Hot water supply system and method thereof

A supply system and hot water technology, applied in residential hot water supply systems, heating methods, household heating, etc., can solve the problems of primary energy efficiency grid user-side power generation efficiency constraints, energy efficiency reduction, and rectification, etc., to achieve Conducive to rational utilization, improvement of energy utilization efficiency, and the effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

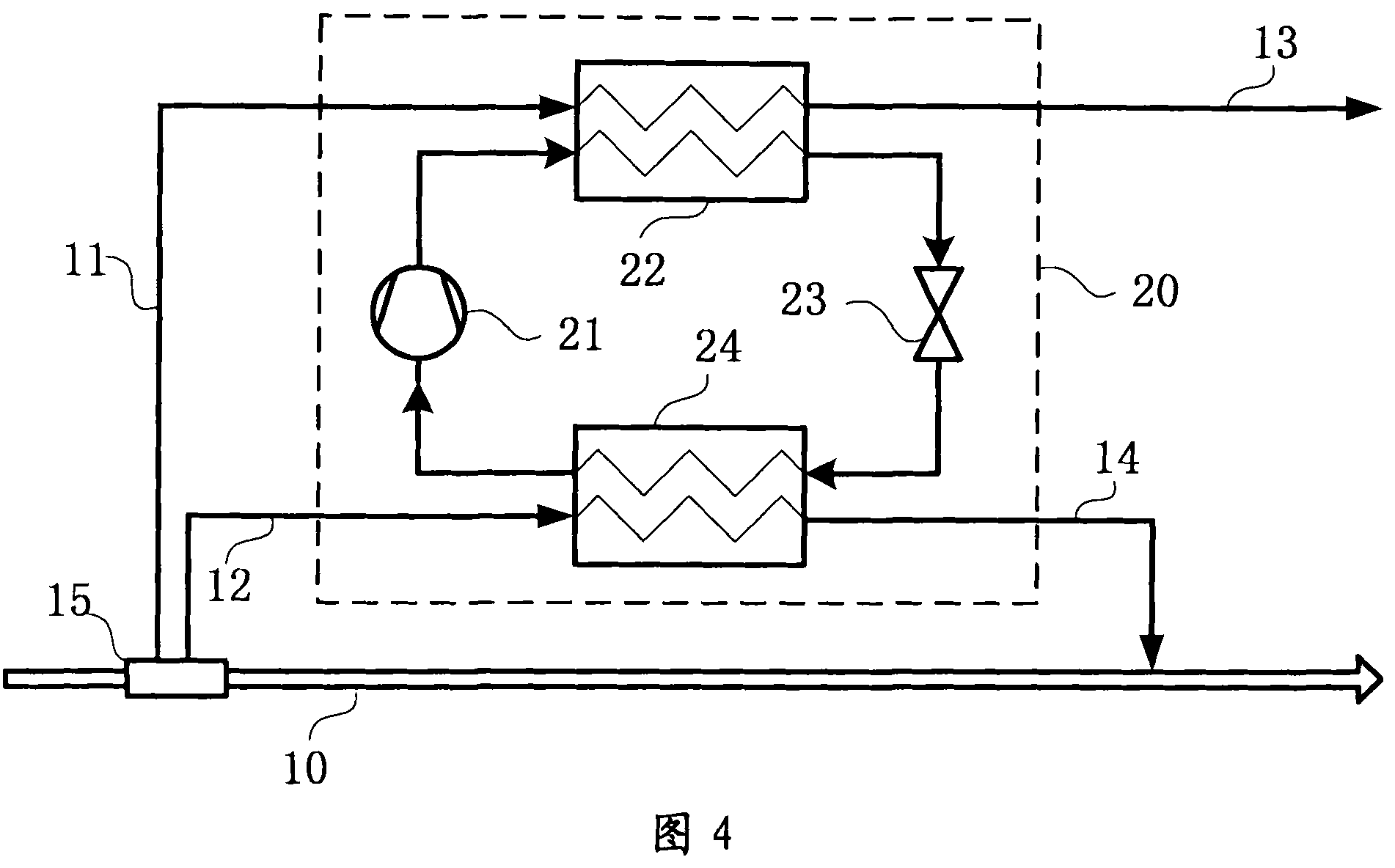

[0076] Using commercial electricity as power, adopt the method of Example 8 to provide hot water, the flow rate ratio of the heat source water and the heated water, that is, the flow rate ratio of the tap water flowing through the evaporator and the condenser respectively is 15. The temperature of the water source water (tap water supplied by the municipality) is 15°C, the temperature of the hot water supplied is 50°C, the evaporation temperature of the refrigerant in the evaporator of the vapor compression heat pump circulation subsystem is 8.2°C, and the outlet temperature of the heat source water is 13.2°C, The condensing temperature of the refrigerant in the condenser is 55°C, the adiabatic efficiency of the compressor is 0.85, the COP of the vapor compression heat pump cycle subsystem in this embodiment is 4.85, and the primary energy efficiency of the overall system is 160%.

example 2

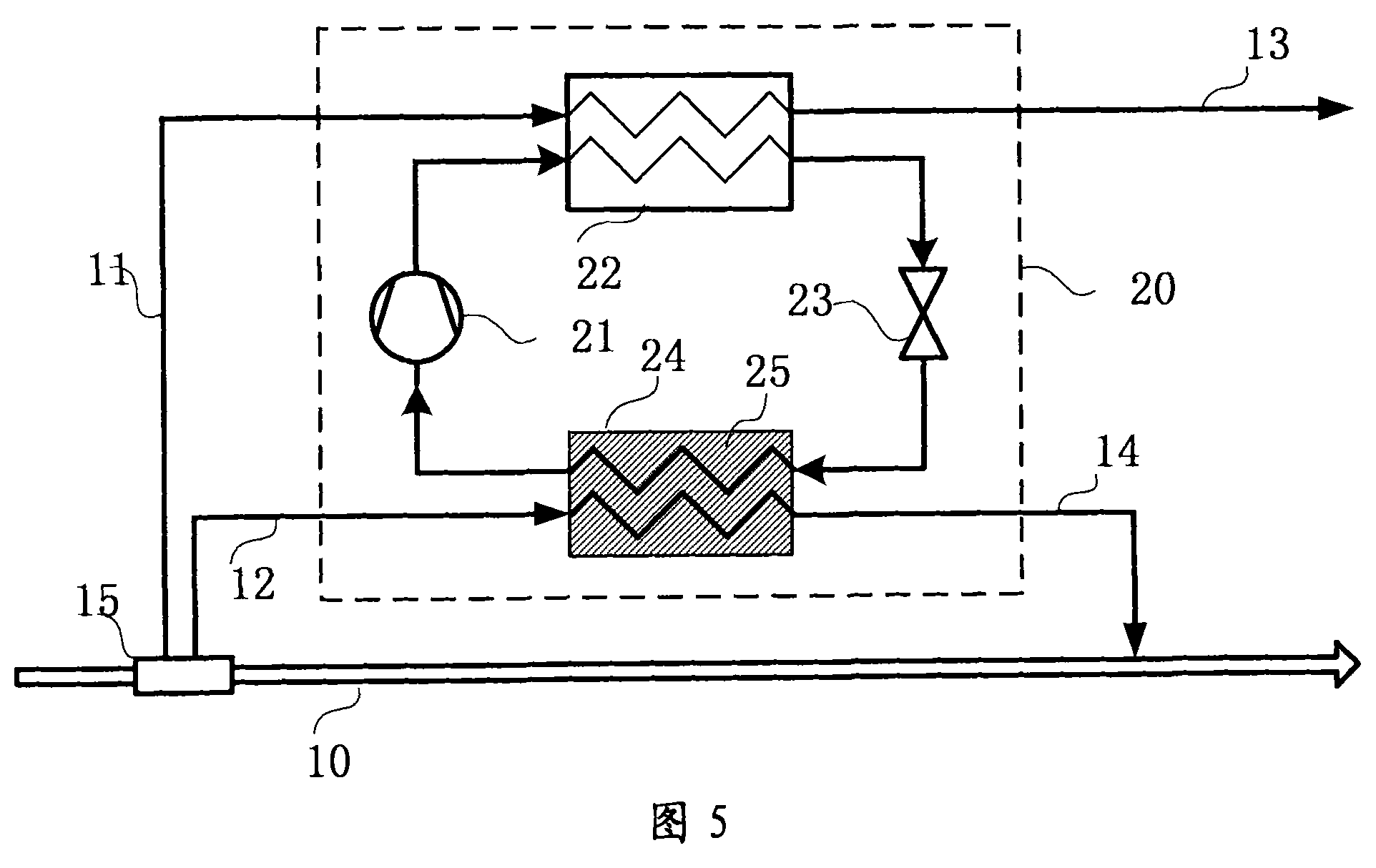

[0078] Adopt the method of embodiment 10 to provide hot water, the flow rate ratio of heat source water and heated water is 15. The evaporator is filled with paraffin wax with a carbon number of 15, and its freezing point and freezing heat are about 10°C and 170kJ / kg respectively. The temperature of the source water (tap water supplied by the municipality) is 15°C, the temperature of the hot water supplied is 50°C, the evaporation temperature of the refrigerant in the evaporator of the heat pump circulation subsystem is 8.4°C, and the outlet temperature of the heat source water is 13.4°C. The condensing temperature of the refrigerant is 49.3°C, and the adiabatic efficiency of the compressor is 0.85. The proton exchange membrane fuel cell power generation sub-system uses natural gas as raw material, its power generation efficiency is 37%, and the heat recovery efficiency is 40%. The COP of the vapor compression heat pump cycle subsystem in this embodiment is 5.60, and the prim...

example 3

[0080] The method in Example 10 is used to provide hot water, and the flow rate ratio of the heat source water to the heated water is 5. The evaporator is filled with paraffin wax with a carbon number of 15, and its freezing point and freezing heat are about 10°C and 170kJ / kg respectively. The temperature of the source water (tap water supplied by municipalities) is 15°C, the temperature of the hot water supplied is 50°C, the evaporation temperature of the refrigerant in the evaporator of the heat pump circulation subsystem is 5.3°C, and the outlet temperature of the heat source water is 10.3°C. The condensing temperature of the refrigerant is 49.0°C, and the adiabatic efficiency of the compressor is 0.85. The proton exchange membrane fuel cell power generation sub-system uses natural gas as raw material, its power generation efficiency is 37%, and the heat recovery efficiency is 40%. The COP of the vapor compression heat pump cycle subsystem in this embodiment is 5.22, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com