Patents

Literature

34results about How to "High heating coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

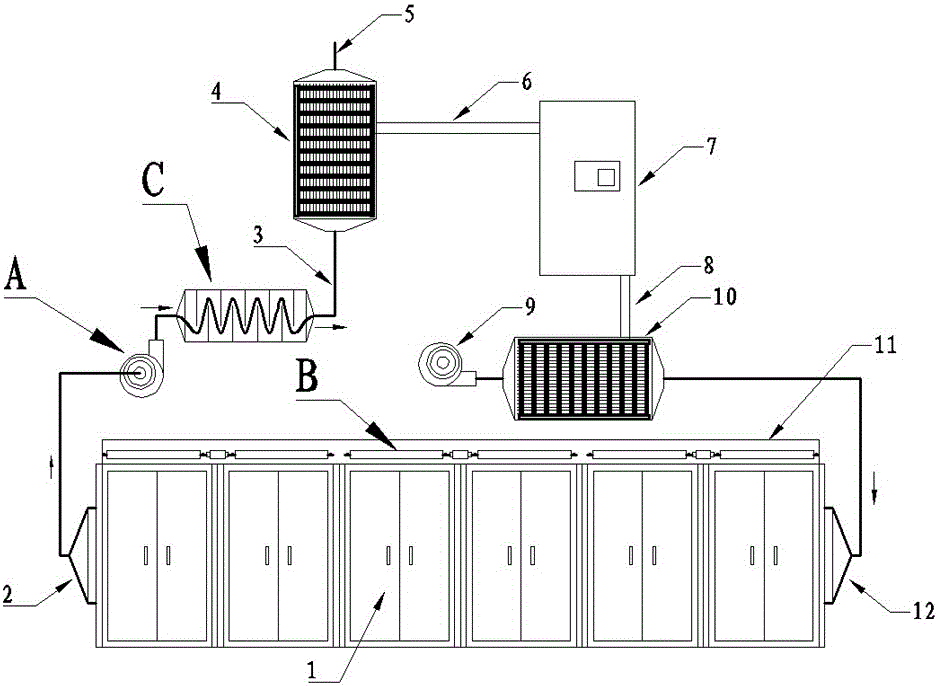

Mud drying system and use method thereof

ActiveCN101618930AHigh drying yieldReduce drying energy consumptionSludge treatment by de-watering/drying/thickeningHeat pumpsSludgeWater circulation

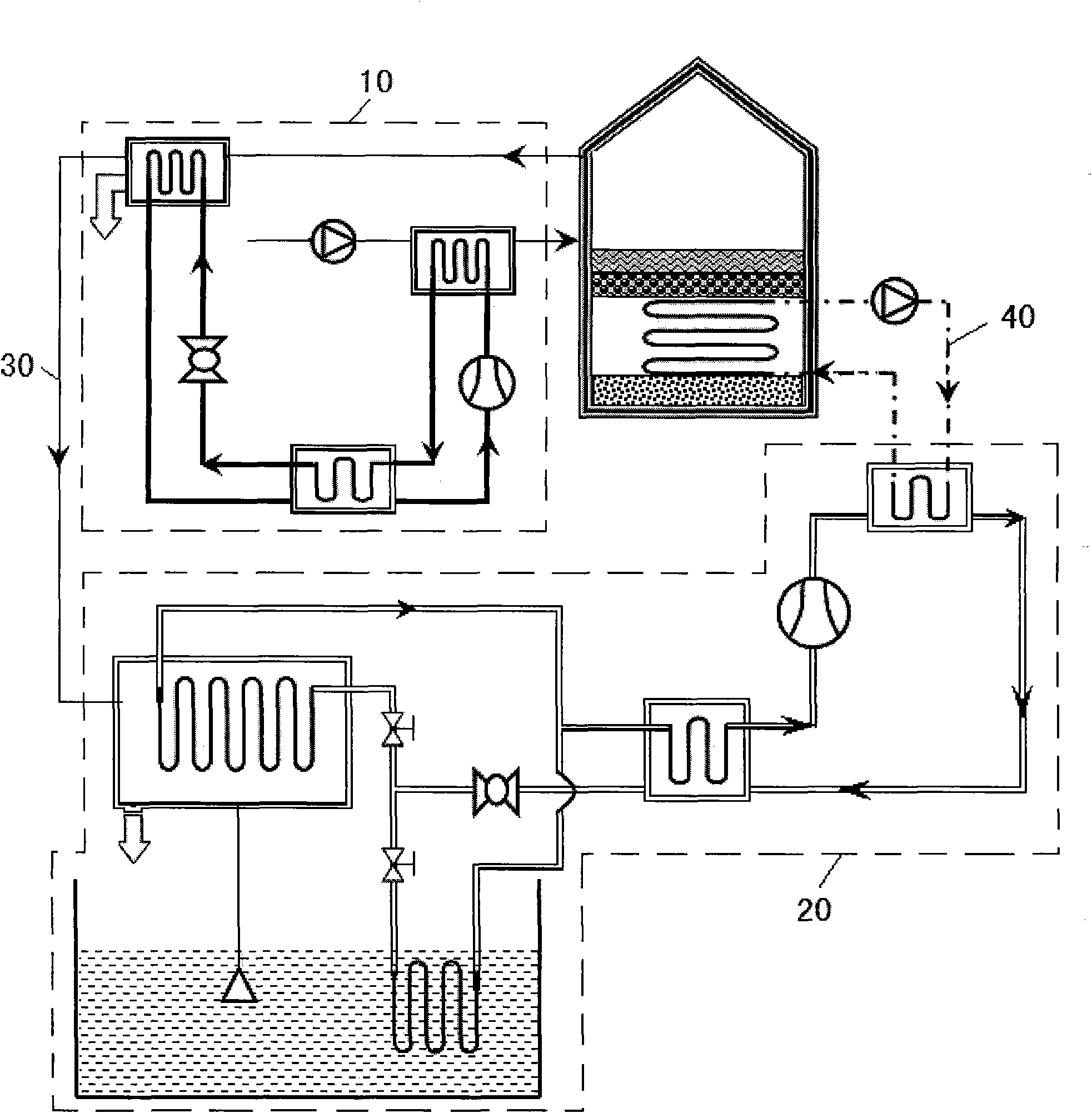

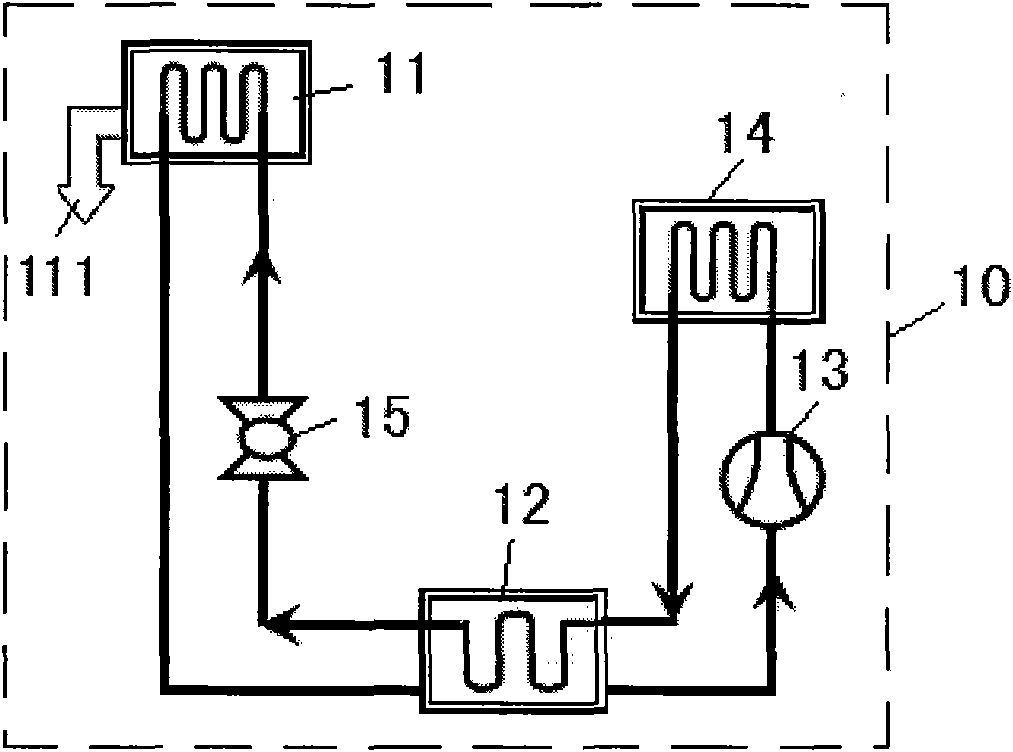

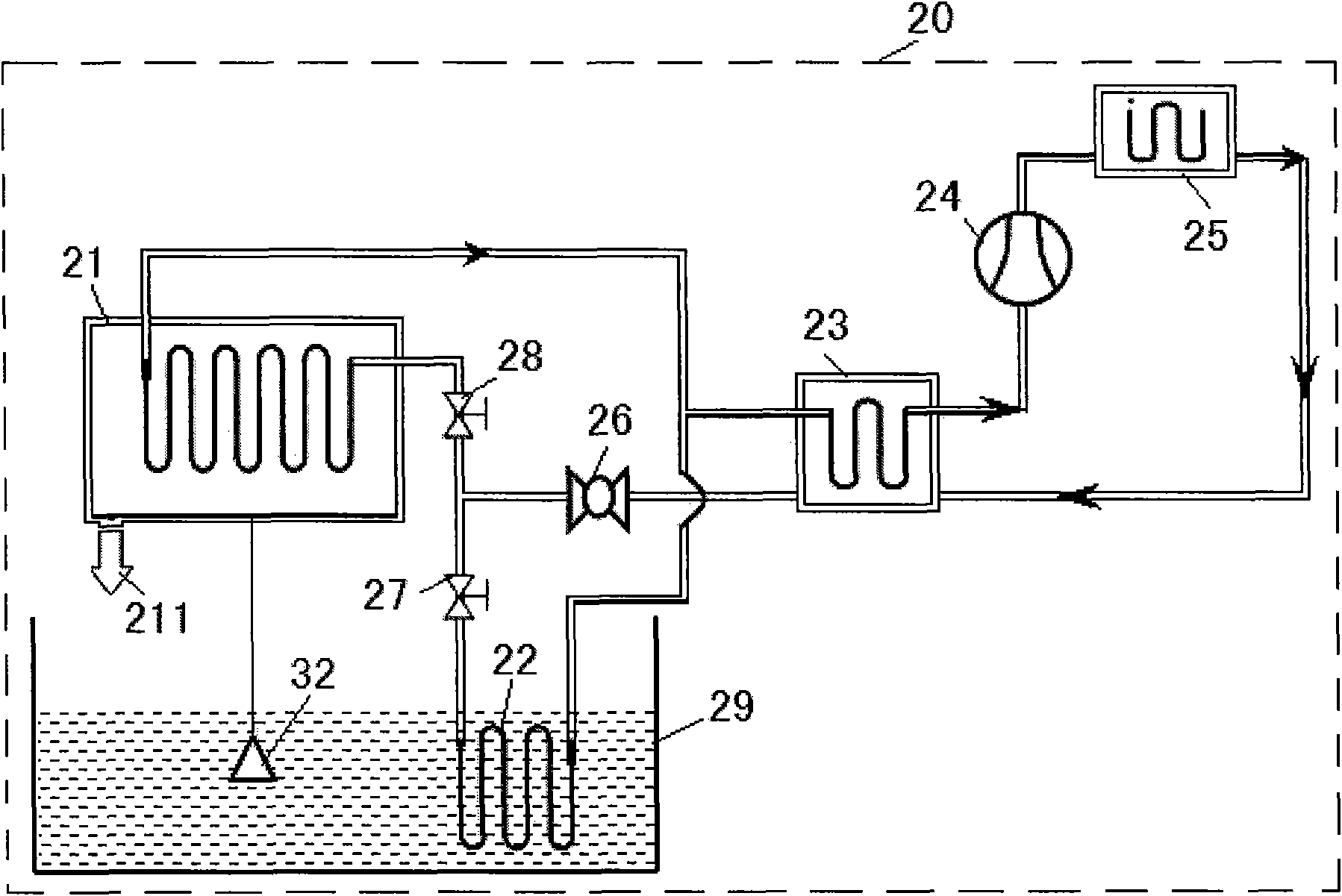

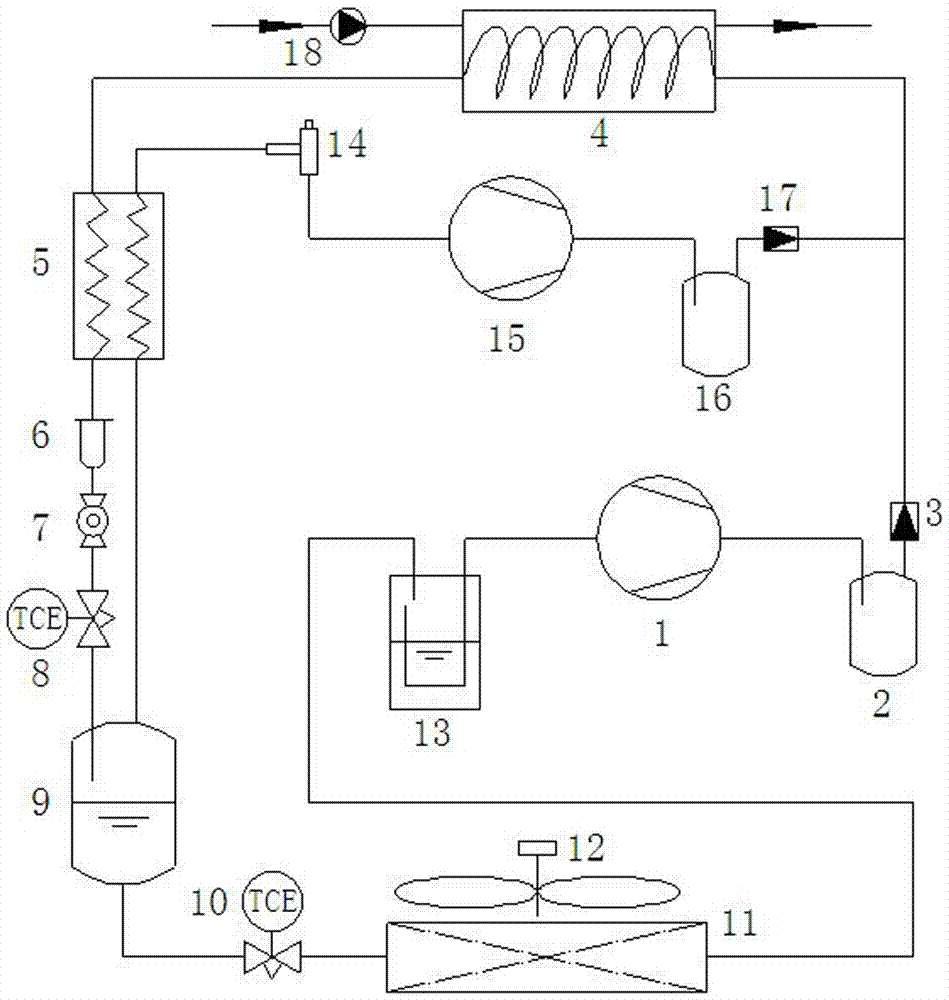

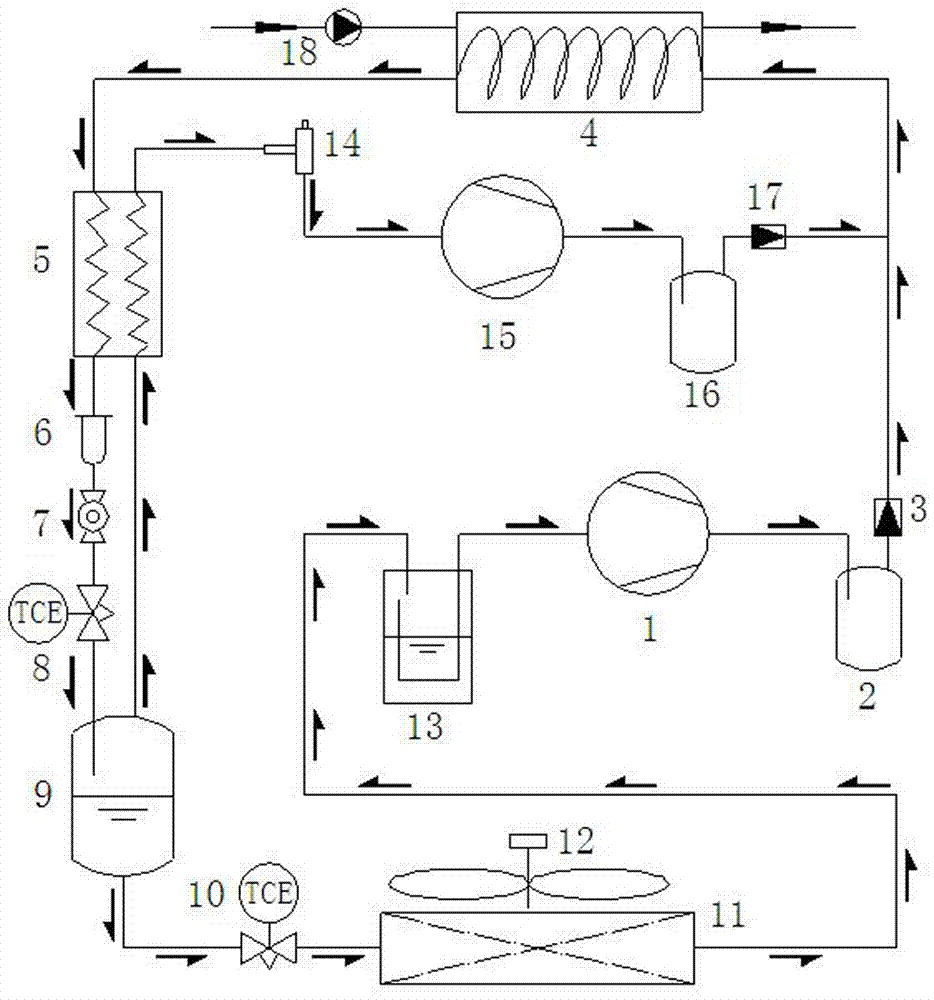

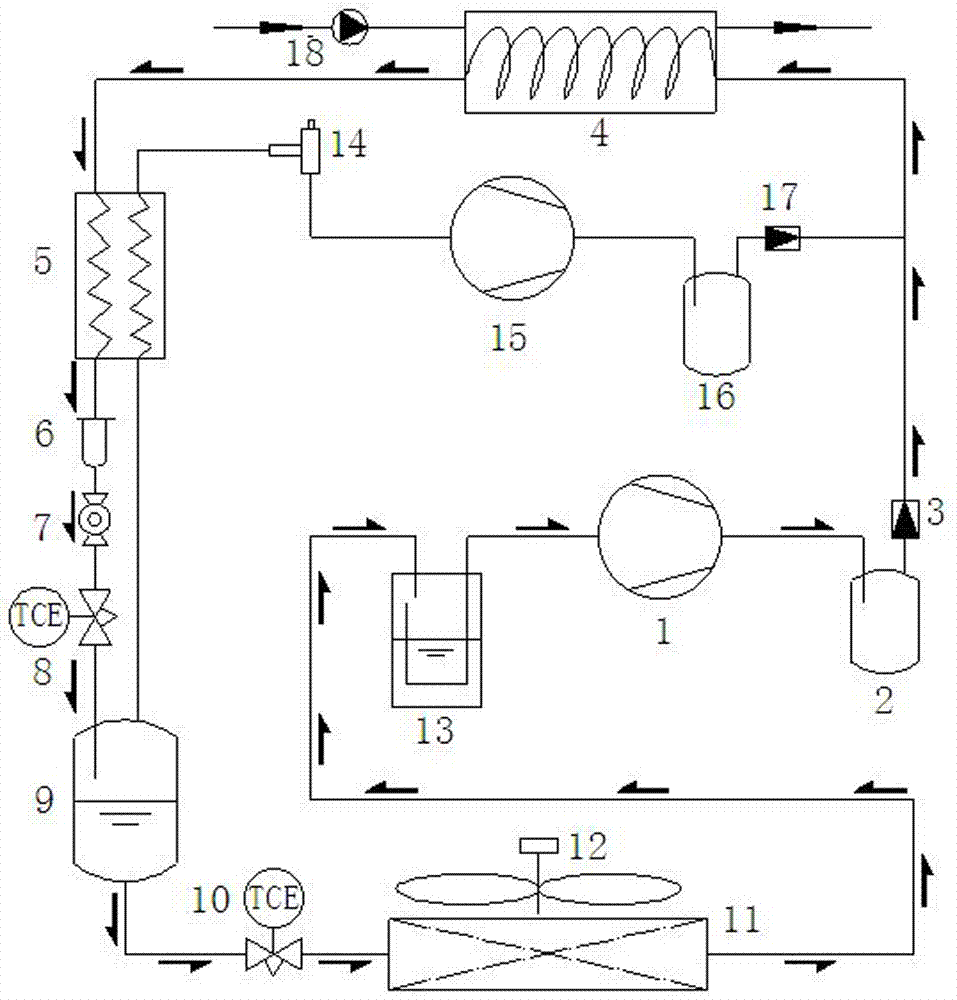

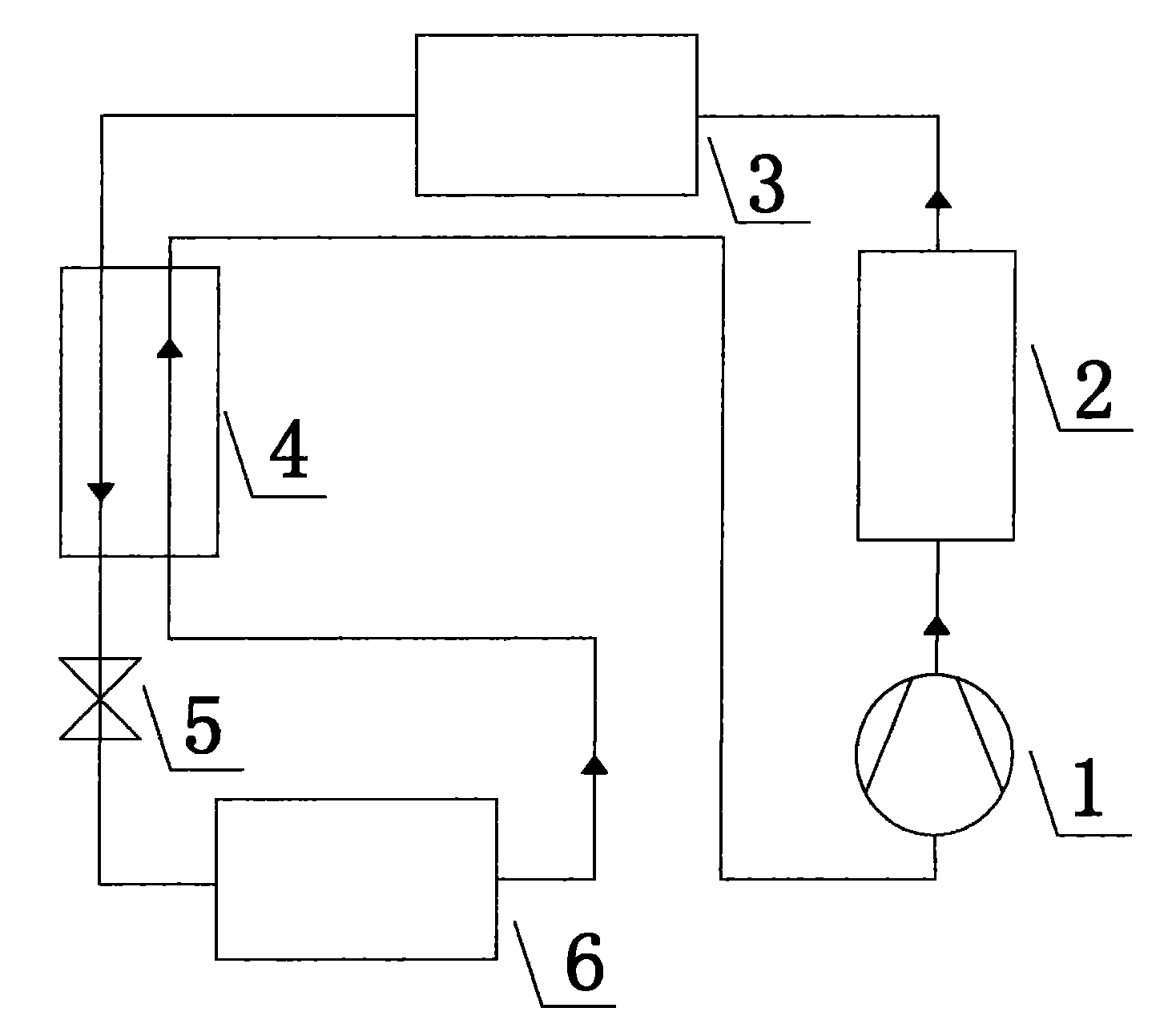

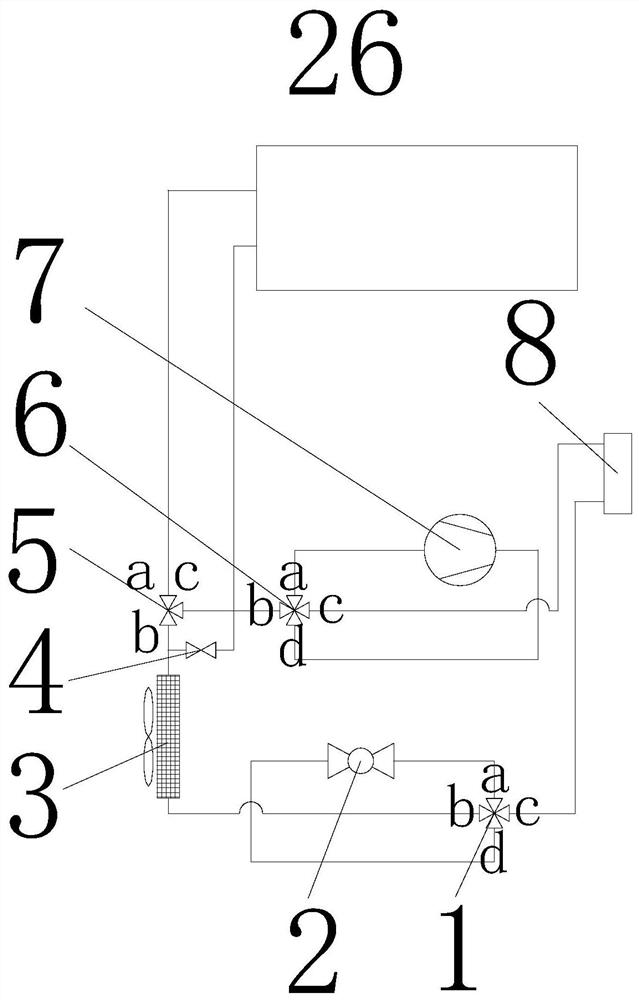

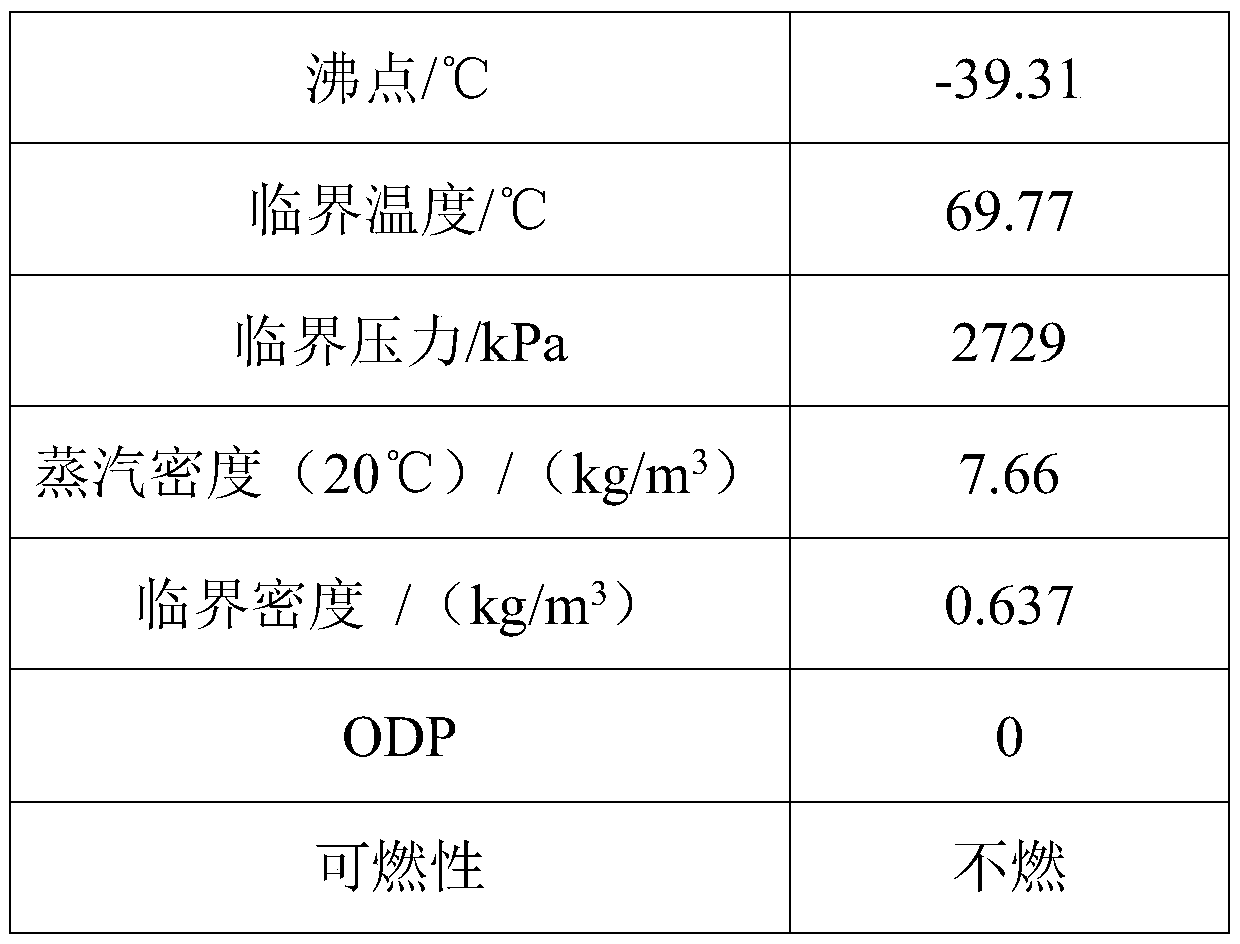

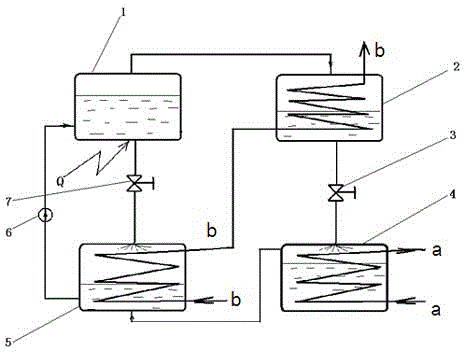

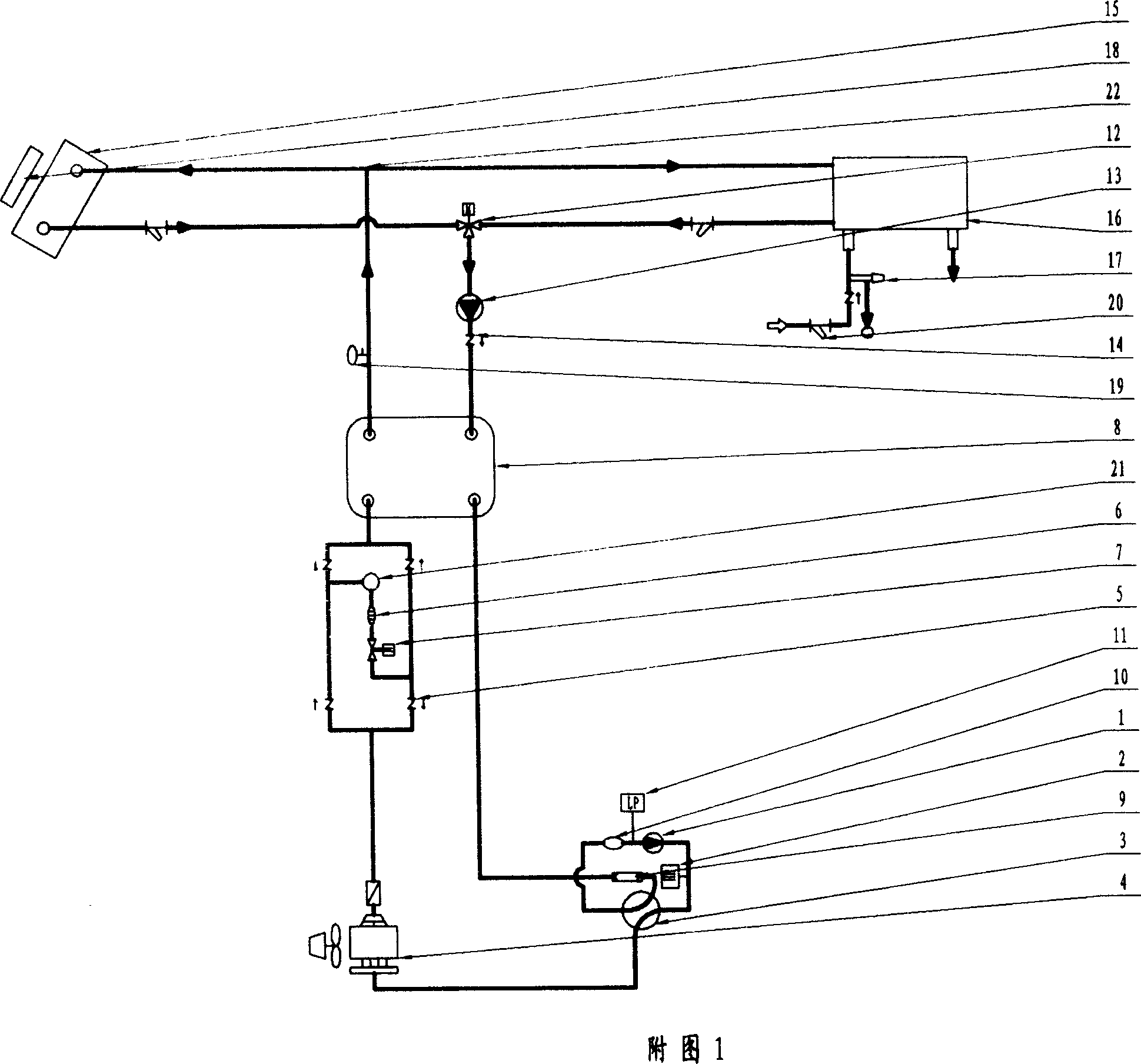

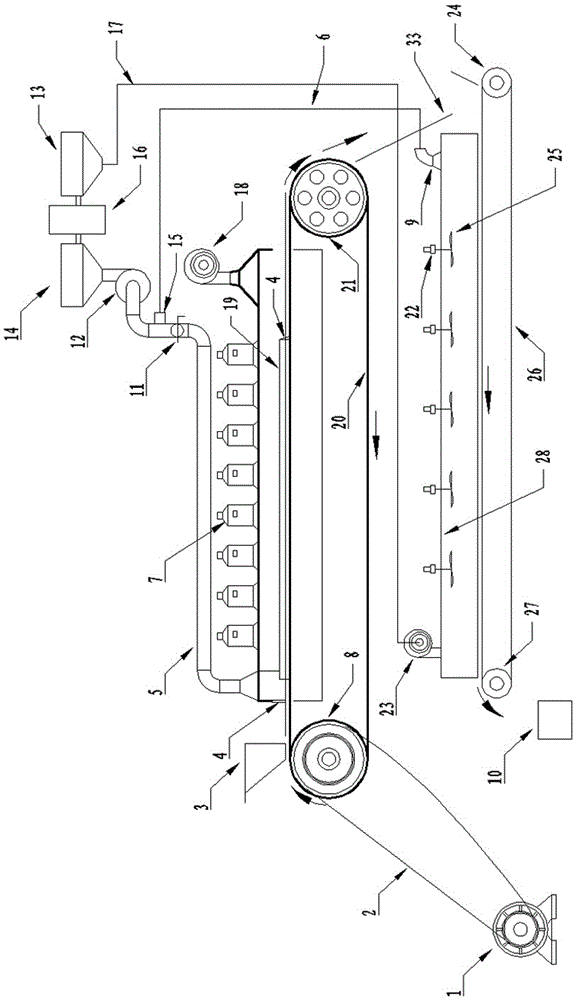

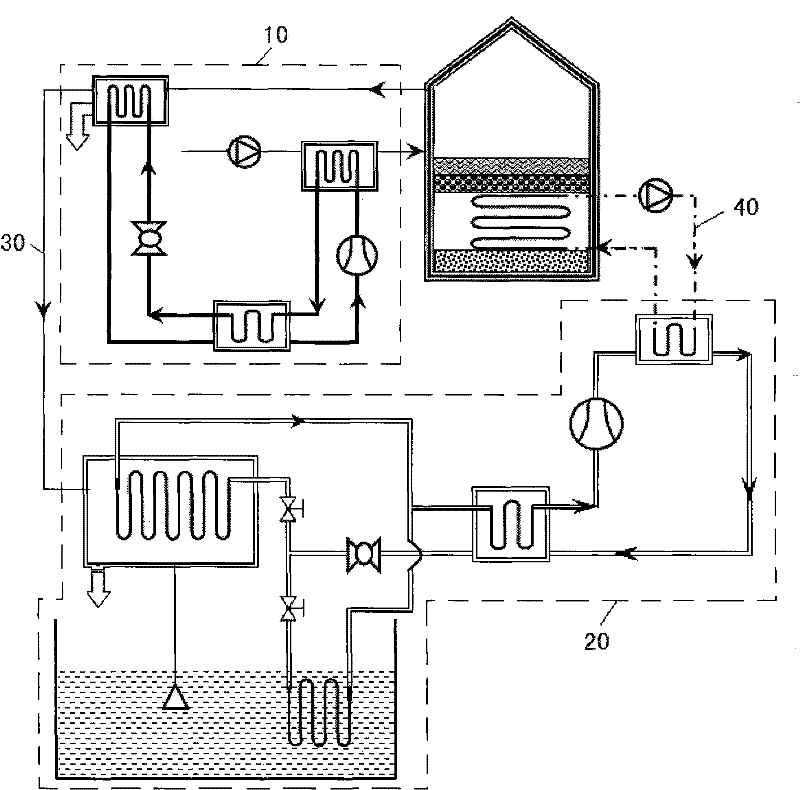

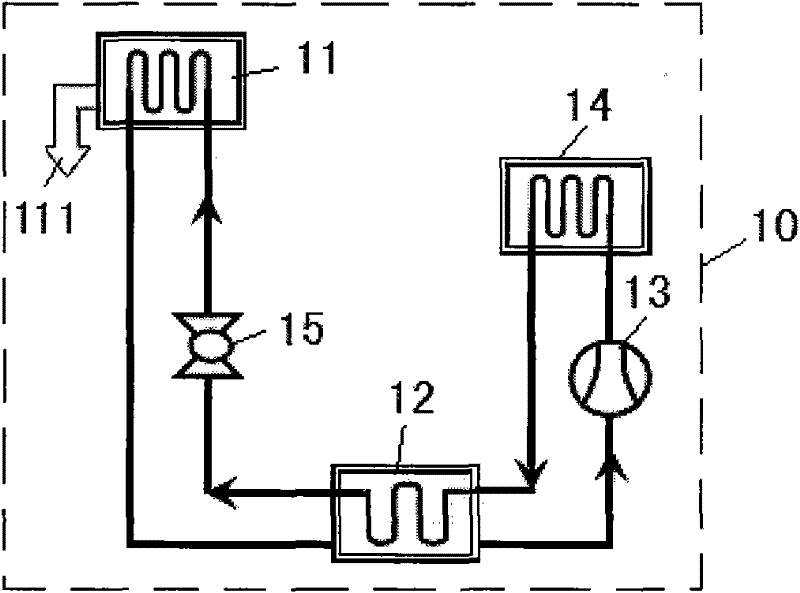

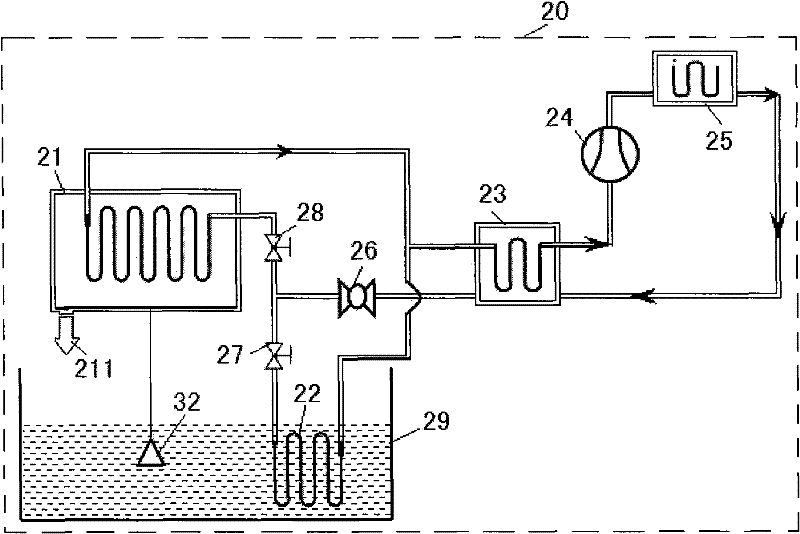

The invention relates to a mud drying system and a use method thereof. The mud drying system comprises a transcritical heat pump auxiliary heat supplying loop, a heat pump auxiliary heat supplying loop, an air heating and waste heat recovering loop and a hot water circulation loop; the transcritical heat pump auxiliary heat supplying loop comprises an evaporator, an internal heat exchanger, a compressor, a gas cooler and a throttle valve; the heat pump auxiliary heat supplying loop comprises an evaporator, a wastewater and waste heat recovering evaporator, an internal heat exchanger, a compressor, a condenser, a throttle valve, two stop valves and a wastewater tank; the air heating and waste heat recovering loop comprises a hothouse, an air compressor, a gas discharging and carrying port, a first evaporator, the other evaporator and a condenser; and the hot water circulation loop comprises a pump, a hothouse and the condenser in the heat pump auxiliary heat supplying loop. The invention adopts the hothouses to obtain solar energy to heat mud and utilizes the transcritical heat pump auxiliary heat supplying loop and the heat pump auxiliary heat supplying loop to recover the sensible heat and the latent heat in humid air to heat mud, thereby lowering the energy consumption for drying the mud. The invention can be widely applied to various mud processing fields.

Owner:TSINGHUA UNIV +3

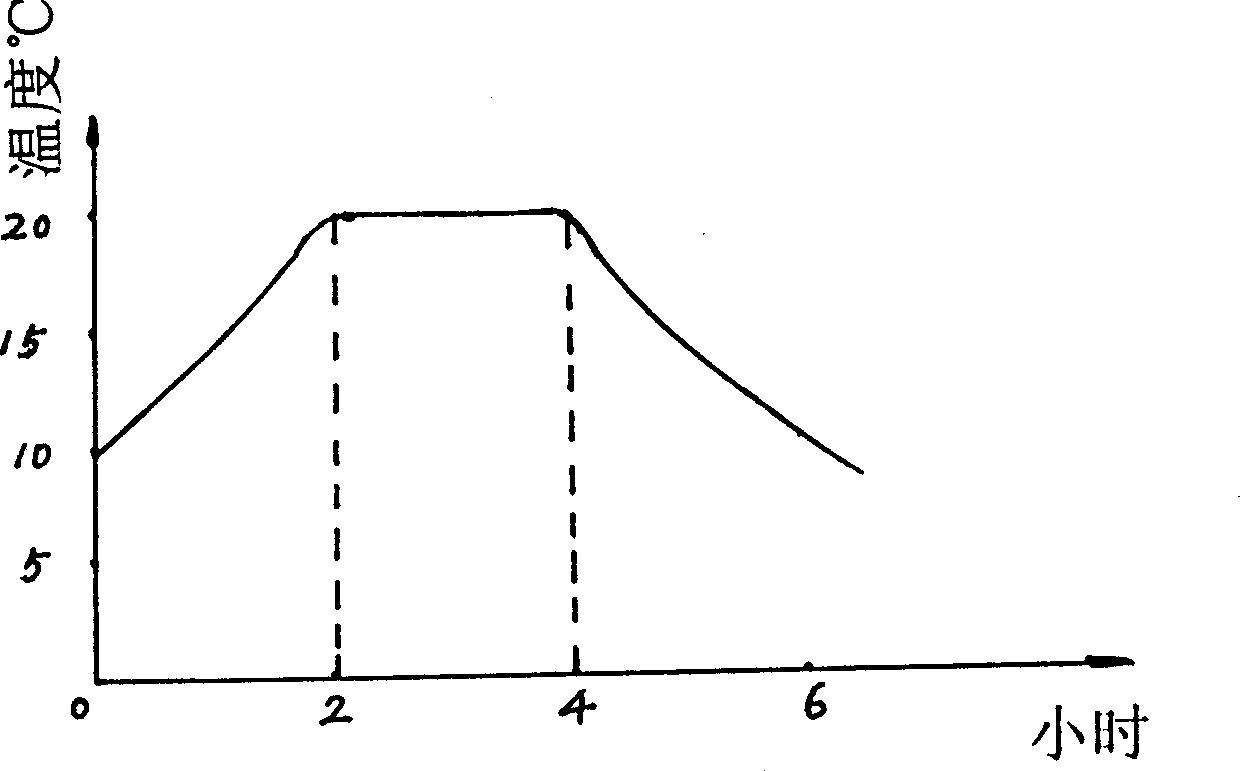

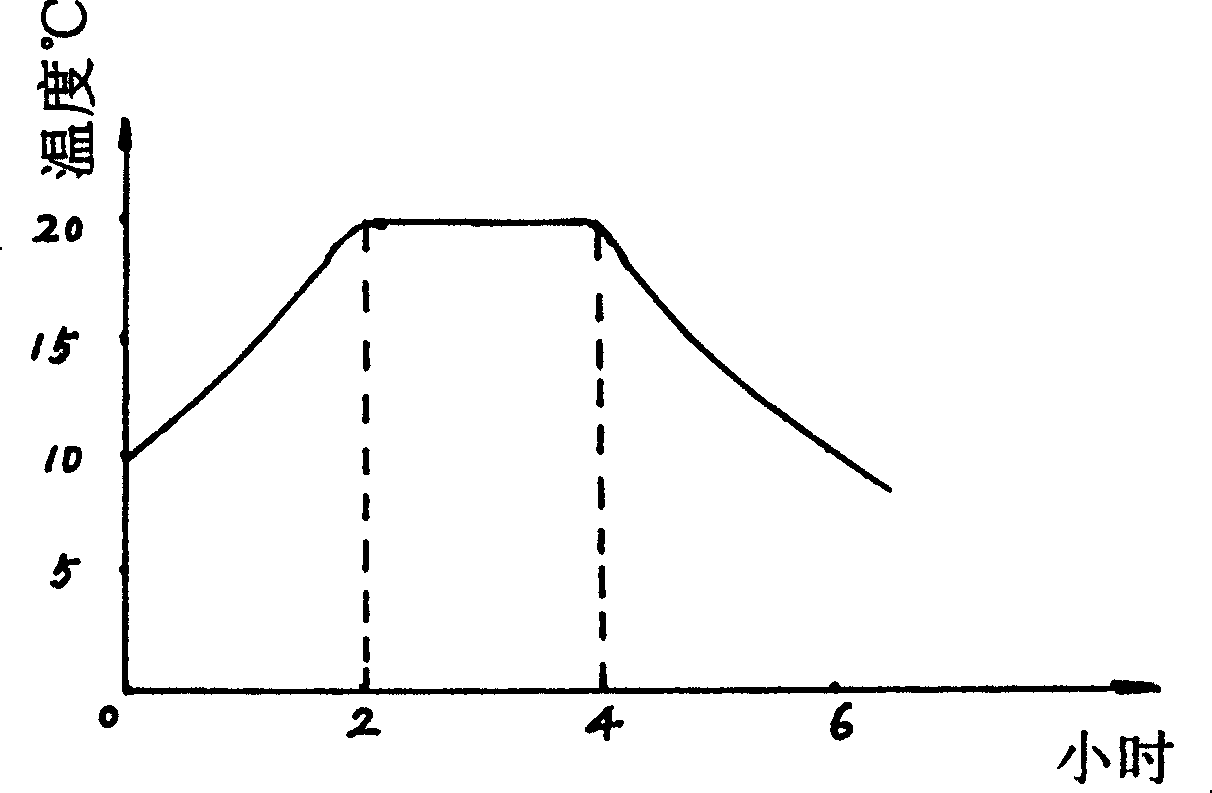

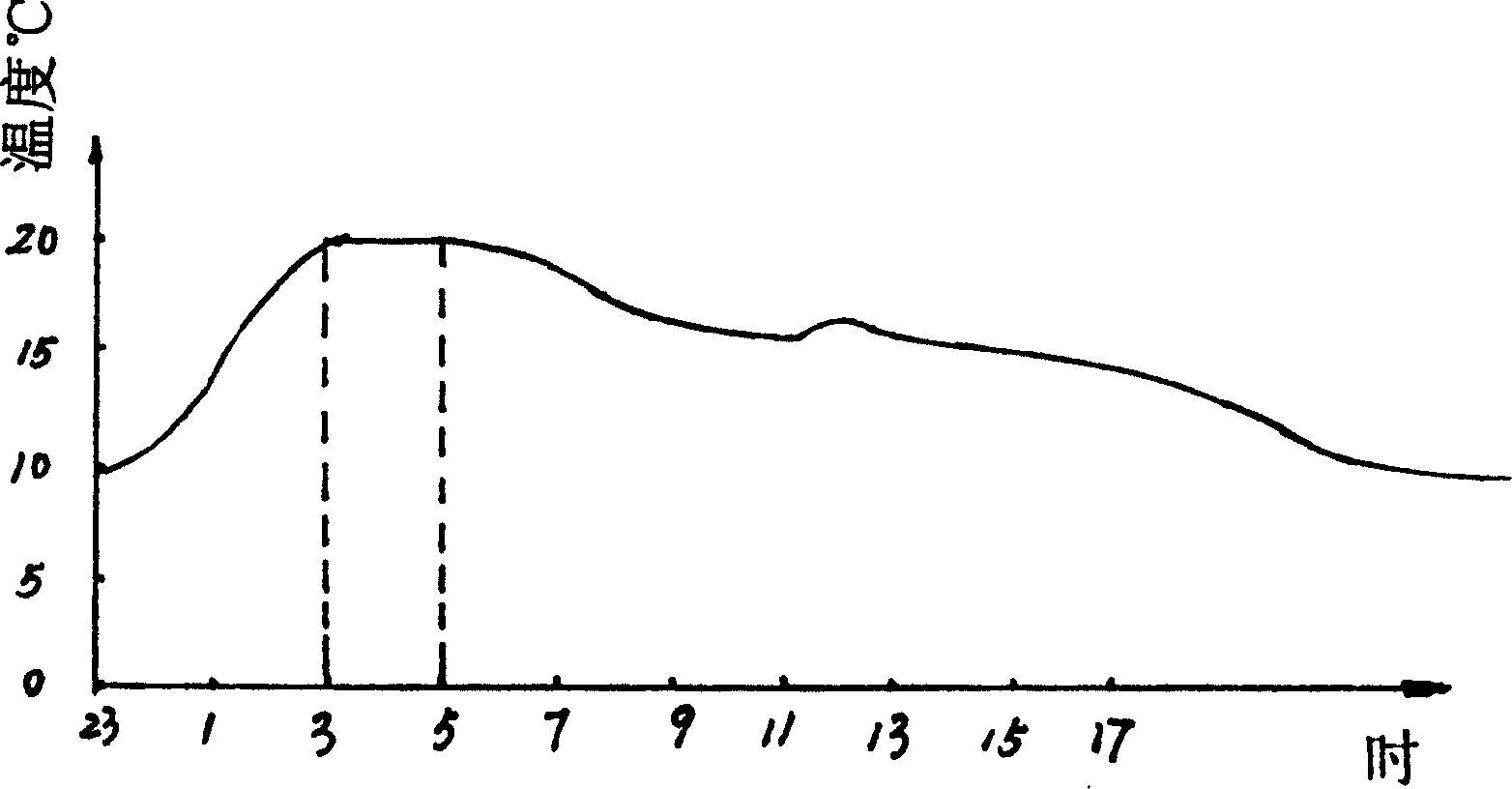

Method and device for heating by heat electric heating pump phase-change thermal storage

InactiveCN101298925AImprove heating efficiencyReduce usage costsCentral heating with accumulated heatLighting and heating apparatusThermal energyHeat storage material

Disclosed is a thermoelectric heat pump phase change heat storage heating method and a device. When in energized heat storage during the trough electrovalency phase, the thermoelectric chip set is connected with one end of the phase change heat storage materials as the fire end, and the heat energy generated is transferred to the phase change heat storage materials for storage, while the other end of the thermoelectric chip set becomes the cool end and adsorbs the waste heat from the surrounding air. When in heat emission heating, there is provided with two working modes, the first working mode is an energy saving mode, wherein the surrounding air directly exchange the heat with the regenerative phase change heat storage materials to realize the heat release warm; when the first working mode can not satisfy the warm request, the current direction of the thermoelectric chip set is changed, to make the cold and heat end faces changed; one end of the thermoelectric chip set connected with the phase change heat storage materials becomes the cold end, which adsorbs the heat energy of the phase change heat storage materials, and the heat of the other end of the thermoelectric chip set is released for the warm.

Owner:HUNAN UNIV

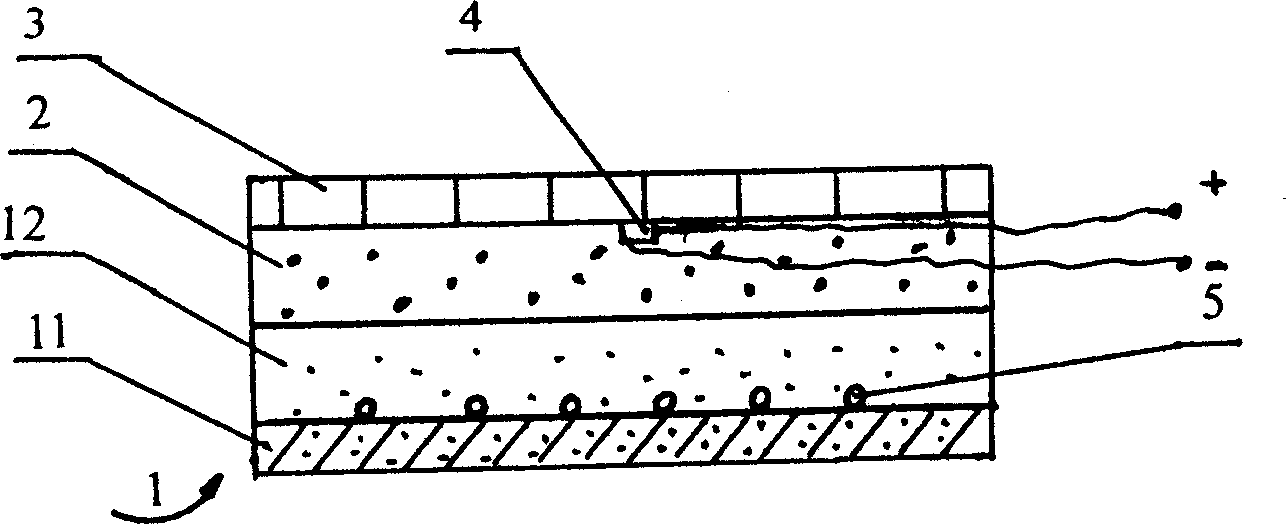

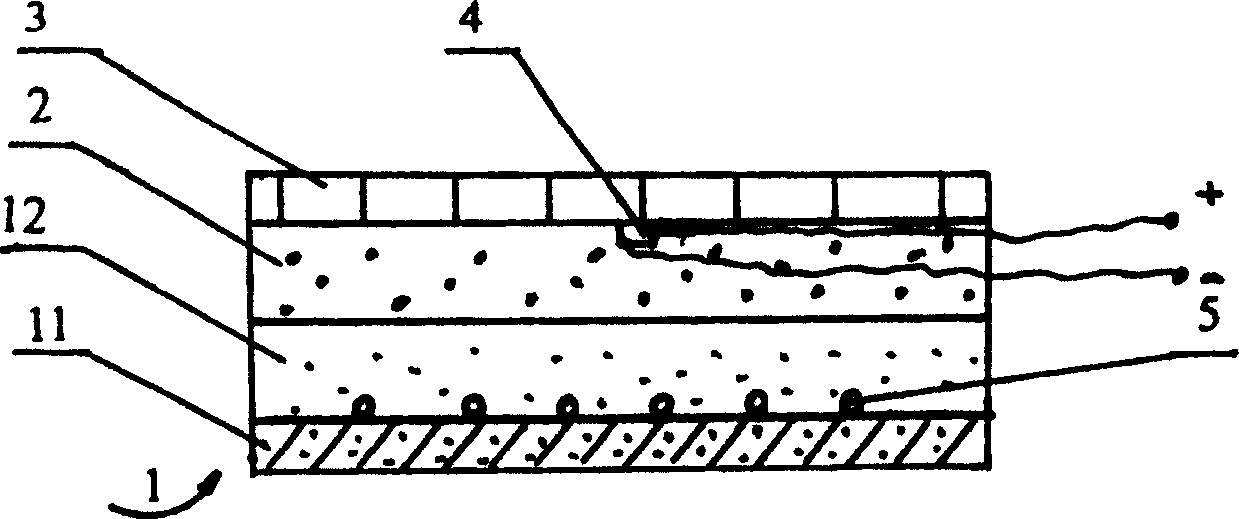

Static thermal-storage heating-amount slow-release structure and construction process and use thereof

InactiveCN1488895APreferential electricity priceLower heating costsLighting and heating apparatusElectric heating systemControl modeElectric energy

The present invention relates to a geothermic electric heating static heat-stored heating heat quantity slowly-releasing structure, its construction process and application. Its structure comprises up-down laminated heat-storing layer and heat quantity slowly-releasing layer, the geothermic cable is embedded in the heat-storing layer formed from heat-storing material whose heat-conducting coefficient is 0.3-0.79w.m(-1).k(-1), said heat-storing layer is covered with the slowly-releasing layer formed from slowly-releasing material whose heat-conducting coefficient is 0.04-0.07 w.m(-1).k(-1), and the temp. sensor is embedded in the slowly-releasing layer, and is series-connected with geothermal cable loop. Its application includes the following steps: starting power supply to supply power to geothermic cable, and storing heat energy in heat-storing layer, then slowly-releasing the heat energy to heating space by means of slowly-releasing layer.

Owner:孙侠

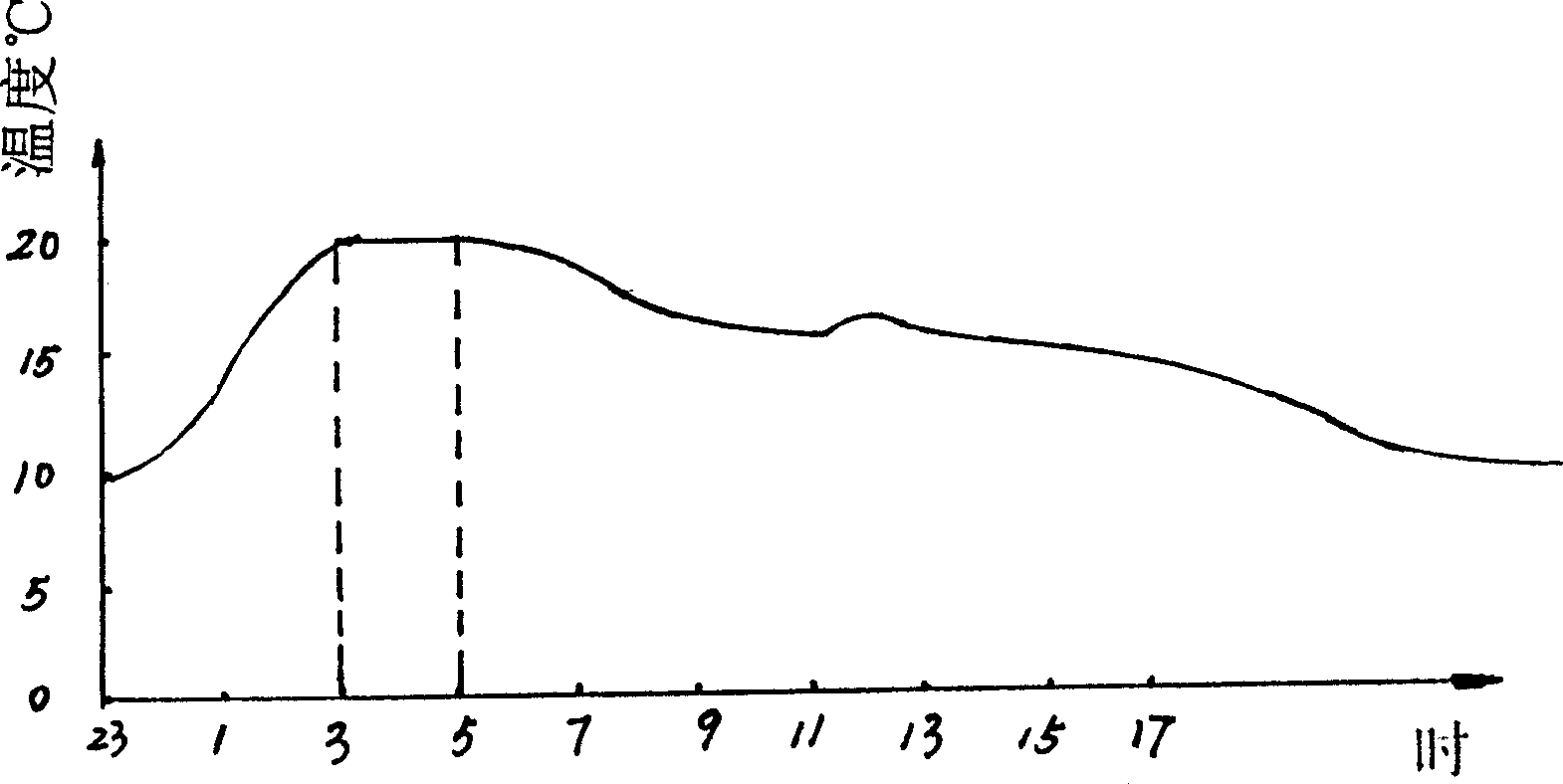

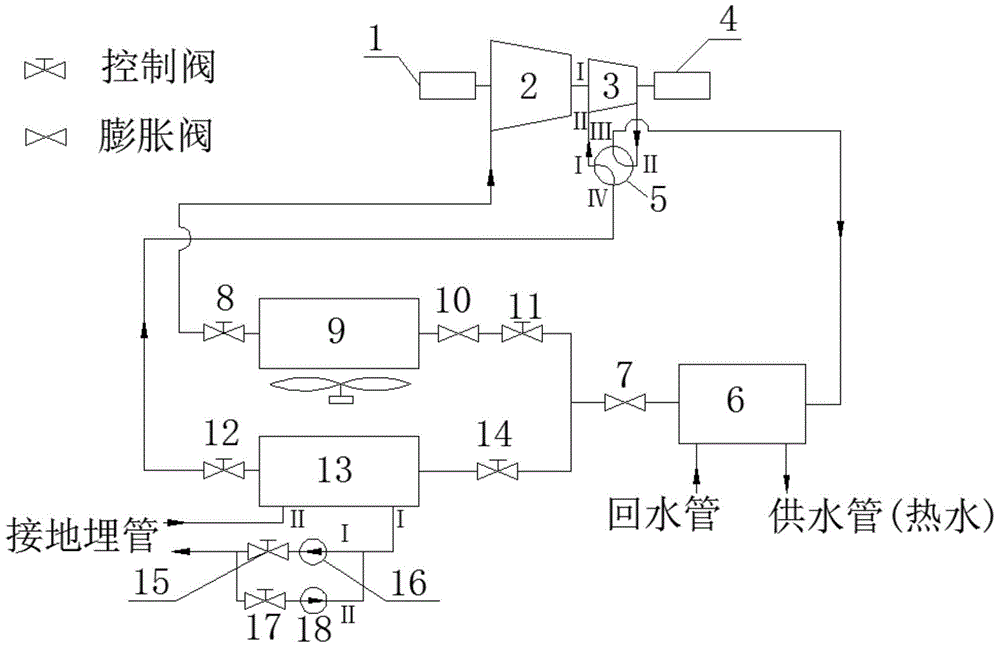

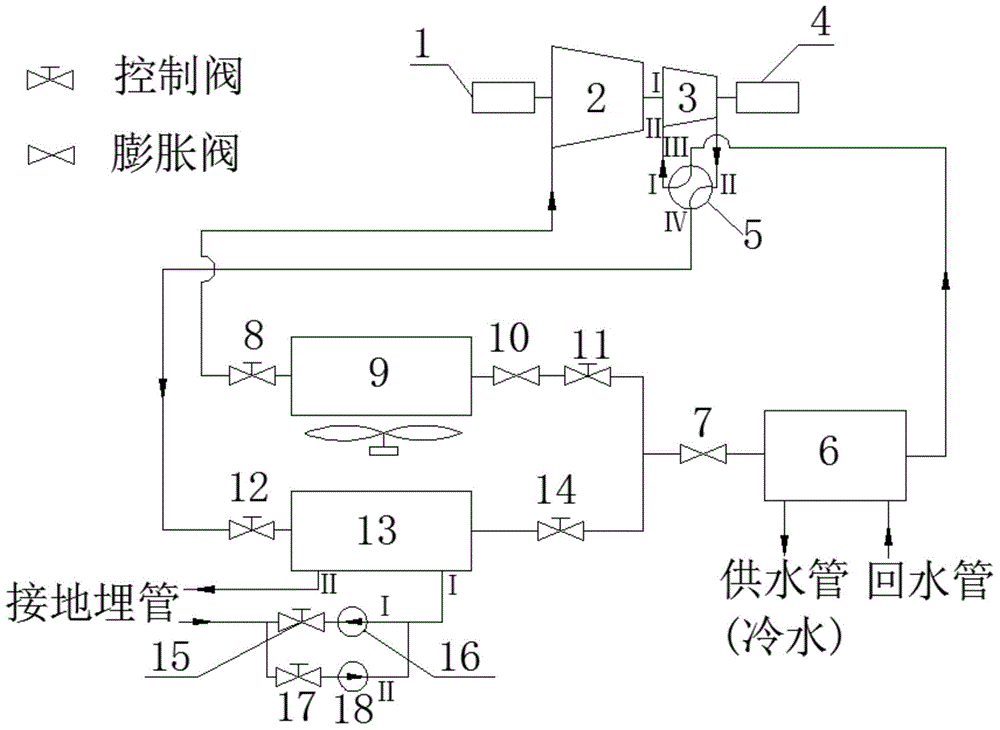

Low-temperature air source and ground source dual-source heat pump unit and control method thereof

ActiveCN104676937AGuaranteed uptimeSolve the problem of unbalanced heat absorption and exhaustMechanical apparatusCompression machines with non-reversible cycleBusiness efficiencyEngineering

The invention relates to a low-temperature air source and ground source dual-source heat pump unit and a control method thereof, aiming at solving the problems that the heating capacity of an air source heat pump under a low-temperature environment is reduced and soil heat absorption and discharge of a ground source pump are not balanced. The low-temperature air source and ground source dual-source heat pump unit comprises a low-pressure compressor, a high-pressure compressor, a four-way reversing valve, a refrigerant-water heat exchanger, a refrigerant-air heat exchanger, a refrigerant-ground source water heat exchanger, a primary expansion valve and a secondary expansion valve, wherein the refrigerant-air heat exchanger is used for exchanging heat with outdoor air, the refrigerant-ground source water heat exchange is used for exchanging heat with circulating water in a soil buried pipe, and the refrigerant-water heat exchanger is used for exchanging heat with user circulating water. By adjusting the four-way reversing valve, the heat pump unit can be enabled to be in heating and refrigeration states. The heat pump unit provided by the invention not only can effectively use the air as an auxiliary heat source to solve the problem of unbalanced soil heat absorption and discharge, but also can solve the technical problems that the heat supply operation efficiency of the air source heat pump in winter is low, the operation stability and reliability are poor and the like to achieve the goal of improving the energy-efficiency ratio and operation reliability of the unit.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

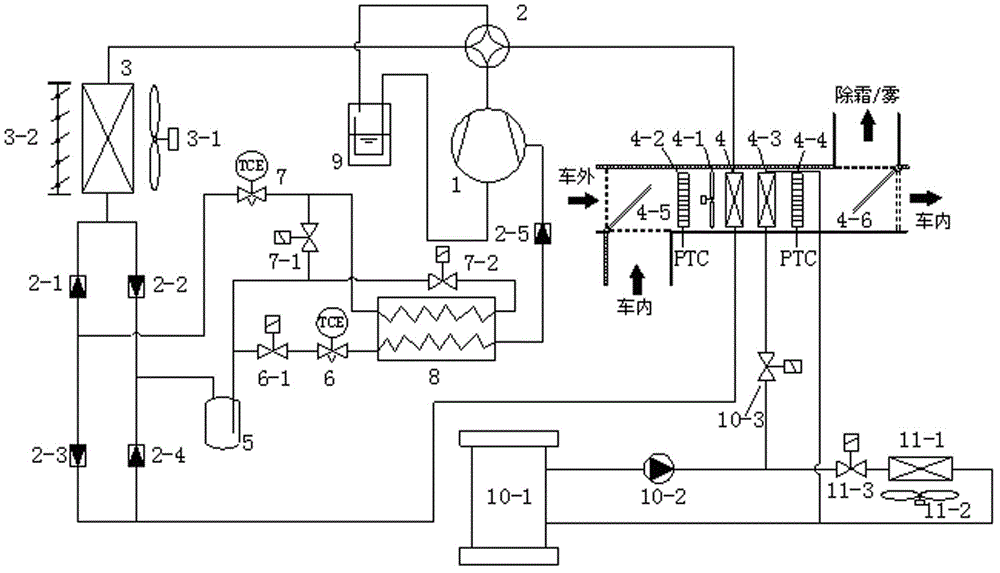

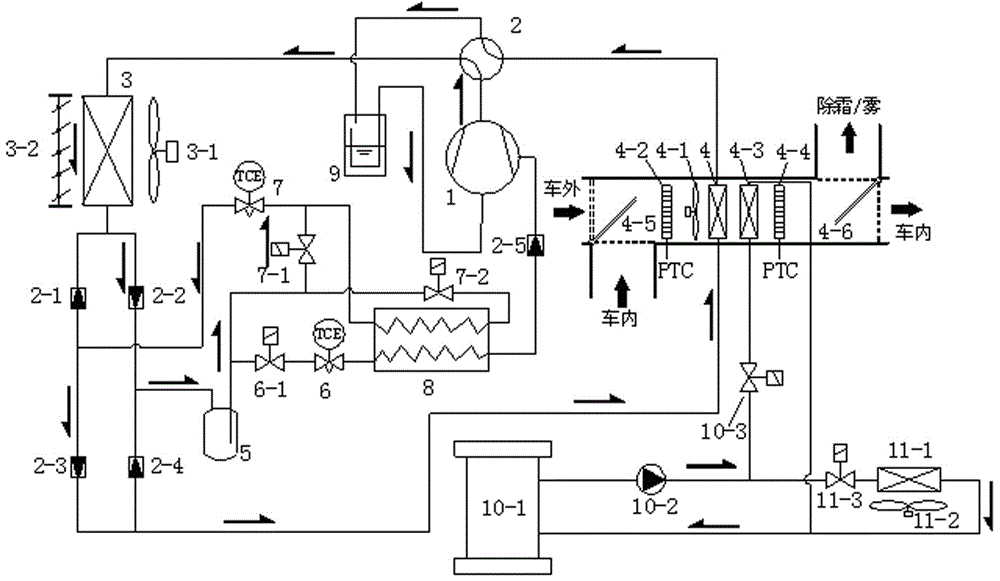

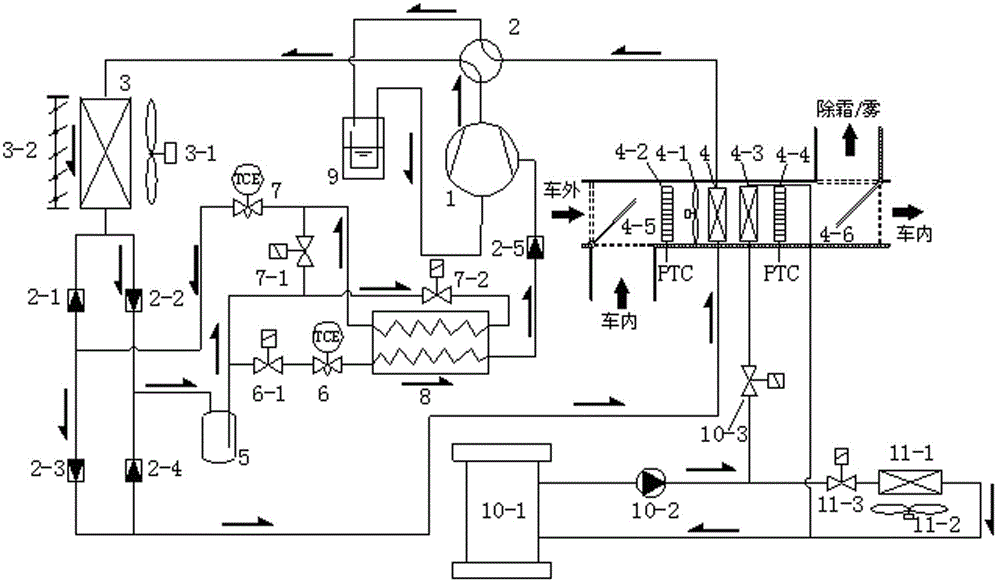

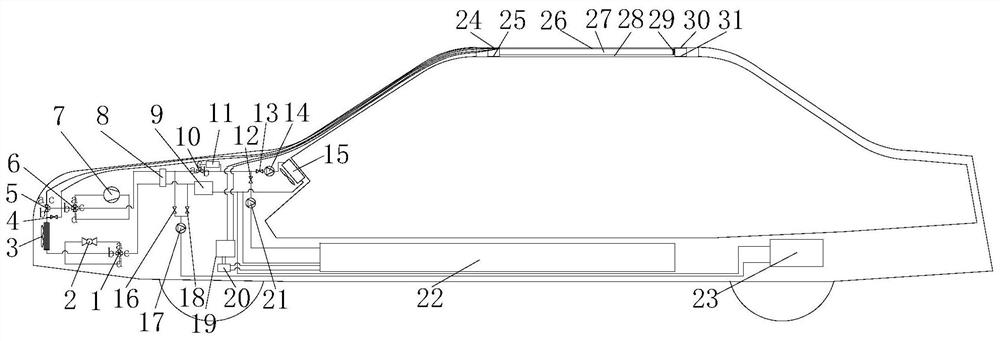

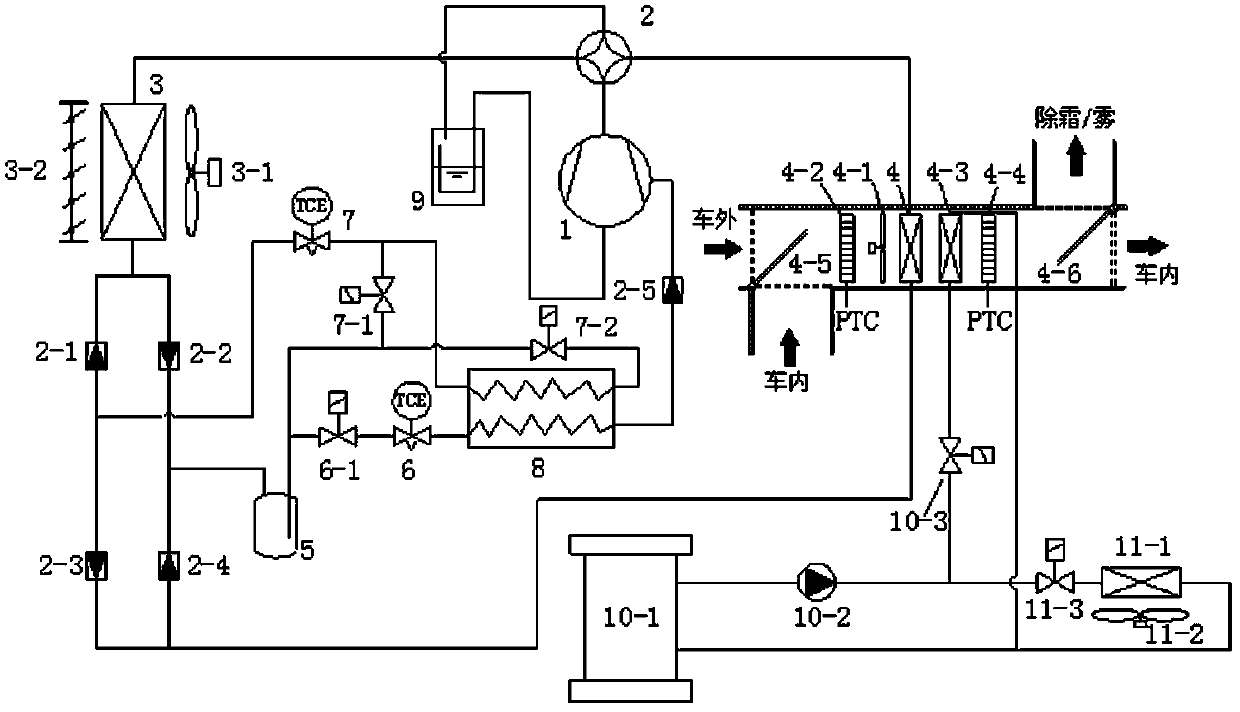

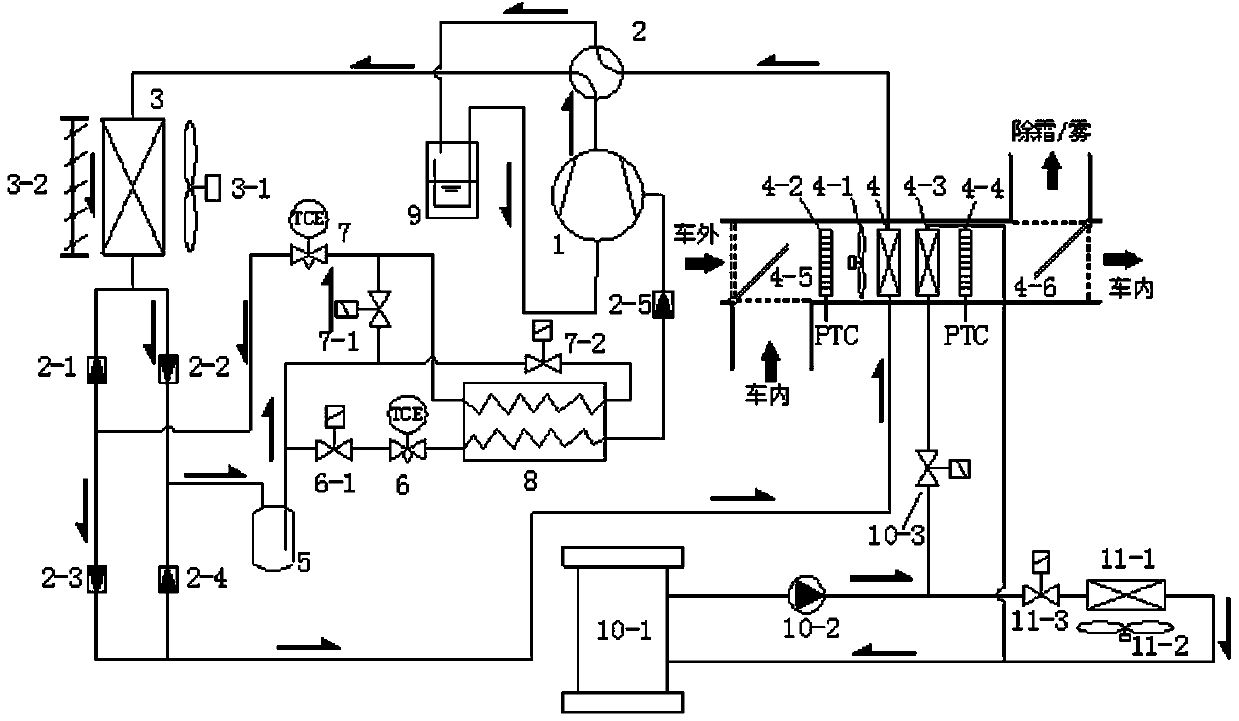

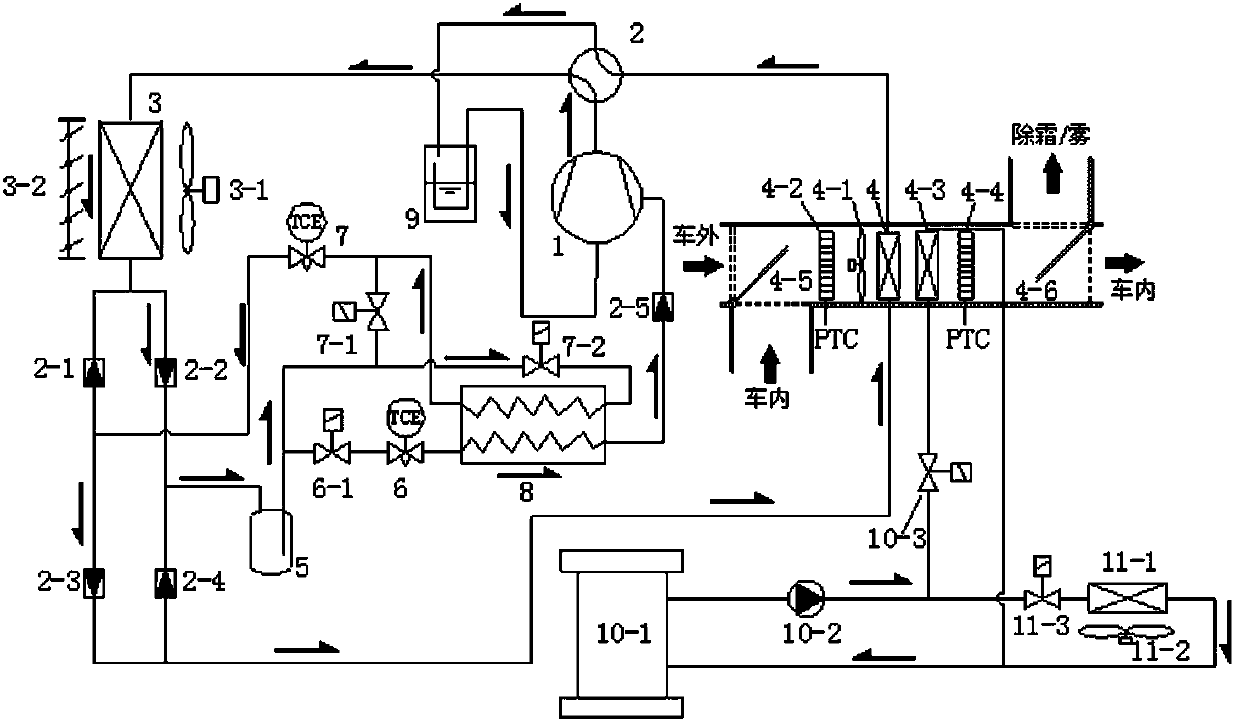

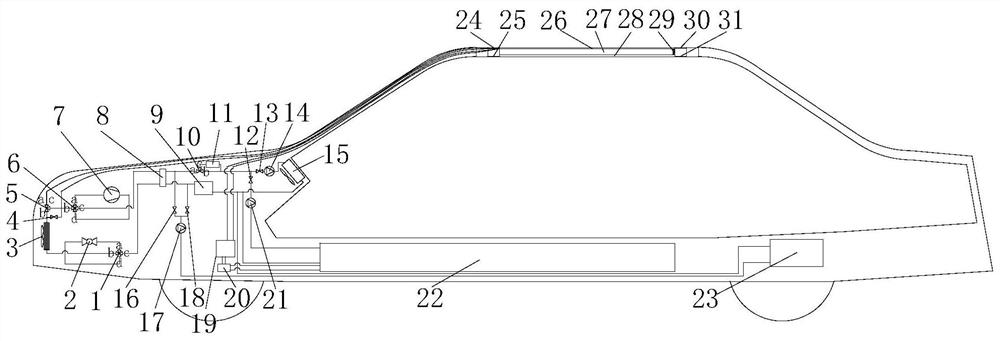

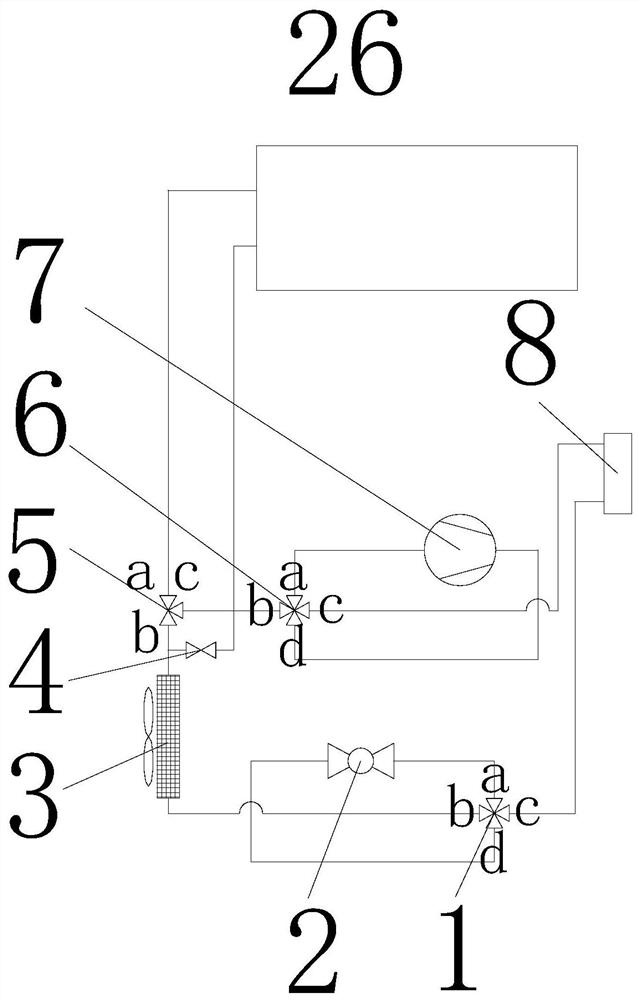

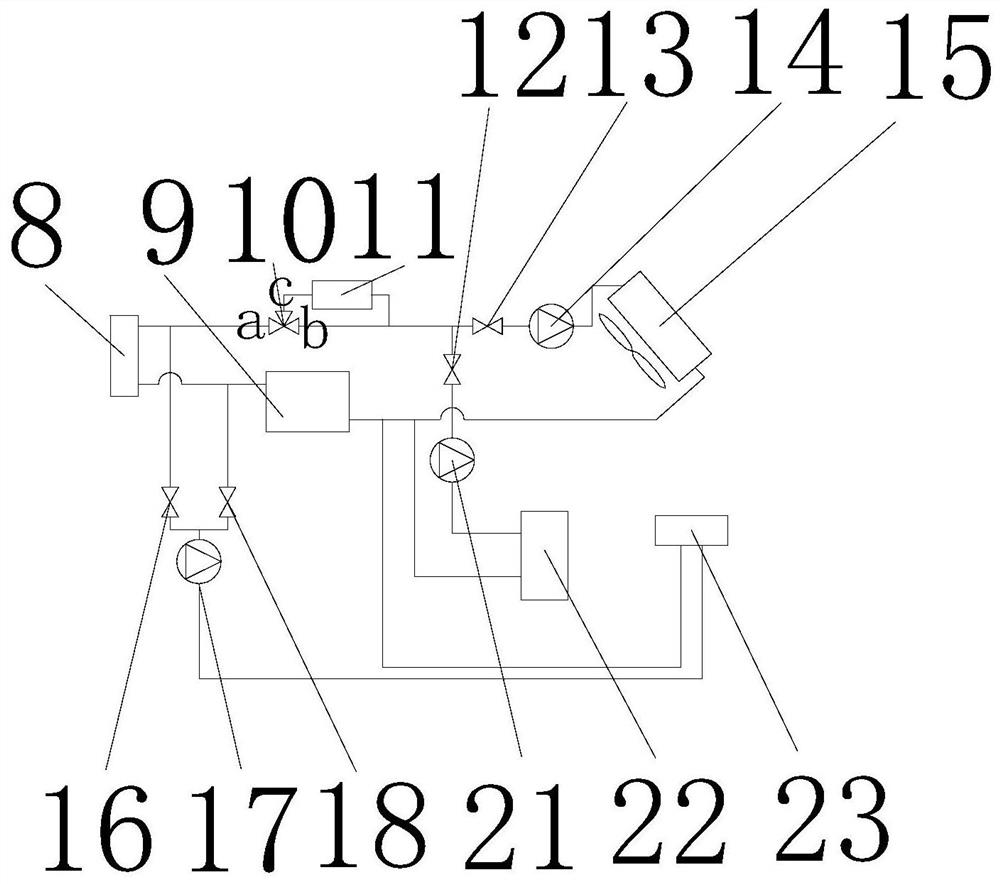

New energy automotive air conditioning system with rapid defrosting and demisting functions

ActiveCN106585323AReduce exhaust temperatureHigh heating coefficientAir-treating devicesVehicle heating/cooling devicesAutomotive air conditioningFrost

The invention discloses a new energy automotive air conditioning system with rapid defrosting and demisting functions. The system is characterized by being mainly composed of an interior heat exchanger side primary temperature rise and heat increase subsystem, a compressor side secondary temperature rise and heat increase subsystem, an exterior heat exchanger side third-stage temperature rise and heat increase subsystem, a power device composite heat recovery subsystem, a decompression expansion mechanism, auxiliary equipment, a connecting pipeline and the like. According to the new energy automotive air conditioning system with the rapid defrosting and demisting functions, provided by the invention, due to a combination of three temperature rise and heat increase subsystems such as the interior heat exchanger side primary temperature rise and heat increase subsystem, the compressor side secondary temperature rise and heat increase subsystem and the compressor side secondary temperature rise and heat increase subsystem, the prominent problems that the exhaust temperature of the compressor is extremely high, the interior heat exchanger has thick frost and defrosting difficulty, the system heat supply capacity and efficiency are low and the system operating reliability is low during heat pump air-conditioning low-temperature operation and the like can be obviously solved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

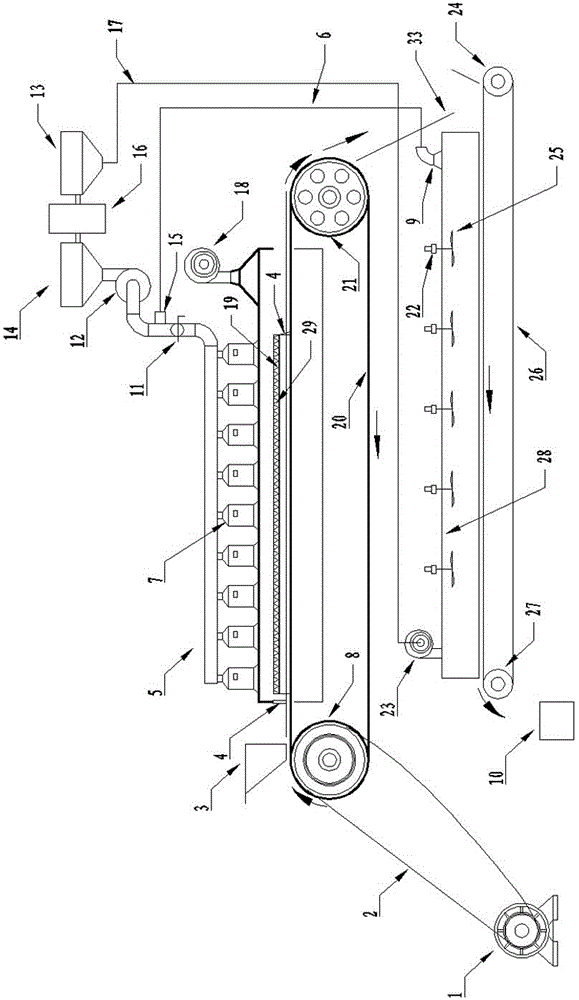

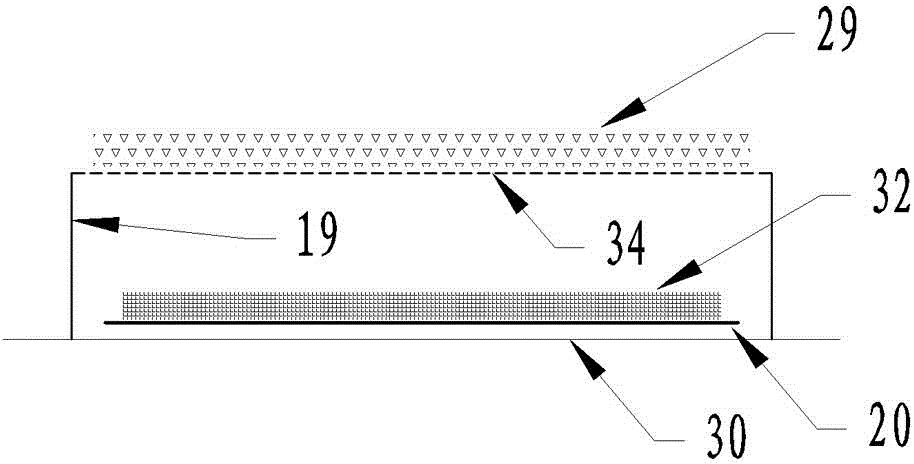

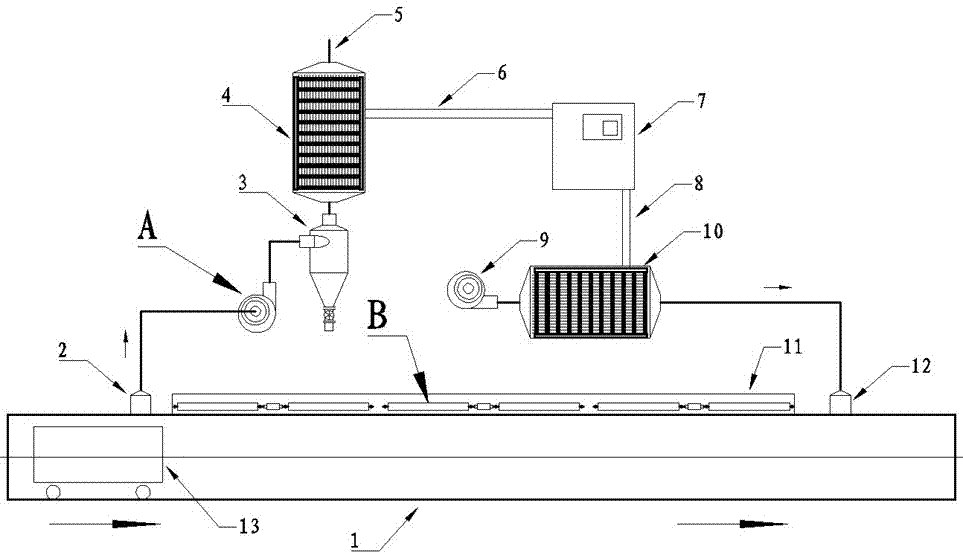

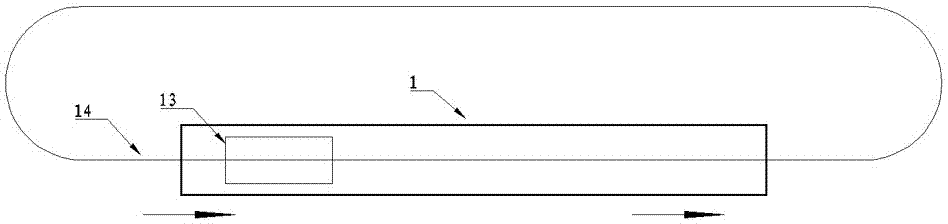

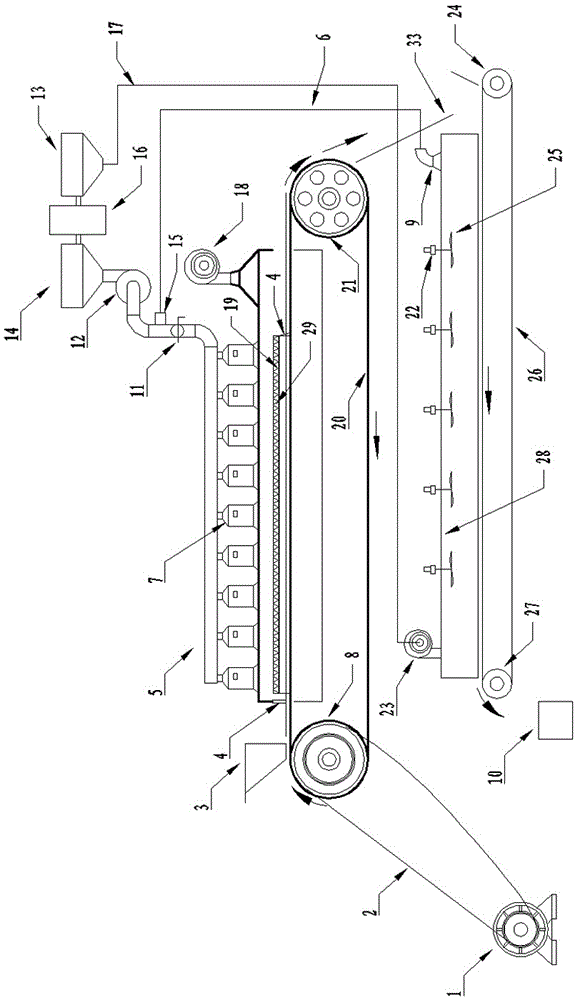

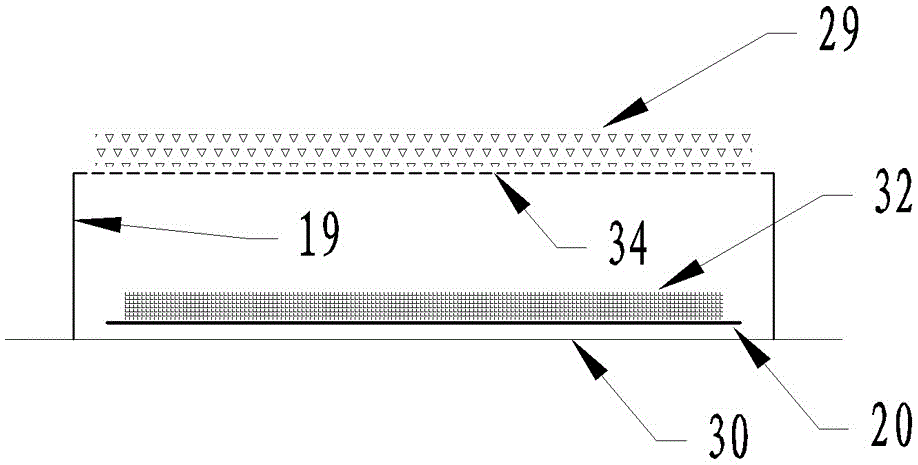

Heat pump type waste-heat recovery microwave oxygen-insulation drying machine

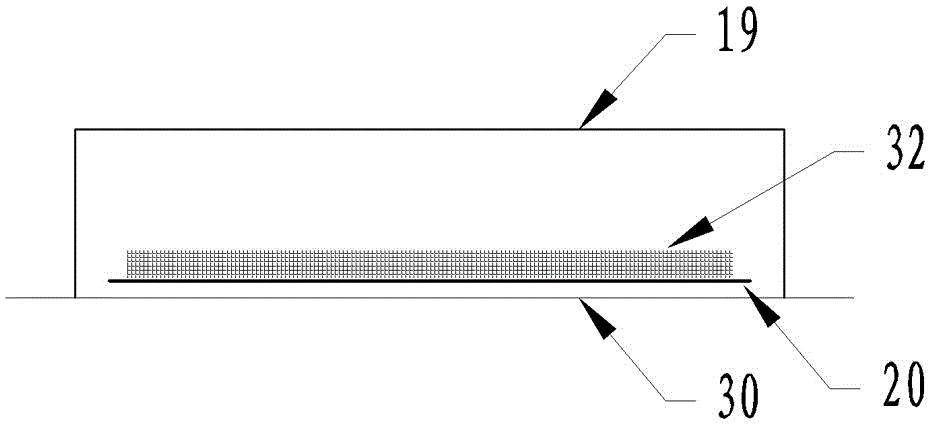

ActiveCN104567316ATake it away in timeTake away does not affectDrying gas arrangementsDrying machines with progressive movementsGlass coverEvaporation

The invention discloses a heat pump type waste-heat recovery microwave oxygen-insulation drying machine. A tunnel-shaped glass cover is fixed on a base plate of a conveying belt, an upper plate of the tunnel-shaped glass cover is provided with ventilation screen holes and covered with a glass packing ring, a microwave unit is arranged above the packing ring, materials on the conveying belt is heated by microwaves in the glass cover and reach the conveying belt of an insulation tank body through a slide plate, a cutoff curtain and a blower are arranged at an outlet of the glass cover, and another cutoff curtain is arranged at an inlet of the glass cover. An exhaust pipe is communicated with a microwave unit above the ventilation screen holes, and heat in the exhaust pipe is transferred through a heat pump and then enters a hot air drying system of the insulation tank body. By the heat pump type waste-heat recovery microwave oxygen-insulation drying machine, continuous efficient enzyme deactivation and synchronous oxygen-insulation drying are realized in a non-vacuum condition, and industrialized implementation is facilitated. The heat pump is low in power consumption and high in heating coefficient, waste heat can be completely recovered, and cost and energy consumption are reduced. The packing ring insulates the air and timely evaporation of moisture is guaranteed. Hot-air countercurrent is kept in uniform quality, and the drying machine is particularly suitable for drying agricultural products which are prone to enzyme promoting and high-temperature oxidation browning and is wide in prospect.

Owner:重庆信奇建材机械制造有限公司

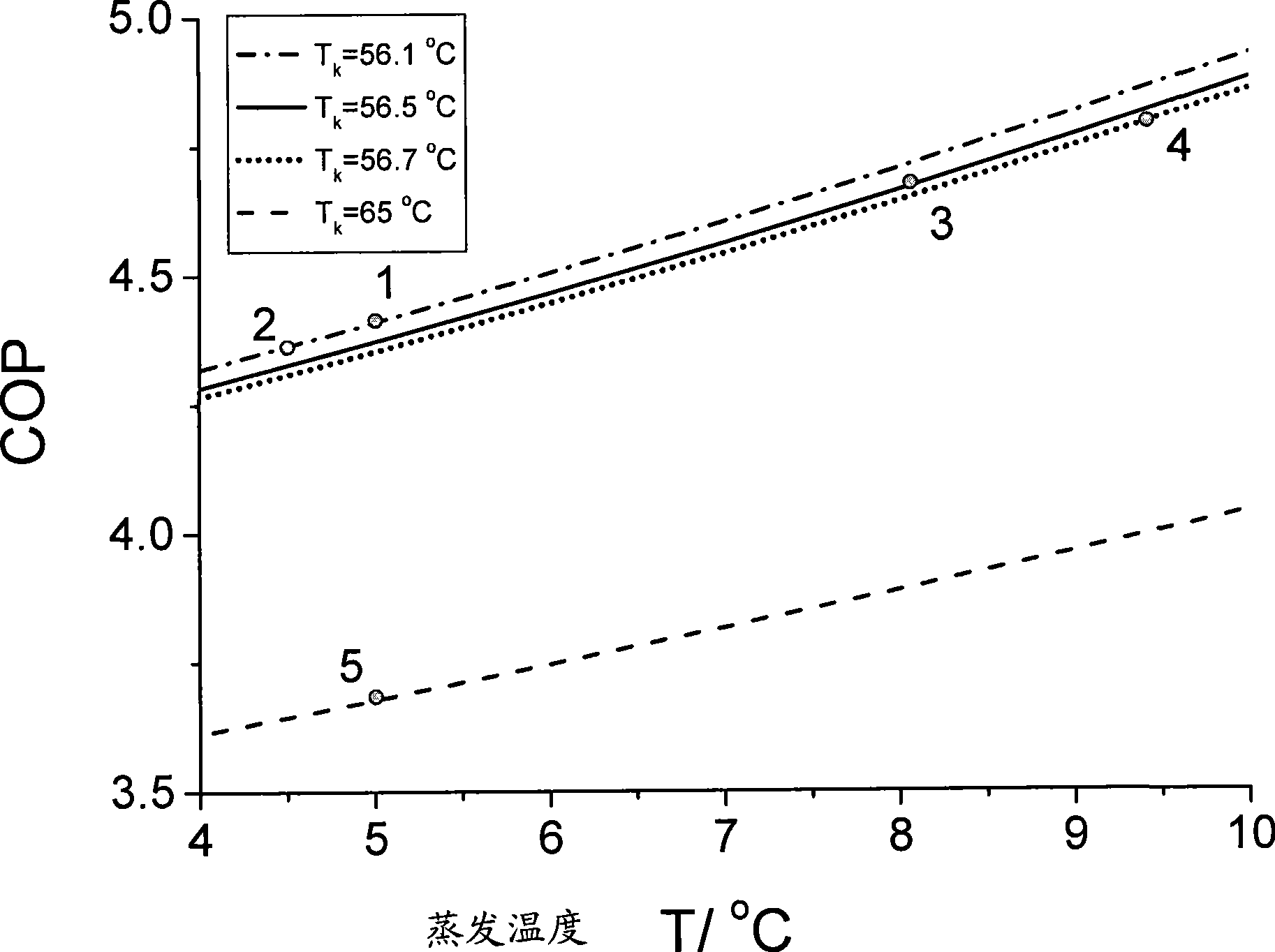

Three-pressure efficient air cooled heat pump water heater suitable for high and low temperature environment

ActiveCN107014076ANovel ideaSmart design optimizationFluid heatersMechanical apparatusBusiness efficiencyEngineering

The invention provides a three-pressure efficient air cooled heat pump water heater suitable for the high and low temperature environment. According to the three-pressure efficient air cooled heat pump water heater, two expansion valves, an aftercooler and a medium pressure gas-liquid separator are ingeniously matched and combined, a side road compressor and an evaporating pressure regulator are used for auxiliary optimizing regulation, and therefore the prominent problem that during high temperature heating in summer, the evaporating temperature and the air suction pressure are too high, too large motor loads are prone to being caused, and a motor can be burnt is solved, the prominent problem that in a low temperature heating working mode in winter, the evaporating temperature is too low, evaporator surface frosting is serious, the compression ratio of a compressor is too large, the exhaust gas temperature is too high, the heating capacity and the energy efficiency ratio are sharply reduced is solved, and the application field of the air cooled heat pump water heater is expanded.

Owner:ZHONGYUAN ENGINEERING COLLEGE

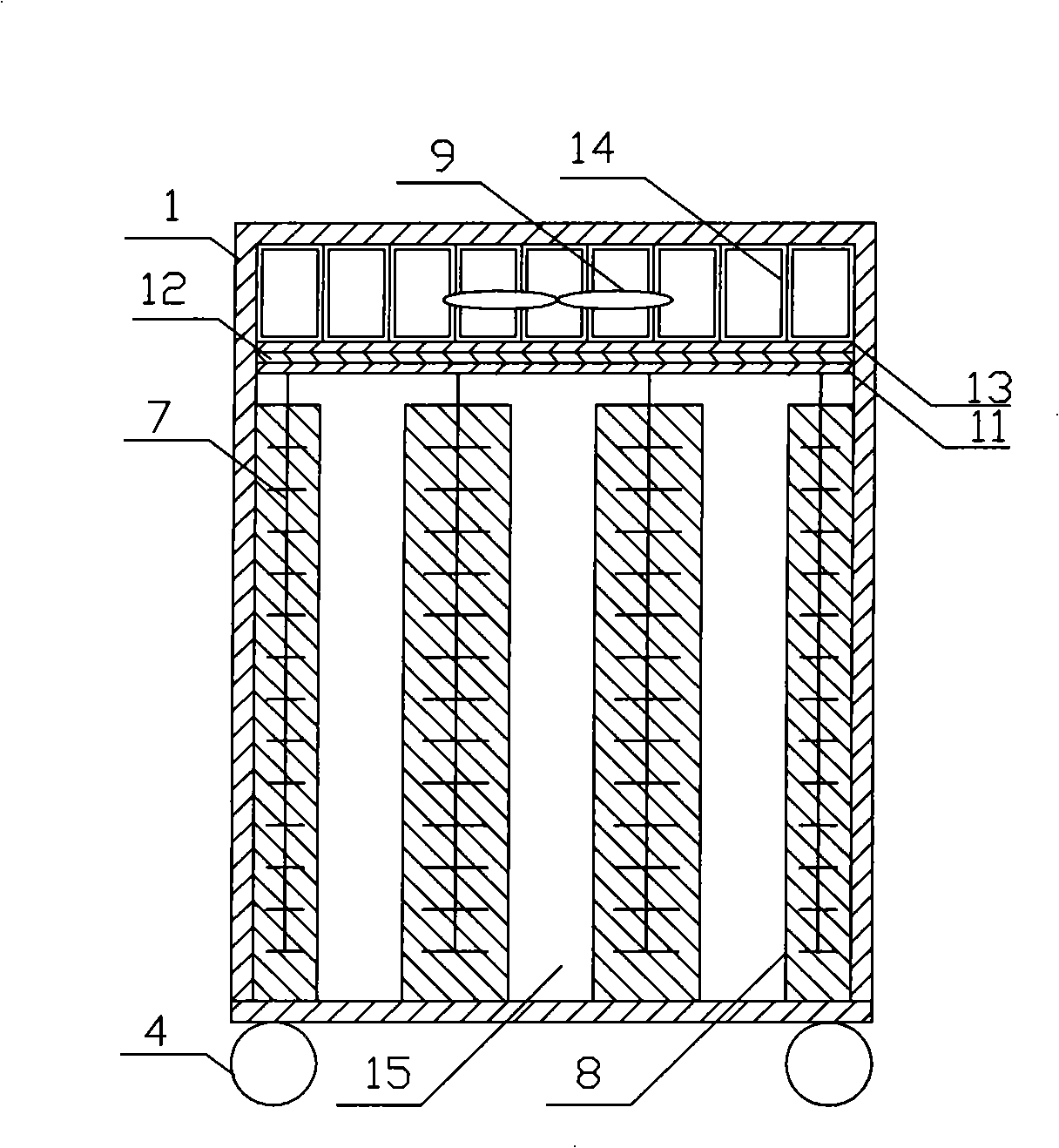

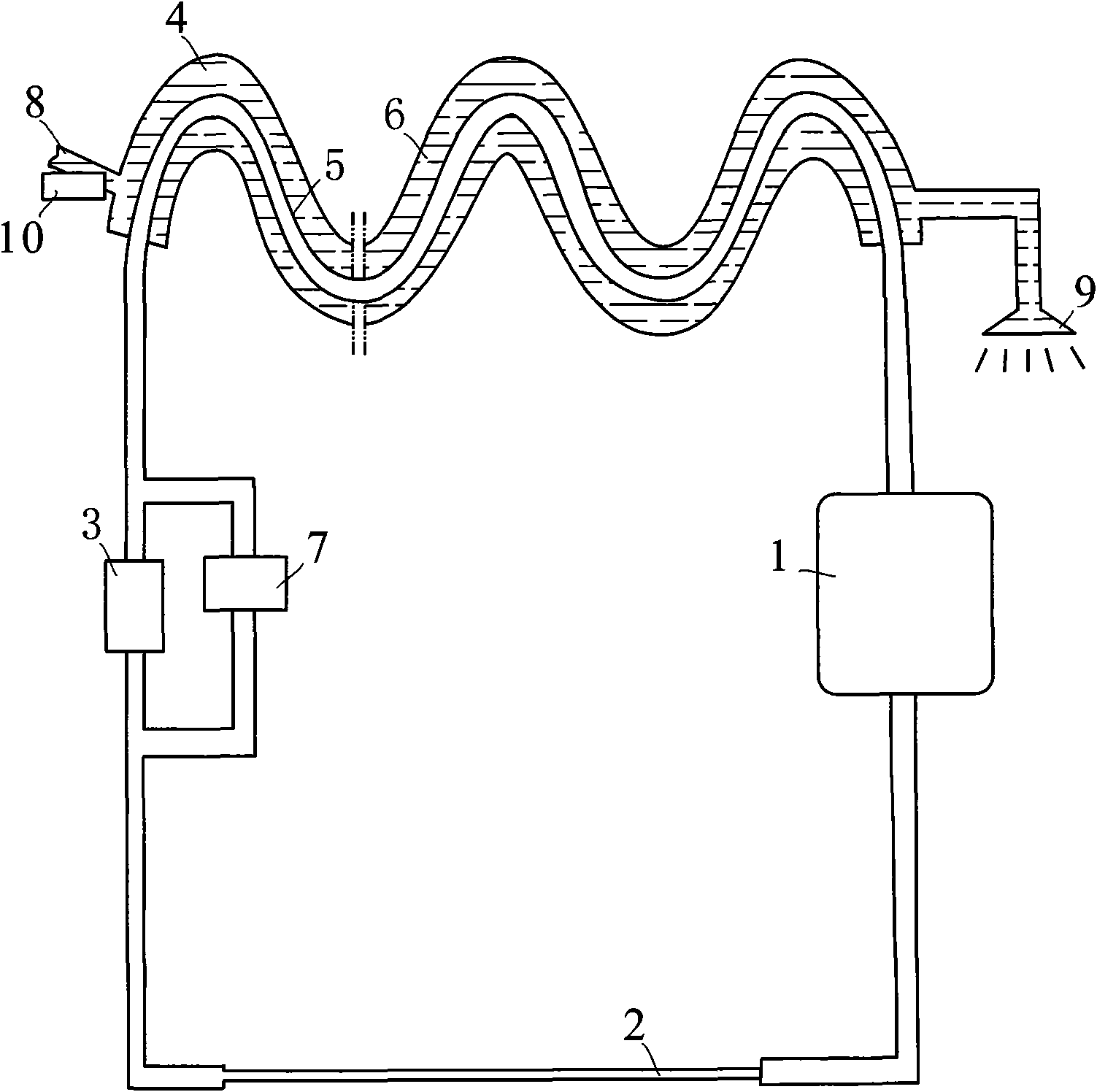

Compact type heat-pump water heater

InactiveCN101566390AImprove exchange efficiencyReduce work intensityFluid heatersThermal energyWastewater

The invention relates to a compact type heat-pump water heater fully utilizing remaining heat of wastewater generated by a shower. The compact type heat-pump comprises a compressor, a throttle device, a two-layer bushing and an evaporator; a circulation loop is formed by connecting the evaporator, the throttle device and the compressor through a cold medium pipe; the evaporator appears as flat and hollow form and two ends of the evaporator are respectively connected with the cold medium pipe, and then the cold medium can flow through the hollow part of the evaporator; and the evaporator is arranged at a position where the showering can reach after showering with hot water. The water heater has the advantages of high heating coefficient, compact volume, safe performance and environment-friendly property.

Owner:蔡恢岳

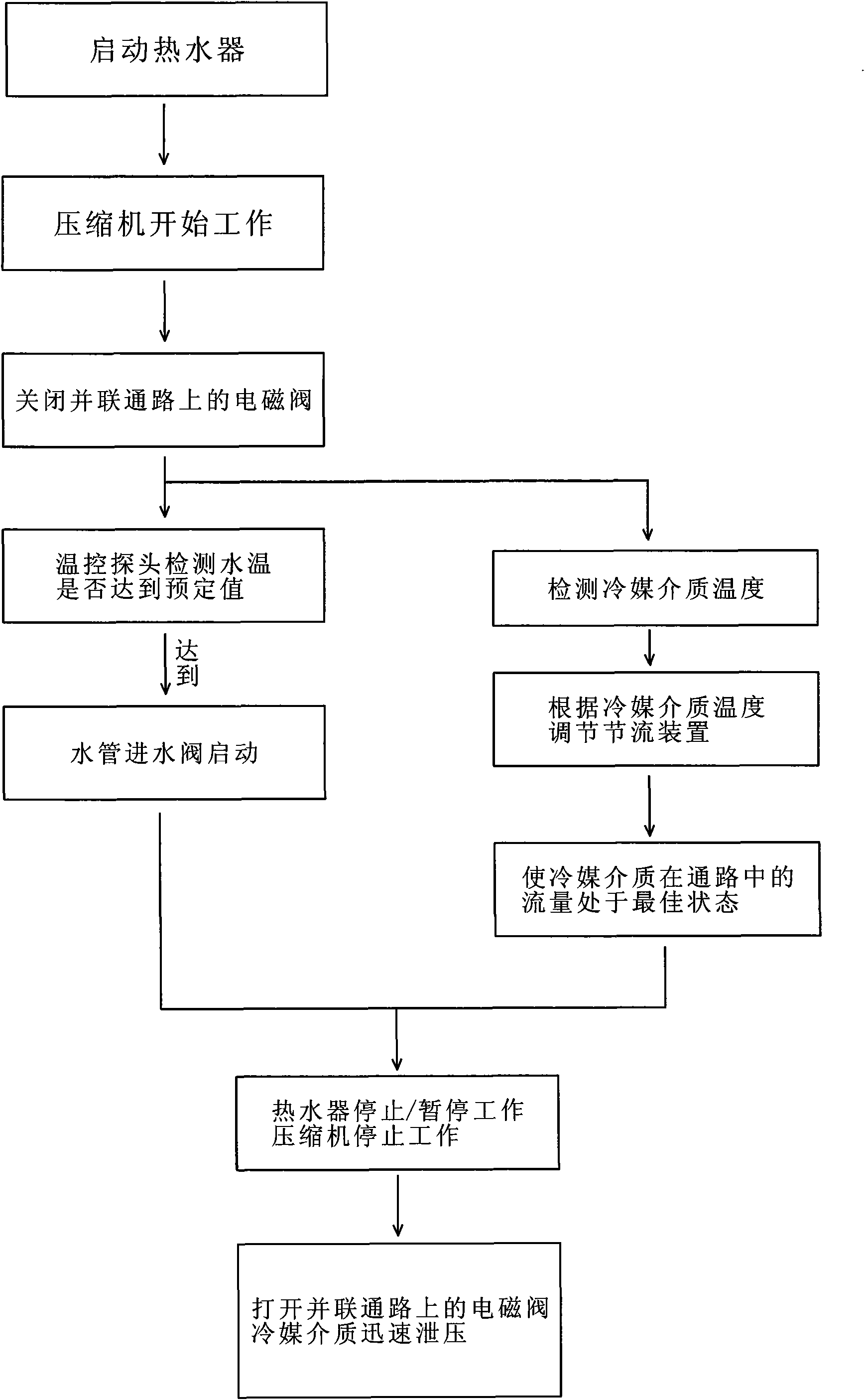

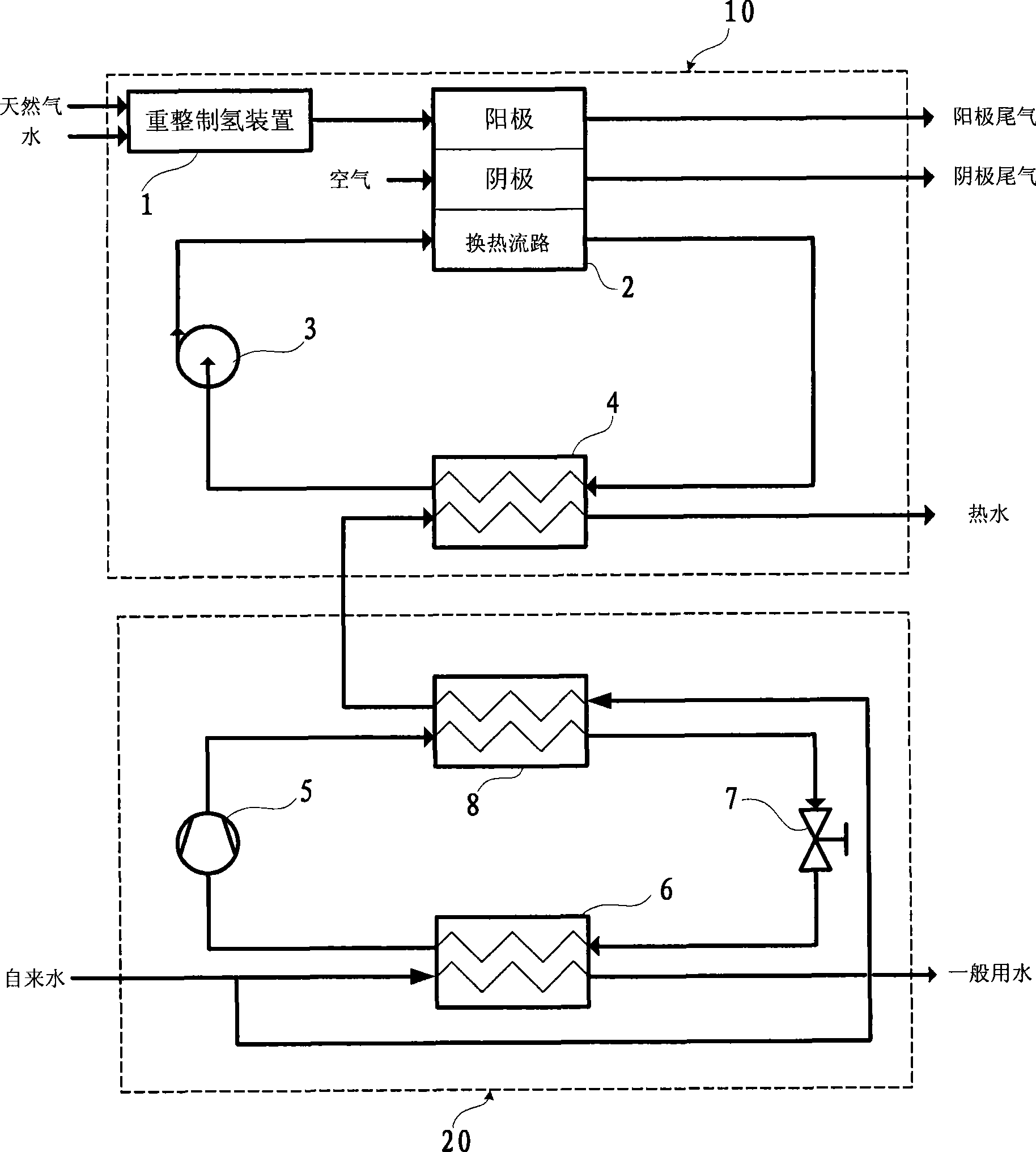

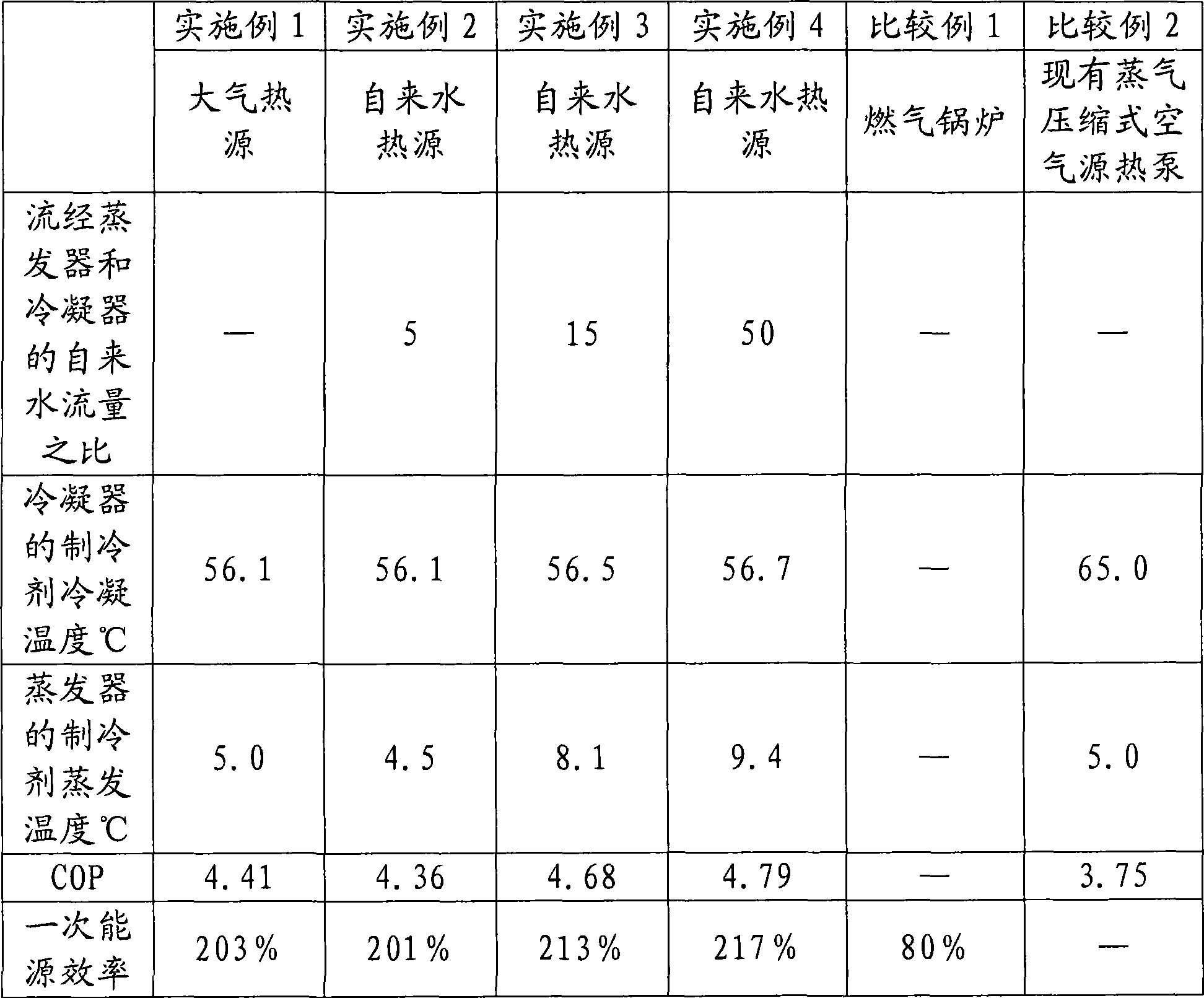

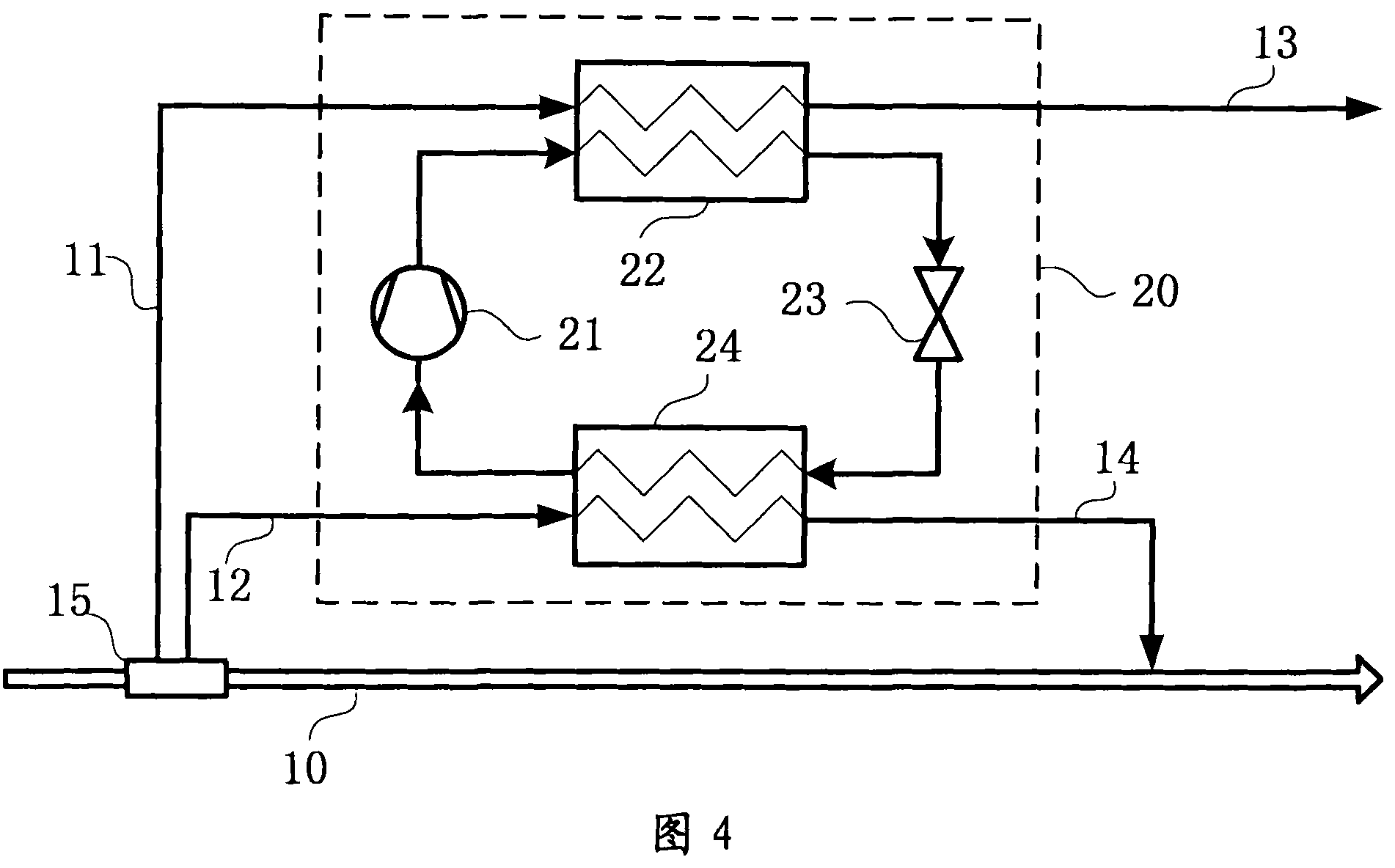

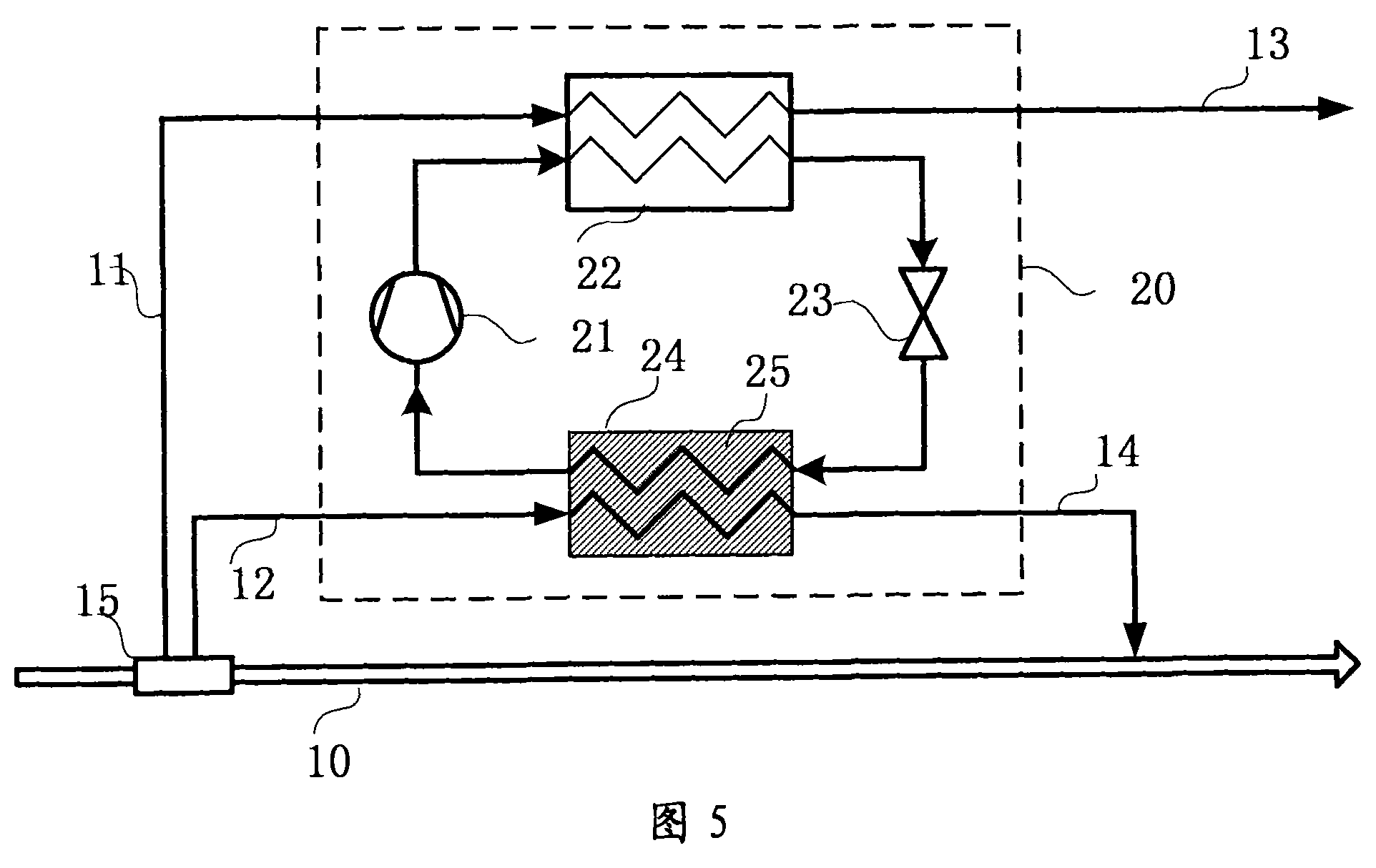

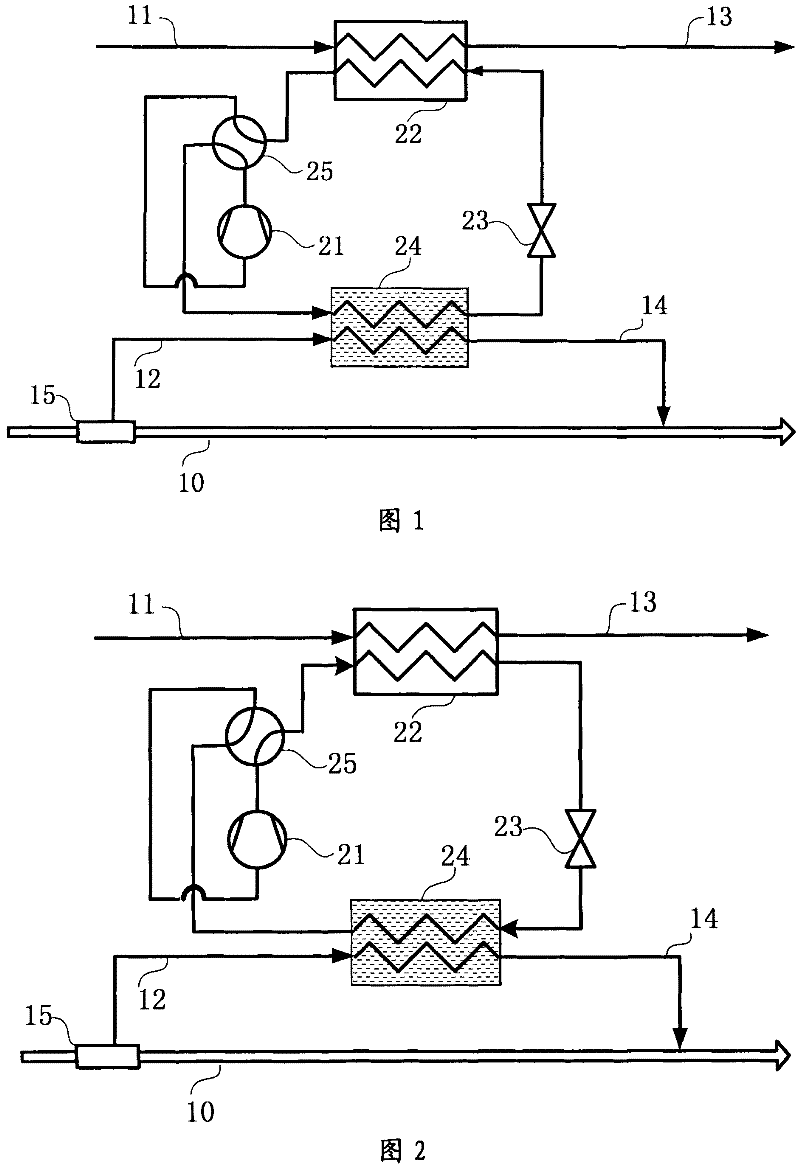

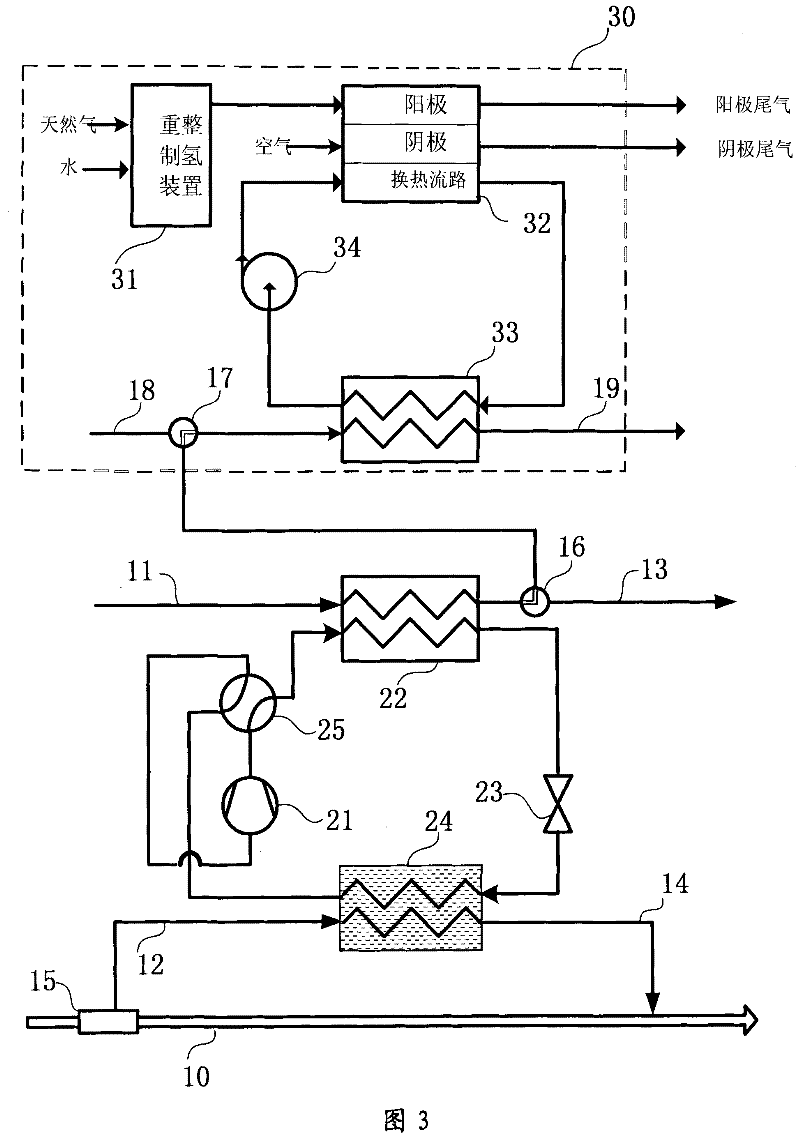

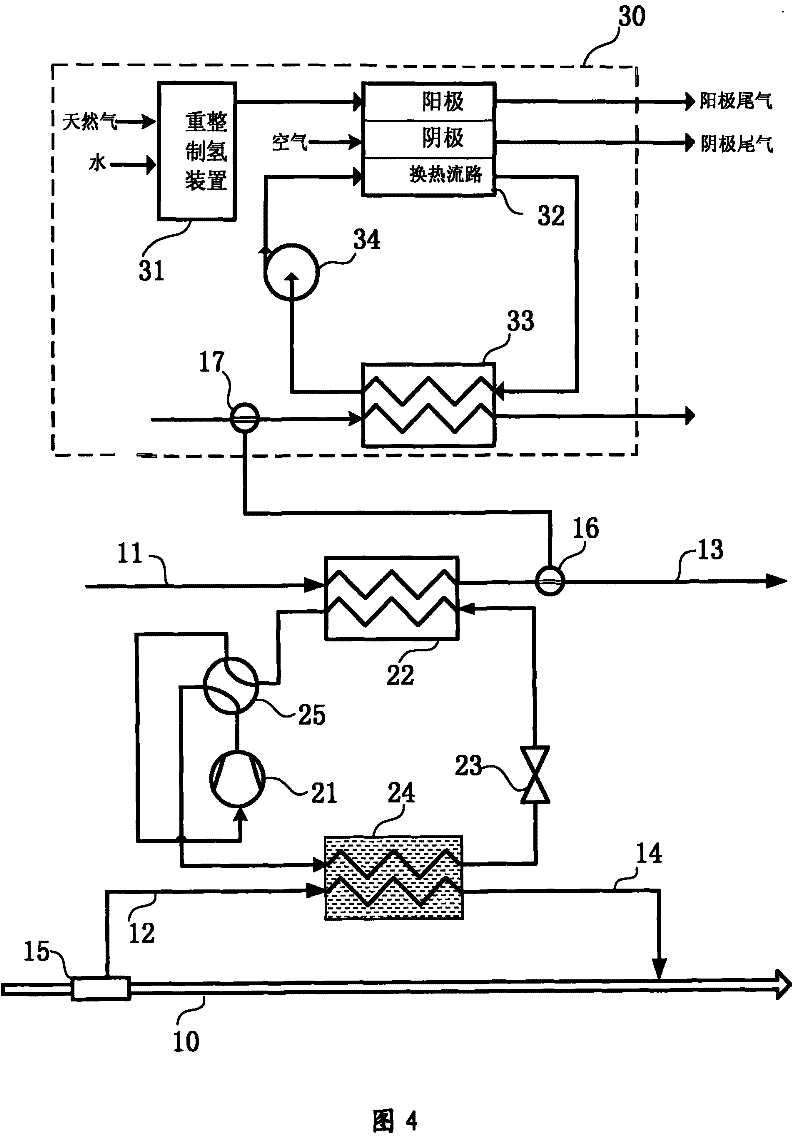

Hot water supply system and method

InactiveCN101464055AImprove energy efficiencyEasy to cleanFluid heatersFuel cell auxillariesEngineeringElectric power

The invention relates to a hot water supply system and a method. The hot water supply system comprises a vapor compression type heat pump circulation subsystem and a fuel cell power generation subsystem. The vapor compression type heat pump circulation subsystem comprises a compressor, a condenser, a throttle valve and an evaporator, and the fuel cell power generation subsystem comprises a reformation and hydrogen production device, a fuel cell, a heat exchange device and a circulating pump. The reformation and hydrogen production device takes natural gas as raw material for preparing hydrogen; the fuel cell takes reformed hydrogen as fuel for carrying out the power generation for supplying direct current and by-product heat; furthermore, the heat exchange device takes cooling water of the fuel cell as high-temperature fluid and takes water from an outlet of the condenser as low-temperature fluid for carrying out heat exchange, so as to improve the temperature of water supplied by the hot water system and significantly improve the energy efficiency of the hot water supply system. The hot water system of the embodiment has significant advantages of cleanness and high efficiency, and the heat supply coefficient thereof is also higher than the heat supply coefficient of the existing vapor compression type heat pump circulation hot water system which takes electricity of a power grid as the power.

Owner:北京优利康达科技股份有限公司 +1

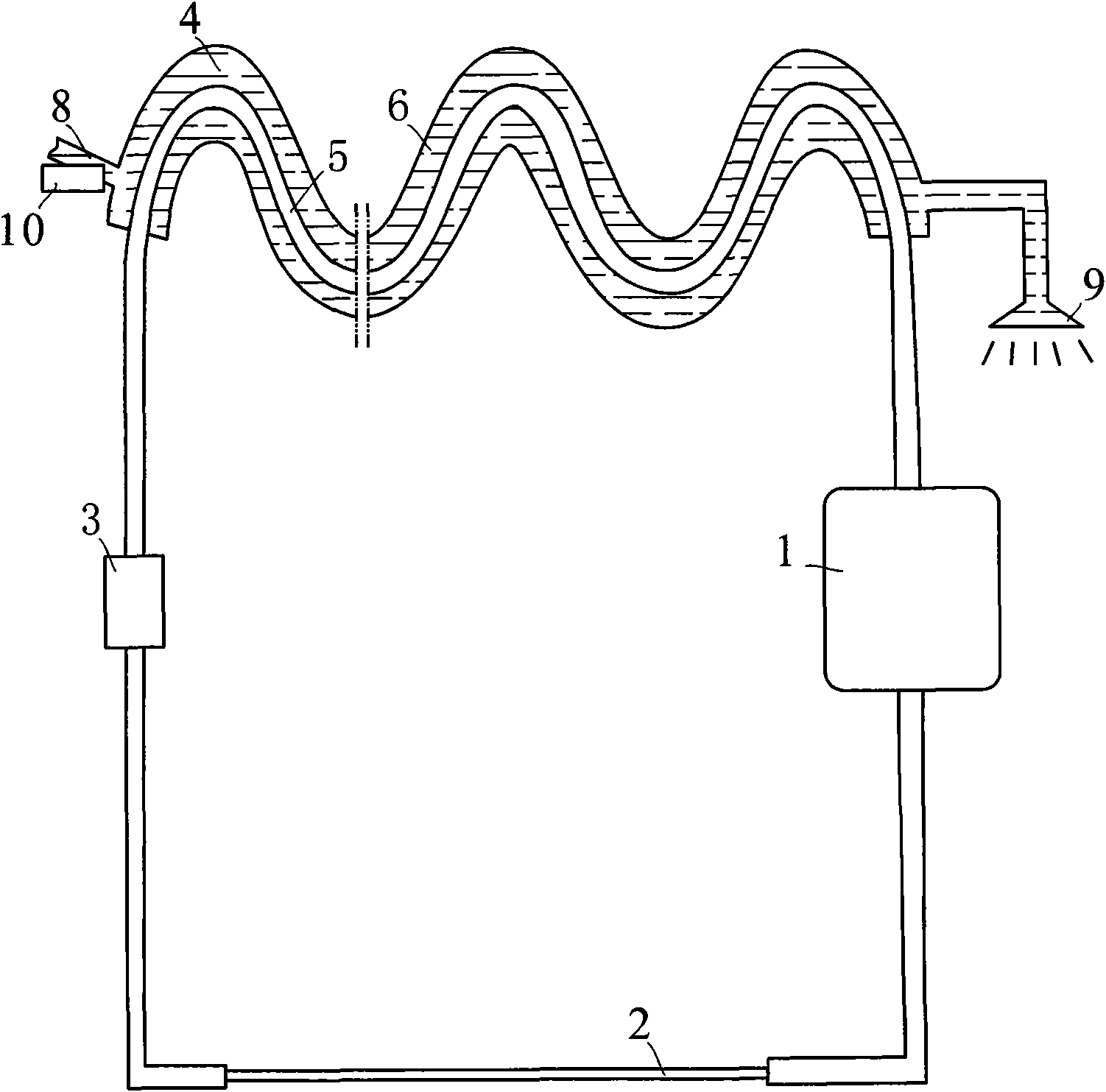

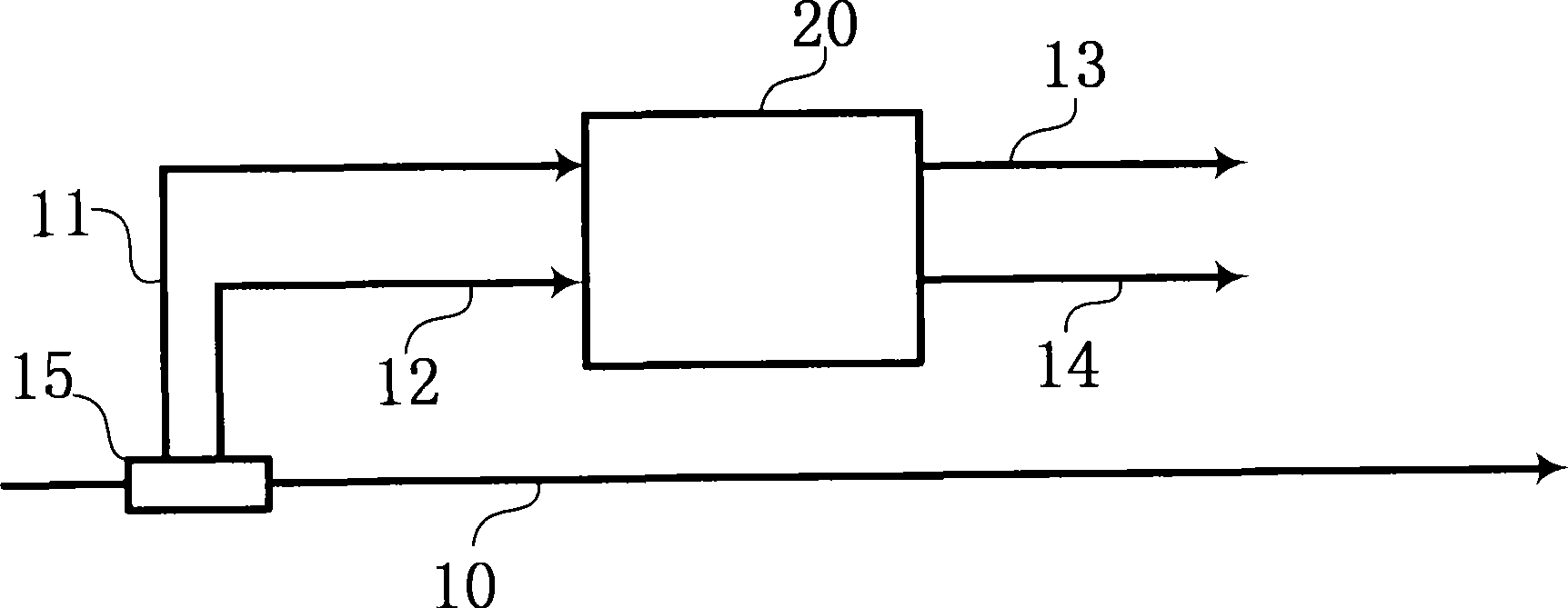

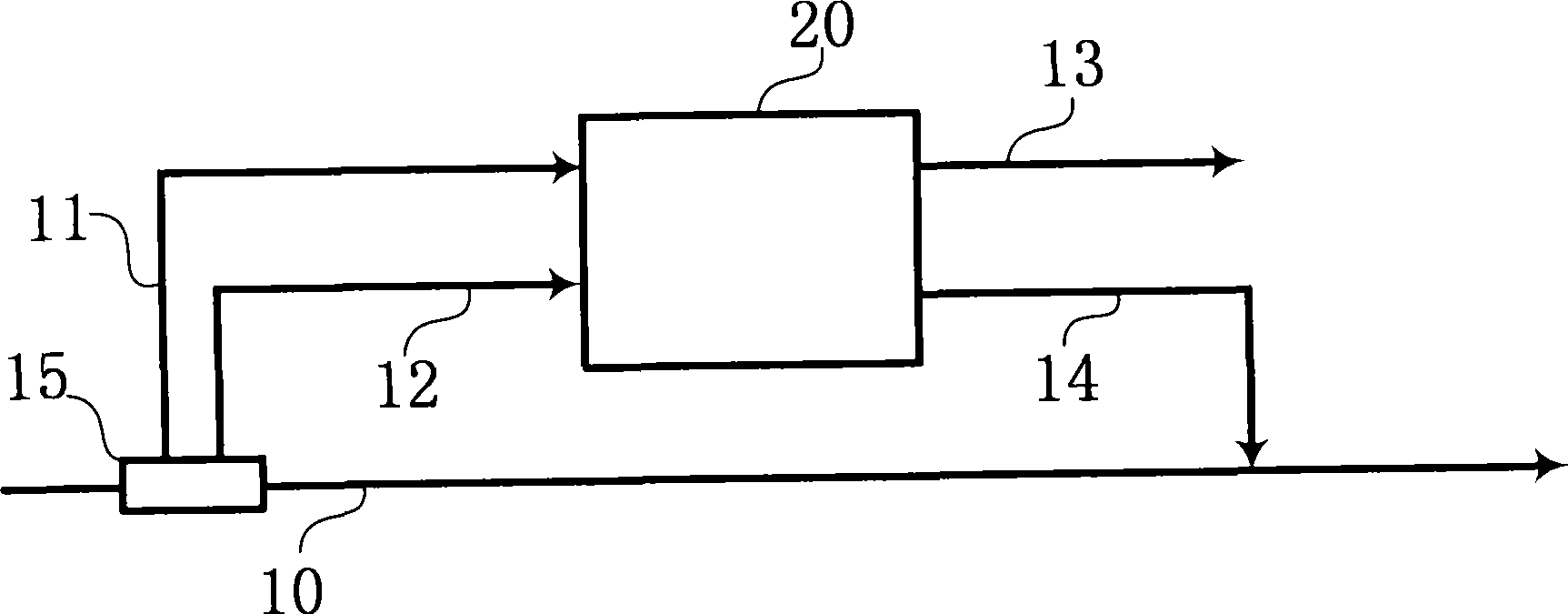

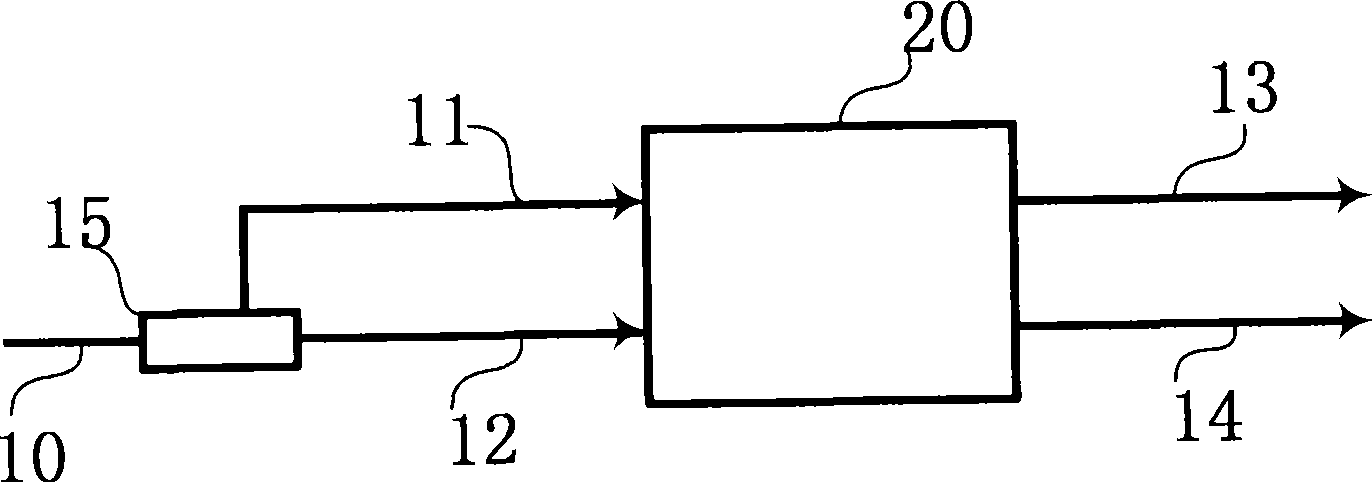

Hot water supply system and method thereof

InactiveCN101532700AStable working temperatureImprove energy efficiencyLighting and heating apparatusDomestic hot-water supply systemWater sourceEngineering

The invention relates to a hot water supply system and a method thereof. The hot water supply system comprises a main water supply pipeline used for providing water sources, a heat transfer subsystem used for conducting heat transfer between hot-source water and heated water and causing the heat quantity of the hot-source water to transfer to the heated water; and the hot-source water and the heated water come from the main water supply pipeline. The hot water supply method comprises the following steps: tap water of the same water source is divided into the hot-source water and the heated water; and heat transfer is carried out. The heat quantity of the hot-source water is transferred to the heated water by a vapor compression heat pump circulating subsystem to increase the temperature of the heated water. The hot water supply system and the method thereof carry out water diversion to the water supply system and heat transfer to the divided water so as to be capable of effectively utilizing the large amount of heat existing in the water supply system, thereby greatly improving the energy efficiency of the hot water supply system, having obvious advantages of cleanness and high efficiency and being beneficial to the reasonable utilization of energy.

Owner:苏庆泉

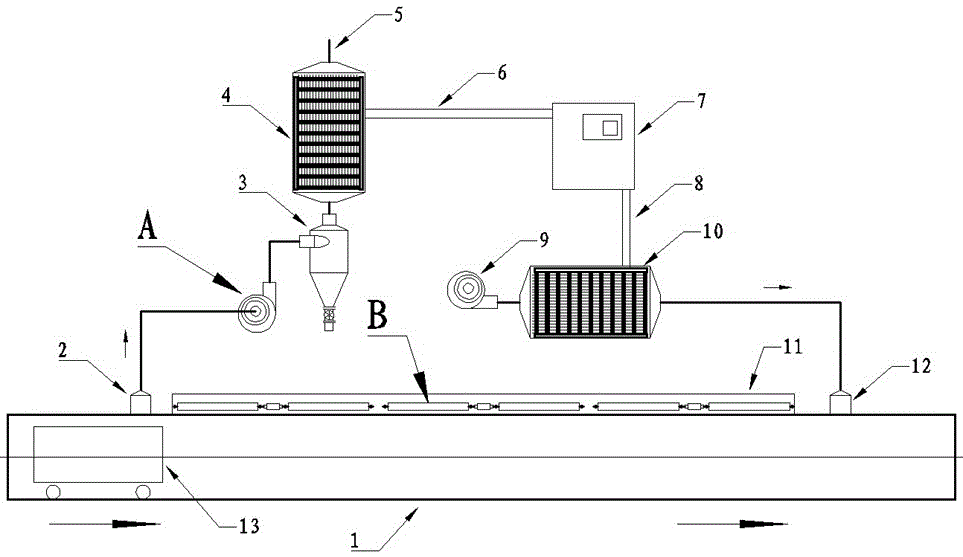

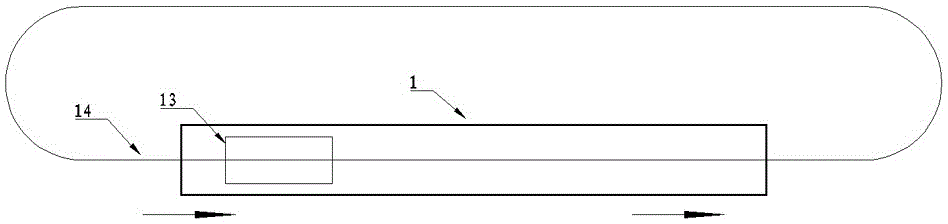

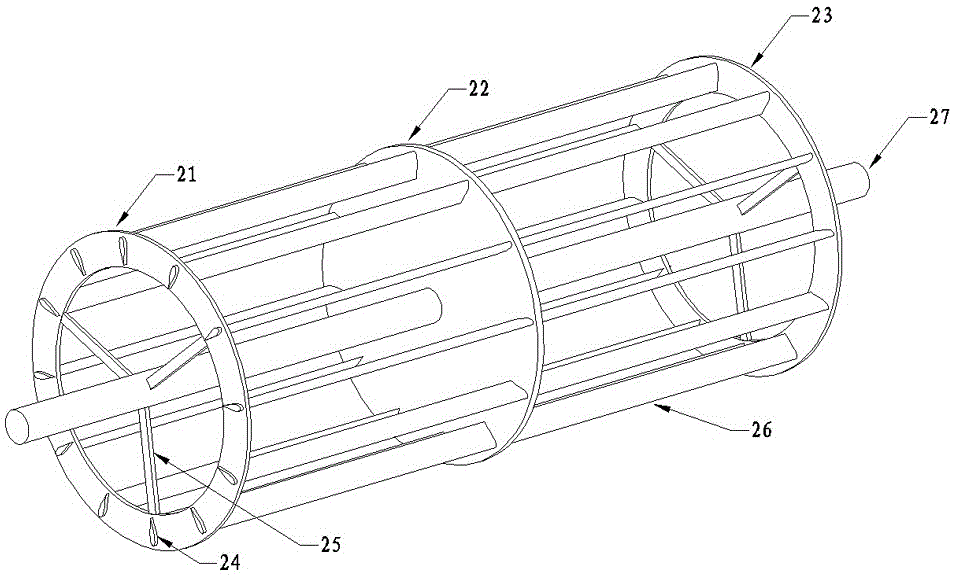

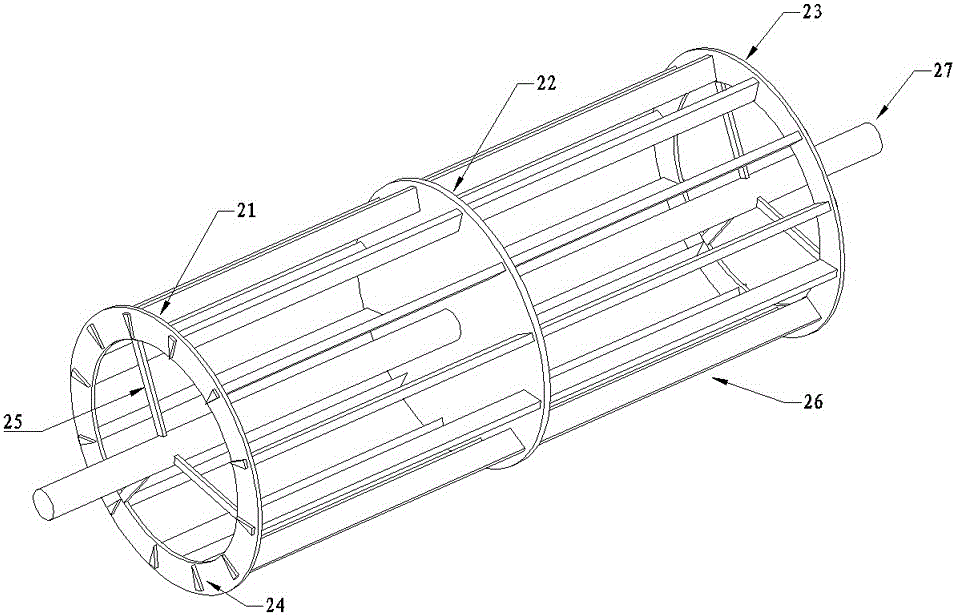

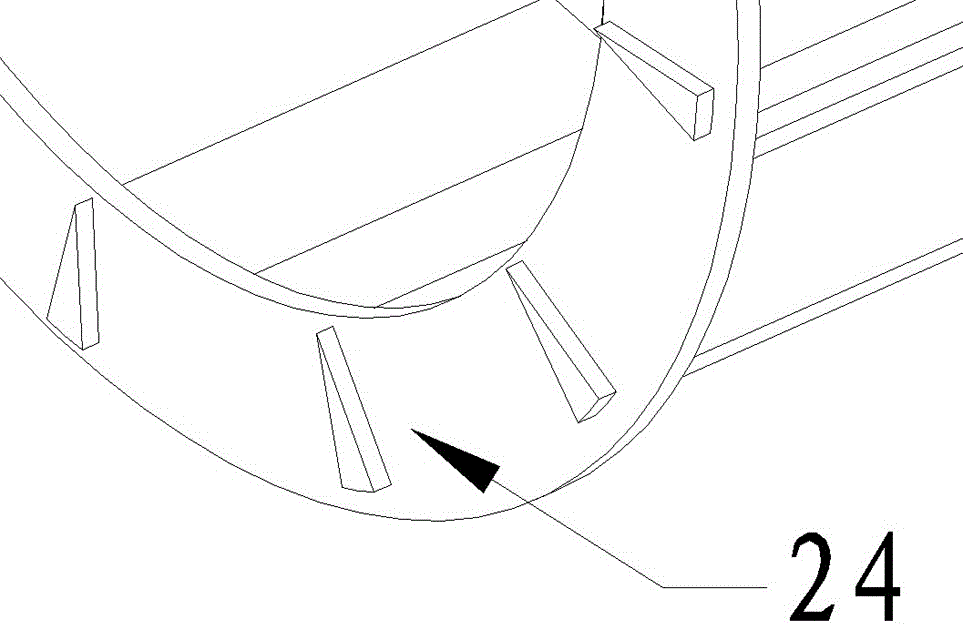

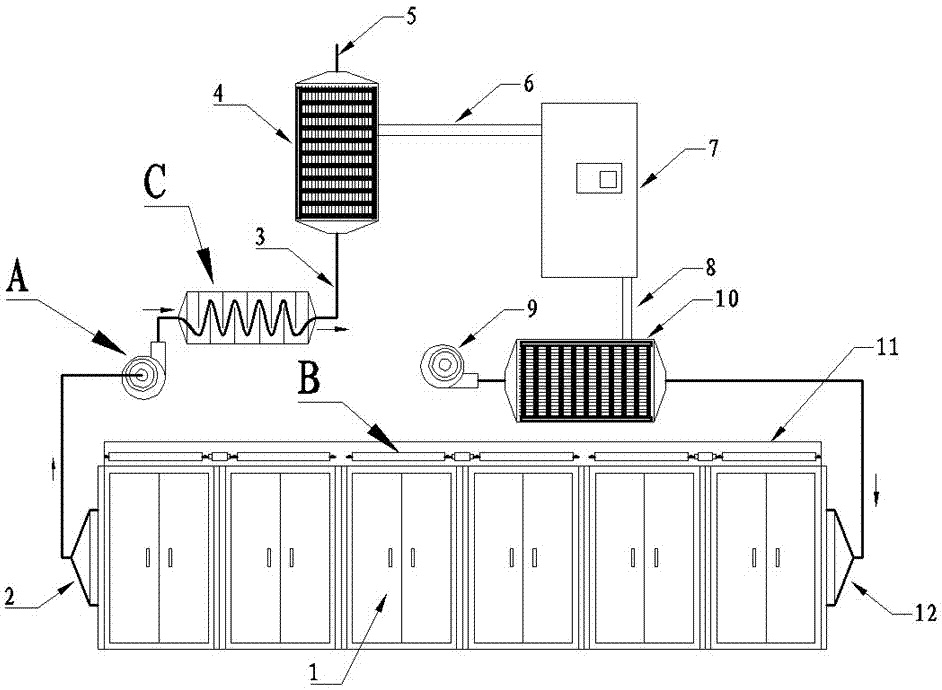

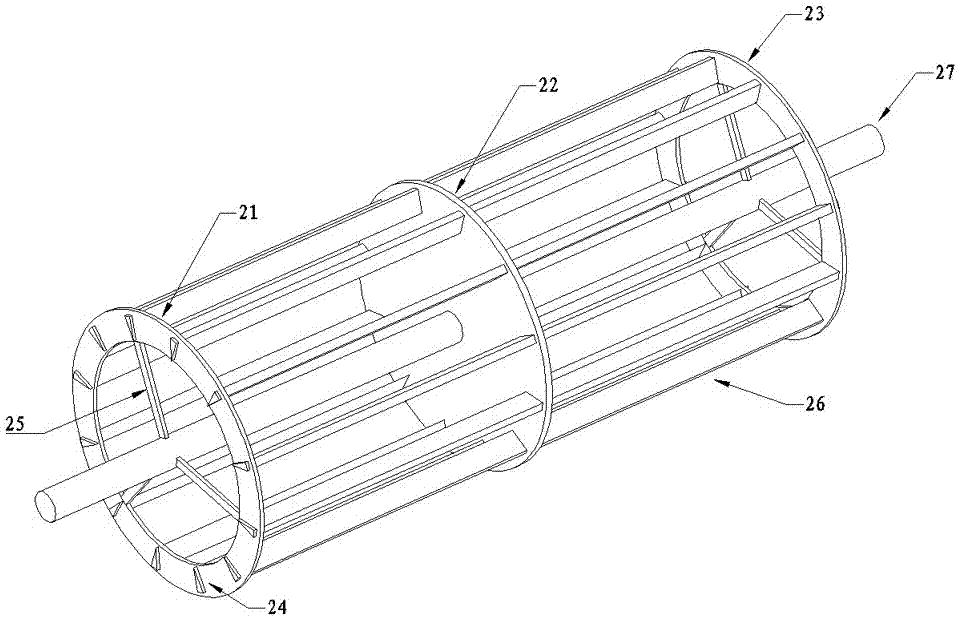

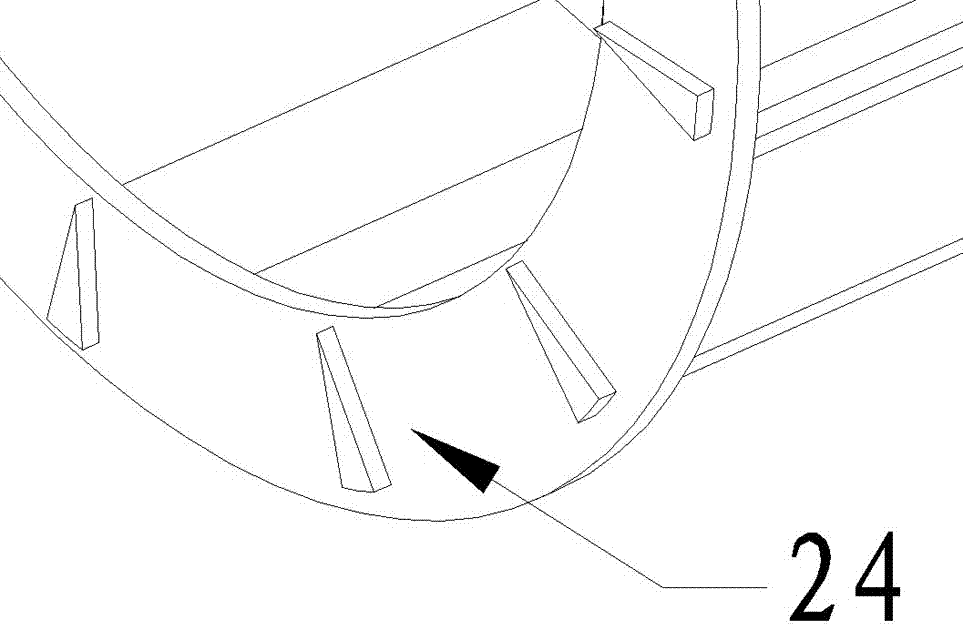

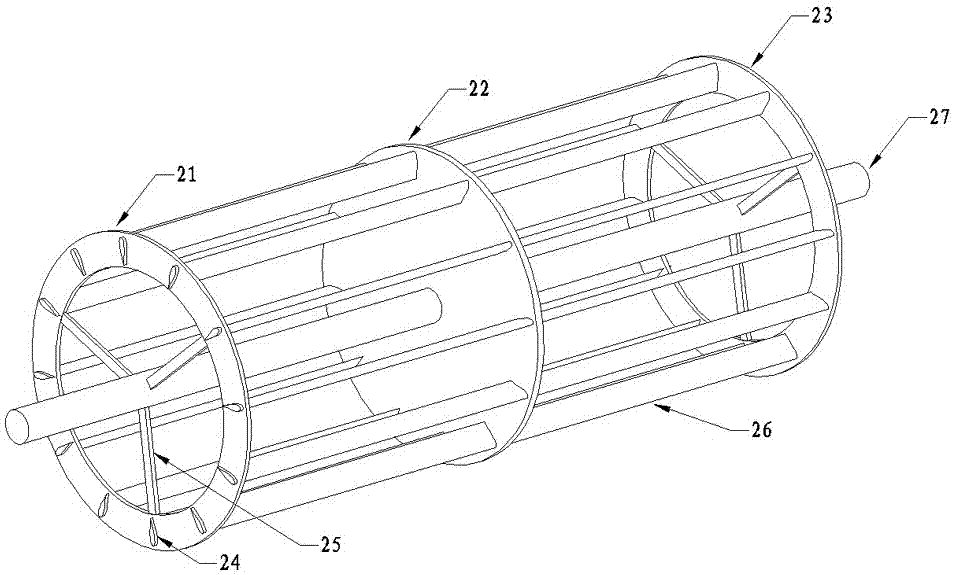

Cyclone dust removal heat pump type tunnel drying device

ActiveCN105066629AHigh wind resistance bendingHigh strengthDrying gas arrangementsDrying machines with progressive movementsImpellerCyclone

The invention discloses a cyclone dust removal heat pump type tunnel drying device. A trolley is arranged on a track path of a tunnel, an internal recycling long-shaft fan is arranged in the tunnel, the long-shaft fan comprises a long shaft and blades which are all shaped like a long stripe, and the cross section of each blade is a shaped like a hollow reversed water drop symmetrical to the radial direction and the center of an impeller shaft; the two ends of each blade are inserted into end plates respectively, and the long shaft is connected and fixed with the end plates through spokes; the two ends of the closed type tunnel are provided with an air draft hood and an air intake hood respectively, the air draft hood is connected with a draft fan, and the draft fan is connected with an evaporator through a cyclone dust collector for emptying; the evaporator of a heat pump system is connected with a main machine which is connected with a condenser; an air outlet end of an air blower is connected into an air hood through the condenser; the draft fan and the long-shaft fan impellers are both designed to be of a hollow symmetrical structure, dirt retention does not exist, and lightness, firmness and durability are achieved. According to the cyclone dust removal heat pump type tunnel drying device, heat pump cross flow drying and tail heat recovery are suitable for being adopted by a low-temperature drying system, destroy to heat sensitive components can be prevented, and the system can complete drying, dust removing and heat recovery efficiently with low energy.

Owner:倡创(上海)咨询管理事务所

Heating and refrigerating system with ultrahigh efficient ground source heat pump capable of realizing heat recovery

InactiveCN102032708AChange efficiencyImprove work efficiencyRefrigeration safety arrangementHeating and refrigeration combinationsTemperature controlProcess engineering

The invention provides a heating and refrigerating system with an ultrahigh efficient ground source heat pump capable of realizing heat recovery, and relates to a heating, refrigerating and water-heating system used at ultralow temperature. The heating and refrigerating system consists of a compressor, a hot water heat exchanger, a condenser, a throttling device and an evaporator, wherein the compressor is provided with a temperature controller; and the compressor is provided with a set of fluorine output and input joints which are respectively connected with fluorine inlet and outlet joints of the hot water heat exchanger and the evaporator. The heating and refrigerating system has the advantages that the structure is novel, the installation is convenient, the application is wide, the cost is low, and the safety and environmental protection are achieved and the like, thus being a novel heating and refrigerating system with the ultrahigh efficient ground source heat pump capable of realizing heat recovery.

Owner:大连奥华来机电发展有限公司

Baffling dust removal heat pump type drying room

ActiveCN105135832AHigh heating coefficientPromote energy saving and emission reductionHeat recovery systemsPump componentsImpellerAdditive ingredient

The invention discloses a baffling dust removal heat pump type drying room. An inner circulating bifurcated fan is arranged in the drying room, and comprises a long shaft and blades. The blades are in a long strip shape, and the sections of the blades are in the shape of a hollow wedge symmetric about the radial direction and center of an impeller shaft. The two ends of each blade are inserted into end discs, and the long shaft is connected and fixed with the end discs through spokes. A draught hood and an air inlet hood are arranged at the two ends of the drying room respectively, the draught hood is connected with an induced draft fan, and the induced draft fan is connected with an evaporator of a heat pump system through a dust remover and then is evacuated. The evaporator of the heat pump system is connected with a main engine through a refrigerant pipe, and the main engine is connected with a condenser through a refrigerant pipe. The air outlet end of an air blower is connected with the air inlet hood through the condenser. The induced draft fan and the impeller of the bifurcated fan are both designed to be of a hollow symmetric structure, and are free of dust accumulation, light, firm and durable. Heat pump cross flow drying and tail heat recovery are especially suitable for being adopted in a low drying temperature system, the nutritional ingredients of thermosensitive substances can be prevented from being damaged, and efficient drying, dust removal and heat recovery are completed with low energy consumption through the system.

Owner:YANCHENG DEZHENG MACHINERY CO LTD

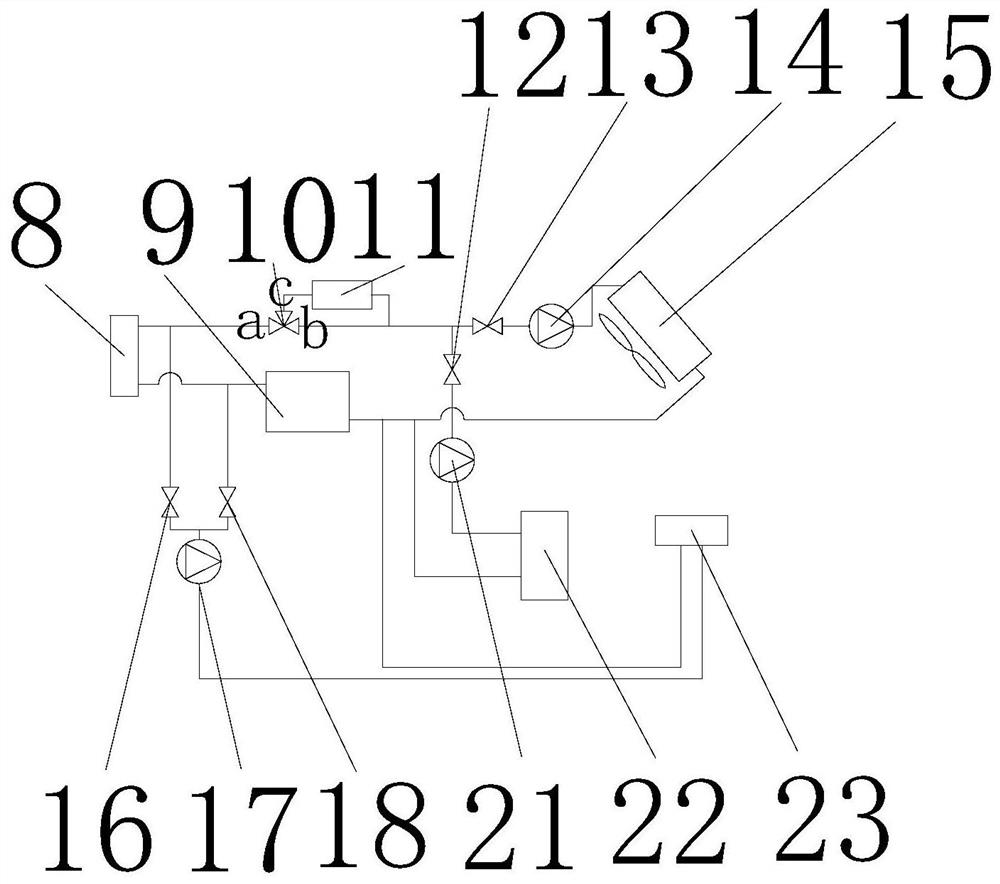

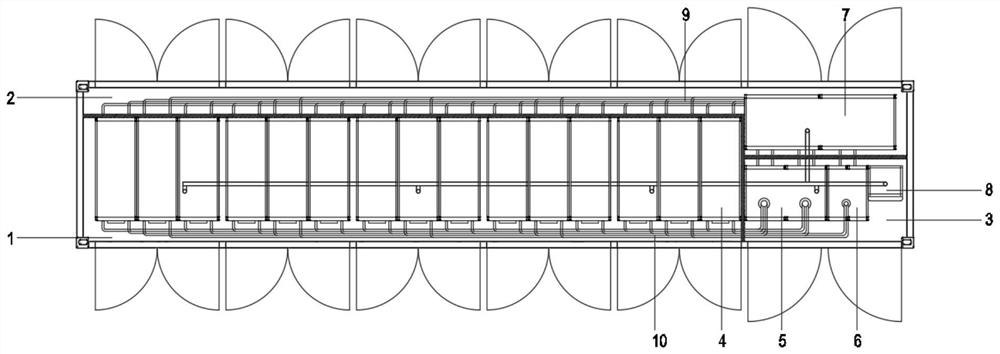

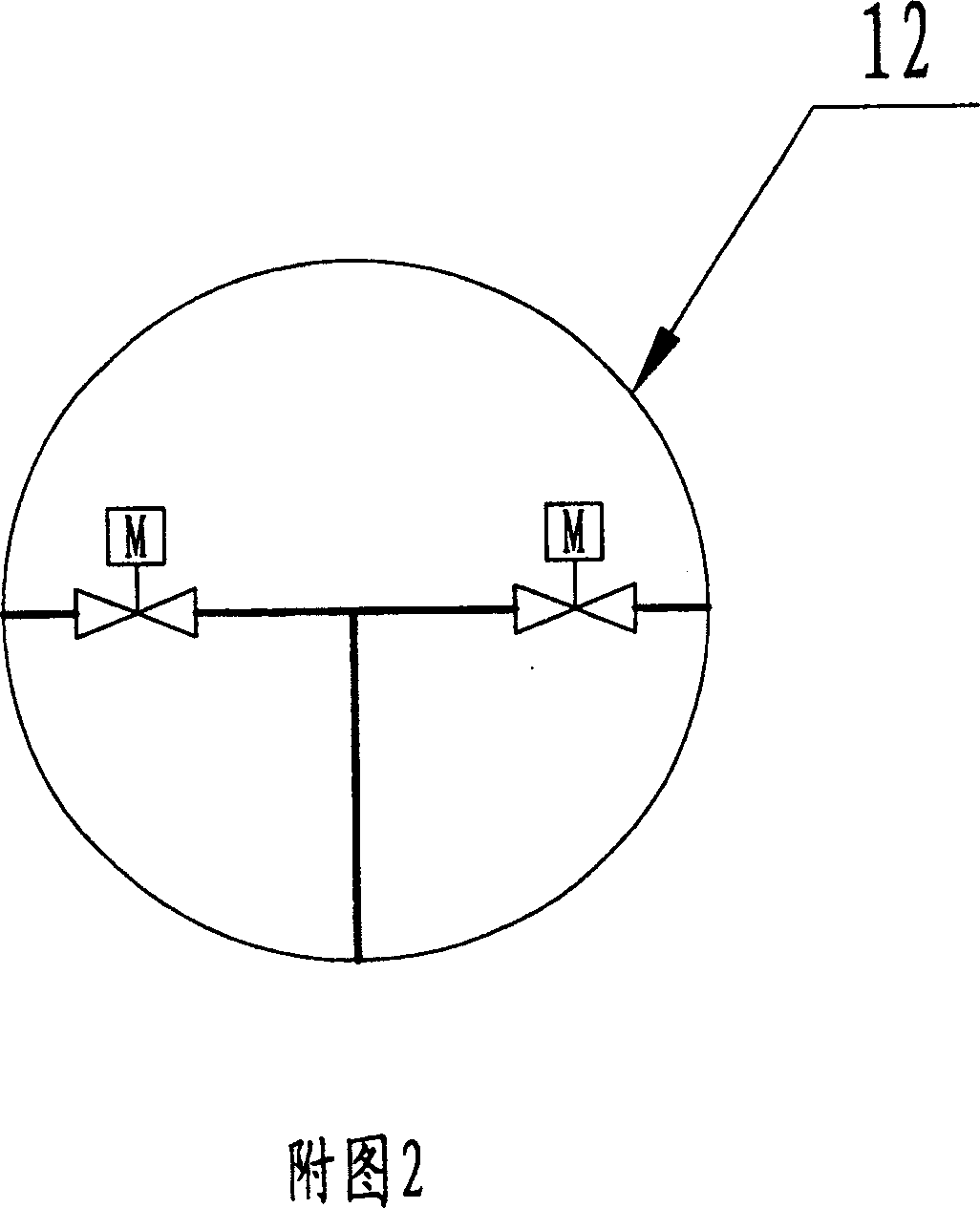

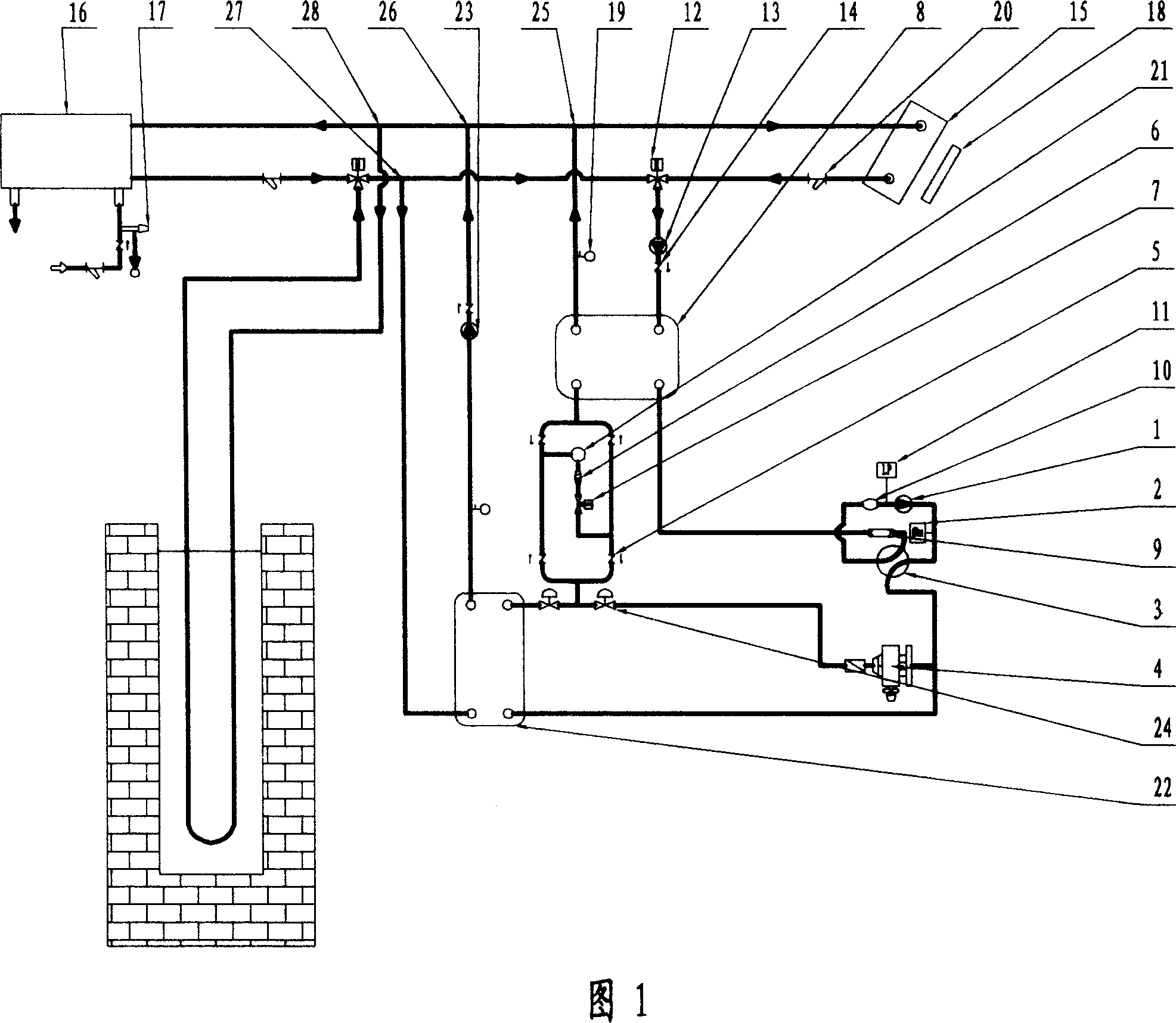

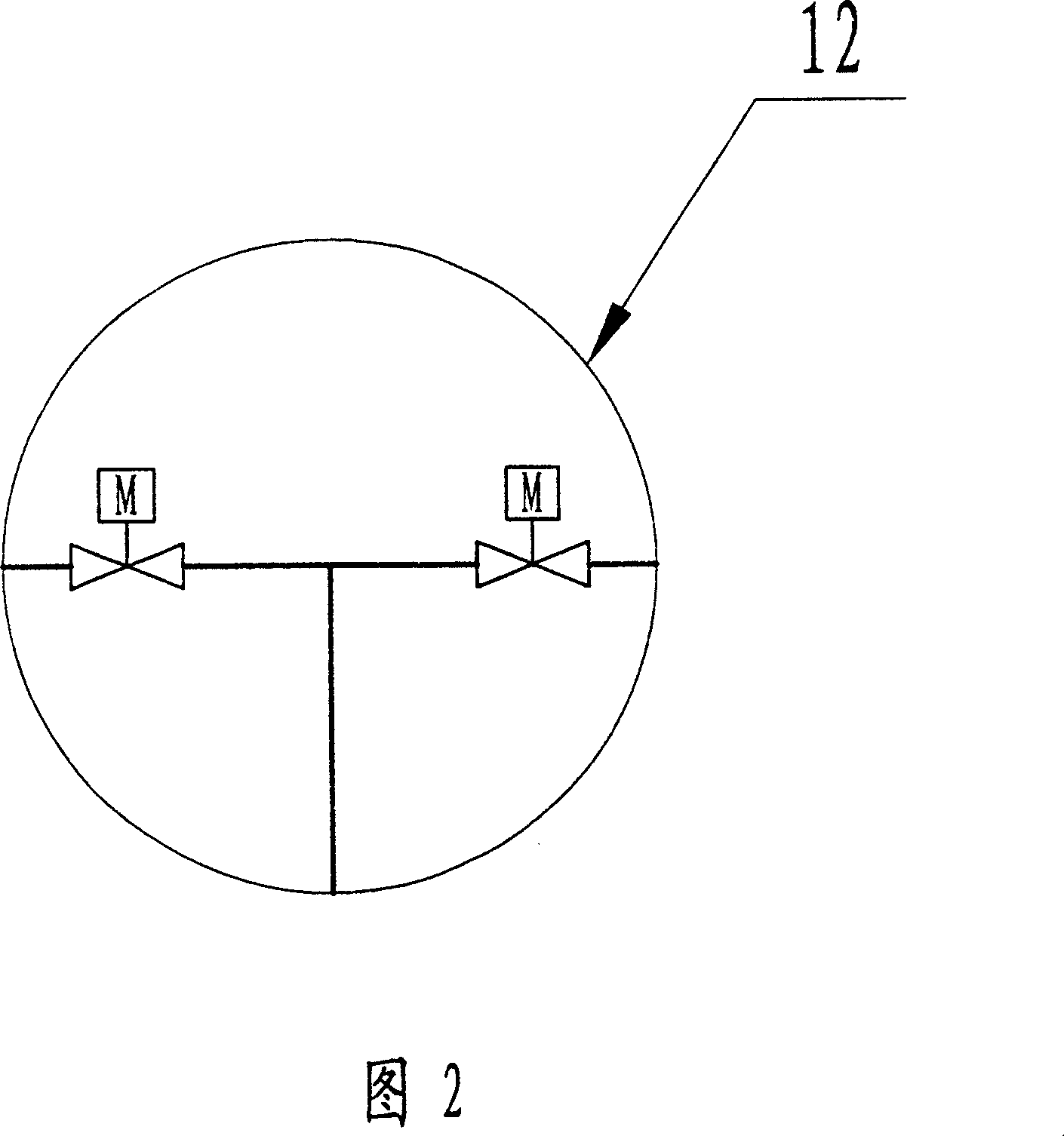

A dual heat source heat pump system suitable for electric vehicles and its operating method

ActiveCN113103841BHigh heating coefficientReduce the temperatureAir-treating devicesVehicle heating/cooling devicesPower batterySolenoid valve

The invention relates to a dual heat source heat pump system suitable for electric vehicles, including a heat pump heating / refrigerating cycle system, a power battery system heating / cooling cycle system, a photovoltaic-power battery charging system and a PVT evaporator heat dissipation system; the heat pump heating / cooling system Refrigeration cycle system, including No. 1 four-way reversing valve, expansion valve, No. 1 air-cooled heat exchanger, No. 1 solenoid valve, No. 1 three-way valve, No. 2 four-way reversing valve, compressor and PVT evaporator; The heating / cooling circulation system of the power battery system includes a No. 1 heat exchanger, a liquid storage tank, a No. 2 three-way valve, an electric heater, a No. 2 solenoid valve, a No. 3 solenoid valve, a No. 1 pump, and a No. 2 air-cooled valve. Heat exchanger, No. 4 solenoid valve, power battery system and motor system. The beneficial effects of the present invention are: the present invention combines the PVT evaporator with the air source heat pump system of the electric vehicle, which can increase the heating coefficient of the heat pump system, reduce power consumption, and improve the battery life of the power battery system in winter.

Owner:ZHEJIANG ZHENENG TECHN RES INST +2

A working mode of a new energy vehicle air conditioning system with fast defrosting and defogging functions

ActiveCN106585323BReduce exhaust temperatureHigh heating coefficientAir-treating devicesVehicle heating/cooling devicesFrostNew energy

The invention discloses a new energy automotive air conditioning system with rapid defrosting and demisting functions. The system is characterized by being mainly composed of an interior heat exchanger side primary temperature rise and heat increase subsystem, a compressor side secondary temperature rise and heat increase subsystem, an exterior heat exchanger side third-stage temperature rise and heat increase subsystem, a power device composite heat recovery subsystem, a decompression expansion mechanism, auxiliary equipment, a connecting pipeline and the like. According to the new energy automotive air conditioning system with the rapid defrosting and demisting functions, provided by the invention, due to a combination of three temperature rise and heat increase subsystems such as the interior heat exchanger side primary temperature rise and heat increase subsystem, the compressor side secondary temperature rise and heat increase subsystem and the compressor side secondary temperature rise and heat increase subsystem, the prominent problems that the exhaust temperature of the compressor is extremely high, the interior heat exchanger has thick frost and defrosting difficulty, the system heat supply capacity and efficiency are low and the system operating reliability is low during heat pump air-conditioning low-temperature operation and the like can be obviously solved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

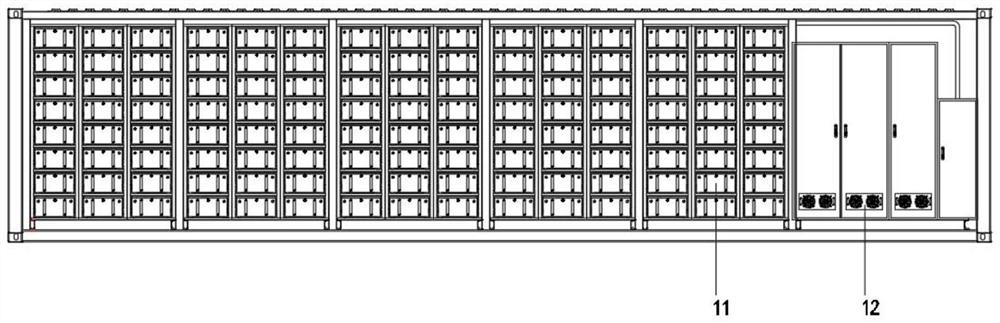

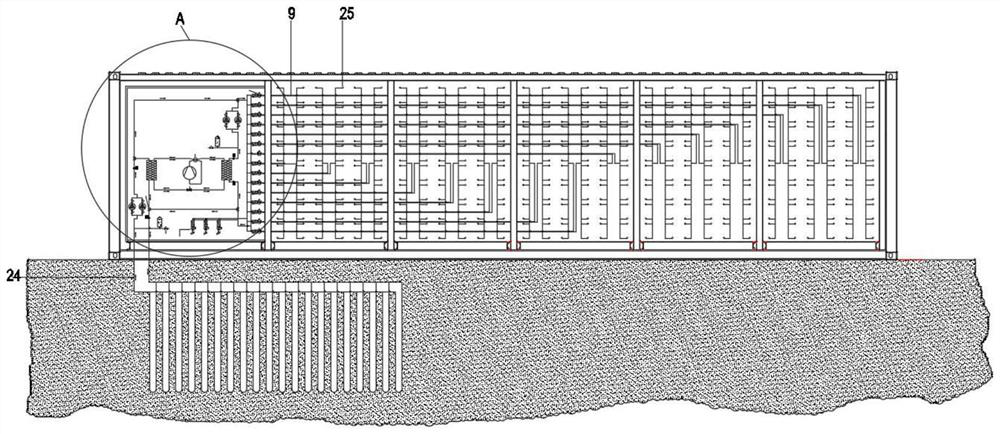

Container energy storage environment management system

ActiveCN114361699AExtend your lifeSmall temperature differenceBattery isolationFire rescueTemperature controlHeat management

The invention relates to the technical field of environment management, and discloses a container energy storage environment management system, which adopts a liquid cooling technology to dissipate heat of battery modules, so that the temperature distribution of each battery module in a container can be balanced; the temperatures of the middle area and the edge area of the single battery module can be balanced; the energy density of the battery module can be high; a ground source heat pump technology is adopted, so that the environmental management energy consumption of energy storage equipment is saved, and the ground source heat energy utilization characteristic of container field deployment is met; a compartment management framework with different functional areas is adopted, and a battery compartment, a temperature control compartment and an equipment compartment are managed in an isolated mode. The power supply cable and the liquid cooling pipeline are arranged in different cabins for wiring and pipe arrangement, the installation and maintenance efficiency is improved, when the liquid cooling pipeline breaks down, normal work of the energy storage equipment is not affected, and the reliability of the equipment is greatly improved through disaster recovery backup; the battery compartment adopts a liquid cooling module to perform thermal management on batteries, and the equipment compartment adopts a fan coil to perform thermal management on equipment.

Owner:HUIZHOU HUIJI SPECIAL EQUIP MFG CO LTD

Energy-saving and environment-friendly mixed refrigerant with temperature application range of -17 to -42 DEG C

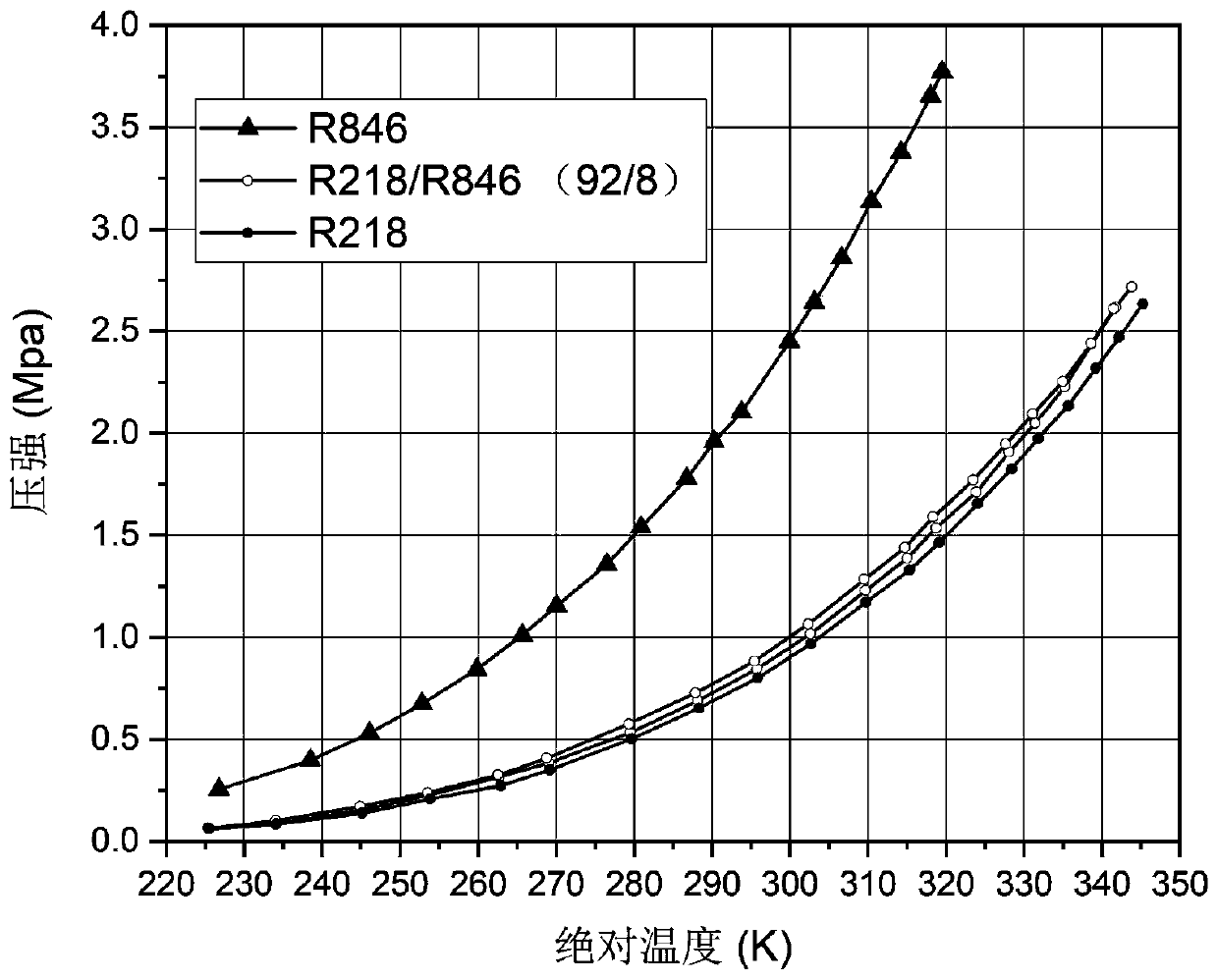

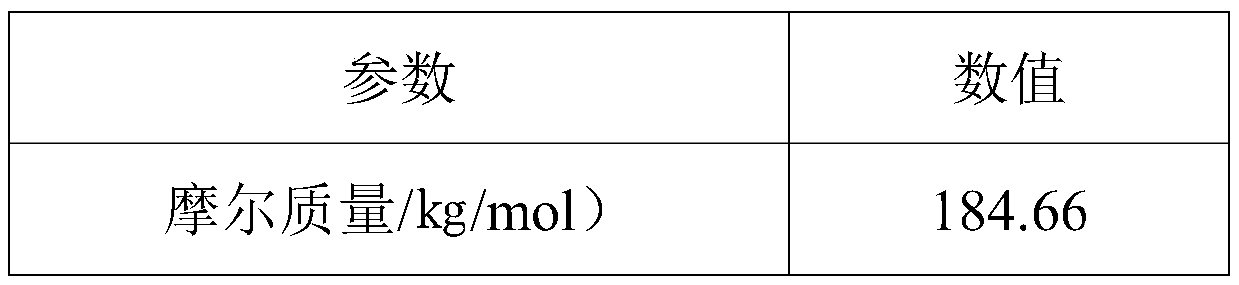

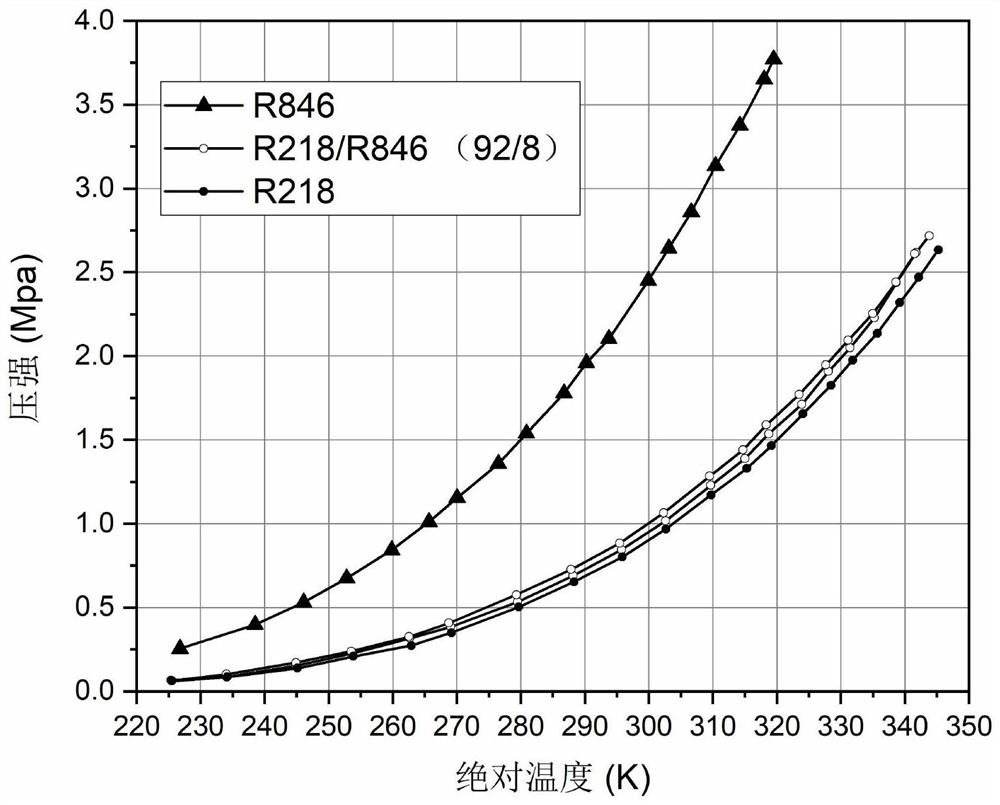

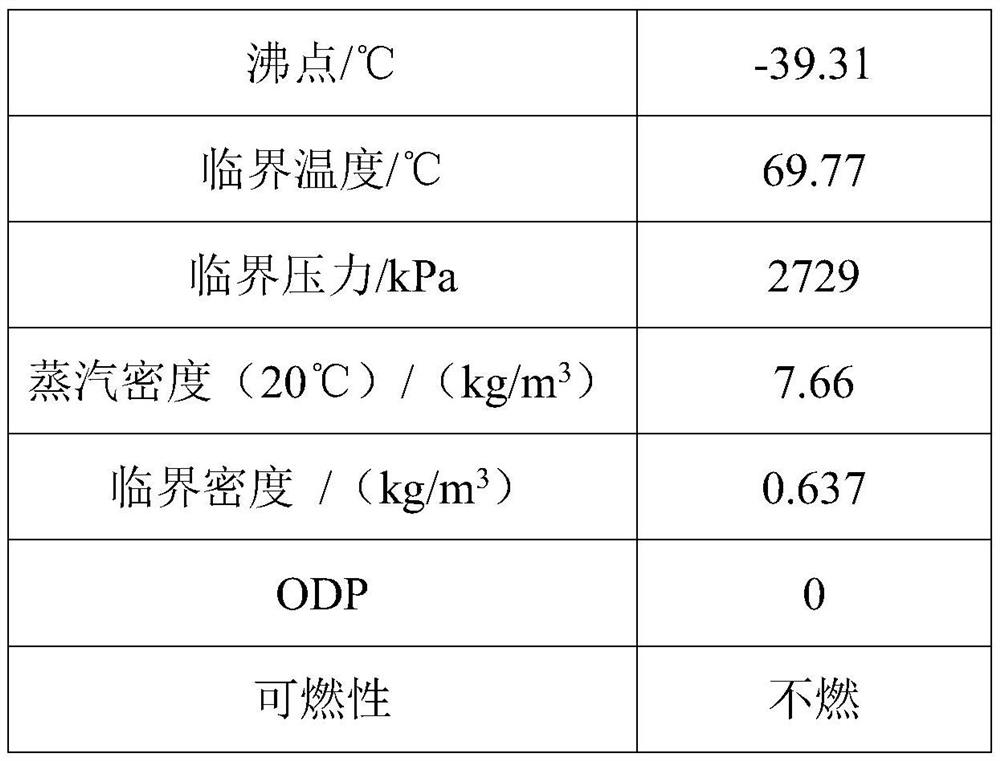

ActiveCN111019610AReduce heat transfer irreversible lossIncrease loopChemical industryHeat-exchange elementsOzone layerEngineering

The invention discloses an energy-saving and environment-friendly mixed refrigerant with a temperature application range of -17 to -42 DEG C. The mixed refrigerant is formed by mixing 91.83 wt% of R218 and 8.17 wt% of R846. The mixed refrigerant has the following advantages: (1) when the mixed refrigerant is used for replacing CFC, the heating performance of a system can be remarkably improved, and the structure of existing equipment does not need to be substantially changed; (2) the mixed refrigerant is a non-azeotropic mixed refrigerant, temperature slippage exists in the phase change process, the efficiency of heat pump circulation and refrigeration circulation can be improved, and the mixed refrigerant is very suitable for being applied to a variable-temperature heat source; (3) the R846 is added, so the oil solubility of the R218 can be improved, and the possibility of leakage of the mixed refrigerant in equipment is reduced to a certain extent; (4) the ODP value of the mixed refrigerant is 0, and the mixed refrigerant has no destructive effect on the ozone layer of the atmosphere; and (5) the mixed refrigerant can be widely applied to heat pumps, air conditioners and refrigeration equipment.

Owner:SHIHEZI UNIVERSITY

Hot water supply system and method thereof

InactiveCN101532700BEfficient use ofReasonable useLighting and heating apparatusDomestic hot-water supply systemWater sourceWater diversion

The invention relates to a hot water supply system and a method thereof. The hot water supply system comprises a main water supply pipeline used for providing water sources, a heat transfer subsystem used for conducting heat transfer between hot-source water and heated water and causing the heat quantity of the hot-source water to transfer to the heated water; and the hot-source water and the heated water come from the main water supply pipeline. The hot water supply method comprises the following steps: tap water of the same water source is divided into the hot-source water and the heated water; and heat transfer is carried out. The heat quantity of the hot-source water is transferred to the heated water by a vapor compression heat pump circulating subsystem to increase the temperature of the heated water. The hot water supply system and the method thereof carry out water diversion to the water supply system and heat transfer to the divided water so as to be capable of effectively utilizing the large amount of heat existing in the water supply system, thereby greatly improving the energy efficiency of the hot water supply system, having obvious advantages of cleanness and high efficiency and being beneficial to the reasonable utilization of energy.

Owner:苏庆泉

Double-heat-source heat pump system suitable for electric automobile and operation method thereof

ActiveCN113103841AHigh heating coefficientReduce the temperatureAir-treating devicesVehicle heating/cooling devicesElectric machineryElectric vehicle

The invention relates to a double-heat-source heat pump system suitable for an electric automobile. The double-heat-source heat pump system comprises a heat pump heating / refrigerating circulating system, a power battery system heating / cooling circulating system, a photovoltaic-power battery charging system and a PVT evaporator cooling system. The heat pump heating / refrigerating circulating system comprises a first four-way reversing valve, an expansion valve, a first air cooling heat exchanger, a first electromagnetic valve, a first three-way valve, a second four-way reversing valve, a compressor and a PVT evaporator. The power battery system heating / cooling circulation system comprises a first heat exchanger, a liquid storage tank, a second three-way valve, an electric heater, a second electromagnetic valve, a third electromagnetic valve, a first pump, a second air cooling heat exchanger, a fourth electromagnetic valve, a power battery system and a motor system. The double-heat-source heat pump system has the beneficial effects that the PVT evaporator is combined with the electric vehicle air source heat pump system, the heating coefficient of the heat pump system can be increased, the power consumption is reduced, and the durability of a power battery system in winter is improved.

Owner:ZHEJIANG ZHENENG TECHN RES INST +2

Baffle dust removal heat pump drying room

ActiveCN105135832BHigh heating coefficientPromote energy saving and emission reductionHeat recovery systemsPump componentsImpellerEngineering

Owner:YANCHENG DEZHENG MACHINERY CO LTD

A direct-fired heat pump process and equipment for produced water in strong corrosion and high salinity oilfields

InactiveCN104075481BAvoid corrosionReduce foulingFluid heatersMechanical apparatusWater vaporLithium bromide

The invention relates to a direct-fired heat pump process and equipment for produced water in strong corrosion and high salinity oilfields. The process first sends the oilfield produced water from the sewage tank to the tube side of the produced water low-pressure heat exchange evaporator, and the produced water low-pressure heat exchange evaporator shell side has low-pressure clean water, which enters the low-pressure absorber shell side after absorbing heat and vaporized, and is concentrated After the lithium bromide solution is absorbed, it becomes a dilute lithium bromide solution and releases heat. The dilute lithium bromide solution is boosted by an anti-corrosion water pump and then sent to the direct-fired generator to be heated to boiling. The vaporized atmospheric pressure water vapor is sent to the shell side of the atmospheric pressure condenser through the pipeline. The present invention extracts part of the heat energy from the oilfield produced water, and uses it for production or daily life after the direct-fired heat pump drives the temperature up, not only can the low-grade heat energy of the oilfield produced water be efficiently utilized, but also the thermal efficiency of the system is about 1.85, which is about the same as that of a common heating furnace. Compared with the existing technology, the heating coefficient has been improved three times, two processes and water pumps have been omitted, and the corrosion and scaling problems of oilfield produced water have been solved.

Owner:周立超 +3

Static thermal-storage heating-amount slow-release structure and construction process and use thereof

InactiveCN1229595CLower heating costsAvoid discomfortLighting and heating apparatusElectric heating systemThermal energyControl manner

Owner:孙侠

Heat pump circulating system and method thereof

InactiveCN101532744BLower working temperatureGood synergyHeat pumpsCompression machines with reversible cycleFour-way valveEngineering

The invention relates to a heat pump circulating system and a method thereof. The heat pump circulating system comprises a compressor, an internal heat exchanger, a throttling valve, an external heat exchanger and a four-way valve. The four-way valve is respectively connected with the refrigeration working medium entrance of the compressor, the refrigeration working medium exit of the compressor,the internal heat exchanger and the external heat exchanger; the four-way valve is provided with a first valve position and a second valve position; when the four-way valve is positioned at the firstvalve position, the refrigeration working medium exit of the compressor is connected with the external heat exchanger and the refrigeration working medium entrance thereof is connected with the internal heat exchanger; and when the four-way valve of the compressor is positioned at the second valve position, the refrigeration working medium exit of the compressor is connected with the internal heat exchanger and the refrigeration working medium entrance thereof is connected with the external heat exchanger which is internally filled with a heat storage agent. The heat pump circulating system and the method thereof adopt water, especially tap water, as a heat source with low cost and high heat exchange efficiency so as to be capable of improving the circulating heat efficiency of the heat pump.

Owner:苏庆泉

An apparatus for heating, air-conditioning and hot-water generation

InactiveCN1323262CImprove reliabilityPurchasing cost simplificationHot-air central heatingLighting and heating apparatusExpansion tankInlet pressure

The invention discloses a heating / air condition / hot water machine, which can simple the cost 40%. The invention couple heating, air condition, hot water system totally, uses air condition heat pump and its circulating pump and heat exchanger produces hot water by little difference in temperature and direct heat changing method; electronic expanding valve changing flux regulation make producing heat attenuation rate at -7 deg.C be improved from 62% to 75%; decreases heating, hot water circulation temperature upper limit, to achieve heat pump producing heat under -7deg.C; uses the water inlet and accordant junction triple valve to achieve water inlet and level pressure behind pump, in order to save pressure reducing valve, flux switch, expansion tank, and make the highest pressure point be less then water inlet pressure, and improve the reliability of the system.

Owner:大连冰山集团有限公司

An apparatus for heating, air-conditioning and hot-water generation

InactiveCN100348906CLess investmentEasy to controlLighting and heating apparatusEnergy efficient heating/coolingExpansion tankUltrasound attenuation

The invention discloses a The invention discloses a heating / air condition / hot water machine, which can simple the cost 40%. It has five optimizing functions including refrigeration / heat pump-air condition + hot water circulation, gas-water hot pump hot water circulation, gas-water hot pump heating circulation, the second grade heat pump heating / hot water circulation, water-water hot pump heating circulation, it produces hot water by little difference in temperature and direct heat changing method; electronic expanding valve changing flux regulation make producing heat attenuation rate at -7 deg.C be improved from 62% to 75%; decreases heating, hot water circulation temperature upper limit, to achieve heat pump producing heat under -7deg.C; uses the water inlet and accordant junction triple valve to achieve water inlet and level pressure behind pump, in order to save pressure reducing valve, flux switch, expansion tank, and make the highest pressure point be less then water inlet pressure, and improve the reliability of the system.

Owner:大连冰山集团有限公司

Cyclone dust removal heat pump tunnel drying device

ActiveCN105066629BHigh wind resistance bendingHigh strengthDrying gas arrangementsDrying machines with progressive movementsCycloneImpeller

The invention discloses a cyclone dust removal heat pump type tunnel drying device. A trolley is arranged on a track path of a tunnel, an internal recycling long-shaft fan is arranged in the tunnel, the long-shaft fan comprises a long shaft and blades which are all shaped like a long stripe, and the cross section of each blade is a shaped like a hollow reversed water drop symmetrical to the radial direction and the center of an impeller shaft; the two ends of each blade are inserted into end plates respectively, and the long shaft is connected and fixed with the end plates through spokes; the two ends of the closed type tunnel are provided with an air draft hood and an air intake hood respectively, the air draft hood is connected with a draft fan, and the draft fan is connected with an evaporator through a cyclone dust collector for emptying; the evaporator of a heat pump system is connected with a main machine which is connected with a condenser; an air outlet end of an air blower is connected into an air hood through the condenser; the draft fan and the long-shaft fan impellers are both designed to be of a hollow symmetrical structure, dirt retention does not exist, and lightness, firmness and durability are achieved. According to the cyclone dust removal heat pump type tunnel drying device, heat pump cross flow drying and tail heat recovery are suitable for being adopted by a low-temperature drying system, destroy to heat sensitive components can be prevented, and the system can complete drying, dust removing and heat recovery efficiently with low energy.

Owner:倡创(上海)咨询管理事务所

A heat pump tail heat recovery microwave oxygen insulation dryer

ActiveCN104567316BTake it away in timeTake away does not affectDrying gas arrangementsDrying machines with progressive movementsGlass coverEvaporation

The invention discloses a heat pump type waste-heat recovery microwave oxygen-insulation drying machine. A tunnel-shaped glass cover is fixed on a base plate of a conveying belt, an upper plate of the tunnel-shaped glass cover is provided with ventilation screen holes and covered with a glass packing ring, a microwave unit is arranged above the packing ring, materials on the conveying belt is heated by microwaves in the glass cover and reach the conveying belt of an insulation tank body through a slide plate, a cutoff curtain and a blower are arranged at an outlet of the glass cover, and another cutoff curtain is arranged at an inlet of the glass cover. An exhaust pipe is communicated with a microwave unit above the ventilation screen holes, and heat in the exhaust pipe is transferred through a heat pump and then enters a hot air drying system of the insulation tank body. By the heat pump type waste-heat recovery microwave oxygen-insulation drying machine, continuous efficient enzyme deactivation and synchronous oxygen-insulation drying are realized in a non-vacuum condition, and industrialized implementation is facilitated. The heat pump is low in power consumption and high in heating coefficient, waste heat can be completely recovered, and cost and energy consumption are reduced. The packing ring insulates the air and timely evaporation of moisture is guaranteed. Hot-air countercurrent is kept in uniform quality, and the drying machine is particularly suitable for drying agricultural products which are prone to enzyme promoting and high-temperature oxidation browning and is wide in prospect.

Owner:重庆信奇建材机械制造有限公司

Heat pump tail heat recovery microwave oxygen insulation dryer

ActiveCN104596223BLess power consumptionKeep dryFood processingFruits/vegetable preservation by heatingGlass coverSlide plate

The invention discloses a heat pump type tail heat recovery microwave oxygen-isolating drying machine. A glass cover is in a tunnel shape; a microwave unit is arranged on the exterior of the glass cover and is fixed on a base plate under a conveying belt; after the material on the conveying belt is heated by the microwave unit in the tunnel-shaped glass cover, the material reaches the conveying belt of an isolating box through a sliding plate; an isolating curtain and an air blower are arranged at an outlet of the tunnel-shaped glass cover; the isolating curtain and an exhaust pipe are arranged at an inlet of the tunnel-shaped glass cover; the heat in the exhaust pipe is transferred through a heat pump and then enters into a hot air drying system of the isolating box. The continuous high-efficient enzyme deactivation and synchronous oxygen-isolating drying under a non-vacuum condition are realized by the heat pump type tail heat recovery microwave oxygen-isolating drying machine and the industrial implementation is conveniently performed; the power consumption of the heat pump is low, the heating efficiency is high, the complete recovering of the tail heat is realized and the cost and the energy consumption are lowered; the rear-section hot air countercurrent is beneficial to mild drying and maintenance for the uniform quality; the heat pump type tail heat recovery microwave oxygen-isolating drying machine is fit for drying the agricultural products which are easily subjected to enzymatic and high-temperature oxidation browning and is wide in application prospect.

Owner:重庆信奇建材机械制造有限公司

An energy-saving and environment-friendly mixed refrigerant with a temperature application range of -17°C to -42°C

ActiveCN111019610BIncrease power consumptionImprove heat transfer effectChemical industryHeat-exchange elementsOzone layerProcess engineering

The invention discloses an energy-saving and environment-friendly mixed refrigerant with a temperature application range of -17°C to -42°C. The mixed refrigerant is formed by mixing 91.83wt% of R218 and 8.17wt% of R846. The benefits of the present invention are: (1) when the mixed refrigerant is used to replace CFC, not only the heating performance of the system can be significantly improved, but also there is no need to make substantial changes to the structure of existing equipment; (2) the mixed refrigerant It is a non-azeotropic mixed refrigerant, and there is a temperature glide during the phase change process, which is conducive to improving the efficiency of the heat pump cycle and refrigeration cycle, and is very suitable for the application of variable temperature heat sources; (3) After adding R846, the R218 can be increased Oil-soluble, which reduces the possibility of the mixed refrigerant leaking in the equipment to a certain extent; (4) The ODP value of the mixed refrigerant is 0, and has no effect on the ozone layer of the atmosphere; (5) The mixed refrigerant can be used widely Used in heat pumps, air conditioners and refrigeration equipment.

Owner:SHIHEZI UNIVERSITY

Mud drying system and use method thereof

ActiveCN101618930BHigh drying yieldReduce drying energy consumptionSludge treatment by de-watering/drying/thickeningHeat pumpsSludgeWater circulation

The invention relates to a mud drying system and a use method thereof. The mud drying system comprises a transcritical heat pump auxiliary heat supplying loop, a heat pump auxiliary heat supplying loop, an air heating and waste heat recovering loop and a hot water circulation loop; the transcritical heat pump auxiliary heat supplying loop comprises an evaporator, an internal heat exchanger, a compressor, a gas cooler and a throttle valve; the heat pump auxiliary heat supplying loop comprises an evaporator, a wastewater and waste heat recovering evaporator, an internal heat exchanger, a compressor, a condenser, a throttle valve, two stop valves and a wastewater tank; the air heating and waste heat recovering loop comprises a hothouse, an air compressor, a gas discharging and carrying port,a first evaporator, the other evaporator and a condenser; and the hot water circulation loop comprises a pump, a hothouse and the condenser in the heat pump auxiliary heat supplying loop. The invention adopts the hothouses to obtain solar energy to heat mud and utilizes the transcritical heat pump auxiliary heat supplying loop and the heat pump auxiliary heat supplying loop to recover the sensible heat and the latent heat in humid air to heat mud, thereby lowering the energy consumption for drying the mud. The invention can be widely applied to various mud processing fields.

Owner:TSINGHUA UNIV +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com