Stage refrigerating cycle liquefaction process

A refrigeration cycle and cascaded technology, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of LNG technology starting late, and achieve the effects of reduced risk, reduced surge, and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

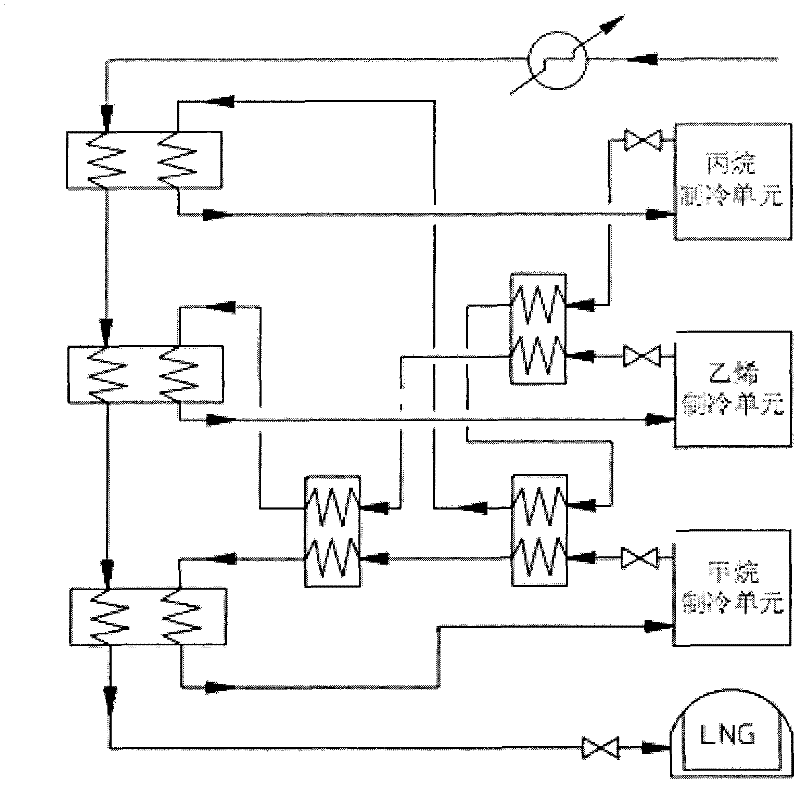

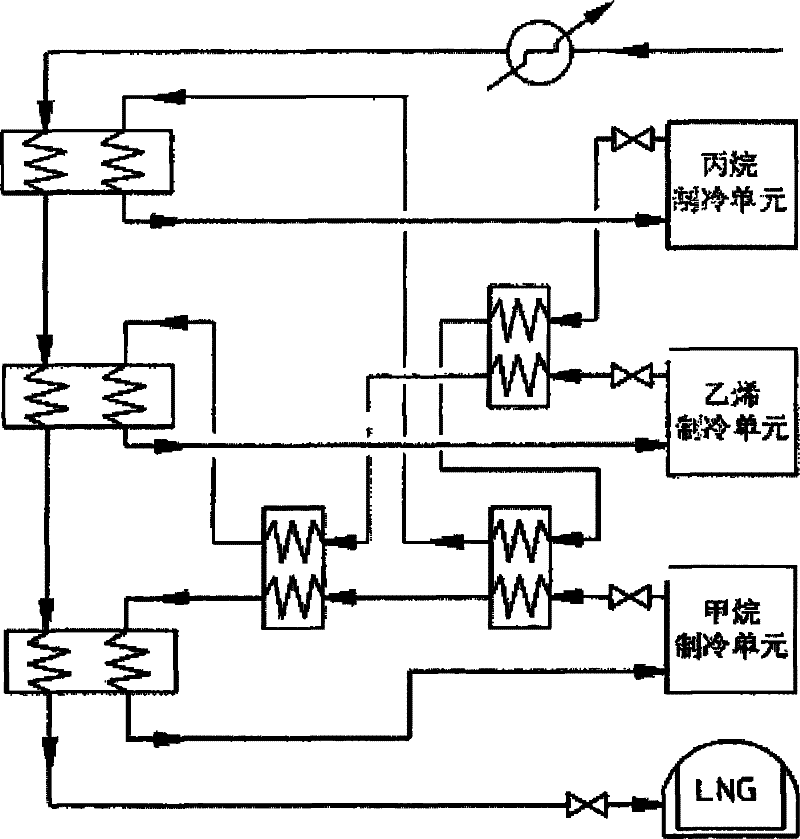

[0028] The present invention includes propane cycle process, ethylene cycle process, and methane cycle process.

[0029] Described propane cycle process comprises the following steps;

[0030] (a) The low-pressure propane vapor is compressed by a propane compressor and conventionally cooled by cooling water to achieve full condensation;

[0031] (b) The liquid propane refrigerant is throttled and expanded step by step under different pressures, so that the propane evaporates at different temperatures, so that the propane refrigerant cools the natural gas and the circulating refrigerant step by step in different temperature ranges ;

[0032] (c) The propane vapors at different pressures are returned to the corresponding inlets of the cycle compressor, completing a closed refrigeration cycle for propane.

[0033] The ethylene recycling process comprises the following steps;

[0034] (d) The low-pressure ethylene vapor is compressed by an ethylene compressor, and is convention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com