Chemical combination exhausting device for reaction of manganese mineral powder with sulfuric acid

A technology of air extraction device and manganese ore powder, which is applied in the parts of pumping device for elastic fluid, feeding device, chemical/physical/physicochemical fixed reactor, etc., which can solve personnel and equipment safety accidents, strong Vibration and other problems to achieve the effect of ensuring stability, high strength, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Now in conjunction with accompanying drawing, the present invention is described in further detail.

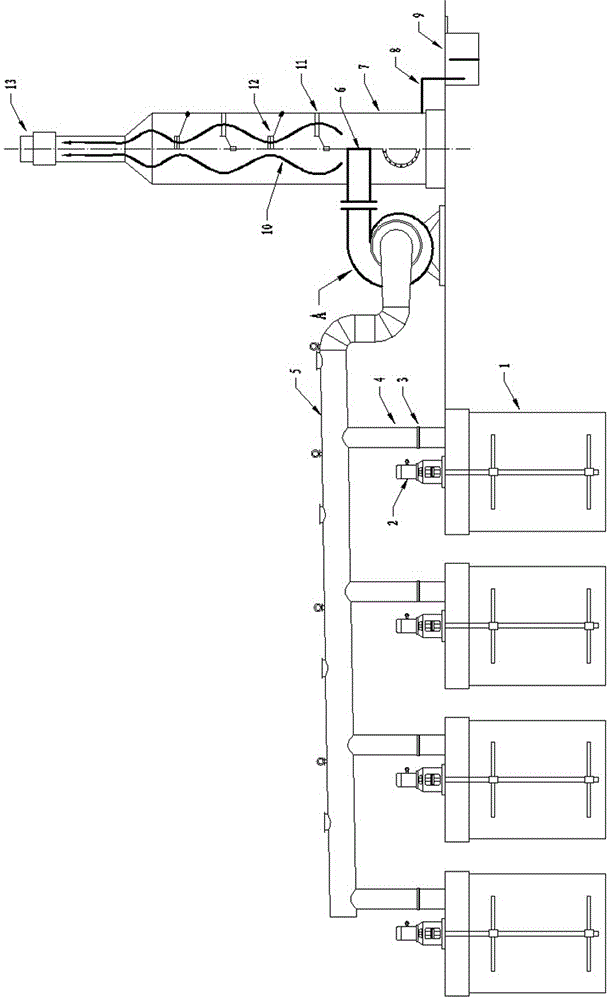

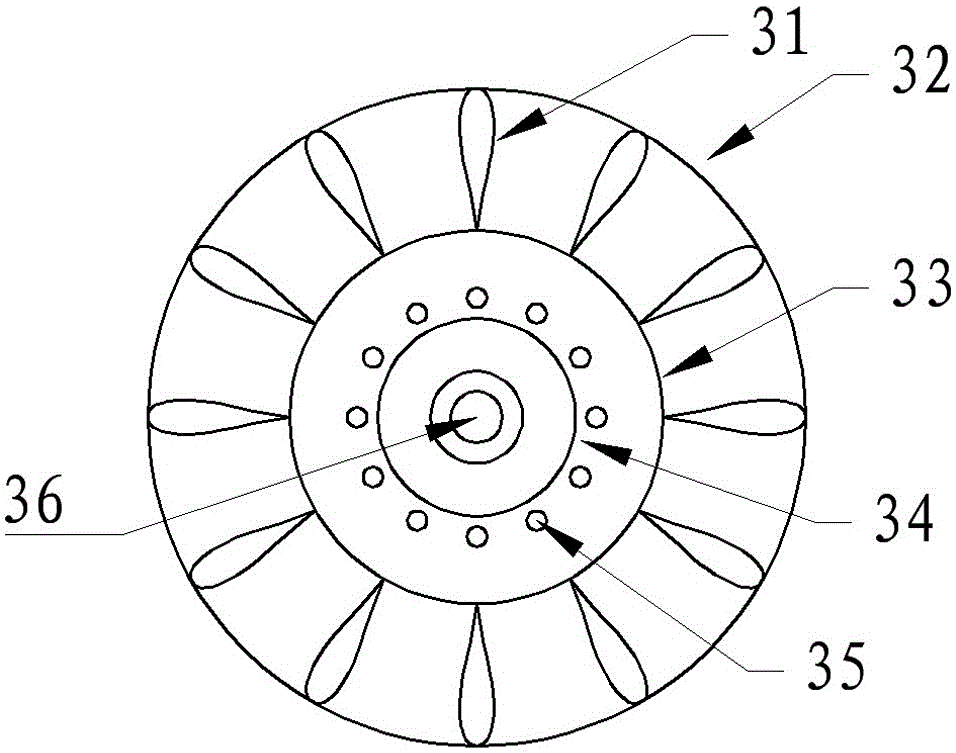

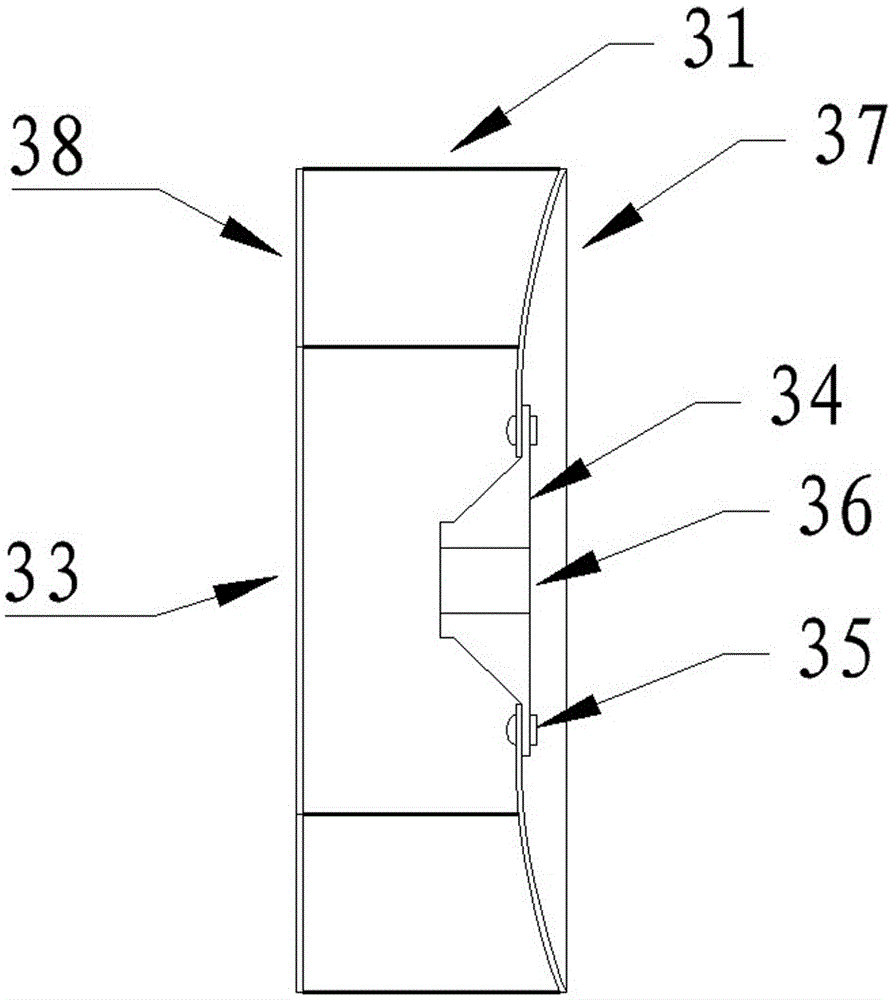

[0035] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 The compound air extraction device for the reaction of manganese ore powder and sulfuric acid includes a compound tank 1 and an induced draft fan A. The compound tank 1 is provided with a stirring system 2. The compound tank 1 is connected to the induced draft fan A through the exhaust pipe 4, and the induced draft fan A is connected tangentially. After the swirl tower 7 is emptied, the air intake pipe 4 is provided with a damper 3; the induced draft fan includes a fan impeller 41 and a casing 45, and the fan impeller 41 includes an impeller back plate 37, an impeller panel 38 and a blade 31, and the blade 31 is arranged as The impeller shaft is radially and centrally symmetrical in a hollow anti-drop shape, and the impeller back plate 37 is dish-shaped; the hollow anti-drop-shaped bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com