Organic Rankin waste heat power generation method based on high-temperature highly-dusty smoke of metallurgical furnace

A waste heat power generation and metallurgical furnace technology, applied in the field of metallurgical furnace dust removal, can solve the problem of low steam output, achieve low dust content, improve stability, and improve thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

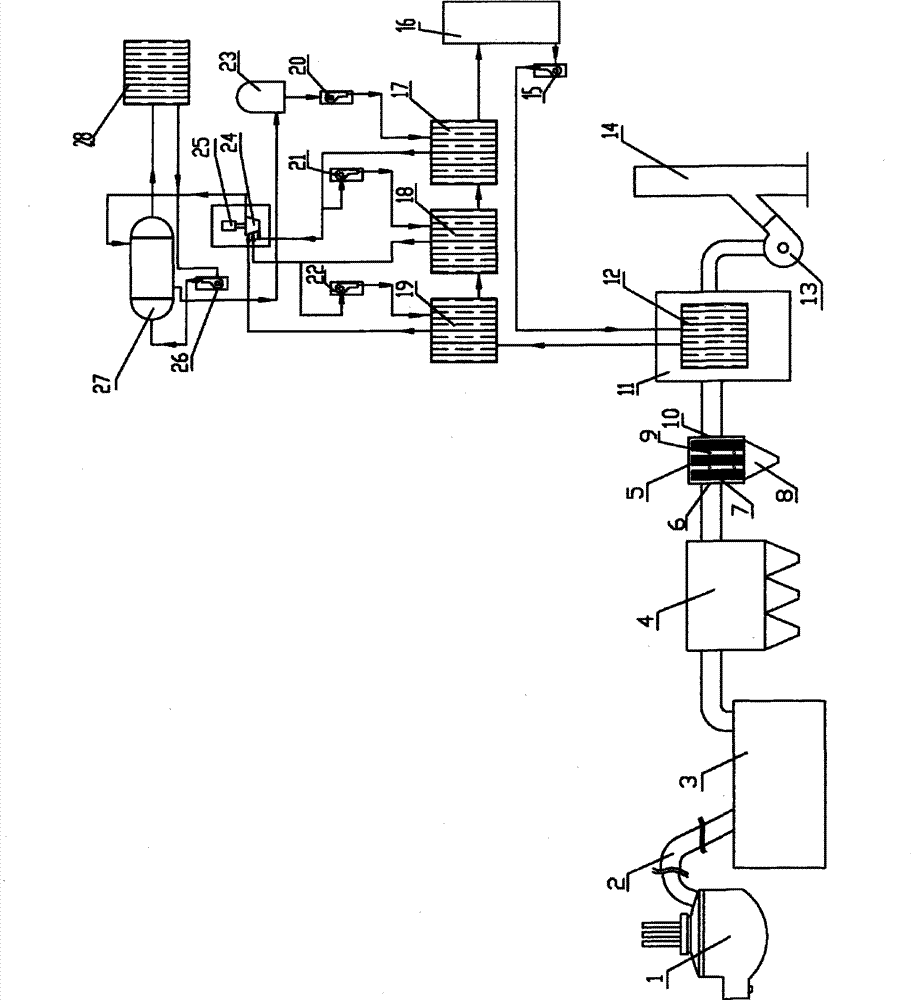

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

[0023] Such as figure 1 As shown: the steps of the organic Rankine waste heat power generation method of metallurgical furnace high-temperature and high-dust flue gas in the present invention are as follows:

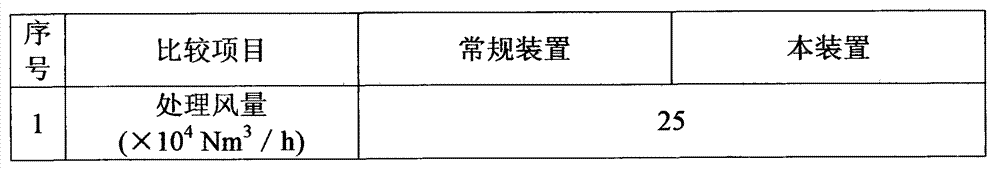

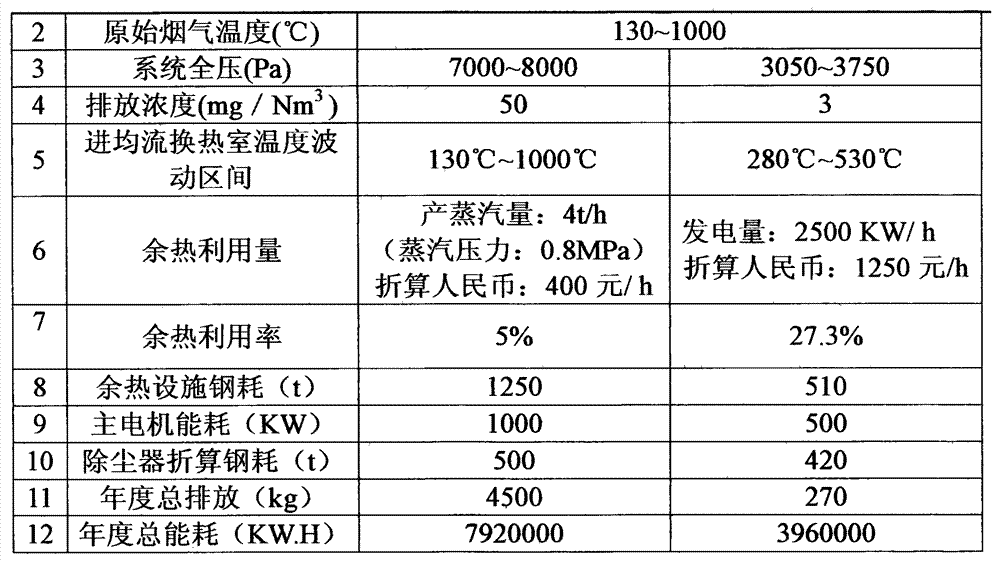

[0024] 80t / h metallurgical furnace 1 flue gas flow rate 25×10 4 N m 3 / h, temperature 1000℃, dust concentration 35g / Nm 3 It is discharged from the fourth hole, mixed with cold air through the water-cooled sliding sleeve 2, and enters the combustion settling chamber 3 after burning carbon monoxide gas; Mix in the cold air, finally burn the carbon monoxide gas, adjust and control the temperature of the flue gas in the settling chamber to 750°C, the flue gas from the combustion settling chamber 3 enters the plastic burning plate dust collector 4, and the dust concentration after dust removal is 3mg / Nm 3, into the heat storage homogenizer 5, after the carbon-manganes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com