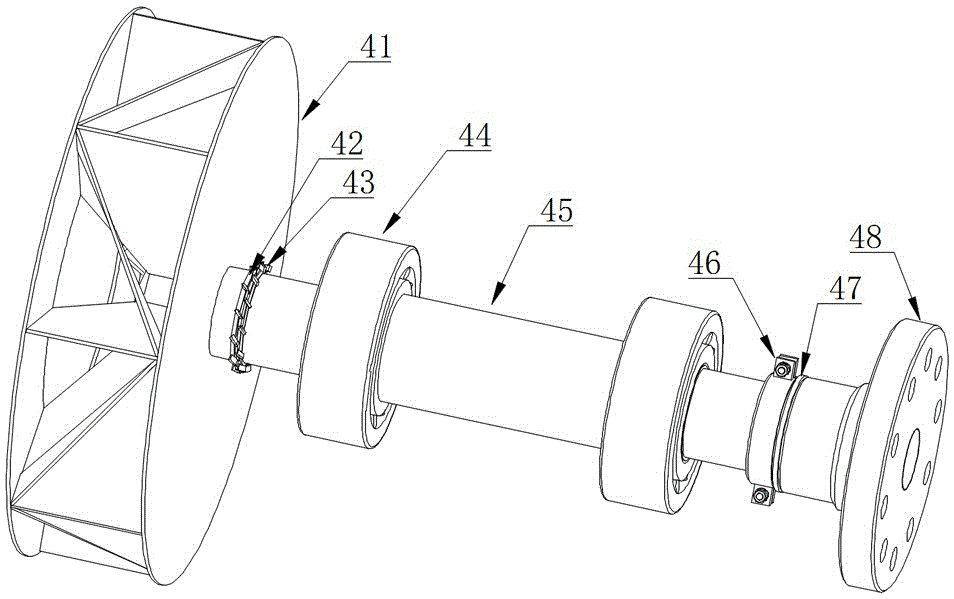

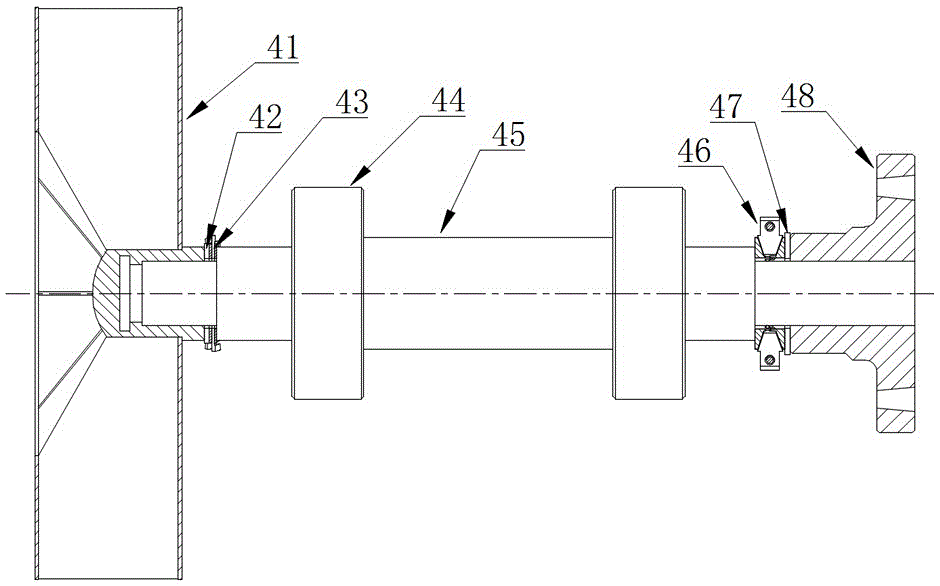

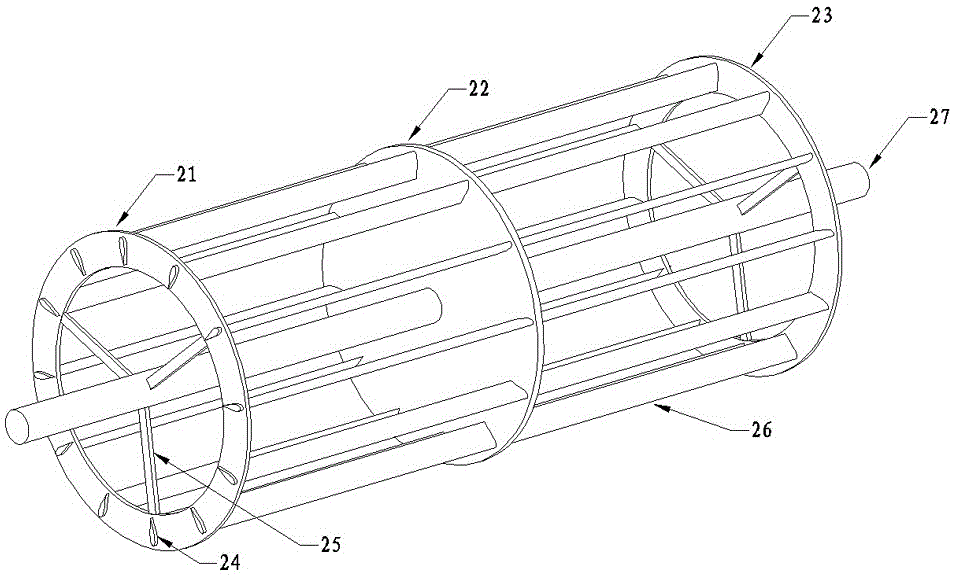

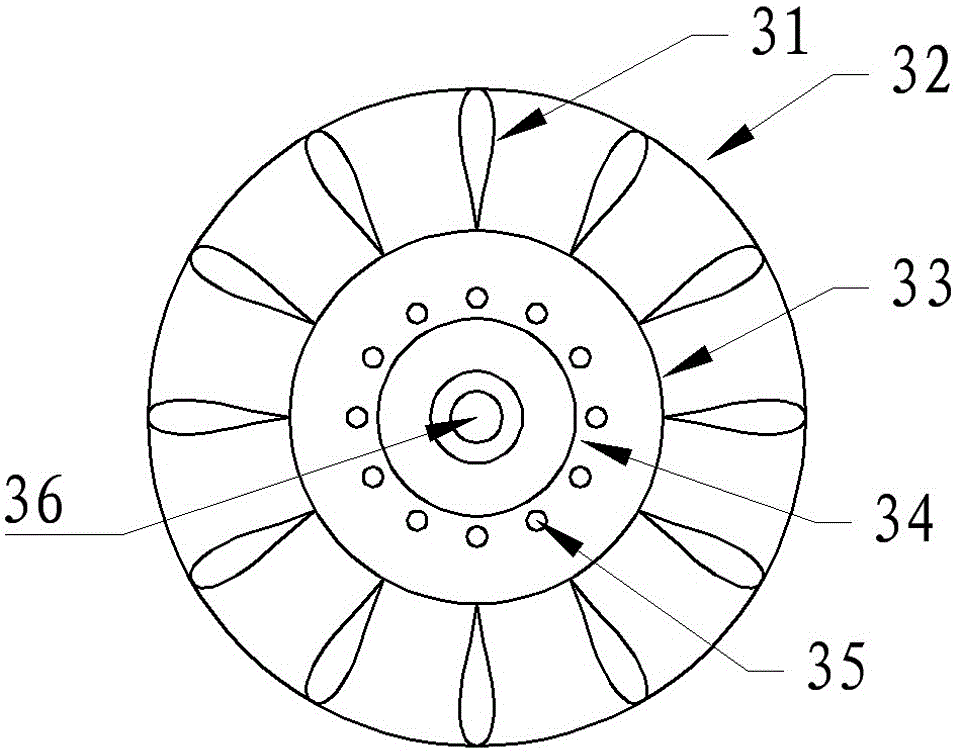

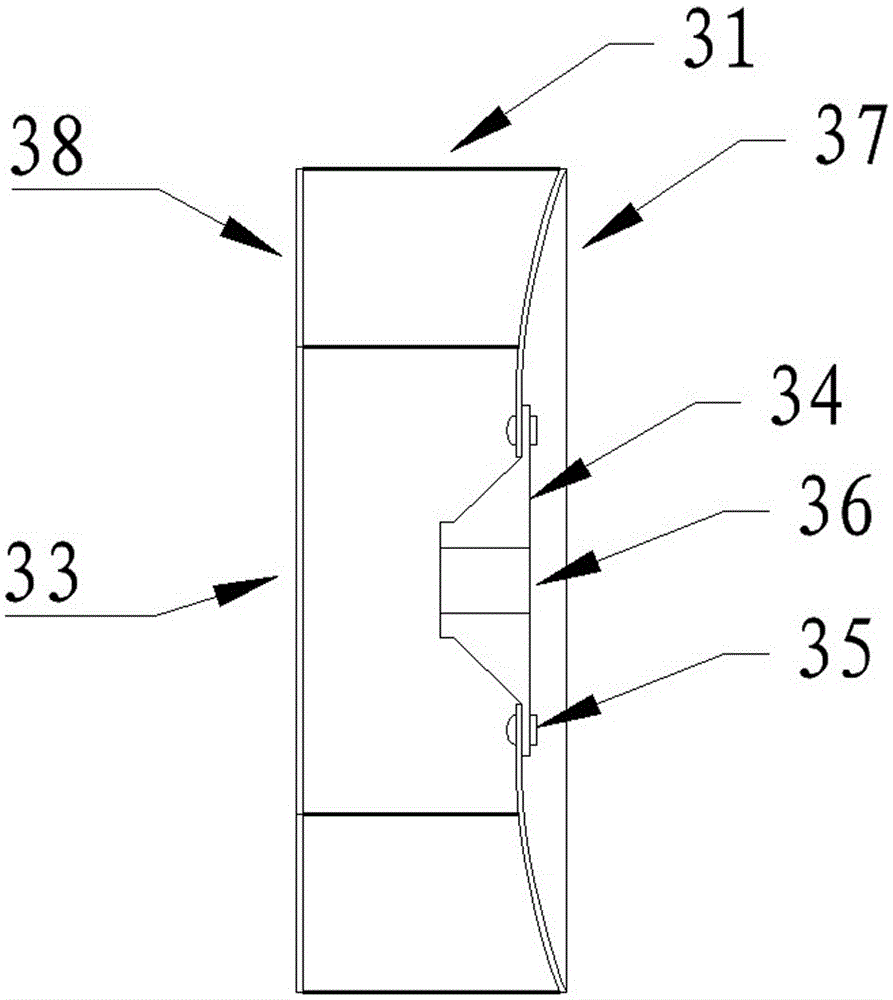

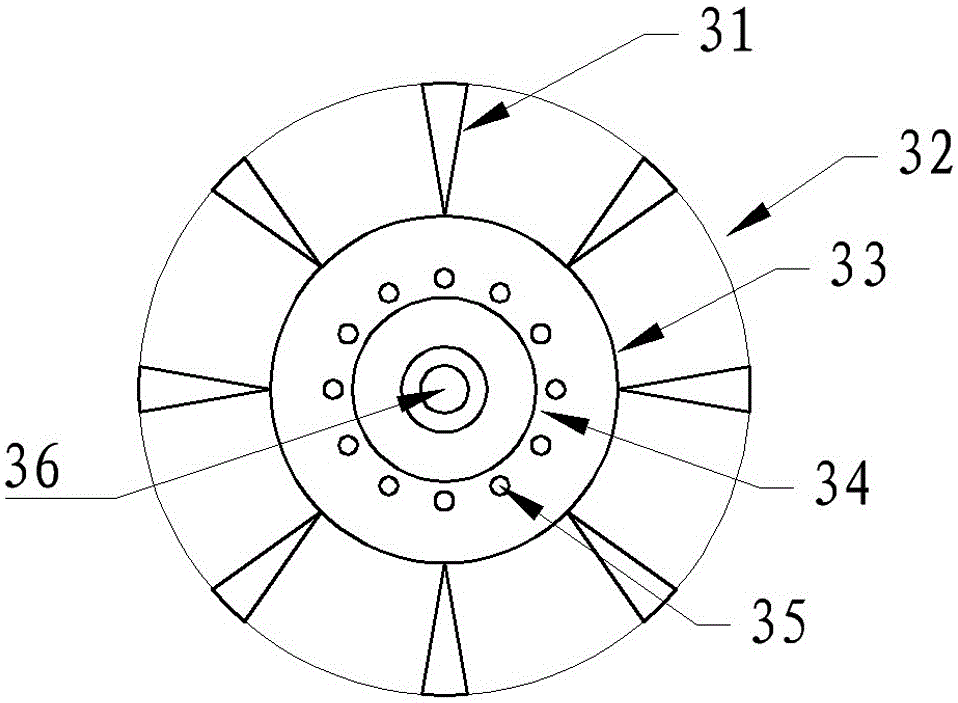

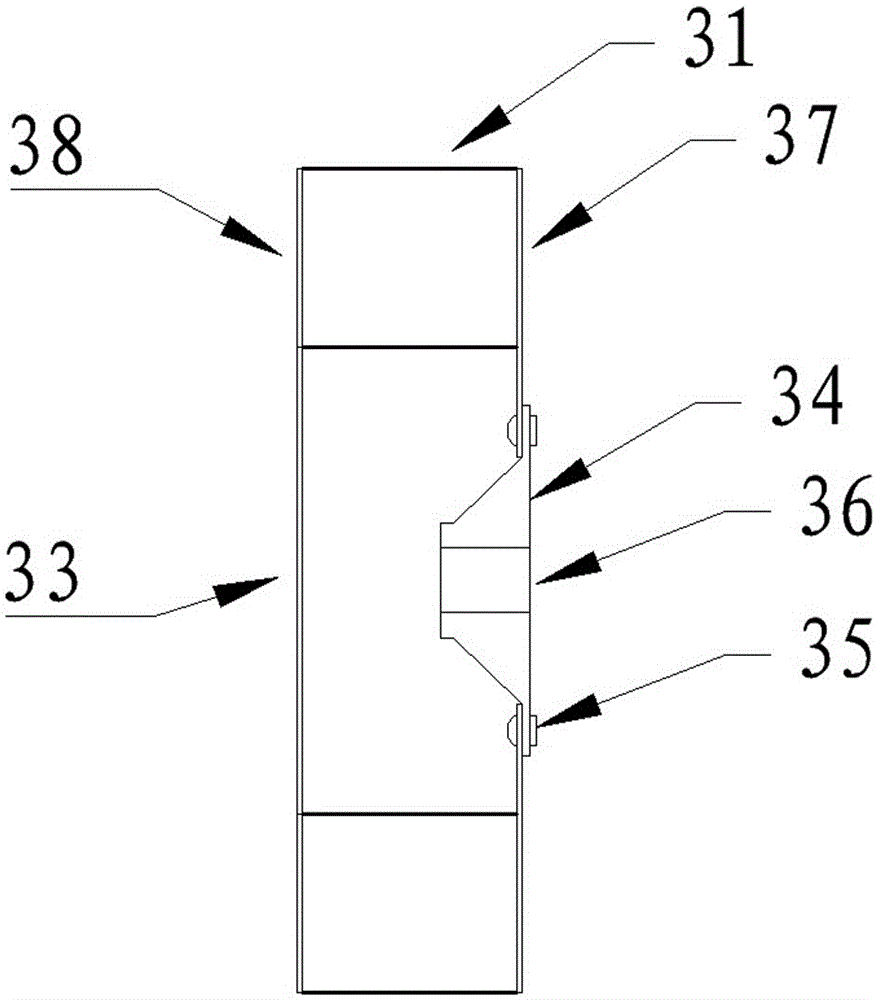

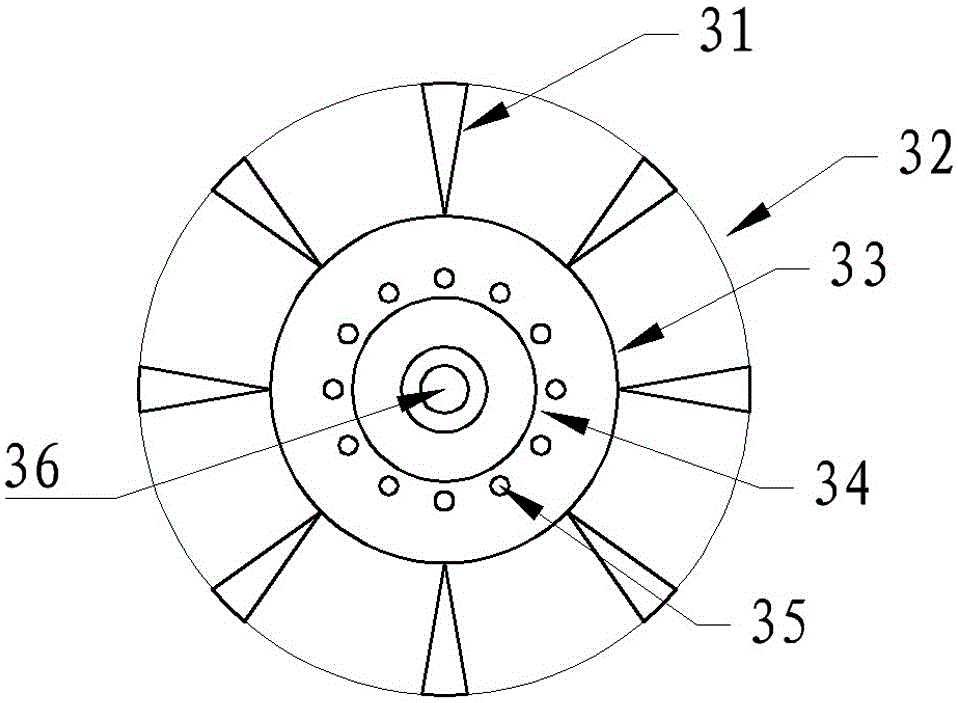

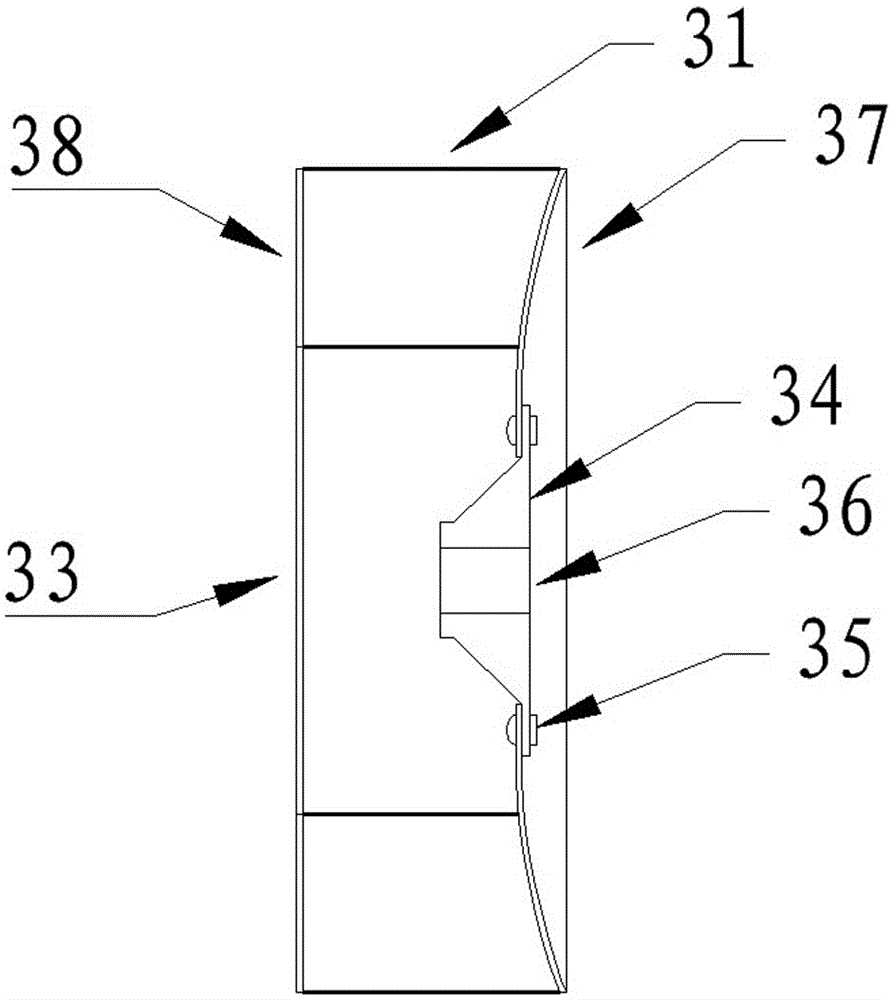

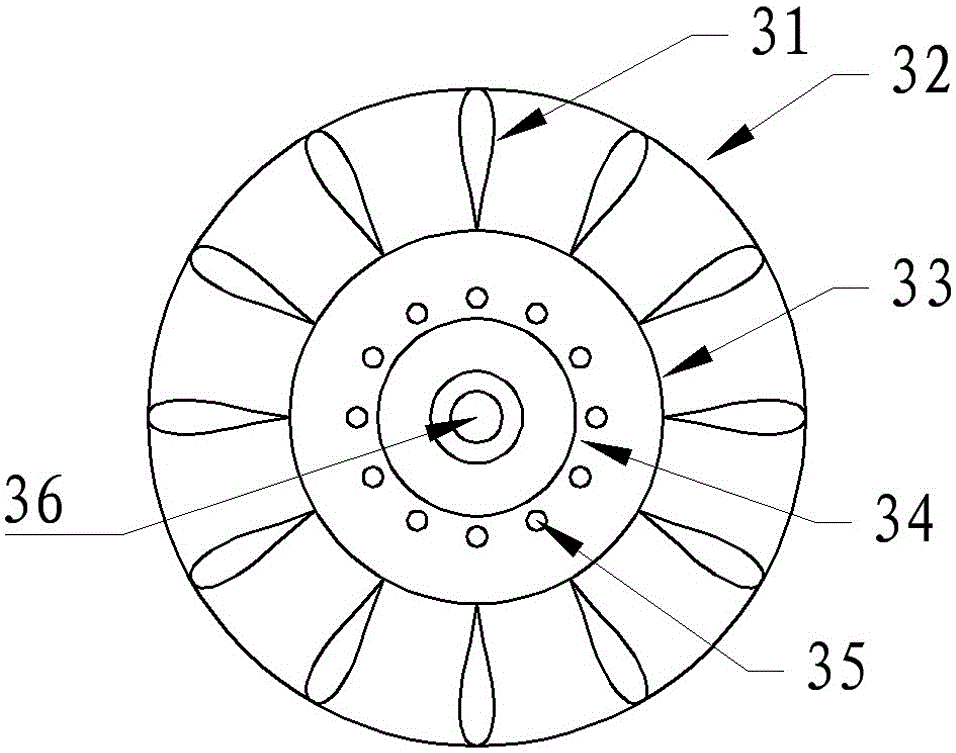

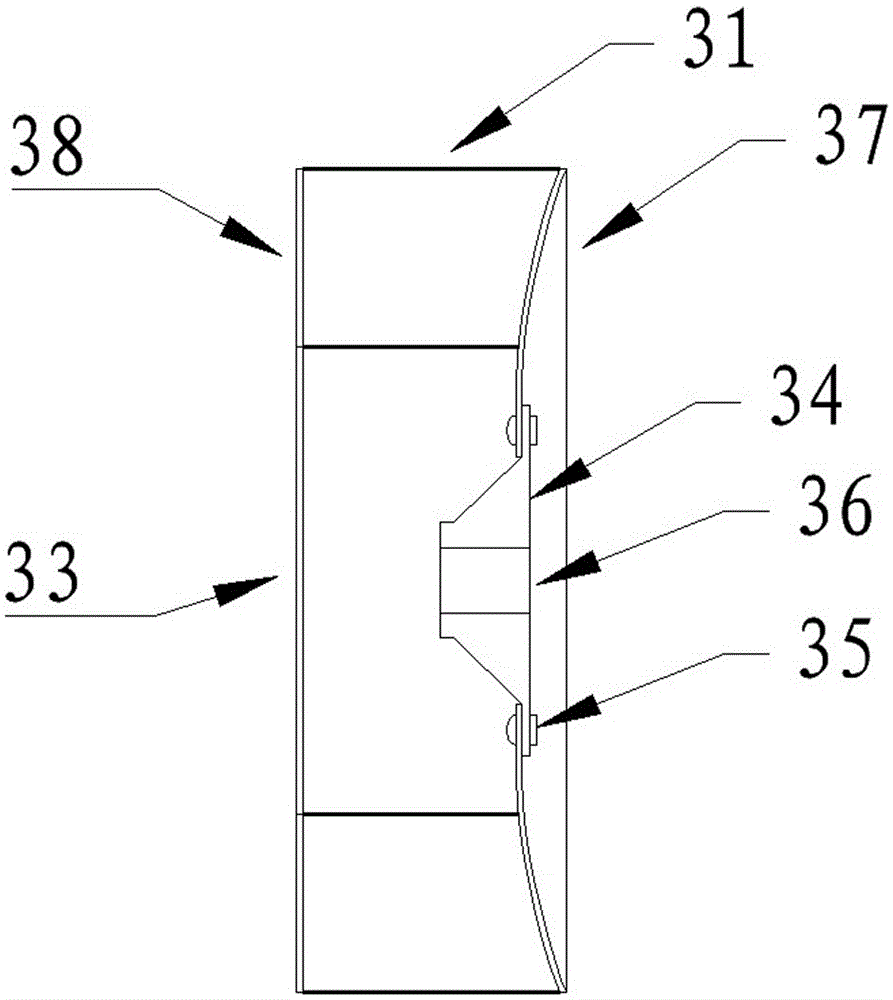

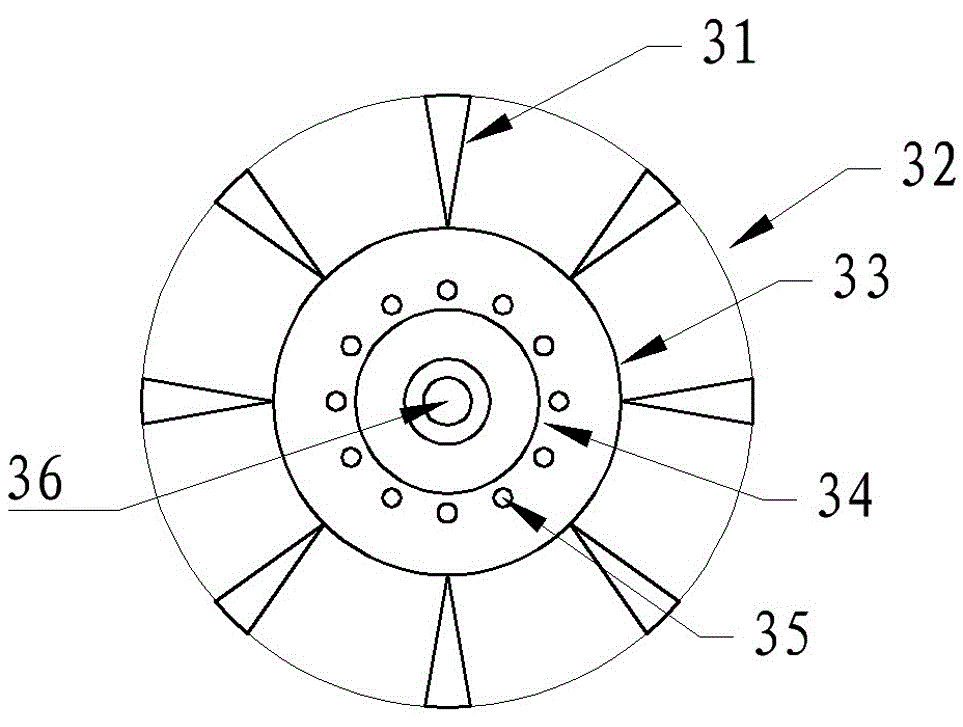

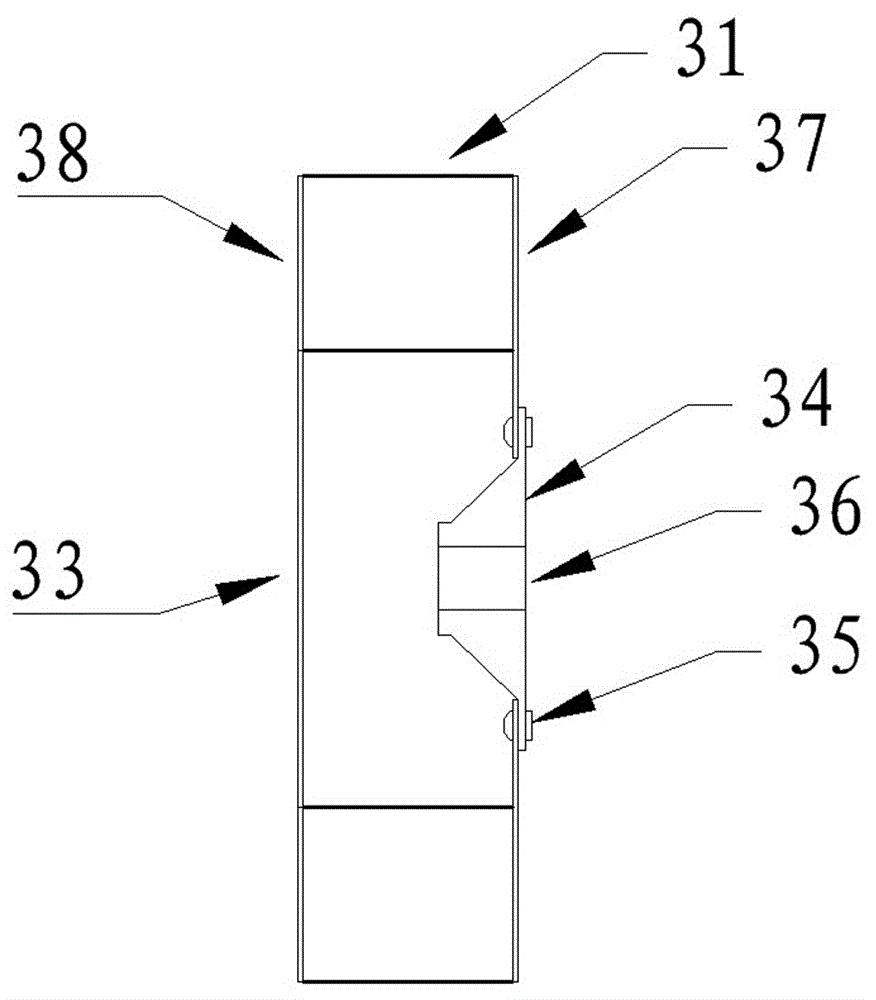

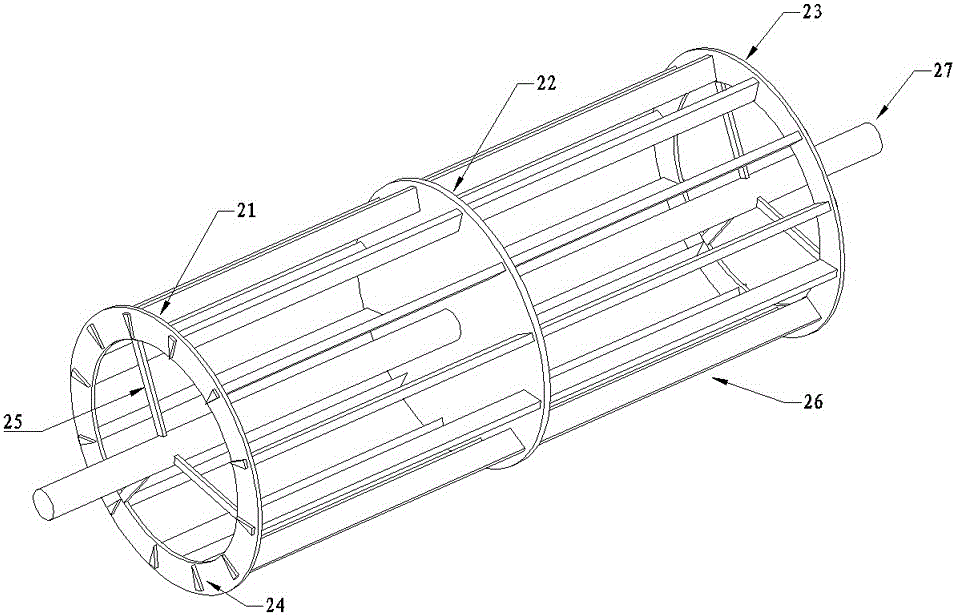

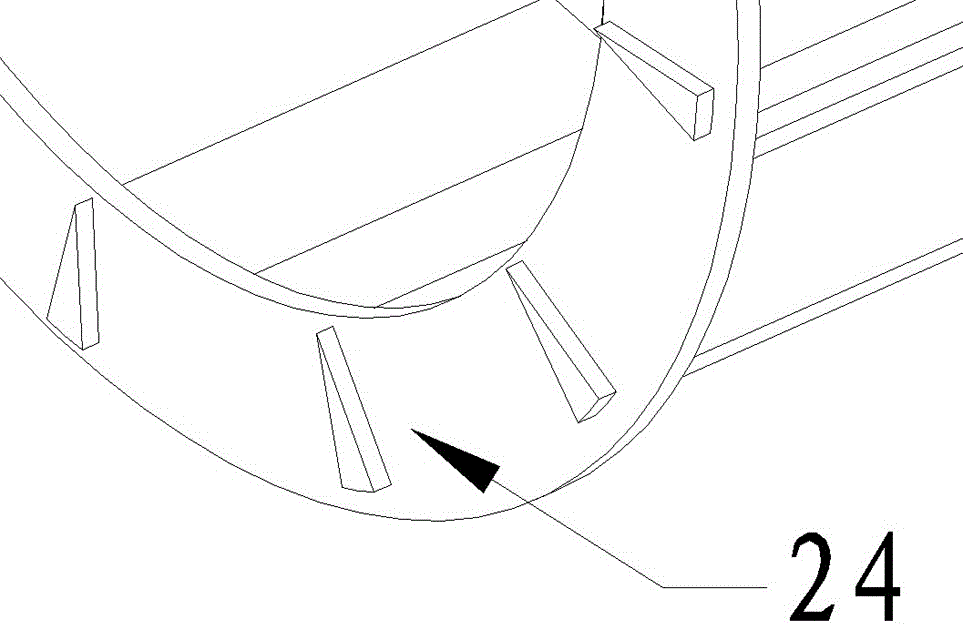

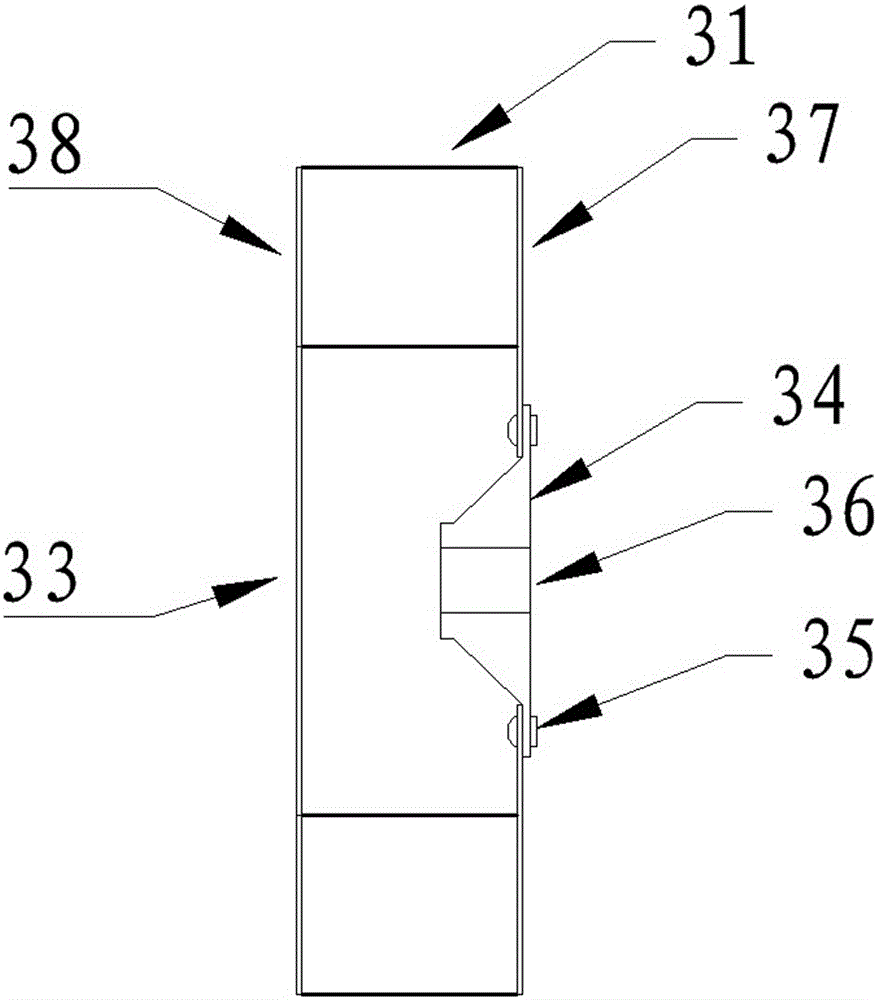

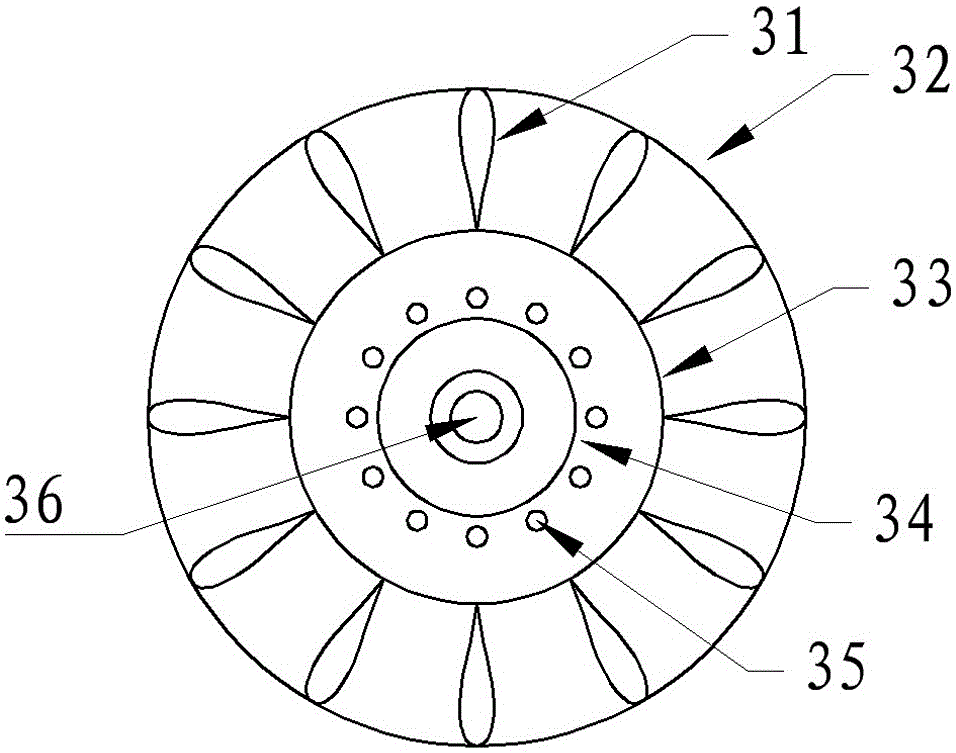

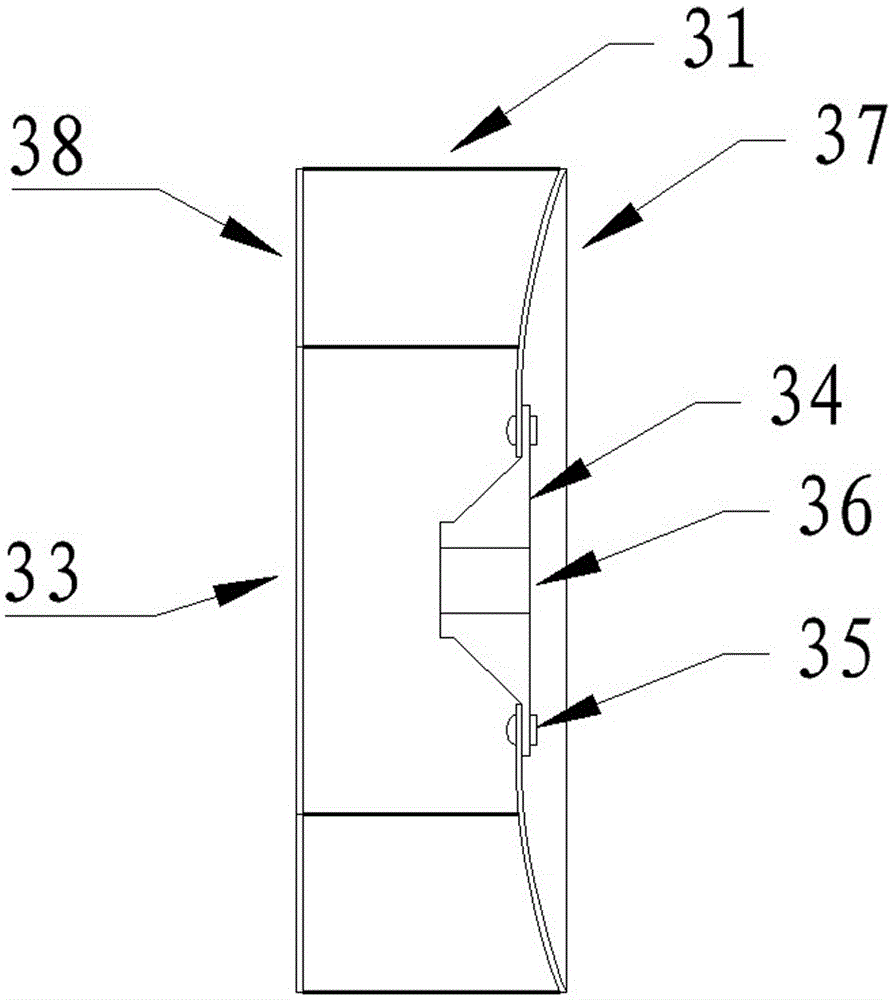

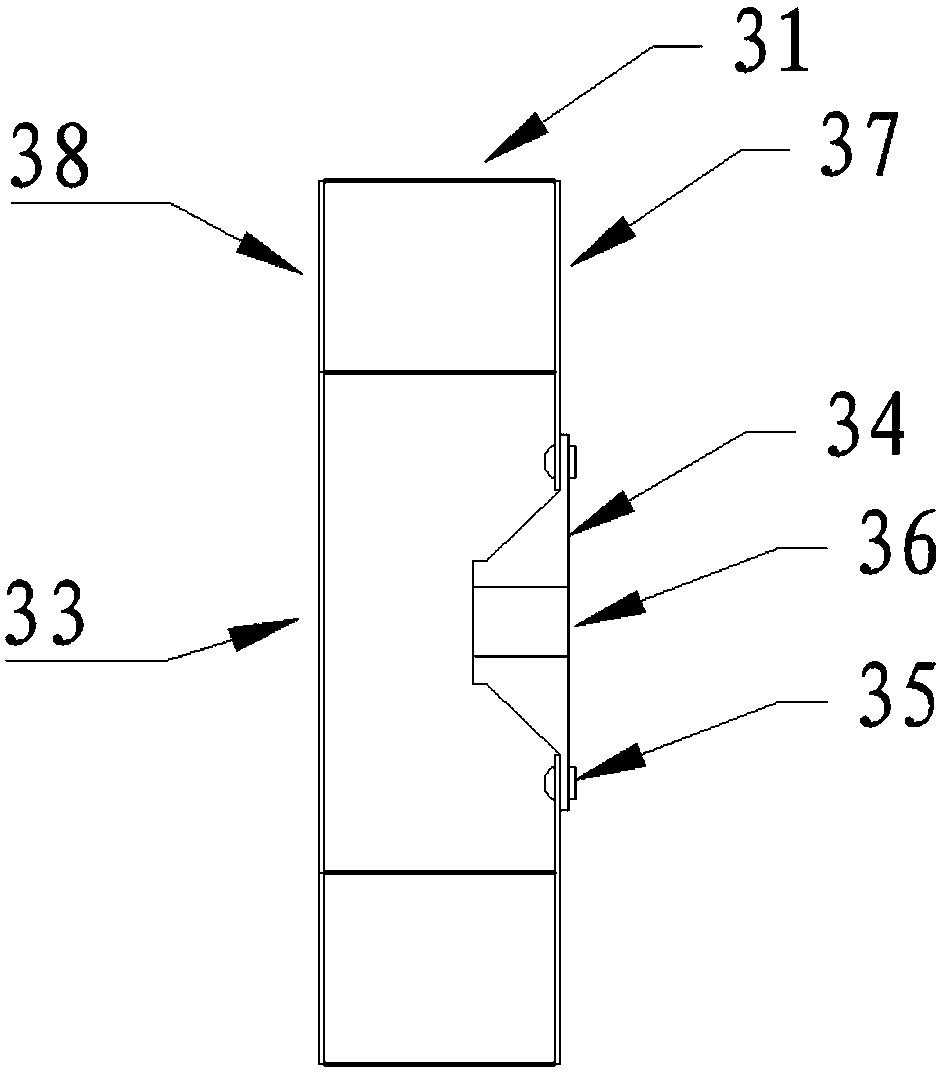

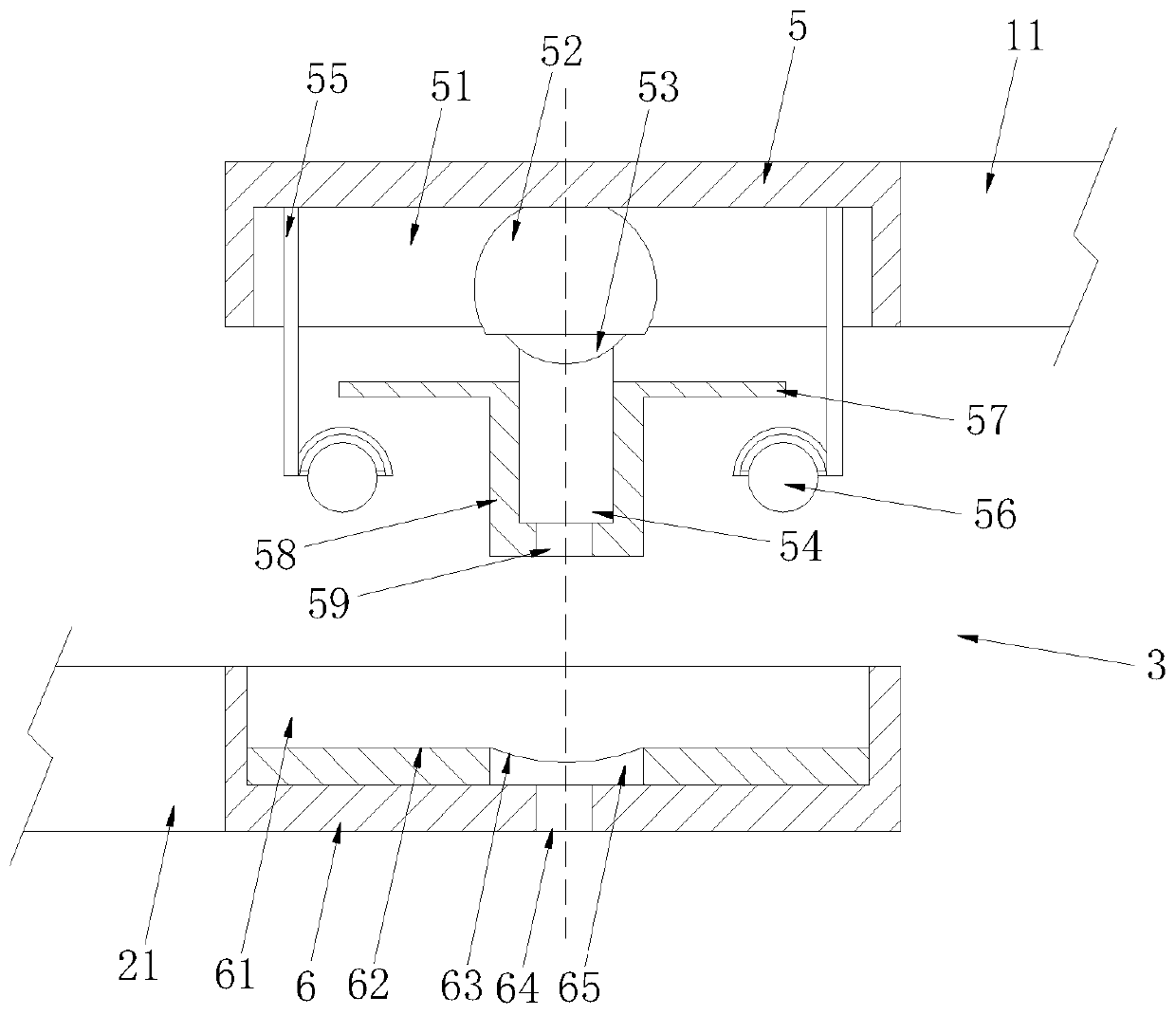

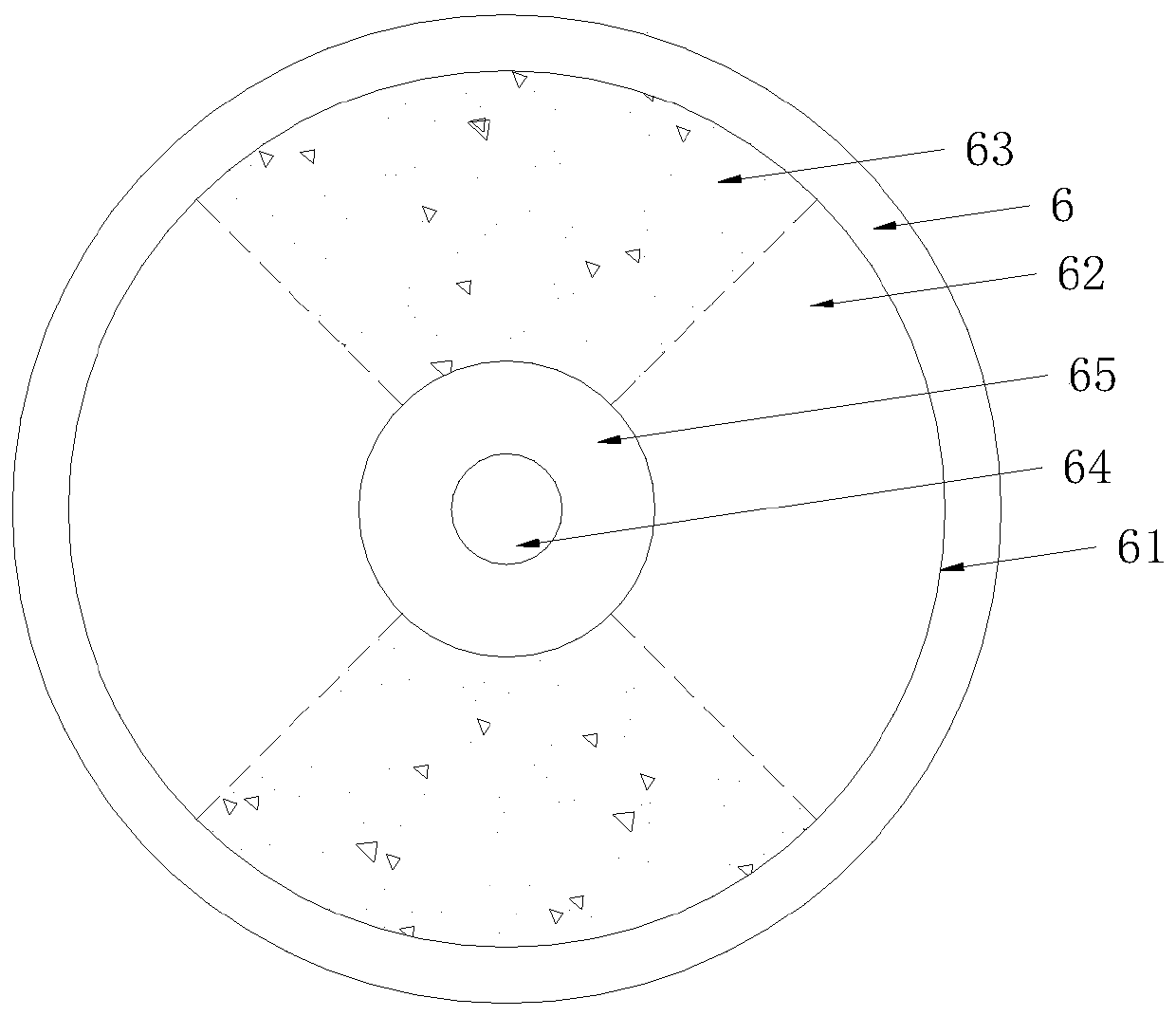

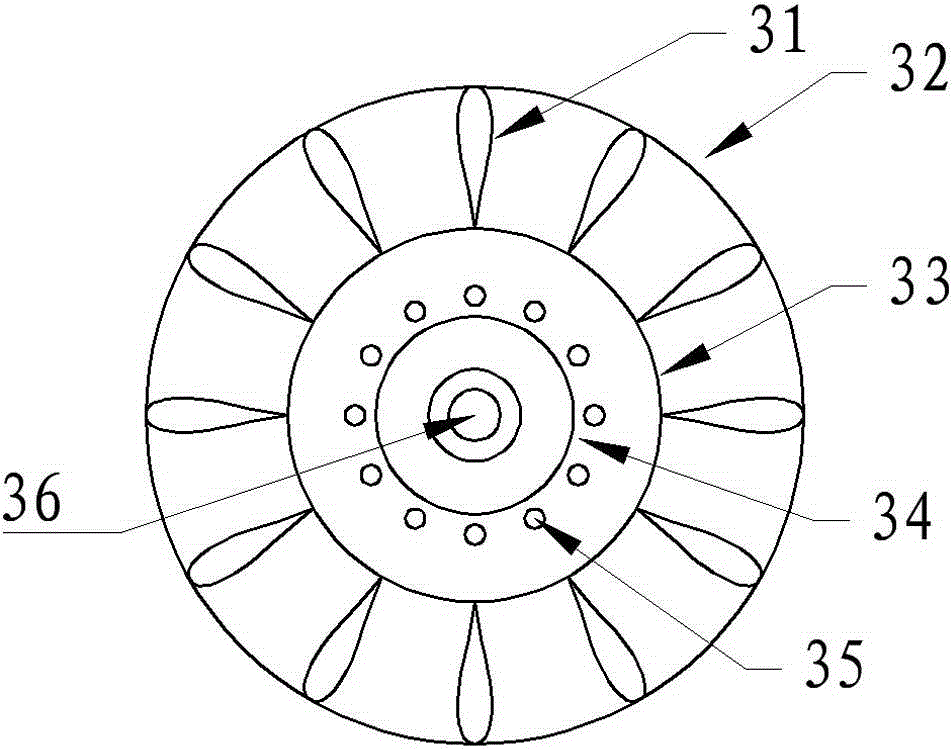

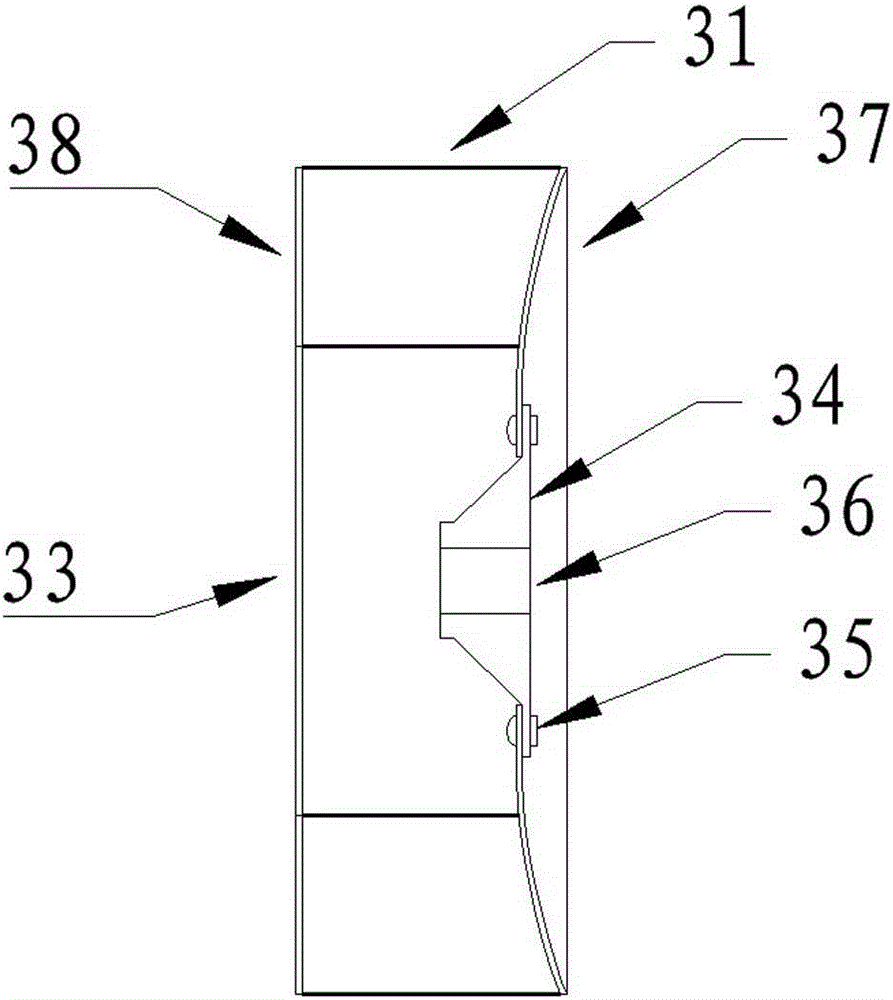

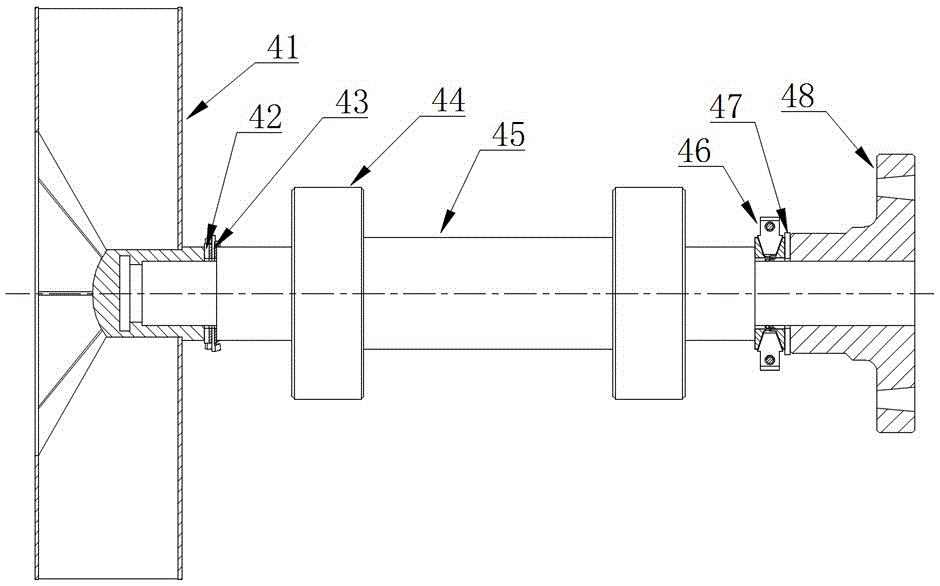

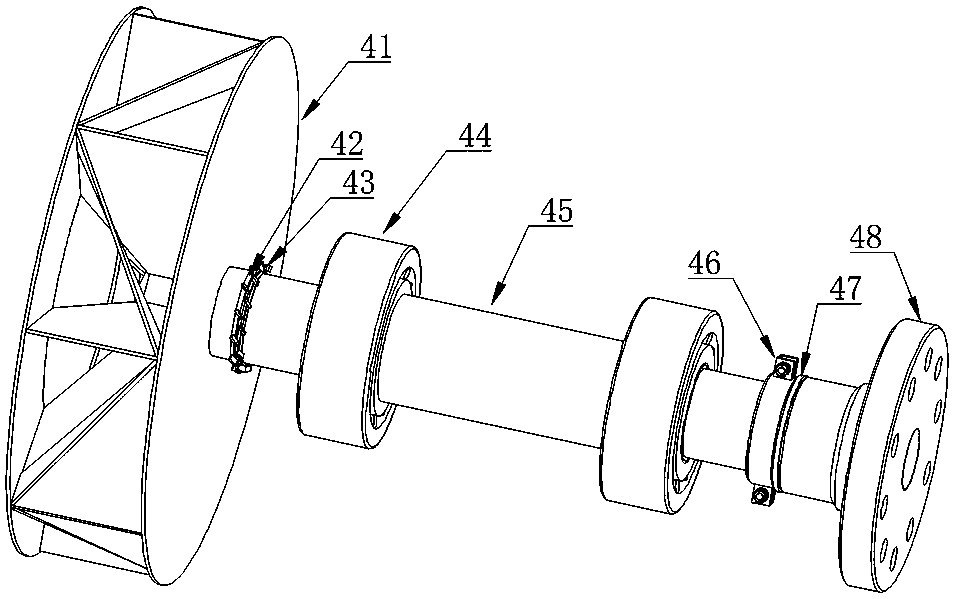

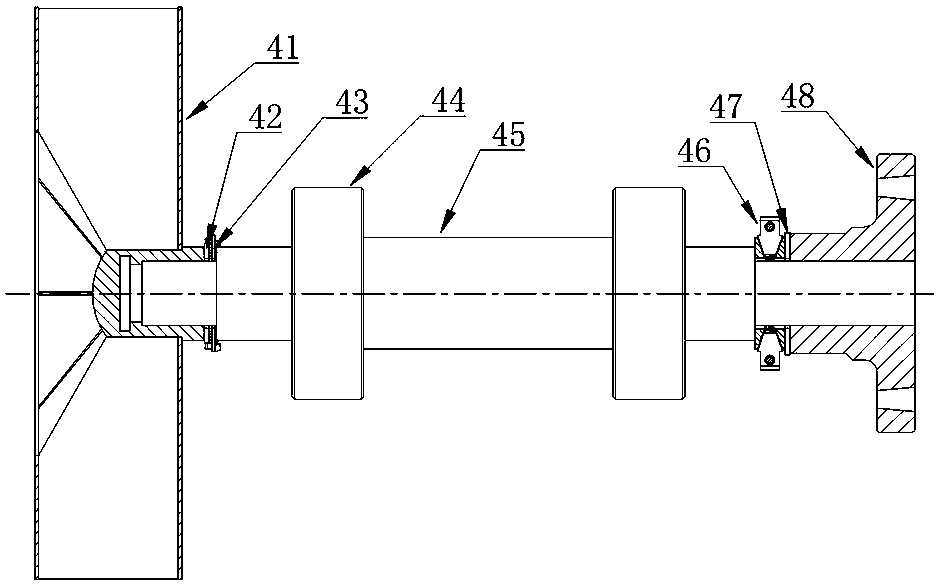

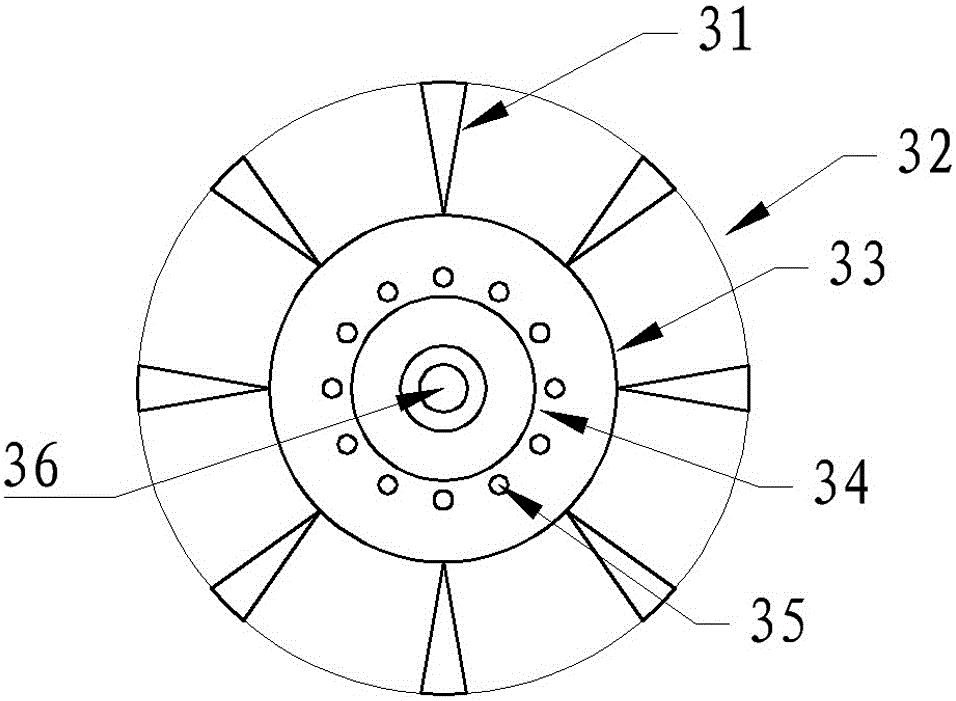

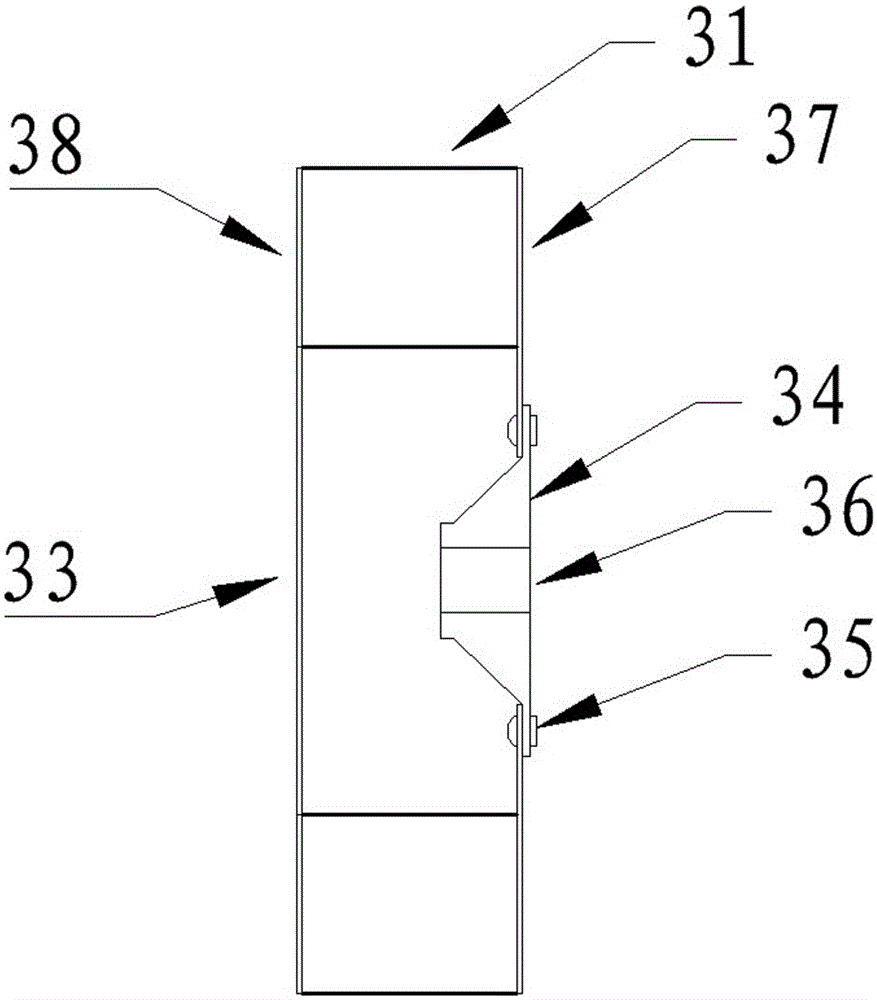

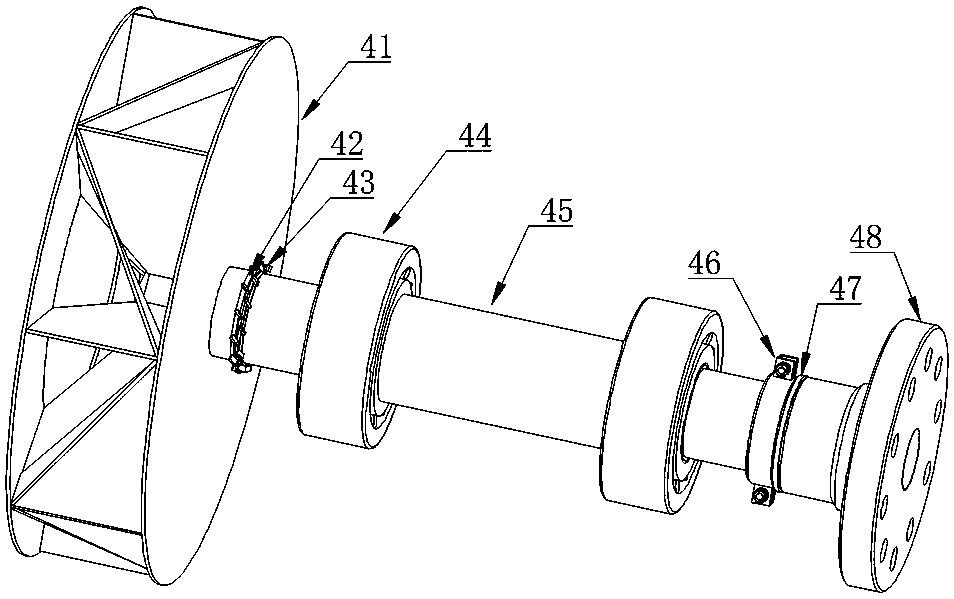

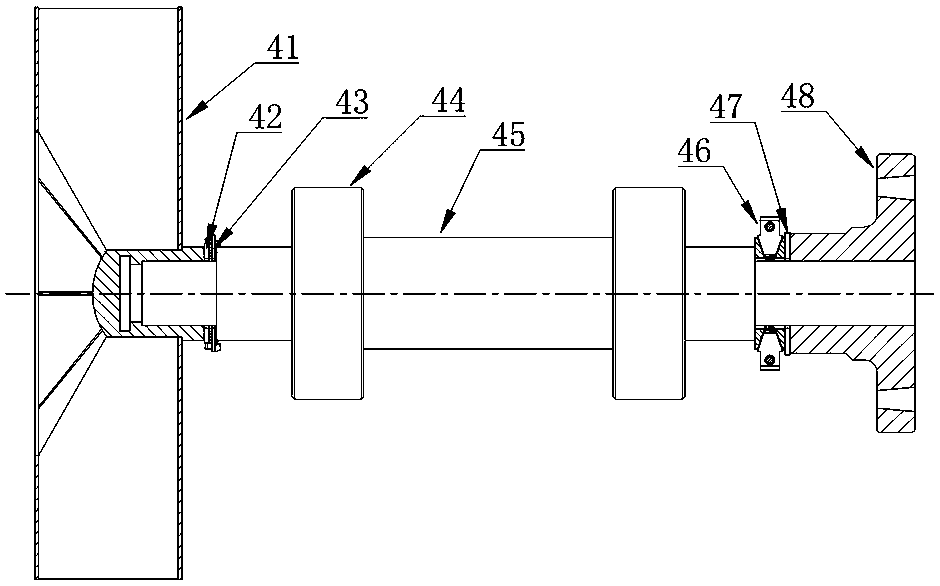

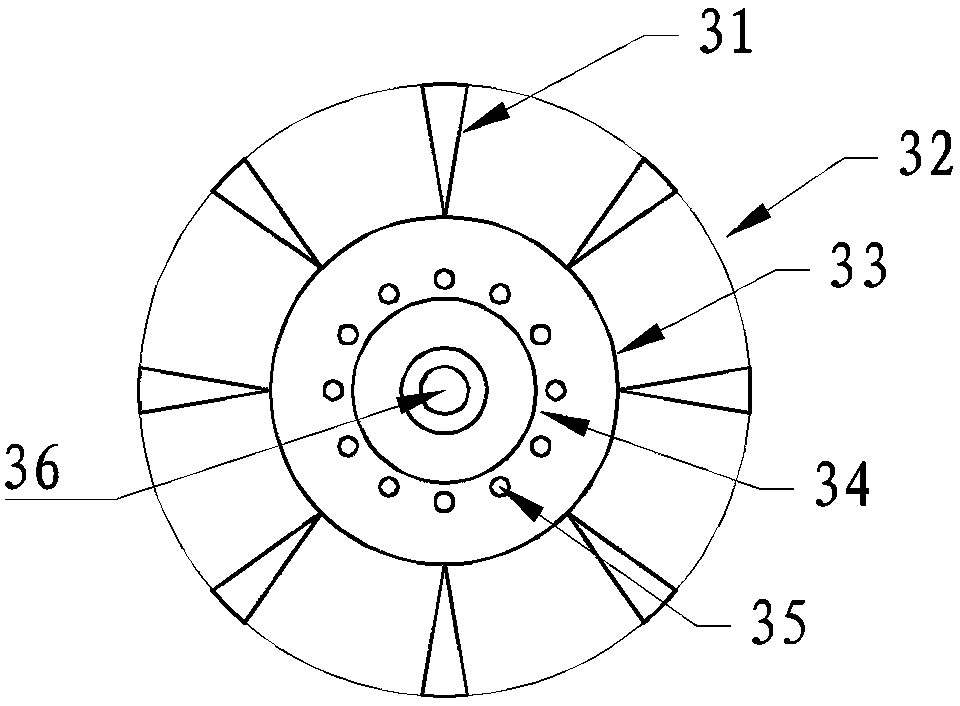

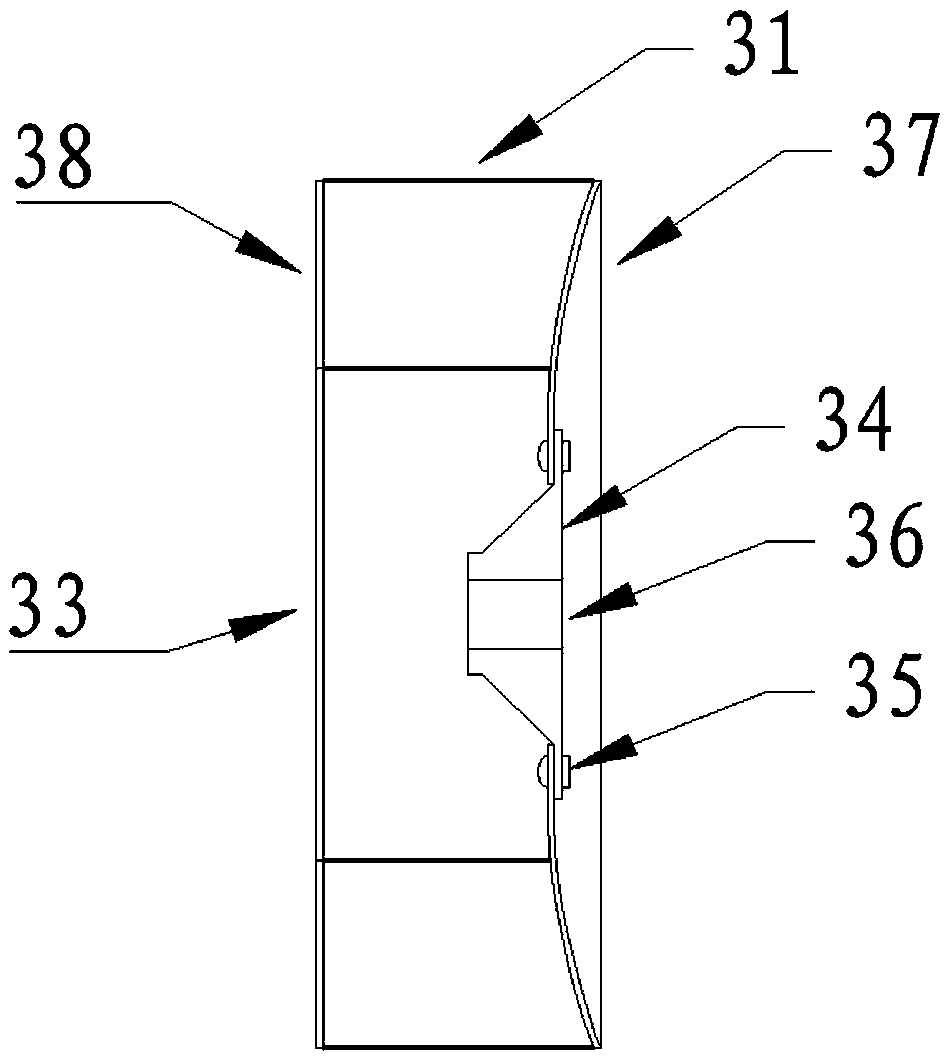

Dirt retention prevention draught fan impeller with wedge-shaped blades and disk-shaped back plate

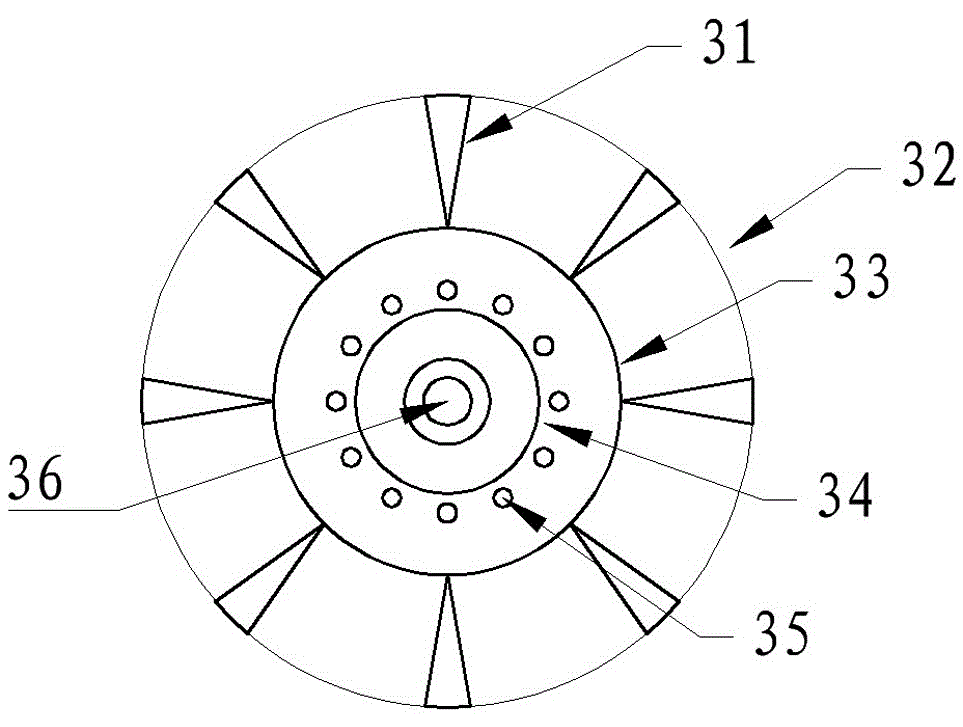

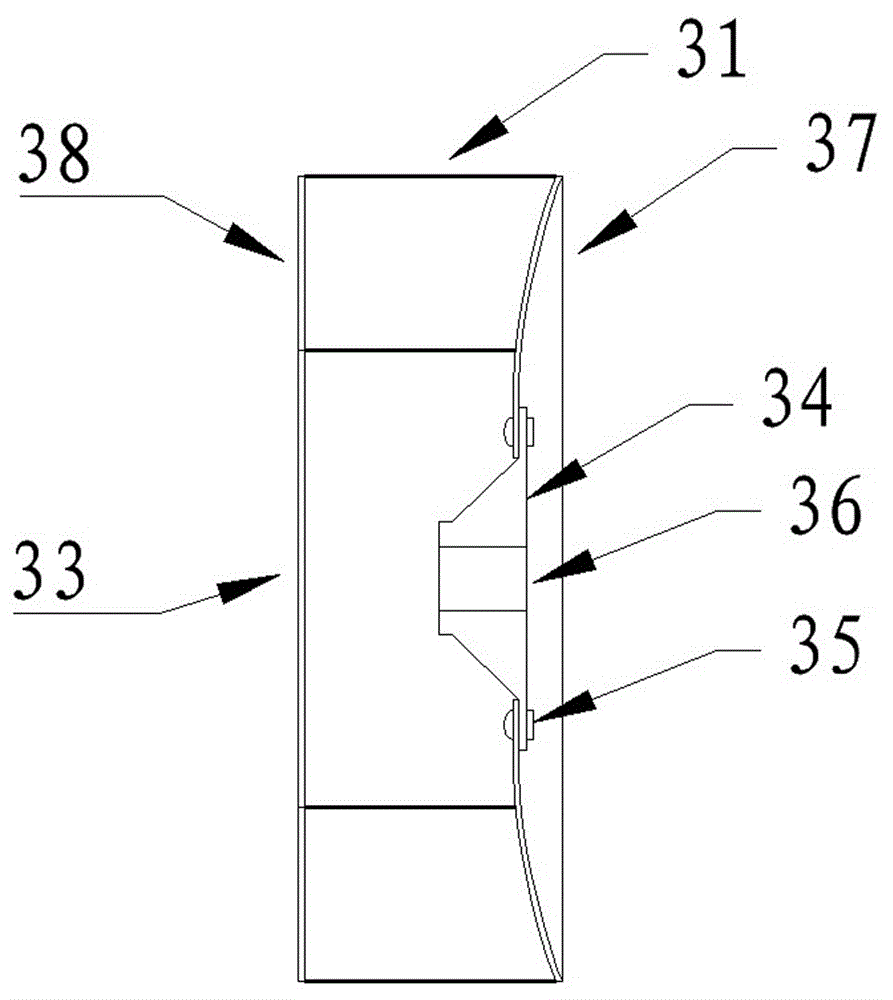

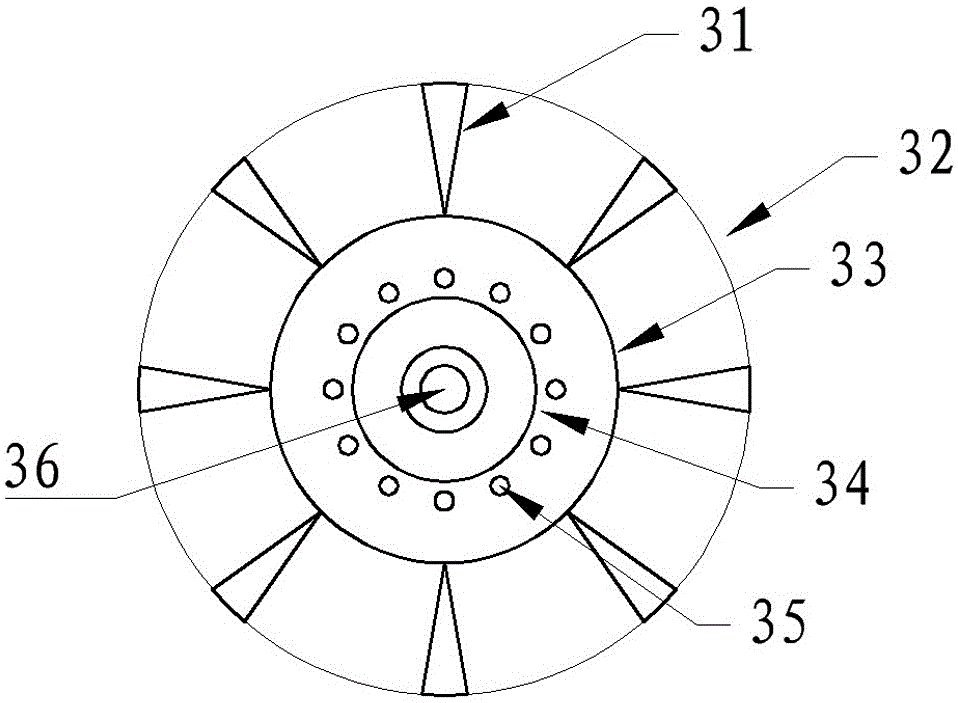

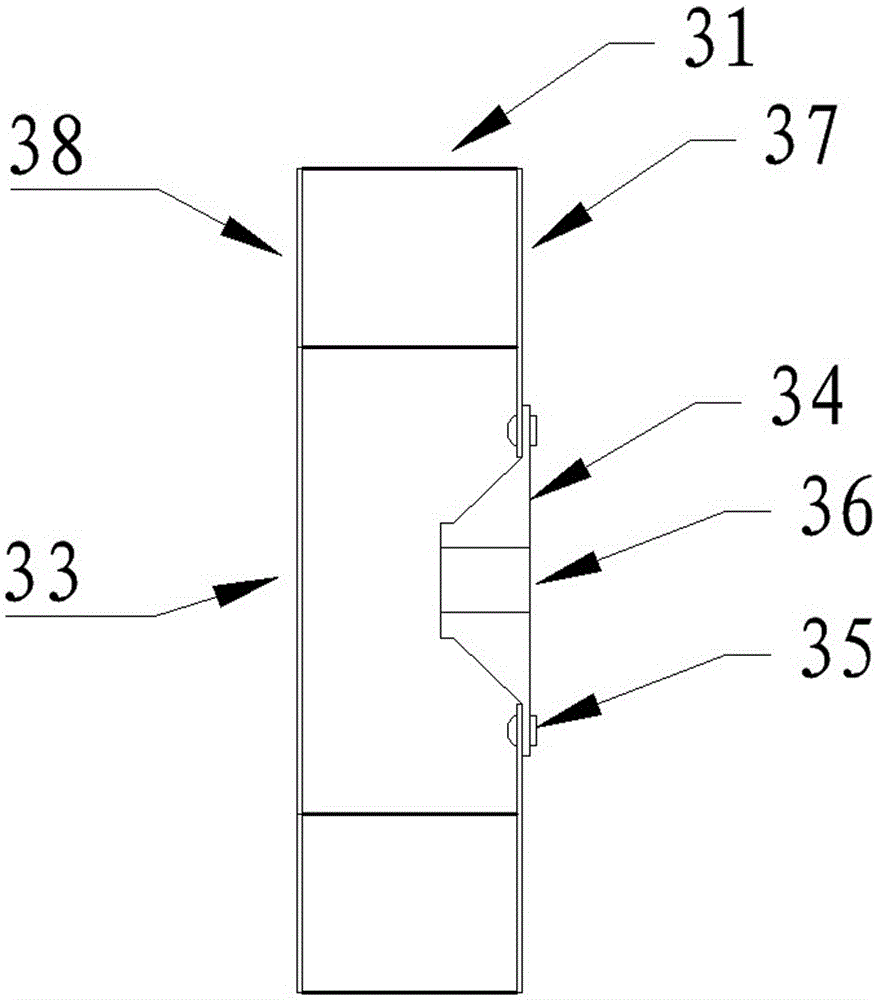

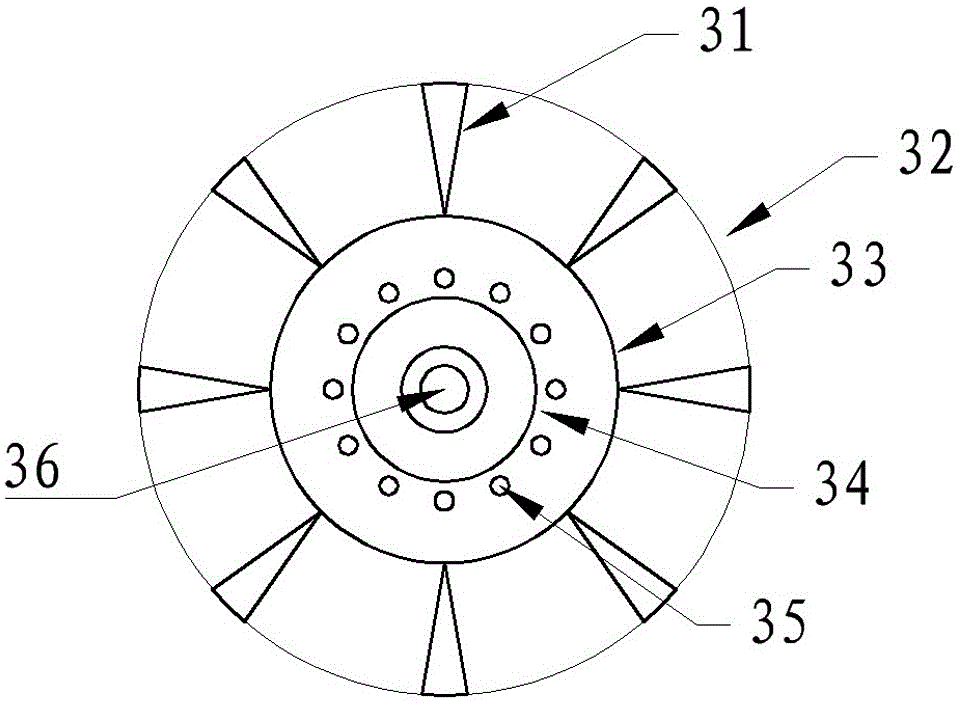

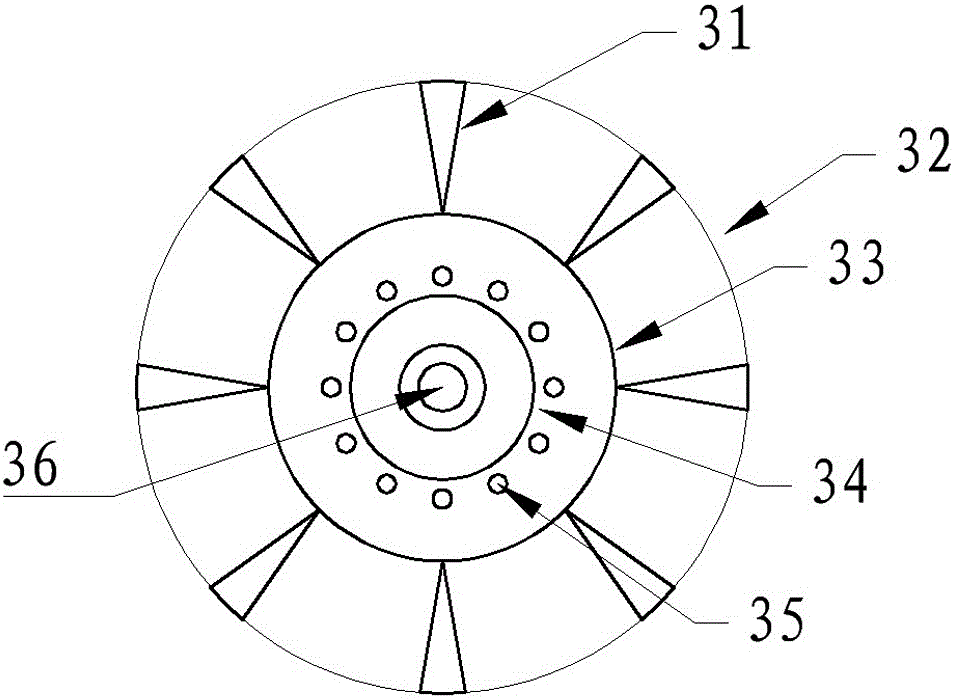

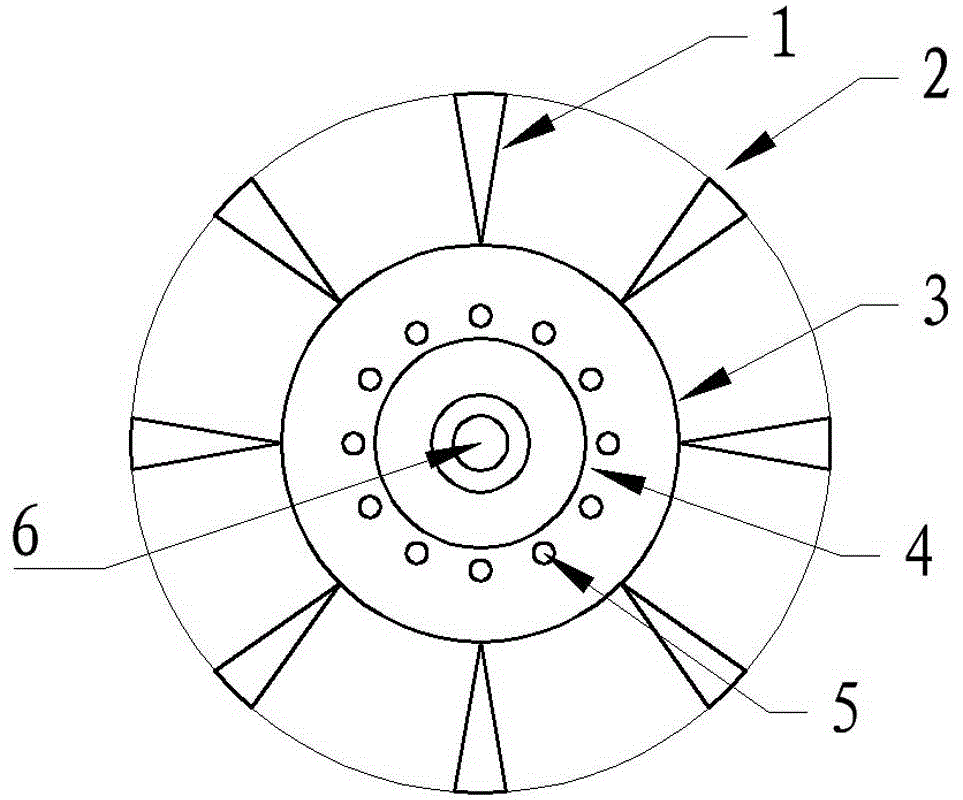

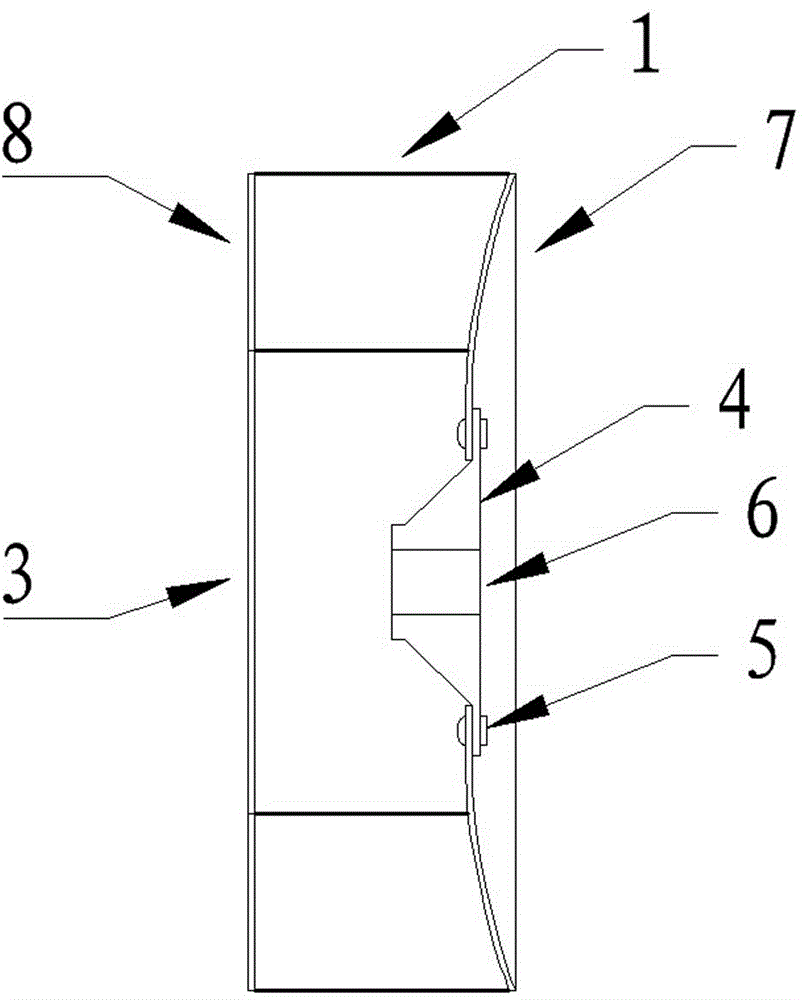

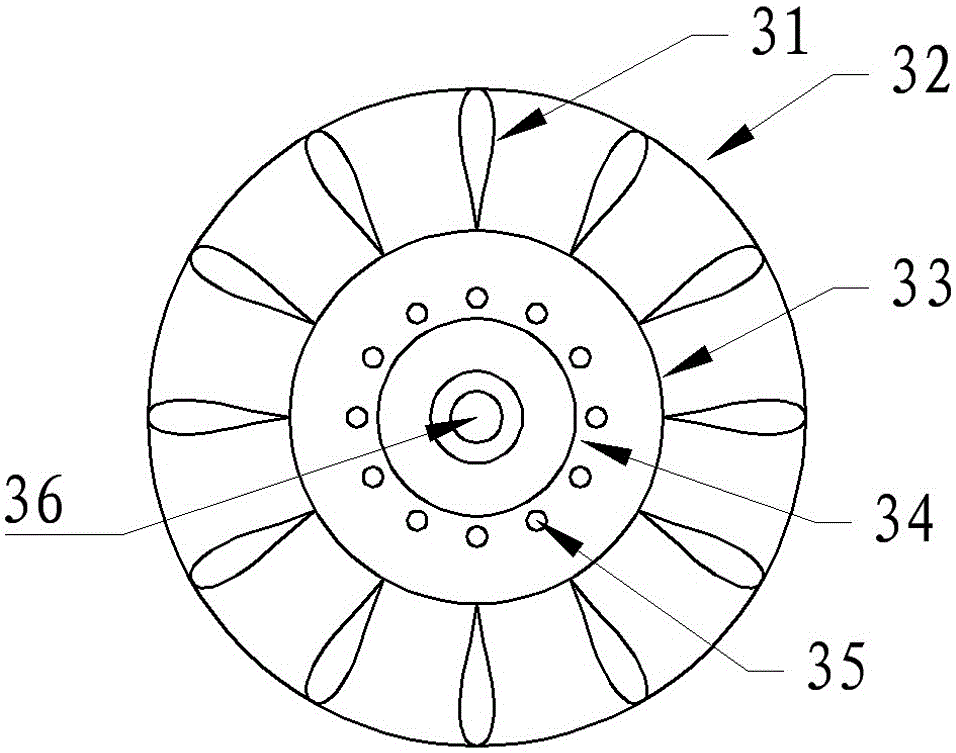

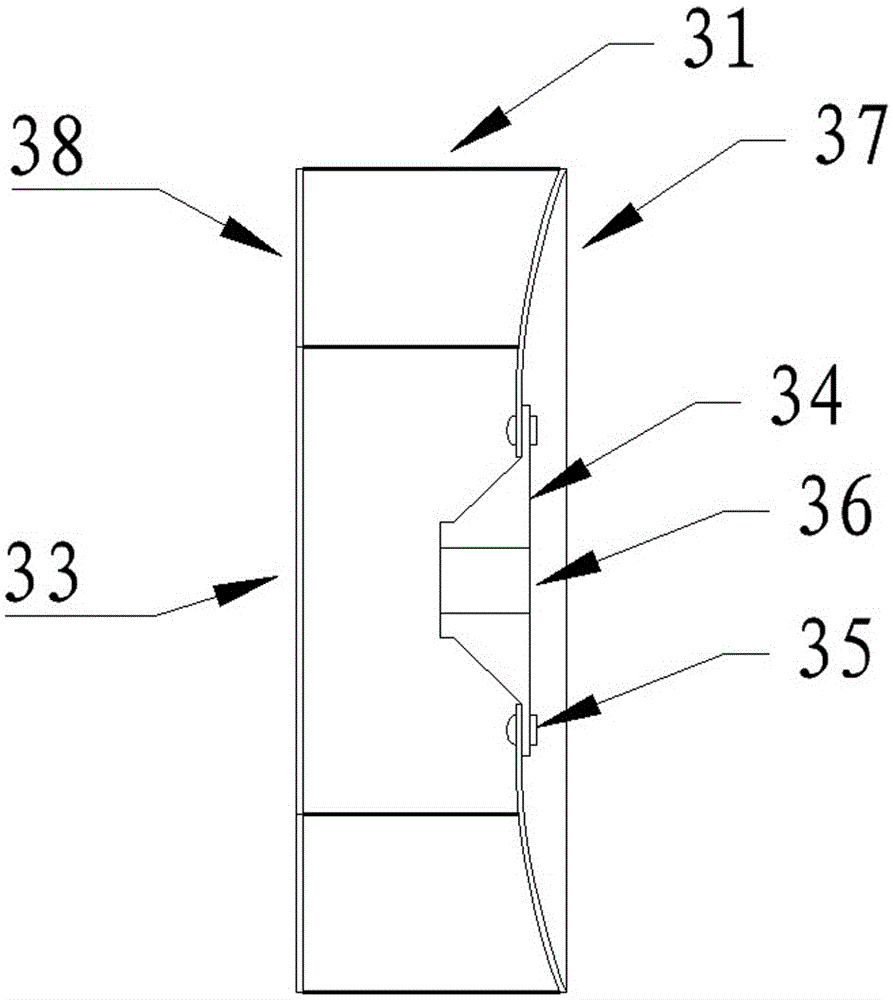

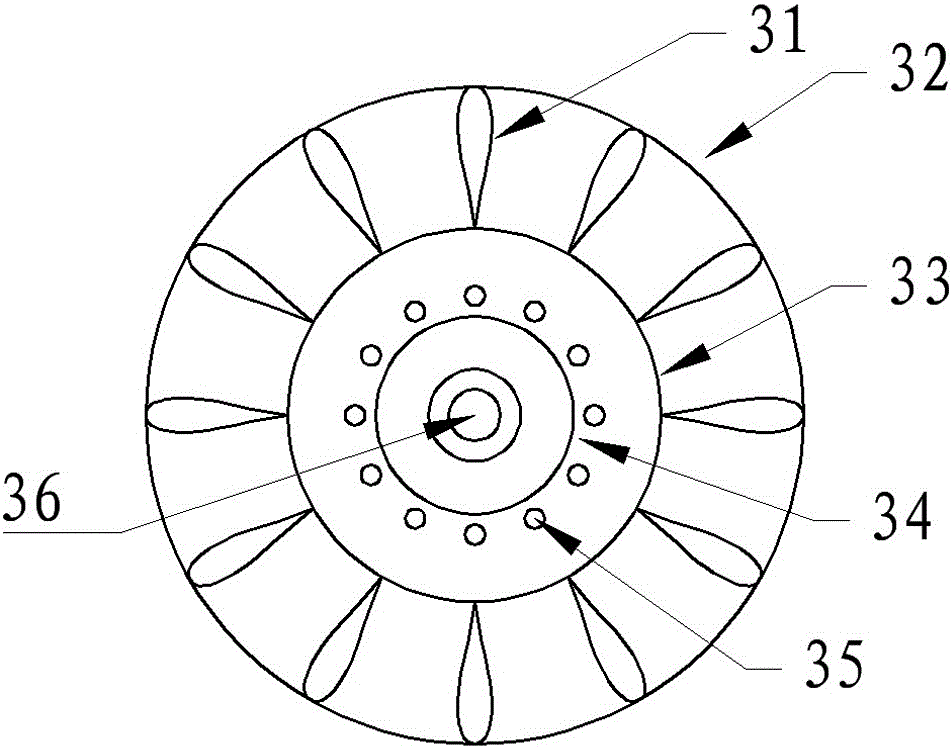

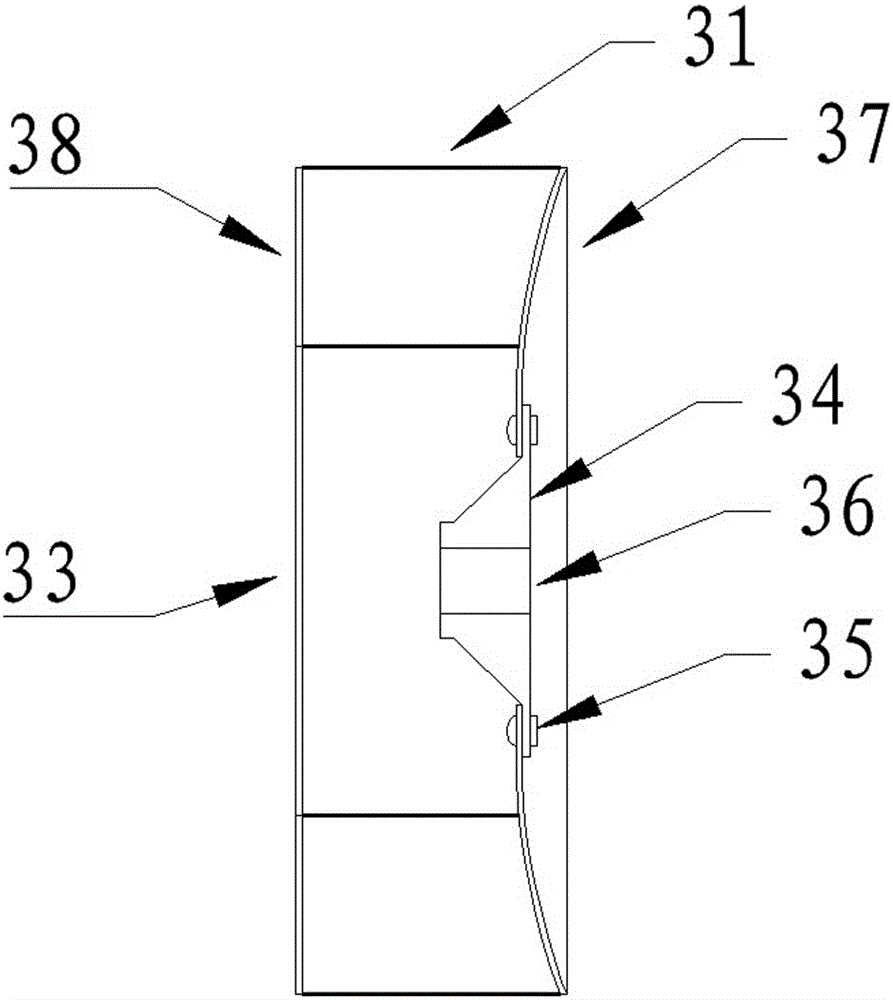

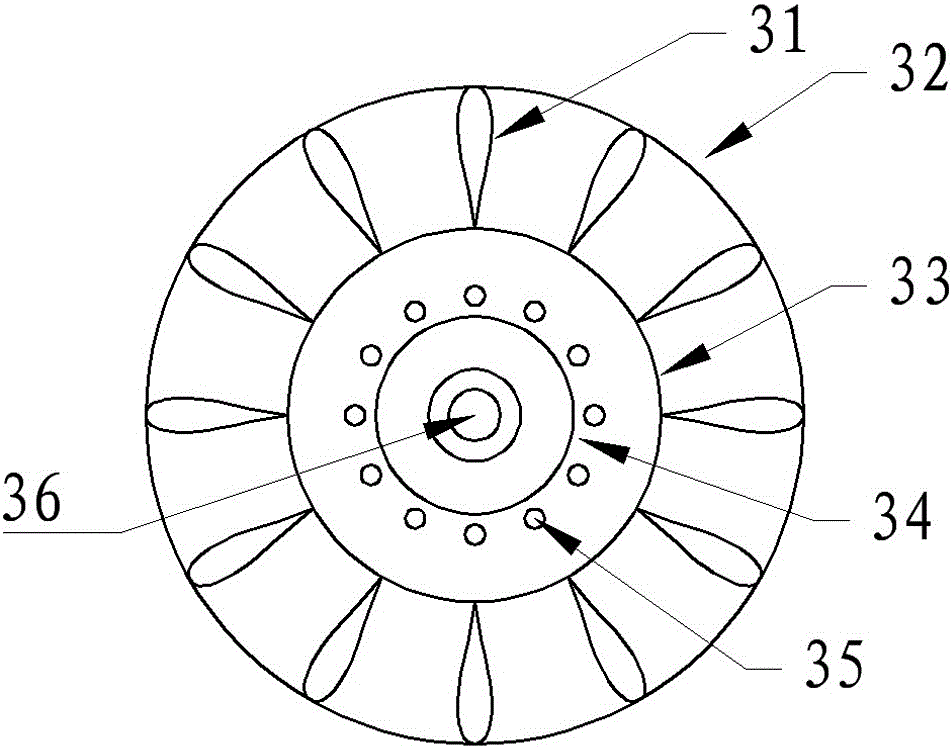

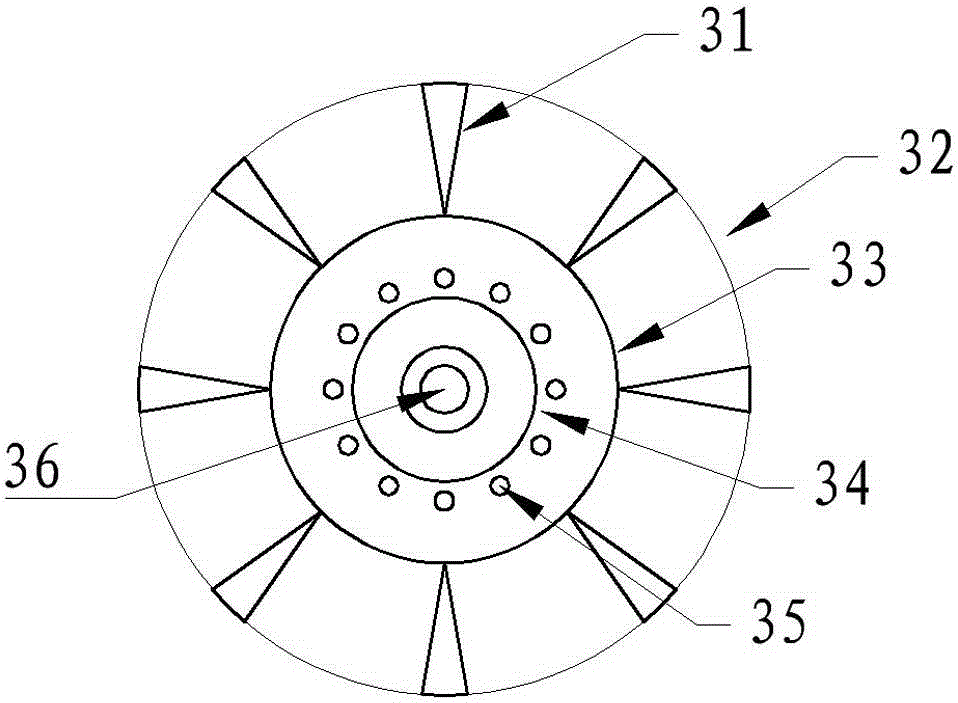

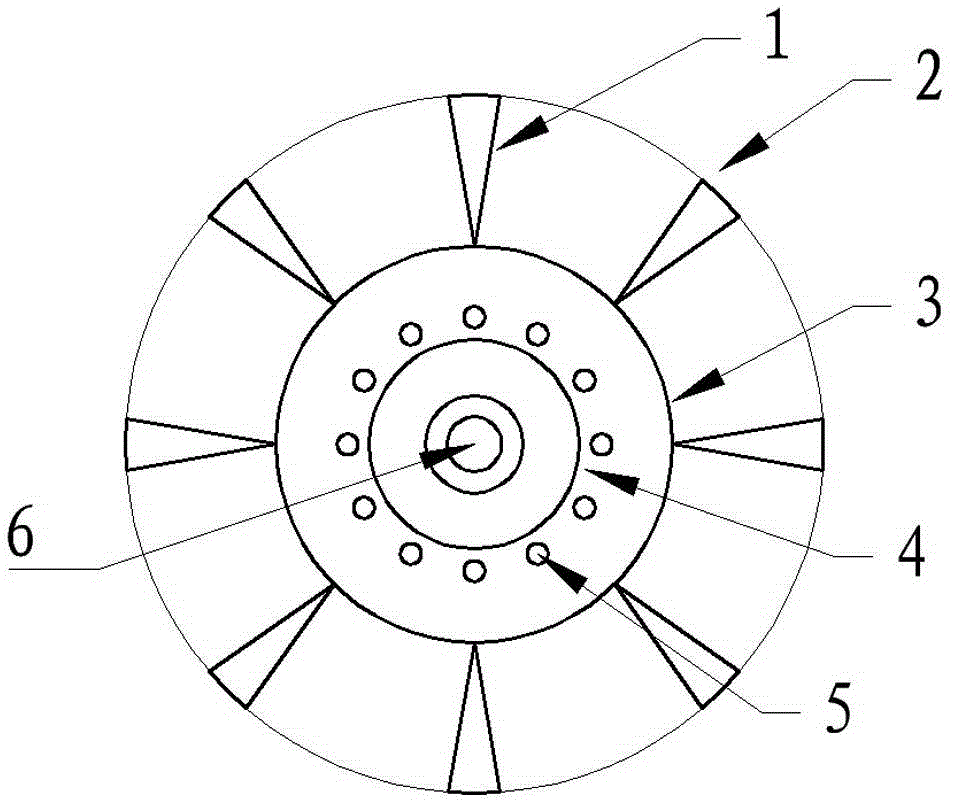

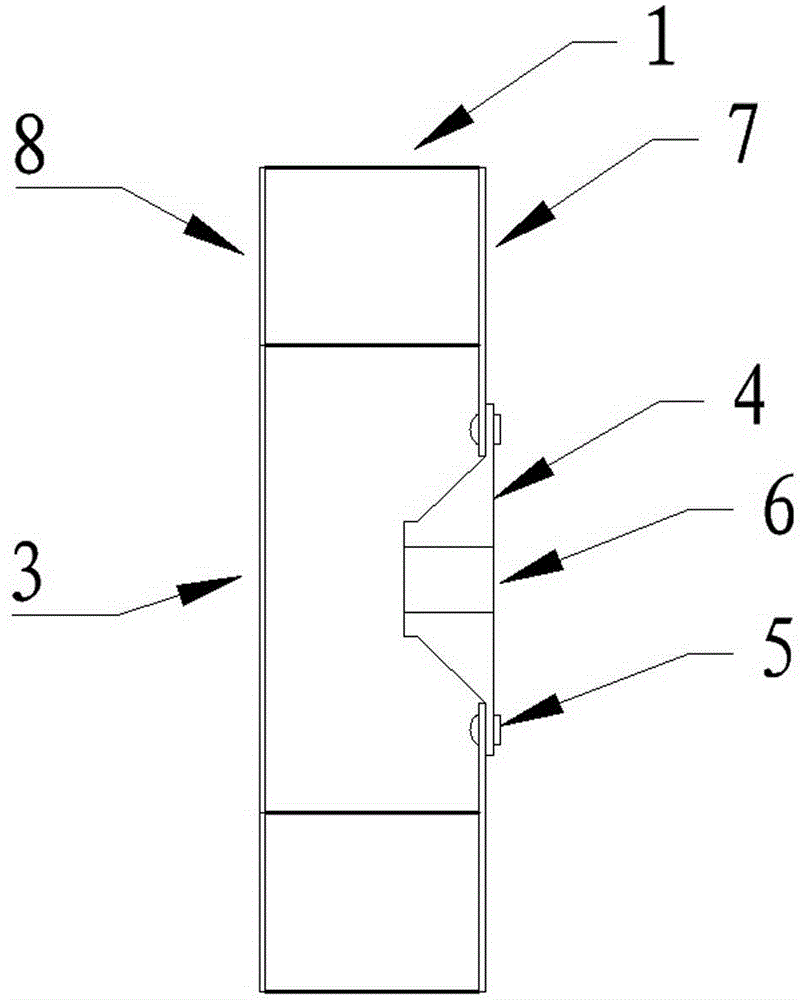

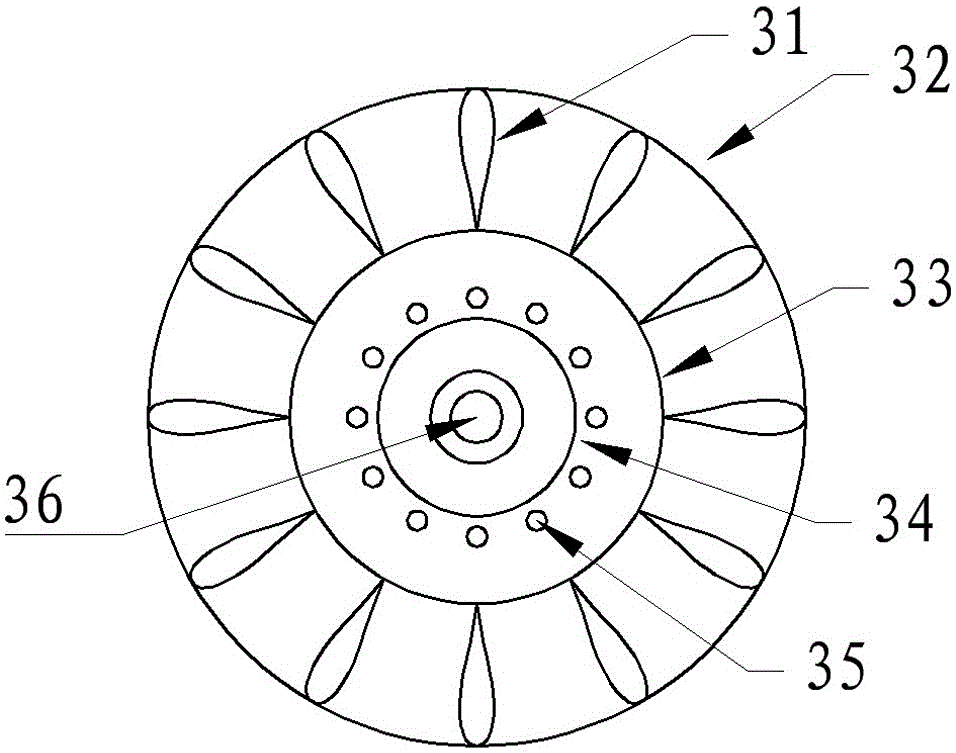

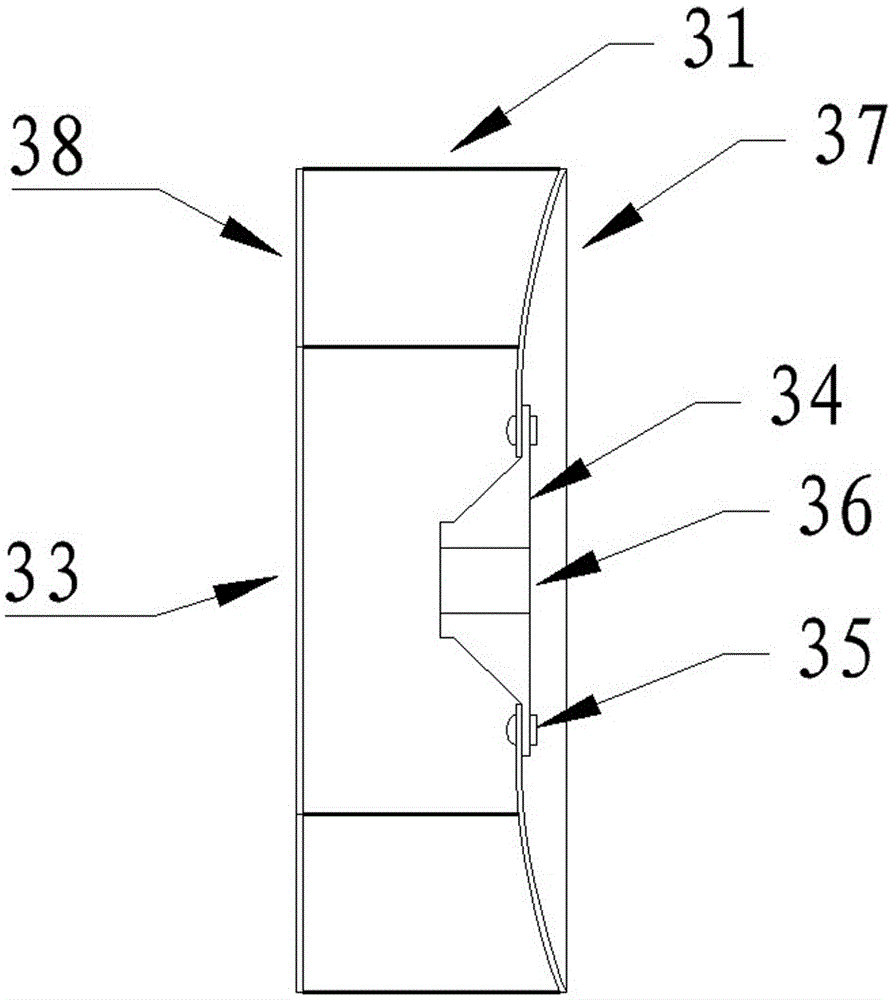

InactiveCN104963891AIncreasing the thicknessLarge delivery air flowPump componentsPumpsImpellerCentrifugal force

The invention discloses a dirt retention prevention draught fan impeller with a wedge-shaped blades and a disk-shaped back plate. The dirt retention prevention draught fan impeller with the wedge-shaped blades and the disk-shaped back plate comprises the impeller back plate, an impeller panel and the blades, the blades are arranged to be in a hollow wedge shape symmetric about the radial direction and center of an impeller shaft, and the impeller back plate is in a disk shape; the hollow wedge-shaped blades are connected with the impeller panel and welded to the disk-shaped impeller back plate to form an impeller body; an air inlet is formed in the impeller panel, the disk-shaped impeller back plate is fixed and connected with a shaft base through rivets, and the shaft base is connected with a draught fan shaft through a shaft hole in a matched mode. When the dirt retention prevention draught fan impeller with the wedge-shaped blades and the disk-shaped back plate is used, since the blades are designed to be in a hollow wedge shape with blade shafts centrosymmetric in the radial directions, during high-speed rotating, the centrifuge self-cleaning function of the surfaces of the blades is achieved under the centrifugal force function, dirt is subjected to the centrifugal force function and can not be attached to the blades, dirt retention can not occur, and the dirt retention prevention draught fan impeller with the wedge-shaped blades and the disk-shaped back plate is particularly suitable for wide impeller large draught fans that the distance between a front end plate and a rear end plate of each impeller is large and the transporting air flow is also particularly large; by means of the disk-shaped back plate, the compressive strength is improved, and the service life of the draught fan is prolonged.

Owner:JISHOU UNIVERSITY

Heat pump type tunnel drying device with baffling dust removal function

ActiveCN105202886ADoes not affect dynamicDoes not affect balanceCombination devicesPump componentsImpellerAir blower

The invention discloses a heat pump type tunnel drying device with a baffling dust removal function. A trolley is arranged on a rail of a tunnel, long-shaft fans for internal circulation are arranged in the tunnel, vanes of each long-shaft fan are long-strip-shaped, the section of each vane is in a hollow wedge shape centrosymmetric about the axial radial direction of an impeller, two ends of each vane are inserted into end plates, and each long shaft is fixedly connected with the corresponding end plates through spokes; an air suction hood and an air inlet hood are arranged at two ends of the tunnel adopting a sealed structure, the air suction hood is connected with an induced draft fan, and the induced draft fan is connected with an evaporator of a heat pump system through a dust remover and then emptied; the evaporator of the heat pump system is connected with a main unit, and the main unit is connected with a condenser; an air outlet end of an air blower is connected with the air inlet hood through the condenser; the induced draft fan and the impeller of the long-shaft fans are designed to adopt a hollow symmetric structure and are light, ingenious, solid and durable, and dust cannot be accumulated. Crossflow drying and waste heat recovery of a heat pump are especially suitable for low-temperature drying, nutritional ingredients of thermosensitive substances can be prevented from being damaged, and the system can finish drying, dust removal and heat recovery efficiently at low energy consumption.

Owner:湖南美林住宅工业有限公司

Aconitum brachypodum ventilation type crusher

The invention discloses an aconitum brachypodum ventilation type crusher. The aconitum brachypodum ventilation type crusher comprises a crusher body and an induced draught fan. The discharging end of the crusher body is connected with the induced draught fan through a storage tank, exhaust pipes and a cyclone separator. The exhaust pipes are provided with an air door adjusting the air volume. An impeller of the induced draught fan is provided with a structure that blades are in a hollow inverted water drop shape, and a back plate is in a dish shape. The contour line of the appearance of the induced draft fan is an involute. In the pneumatic conveying process, particle sorting and material cooling are achieved. Rough particle returning and secondary crushing are finished by one step, qualified material output is achieved, and meanwhile dust capturing is achieved. Good-time smooth discharging of the crusher body is guaranteed through a ventilation system, materials are prevented from being excessively crushed, and electric power is saved. Through the structure that the blades are in the hollow inverted water drop shape, and the back plate is in the dish shape, dust on the impeller of the induced draft fan is cleaned away in real time, the impeller strength of the draught fan is increased, stability is increased, safety accidents caused by dust accumulation are effectively eradicated, and the application prospect is wide.

Owner:JISHOU UNIVERSITY

Combination exhausting system adopting reaction of manganese ore powder and sulfuric acid

ActiveCN105056870AReal-time dischargeAchieve energy saving and emission reductionPump componentsChemical industryImpellerCyclone

The invention discloses a combination exhausting system adopting a reaction of manganese ore powder and sulfuric acid. The combination exhausting system is characterized in that stirring systems are arranged in combination barrels which are connected with an induced draft fan through exhausting pipes, the induced draft fan is tangentially connected with a cyclone tower for exhausting, and throttles are arranged in the exhausting pipes; multiple groups of cyclones comprising large cyclone plates, small cyclone plates and cone hopper plates are vertically arranged in the cyclone tower; an impeller of the induced draft fan has hollow wedge-shaped blades; the shape contour of the induced draft fan is involute. By the aid of the induced draft fan and the cyclones, carbon dioxide gas produced by the reaction of the manganese ore powder and sulfuric acid is exhausted in real time, reaction proceeding is facilitated, carried ore powder is recovered effectively through gas cyclone, and energy conservation and emission reduction are realized; with adoption of the blades adopting the hollow wedge-shaped structure, dust on the impeller of the induced draft fan is cleaned in real time, the impeller strength of the induced draft fan is improved, the stability is enhanced, safety accidents caused by dust accumulation are eradicated effectively, and the combination exhausting system has broad application prospects.

Owner:大同市金盛豪达炭业有限责任公司

Tail heat utilization and dust removal integrated coal fired boiler

ActiveCN105020727AHigh strengthReliable usePump componentsLighting and heating apparatusExhaust gasImpeller

The invention discloses a tail heat utilization and dust removal integrated coal fired boiler. According to the tail heat utilization and dust removal integrated coal fired boiler, a tail gas pipe of the boiler is tangentially connected with a cyclone dust remover, and dust is discharged at the cone base through a closed-air aspirator after rotational flow dust removal; tail gas is connected with a cone through a rotational flow ascending pipe and penetrates row pipes after being uniformly dispersed, and the tail gas is centralized by a cone hopper on the upper portion and exhausted out by an induced draft fan through an exhaust pipe; an impeller of the induced draft fan is of a structure with blades in a hollow wedge shape and a backboard is in a dish shape; and the shape contour line of the induced draft fan is an involute. According to the tail heat utilization and dust removal integrated coal fired boiler, tail heat utilization and the dust removal of the boiler are creatively integrated, and a cyclone dust removal tail heat efficient using device is designed; the tail heat utilization and the dust removal are completed in one step, the equipment input is reduced, and the working efficiency is also improved; by means of the structure with the blades in the hollow wedge shape and the backboard in the dish shape, the real-time cleaning of the dust on the impeller of the induced draft fan and the increase of the strength of the impeller of the draught fan are achieved, the stability is improved, and safety accidents caused by dust accumulation are effectively eradicated; and the application prospect is wide.

Owner:湖北布实非织造布有限公司

Hot wind type penetration reverse flow drying machine capable of recycling tail heat

ActiveCN105021008AImprove rigidityImprove carrying capacityDrying gas arrangementsDrying machines with progressive movementsDish structureImpeller

The invention discloses a hot wind type penetration reverse flow drying machine capable of recycling tail heat. A draught hood and a wind inlet hood are arranged at the two ends of a case body of the drying machine respectively. The draught hood is tangentially connected with a cyclone dust removing tail heat efficient recoverer through a draught fan and then evacuation is conducted. A blast blower is connected with the wind inlet hood through a tube type heat exchanger and a steam fin heater. A draught fan impeller is provided with hollow inverse-drop-shaped blades, and a back plate is of a dishing structure. The outline of the draught fan is an involute. According to the hot wind type penetration reverse flow drying machine capable of recycling tail heat, tail heat recovery and dust removal are creatively integrated, the cyclone dust removing tail heat efficient recoverer is designed, the equipment investment is reduced, and the working efficiency is improved. By means of the draught fan, a soft partition plate and an axial fan, penetration type reverse flow drying is ingeniously achieved, and the working efficiency is improved. The blades are in the hollow inverse drop shape, the back plate is of the dishing structure, and therefore real-time cleaning of dust on the impeller is achieved, the strength of the impeller of the draught fan is improved, stability is enhanced, accidents caused by dust accumulation are effectively eradicated, and the application prospects are wide.

Owner:湖北楚佳茶业有限公司

Tail heat utilization screen hole plate turnover type dryer

ActiveCN105066626ADoes not affect dynamicDoes not affect balanceDrying gas arrangementsDrying machines with progressive movementsImpellerPulp and paper industry

The invention discloses a tail heat utilization screen hole plate turnover type dryer. Screen hole plate turnover type conveying from top to bottom is adopted in a box of the dryer, and the box of the dryer is divided into an upper drying area, a middle drying area and a lower drying area. The upper drying area is connected with an inducted draft fan through an air heat exchanger and then emptied. A fresh air outlet of the air heat exchanger is connected with an air inlet of an air blower, and an air outlet of the air blower is connected with a steam fin heater in the middle drying area. An impeller of the induced draft fan is of the structure that blades are in a hollow wedge shape, and the contour line of the appearance of the induced draft fan is an involute. Tail heat utilization is simple and reasonable, damp and hot tail gas obtained through heat recovery is exhausted out through the induced draft fan, dried materials are effectively cooled, tail heat utilization is further conducted, and energy saving and emission reduction are promoted. Through the structure that the blades are in the hollow wedge shape, dust is cleaned away in real time, the impeller strength of the fan is increased, stability is increased, safety accidents caused by dust accumulation are effectively eradicated, and the application prospect is wide.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

Baffling dust removal heat pump type drying room

ActiveCN105135832AHigh heating coefficientPromote energy saving and emission reductionHeat recovery systemsPump componentsImpellerAdditive ingredient

The invention discloses a baffling dust removal heat pump type drying room. An inner circulating bifurcated fan is arranged in the drying room, and comprises a long shaft and blades. The blades are in a long strip shape, and the sections of the blades are in the shape of a hollow wedge symmetric about the radial direction and center of an impeller shaft. The two ends of each blade are inserted into end discs, and the long shaft is connected and fixed with the end discs through spokes. A draught hood and an air inlet hood are arranged at the two ends of the drying room respectively, the draught hood is connected with an induced draft fan, and the induced draft fan is connected with an evaporator of a heat pump system through a dust remover and then is evacuated. The evaporator of the heat pump system is connected with a main engine through a refrigerant pipe, and the main engine is connected with a condenser through a refrigerant pipe. The air outlet end of an air blower is connected with the air inlet hood through the condenser. The induced draft fan and the impeller of the bifurcated fan are both designed to be of a hollow symmetric structure, and are free of dust accumulation, light, firm and durable. Heat pump cross flow drying and tail heat recovery are especially suitable for being adopted in a low drying temperature system, the nutritional ingredients of thermosensitive substances can be prevented from being damaged, and efficient drying, dust removal and heat recovery are completed with low energy consumption through the system.

Owner:YANCHENG DEZHENG MACHINERY CO LTD

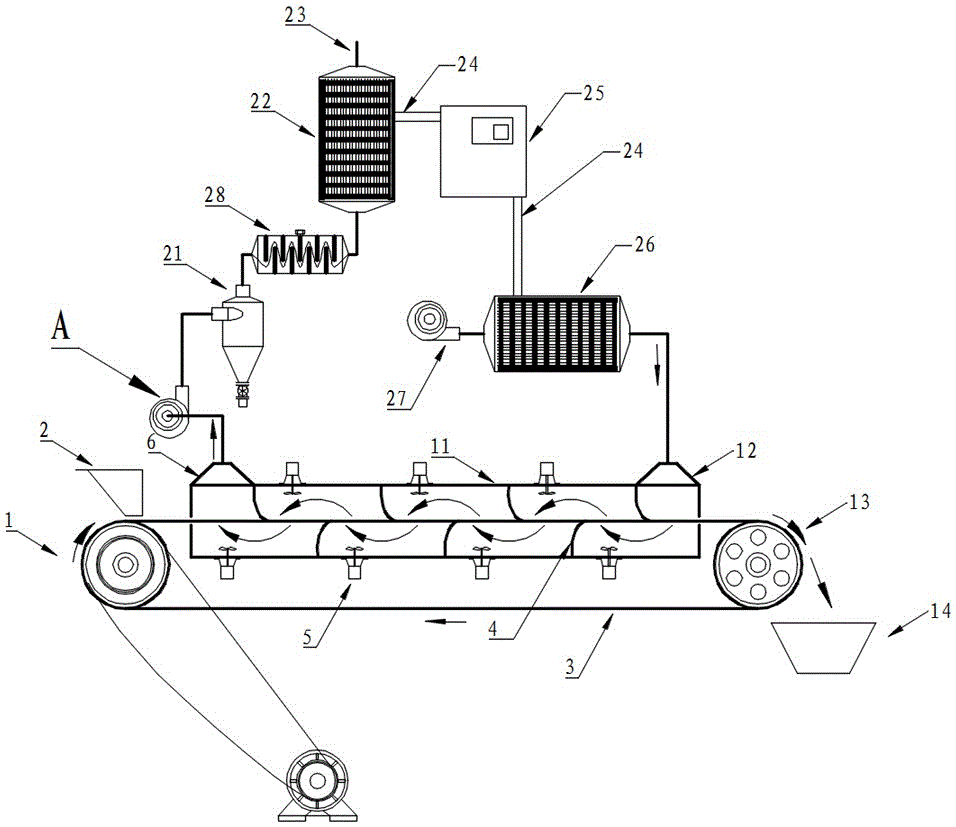

Raymond mill device with non-dust-accumulation draught fan

The invention discloses a Raymond mill device with a non-dust-accumulation draught fan. An air flow circulation abrasive powder discharge system is formed by the draught fan, a Raymond mill, a cyclone separation discharge device and an air return air pipe. A pressure equalizing exhaust branch pipe is connected with the upper end of a cyclone pipe. A plurality of cyclones are arranged in the cyclone pipe. The lower end of the cyclone pipe is connected with a cyclone separator in the tangent direction. A lower pipe opening of the cyclone separator is soaked in a circulation pool which is connected with the upper end of the cyclone pipe. An impeller of the draught fan is of a structure that blades are in hollow reverse water drop shapes and a back plate is in a dish shape. The appearance contour line of the draught fan is an involute. According to the Raymond mill device, low-resistance pressure-equalized exhausting is achieved through the cyclone pipe and the cyclones, and therefore dust overflow caused by system positive pressure is eradicated. Wet-method efficient dust removal and mineral powder recycle are achieved through the circulation pool. By means of the structure that the blades are in the hollow reverse water drop shape and the back plate is in the dish shape, dust on the impeller of the induced draught fan is removed in real time, the strength of the impeller of the draught fan is improved, stability is enhanced, accidents caused by dust accumulation are effectively eradicated, and application prospects are wide.

Owner:JISHOU UNIVERSITY

Combination exhausting device for manganese ore powder and sulfuric acid reaction

ActiveCN105110333AHigh strengthEnsure stabilityCarbon compoundsChemical industryImpellerCarbon dioxide

The invention discloses a combination exhausting device for manganese ore powder and sulfuric acid reaction. Stirring systems are arranged in combination barrels, the combination barrels are connected with a draught fan through exhaust pipes, the draught fan is tangentially connected with a swirl tower and then is exhausted, and air valves are arranged in the exhaust pipes; multiple groups of swirlers, which consist of large swirl plates, small swirl plates and conical hopper plates, are vertically arranged in the swirl tower; an impeller of the draught fan has hollow and inverted-droplet-shaped vanes; and the appearance contour line of the draught fan is involute. According to the combination exhausting device, the real-time exhaust of carbon dioxide gas produced from the reaction between the manganese ore powder and the sulfuric acid is realized through the draught fan and the swirlers, the proceeding of the reaction is facilitated, carrying powdered ore is effectively recovered through gas swirling, and energy saving and emission reduction are realized; and the vanes are of hollow and inverted-droplet-shaped structures, thus dust on the impeller of the draught fan can be cleaned in real time, the strength of the impeller of the fan is improved, the stability is enhanced, and safety accidents caused by dust accumulation are effectively avoided, so that the application prospect is broad.

Owner:SUZHOU RUIPENGCHENG SCI & TECH CO LTD

Tail heat recovery screen mesh plate turning type drying machine

ActiveCN105066627ADoes not affect dynamicDoes not affect balanceDrying gas arrangementsDrying machines with progressive movementsImpellerPulp and paper industry

The invention discloses a tail heat recovery screen mesh plate turning type drying machine. A box of the drying machine is provided with a screen mesh plate turning plate type conveying device from top to bottom. The box of the drying machine is divided into an upper drying area, a middle drying area and a lower drying area. The upper drying area is connected with an induced draft fan through an air heat exchanger, and then evacuation is carried out. A fresh air outlet of the air heat exchanger is connected with an air inlet of an air blower, and an air outlet of the air blower is connected with a steam fin heater in the middle drying area. An impeller of the induced draft fan is provided with a structure with hollow inverted-drop-shaped blades and a dish-shaped back plate. The contour line of the appearance of the induced draft fan is an involute. The tail heat recovery screen mesh plate turning type drying machine is simple and reasonable in tail heat recovery, damp and hot tail gas obtained after heat recovery is exhausted through the induced draft fan, effective cooling and further tail heat recovery are carried out on dried materials, and energy saving and emission reducing are promoted. Due to the structure that the blades are in a hollow inverted drop shape and the back plate is in a dish shape, dust is removed in real time, and the strength of the impeller of the fan is increased; and stability is improved, potential safety hazards caused by dust accumulation are effectively eradicated, and wide application prospects are achieved.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

Rotary kiln system capable of utilizing residual heat for stoving and with no dirt retention on induced draft fan

ActiveCN105180645AEasy flipIncrease the heating areaPump componentsRotary drum furnacesEngineeringThermal efficiency

The invention discloses a rotary kiln system capable of utilizing residual heat for stoving and with no dirt retention on an induced draft fan. A rotary kiln is arranged in an inclined manner; a burner is arranged in the rotary kiln; the high end of the rotary kiln and one end of a dryer are connected with an air hose in a bidirectional manner through a discharging pipe; a conveyer belt is arranged in the dryer and is connected with the discharging pipe; a star discharger is arranged at the other end of the dryer; a bulged refractory slab is arranged in the rotary kiln; the induced draft fan for dust removal has the structure of wedge-shaped blades and a dished backboard. According to the invention, the bulged refractory slab increases the heat transfer area of the rotary kiln, promotes stirring of a material, and facilitates improvement of thermal efficiency; the dryer utilizes residual heat to facilitate forming and drying of a globular material; residual heat utilization and heat preservation consequent reaction of hot material have the remarkable energy-saving characteristic; a quenching liquid pool rapidly cools a pellet material, and plenty of water is evaporated through reaction, so that the environmental protection pressure caused by expansion of producing fluid is effectively relieved; the induced draft fan does not accumulate dirt to completely eradicate a safety accident; the rotary kiln system is particularly suitable for burning processing of vanadium ore and is broad in application prospect.

Owner:NANTONG HENGDA MACHINERY MFG

Anti-dust accumulation fan with wedge-shaped blades

The invention discloses an anti-dust accumulation fan with wedge-shaped blades. The anti-dust accumulation fan comprises an impeller and a shell; the impeller comprises an impeller backplane, an impeller face panel and the blades; the blades are set to hollow wedge-shaped blades; the axes of the blades are in radial and central symmetry; the hollow wedge-shaped blades are connected with the impeller face panel and are welded to the impeller backplane, so that an impeller main body can be formed; the impeller face panel is provided with an air inlet; the impeller backplane is fixed through a rivet and is connected with a shaft seat; the shaft seat is in matched connection with a fan shaft through a shaft hole; the shell is provided with an air inlet and an air outlet; the outline of the shell is in the shape of an involute; and the air inlet of the shell is provided with a cover plate. According to the anti-dust accumulation fan with the wedge-shaped blades, the blades are ingeniously designed into the wedge-shaped blades; the axes of the blades are in radial and central symmetry; and therefore, real-time cleaning of dust can be realized, and the service life of equipment can be prolonged, and safety accidents caused by dust accumulation can be effectively prevented. The anti-dust accumulation fan is especially suitable for being adopted as a large-conveying airflow wide-impeller fan with an impeller provided with large-spacing front and rear end plates.

Owner:JISHOU UNIVERSITY

Heat pump tail heat recovery countercurrent dryer

ActiveCN105066643BRealize penetrating countercurrent low temperature dryingRecycling fitDrying solid materials with heatHeat recovery systemsInvoluteAir blower

The invention discloses a heat pump type tail heat recovery counterflow drying machine. A draught hood of the drying machine is connected with an induced draft fan, the induced draft fan is connected with an evaporator of a heat pump system through a cyclone dust collector, and then evacuation is carried out. The evaporator of the heat pump system is connected with a main engine through a refrigerant tube, and the main engine is connected with a condenser through a refrigerant tube. The air outlet end of an air blower is connected with an air inlet hood through the condenser. An impeller of the induced draft fan is provided with a structure with hollow inverted-drop-shaped blades. The contour line of the appearance of the induced draft fan is an involute. The induced draft fan, a heat exchanger and a closed cone hopper below a screen plate steel rip are arranged, an axial fan is arranged in the cone hopper, so that penetrating type counterflow low-temperature drying of materials is achieved, and the heat pump system is especially suitable for recovery of heat of low-temperature tail gas. The blades are of a hollow inverted drop shape, so that dust on the impeller of the induced draft fan is removed in real time, the strength of the impeller of the fan is increased, and stability is improved; and potential safety hazards caused by dust accumulation are effectively eradicated, and wide application prospects are achieved.

Owner:安徽上元家居材料股份有限公司

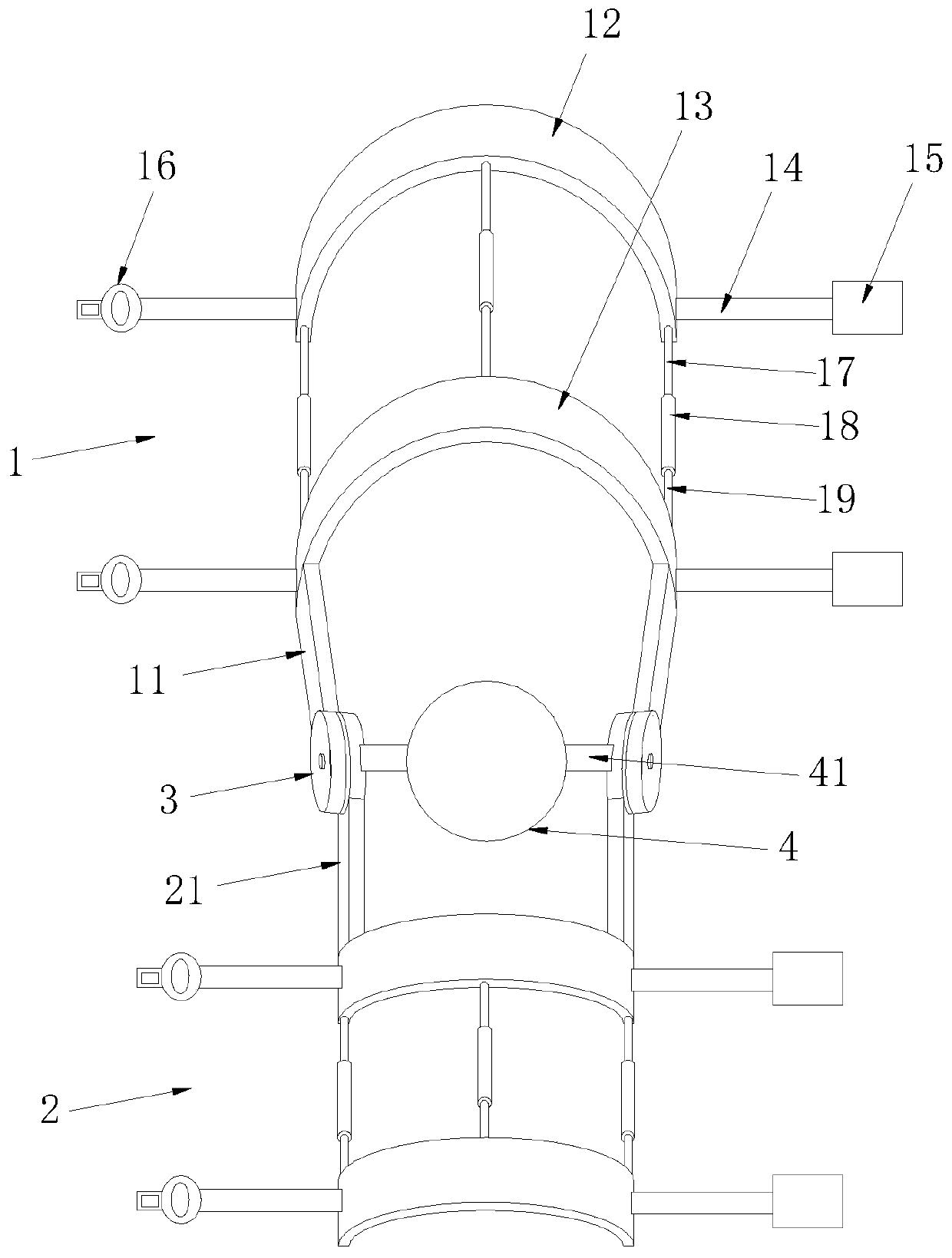

Knee joint orthosis

ActiveCN111000701AChange the maximum rotation angleChange the load intensityChiropractic devicesThighKnee orthosis

The invention discloses a knee joint orthosis, relates to the technical field of orthosis, and solves the problems of single function and poor orthosis effect of the existing orthosis. According to the technical scheme, a connecting structure comprises a medial plate and a lateral plate; the lateral plate is provided with a supporting column, which is provided with a universal ball; the medial plate is provided with a universal shell, which is movably connected with the universal ball; the medial plate is provided with a limiting piece, which comprises two connecting rods and a limiting ball;the limiting ball is movably connected with the connecting rods; the lateral plate is provided with a limiting surface for the limiting ball to contact and roll; the limiting surface comprises convexsurfaces and concave surfaces, which are alternately arranged; when the thigh and the shank are unfolded and straightened, the limiting ball is located in the center of the convex surfaces; when the thigh is bent to be perpendicular to the shank, the limiting ball is located in the center of the concave surfaces; the device can support the knee joint to do stretching and bending motion and can also support the knee joint to do inward and outward rotation motion, and the inward and outward rotation motion performance of the knee joint is changed in a self-adaptive mode along with the stretchingand bending motion of the knee joint.

Owner:王星亮

Tail heat recovery type steam flat-plate dryer

ActiveCN105180620ADoes not affect dynamicDoes not affect balanceDrying gas arrangementsDrying machines with progressive movementsDrive wheelInvolute

The invention discloses a tail heat recovery type steam flat-plate dryer. Driving wheels, driven wheels and scraping plates are arranged on the dryer and used for driving materials to be conveyed on steam flat-plates. An upper drying zone is connected with a cyclone dust collection and tail heat high-efficiency recoverer through a draught fan in the tangential direction, and the cyclone dust collection and tail heat high-efficiency recoverer is formed by overlapping a tubular heat exchanger and a cyclone dust collector. The upper end of a shell pass of the tubular heat exchanger is connected with an air inlet pipe. The lower end of the shell pass of the tubular heat exchanger is connected with a lower drying zone through an air blower. An impeller of the draught fan is provided with blades which are in a hollow inverted water drop shape, and a back plate of the impeller is of a dish-shaped structure. The contour line of the draught fan is an involute. According to the tail heat recovery type steam flat-plate dryer, tail heat recovery and dust collection are creatively integrated, and the cyclone dust collection and tail heat high-efficiency recoverer is designed, so that tail heat recovery and dust collection are completed in one step, equipment investment is reduced, and the working efficiency is improved; the blades are in the hollow inverted water drop shape, and the back plate is of the dish-shaped structure, so dust is cleaned away in real time, the strength of the impeller of the draught fan is improved, stability is enhanced, safety accidents caused by dust accumulation are effectively eradicated, and the application prospects are wide.

Owner:临沂新科绿色建材有限公司

Chemical combination exhausting device for reaction of manganese mineral powder with sulfuric acid

ActiveCN105056838AHigh strengthEnsure stabilityPump componentsDispersed particle separationChemical combinationImpeller

The invention discloses a chemical combination exhausting device for a reaction of manganese mineral powder with sulfuric acid. Stirring systems are arranged in chemical combination barrels connected with a draught fan through exhaust pipes, the draught fan is tangentially connected with a rotational flow tower and then emptied, and air doors are arranged in the exhaust pipes; multiple rotational flow devices comprising large rotational flow plates, small rotational flow plates and conical hopper plates are vertically arranged in the rotational flow tower; an impeller of the draught fan adopts such a structure that blades are in a hollow reversed water droplet shape and a back plate is in a dish shape; the contour line of the draught fan is an involute. Carbon dioxide gas produced due to the reaction of the manganese mineral powder with the sulfuric acid is exhausted in real time by the aid of the draught fan and the rotational flow devices, the reaction is facilitated, carried mineral powder is effectively recovered through rotational gas flows, and energy saving and emission reduction are realized; with the adoption of the structure that the blades are in the hollow reversed water droplet shape and the back plate is in the dish shape, dust on the impeller of the draught fan is cleaned in real time, the strength of the impeller of the draught fan is enhanced, the stability is enhanced, accidents caused by accumulation of the dust are effectively eliminated, and the device has the broad application prospect.

Owner:JISHOU UNIVERSITY

Healthy dampness removing type smoked and roasted product smoking and roasting device convenient for induced draft fan disassembly

InactiveCN105767120ADoes not affect dynamicDoes not affect balanceMeat/fish preservationPump componentsImpellerWater storage tank

The invention discloses a healthy dampness removing type smoked and roasted product smoking and roasting device convenient for induced draft fan disassembly. Fins are arranged at both inside and outside of a smoking chamber wall body and connected to a water storage tank via an upper connecting pipe and a lower connecting pipe; a smoke producing pipeline of a smoke producing stove passes the wall body and is connected to an air inlet pipe of a cyclone separator, the cyclone separator is connected to an induced draft fan via a pipeline, and an air outlet of the induced draft fan is arranged inside the wall body; a flashboard is arranged on the smoke producing pipeline of the smoke producing stove; a light-weight valve is arranged at the bottom of the cyclone separator, and a heat radiator and a vibrator are arranged on the surface of the cyclone separator; and an impeller of the induced draft fan can use a centrifugal force to timely clean dust. The smoking and roasting device can realize green and energy-efficient smoking and roasting and more importantly greatly improve the disassembly and assembly technologies of the induced draft fan, so that during the disassembly, the device can simply eliminate similar pressures of blind nut parts for shoulder end surfaces of screw shafts, effectively solves the problem that the screw assembly of the induced draft fan is continuously automatically locked and not easy for disassembly under a loading effect, and is especially suitable for and has a particularly significant effect for a convenient disassembly after thread locking of large-sized fans.

Owner:JISHOU UNIVERSITY

A simple Raymond mill device that is easy to disassemble the fan

ActiveCN105665080BHigh extrusion rigidityStrong extrusion rigidityUsing liquid separation agentGrain treatmentsImpellerCyclone

The invention discloses a simple Raymond mill device with a fan convenient to disassemble. The fan, a Raymond mill, a cyclone separating and discharging device and an air return duct form an air-flow-circulating ground-powder discharging system. An isolating temporary storage barrel is arranged at an inlet, connected with the air return duct, of the fan. A gravity material door is arranged on the isolating temporary storage barrel. A temporary powder storage barrel is arranged below the gravity material door. A valve and a discharging gate are arranged on the temporary powder storage barrel. Blades of an impeller of the induced draft fan are arranged symmetrical about the center of an impeller shaft in the radial direction in a radial manner, dust can be cleared up in time through centrifugal force, and safety accidents are avoided. The simple Raymond mill device is simple in structure, and more importantly, the disassembly technology of the induced draft fan is improved greatly, so that pressure applied to the shaft shoulder end face of a screw by components similar to a nut component can be eliminated easily when the induced draft fan is disassembled, and the problem that the induced draft fan is locked continuously and automatically and cannot be disassembled easily under the load action due to threaded assembly is solved effectively; and the simple Raymond mill device is especially suitable for convenient and fast disassembly of the large-scale fan which is locked in a threaded manner, and the effect is especially remarkable.

Owner:HENAN TIANXIANG NEW MATERIALS

Heat pump type tail heat utilizing penetration reverse flow dryer

ActiveCN105066637ADoes not affect dynamicDoes not affect balancePump componentsDrying gas arrangementsImpellerEngineering

The invention discloses a heat pump type tail heat utilizing penetration reverse flow dryer. A draught hood and an air inlet cover are arranged at the two ends of a box of the dryer respectively, the draught hood is connected with an induced draft fan, and the induced draft fan is connected with an evaporator of a heat pump system through a cyclone dust collector and then emptied. The evaporator of the heat pump system is connected with a main machine through a refrigerant pipe, and the main machine is connected with a condenser through a refrigerant pipe. The air outlet end of an air blower is connected with the air inlet cover through the condenser. A plurality of vertically-arranged flexible separation plates are arranged in the box of the dryer and divide an upper case body and a lower case body into a plurality of units. Through the induced draft fan, the flexible separation plates and axial fans, penetration type reverse flow drying is ingeniously achieved, and work efficiency is improved. Heat pump type tail heat utilization is suitable for heat recovery of low-temperature tail gas, and is particularly efficient and convenient. Through the structure that blades are in a hollow inverted drop shape, dust on impellers is cleaned away in real time, the impeller strength of the fan is increased, stability is increased, safety accidents caused by dust accumulation are effectively eradicated, and the application prospect is wide.

Owner:可道(恩施)健康科技有限公司

Tail heat utilization sieve hole flap dryer

ActiveCN105716402BHigh extrusion rigidityStrong extrusion rigidityPump componentsDrying gas arrangementsEngineeringCentrifugal force

The invention discloses a tail heat utilization sieve mesh turning-plate type drier. A drier box body is provided with a structure of sieve mesh turning-plate type conveying from top to bottom and is divided into an upper drying area, a middle drying area and a lower drying area by a middle baffle and a lower baffle. The upper drying area is connected with an induced draft fan through an air heat exchanger and then is drained; the air outlet end of the upper drying area is connected with an air inlet of an air blower through an air pipe; and an air outlet of the air blower is connected with a steam fin heater in the middle drying area. Blades of an impeller of the induced draft fan are arranged in a radiated mode with an impeller shaft being in radial symmetry and central symmetry, dust is cleaned up in time by centrifugal force, and safety accidents are avoided. The tail heat utilization sieve mesh turning-plate type drier improves the drying efficiency and achieves energy saving and emission reduction; more importantly, the disassembling technology of the induced draft fan is greatly improved, and the induced draft fan can simply eliminate the pressure of nut-like parts to the shaft shoulder end faces of screw rods when being disassembled, so that the problem that due to the threaded assembly mode, the induced draft fan is continuously and automatically locked under the load action and is not likely to be disassembled is effectively solved; and the tail heat utilization sieve mesh turning-plate type drier is particularly suitable for convenient disassembling of large draft fans after threaded locking, and the effect is very obvious.

Owner:武汉新实诚诺资源开发有限公司

A compound pumping system for the reaction of manganese ore powder and sulfuric acid

ActiveCN105148801BImprove rigidityImprove carrying capacityPump componentsDispersed particle separationCycloneImpeller

The invention discloses a combination gas exhaust system for the manganese mineral powder and sulfuric acid reaction. The system is characterized in that stirring systems are arranged in combination barrels; the combination barrels are connected with an induced draft fan through gas exhaust pipes; the induced draft fan is tangentially connected with a cyclone tower for exhaust, and dampers are arranged in the gas exhaust pipes; multiple groups of cyclone devices are vertically arranged in the cyclone tower, and each cyclone device comprises a large cyclonic plate, a small cyclonic plate and a conical bucket plate; an impeller of the induced draft fan has a structure comprising hollow wedge-shaped blades and a dish-shaped back plate; the shape contour line of the induced draft fan is an involute line. By means of the induced draft fan and the cyclone devices, carbon dioxide gas produced in the manganese mineral powder and sulfuric acid reaction is exhausted in real time, the reaction is facilitated, carried mineral powder is effectively recovered through gas cyclone, and energy conservation and emission reduction are realized; according to the structure comprising the hollow wedge-shaped blades and the dish-shaped back plate, dust on the impeller of the induced draft fan is cleaned in real time, the strength of the impeller of the induced draft fan is increased, the stability is enhanced, the safety accidents caused by dust accumulation are effectively eliminated, and the application prospect is broad.

Owner:钦州南海化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com