Air turbine rocket engine based on pulse detonation

A rocket engine and pulse detonation technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of low total pressure, high temperature, and high airflow velocity, and achieve reduced entropy, fast combustion rate, and high thermal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

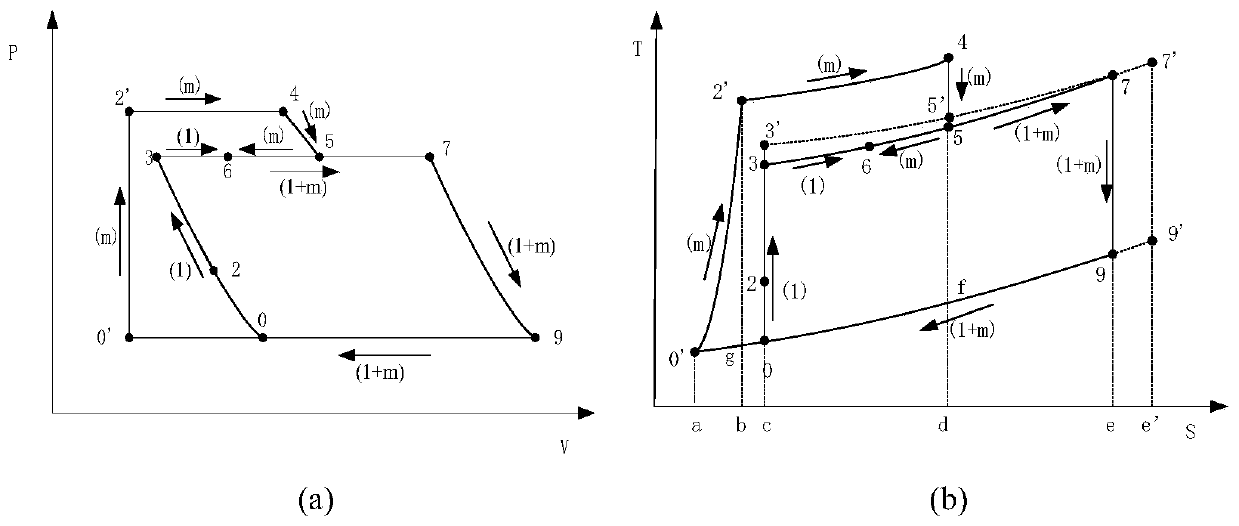

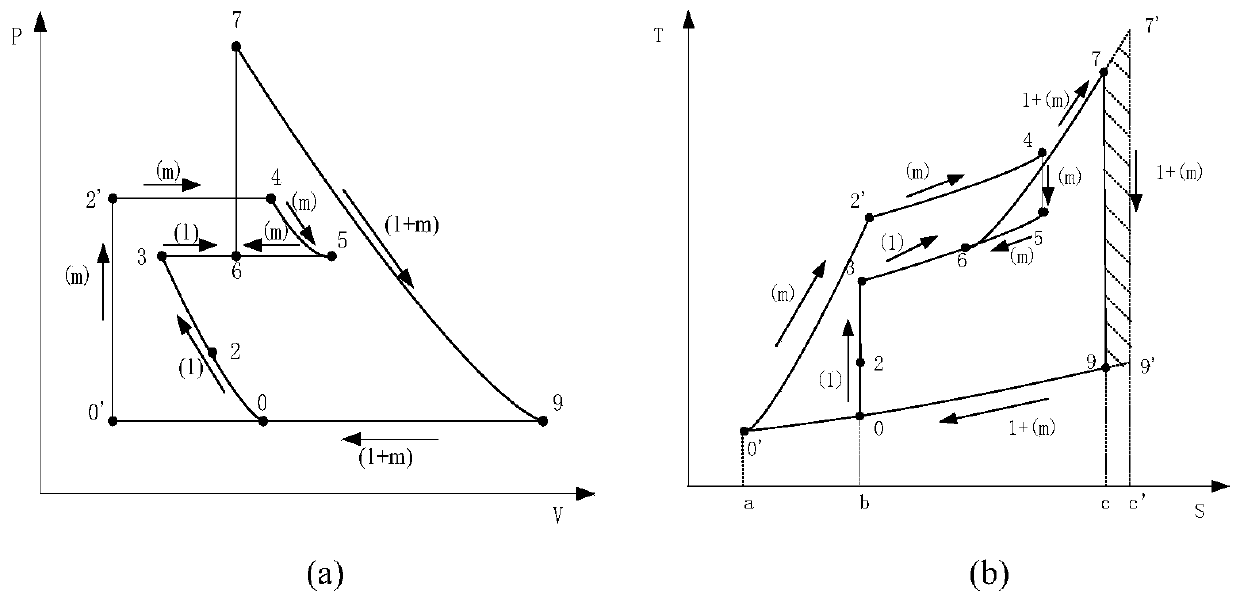

[0024] The difference between a Pulse Detonation Engine (PDE) and an ordinary engine is that the thrust is generated by the high-temperature and high-pressure gas generated by the pulse detonation wave (about 13-15 times), which allows the engine to run at Mach number 0- 5 has a very wide Mach number range, and can work efficiently at subsonic and supersonic speeds. In addition, detonation combustion has the remarkable advantages of high thermal efficiency (up to 49%) and fast combustion rate (2000m / s). The PDE using this technology has high heat capacity, which can enable the power plant to obtain lower fuel consumption and greater unit thrust.

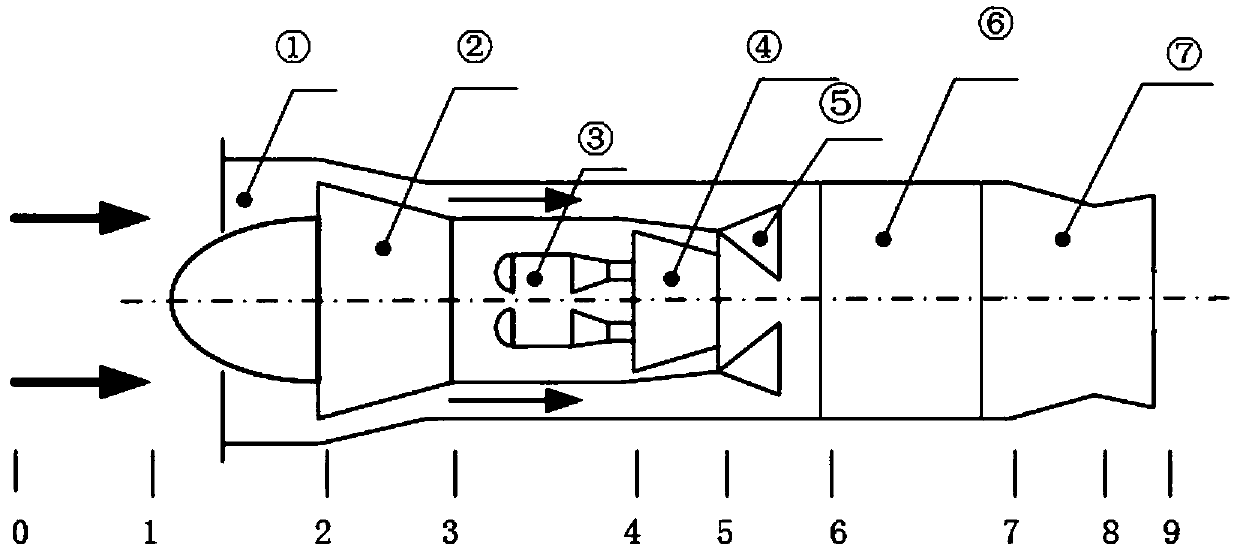

[0025] The PD-ATR (air turbine rocket engine) proposed by the present invention combines the advantages of high detonation combustion efficiency and self-pressurization with the advantages of high thrust-to-weight ratio, high unit thrust and high unit head-on thrust of traditional ATR engines, and has broad military applications. It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com