Semi-closed electric furnace flue gas multi-stage organic Rankine cycle waste heat power generation method

A waste heat power generation and Rankine cycle technology, applied in machines/engines, furnaces, waste heat treatment, etc., can solve the problems of large horse-drawn trolleys and low steam output, and achieve lower emission temperature, lower operating energy consumption, lower investment and The effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

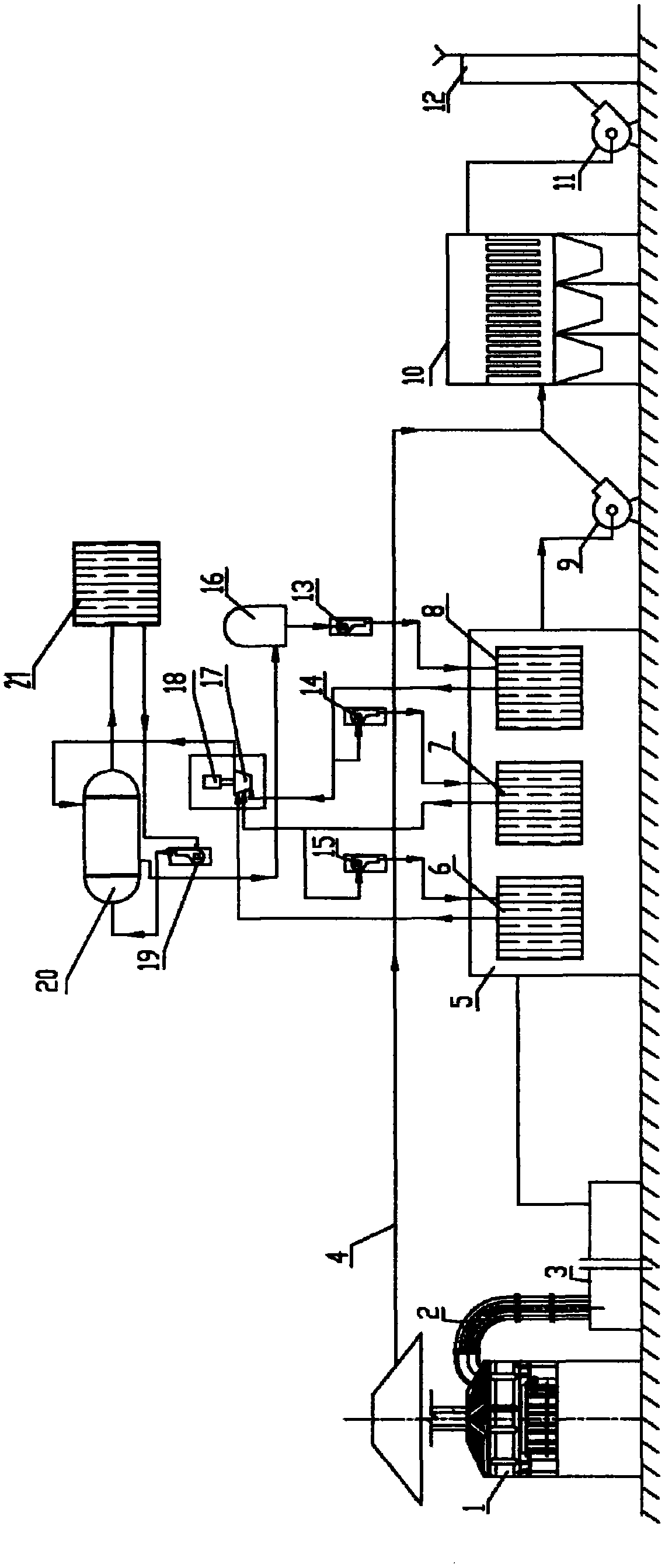

[0019] Below in conjunction with accompanying drawing, the present invention will be further described:

[0020] Such as figure 1 Shown: the steps of the method for power generation by waste heat of semi-closed electric furnace flue gas multi-stage organic Rankine cycle are as follows:

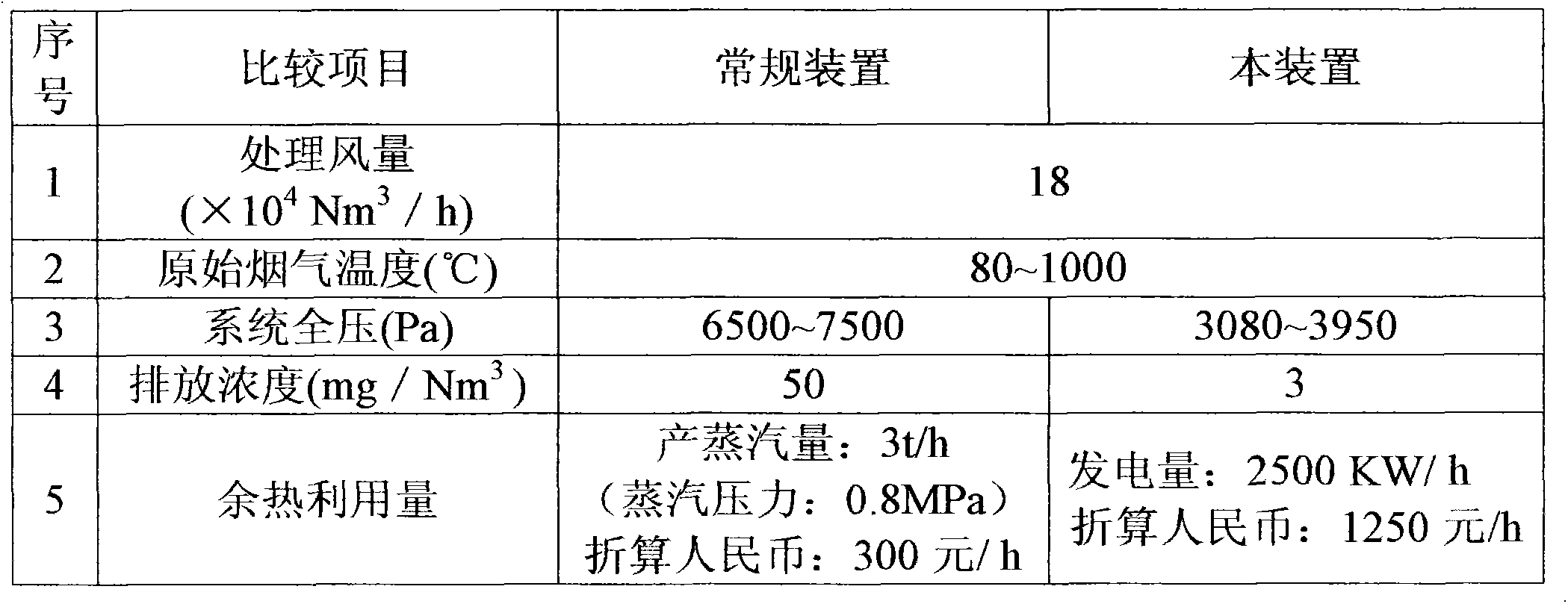

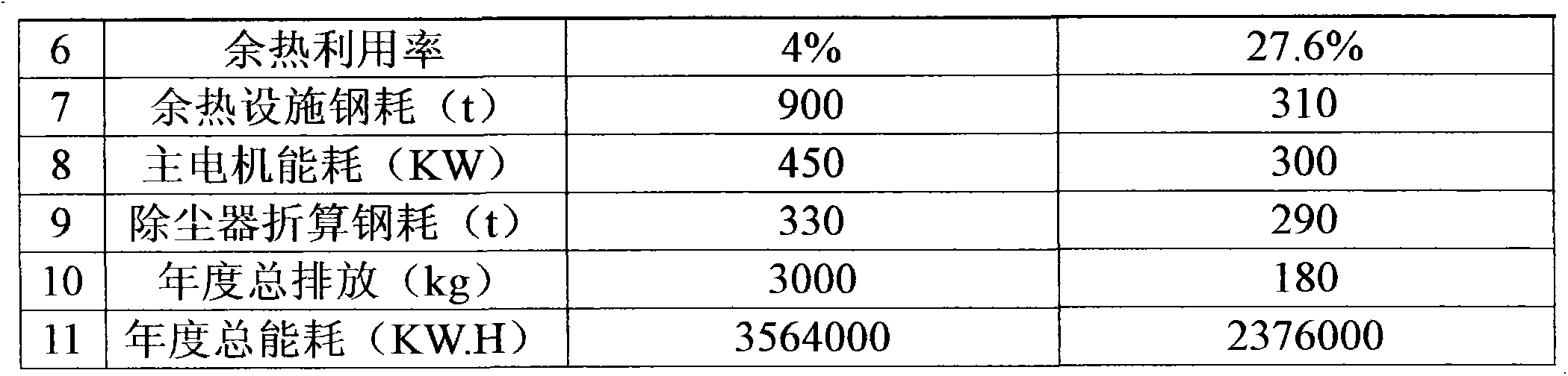

[0021] 50t / h steelmaking semi-hermetic electric furnace 1 exhaust gas flow rate 18×10 4 N m 3 / h, temperature 1000℃, dust concentration 25g / Nm 3 It is discharged from the fourth hole, mixed with cold air through the water-cooled sliding sleeve 2, and enters the combustion settling chamber 3 after burning carbon monoxide gas; Mixed with cold air, the carbon monoxide gas is finally burned, and the flue gas passing through the combustion settling chamber 3 enters the waste heat exchange chamber 5. The high-temperature flue gas releases heat, and the temperature drops to 80°C. The cooled flue gas comes out from the booster fan 9 and is connected to the The flue gas from the exhaust pipe 4 abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com