A direct-fired heat pump process and equipment for produced water in strong corrosion and high salinity oilfields

A high salinity, produced water technology, used in lighting and heating equipment, mechanical equipment, sorption machines, etc., can solve the problems of no cascade utilization of temperature difference, increased system entropy, strong metal corrosion, etc., to reduce replacement. The effect of thermal temperature difference, improvement of heating coefficient, and high outlet temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

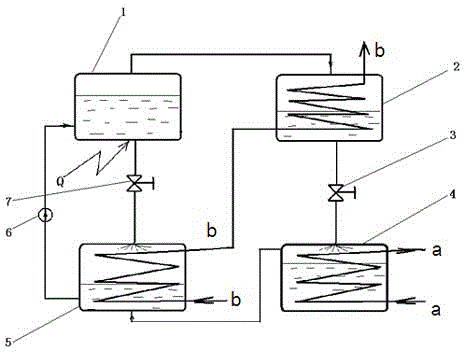

[0023] combined with figure 1 , to further describe the present invention:

[0024] The present invention mentions a direct-fired heat pump process for oilfield produced water with strong corrosion and high salinity, which is implemented through the following processes:

[0025] First, the oilfield produced water a is sent from the sewage tank to the produced water low-pressure heat exchange evaporator 4 tubes, the gauge pressure of the sewage tank is 0.06MPa, and the oilfield produced water releases heat and cools down and enters the produced water discharge pumping station Pipeline: Produced water has low-pressure clean water in the shell side of low-pressure heat exchange evaporator 4. After absorbing heat and vaporizing, it enters the shell side of low-pressure absorber 5. After being absorbed by concentrated lithium bromide solution with a concentration of 60%, it becomes a dilute lithium bromide solution with a concentration of 52%. And release heat, the dilute lithium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com