Double-heat-source heat pump system suitable for electric automobile and operation method thereof

A heat pump system and electric vehicle technology, applied in the field of solar energy utilization, can solve problems such as poor battery life, achieve the effects of improving power generation efficiency, increasing heating coefficient, and reducing HVAC energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

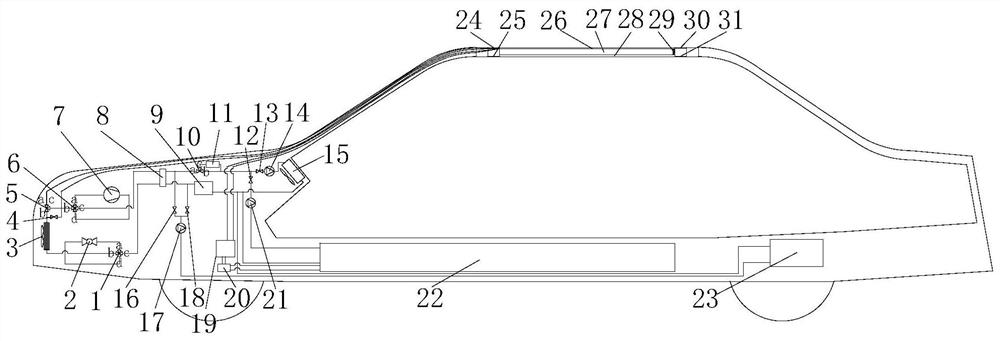

[0045] The double heat source heat pump system suitable for electric vehicles, including heat pump heat / refrigeration cycle systems, powertrain system warming / cooling circulation system, photovoltaic-powered battery charging system and PVT evaporator heat dissipation system.

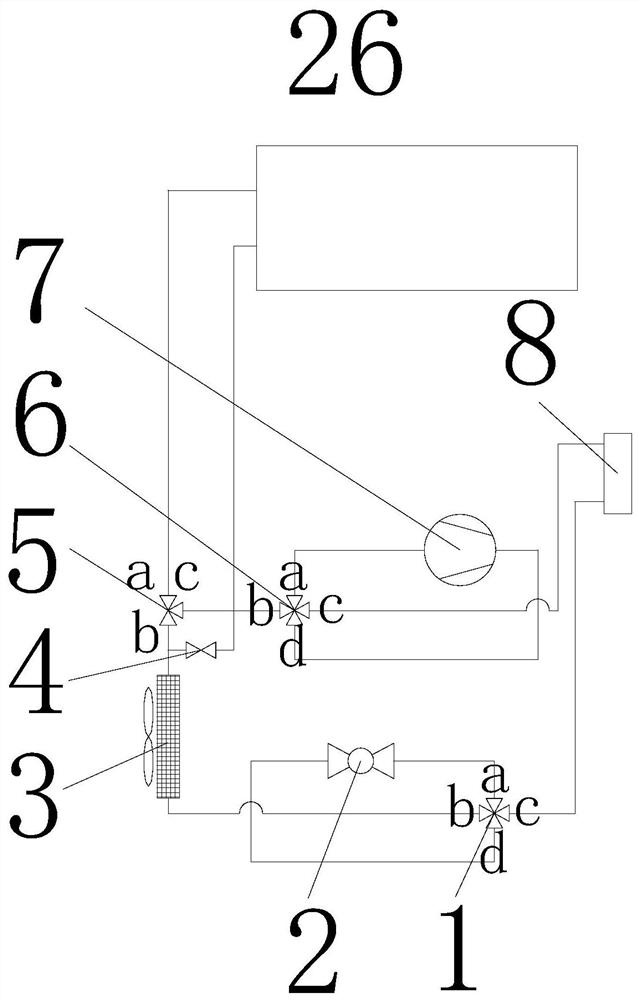

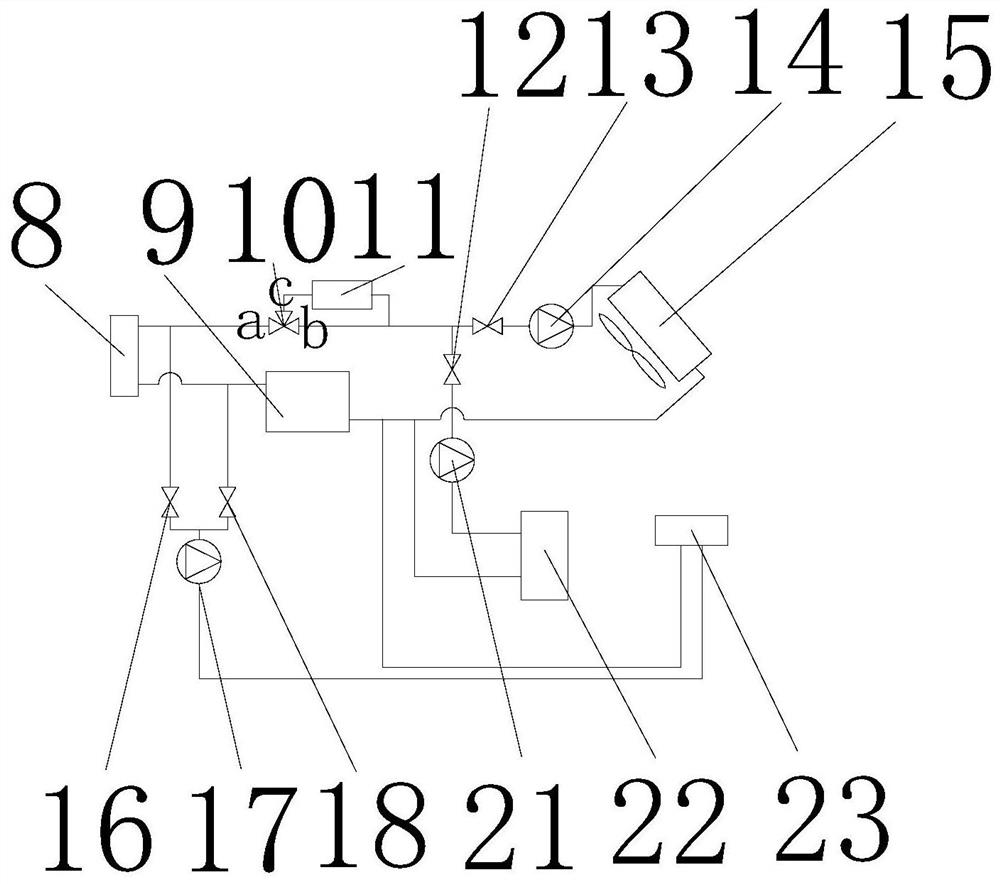

[0046] The heat pump heat / refrigeration circulation system includes a four-way reversing valve 1, an expansion valve 2, a hot-cooling heat-cooling heat exchanger 3, a No. 1 solenoid valve 4, a three-way valve 5, and No. 2 The reversing valve 6, the compressor 7, the first heat exchanger 8, and the PVT evaporator 26. The first ventilation heat exchanger 3 connects the PVT evaporator 26 inlet by one three-way valve 5, and the PVT evaporator 26 is connected to the second four-way commutation valve 6, the second four-way reversing valve 6 is connected to the compressor 7, The second four-way reverse valve 6 is also connected to the first heat exchanger 8, one heat exchanger 8 connected to the four-way reve...

Embodiment 2

[0055] The operation method of the double heat source heat pump system suitable for electric vehicles, including heat pump heat / refrigeration cycles and power battery systems for warming / cooling cycles, the operation methods include:

[0056] When the ambient temperature is low, it is necessary to heat the power battery system 22 to ensure that the battery is working properly, there are three running schemes:

[0057] (1) There is solar irradiation and the heat pump can operate normally. The A end and C-terminal communication, B-terminal and D end connectivity, B-terminal and D-terminal communication; the second four-way reversing valve 6, C-terminal and D-terminal communication; No. 1 solenoid valve 4 Turn off; the A end and B end of the three-way valve 5; the A end and B end of the second three-way valve 10; the No. 2 solenoid valve 12 is opened; the No. 5 solenoid valve is opened; the four solenoid valve 16 shut down.

[0058] Heat pump heat cycle: refrigerant absorbs the h...

Embodiment 3

[0067] The operation method of the double heat source heat pump system suitable for electric vehicles also includes a PVT evaporator heat dissipation system, and its operational methods include:

[0068] The car is under solar radiation, the ambient temperature is high, and the air conditioner in the vehicle is closed. At this time, the second type 25, the third ventilator 15, and the second air cooling heat exchanger 15 and the fan 29 are opened. The air outside the car passes through the No. 2 air-cooling heat transfer, and then sequentially passes through the No. 2 ventilation port 25, the air passage 27, the fan 29, and finally drain the car from the three vents 30, one can give the car Cooling, improving the comfort of the car, two, can cool the PVT evaporator 26 to ensure the safety of the battery while increasing power generation efficiency.

[0069] The car is under solar radiation, the ambient temperature is high, and the air conditioner in the vehicle is in operation. At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com