Method and device for power generation by utilizing steam generated from waste heat of steel mill in cascade mode

A technology for steam and steel mills, which is applied in the steam generation method using heat carrier, steam engine device, waste heat treatment, etc. It can solve the problems that affect the economy and safety of waste heat utilization, and it is difficult to ensure the consistency of steam parameters and the consistency of steam. , to achieve the effect of prolonging life, improving quantity and quality, and improving steam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

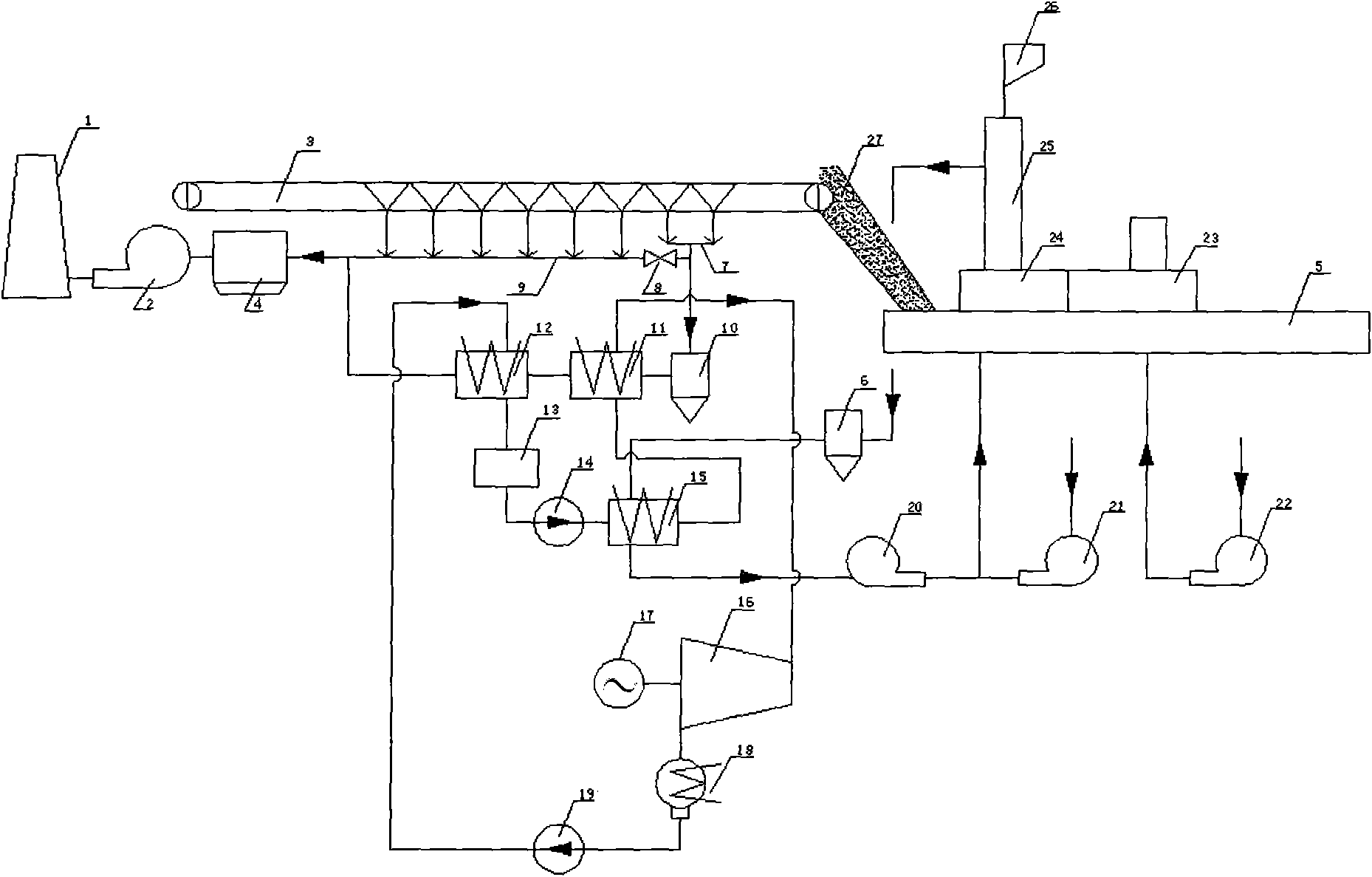

[0052] A cascaded device for generating steam by using waste heat in steel mills, see attached figure 1 . Including chimney 1, spindle fan 2, sintering machine 3, large flue dust collector 4, cooling machine 5, cooling machine dust collector 6, sintering machine tail gas outlet 7, sintering flue gas outlet bypass valve 8, sintering machine large Flue 9, sintering flue gas dust collector 10, sintering machine tail gas superheater 11, sintering machine tail gas preheater 12, deaerator 13, feed water pump 14, cooler waste heat boiler 15, steam turbine 16, Generator 17, condenser 18, condensate pump 19, circulation fan 20, blower 22, backup fan 21;

[0053] The inlets of the backup fan 21 and the blower 22 are directly communicated with the atmosphere respectively;

[0054] The outlet of the blower 22 is connected to the middle temperature section 23 of the cooler 5;

[0055] Cooler waste heat boiler 15 is provided with flue gas inlet and outlet, working fluid inlet and outlet;...

Embodiment 2

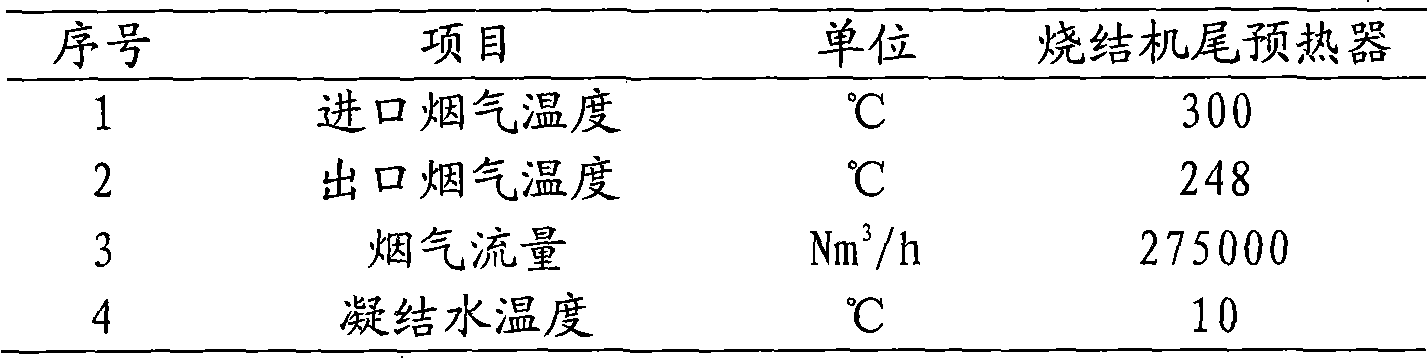

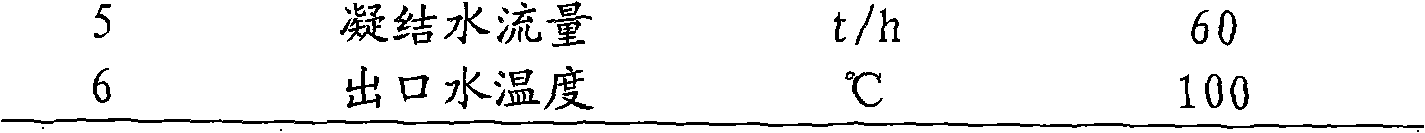

[0064] Taking a certain sintering machine of Baosteel as an example, the sintering area of this sintering machine is 450m2, adopting the cooling waste heat boiler of the present invention + sintering machine exhaust gas preheater + sintering machine exhaust gas superheater, that is, a cascade utilization sintering The method for generating steam and generating electricity from the heat of the flue gas of the tail gas and the flue gas of the cooler, the process steps are as follows:

[0065] (1), use the sintering machine exhaust gas preheater 12 to preheat the condensed water of the steam turbine 16

[0066] Flue gas side flow:

[0067] The sintering flue gas with a temperature of 350°C enters the sintering flue gas dust collector 10 from the tail flue gas outlet 7 of the sintering machine 3, passes through the tail flue gas superheater 11 of the sintering machine after dust removal, and the tail flue gas superheater 11 of the sintering machine The flue gas with an outlet t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com