A kind of composite refrigeration natural gas liquefaction method

A composite refrigeration and natural gas technology, applied in the field of natural gas liquefaction, can solve the problem of high process energy consumption, achieve the effects of high operational safety, stable operation and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

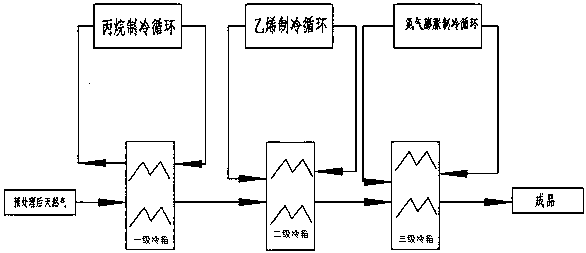

[0015] A compound refrigeration natural gas liquefaction method, which is used to exchange heat between pretreated natural gas and the compound refrigerant in a cold box heat exchanger, and liquefy the natural gas into liquefied natural gas, comprising the following steps:

[0016] First, the pretreated natural gas enters the first-stage cold box, and is cooled with the propane refrigeration cycle to -30°C ~ -60°C. In the propane refrigeration cycle, after the propane is pressurized and cooled by the compressor, a part of the propane is throttled and cooled to enter The first-stage cold box exchanges heat with natural gas and heavy hydrocarbons. After the other part of propane is throttled and cooled, the gas phase returns to the inlet of the propane compressor, and the liquid phase and the propane at the outlet of the first-stage cold box enter the second-stage cold box after throttling and cooling. Natural gas and ethylene are vaporized after heat exchange, and return to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com