Patents

Literature

33results about How to "Reduce entropy increase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

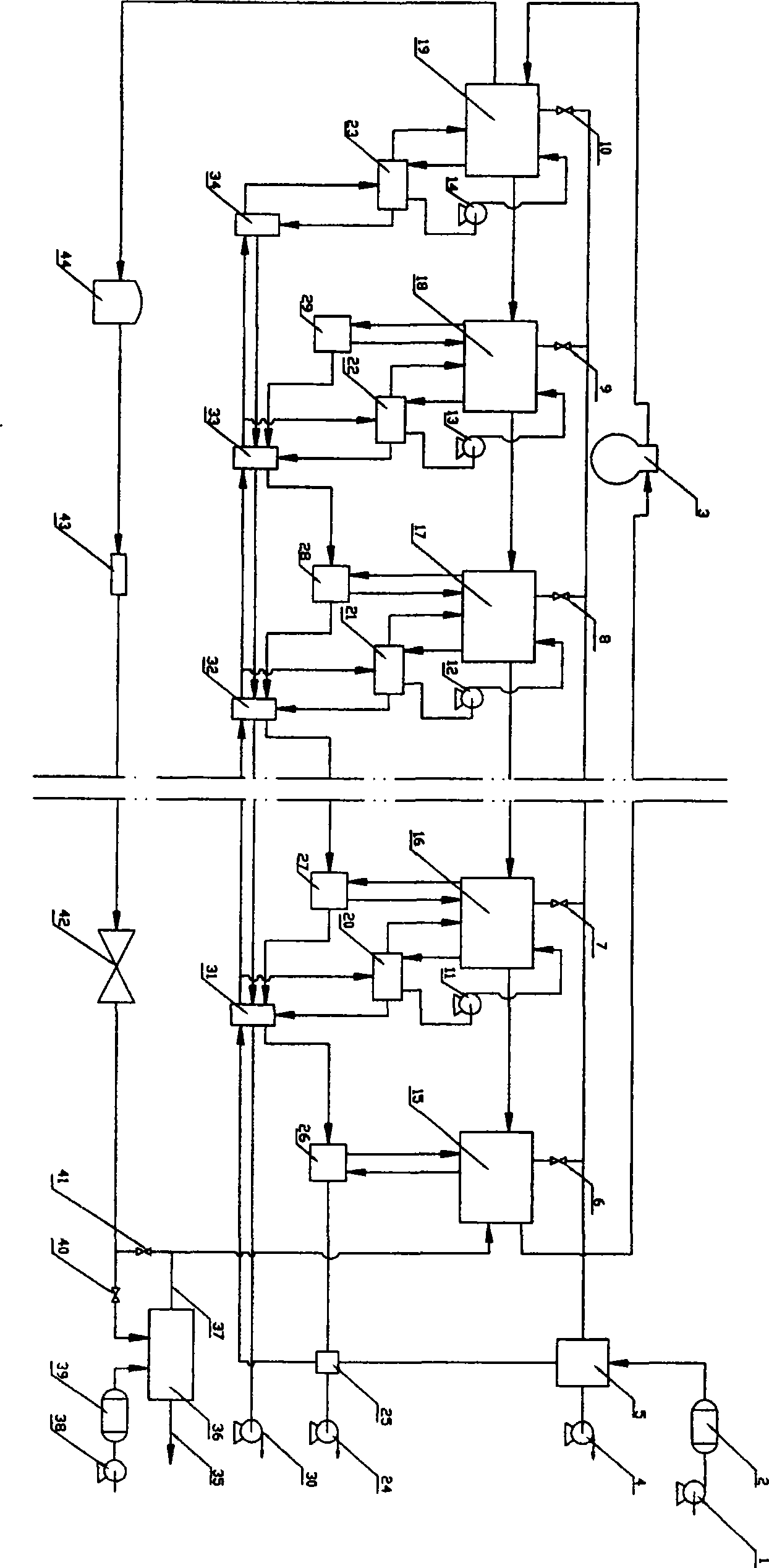

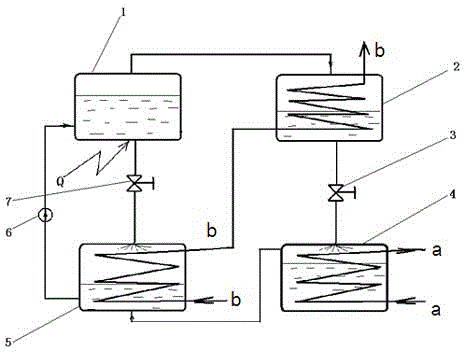

Low-temperature multi-effect seawater desalination process

InactiveCN1837075AEfficient recyclingIncrease temperatureGeneral water supply conservationSeawater treatmentSpecial designEnergy recovery

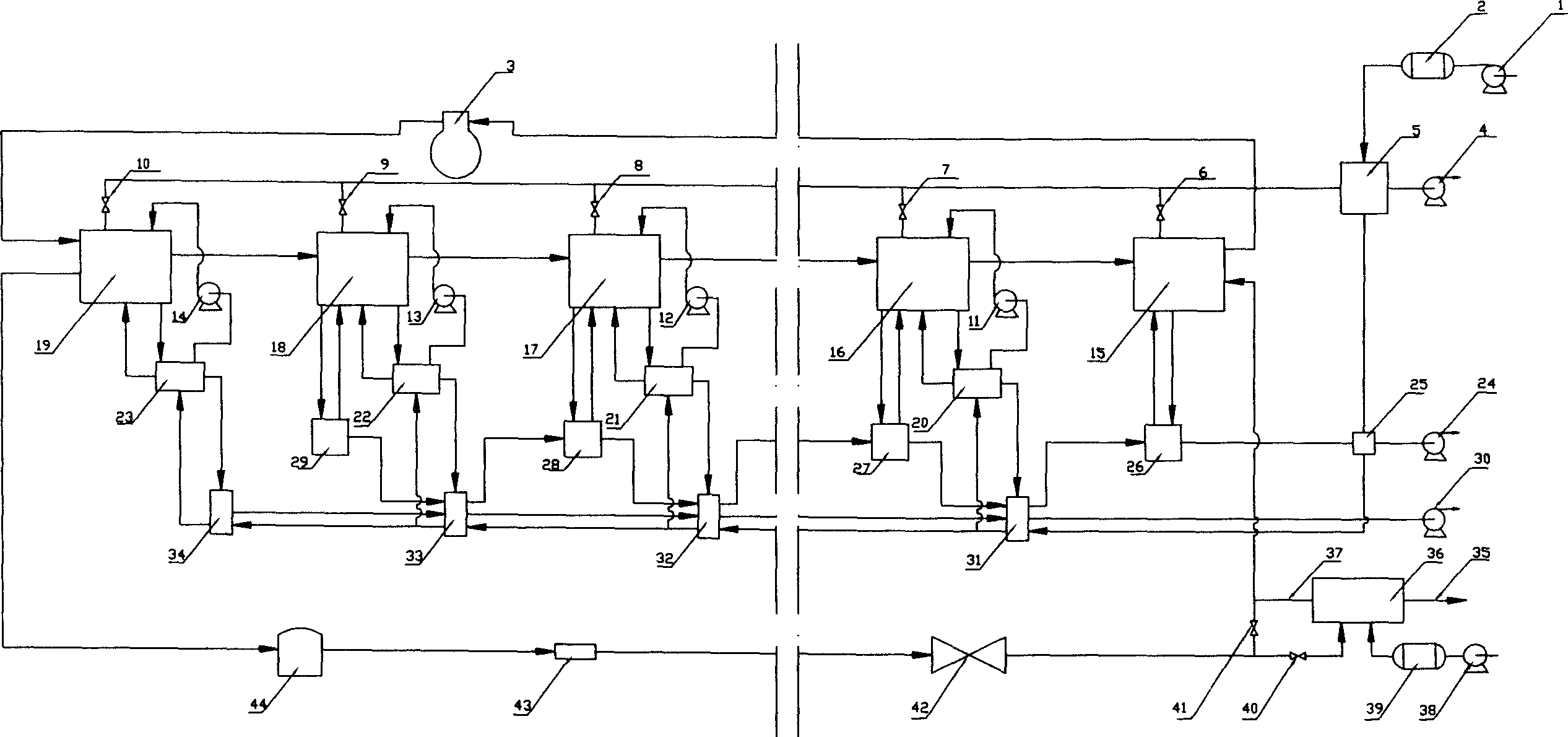

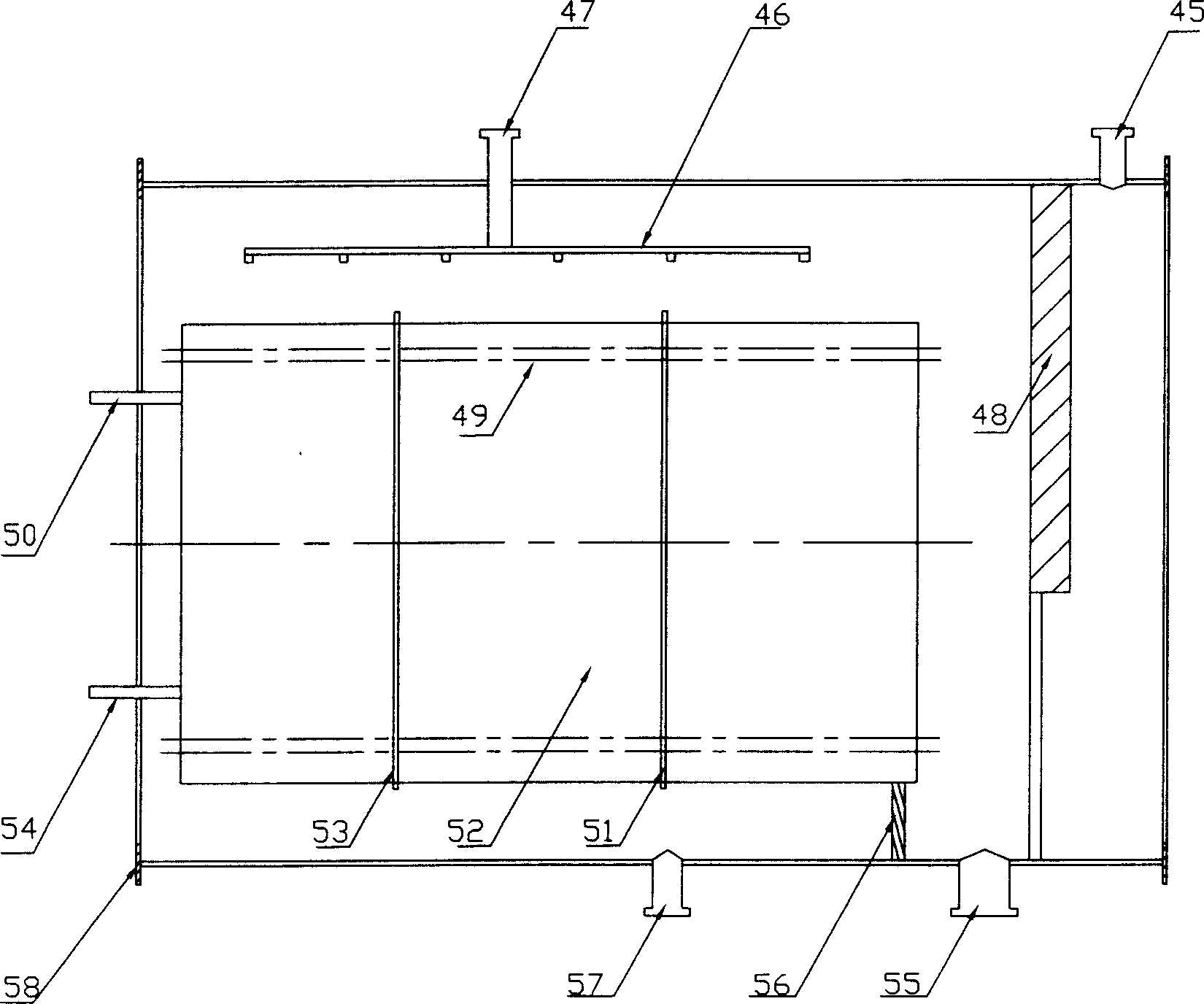

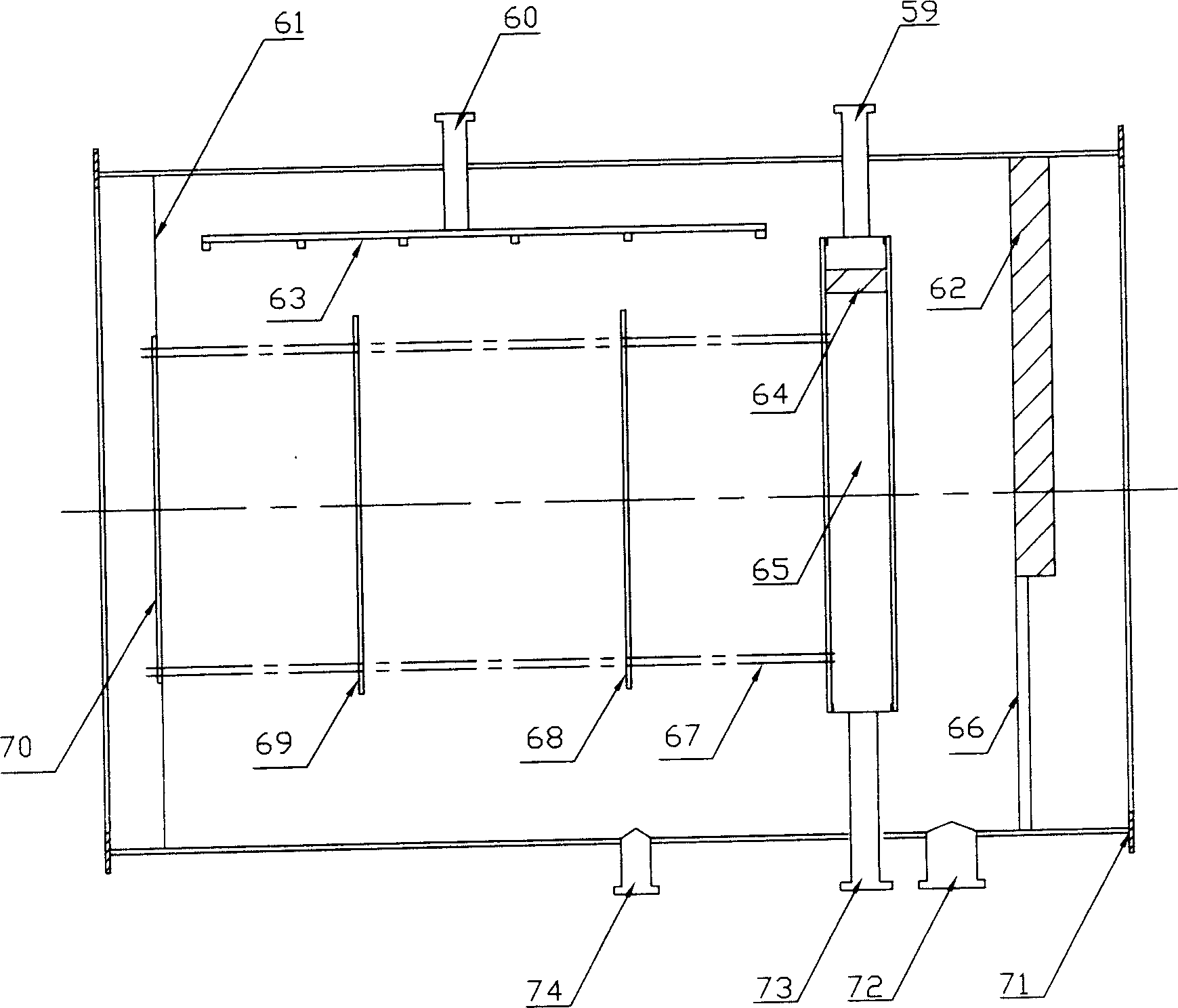

This invention refers to a method about low-temperature multiple-effect desalination of sea water, especially about a new method which effectively applied thermal pumping power-saving technology to desalination of sea water. The desalination of sea water system which apply this method has n effect evaporator(n=2-50) and one condensator aggregately, containing six systems of feeding seawater, recirculated salt water, product water, vacuum, incoagulable gas removal, thermal pumping circulation and starting heating in addition. This invention is based on irreversible thermodynamics principle, via organic integration of evaporator, condensator and low-temperature multiple-effect desalination of sea water system in closed circuit thermal pumping system, as well as special design of energy recovery tache in low-temperature multiple-effect desalination of sea water, decreasing irreversible loss of diversified thermal transmission course which the desalination of sea water refers to in maximum limit, sequentially letting the entropy increasing of whole desalination of sea water course be the least, realizing efficient energy-saving desalination of sea water course.

Owner:QINGDAO UNIV

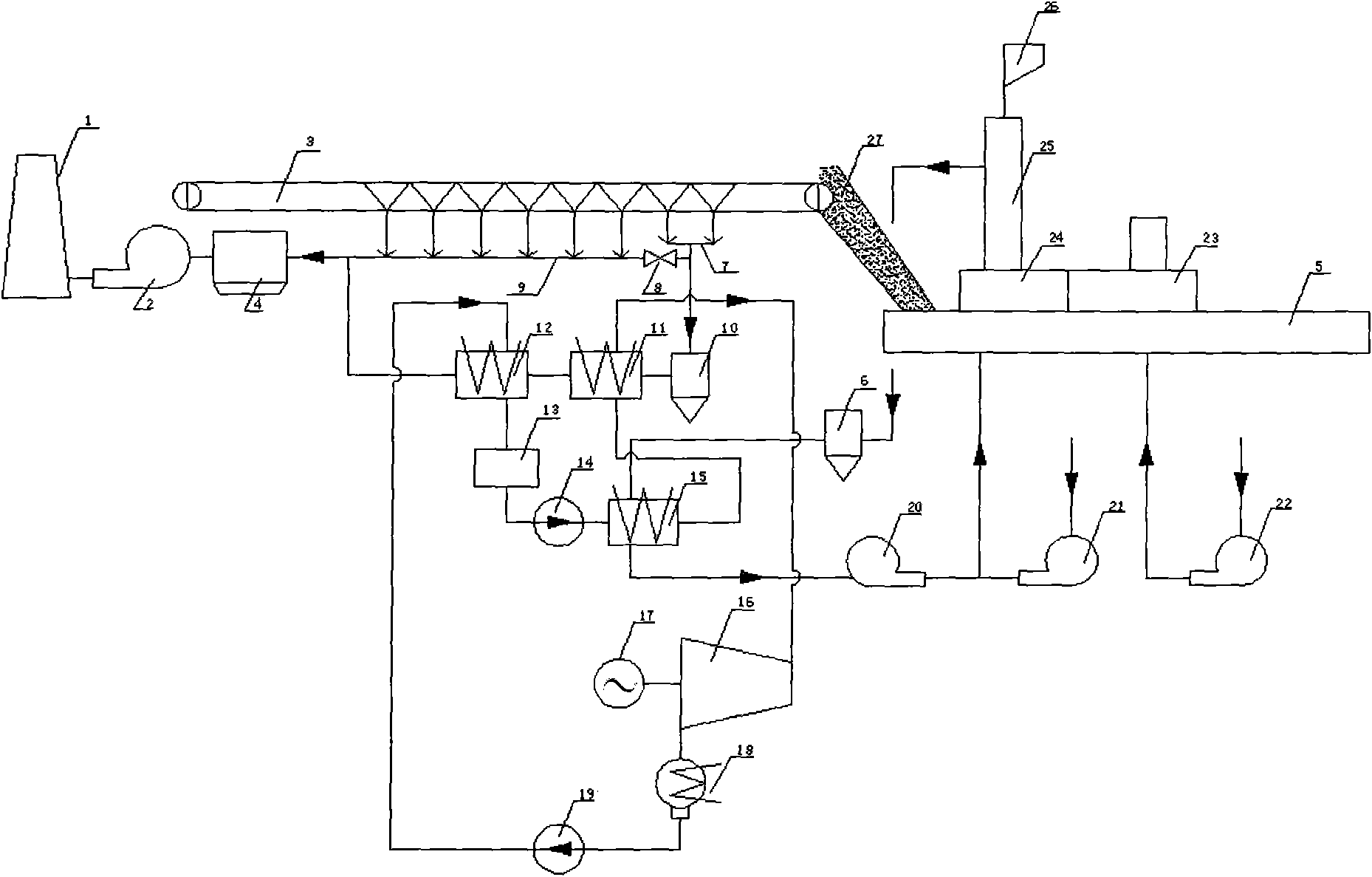

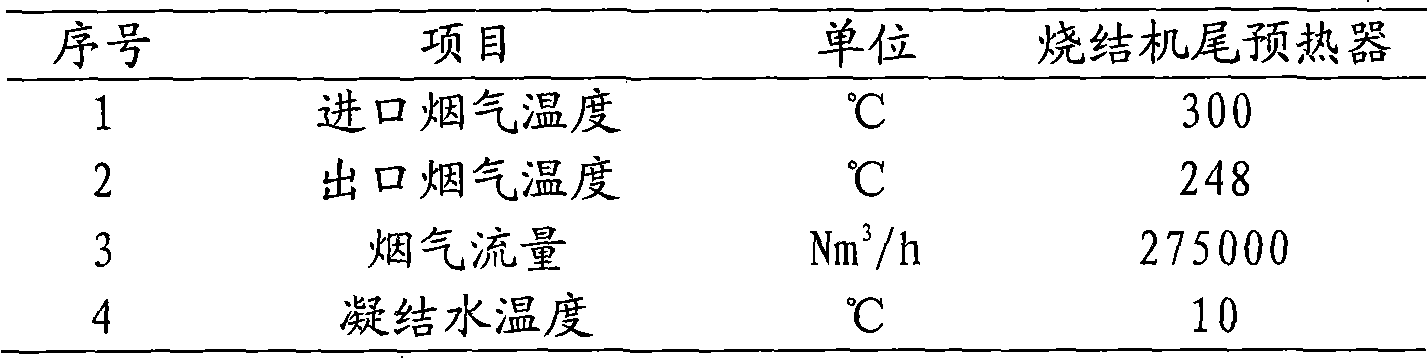

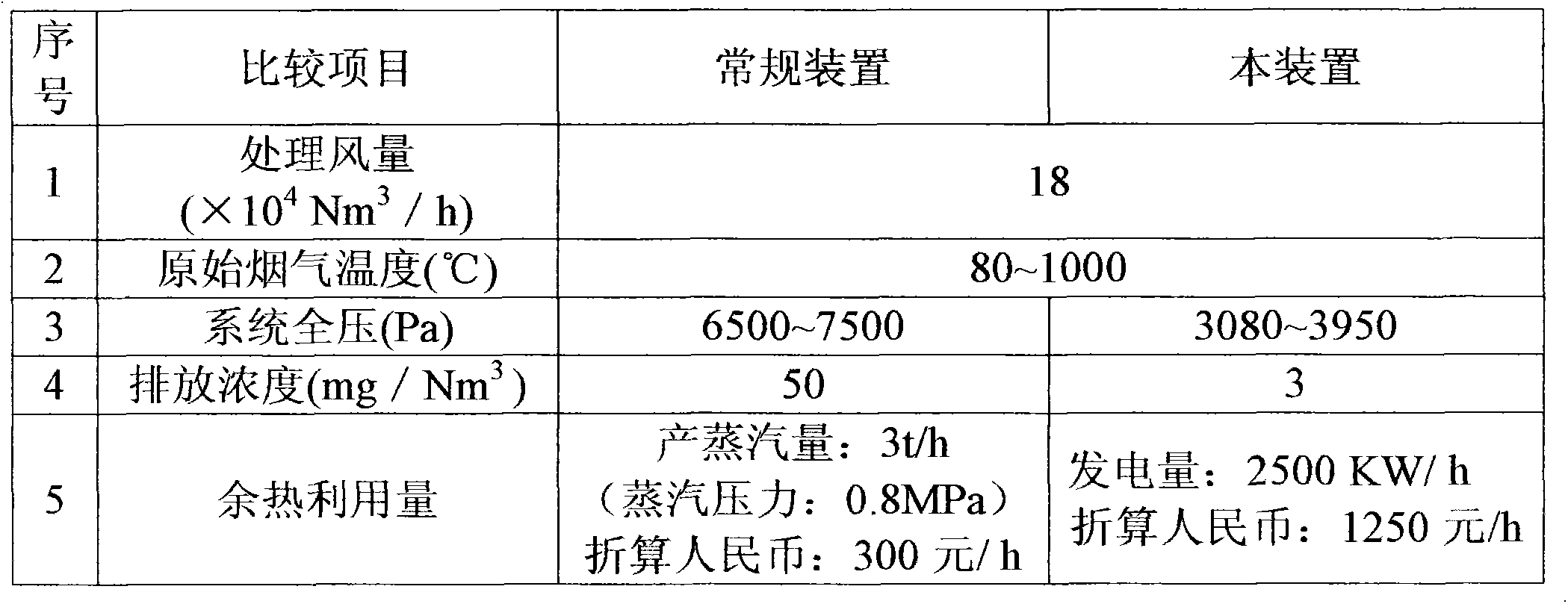

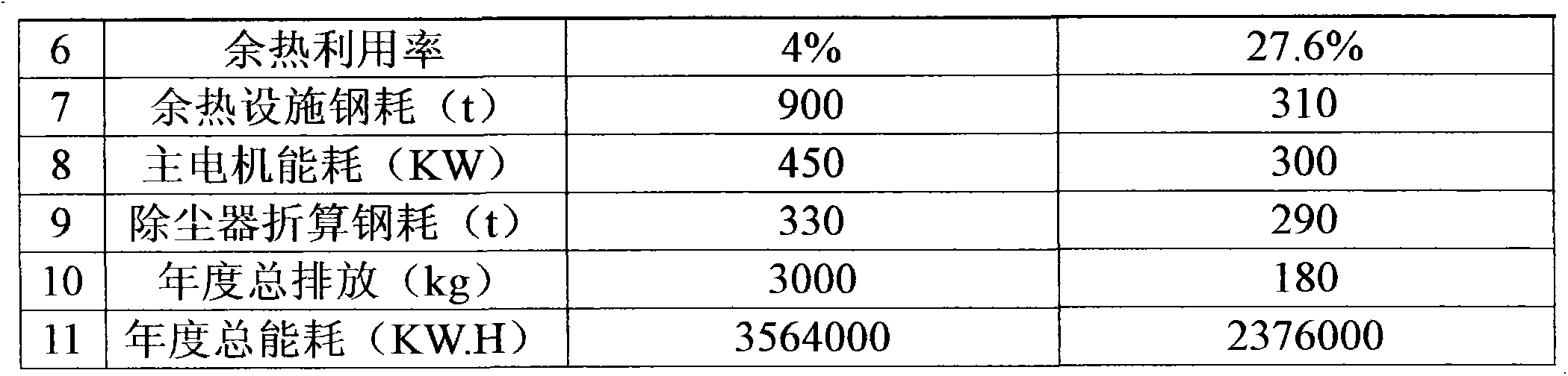

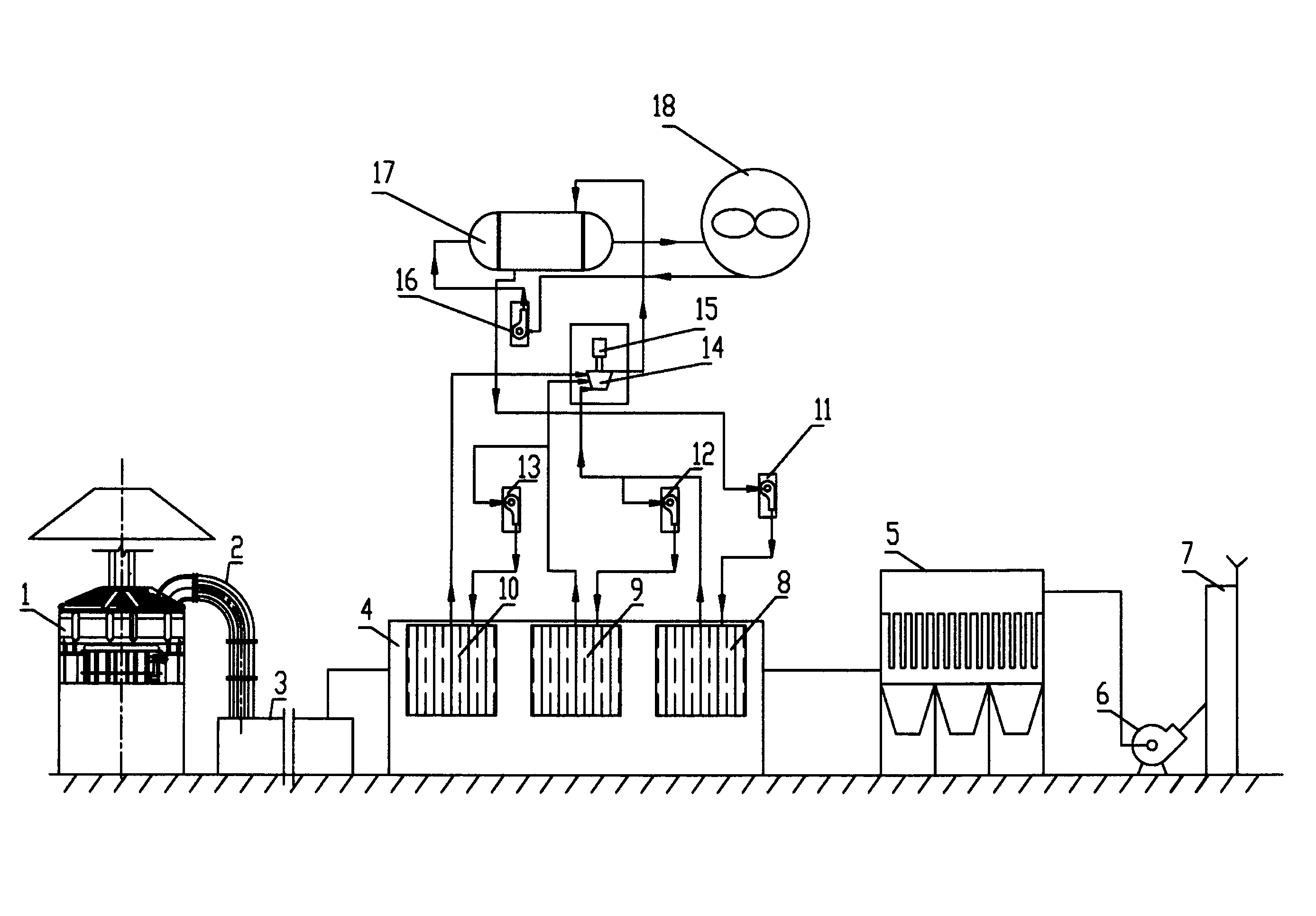

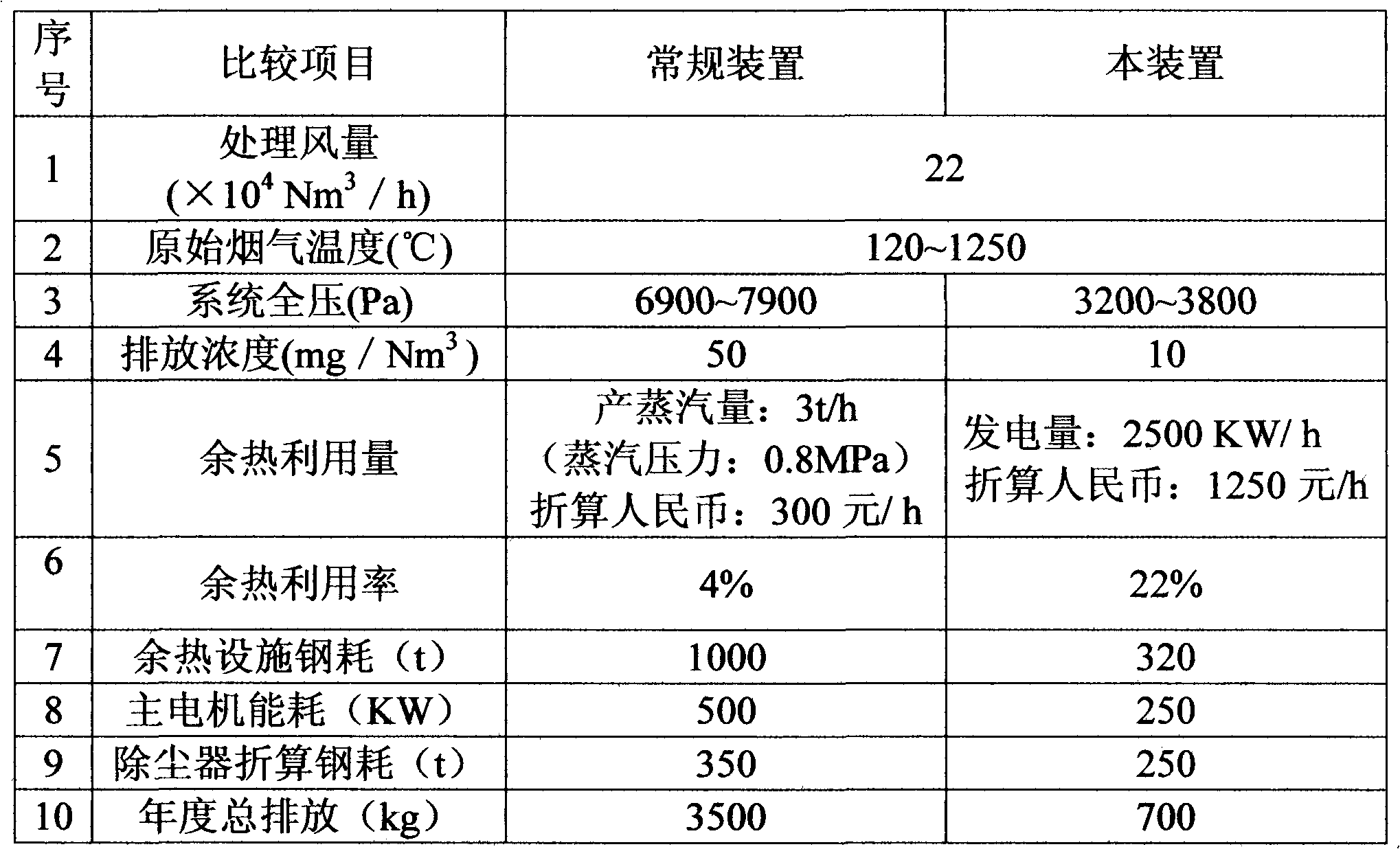

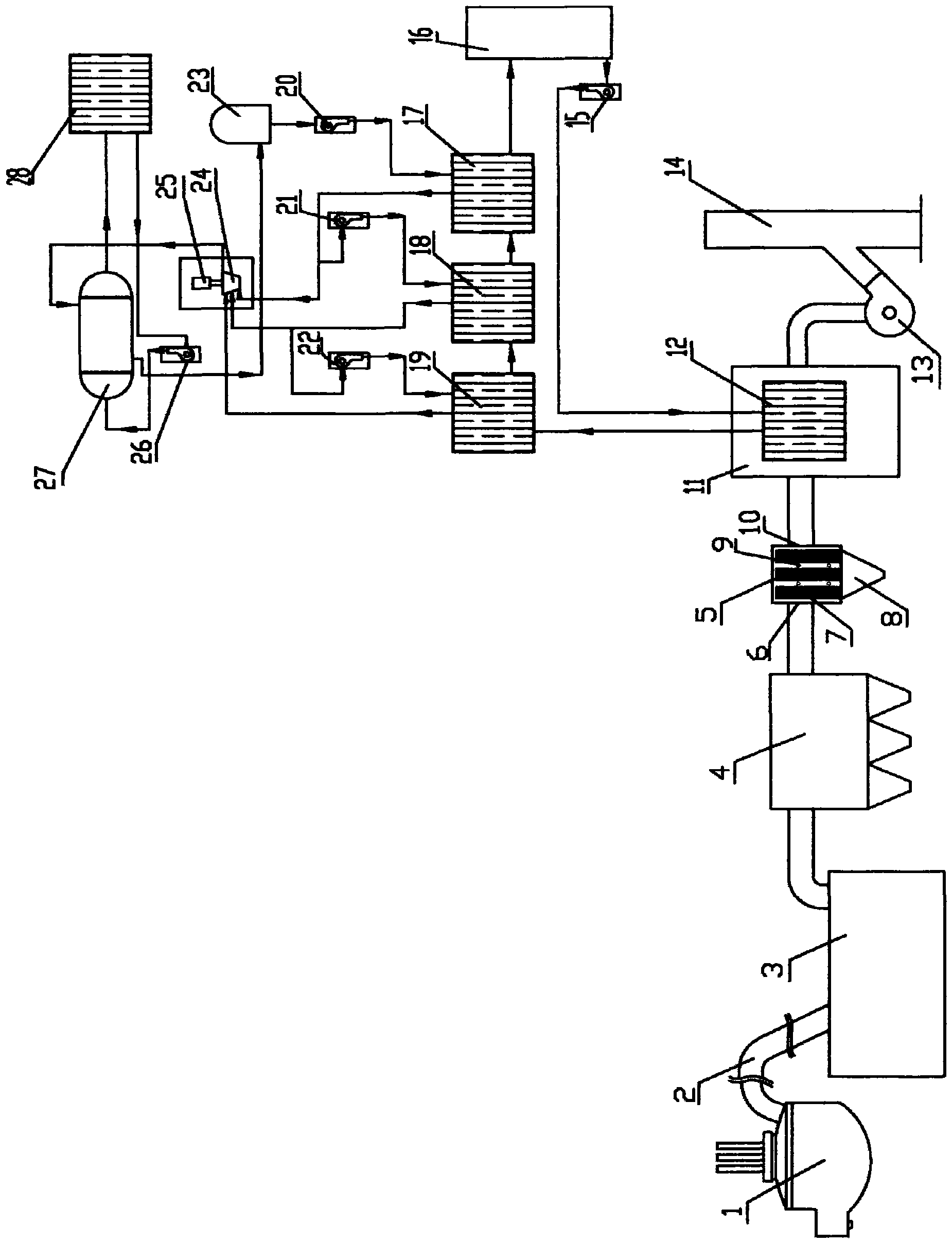

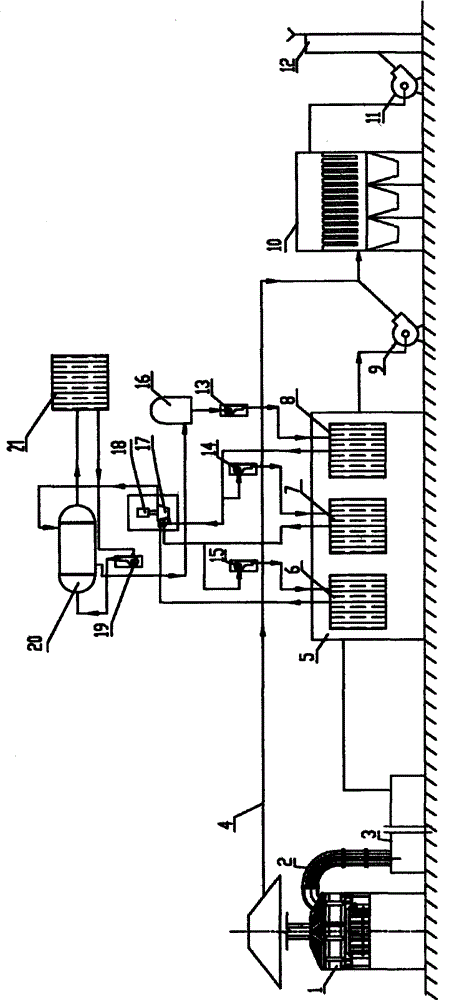

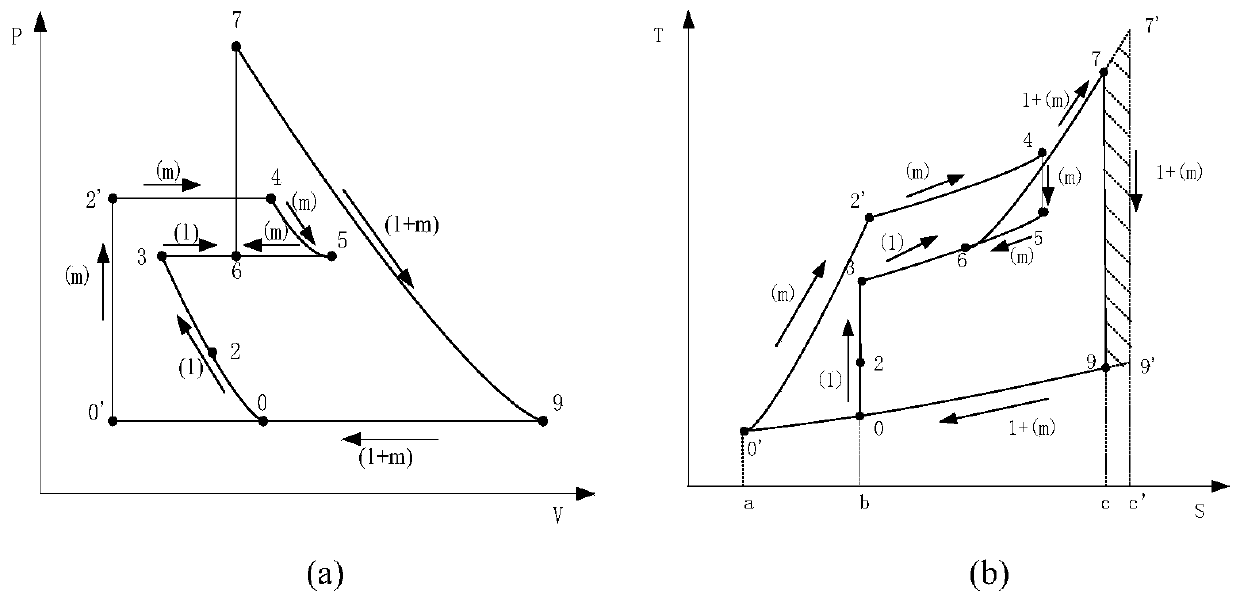

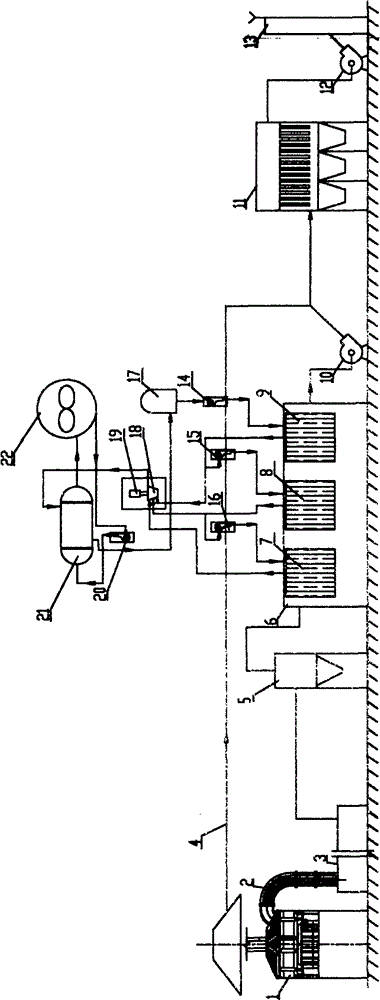

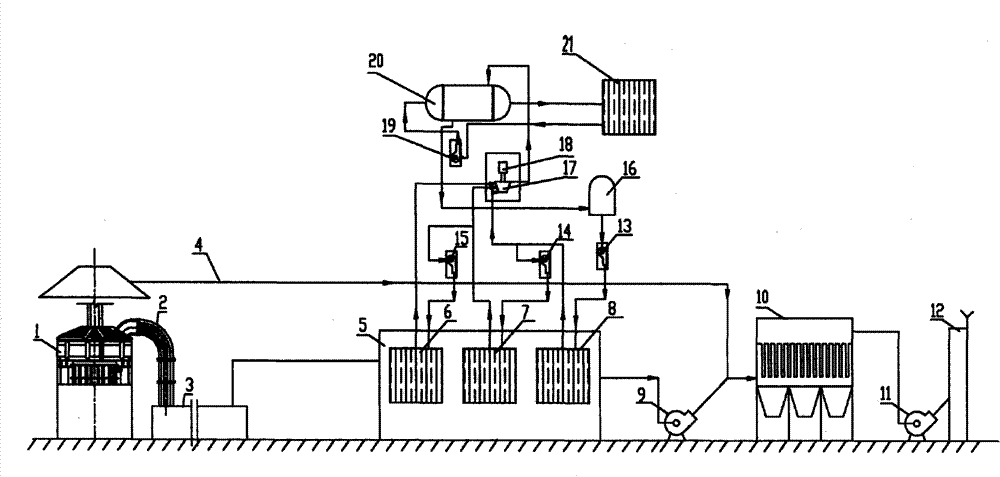

Method and device for power generation by utilizing steam generated from waste heat of steel mill in cascade mode

InactiveCN101915507AIncrease the number ofQuality improvementEnergy industryIncreasing energy efficiencyFlue gasSuperheater

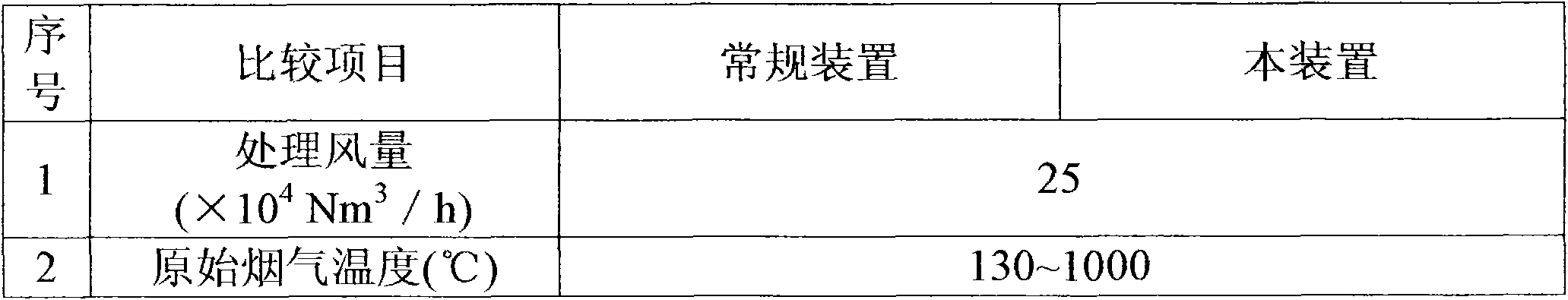

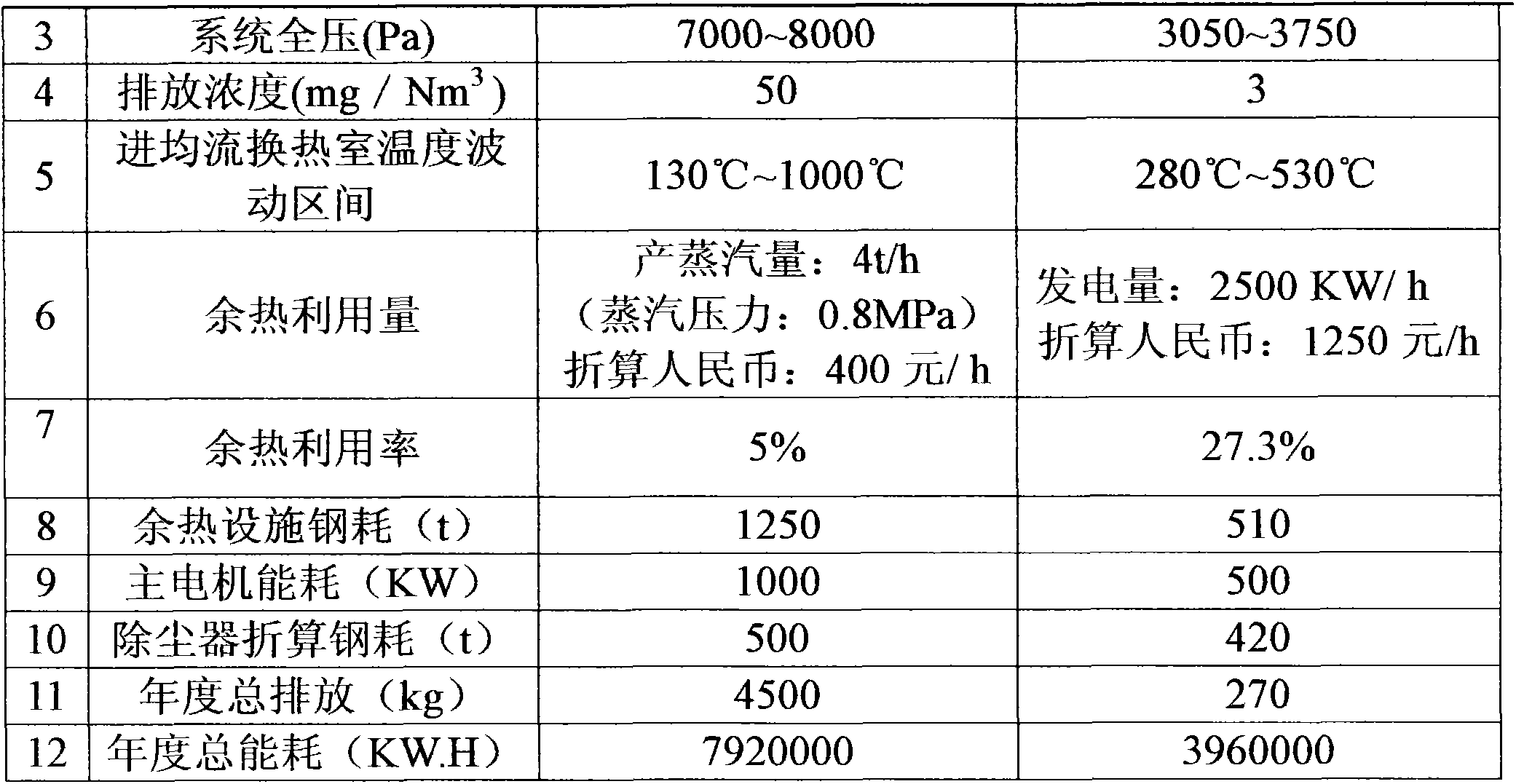

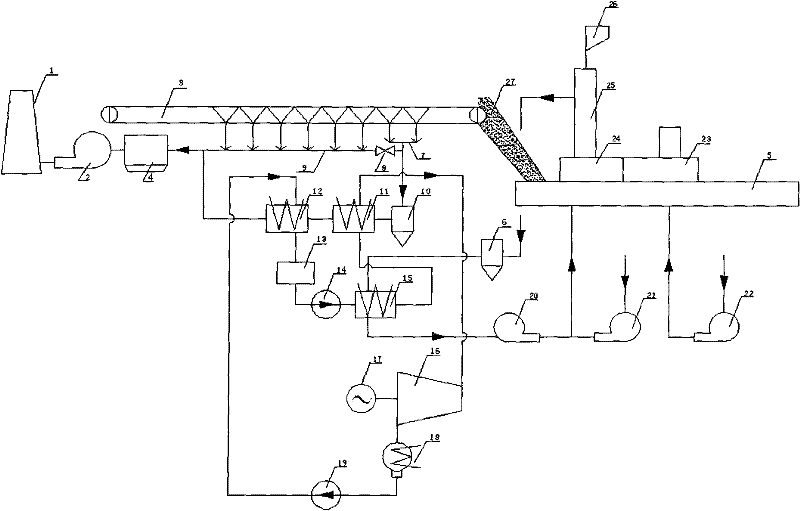

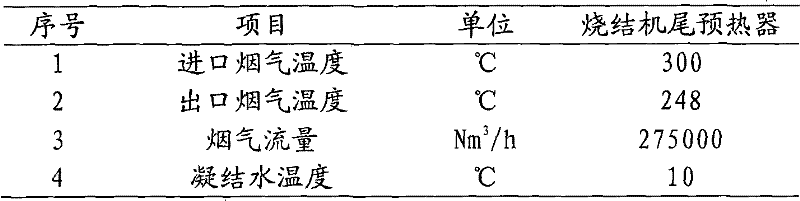

The invention discloses a method and a device for power generation by utilizing steam generated from waste heat of a steel mill in a cascade mode. The device comprises a chimney, a main shaft fan, a sintering machine, a cooling machine, a large flue of the sintering machine, a machine tail flue gas superheater of the sintering machine, a machine tail flue gas preheater of the sintering machine, a deaerator, a feed pump, a waste heat boiler of the cooling machine, a steam turbine, a generator, a condenser, a condensate pump, a circulating fan and the like. Through three process steps of preheating condensed water of the steam turbine by utilizing the preheater in machine tail flue gas of the sintering machine, generating intermediate-temperature steam by heating the waste heat boiler of the cooling machine, heating the intermediate-temperature steam further through the machine tail flue gas superheater of the sintering machine to generate high-temperature steam and the like, the power generation is performed by utilizing the steam generated from the flue gas waste heat of a sintering machine plant fully. The power generation is performed by utilizing the steam generated from the heat of the machine tail flue gas of the sintering machine and the flue gas of the cooling machine of the steel mill, so the quality of the generated steam is improved greatly and meets the requirement of waste heat generation, and a process flow is simple.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

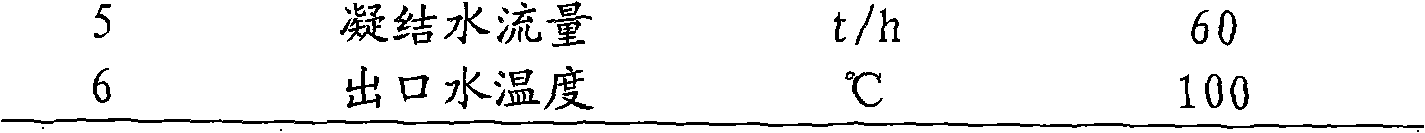

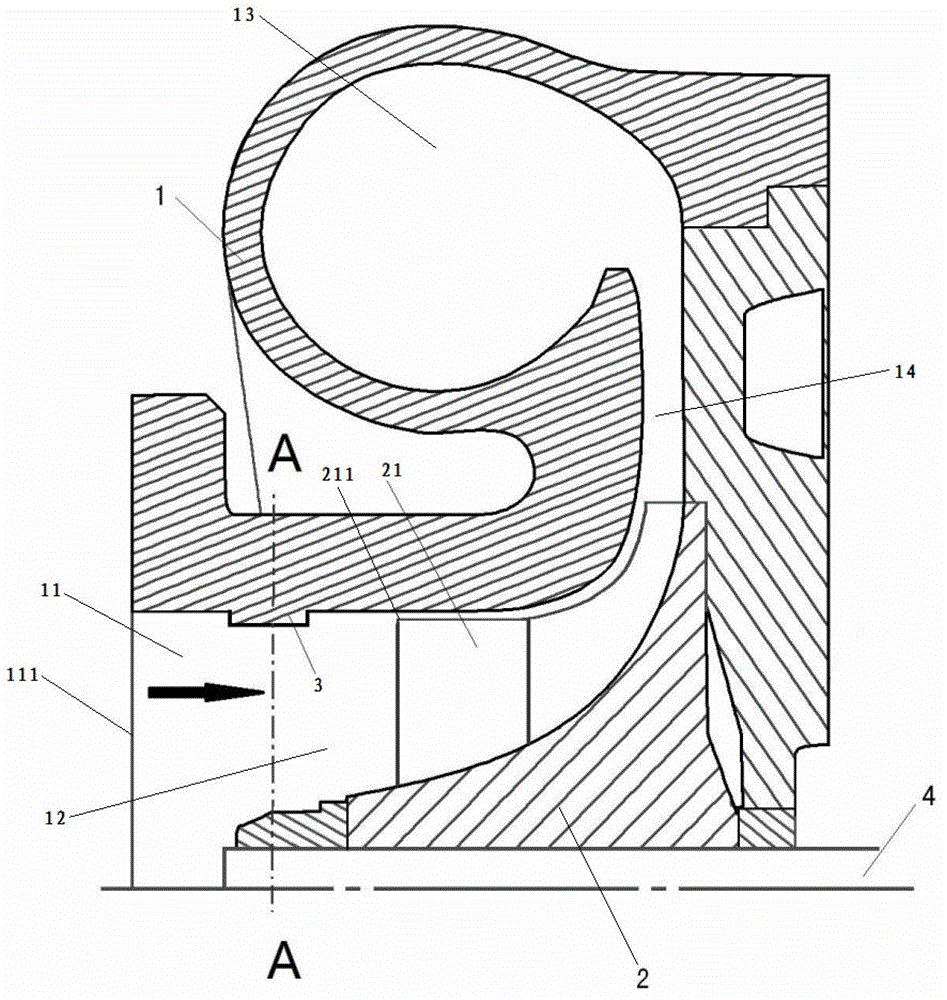

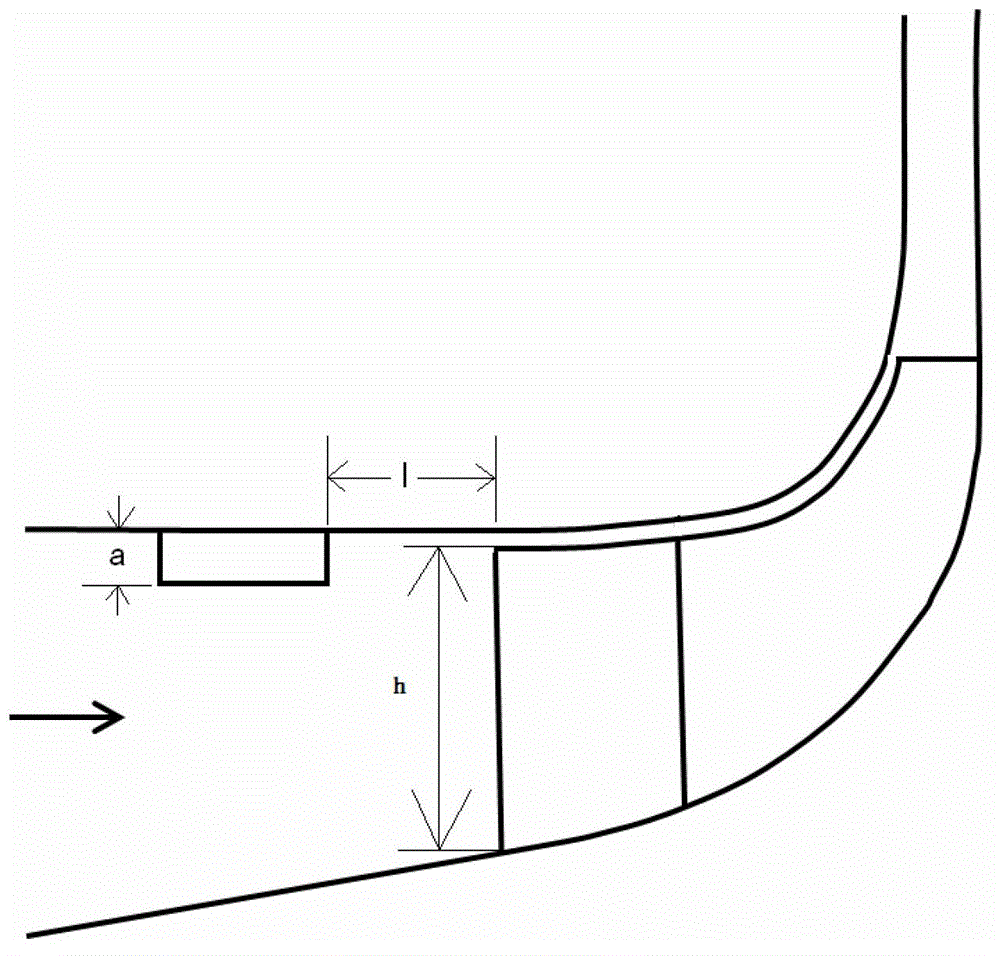

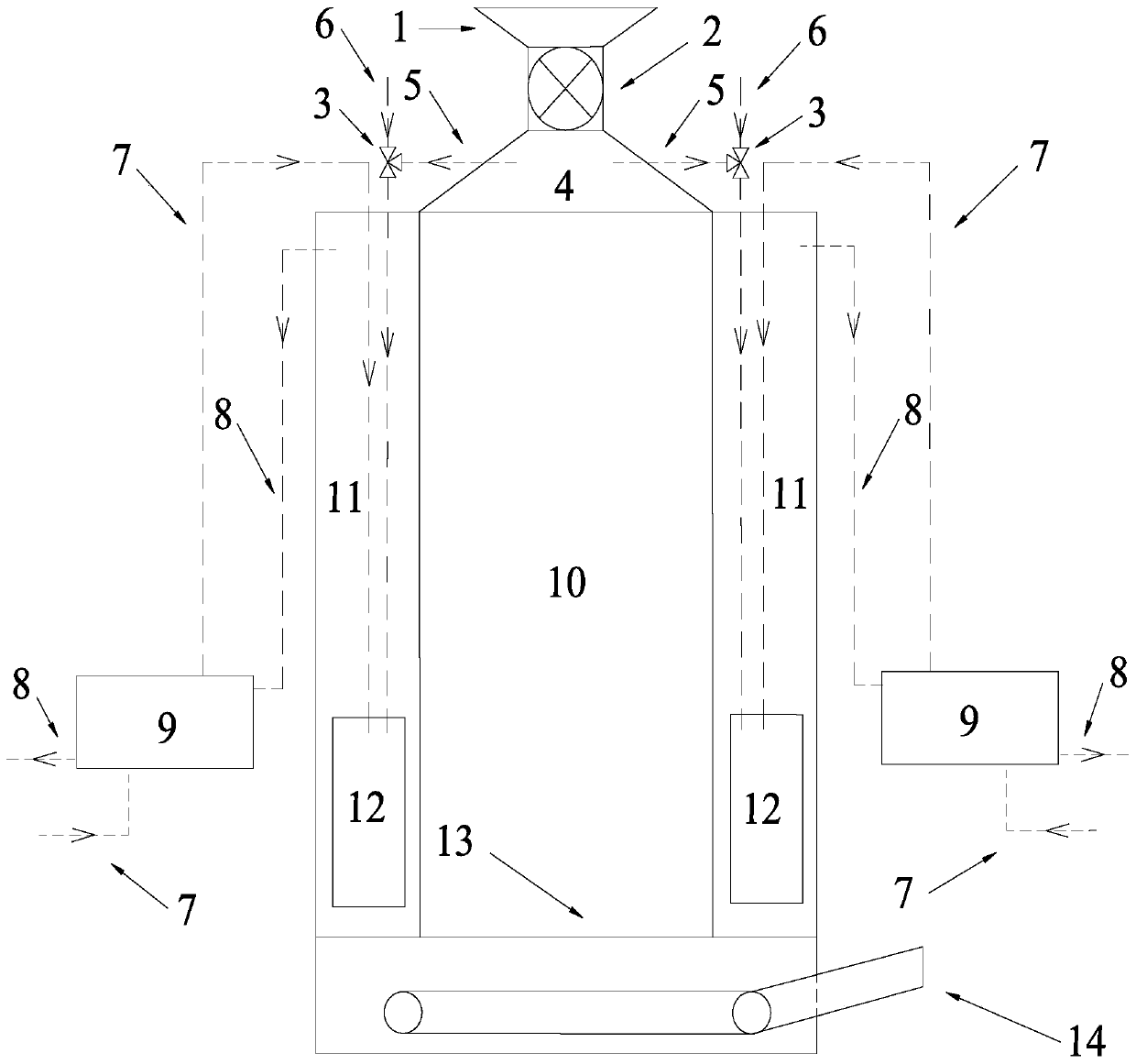

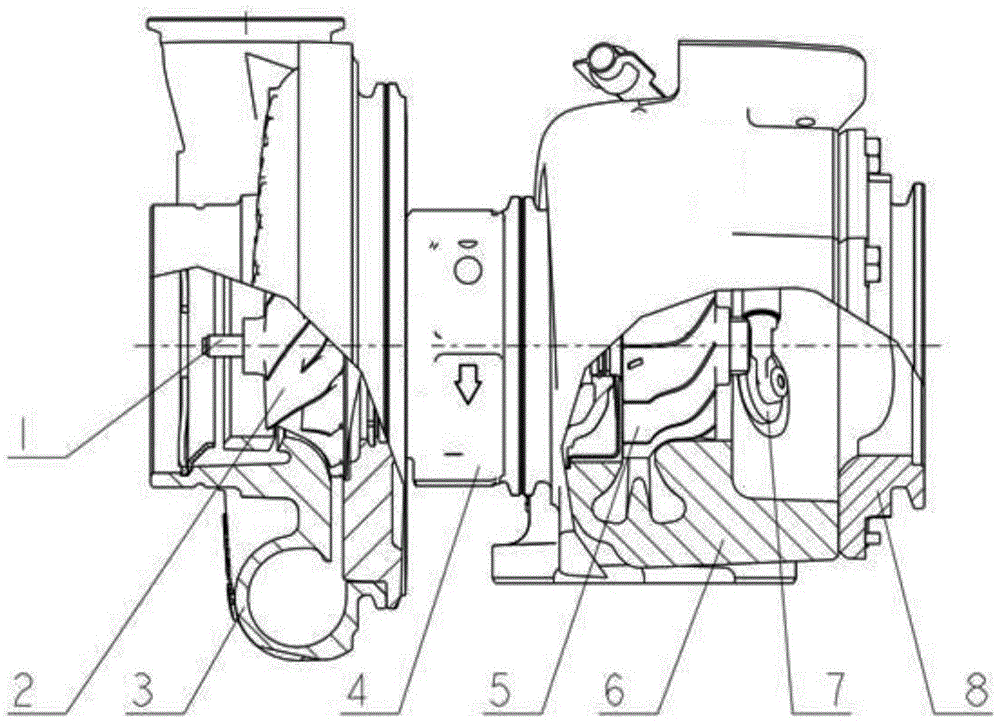

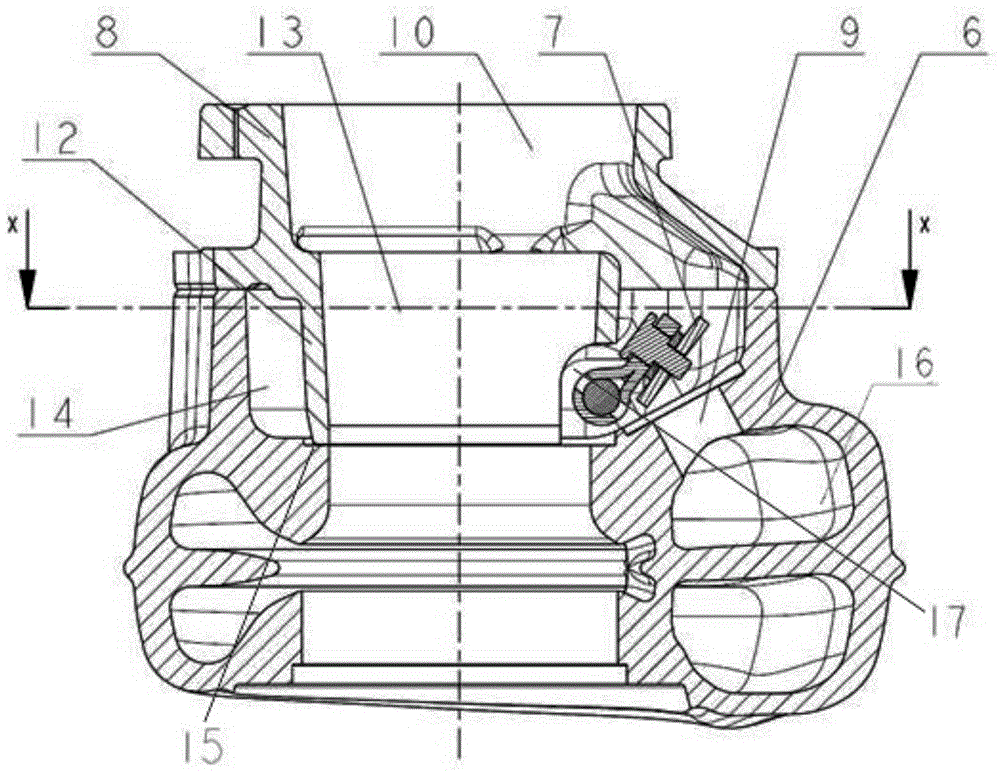

Centrifugal compressor with inlet guide blades and turbocharger

ActiveCN103148021AImprove performanceReduce peripheral speedEngine manufacturePump componentsInlet channelTurbocharger

The invention discloses a centrifugal compressor with inlet guide blades and a turbocharger. The centrifugal compressor comprises a volute, an impeller and guide blades, wherein an air inlet channel, an impeller mounting space and an air outlet channel are defined in the volute, the impeller mounting space is respectively communicated with the air inlet channel and the air outlet channel, and the air inlet channel is provided with an air inlet and the air outlet channel is provided with an air outlet; the impeller can be rotationally arranged in the impeller mounting space by surrounding around a revolving shaft and is provided with a plurality of blades; and guide blades are arranged on a peripheral wall of the air inlet channel. According to the centrifugal compressor provided by the invention, the peripheral speed of fluid such as air in the air inlet channel is reduced by the fact that the guide blades are mounted, so that air inflows at the tips of the blades can be more uniform; and moreover, and the sudden change of the peripheral speed can be reduced, so that the increasing ranges of thermal charges at the tips of the blades can be reduced, the property of the centrifugal compressor can be further improved, especially, the property can be remarkably improved under the small flow working condition.

Owner:TSINGHUA UNIV

Low-temperature multi-effect seawater desalination process

InactiveCN100506706CQuality improvementIncrease productionGeneral water supply conservationSeawater treatmentSpecial designEnergy recovery

This invention refers to a method about low-temperature multiple-effect desalination of sea water, especially about a new method which effectively applied thermal pumping power-saving technology to desalination of sea water. The desalination of sea water system which apply this method has n effect evaporator(n=2-50) and one condensator aggregately, containing six systems of feeding seawater, recirculated salt water, product water, vacuum, incoagulable gas removal, thermal pumping circulation and starting heating in addition. This invention is based on irreversible thermodynamics principle, via organic integration of evaporator, condensator and low-temperature multiple-effect desalination of sea water system in closed circuit thermal pumping system, as well as special design of energy recovery tache in low-temperature multiple-effect desalination of sea water, decreasing irreversible loss of diversified thermal transmission course which the desalination of sea water refers to in maximum limit, sequentially letting the entropy increasing of whole desalination of sea water course be the least, realizing efficient energy-saving desalination of sea water course.

Owner:QINGDAO UNIV

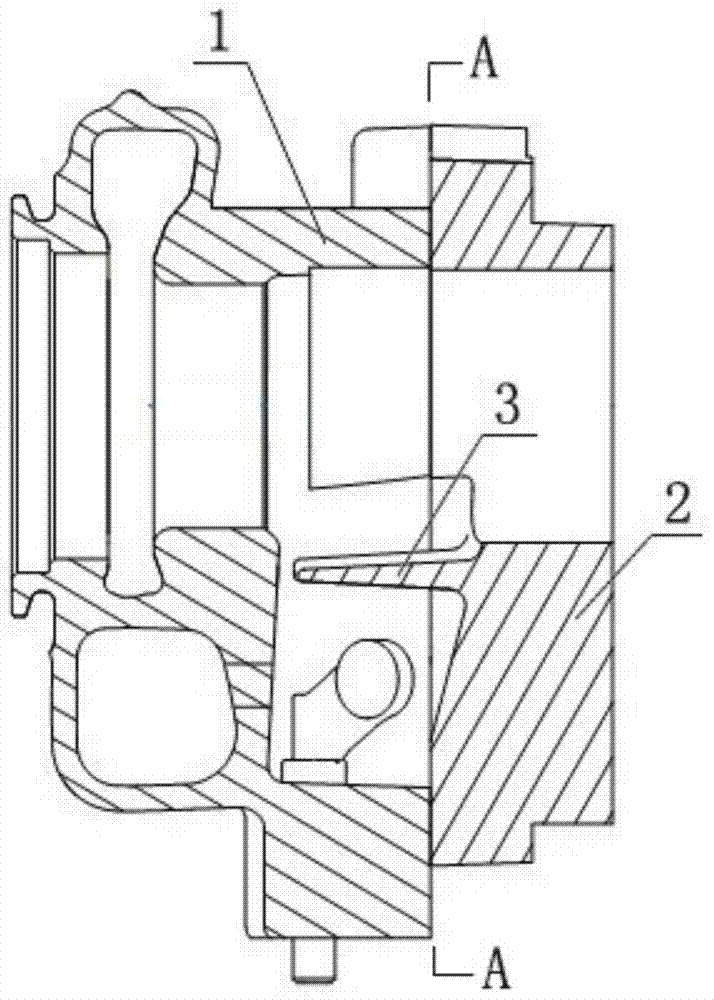

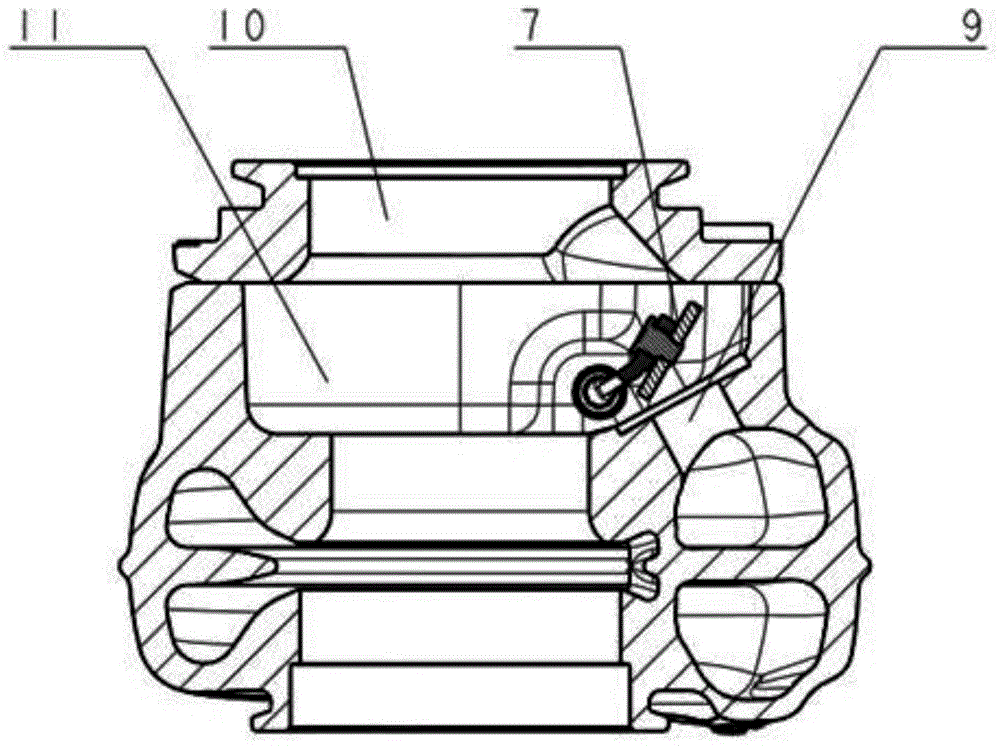

Turbocharger

InactiveCN103670671AImprove efficiencySpeed up the flowInternal combustion piston enginesEngine componentsImpellerWorking capacity

The invention relates to a turbocharger. The turbocharger comprises a volute, a transition connector is fastened and connected to the installation face of the volute, a partition wall is arranged in an inner cavity of the transition connector, and a channel is formed in the bottom face of the inner cavity of the transition connector. Firstly, due to the fact that the partition wall is arranged, bypass flow and main flow can hardly be mixed, so that entropy production is reduced; in addition, due to the fact that the special channel is design, flowing of the bypass flow can be smoother compared with the flowing of the bypass flow under the condition that the special channel is not formed, turbulence intensity is lowered, and entropy production can be reduced as well; efficiency can be lowered due to entropy production, and efficiency can be lowered when entropy production is reduced. Secondly, due to the existence of the partition wall and the special channel, mixing of the bypass flow and the main flow is farther away from an impeller compared with the traditional design that no partition wall or channel is formed, and the work capacity of the impeller can be lowered although the backpressure of the impeller can still be increased. The farther the mixing position is, the smaller the backpressure is, and therefore the lowering amplitude of the work capacity is smaller.

Owner:WUXI CUMMINS TURBO TECH

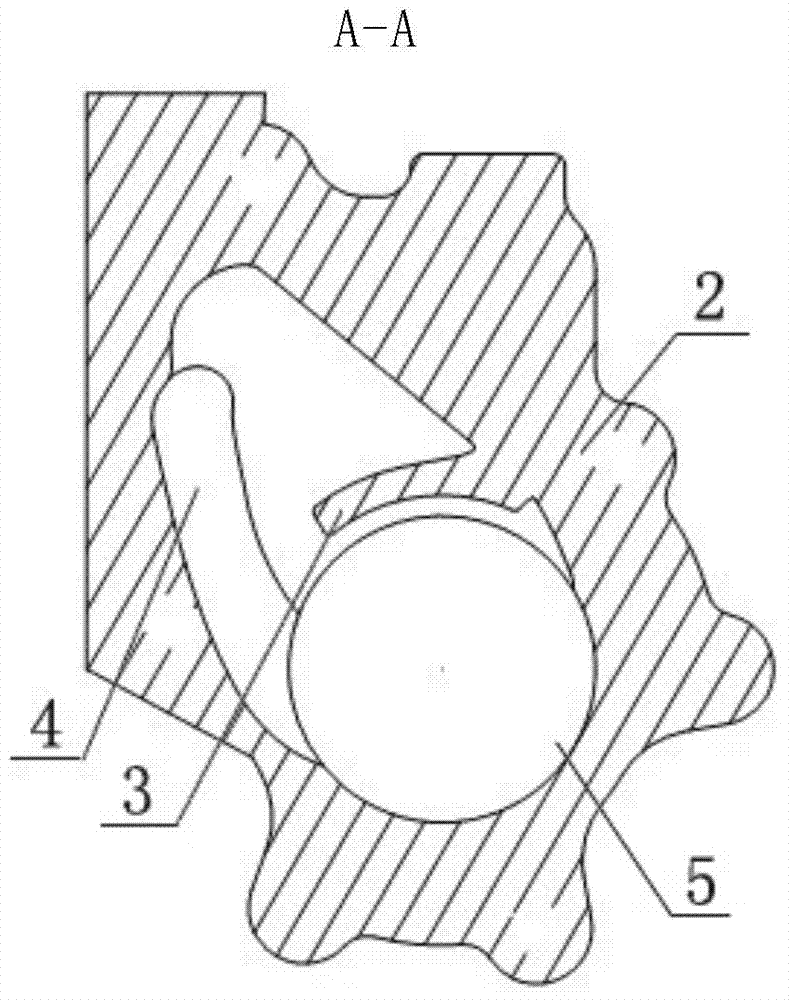

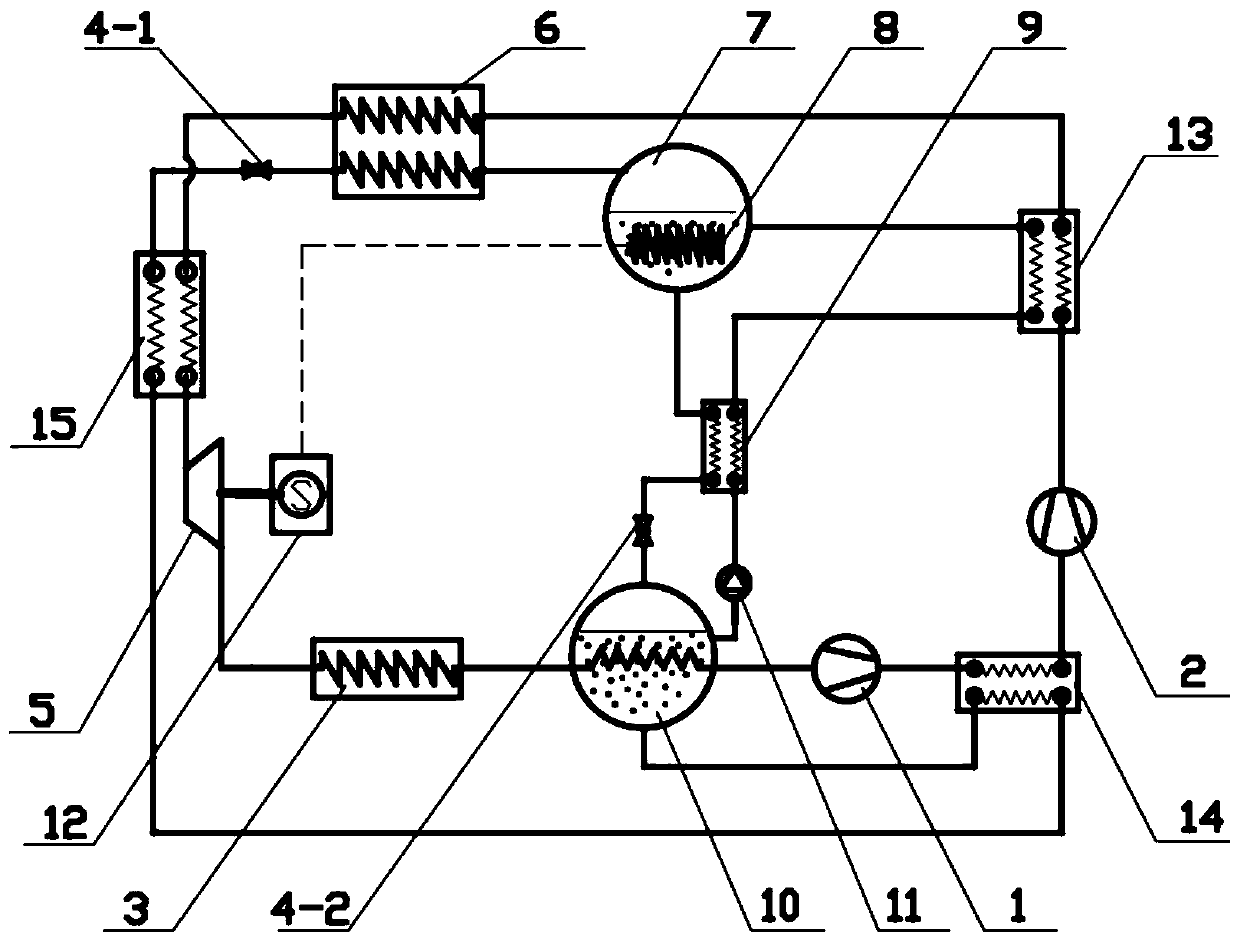

Two-stage compression refrigerating system

PendingCN108489129AImprove energy efficiency ratioReduce working pressure differenceCompressorCompression machines with non-reversible cycleBusiness efficiencyEvaporation

The invention discloses a two-stage compression refrigerating system which is a system aiming at reducing losses in the throttling process and improving the system energy efficiency. The exhaust portof a function compressor is connected with the inlet of a condenser, the outlet of the condenser is connected with the inlet end of an expansion machine, the outlet end of the expansion machine is connected with the gas-liquid inlet of a receiver, the liquid outlet of the receiver is connected with the inlet of an evaporator through a restricting element, the outlet of the evaporator is connectedwith the air sucking opening of a booster compressor, the exhaust opening of the booster compressor is connected with the gas inlet of the receiver, the gas outlet of the receiver is connected with the air sucking opening of the function compressor, and the booster compressor is driven by the expansion machine. By means of the system, the expansion machine expands to act to drive the booster compressor to run, the losses of the throttling process are reduced, and the energy efficiency ratio of a refrigerating cycle is improved. Meanwhile, compressor liquid hammering caused by unbalanced liquidsupply amount and evaporation capacity in the evaporator is avoided, and the maintaining cost is reduced. In addition, the structure is simple, installation is convenient, and cost is low.

Owner:天津市正源制冷设备有限公司

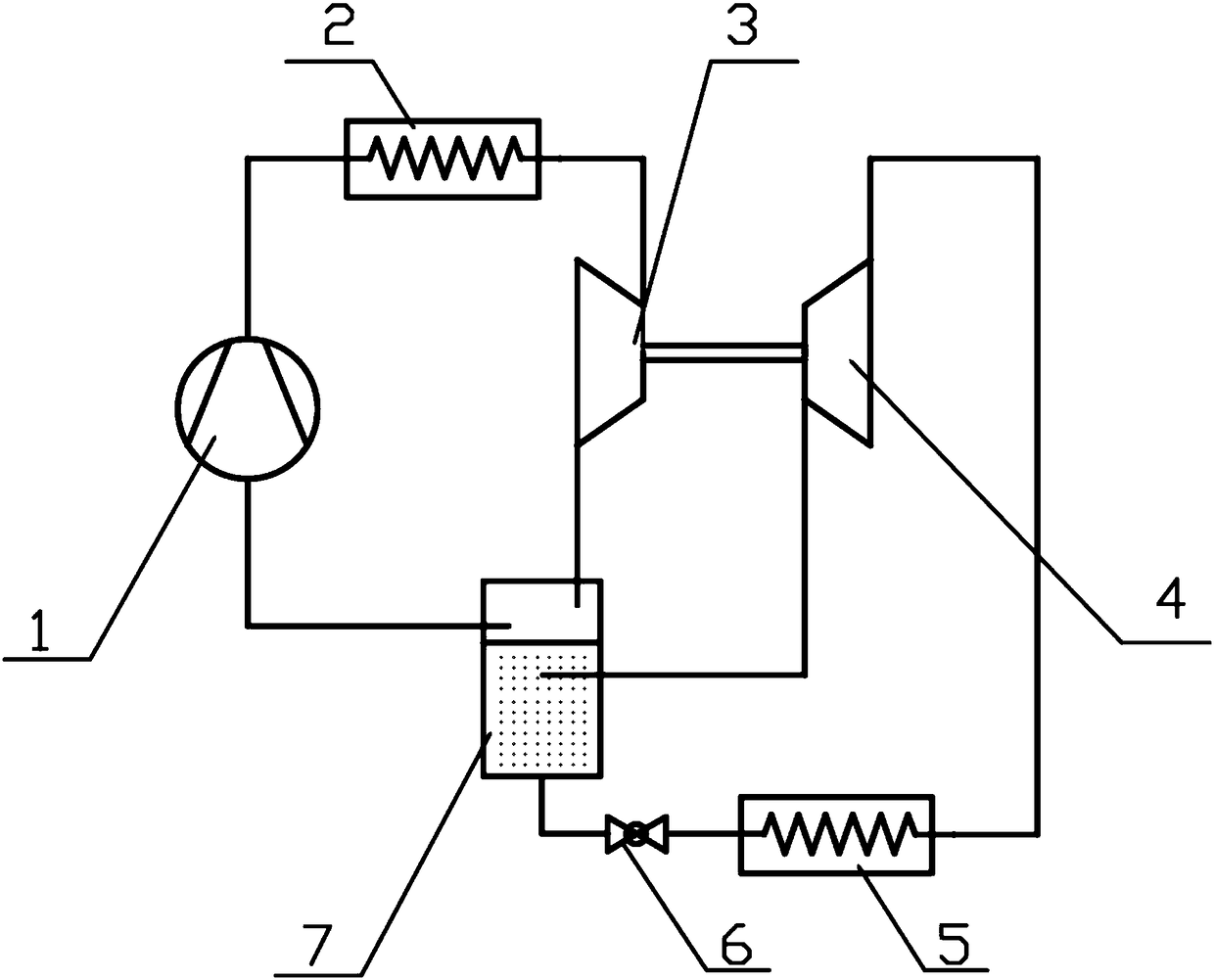

Efficient, energy-saving and environment-friendly pyrolysis furnace

PendingCN110701615AReduce entropy increaseEasy accessIndirect carbon-dioxide mitigationSpecial form destructive distillationCombustion chamberThermodynamics

The invention discloses an efficient, energy-saving and environment-friendly pyrolysis furnace. A main structure of the pyrolysis furnace is sequentially provided with a feeding hopper, a star-shapedfeeder, a pyrolysis gas collecting cavity, a pyrolysis cavity, a grate and a slag remover from top to bottom. Pyrolysis gas collecting pipes are arranged in the pyrolysis gas collecting cavity and connected with gas pipelines through three-way valves. The periphery of the pyrolysis cavity is provided with a combustion chamber, two gas burners are arranged in the combustion chamber, and each gas burner is connected with a corresponding gas pipeline, a combustion-supporting air pipeline and a flue gas pipeline. The other end of each combustion-supporting air pipeline and the other end of each flue gas pipeline are connected with a regenerator, and the regenerators are arranged outside a pyrolysis furnace body. The pyrolysis furnace can fully utilize pyrolysis energy of itself, also can effectively avoid pollution substances generated by material incineration, and has the advantages of high efficiency, energy conservation, cleaning, environmental protection, simple operation, high controllability and the like.

Owner:TIANJIN UNIV OF COMMERCE

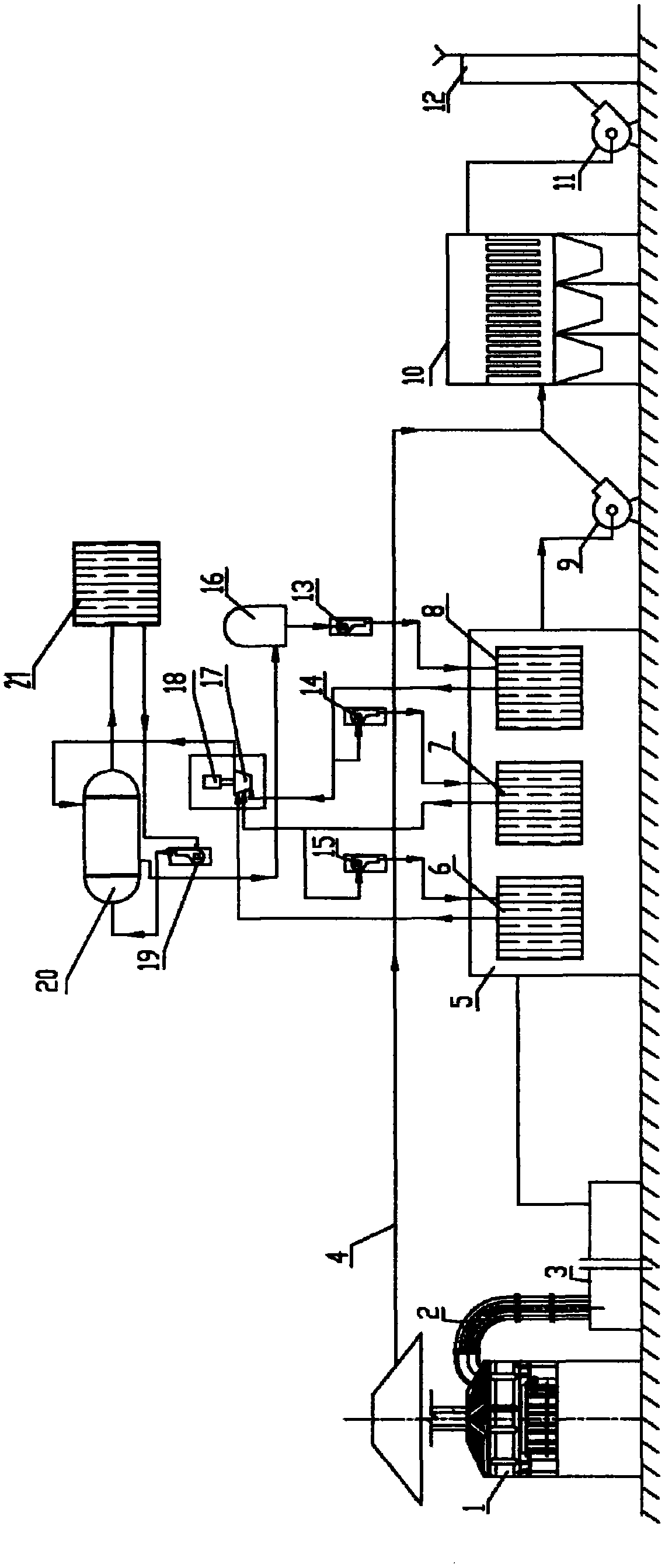

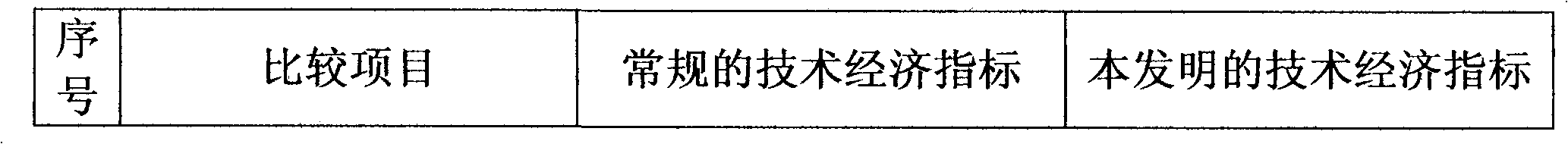

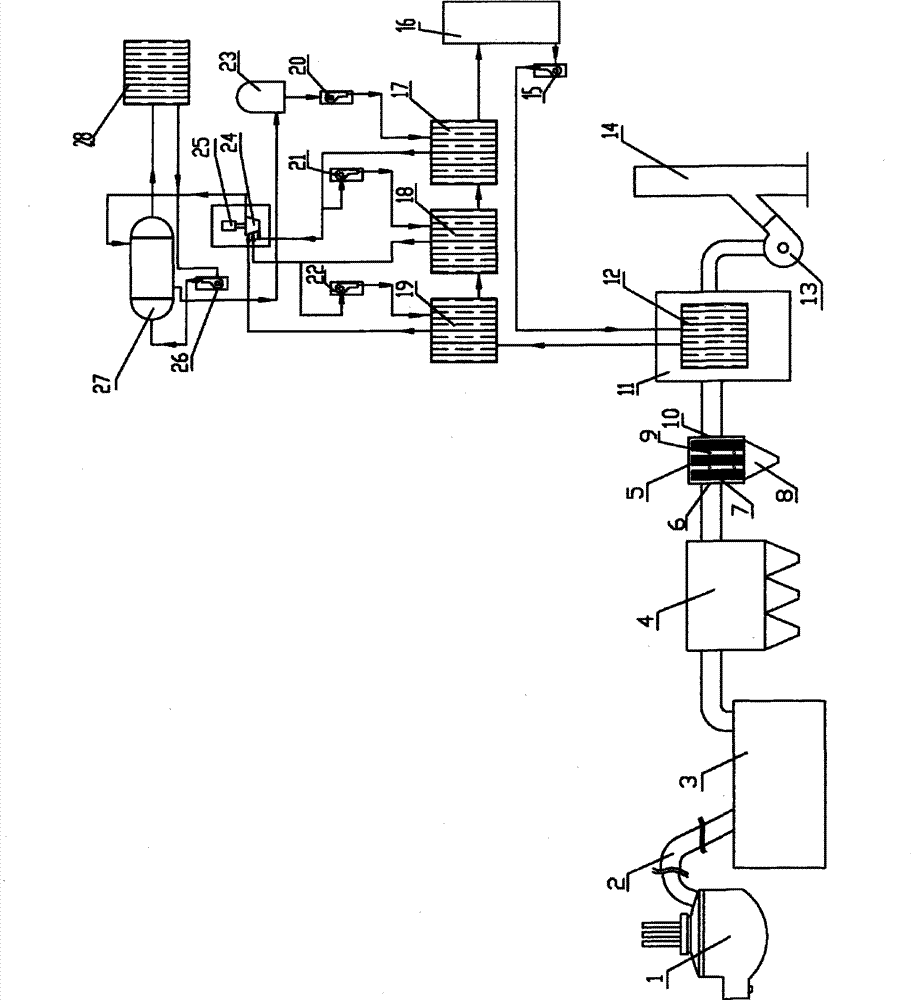

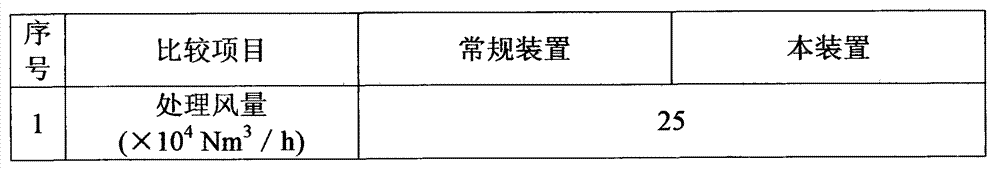

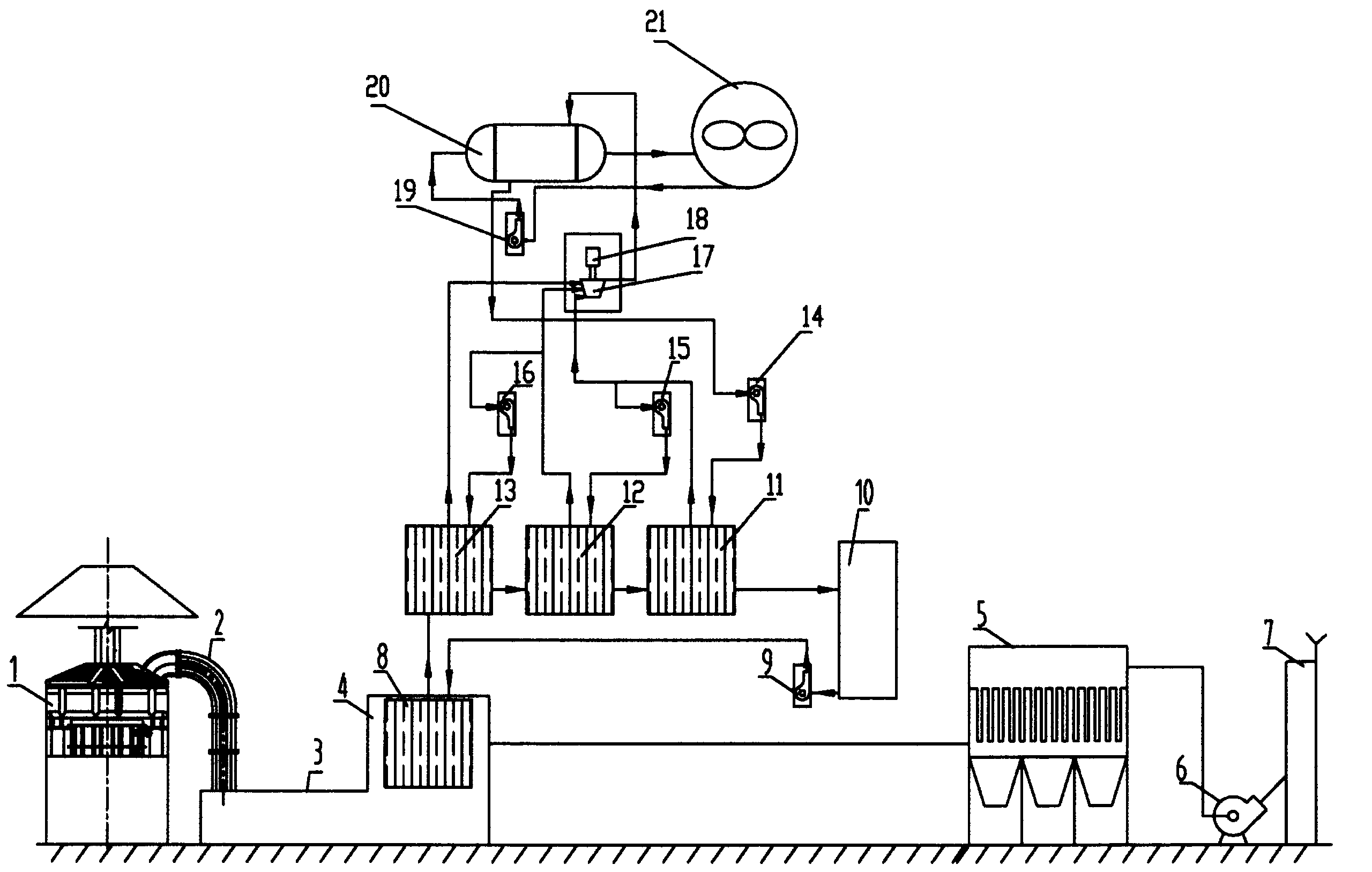

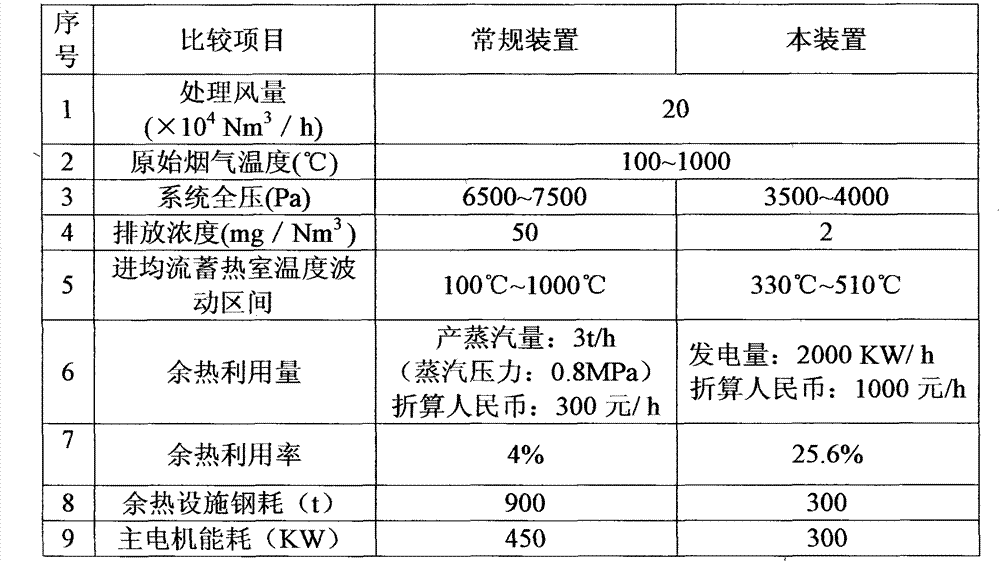

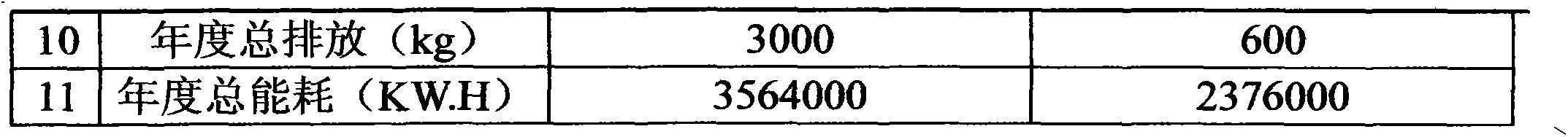

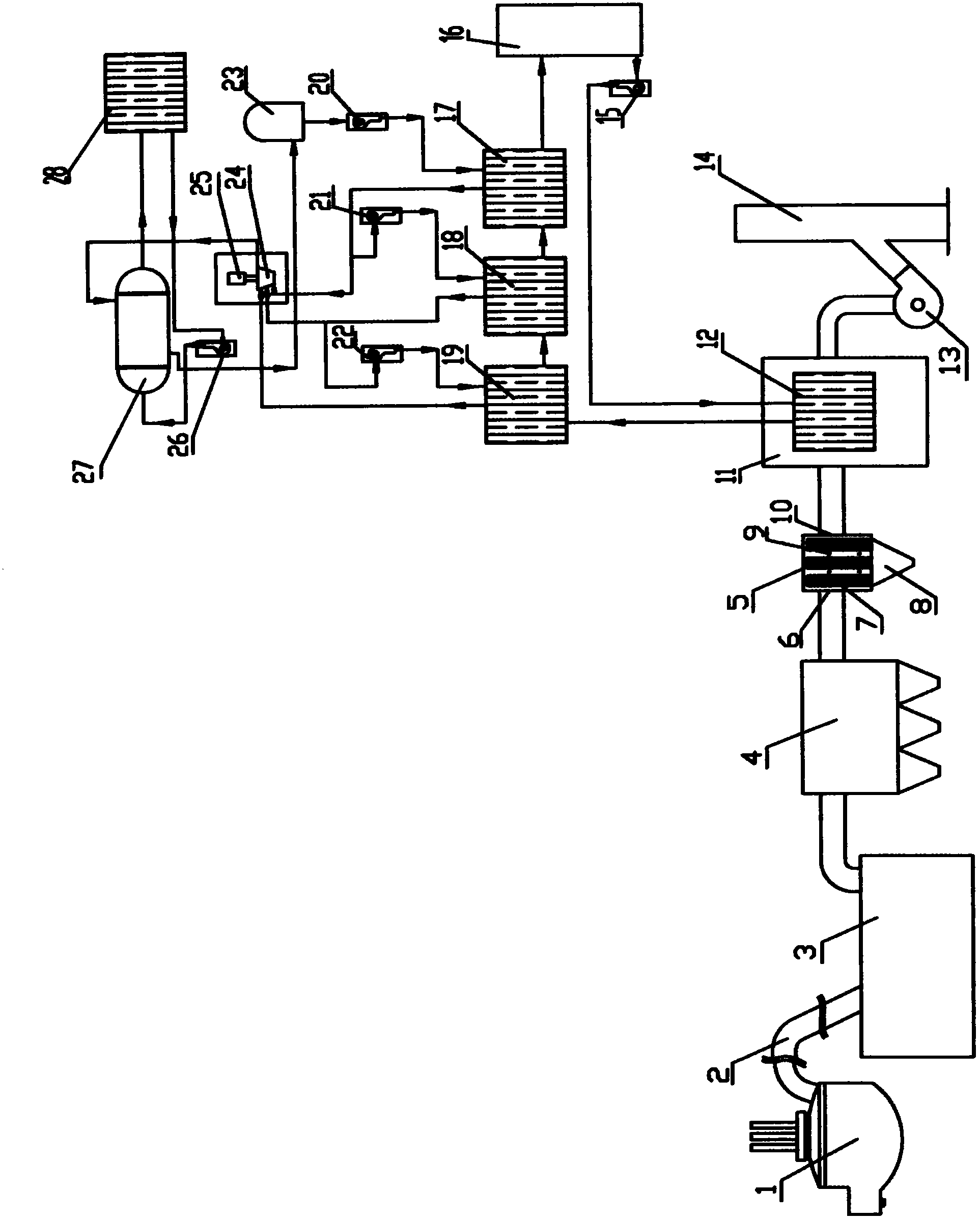

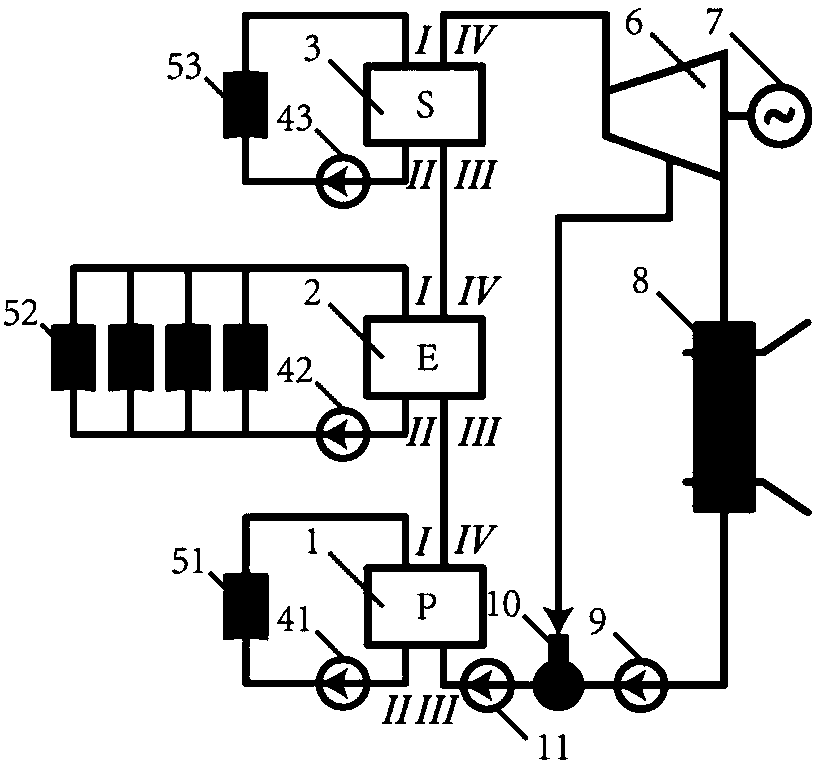

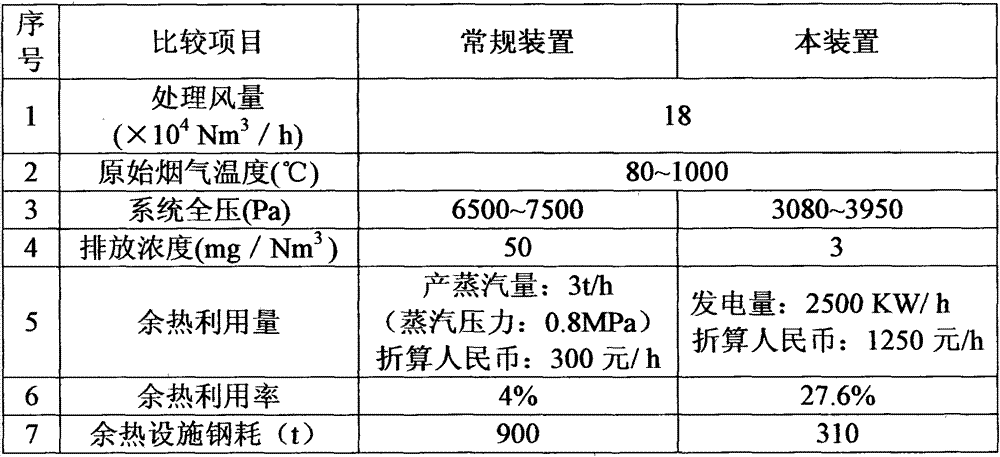

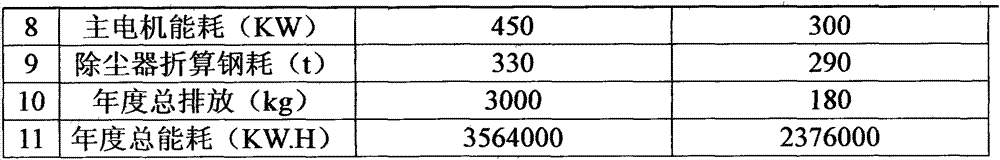

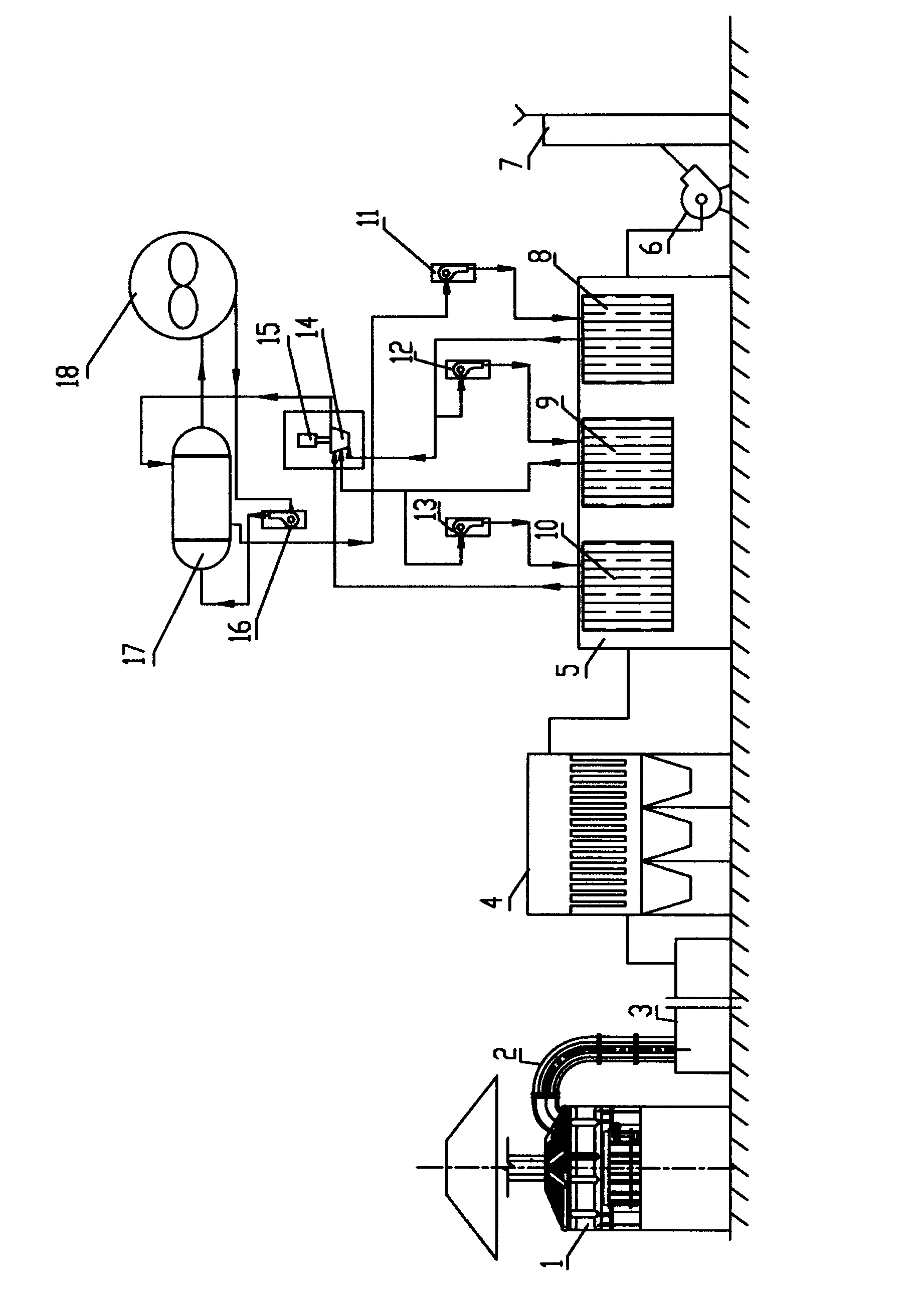

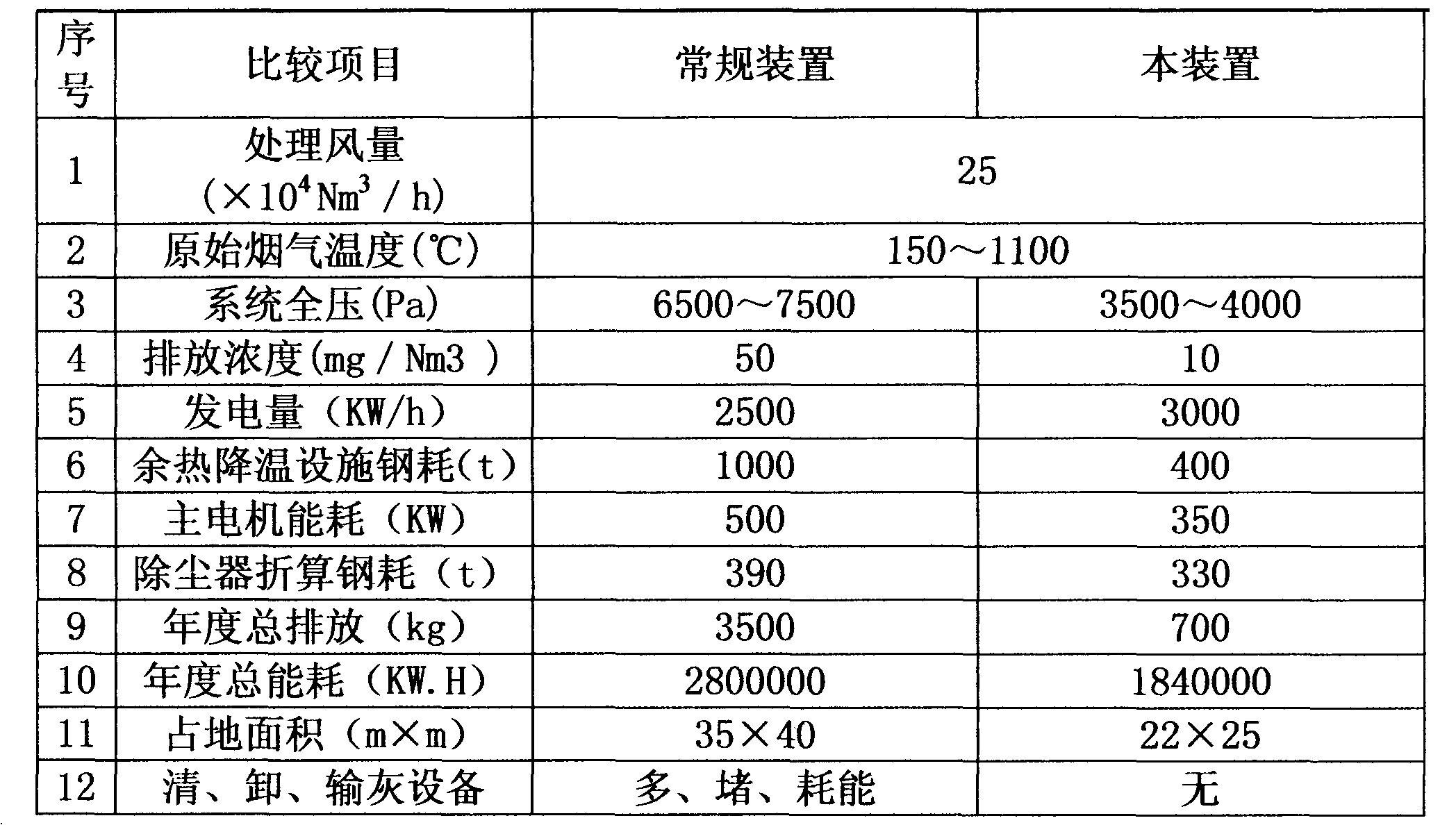

Semi-closed electric furnace flue gas multi-stage organic Rankine cycle waste heat power generation method

InactiveCN104344732ALower discharge temperatureReduce imbalanceIncreasing energy efficiencySteam engine plantsThermal energyOrganic Rankine cycle

The invention discloses a semi-closed electric furnace flue gas multi-stage organic Rankine cycle waste heat power generation method. The method is characterized in that flue gas in a semi-closed electric furnace is exhausted through a fourth hole, and is mixed with cold air through a water-cooled sliding sleeve, the mixture enters a settling chamber and a waste heat exchange chamber, heat is released by high-temperature flue gas, cooled flue gas is exhausted through a booster fan, and is mixed with flue gas discharged from an external discharge pipeline connected above the electric furnace, the mixed flue gas enters a plastic burning board dust remover, is pressed into an exhaust funnel through a main fan after dust is removed, and is exhausted into the atmosphere, organic working medium liquid absorbing the heat of a flue gas waste heat carrier in a low-pressure evaporator, a medium-pressure evaporator and a high-pressure evaporator is converted into working medium steam, and the working medium steam is expanded to apply work to drive a generator to generate power in an organic turbine with a steam supplementing opening. The method is characterized in that R290 is adopted as a circulating organic working medium. According to the method, heat in the flue gas can be maximally recovered, and can be directly converted into high-quality power, the thermal efficiency is improved by 31 to 36 percent compared with that of a single-stage evaporation organic Rankine cycle method, and good environmental protection effects are achieved.

Owner:无锡市东优环保科技有限公司

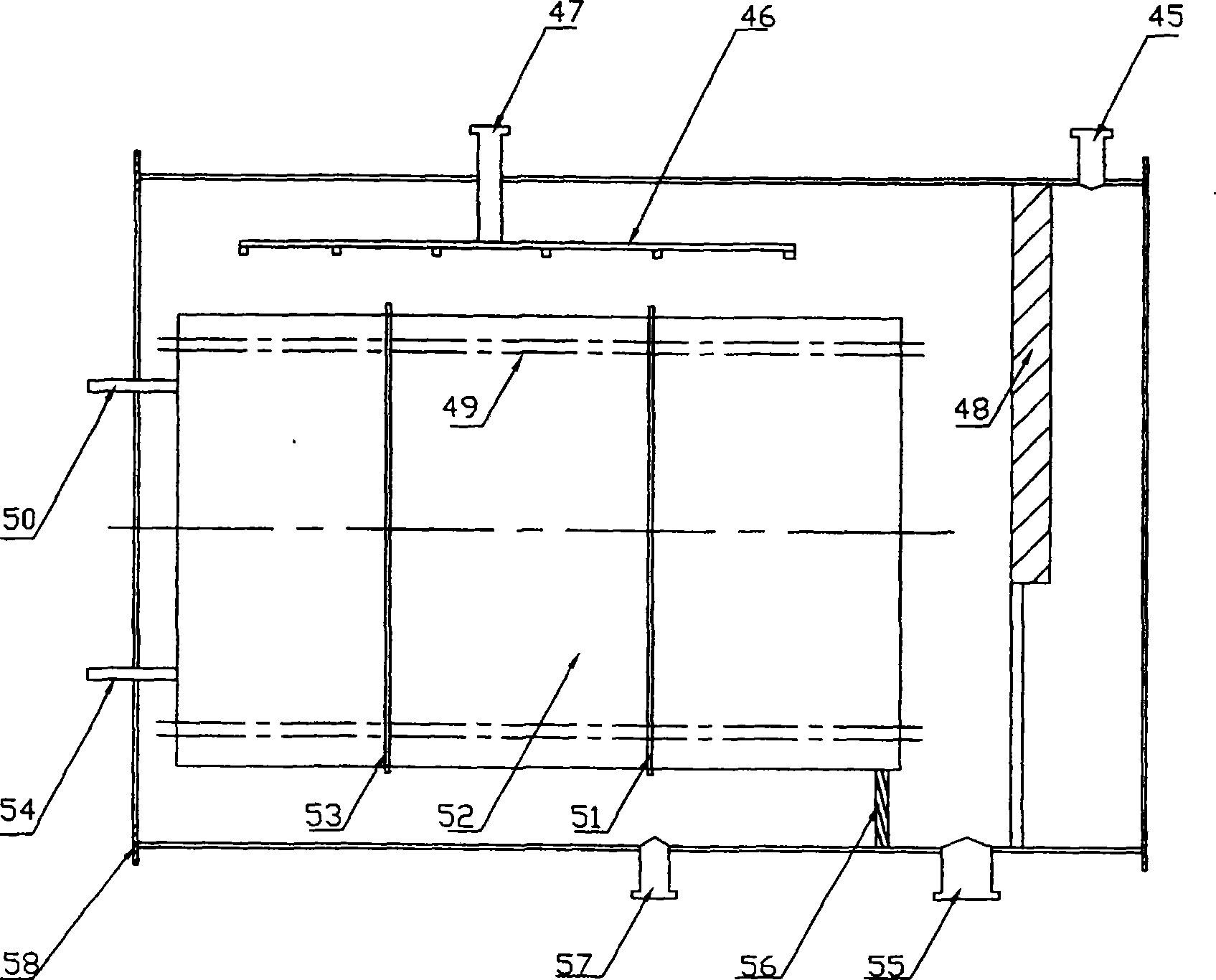

Electric furnace fume multi-stage organic rankine cycle waste heat electricity generation and dust removing method

InactiveCN103105069AReduce imbalanceReduce entropy increaseBiofuelsIncreasing energy efficiencyEnvironmental resistanceElectric generator

An electric furnace fume multi-stage organic rankine cycle waste heat electricity generation and dust removing method is characterized in that fume inside an electric furnace is exhausted, is mixed into cold air through a water-cooling sleeve, and enters into a combustion settling chamber, the fume passing through the combustion settling chamber enters into a waste heat exchanger, and the fume releases heat which enters into a bag dust-removing device and is pressed into an air exhausting cylinder to enter into the air after dust removal. Meanwhile, organic working media pass through a lower-pressure stage working medium pump, a middle-pressure stage working medium pump and a high-pressure stage working medium pump and absorb heat from the lower-pressure stage working medium pump, the middle-pressure stage working medium pump and the high-pressure stage working medium pump to enable the heat to be transmitted into steam, and the working medium steam is expanded to act in a multi-stage organic turbine to drive a generator to generate electricity. The working medium steam exhausted by the organic turbine with a steam adding port is condensed into saturation liquid by a condenser, and a new round of cycle is started. The electric furnace fume multi-stage organic rankine cycle waste heat electricity generation and dust removing method is further characterized in that R152a is utilized as cycling organic media. The electric furnace fume multi-stage organic rankine cycle waste heat electricity generation and dust removing method can recycle heat energy in the fume farthest and enables the heat energy to be converted into high-quality electricity, the efficiency is improved by 10%-20% compared with a single-stage steaming organic rankine, and a good environment-friendly effect is achieved.

Owner:无锡市广运环保机械有限公司

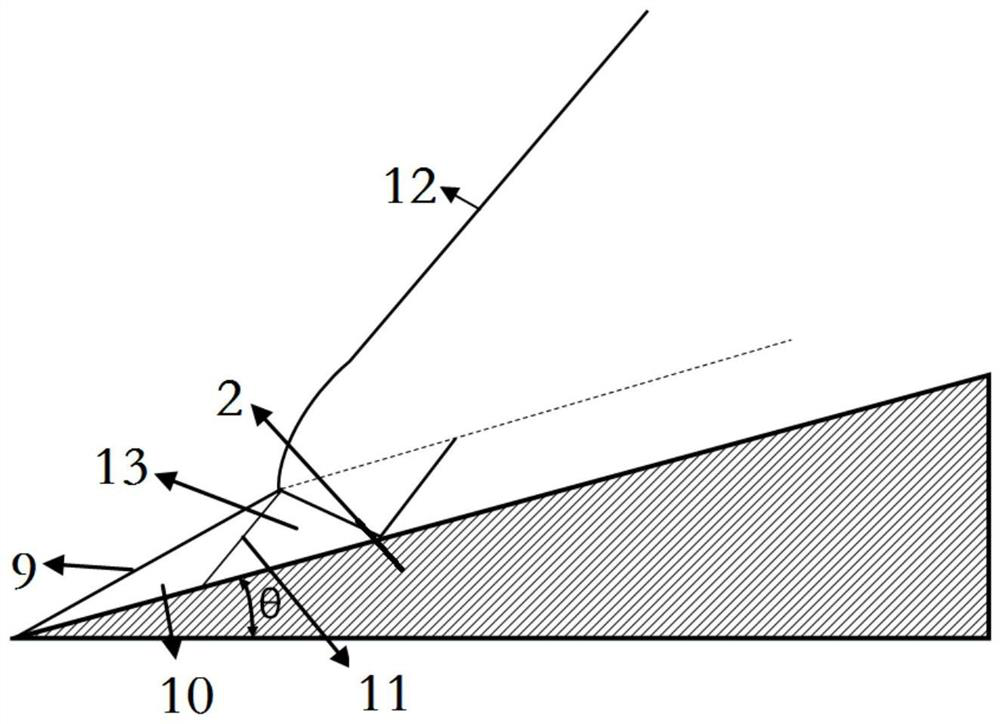

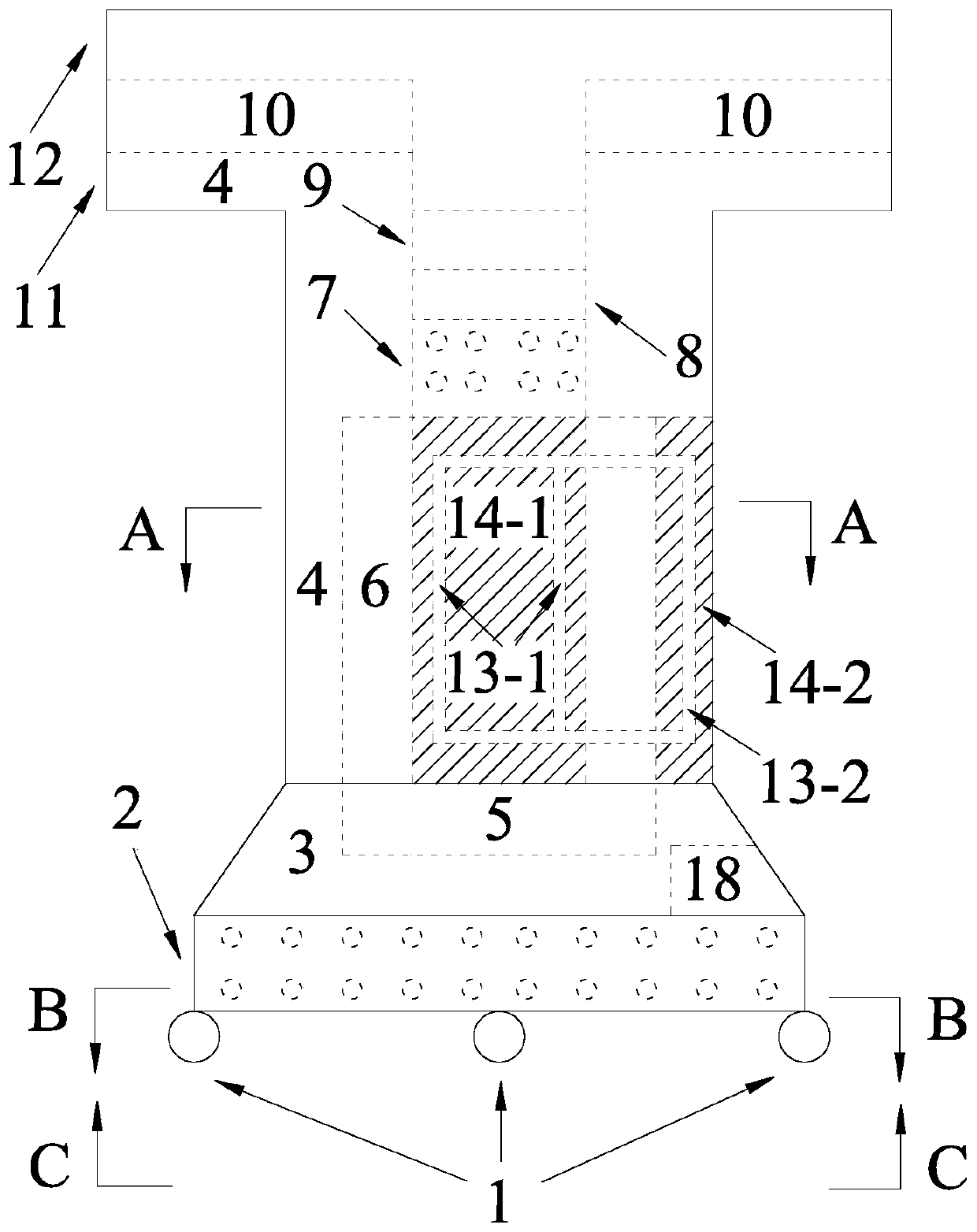

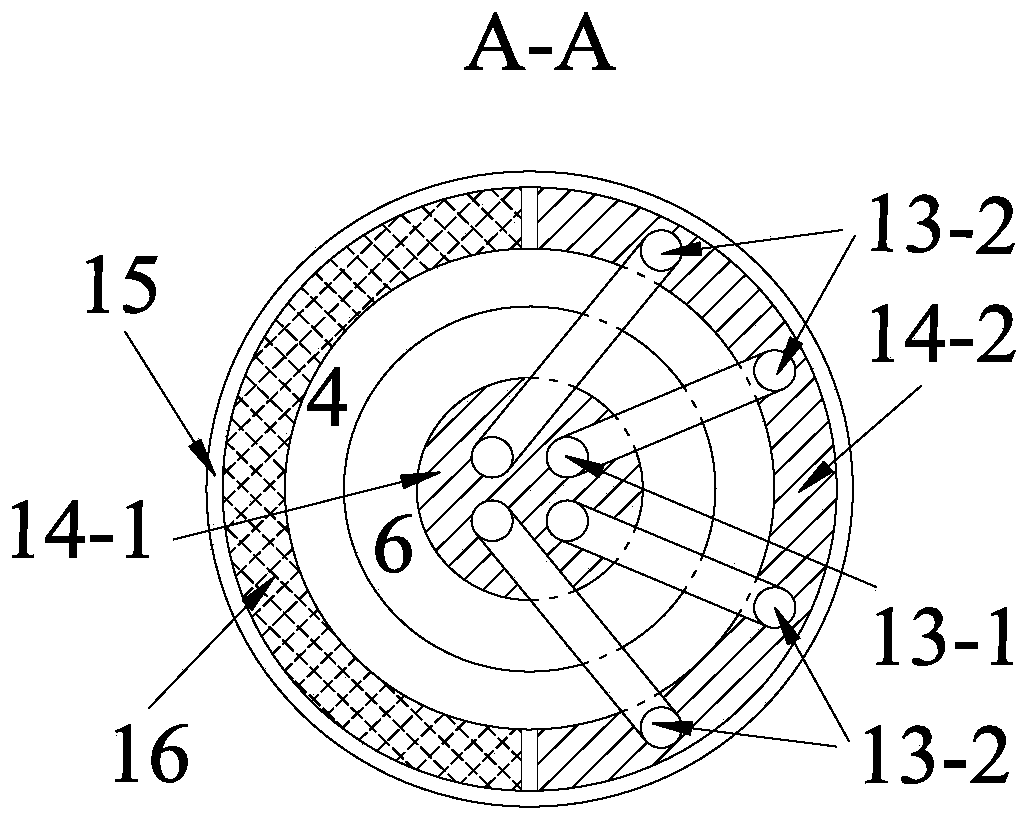

Combustion chamber, engine and aircraft based on supersonic speed ramjet oblique detonation

PendingCN113048515ADetonation enhancementSolve the technical problems of detonationGas turbine plantsIntermittent jet plantsRamjetShock wave

The invention discloses a combustion chamber, an engine and an aircraft based on supersonic speed ramjet oblique detonation. The combustion chamber is internally provided with a slope, the slope is obliquely arranged upwards from the inlet end of the combustion chamber to the outlet end of the combustion chamber, and one side wall face, opposite to the slope, of the combustion chamber is provided with a high-energy laser emitting device; the high-energy laser emitting device can emit laser and focus lasers after inducing oblique shock waves above the slope, the focused laser serves as a high-energy ignition source, energy is injected into a flow field, premixed gas is ignited, and therefore oblique detonation wave detonation is promoted. According to the combustion chamber, high-energy lasers and a small-angle physical slope are combined, high-energy laser focusing is utilized under the condition of slope induction, ignition is carried out after oblique shock wave induction, and therefore oblique detonation wave detonation can be effectively promoted.

Owner:NAT UNIV OF DEFENSE TECH

Solar air purification air heater

PendingCN109899979AComply with thermophysical propertiesReduce consumptionSolar heating energyFluid heatersActivated carbonProgrammable logic controller

The invention discloses a solar air purification air heater. A motor and four universal wheels are installed at the bottom of the solar air purification air heater. A primary filter is arranged on theinner side of a double-layer pore plate air inlet, and an air valve is installed on the top of a static pressure box. An air heater shell layer, a first air channel and a second air channel are arranged in a concentric circle mode. An electrothermal film heating layer is arranged on the outer side of the left semicircle of the first air channel, a phase change heat storage material is arranged onthe outer side of the right semicircle of the first air channel, and a phase change heat storage material is also distributed on the inner side of the second air channel. Four circulating water pipesare evenly arranged in the phase change heat storage materials on the two portions. The air passes through the pore plate air inlet, a fan and an efficient filter in sequence so that the deep purification of the air can be achieved. The top of the solar air purification air heater is divided by an activated carbon box into two channels which include a primary purification outlet and an efficientpurification outlet, a solar absorption layer covers the outer surface of the whole device, and the intelligent control of the equipment can be achieved by a PLC. The solar air purification air heatercan effectively absorb and store the solar energy, outwards supply the warm air, remove pollutants in the air and be widely applied to indoor heating ventilation and air purification.

Owner:TIANJIN UNIV OF COMMERCE

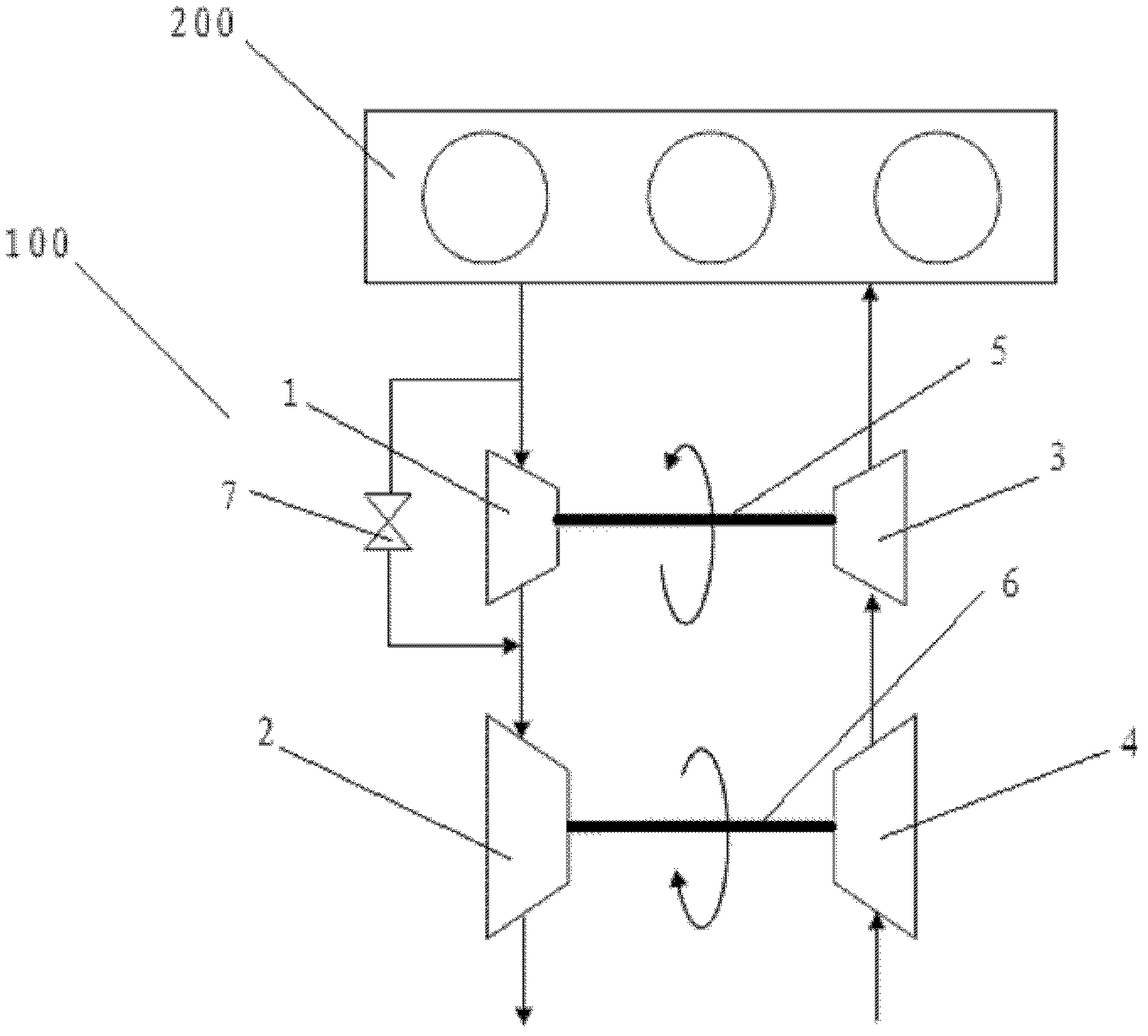

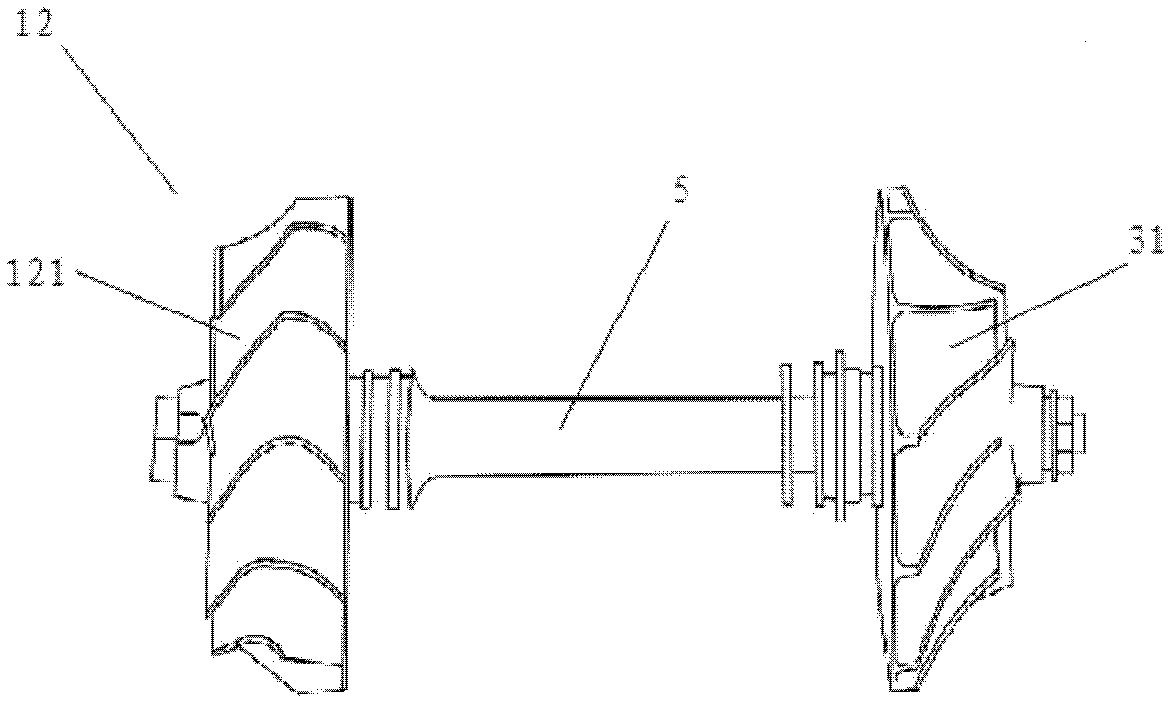

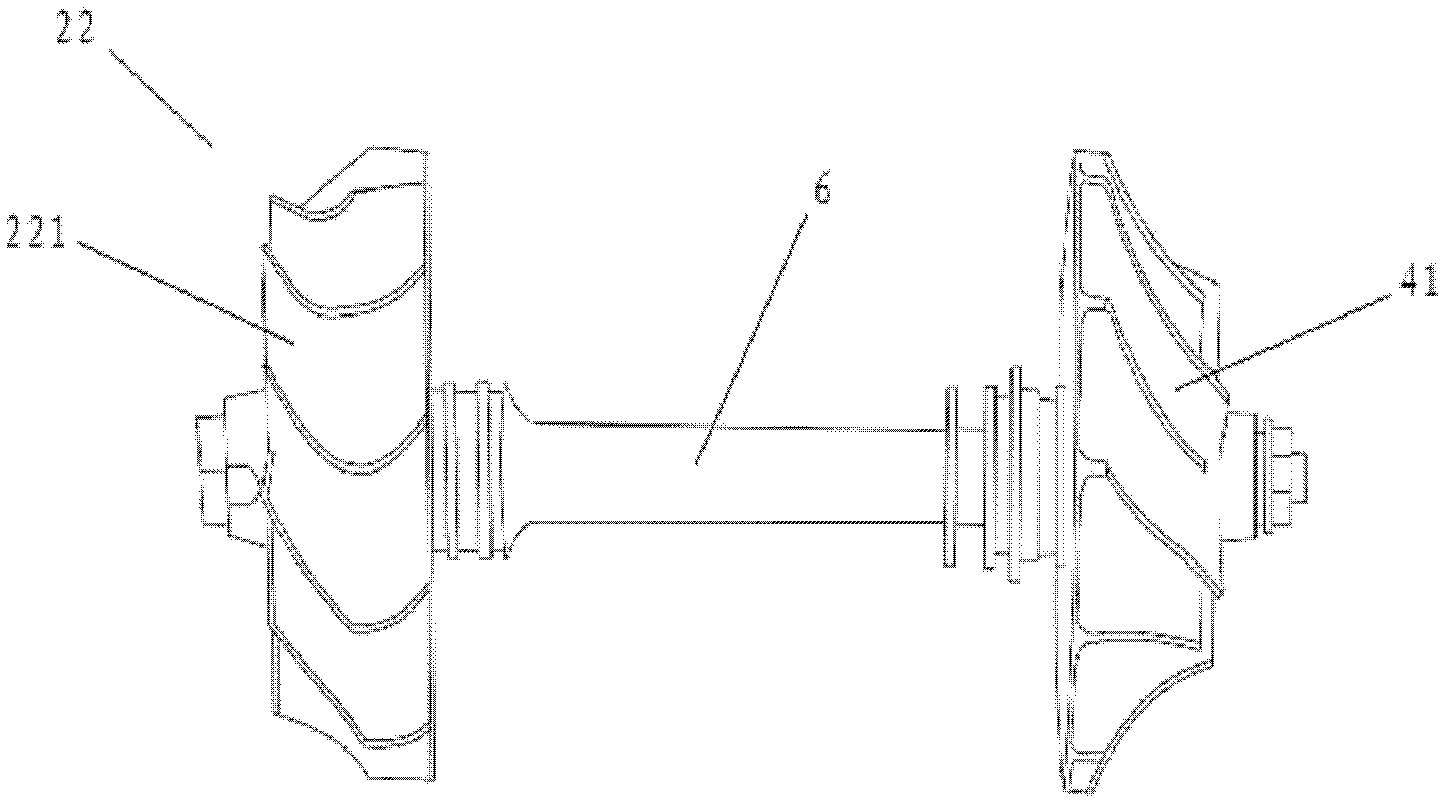

Two-stage turbocharging system

InactiveCN102562265AImprove efficiencyRealize counter-rotation arrangementInternal combustion piston enginesImpellerHigh pressure

The invention discloses a two-stage turbocharging system, which comprises a high-pressure stage turbomachine, a low-pressure stage turbomachine, a high-pressure stage air compressor and a low-pressure stage air compressor. The high-pressure stage turbomachine comprises a first volute casing and a first turbine, wherein the first turbine is arranged in the first volute casing and provided with a plurality of first blades having first bending directions. The low-pressure stage turbomachine comprises a second volute casing and a second turbine, wherein the second turbine is arranged in the second volute casing and provided with a plurality of second blades in directions opposite to the first bending directions. The high-pressure stage air compressor comprises a first casing and a first impeller, wherein the first impeller is arranged in the first casing and driven by the first turbine. The low-pressure stage air compressor comprises a second casing and a second impeller, wherein the second impeller is arranged in the second casing and driven by the second turbine. In the two-stage turbocharging system, the high-pressure stage turbomachine and the low-pressure stage turbomachine are in counter rotating arrangement, so that the efficiency of the low-pressure stage turbomachine is increased and the integral efficiency of the two-stage turbocharging system is increased obviously.

Owner:TSINGHUA UNIV

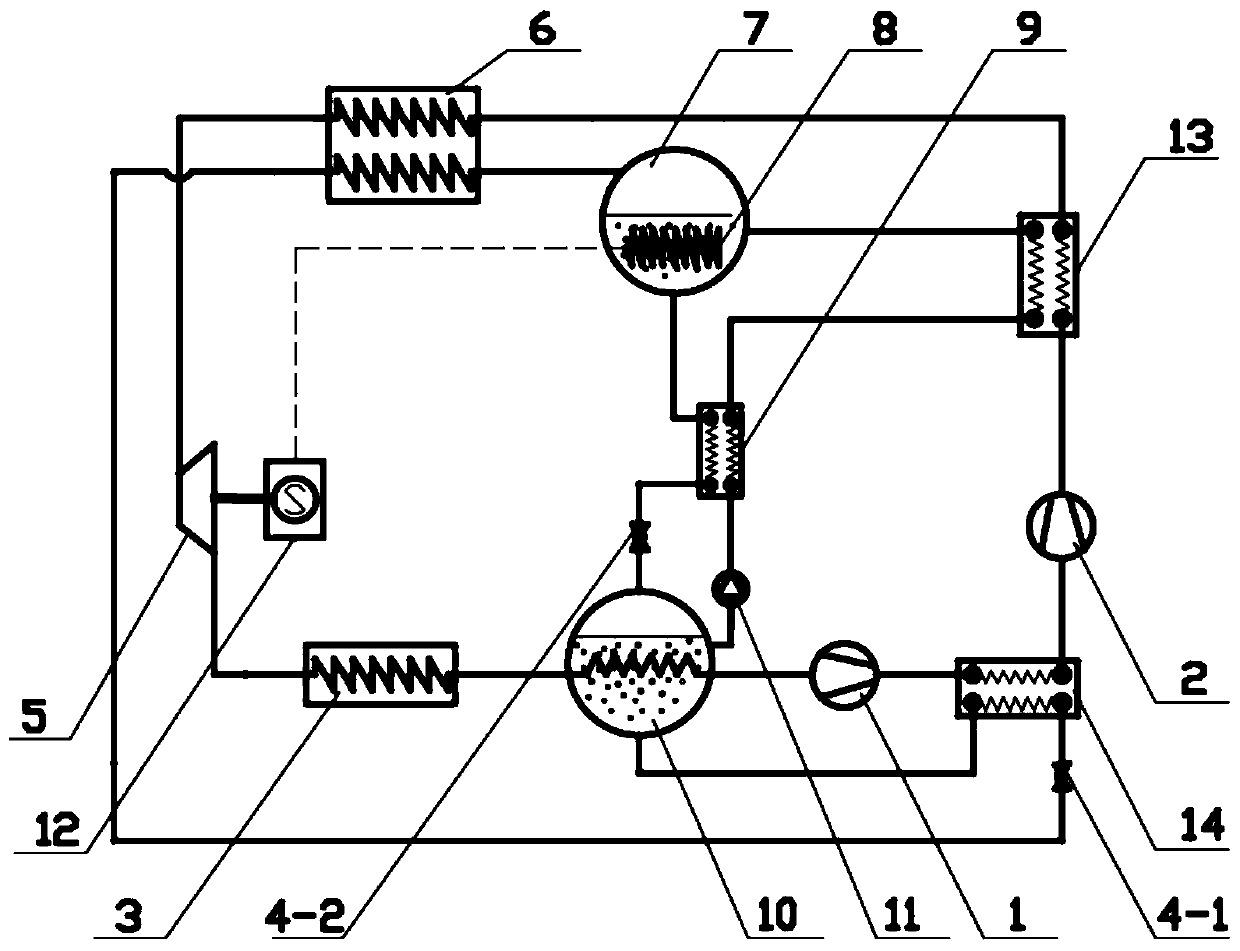

Absorption transcritical carbon dioxide two-stage compression refrigerating system

PendingCN109869945ALow running costReduce heat transfer areaRefrigeration machinesCarnot cycleProcess engineering

The invention discloses an absorption transcritical carbon dioxide two-stage compression refrigerating system, and aims to provide a refrigerating system which adopts CO2 cooling heat and CO2 expansion work to jointly drive an absorption refrigeration cycle to cool an interstage cooler so that the running cost and the initial investment cost of the system can be reduced. The absorption transcritical carbon dioxide two-stage compression refrigerating system comprises a two-stage compression refrigeration cycle and the absorption type auxiliary refrigeration cycle, a working medium of the two-stage compression refrigeration cycle is carbon dioxide, the two-stage compression refrigeration cycle comprises an expansion machine, and the expansion machine is arranged in a refrigerating medium inlet of an evaporator in the two-stage compression refrigeration cycle; and the auxiliary refrigerating cycle is used for reducing the suction temperature at an air suction port of a high-pressure stagecompressor in the two-stage compression refrigeration cycle. According to the system, the CO2 cooling heat and CO2 expansion work are utilized, the absorption type auxiliary refrigeration cycle is organically coupled to the steam compression main refrigeration cycle, the entropy production of the whole CO2 transcritical two-stage compression refrigerating system is smaller than that of an ordinary CO2 refrigerating system, and the thermodynamic process is more complete and is closer to a reverse carnot cycle.

Owner:TIANJIN UNIV OF COMMERCE

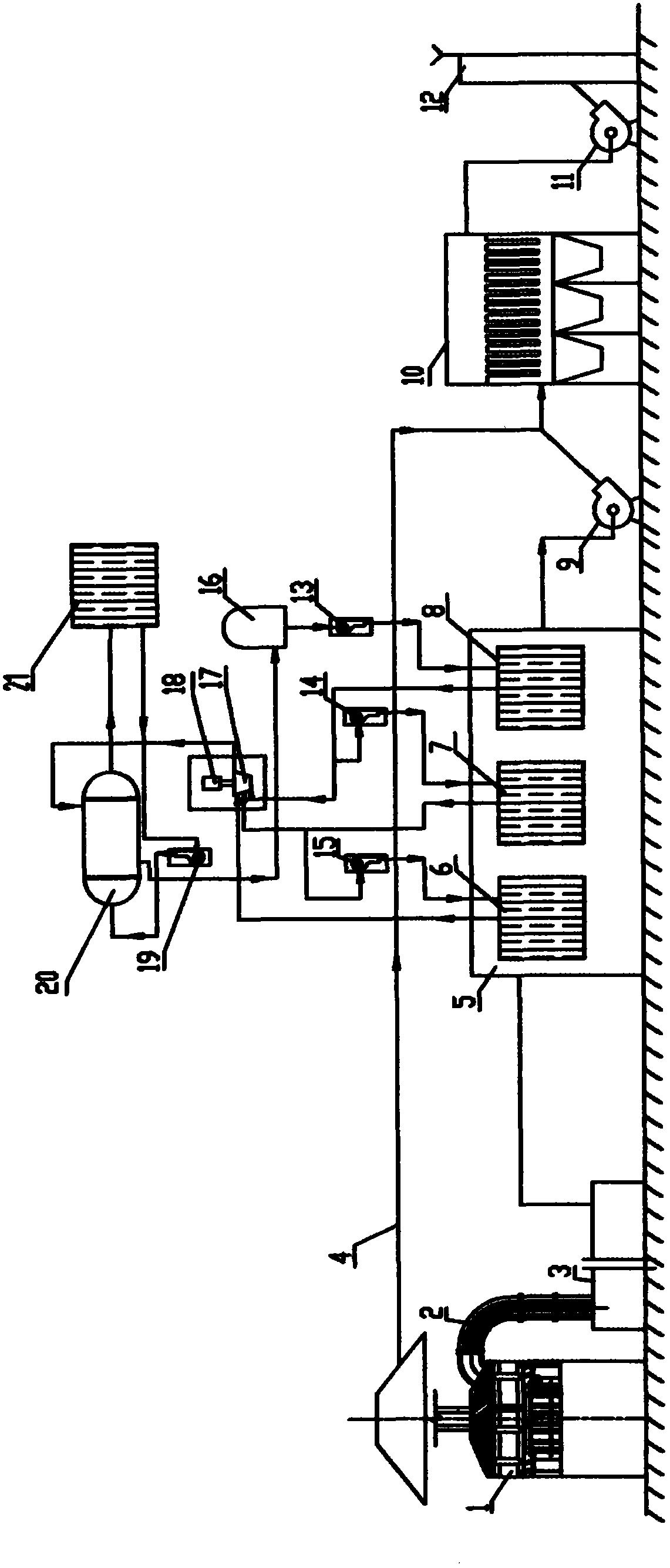

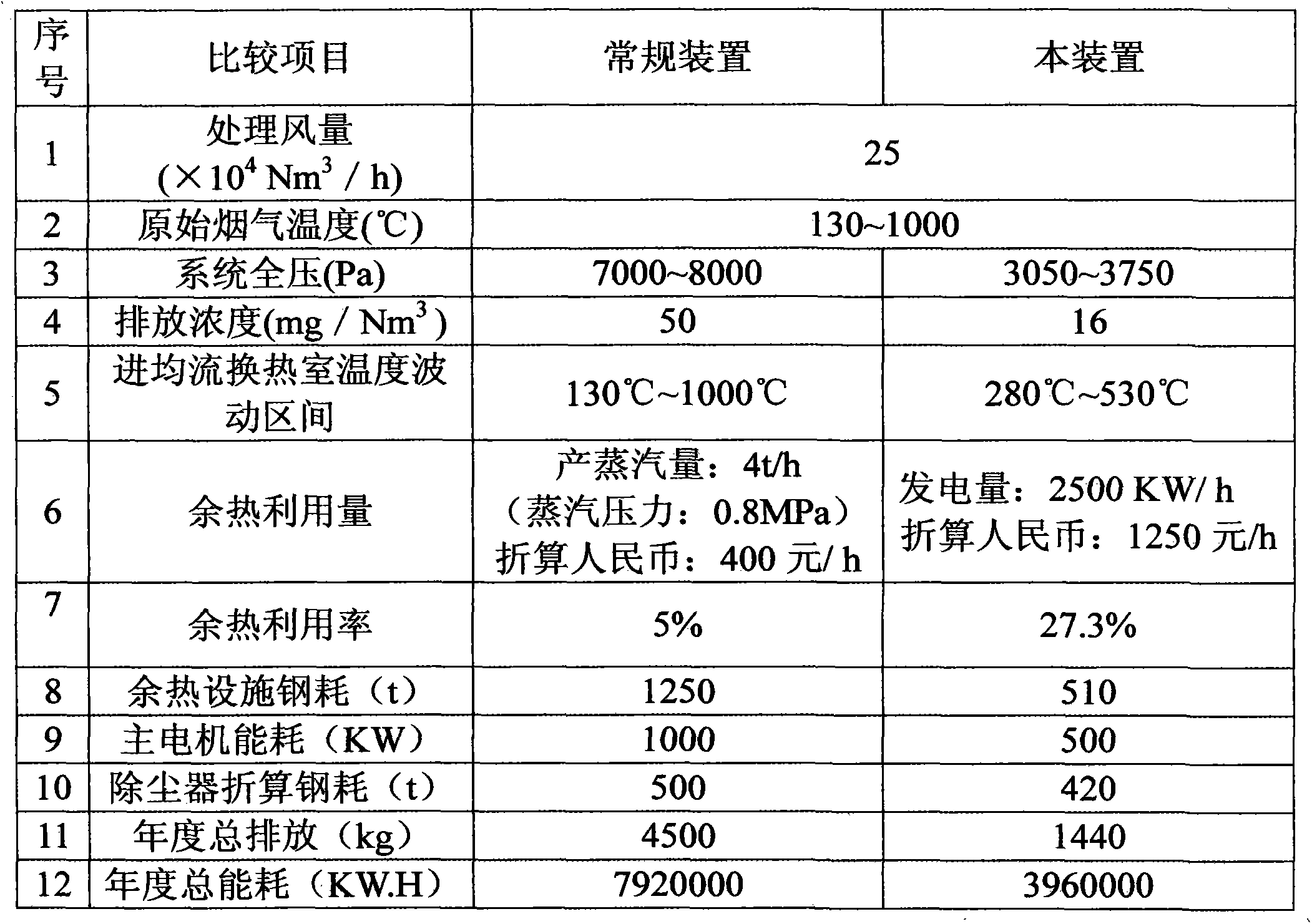

Organic Rankin waste heat power generation method based on high-temperature highly-dusty smoke of metallurgical furnace

InactiveCN104764336ALess investmentReduce dust contentIncreasing energy efficiencySteam engine plantsAtmospheric airOrganic Rankine cycle

The invention discloses an organic Rankin waste heat power generation method based on high-temperature highly-dusty smoke of a metallurgical furnace. The organic Rankin waste heat power generation method based on the high-temperature highly-dusty smoke of the metallurgical furnace is characterized in that the smoke of the metallurgical furnace is discharged from a fourth hole and passes through a water-cooling sliding sleeve so as to be mixed with cold air, the smoke mixed with the cold air enters a settling chamber, enters a sinter board dust catcher and then enters a heat-storage temperature uniformizing device after dust in the smoke is removed, the smoke enters a flow uniformizing heat exchange chamber after heat-storage temperature uniformization is conducted on the smoke, heat is released by the high-temperature smoke, so that heat exchange is completed, and the smoke is pressed into an exhaust cylinder through a main fan so as to be discharged to the atmosphere; heat of the smoke is absorbed by circulating water in a heat exchanger at the same time, a vapor-water mixture is formed and enters an evaporator, heat is released, the heat of the vapor-water mixture is absorbed by organic working medium liquid, so that working medium steam is formed, the working medium steam expands and acts in an organic turbine with a steam supplying port, and then a power generator is driven to generate power. The organic Rankin waste heat power generation method based on the high-temperature highly-dusty smoke of the metallurgical furnace is also characterized in that R227ea is taken as a circulating organic working medium. By the adoption of the organic Rankin waste heat power generation method based on the high-temperature highly-dusty smoke of the metallurgical furnace, heat energy in the smoke can be recovered to the maximum extent so as to be directly converted into high-grade electric energy, the heat efficiency is improved by 23%-28% compared with single-stage evaporation type organic Rankin circulation, and environmental friendliness is high.

Owner:无锡市广运环保机械有限公司

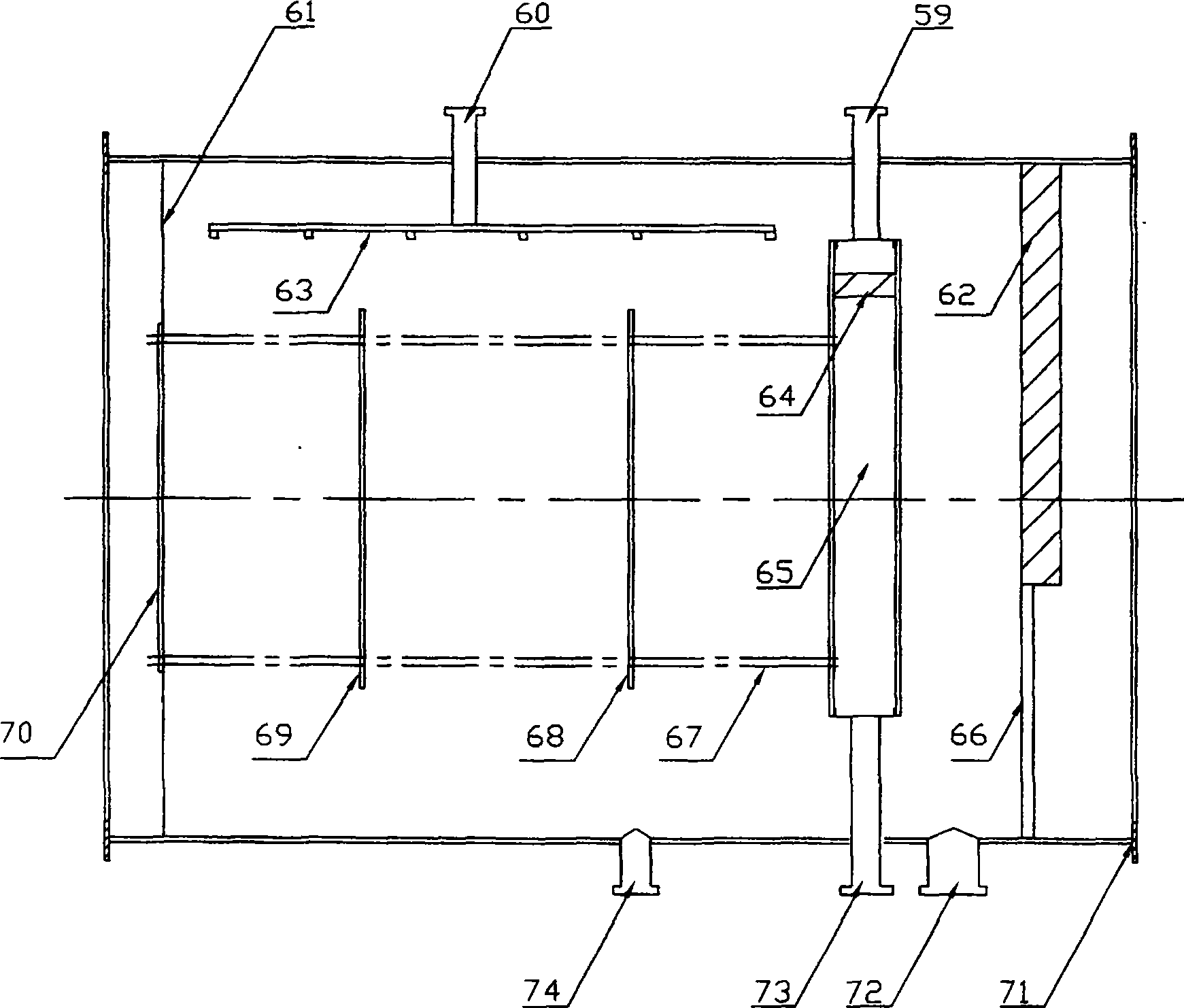

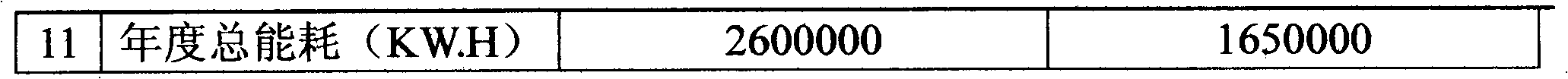

Metallurgical furnace exhaust gas multistage organic Rankine waste heat power generation energy-saving dedusting method

InactiveCN103134332AReduce imbalanceReduce entropy increaseIncreasing energy efficiencySteam engine plantsThermal energyAtmospheric air

The invention provides a metallurgical furnace exhaust gas multistage organic Rankine waste heat power generation energy-saving dedusting method. The method is characterized in that exhaust gas in a metallurgical furnace is discharged from a fourth hole, is mixed with cold air through a water cooling sliding sleeve, enters a combustion settling chamber after carbonic oxide gas is burnt, and then enters a waste heat exchange chamber and finally completes heat exchange. When the temperature of the exhaust gas drops to 120 DEG C, the exhaust gas enters a dust remover, then is subjected to dedusting, is pressed into an exhaust funnel through a main air blower and finally is discharged into atmosphere. Meanwhile, circulating water is driven through a feed water pump of a heat exchanger to flow into a heat exchanger arranged in the waste heat exchange chamber to absorb heat in the exhaust gas, and then steam-water mixture is formed. Organic working medium liquid absorbs the heat of the steam-water mixture, and does work in a multistage organic turbine in an expanding mode to drive a generator to generate electricity. The method is further characterized in that R124 refrigerant is used as the circulating organic working medium. The metallurgical furnace exhaust gas multistage organic Rankine waste heat power generation energy-saving dedusting method is capable of recovering heat energy in the exhaust gas to the maximum extent and directly converting the heat energy to high-grade electric energy. The efficiency through the method is improved by 10-20% more than the efficiency through a single-stage organic Rankine evaporating method. Moreover, the method has good environment-friendly effects.

Owner:无锡市东优环保科技有限公司

Organic Rankine waste heat power generation method for flue gas frommetallurgical furnace

InactiveCN104344733ALess investmentReduce dust contentIncreasing energy efficiencySteam engine plantsThermal energyAtmospheric air

The invention discloses an organic Rankine waste heat power generation method for flue gas from a metallurgical furnace. The organic Rankine waste heat power generation method is characterized in that the flue gas from the metallurgical furnace is exhausted from a fourth hole and is mixed with cold air through a water-cooled sliding sleeve; mixed gases enter a settling chamber and then enter a sinter board dust catcher; the mixed gases subjected to dust collecting enter a regenerative temperature regulator; under the regenerative temperature regulating action, flue gas enters a current-sharing heat exchange chamber; high-temperature gas releases the heat and then heat exchange is finished; the flue gas is pressed in an exhaust funnel and then is exhausted in the atmosphere; meanwhile, circulating water absorbs heat of the flue gas from the heat exchanger to form steam-water mixture; the steam-water mixture enters an evaporator and releases the heat; organic working medium liquid absorbs the heat of the steam-water mixer to become working medium steam; the working medium steam expands in an organic turbine with a steam replenishing opening to do work and drives a power generator to generate power. The organic Rankine waste heat power generation method is characterized in that R227ea is adopted as a circulating organic working medium. According to the method disclosed by the invention, heat energy in the flue gas can be recovered to the maximum extent and is directly converted into high-grade electric energy; compared with a single-stage evaporation organic Rankine cycle mode, the method has the advantages that heat efficiency is improved by 23-28 percent, and a good environment-friendly effect is obtained.

Owner:无锡市东优环保科技有限公司

Method and device for power generation by utilizing steam generated from waste heat of steel mill in cascade mode

InactiveCN101915507BIncrease the number ofQuality improvementEnergy industryIncreasing energy efficiencyFlue gasSuperheater

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Utilizing method for flue gas waste heat of cupola furnace

InactiveCN105318731AReduce imbalanceReduce emission concentrationIncreasing energy efficiencySteam engine plantsOrganic Rankine cycleAtmospheric air

The invention discloses a utilizing method for flue gas waste heat of a cupola furnace. The utilizing method is characterized in that flue gas in the cupola furnace is exhausted from a fourth hole, is mixed into cold air through a water-cooled sliding sleeve, and enters into a precipitating chamber and a waste heat exchange chamber; high-temperature flue gas releases the heat; cooled flue gas is exhausted from a booster fan, and is mixed with flue gas from an external exhaust pipeline connected to the upper part of an electric furnace; mixed flue gas enters into a sinter board dust catcher; dedusted flue gas is pressed into an exhaust funnel through a main air blower and is exhausted into the atmosphere; meanwhile, organic working medium liquid absorbs the heat of a flue gas waste heat carrier in a low-pressure stage evaporator, a medium-pressure stage evaporator and a high-pressure stage evaporator and is changed into working medium steam; the working medium steam expands in an organic turbine with a steam supplementing port to do work, and drives a power generator to generate electricity. The utilizing method is also characterized in that R290 is adopted as a cyclic organic working medium. By adopting the method disclosed by the invention, heat energy in the flue gas can be recovered to the maximum extent and is directly converted into high-grade electric energy; compared with single-stage evaporation organic Rankine's cycle, the utilizing method has the advantages that the heat efficiency is improved by 31 to 36 percent, and a good environment-friendly effect is realized.

Owner:无锡市东优环保科技有限公司

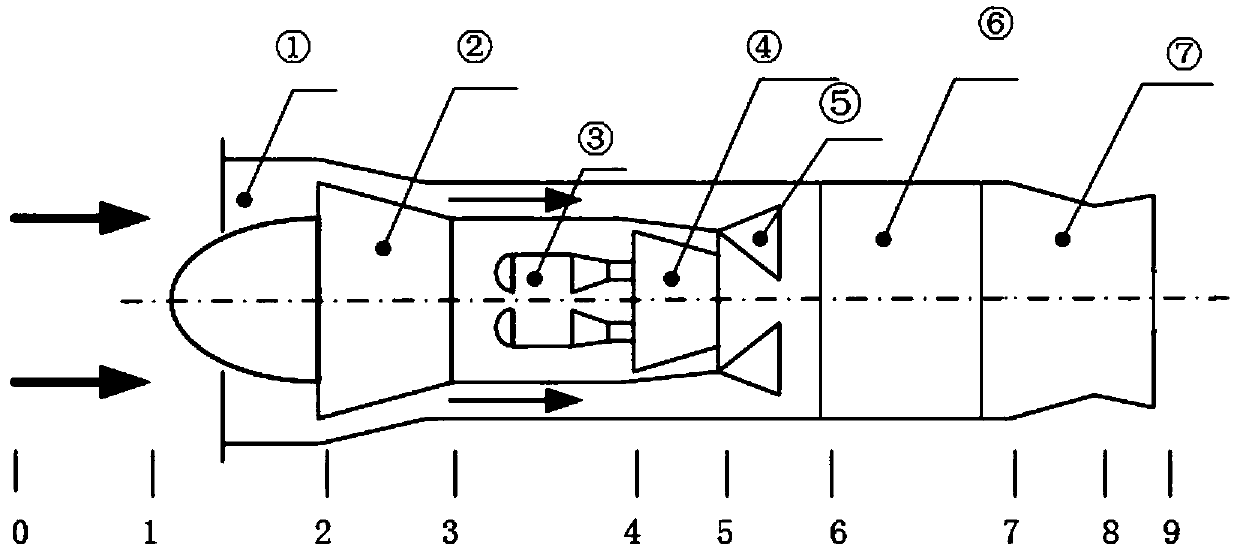

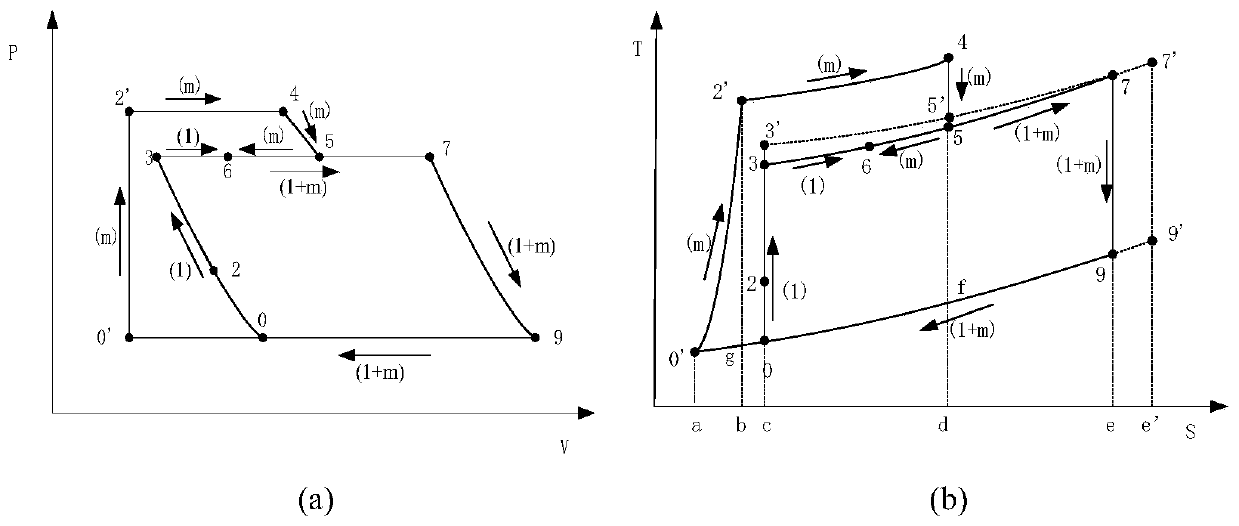

Air turbine rocket engine based on pulse detonation

PendingCN111271192AIncrease thrustImprove parameters such as specific impulseRocket engine plantsCombustion chamberEngineering

The invention provides an air turbine rocket engine based on pulse detonation. A pulse detonation combustor is used for replacing a ram combustor in the air turbine rocket engine. The air turbine rocket engine based on the pulse detonation is mainly composed of an air inlet passage, an air compressor, a gas generator, a turbine, a flow mixing and reverse introducing prevention structure, the pulsedetonation combustor and a spray pipe. The gas generator carrying an oxidant and a fuel is arranged in the engine, fuel-rich gas generated by the gas generator drives the turbine to act, the turbinedrives the air compressor to work, air entering from the air inlet passage is compressed by the air compressor and is uniformly mixed with the rich-rich gas acting through the turbine in a flow mixerand then enters the pulse detonation combustor for detonation combustion, and high-temperature high-pressure gas generated by detonation combustion is discharged through the spray pipe to generate thrust; and the detonation combustion has the significant advantages of being high in thermal cycling efficiency, fast in combustion speed, and the like, the air turbine rocket engine based on the pulsedetonation makes full use of the advantages of the detonation combustion, so that a power device obtains lower oil consumption rate and larger unit thrust.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

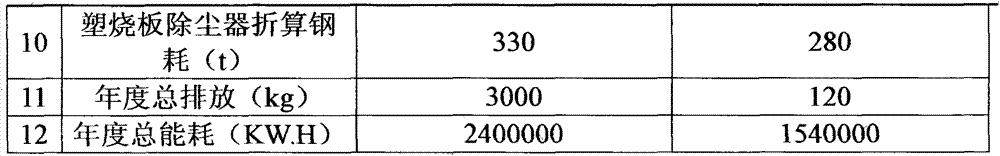

Electric furnace inner-outer exhaust smoke waste heat power generation energy saving dust removing method

InactiveCN104748563AReduce the maximum temperatureReduce volatilityIncreasing energy efficiencySteam engine plantsAtmospheric airOrganic Rankine cycle

An electric furnace inner-outer exhaust smoke waste heat power generation energy saving dust removing method is characterized in that electric furnace inner exhaust smoke is exhausted from a fourth hole, cold air is mixed through a water cooling sliding sleeve, the smoke enters a settling chamber and a heat storage average-temperature device, the smoke goes out of the heat storage average-temperature device and is mixed with smoke out of an outer exhaust pipeline connected above an electric furnace, the mixed smoke enters a flow-equalizing heat storage chamber, the smoke out of the flow-equalizing heat storage chamber enters a sinter board dust catcher, after dust removing, the smoke is pressed into an exhaust funnel by a main fan and is exhausted into the atmosphere, meanwhile, organic working medium liquid absorbs heat of a smoke waste head carrier in a low-pressure stage evaporator, a middle-pressure stage evaporator and a high-pressure stage evaporator and becomes working medium steam, expanding working is carried out in an organic turbine with a steam supplement opening, and a power generator is driven to generate power. The electric furnace inner-outer exhaust smoke waste heat power generation energy saving dust removing method is characterized in that R600a is used as a circulation organic working medium. According to the method, heat energy in the smoke can be recycled to the maximum degree and is directly converted into high-grade electric energy, the heat efficiency is improved by 30%-35% compared with the single-stage evaporation organic Rankine cycle, and environment-protecting effect is good.

Owner:无锡市东优环保科技有限公司

Electric furnace smoke multistage organic Rankine cycle waste heat power generation method

InactiveCN104075578AReduce imbalanceReduce emission concentrationIncreasing energy efficiencySteam engine plantsElectric arc furnaceAtmospheric air

An electric furnace smoke multistage organic Rankine cycle waste heat power generation method is characterized in that smoke discharged from an electric furnace is discharged through a fourth hole, cold air is mixed into the smoke through a water cooling sliding sleeve, the smoke enters a sedimentation chamber and a waste heat exchange chamber, high temperature smoke releases heat, the cooled smoke is discharged from a pressurizing fan to be mixed with smoke discharged from an external discharging pipeline connected with the upper portion of the electric furnace and enter a dust remover together, the mixed smoke is subjected to dust removing and is pressed into a discharging barrel through a main fan and discharged to the atmosphere, and meanwhile organic working medium liquid absorbs heat of a smoke waste heat carrier in a low pressure evaporator, a medium pressure evaporator and a high pressure evaporator to be turned into working medium steam to expand and do work in an organic turbine with a steam supplementation port and drive a power generator to generate power. The method is characterized in that R290 is adopted as a cycle organic working medium. By means of the method, heat energy in the smoke can be recycled to the largest extent and is directly converted into high-grade power, the heat efficiency is increased by 31-36% compared with that of a single-stage evaporation organic Rankine cycle, and the environment protection effect is good.

Owner:无锡市东优环保科技有限公司

Metallurgical furnace high-dust-content smoke organic Rankin waste heat power generation method

InactiveCN104075577ALess investmentReduce dust contentIncreasing energy efficiencySteam engine plantsOrganic Rankine cycleAtmospheric air

A metallurgical furnace high-dust-content smoke organic Rankin waste heat power generation method is characterized in that metallurgical furnace smoke is discharged from a fourth hole, is mixed with cold air through a water cooling sliding sleeve, enters a settling chamber, then enters a high temperature dust remover to be subjected to dust moving and enters a heat accumulation temperature evening device to be subjected to heat accumulation and temperature evening, then the smoke enters a flow evening heat exchange chamber, and high temperature smoke releases heat to finish heat exchange. The smoke is pressed into an exhaust barrel through a main fan to be discharged into the atmosphere. Meanwhile, circulation water absorbs heat of the smoke from a heat exchanger to form steam water mixture which enters an evaporator, the steam water mixture releases heat, organic working medium liquid absorbs heat of the steam water mixture to form working medium steam, and the working medium steam expands and does work in an organic turbine with a steam supplementation port to drive a power generator to generate power. The method is characterized in that R227ea is adopted as the circulation organic working medium. By means of the method, heat energy in the smoke can be recycled to the largest extent and directly converted into high level power, the heat efficiency is increased by 23-28% compared with single-stage evaporation organic Rankin circulation, and the environment protection effect is good.

Owner:无锡市东优环保科技有限公司

A flow control method for heating a heated fluid in stages by using a heat exchange system

ActiveCN106439769BReduce the temperature difference between inlet and outletReduce the temperatureBoiler controlSteam generation using solar heatSuperheaterEngineering

The invention belongs to the field of heat exchange equipment, and discloses a flow control method for heating a heated fluid in stages by adopting a heat exchange system. The heat exchange system comprises a pre-heater, an evaporator and a super-heater; the pre-heater is connected with the evaporator and the super-heater in sequence; the pre-heater is used for heating a sub-cooled fluid to a saturated fluid; the evaporator is used for heating the saturated fluid to a saturated gas; the super-heater is used for heating the saturated gas to a superheated gas. According to the flow control method for heating the heated fluid in stages by adopting the heat exchange system, the terminal temperature difference between an outlet and an inlet of each evaporator is reduced by controlling the flow of the heating fluid in the heat exchange system, so that the entropy production produced in a heat exchange process can be reduced; the energy utilization rate of the system is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Stage refrigerating cycle liquefaction process

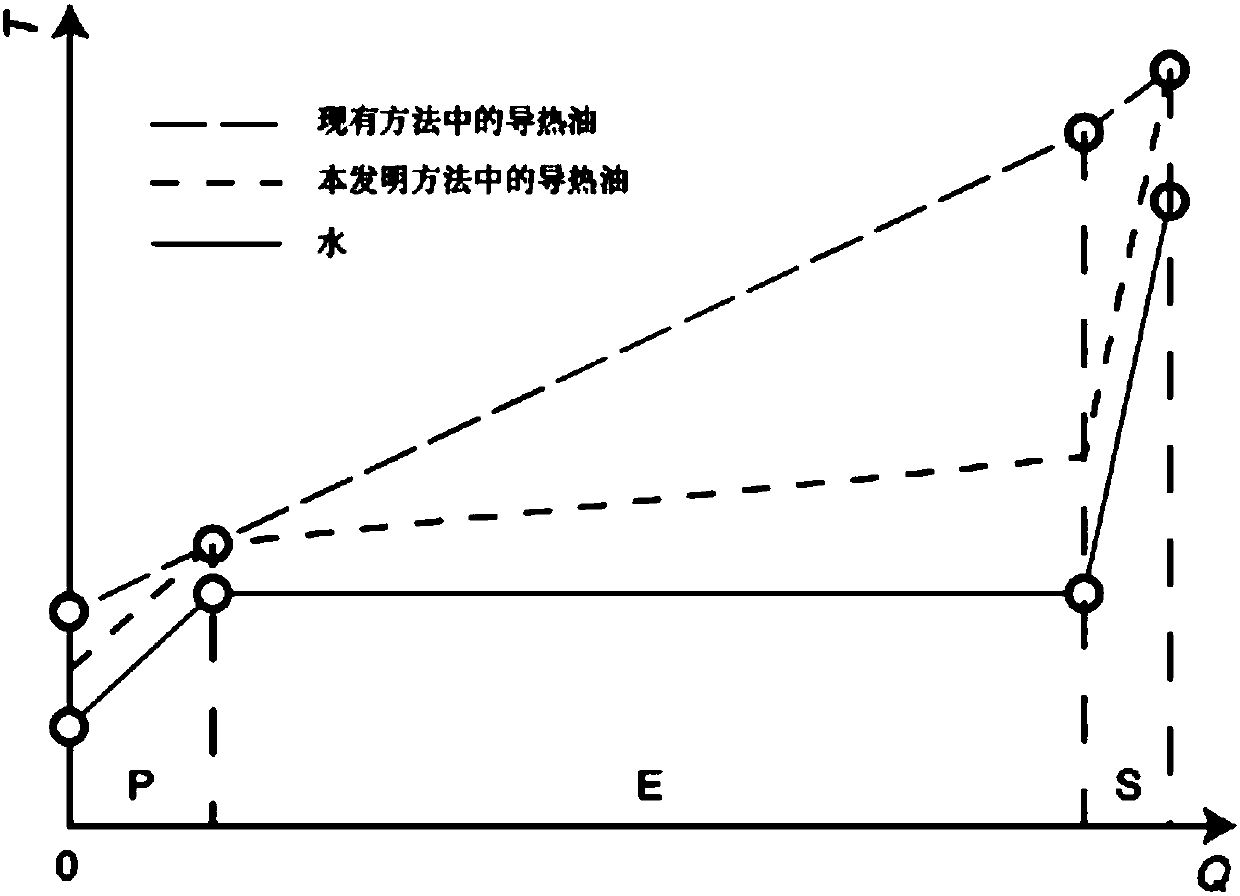

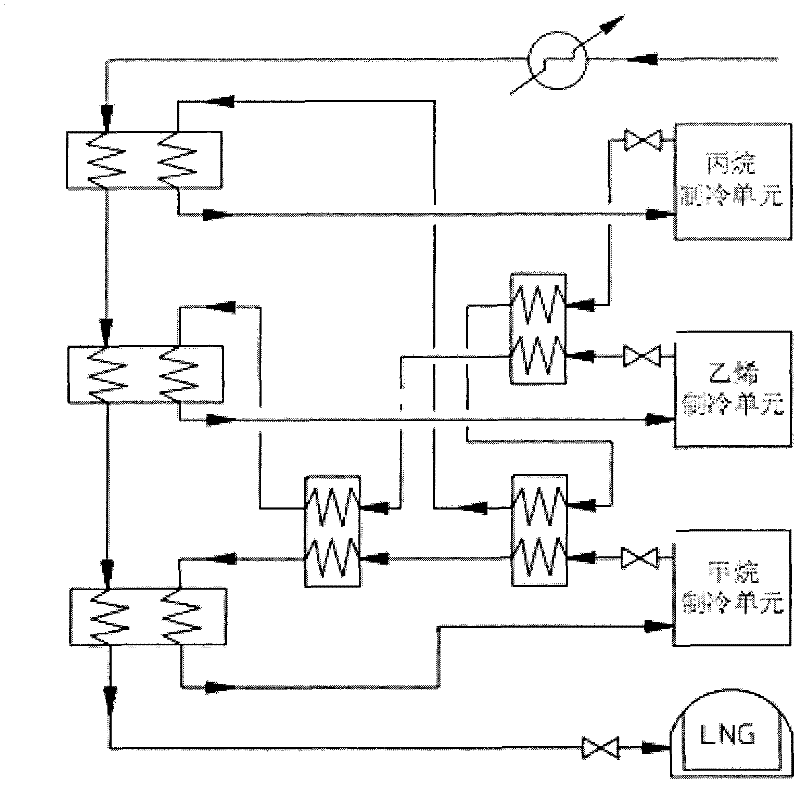

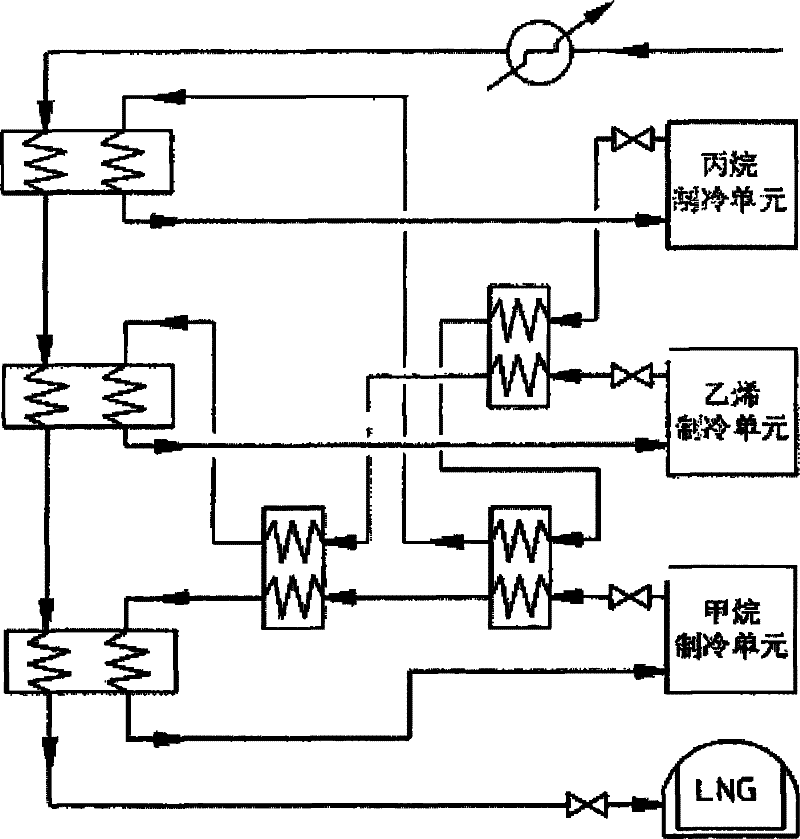

InactiveCN102453573AReduce energy consumptionReduce entropy increaseGaseous fuelsCyclic processRefrigeration temperature

The invention discloses a stage refrigerating cycle liquefaction process, which comprises the propane cycle process, the ethylene cycle process and methane cycle process. The stage refrigerating cycle liquefaction process has low energy consumption; because a nine-stage liquefaction flow is adopted, the refrigeration temperature in each stage approaches a cooling curve of a feed gas, entropy production is decreased, and the energy consumption approaches the theoretical thermodynamic efficiency upper limit; a refrigerant is a pure substance, a proportioning problem is avoided, and the operation is stable; in a cycle, a single refrigerant is adopted and easily keeps the given temperature in the cooling process, and because the components of a cycling medium are always same, a device can quickly start and stop, and the operation is stable; and a technology is mature and the surging of a compressor is reduced; and because the compressor always intakes gas with constant molecular weight, the surging danger of the compressor is reduced.

Owner:袁俊海

A kind of composite refrigeration natural gas liquefaction method

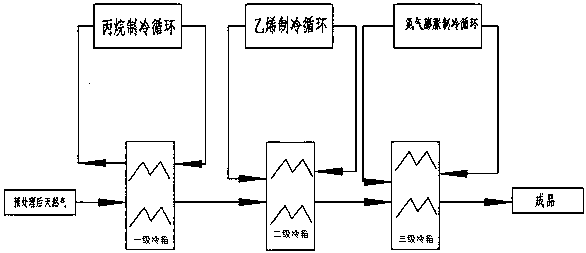

ActiveCN105605882BReduce consumptionImprove operational safetySolidificationLiquefactionIn planeNitrogen

The invention relates to a method for natural gas liquefaction, in particular to a method for composite refrigeration natural gas liquefaction by adopting propane and ethylene refrigerant stepwise refrigeration and nitrogen expansion cycle. The method for composite refrigeration natural gas liquefaction is used for heat exchange of pretreated natural gas and a composite refrigerant in a cold box heat exchanger, so as to liquefy the natural gas into liquefied natural gas. The method comprises the steps of first making the pretreated natural gas enter a primary cold box to be subject to refrigeration cycle heat exchange with propane to -30 DEG C to -60 DEG C; making the natural gas enter a secondary cold box to be subject to refrigeration cycle heat exchange with ethylene to -90 DEG C; and finally making the natural gas enter a third-stage cold box to be subject to expansion refrigeration cycle heat exchange with nitrogen to -150 DEG C to -160 DEG C to form finished liquefied natural gas. According to the method for liquefying the natural gas, the refrigerant is a pure substance, no ratio problem occurs, and the refrigerant is stable to operate. Low temperature level refrigerant nitrogen is non-combustible fluid, space is saved better in plane arrangement, and the operational safety is higher.

Owner:中石化石油工程技术服务有限公司 +1

A direct-fired heat pump process and equipment for produced water in strong corrosion and high salinity oilfields

InactiveCN104075481BAvoid corrosionReduce foulingFluid heatersMechanical apparatusWater vaporLithium bromide

The invention relates to a direct-fired heat pump process and equipment for produced water in strong corrosion and high salinity oilfields. The process first sends the oilfield produced water from the sewage tank to the tube side of the produced water low-pressure heat exchange evaporator, and the produced water low-pressure heat exchange evaporator shell side has low-pressure clean water, which enters the low-pressure absorber shell side after absorbing heat and vaporized, and is concentrated After the lithium bromide solution is absorbed, it becomes a dilute lithium bromide solution and releases heat. The dilute lithium bromide solution is boosted by an anti-corrosion water pump and then sent to the direct-fired generator to be heated to boiling. The vaporized atmospheric pressure water vapor is sent to the shell side of the atmospheric pressure condenser through the pipeline. The present invention extracts part of the heat energy from the oilfield produced water, and uses it for production or daily life after the direct-fired heat pump drives the temperature up, not only can the low-grade heat energy of the oilfield produced water be efficiently utilized, but also the thermal efficiency of the system is about 1.85, which is about the same as that of a common heating furnace. Compared with the existing technology, the heating coefficient has been improved three times, two processes and water pumps have been omitted, and the corrosion and scaling problems of oilfield produced water have been solved.

Owner:周立超 +3

Dedusting method using residual heat from flue gas of fully-closed electric furnace

InactiveCN105890380ALower discharge temperatureReduce imbalanceIncreasing energy efficiencyMachines/enginesHeat carrierElectric arc furnace

The invention discloses a dedusting method using residual heat from flue gas of a fully-closed electric furnace. The dedusting method is characterized in that internally-exhausted flue gas of the electric furnace is exhausted through a fourth hole, and cold air is mixed in through a water-cooling sliding sleeve to enter a settling chamber; the flue gas enters a cyclone dust collector for pre-dedusting; then the flue gas enters a flow equalization regenerative chamber, the high temperature flue gas gives out heat, and when the temperature drops to 80 DEG C, the cooled flue gas comes from a booster fan to be mixed with flue gas from an external pipeline connected above the electric furnace to enter a sinter board dust catcher together, and the flue gas is pressed into an exhaust funnel by a main air blower to be injected into the atmosphere after dedusting; and meanwhile, organic working medium liquid absorbs the heat of flue gas residual heat carrier in a low pressure level evaporator, an intermediate pressure level evaporator and a high pressure level evaporator to be turned into working medium steam, the steam does work by expansion in an organic turbine with a steam adding opening, and accordingly an electric generator is driven to generate electricity. The dedusting method has the characteristic that R600a is used as a circulation organic working medium. By the adoption of the method, heat energy in the flue gas can be recovered to the maximum degree to be converted into high-grade electric energy directly, and therefore the environmental protection effect is good.

Owner:王正新

Turbocharger

ActiveCN104110300BSpeed up the flowReduce angleInternal combustion piston enginesEngine componentsTurbochargerBypass valve

The invention relates to a turbocharger, in particular to a turbocharger with a dividing wall on the transition joint, which has the functions of flow splitting and guiding, including a turbine casing with a flow channel, and the turbine The housing is provided with a bypass channel connecting the flow channel, and a bypass valve is provided on the bypass channel, and a transition joint is fixedly connected to the installation surface of the turbine housing, and the feature is that the transition joint is connected with the turbine housing A partition wall is provided on one side, and the partition wall extends into the inner cavity of the turbine casing and divides the turbine casing into a central area and a peripheral area; an installation slot is opened on the partition wall corresponding to the bypass valve. The supercharger can significantly increase the bypass volume, and at the same time ensure that the efficiency of the turbine is basically unchanged or even slightly improved, so as to meet the performance requirements of the engine.

Owner:WUXI CUMMINS TURBO TECH

Organic Rankin waste heat power generation method based on smoke of semi-closed electric furnace

InactiveCN104764337ALower discharge temperatureReduce imbalanceIncreasing energy efficiencySteam engine plantsComing outOrganic Rankine cycle

The invention discloses an organic Rankin waste heat power generation method based on smoke of a semi-closed electric furnace. The organic Rankin waste heat power generation method based on the smoke of the semi-closed electric furnace is characterized in that smoke of the semi-closed furnace is discharged from a fourth hole and passes through a water-cooling sliding sleeve so as to be mixed with cold air, the smoke mixed with the cold air enters a settling chamber and then enters a waste heat exchange chamber, heat is released by the high-temperature smoke, cooled smoke comes out through a pressurizing fan and is mixed with smoke discharged from an external exhaust pipeline connected to the upper portion of the electric furnace, the smoke mixture enters a sinter board dust catcher and is pressed into an exhaust cylinder through a main fan so as to be discharged to the atmosphere after dust in the smoke mixture is removed; heat of a carrier for the waste heat of the smoke is absorbed by organic working medium liquid in a low-pressure evaporator, a medium-pressure evaporator and a high-pressure evaporator, so that working medium steam is formed and expands and acts in an organic turbine with a steam supplying port, and a power generator is driven to generate power. The organic Rankin waste heat power generation method based on the smoke of the semi-closed electric furnace is also characterized in that R290 is taken as a circulating working medium. By the adoption of the organic Rankin waste heat power generation method based on the smoke of the semi-closed electric furnace, heat energy in the smoke can be recovered to the maximum extent so as to be directly converted into high-grade electric energy, the heat efficiency is improved by 31%-36% compared with single-stage evaporation type organic Rankin circulation, and environmental friendliness is high.

Owner:无锡市广运环保机械有限公司

Metallurgical furnace high ash-laden gas multi-level organic Rankine cycle cogeneration method

InactiveCN103105070AReduce dust contentReduce emission concentrationEnergy industryIncreasing energy efficiencyOrganic Rankine cycleCogeneration

Provided is a metallurgical furnace high ash-laden gas multi-level organic Rankine cycle cogeneration method. The metallurgical furnace high ash-laden gas multi-level organic Rankine cycle cogeneration method is characterized in that smoke evacuation air inside a metallurgical furnace is discharged, after cold-blast air is mixed through a water-cooling sliding sleeve, the smoke evacuation air enters into a combustion settling chamber. Exhaust gas which passes through the combustion settling chamber enters a high-temperature dust remover, after the dust extraction, the exhaust gas enters into a thermal storage heat exchange chamber, a heat exchange is finished, the temperature falls to 90 DEG C, and the exhaust gas is pressed into an air exhaust funnel and discharged into the atmosphere through a main air blower. Meanwhile, an organic working medium absorbs heat in a low-pressure stage evaporator, an intermediate-pressure stage evaporator, and a high-pressure stage evaporator to form steam through a low-stage working medium pump, an intermediate-pressure stage evaporator and a high-pressure stage evaporator. A working medium steam expands and works in a multilevel organic turbine to drive a generator to generate electricity. The metallurgical furnace high ash-laden gas multi-level organic Rankine cycle cogeneration method is further characterized in that R500 is utilized as a recycling organic working medium. For the evaporator, dust is not easy to accumulate, and the evaporator is not easy to block up. The evaporator is capable of recovering the heat energy of the exhaust gas and directly conversing into the high grade electric energy, and the efficiency is improved by 10%-20% compared with a single-stage evaporation organic Rankine.

Owner:无锡市广运环保机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com