Absorption transcritical carbon dioxide two-stage compression refrigerating system

A two-stage compression and carbon dioxide technology, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of large refrigerant flow loss, low refrigeration efficiency, large flow demand, etc., and achieve a large system refrigeration coefficient, Large cooling capacity and reduced heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

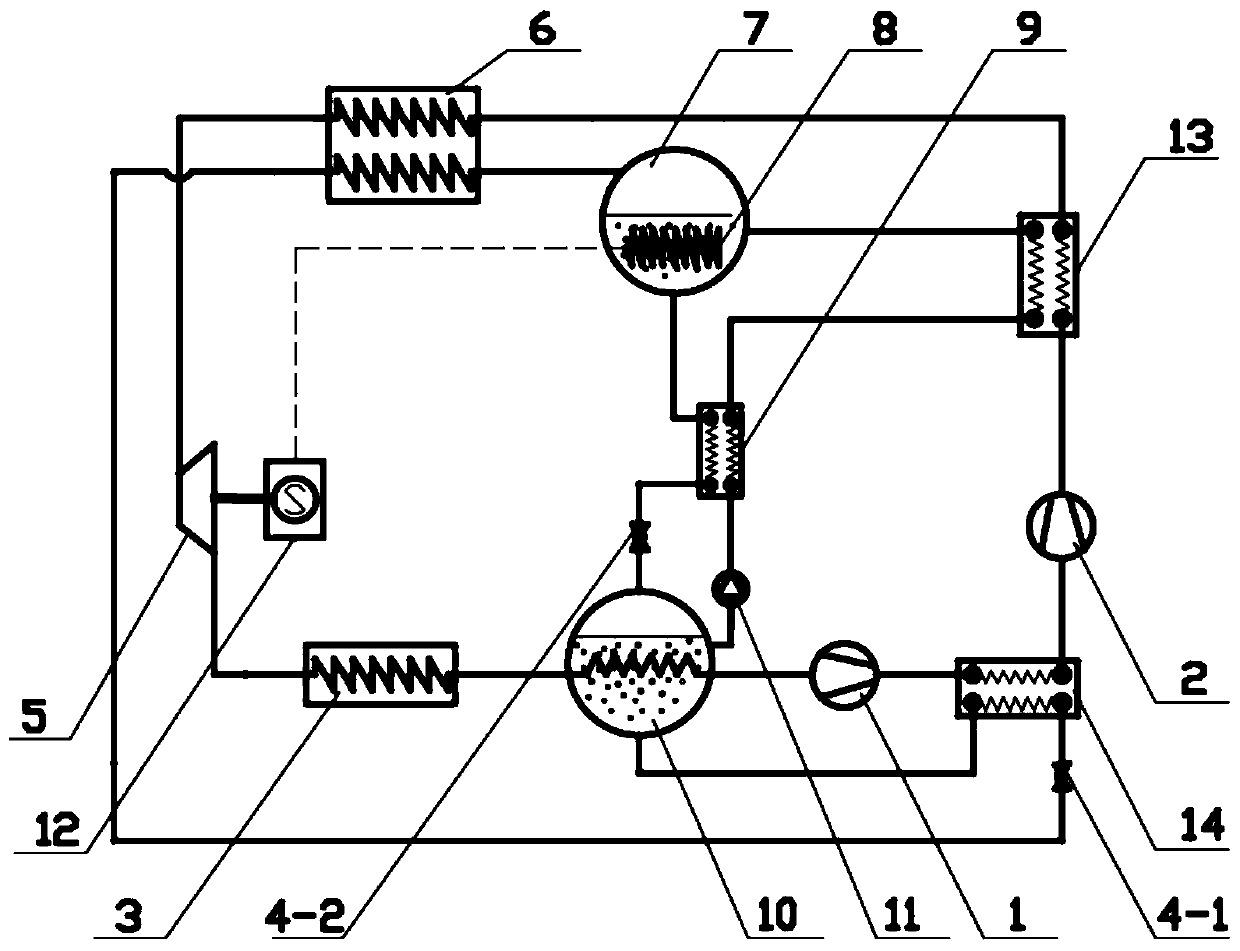

[0024] The schematic diagram of the absorption type transcritical carbon dioxide two-stage compression refrigeration system in this embodiment is as follows: figure 1As shown in the figure, it includes a two-stage compression refrigeration cycle and an absorption auxiliary refrigeration cycle. The refrigerant side channel of 13 , the cooling side channel of the dual-channel condenser 6 , the expander 5 , the evaporator 3 , and the refrigerant side channel of the absorber 10 are connected in sequence and then returned to the main refrigeration cycle of the low-pressure stage compressor 1 . The working medium of the two-stage compression refrigeration cycle is carbon dioxide. The absorption auxiliary refrigeration cycle includes a generator 7, a solution heat exchanger 9, a solution pump 11, a first throttling device 4-1, a second throttling device 4-2, and the solution side channel of the preheater 13 , the condensation side channel of the double-channel condenser 6 , the solu...

Embodiment 2

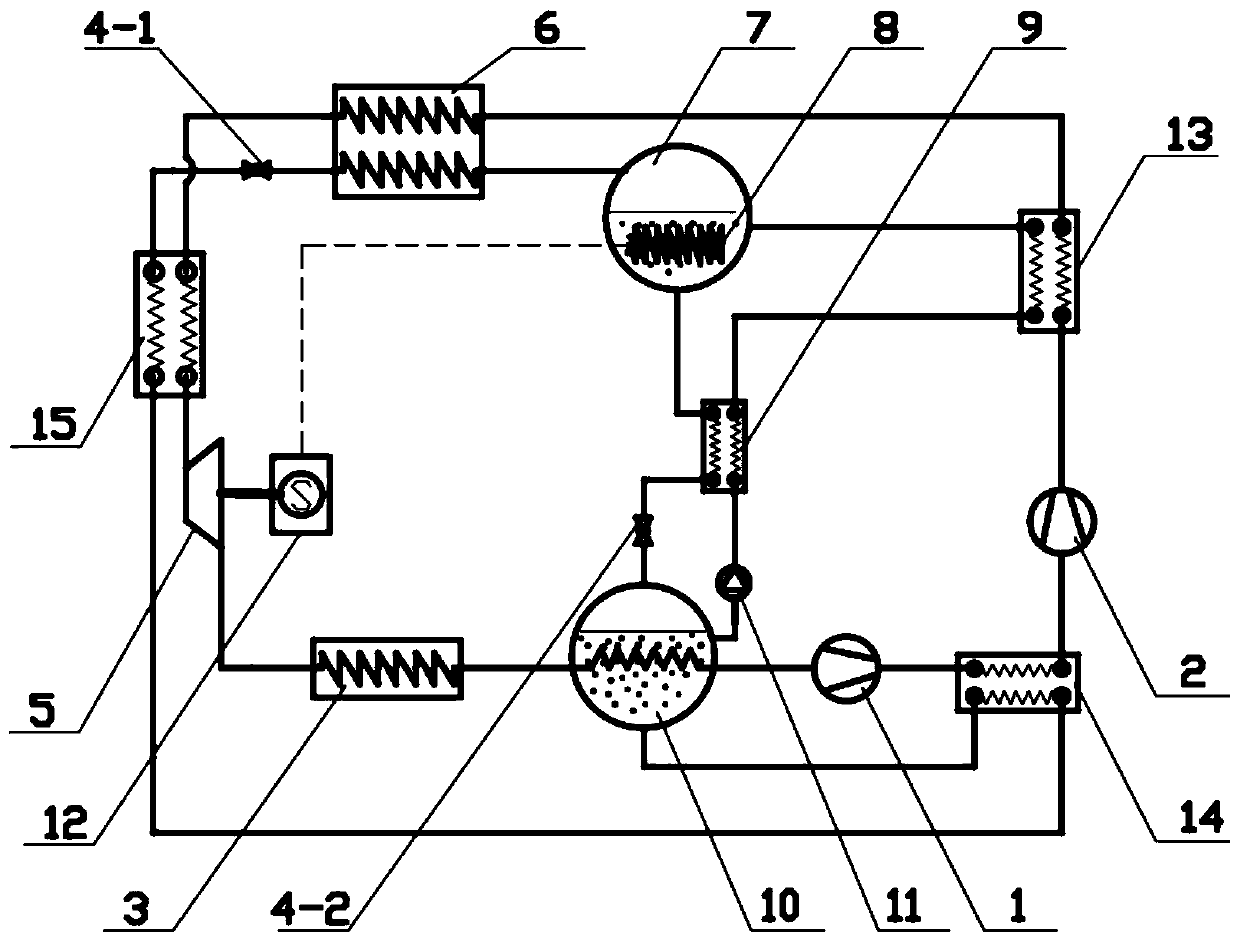

[0029] The schematic diagram of the absorption type transcritical carbon dioxide two-stage compression refrigeration system of the present invention is as follows: figure 2 As shown, it includes a two-stage compression refrigeration cycle and an absorption auxiliary refrigeration cycle. The two-stage compression refrigeration cycle is composed of a low-pressure stage compressor 1 , a refrigerant side channel of an intercooler 14 , a high-pressure stage compressor 2 , a refrigerant side channel of the preheater 13 , and a cooling side channel of the dual-channel condenser 6 . , the subcooling side channel of the subcooler 15 , the expander 5 , the evaporator 3 , and the refrigerant side channel of the absorber 10 are connected in sequence and then return to the main refrigeration cycle of the low pressure stage compressor 1 . The working medium of the two-stage compression refrigeration cycle is carbon dioxide. The absorption auxiliary refrigeration cycle includes a generator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com