An energy-saving and environment-friendly mixed refrigerant with a temperature application range of -17°C to -42°C

A mixed refrigerant technology with a wide range of applications. It is applied in the field of heat pumps and refrigeration. It can solve the problems of increased cost of refrigeration equipment, poor environmental protection performance, and waste of resources, and achieve the effects of reducing irreversible losses in heat transfer, improving efficiency, and reducing renovation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

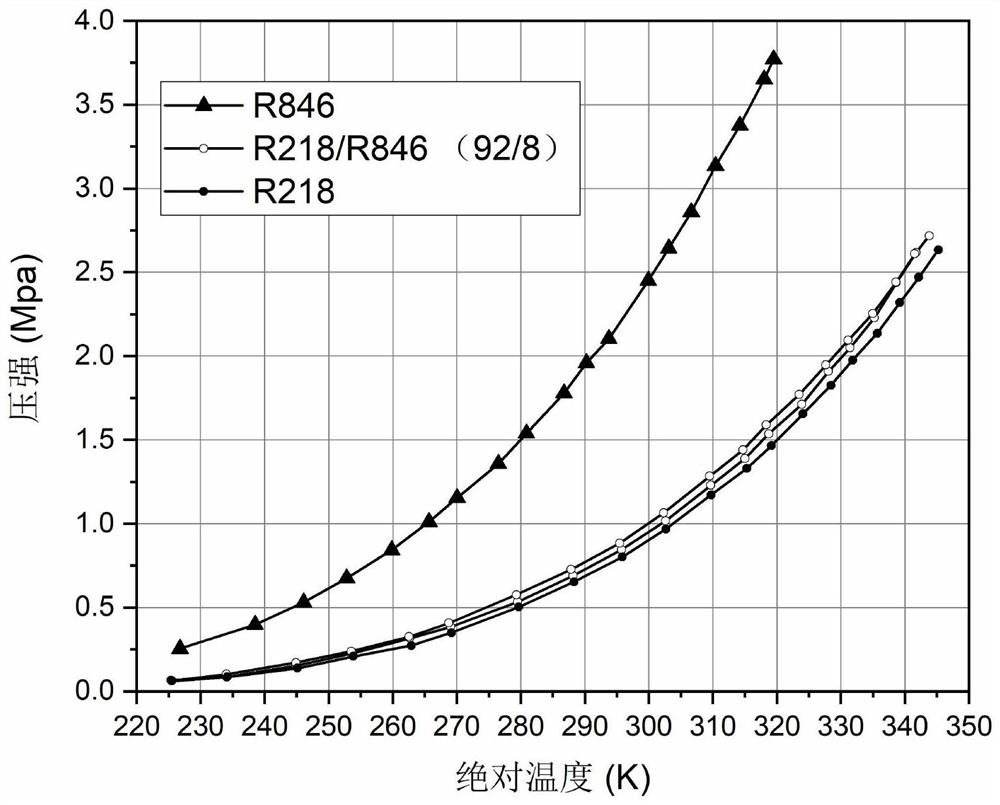

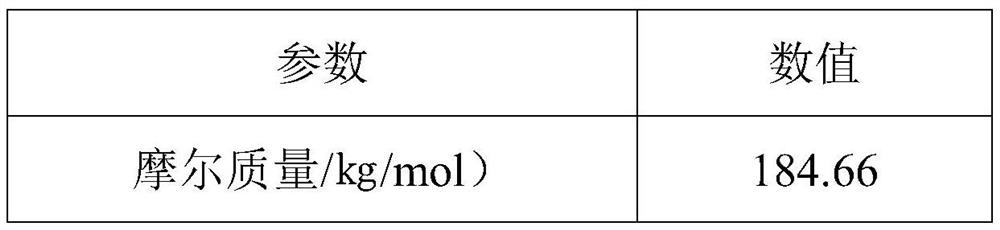

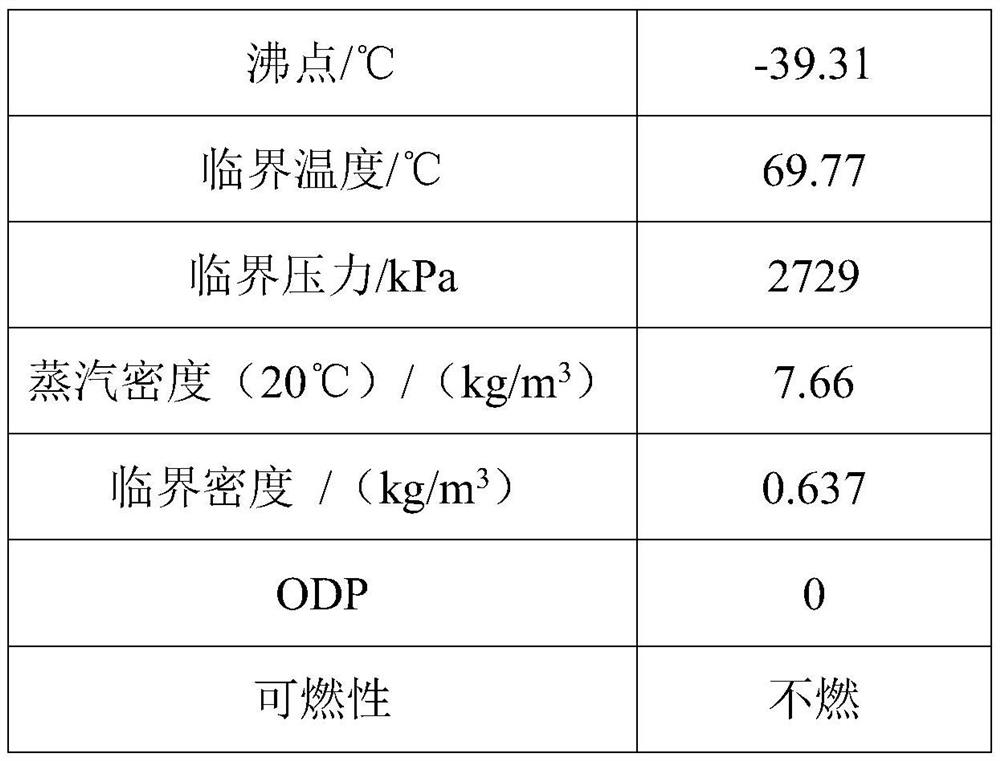

[0024] The mixed refrigerant provided by the invention uses octafluoropropane (R218) and sulfur hexafluoride (R846) as raw materials, both of which have an ODP value of 0. Generally, fluorocarbons are not compatible with lubricating oils, and the amount of oil needs to be strictly adjusted when selecting them as working fluids. After we add R846 to R218, the oil solubility of R218 can be increased, which reduces the mixed refrigerant in the equipment to a certain extent. possibility of leakage.

[0025] In the present invention, the mixing ratio of R218 and R846 is selected by the experimental data analysis method, specifically:

[0026] Weigh R218 and R846, do 36 sets of experiments in the regenerative mixed working fluid throttling heat pump system with different mass ratios, and then combine the experimental data with the refrigerant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com