Patents

Literature

67results about How to "Increase steam production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Power Plant

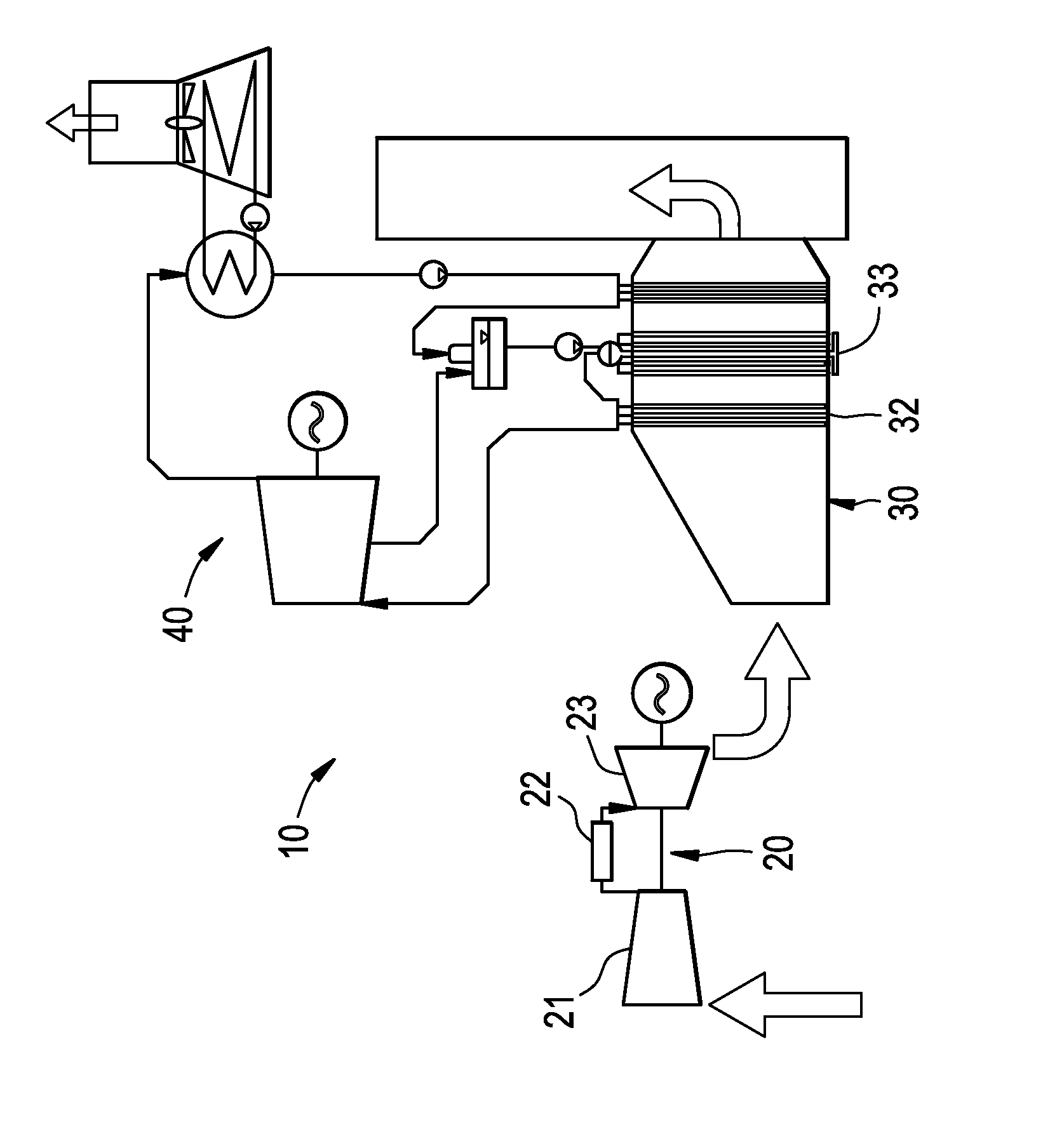

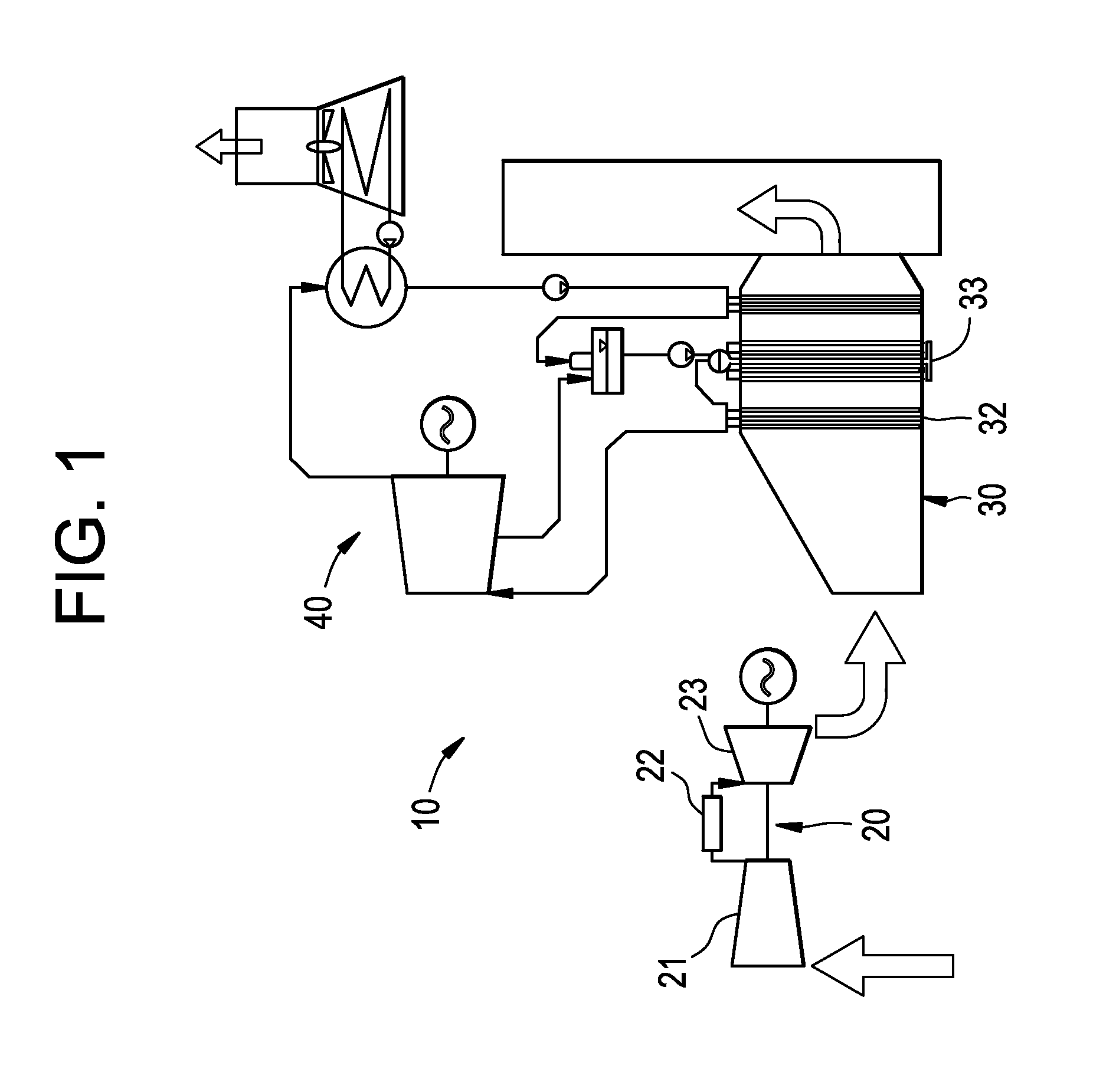

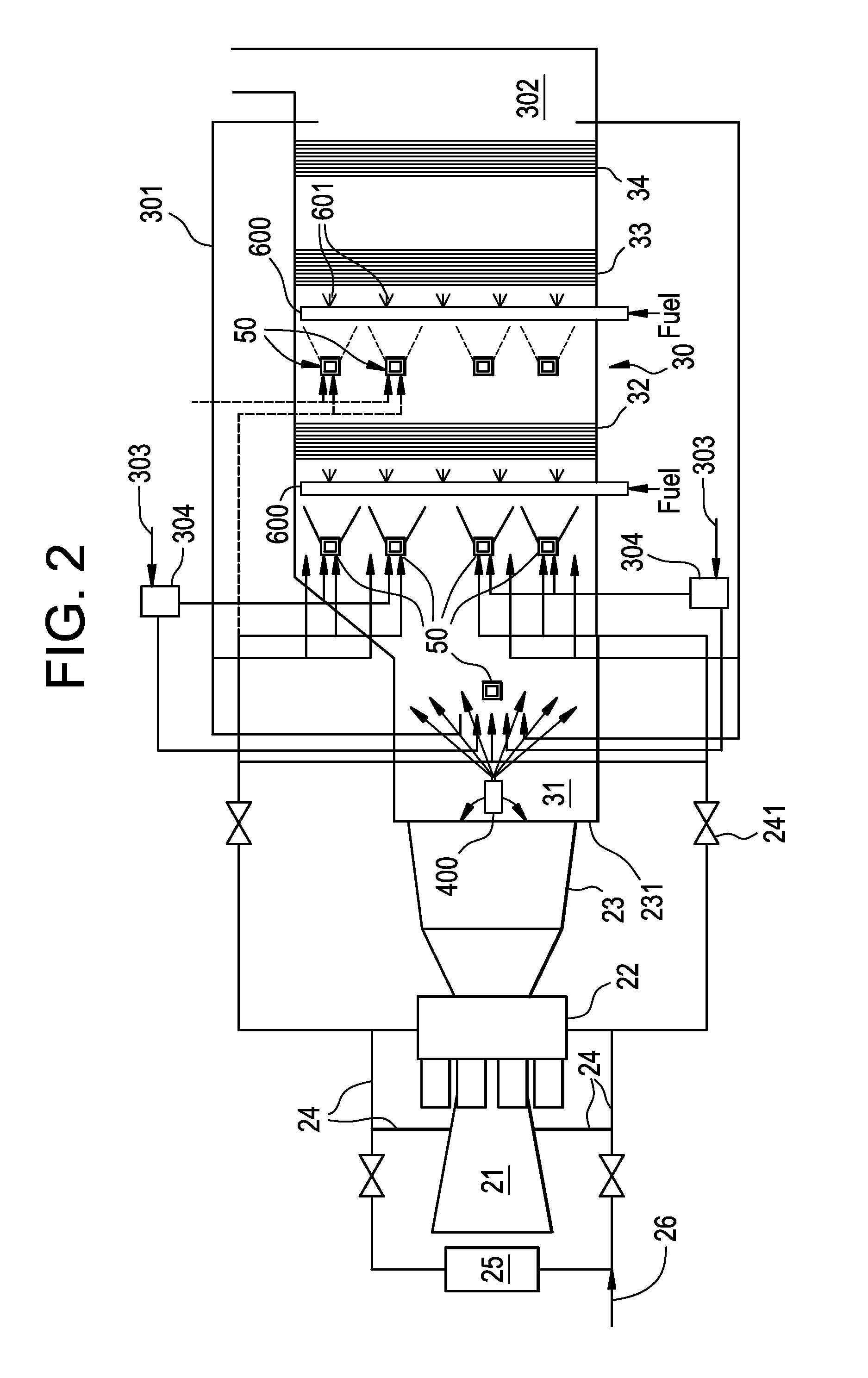

ActiveUS20120260667A1Increase steam productionEngine fuctionsTurbine/propulsion engine coolingHigh energyEngineering

A power plant is provided and includes a gas turbine engine to generate power, a heat recovery steam generator (HRSG) to produce steam from high energy fluids produced from the generation of power in the gas turbine engine, a steam turbine engine to generate additional power from the steam produced in the HRSG and a thermal load reduction system to reduce thermal loading of components of the HRSG and / or the steam turbine engine during at least startup and / or part load operations, which includes an eductor by which a mixture of compressor discharge air and entrained ambient air is injectable into the HRSG and / or an attemperator to cool superheated steam to be transmitted to the steam turbine engine and a detector disposed within the HRSG to facilitate identification of hot spots therein.

Owner:GENERAL ELECTRIC CO

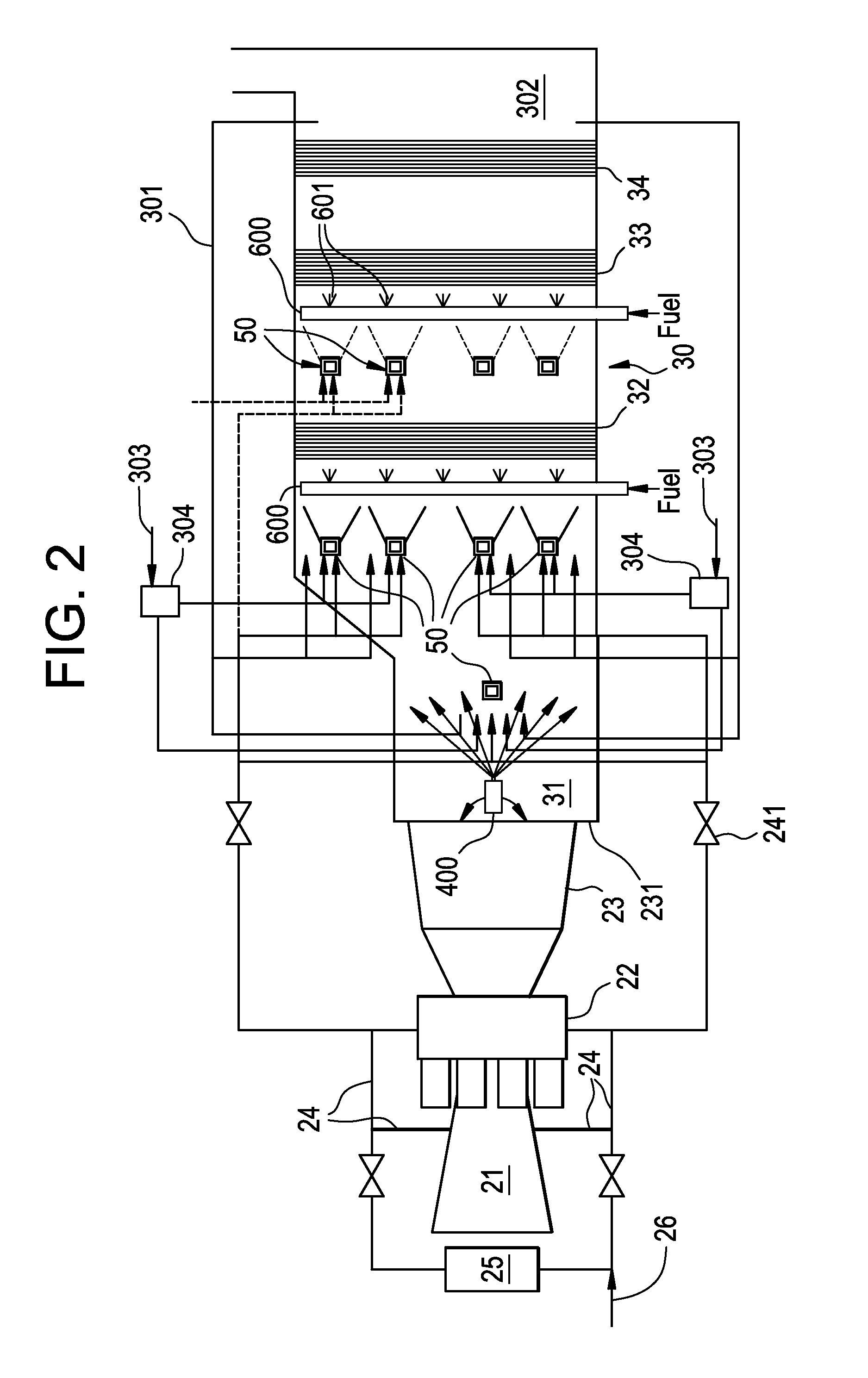

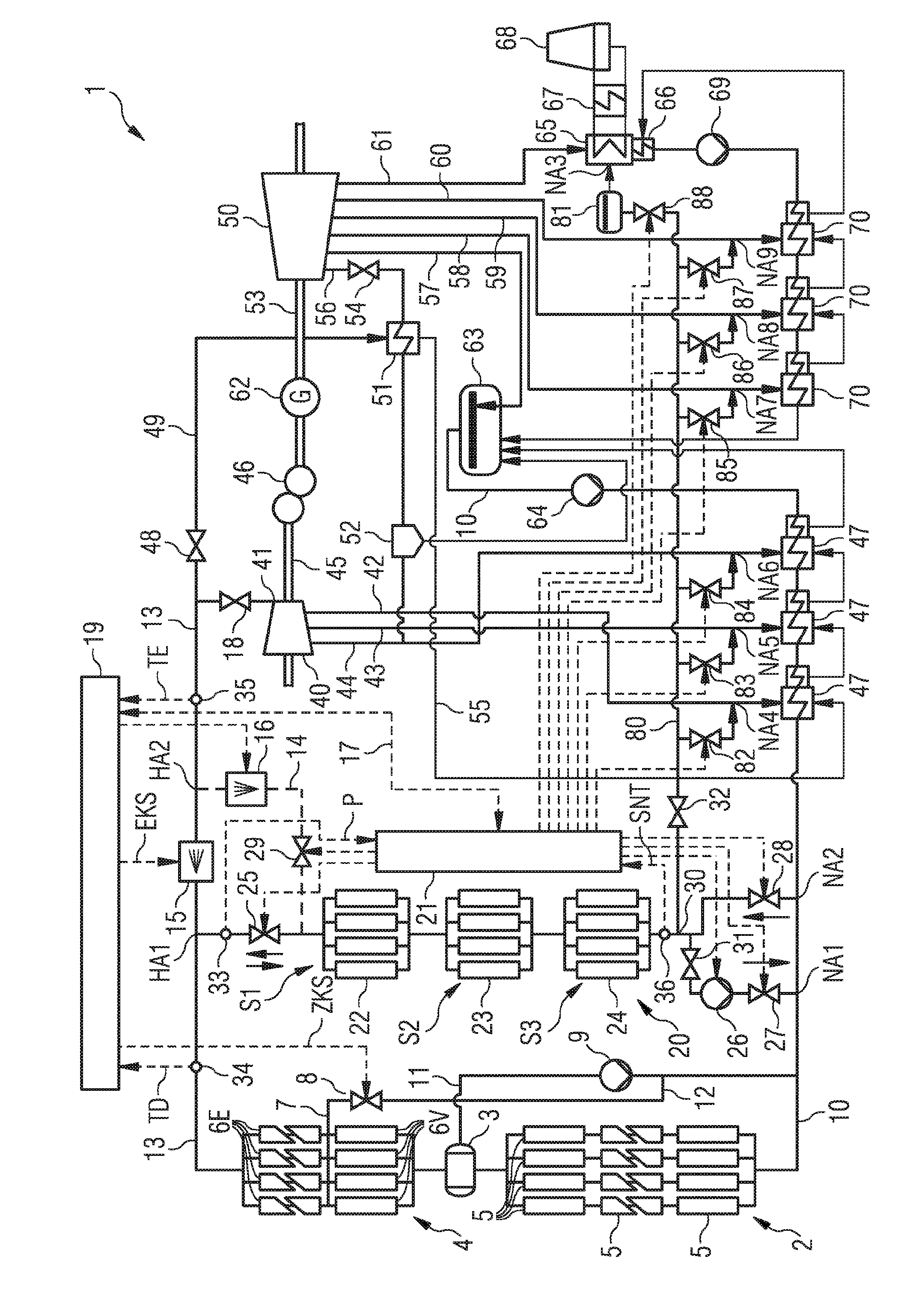

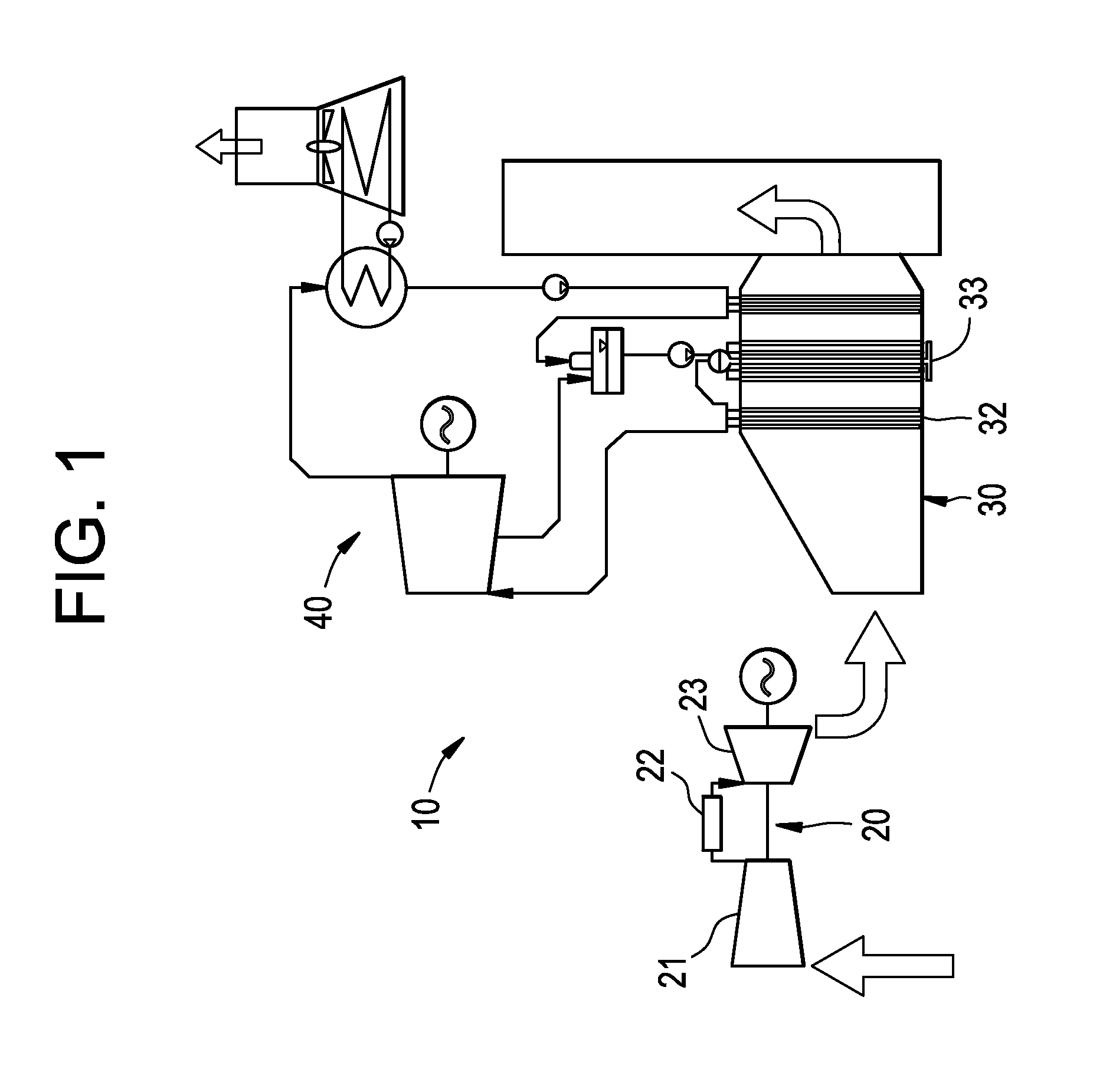

Solar thermal power plant and method for operating a solar thermal power plant

InactiveUS20120255300A1Increase productionIncrease steam productionAuxillary drivesFrom solar energyHigh temperature storageThermal energy

A solar thermal power plant including a solar collector steam generator unit for generating steam, a solar collector steam superheater unit for superheating the steam, and a steam turbine is provided. The solar thermal power plant includes an intermediate storage which is connected to the steam conduit system in a first high-temperature storage connecting point interposed between the solar thermal steam superheater unit and the steam turbine to remove steam superheated in a storage mode from the steam conduit and which includes a heat reservoir in which thermal energy is drained from the steam fed into during the storage mode and is accumulated and the stored thermal energy is given off to the steam in an extraction mode, steam being fed to the steam conduit system from the intermediate storage. The intermediate storage is connected to a condenser and / or a relaxation device of the plant in a low-temperature storage connecting point.

Owner:SIEMENS AG

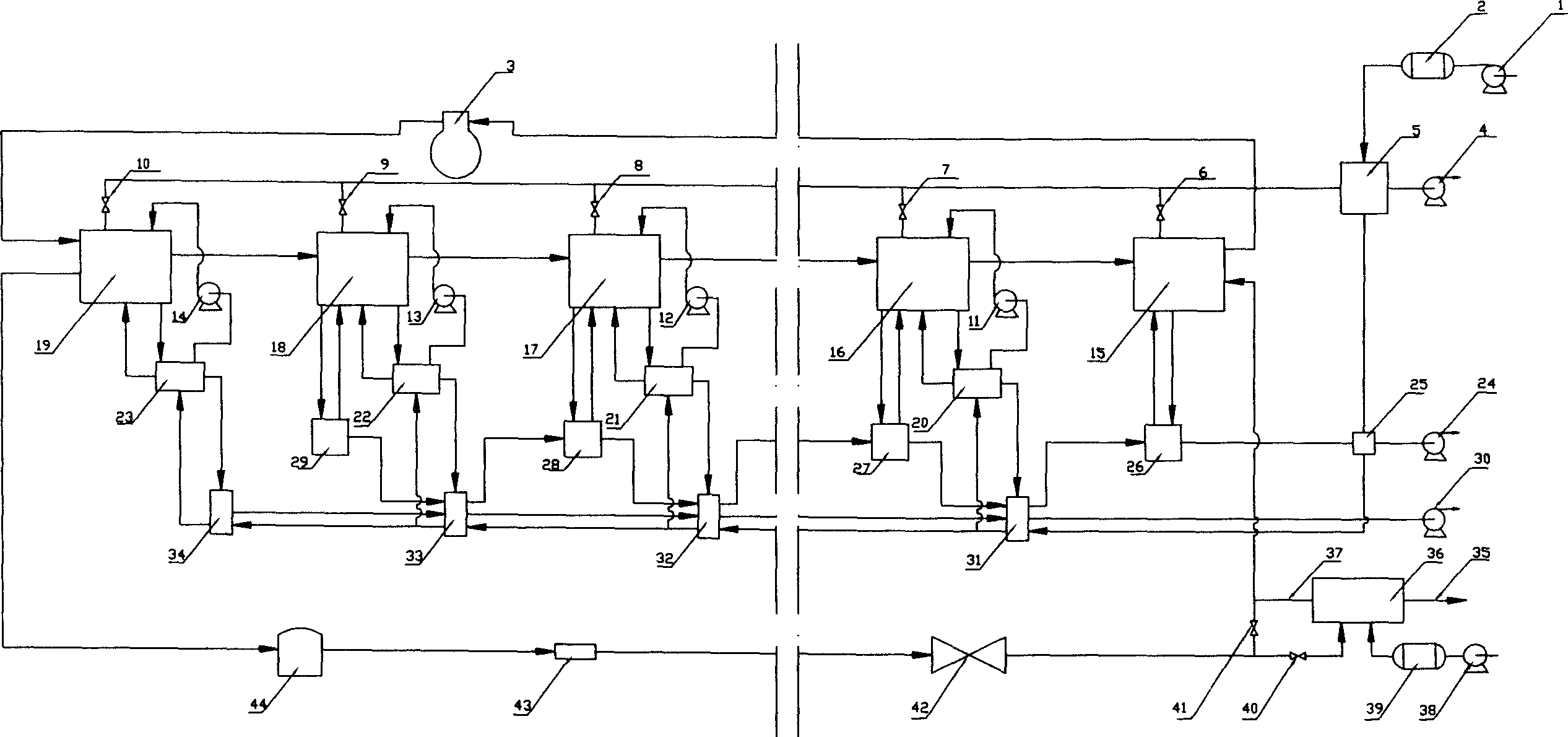

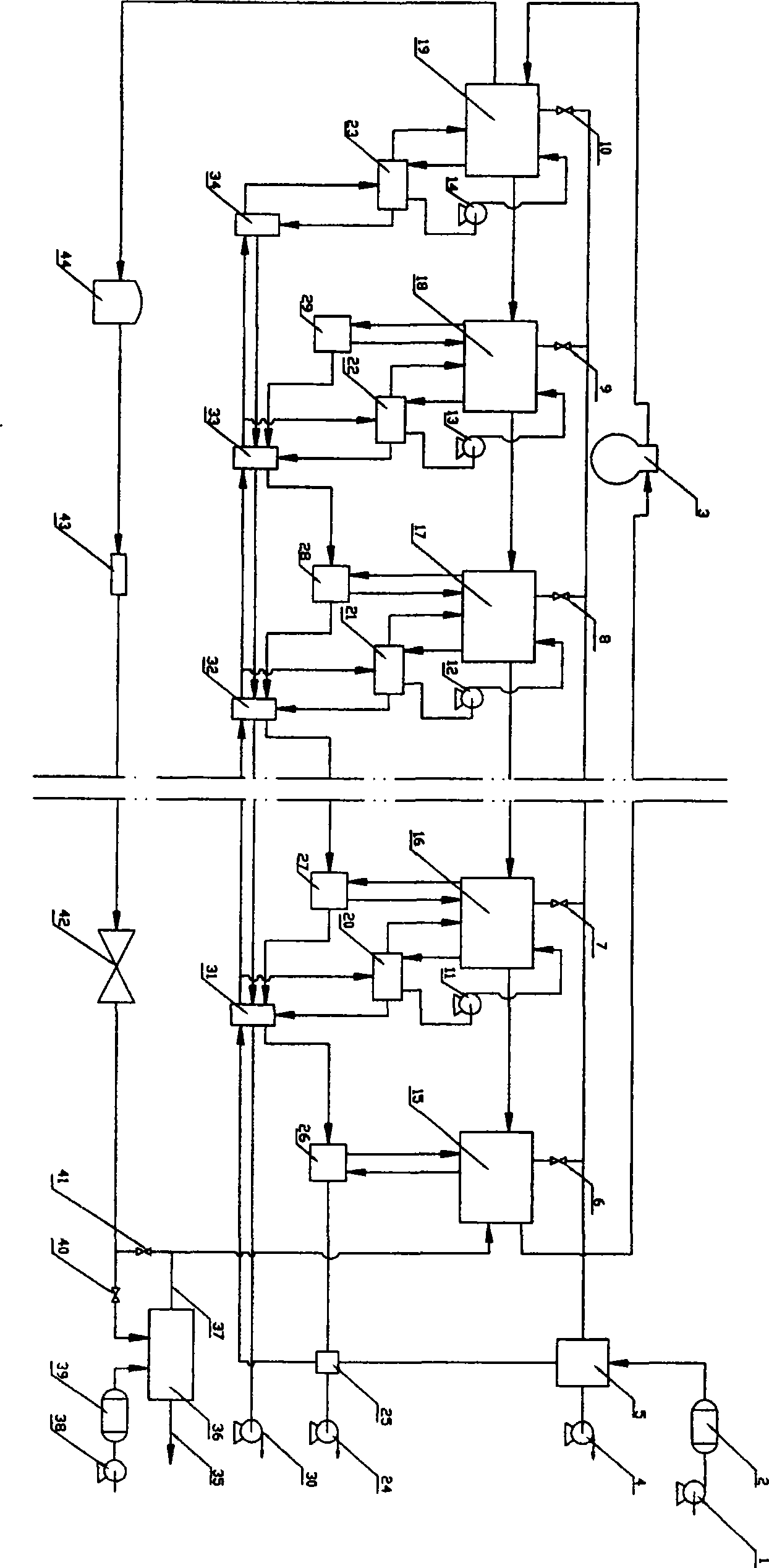

Low-temperature multi-effect seawater desalination process

InactiveCN1837075AEfficient recyclingIncrease temperatureGeneral water supply conservationSeawater treatmentSpecial designEnergy recovery

This invention refers to a method about low-temperature multiple-effect desalination of sea water, especially about a new method which effectively applied thermal pumping power-saving technology to desalination of sea water. The desalination of sea water system which apply this method has n effect evaporator(n=2-50) and one condensator aggregately, containing six systems of feeding seawater, recirculated salt water, product water, vacuum, incoagulable gas removal, thermal pumping circulation and starting heating in addition. This invention is based on irreversible thermodynamics principle, via organic integration of evaporator, condensator and low-temperature multiple-effect desalination of sea water system in closed circuit thermal pumping system, as well as special design of energy recovery tache in low-temperature multiple-effect desalination of sea water, decreasing irreversible loss of diversified thermal transmission course which the desalination of sea water refers to in maximum limit, sequentially letting the entropy increasing of whole desalination of sea water course be the least, realizing efficient energy-saving desalination of sea water course.

Owner:QINGDAO UNIV

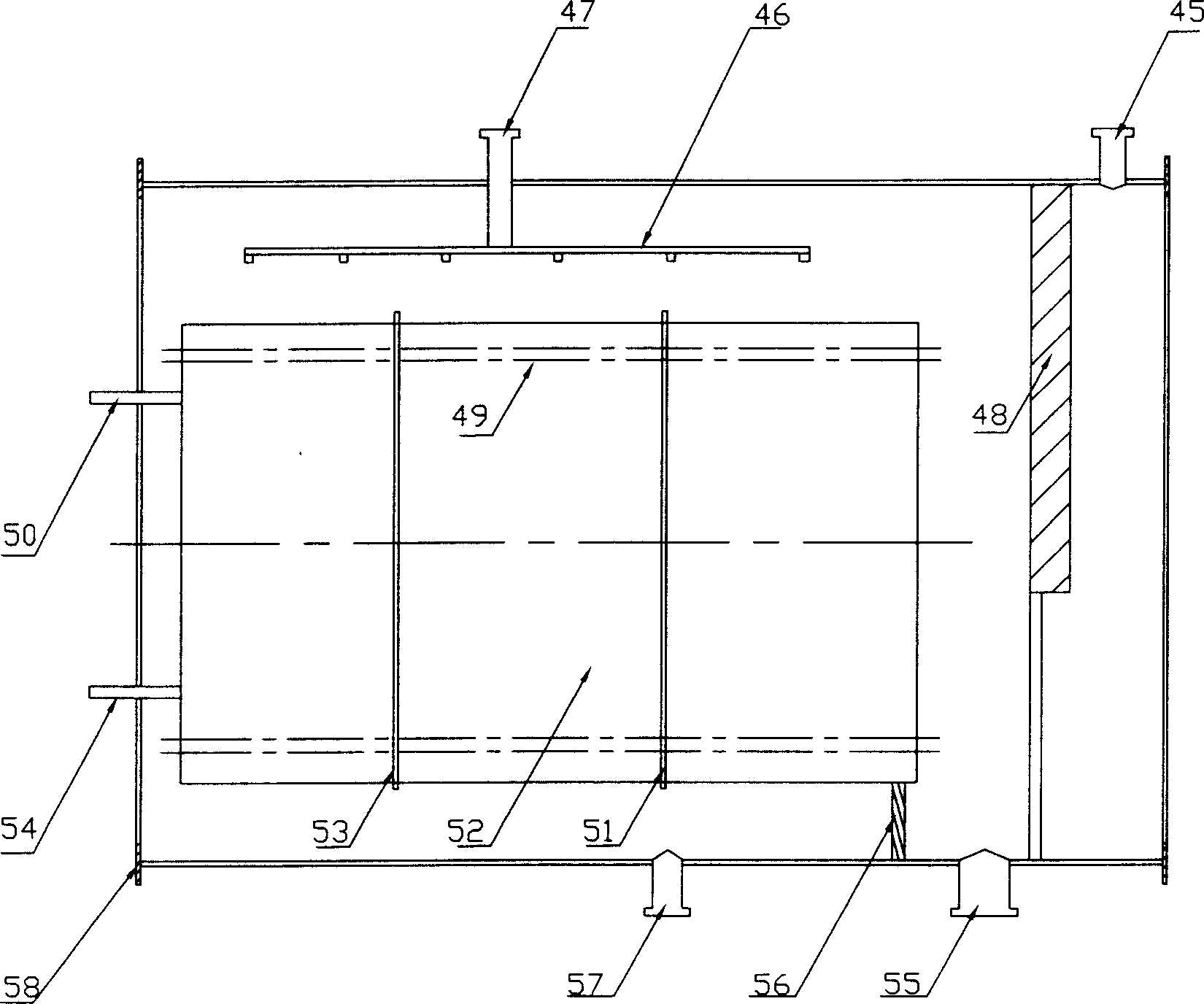

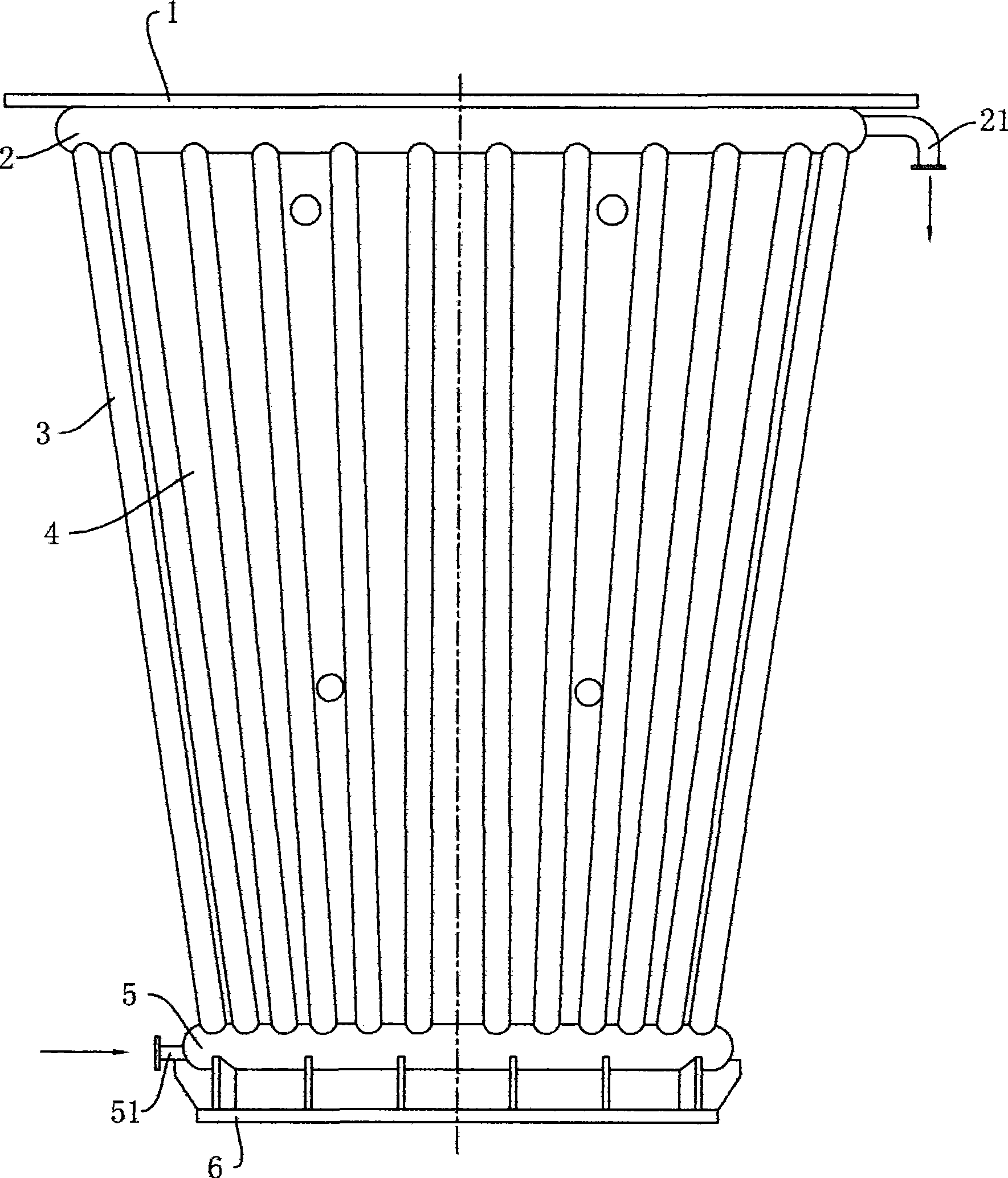

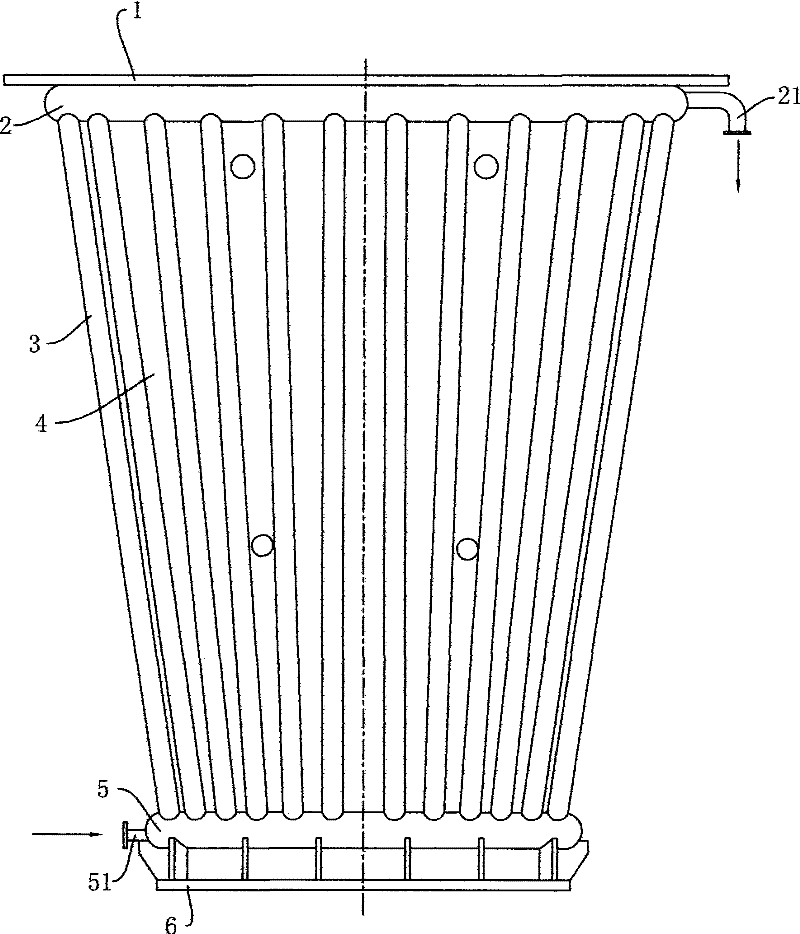

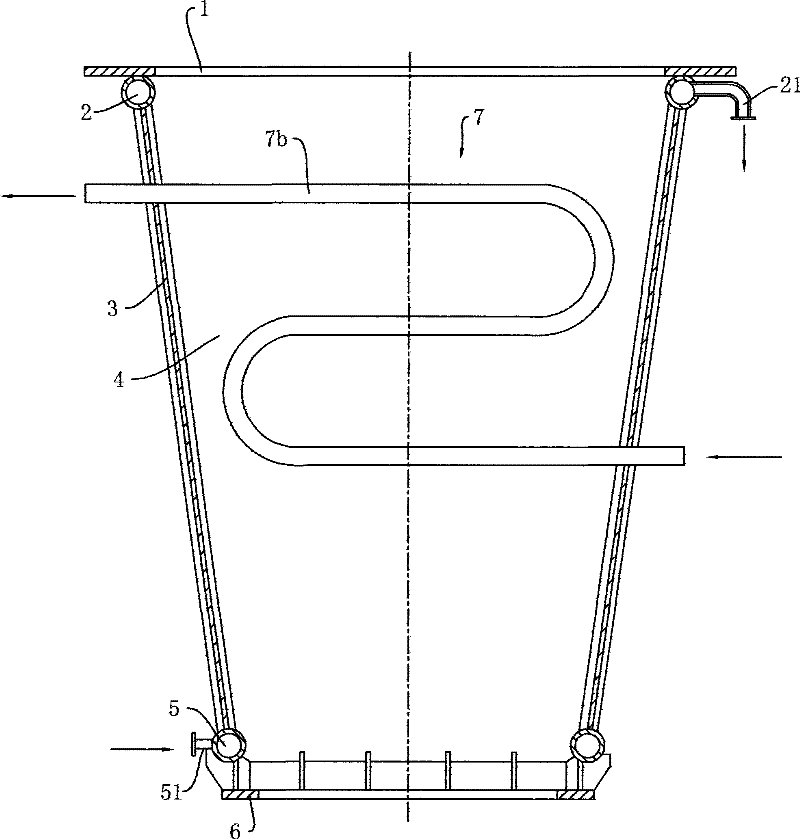

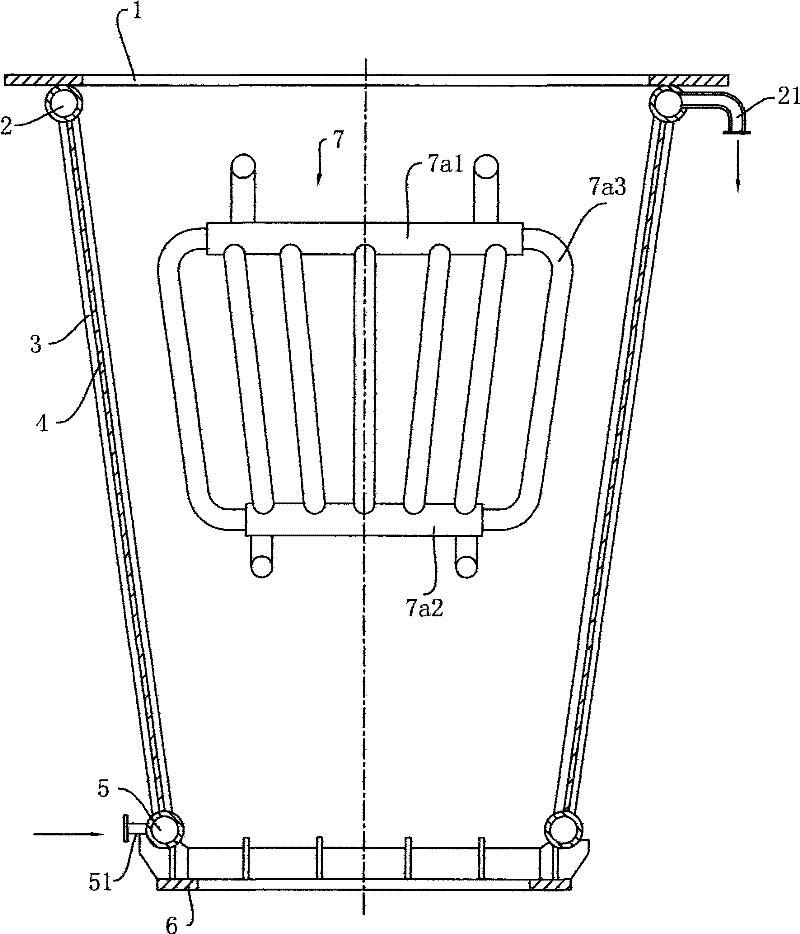

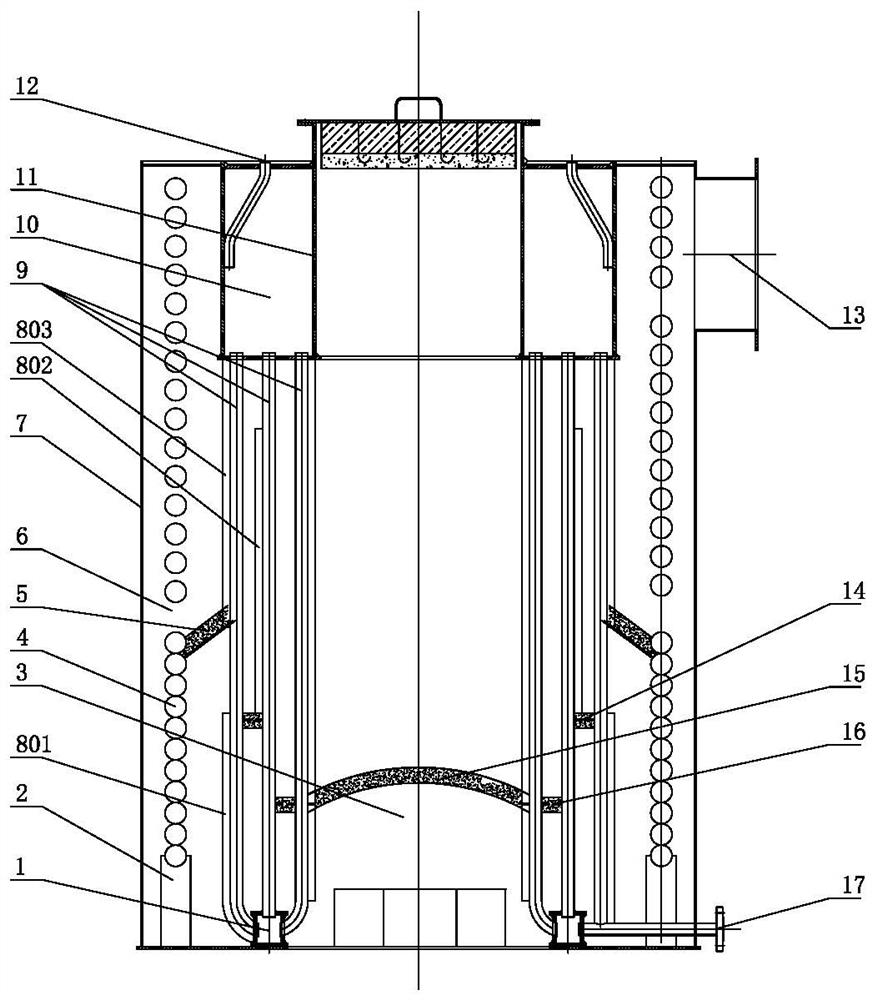

Cooling water jacket of petroleum coke can-type calcine furnace

ActiveCN101362951ANot easy to slitReduce consumptionSpecial form destructive distillationThermal deformationEngineering

The invention discloses a petroleum coke pot typed calciner cooling water jacket, comprising a step-one heat exchanging device which is used for enclosing a high-temperature material passage; the step-one heat exchanging device comprises a ring-shaped upper container which is provided with a water outlet, a ring-shaped lower container which is provided with a water inlet, a plurality of heat exchanging pipes which are fixedly connected with the upper container and the lower container and communicated with each other respectively, a heat guiding baffle which is fixedly connected between two adjacent heat exchanging pipes; the high-temperature material passage which is enclosed by the step-one heat exchanging device is internally provided with a step-two heat exchanging device. The cooling water sleeve has good rigidity, and is not easy to generate thermal deformation; furthermore, the heat exchanging area is large and the cooling and heat exchanging effect is good; by increasing the step-two heat exchanging device, the uniformity of the temperature inside the whole passage is greatly improved, the temperature of the outgoing material is lowered from 300 DEG C to 150 DEG C; with the reduction of the temperature of the material, the service life of the material drainage valve is prolonged, and the malfunction rate of the material drainage system is reduced.

Owner:SHANDONG LIANXING ENERGY SAVING SERVICE

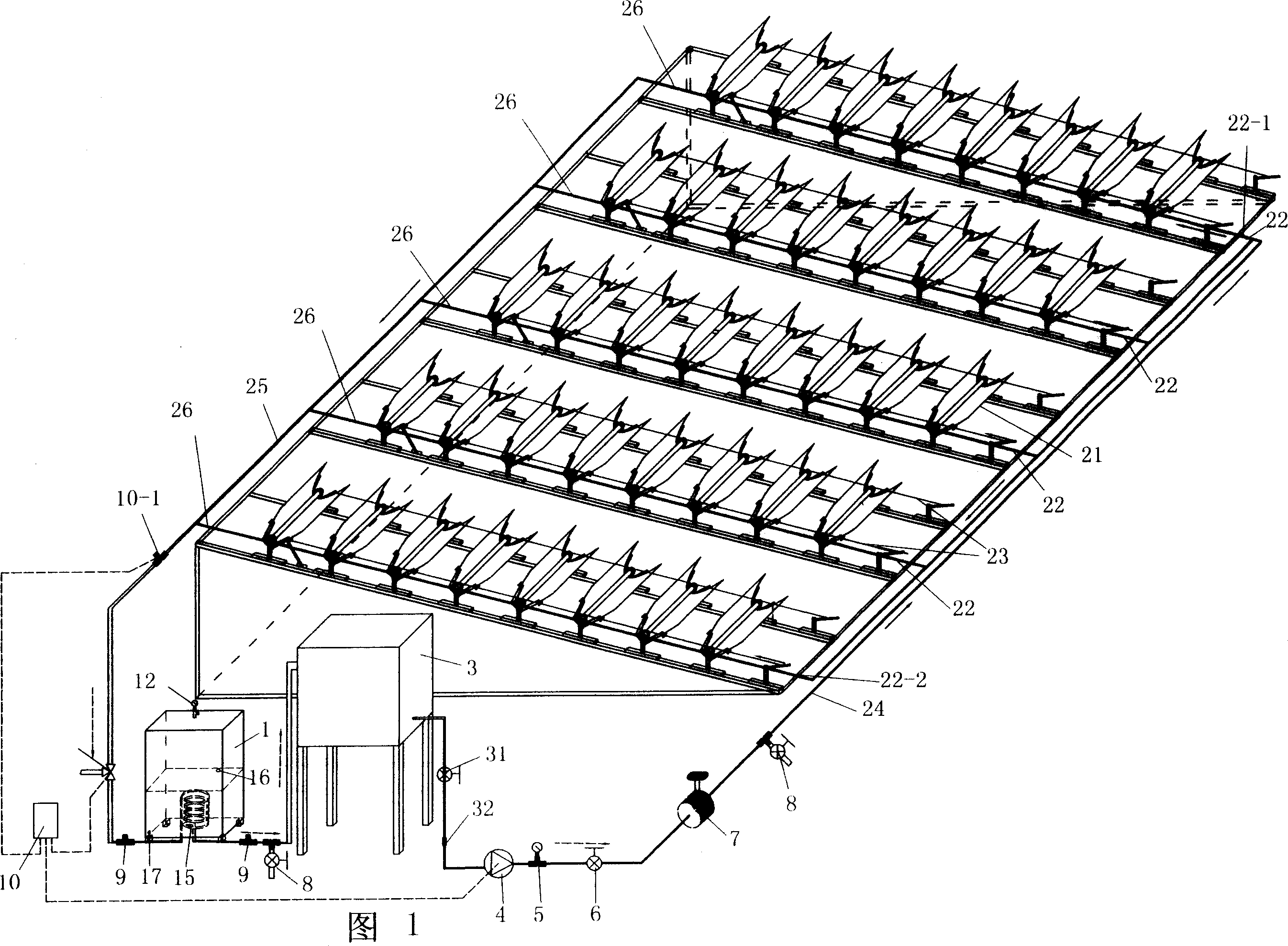

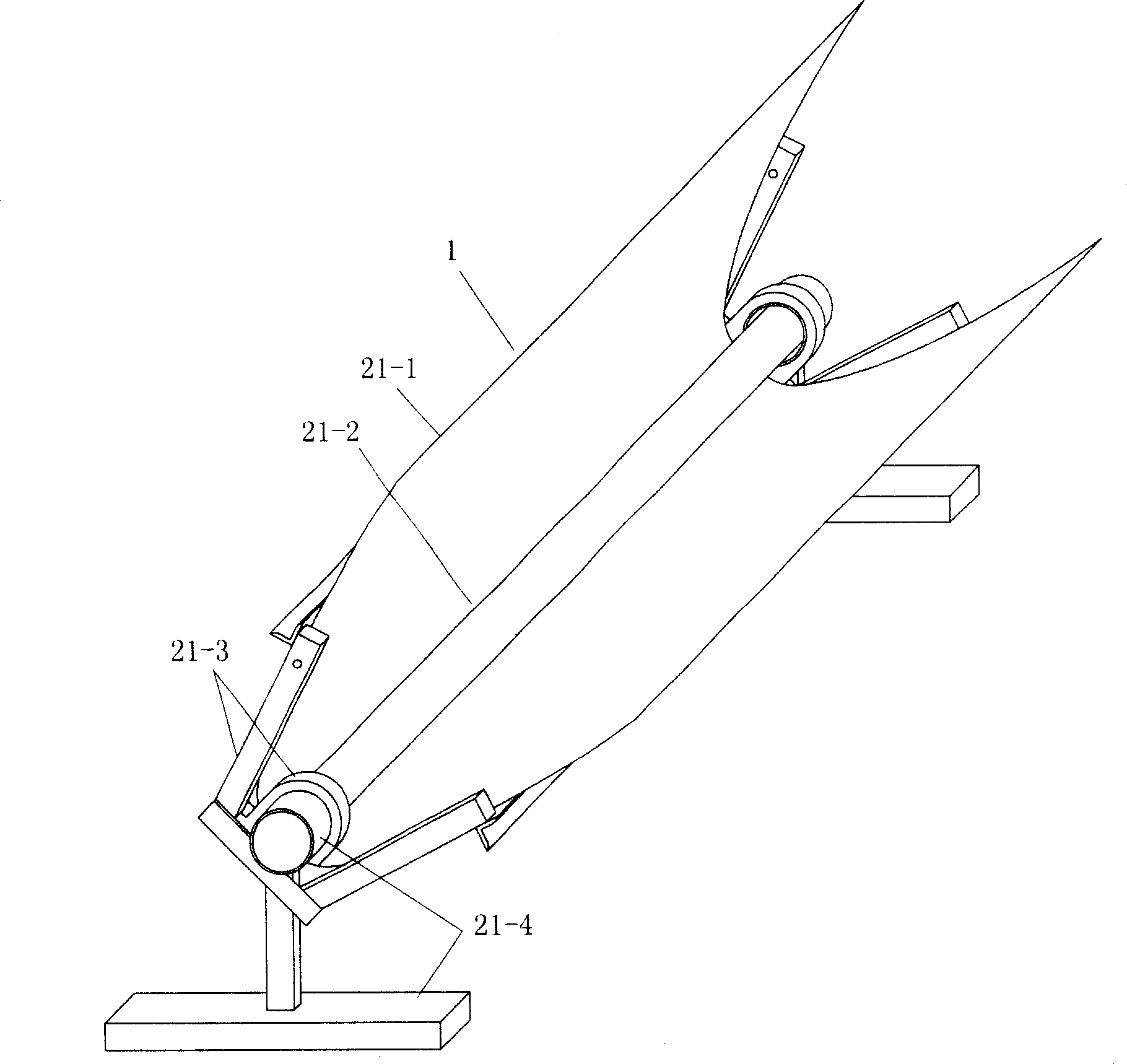

Composite parabolic light focusing type solar rice cooker

InactiveCN1749672ANot easy to damageEasy to useSolar heating energySolar heat devicesPlate heat exchangerCollector device

The composite parabolic light focusing solar rice cooker includes pressure rice cooker and square heat collector array comprising composite parabolic light focusing units. The pressure rice cooker has housing, rice utensil frame, water tank, water pipeline and heat exchanger. The heat exchanger has its two ends extending beyond the housing and connected to the medium input pipe and output pipe of the square heat collector array to form the medium flow loop, in which there are medium storage and circulating pump. The present invention performs heat exchange between heat medium inside the loop and water around the heat exchanger to evaporate water and the heat medium may be scale-proof and cold-proof medium for convenient use. The composite parabolic light focusing units have antiageing light condensers and long period high heat collecting efficiency.

Owner:TRINA SOLAR CO LTD

Power plant

ActiveUS9222410B2Increase steam productionTurbine/propulsion engine coolingEngine fuctionsHigh energyEngineering

Owner:GENERAL ELECTRIC CO

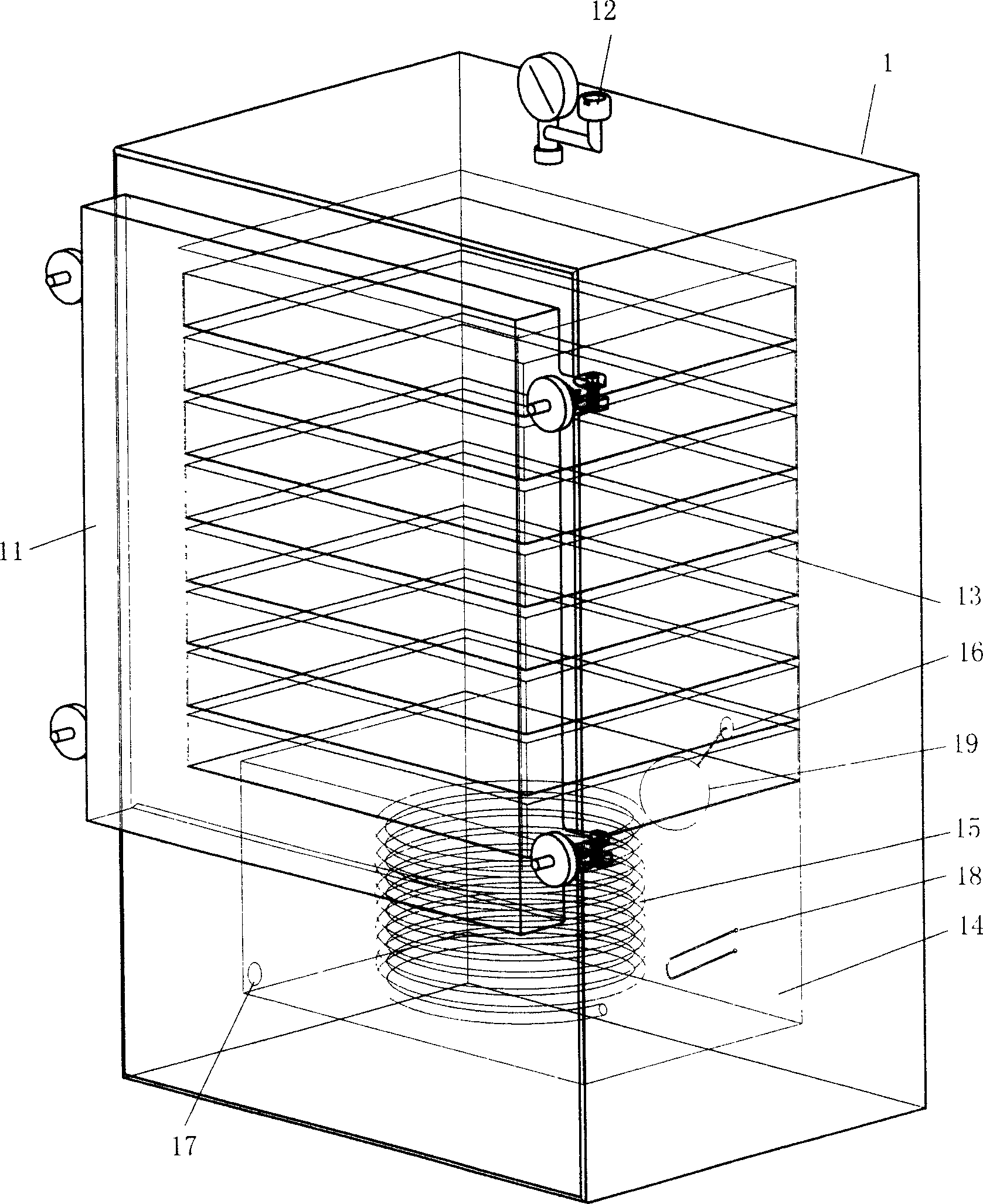

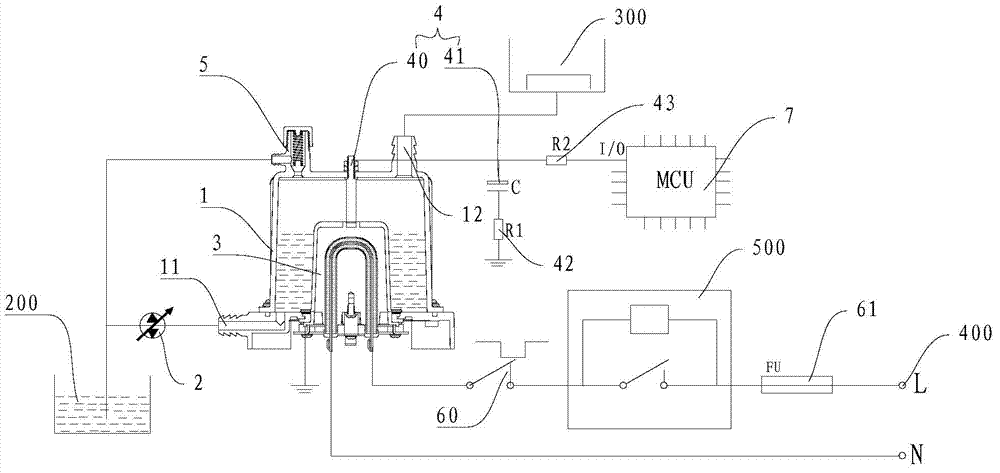

Steam generation system

ActiveCN104515120AIncrease steam productionFast steam productionSteam generation heating methodsWater feed controlEngineeringSteam generation

The invention discloses a steam generation system. The steam generation system comprises a steam generator, a water supply device and a water level control device. The steam generator comprises a shell and a heating body assembly, wherein a containing cavity used for storing water is formed in the shell, a water inlet is formed in the shell, and a steam outlet is formed in the top wall of the shell. The heating body assembly is arranged in the containing cavity. The bottom end of the heating body assembly extends out of the shell so as to be connected with an external power supply. The water supply device is connected with the water inlet so as to supply water into the containing cavity. The water level control device is used for controlling the water level height in the containing cavity so as to ensure that the head portion of the heating body assembly is exposed above the water level line. By means of the steam generation system, the steam yield of the steam generation system can be increased, and the steam generation speed is increased.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

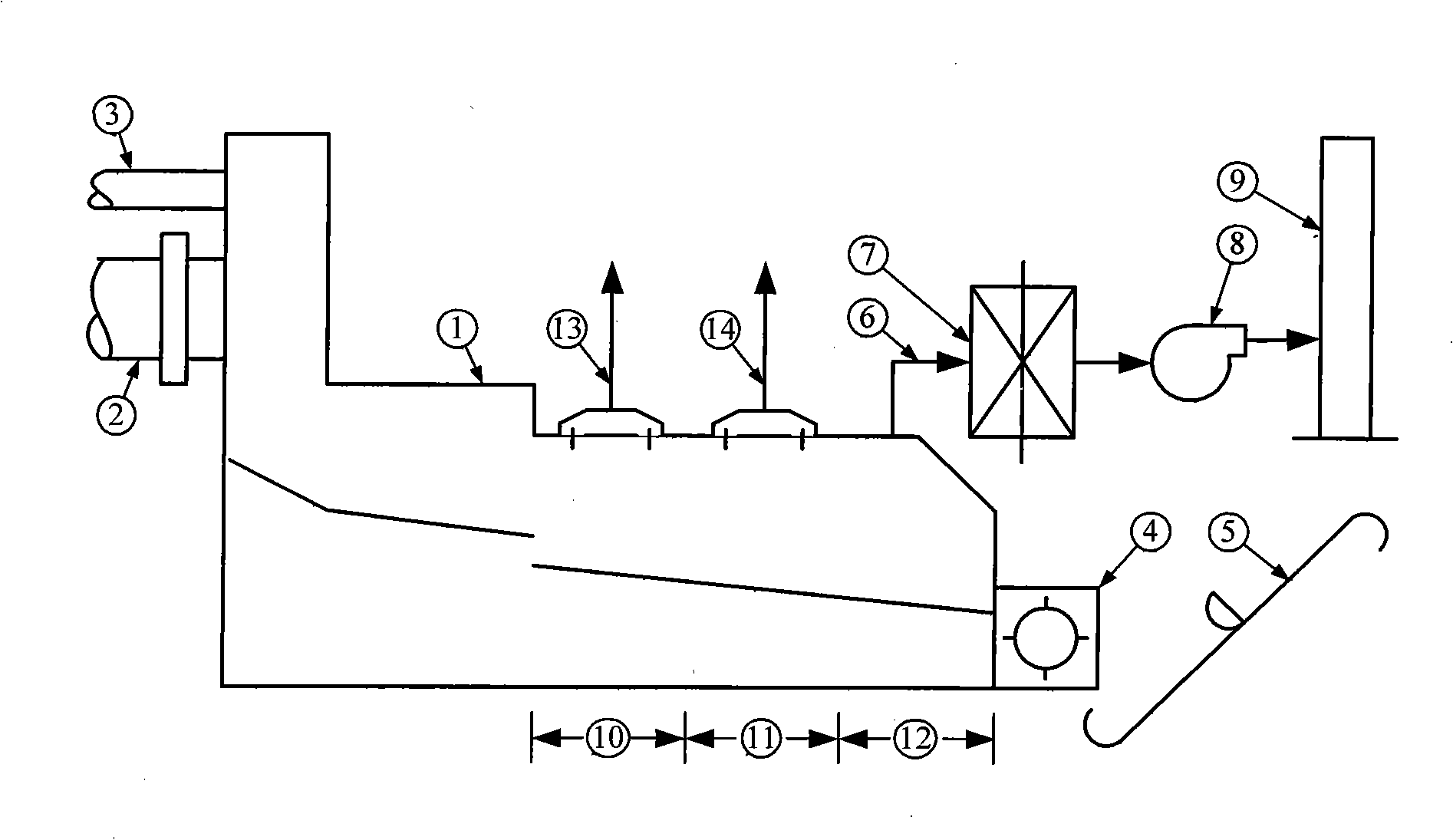

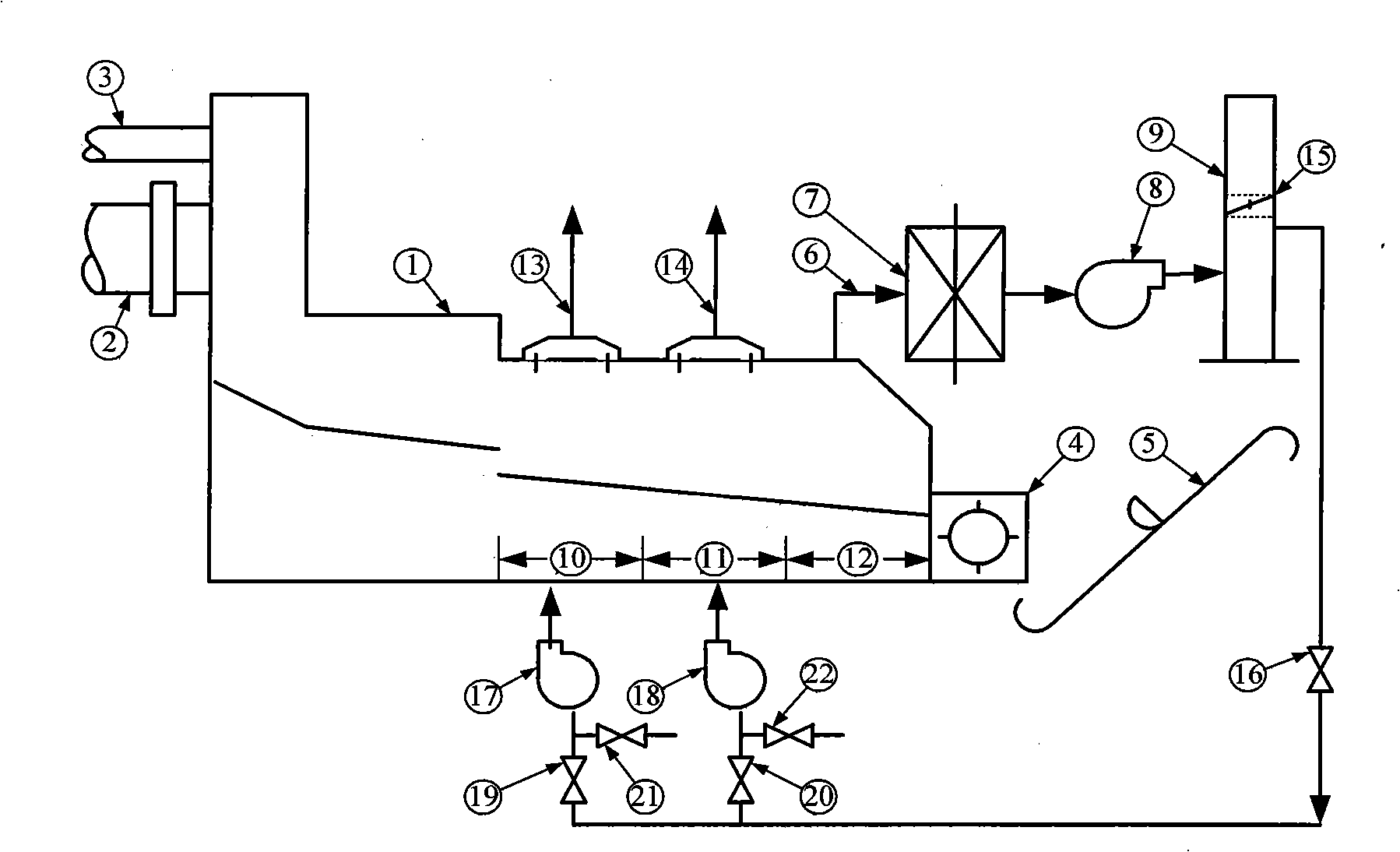

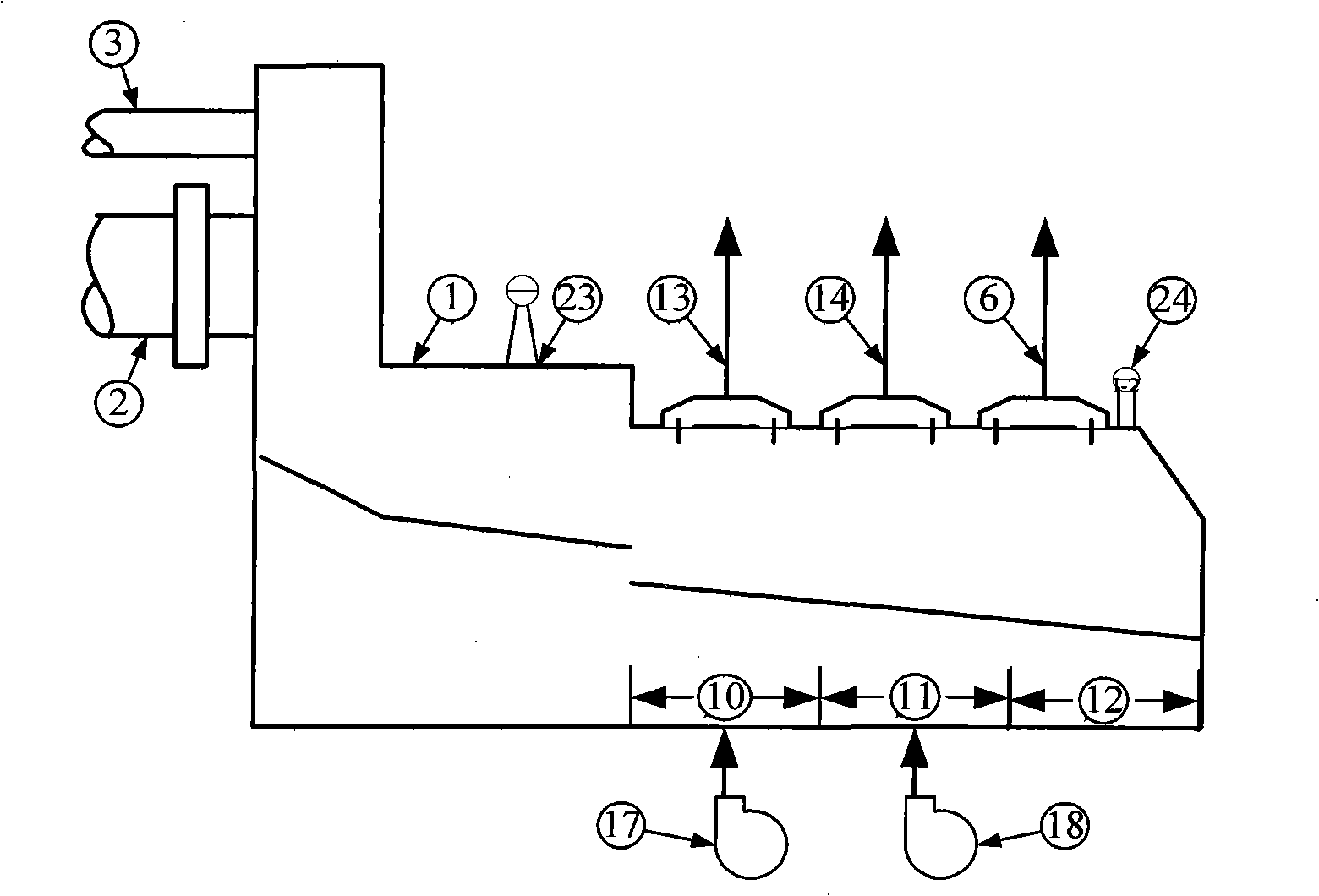

Control method for getting wind process for kiln hood waste heat boiler in dry cement residual heat utilization and apparatus thereof

InactiveCN101407382AStabilization and inlet air temperature and steam productionIncrease the inlet air temperature and steam productionClinker productionCement kilnEngineering

The invention relates to the fields of the recycle and application to electricity generation of waste gas and residual heat of a kiln head clinker cooler of a novel dry method cement production line. On the basis that at the kiln head cooler, the temperature of the cooled clinker is 600-200 DEG C of a cooling grate bed area and the discharging temperature of the cooler is ensured to meet the requirement, the invention controls and improves the temperature of hot air at the upper part of a clinker layer after heat exchange with the clinker, through utilizing first-discharging waste gas discharged to air and with temperature of 80-120 DEG C as cooling air which is corresponding to the area and used for cooling the clinker, effectively controlling the thickness of the clinker layer in the cooler and improving the temperature of the cooling air which is corresponding to the area and used for cooling the clinker. According to the temperature of hot air at the upper part of the corresponding clinker layer, the thickness of the clinker layer in the cooler and the temperature of the cooling air can be regulated in real time. The invention has the advantages of further stabilizing and improving the temperature of inlet air and steam production of residual heat boilers, stabilizing and improving generated energy of residual heat generation, and simultaneously improving the rate of multipurpose utilization of cement kiln residual heat resources.

Owner:昆明阳光基业股份有限公司

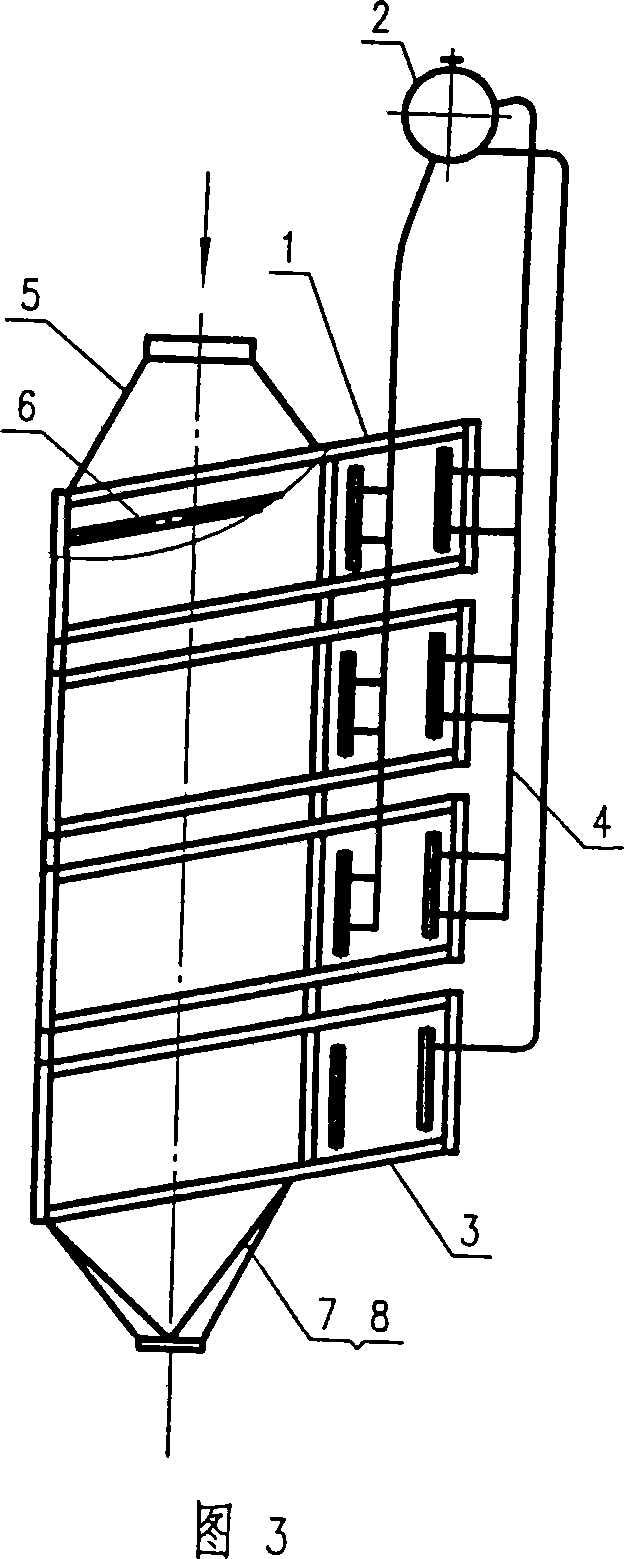

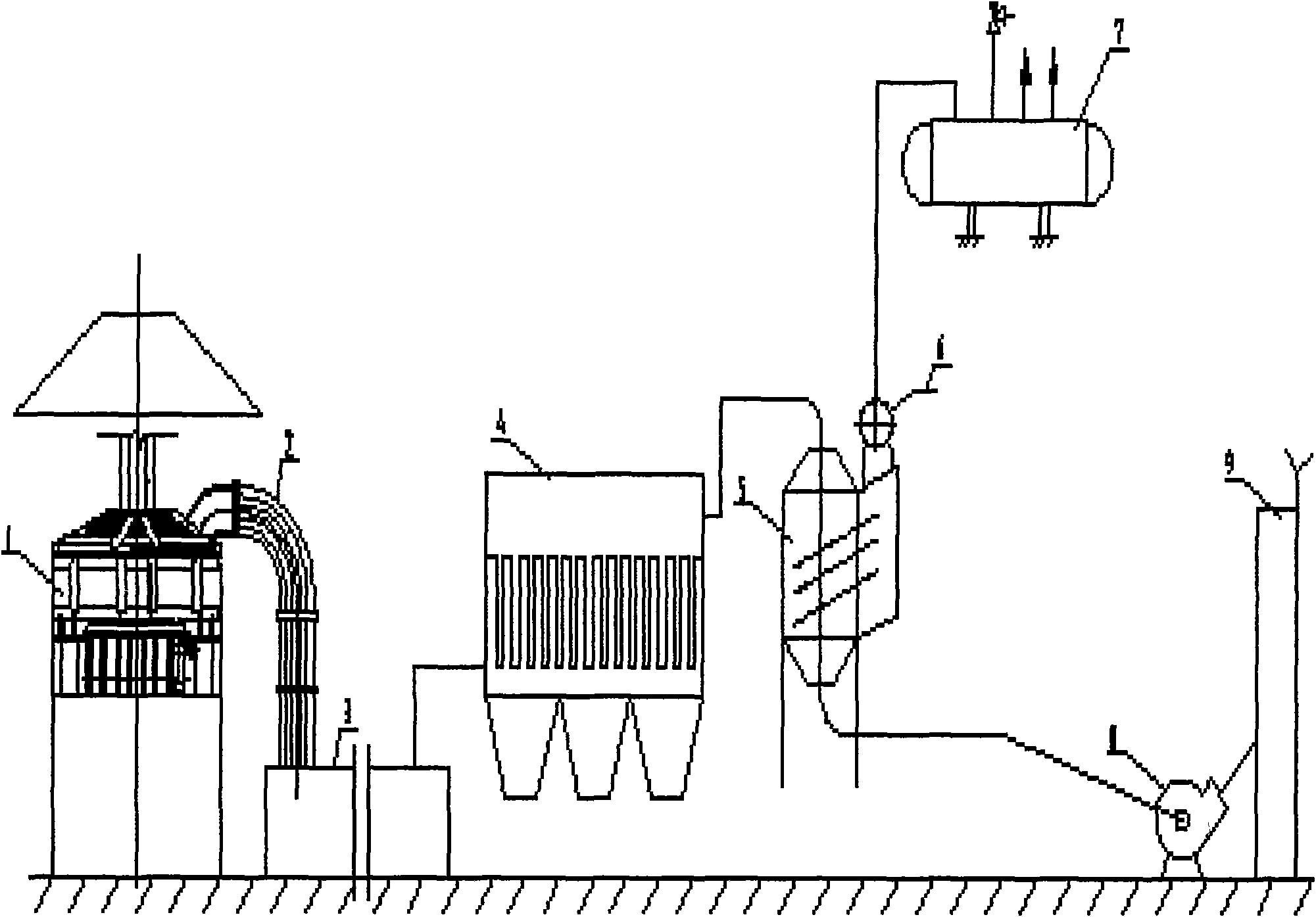

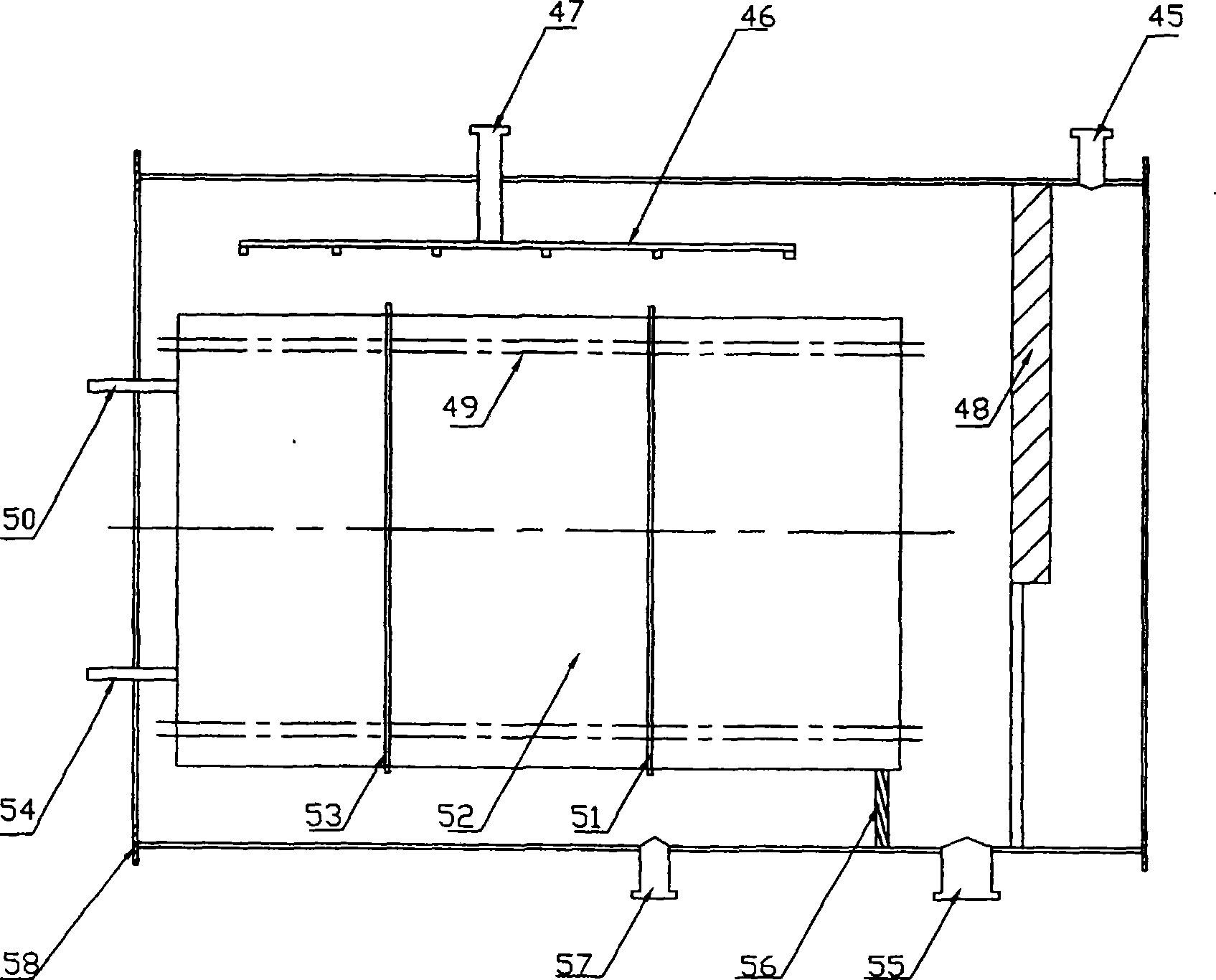

Revolving furnace, electric stove steel-smelting high-temperature gas cooling down heat-recovering steam producing energy conservation system device

InactiveCN101118053AImprove qualityGreat tasteSteam generation using hot heat carriersHeat transfer efficiencyEngineering

The present invention relates to a steel-making high temperature gas cooling waste heat recycling steam producing energy saving system device for a converter and an electric oven. The present invention is characterized in that the device comprises a plurality of steam generators (1) which are connected in series and whose the gas circulating section is decreased in cascade type, an inlet interface (5) is arranged at one end of the steam generator (1), an outlet interface (7) is arranged at the other end, a heat transfer element (6) is arranged inside the steam generator (1), and the steam generator (1) is connected with a steam drum through each steam-water connecting pipe (4). The steam generator system waste heat steam producing energy saving device which is arranged in a high temperature chimney neck makes the gas temperature in the chimney neck decrease from 1000 degrees centigrade to 180 degrees centigrade to discharge, meeting the purposes of waste heat reuse and energy conservation. The present invention has the advantages that heat transfer efficiency is improved, each part of the process is independently arranged dispersedly, the equipment cubage is small, the disassembly is convenient, and the routine maintenance and the servicing and repair are convenient.

Owner:NANJING SHENGNUO HEAT PIPE

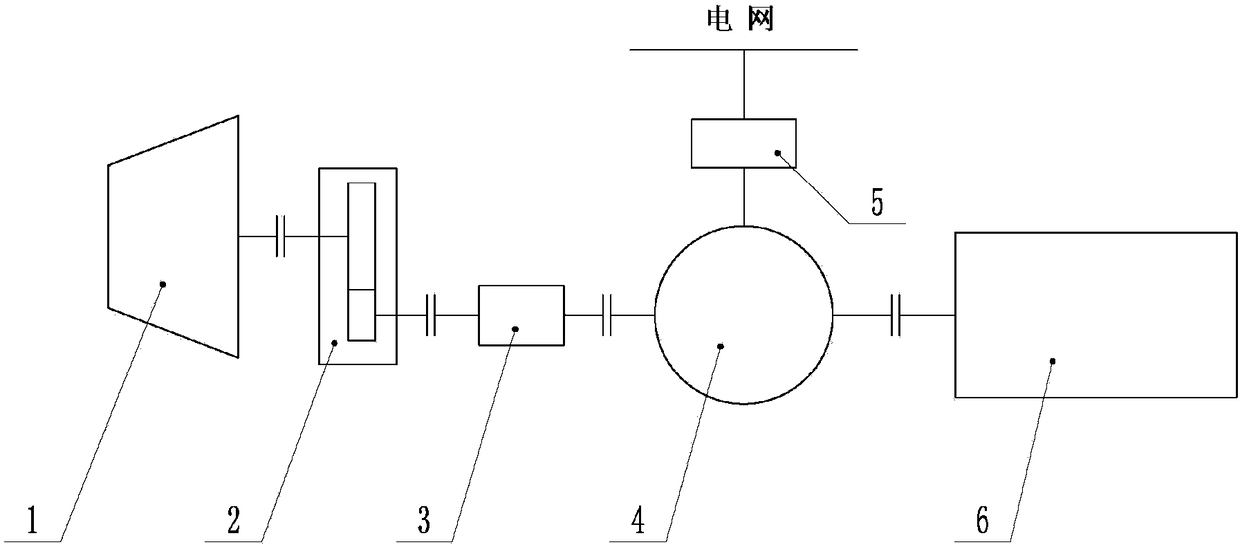

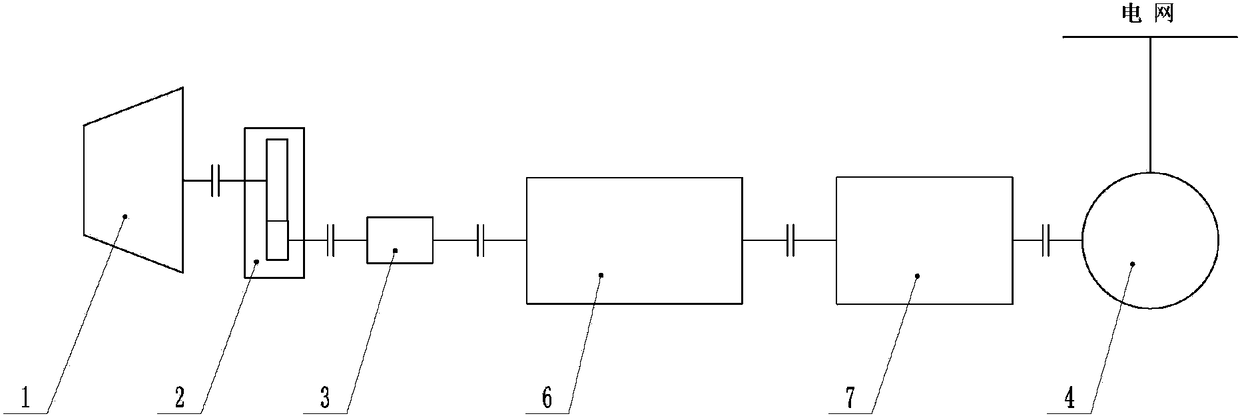

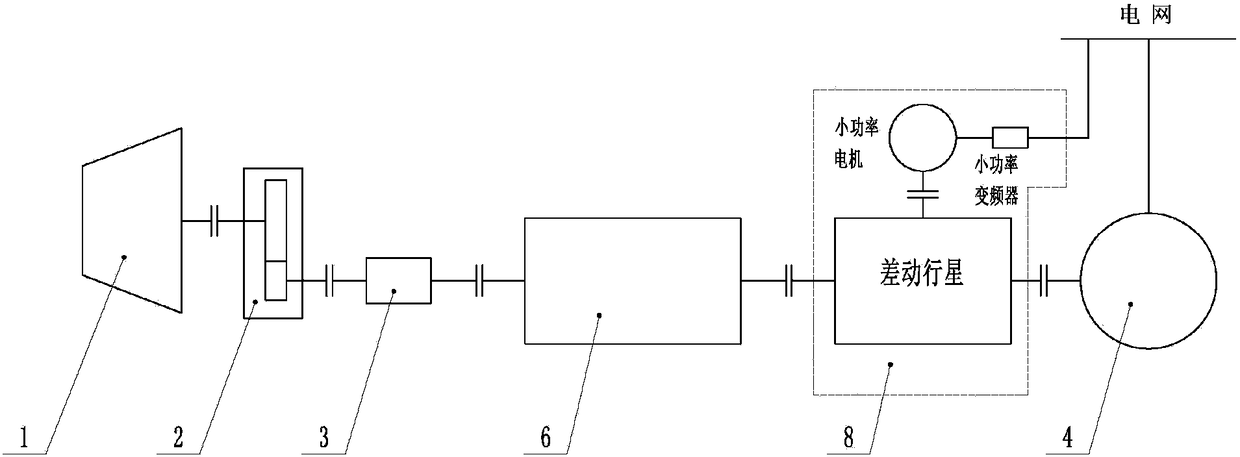

High-efficiency steam-electricity hybrid power speed regulation unit

PendingCN108462316AImprove operational efficiencyIncrease steam productionMechanical energy handlingElectric generator controlElectricityPower station

The invention relates to the field of speed regulation of a power station fan and a water pump unit, in particular to a high-efficiency steam-electricity hybrid power speed regulation unit. The unit includes a steam turbine, a gear box, a synchronous automatic clutch, a motor, a full-power frequency converter, a load, a planetary hydraulic speed regulation / constant speed device, and a planetary variable frequency speed regulation / constant speed device. Through the different arrangements and applications of the device, the hybrid power speed regulation driving unit is realized, the unit integrates the advantages of the steam-driving and electricity-driving parties, has the characteristics of being energy-saving, efficient, high in reliability, saving in investment, and is particularly suitable for actual conditions of peak shaving and future deep peak shaving operation of a current power station.

Owner:中国船舶重工集团公司第七0三研究所

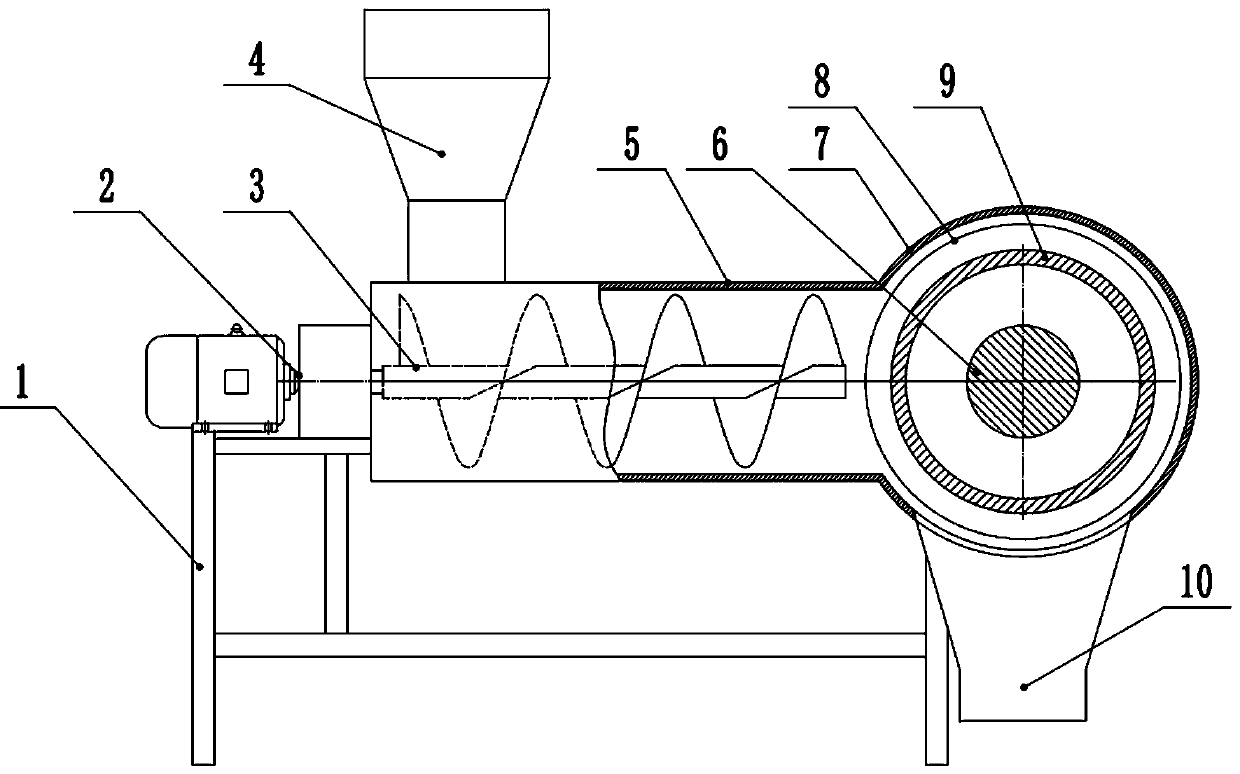

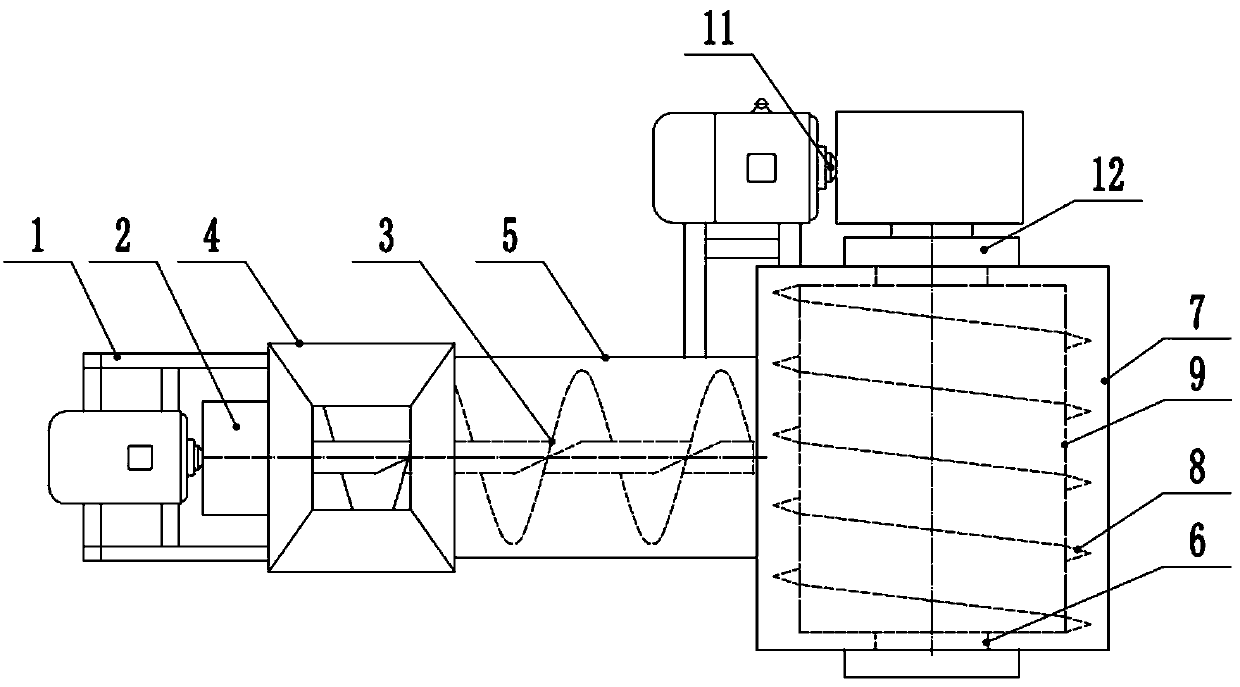

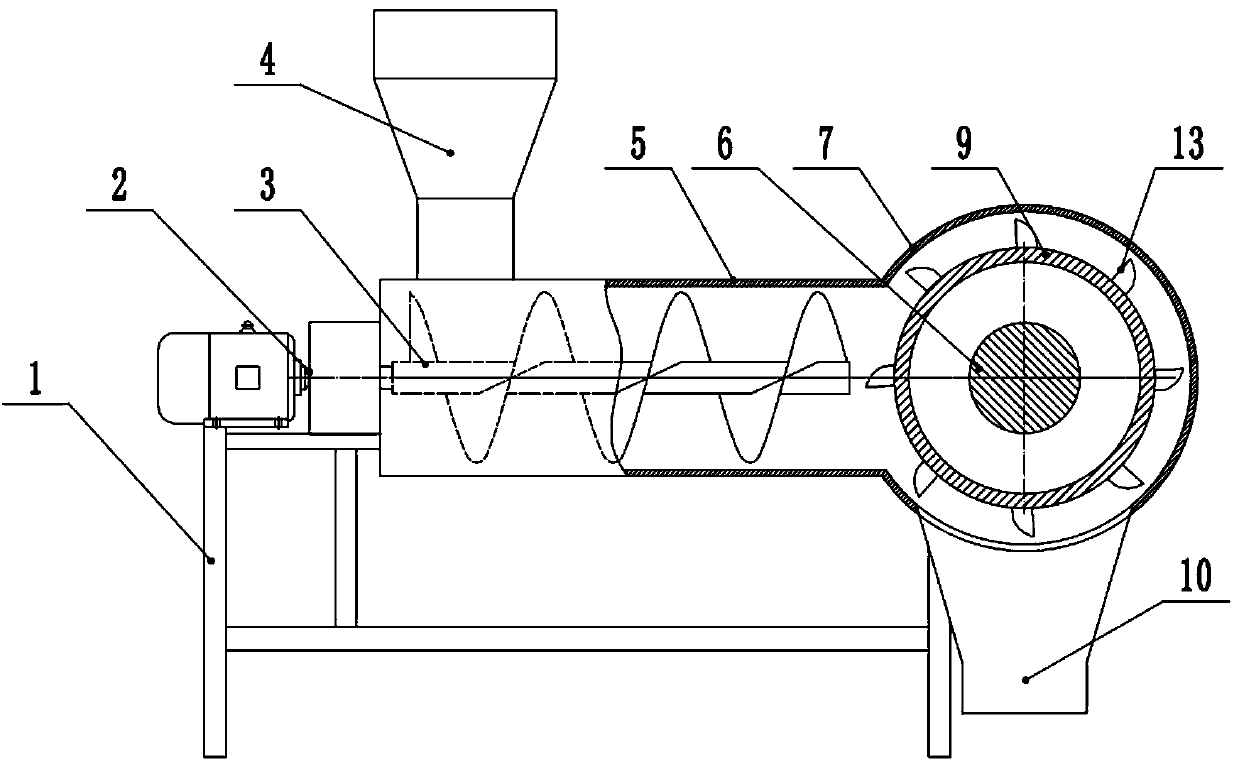

Crushing method of bagasse

InactiveCN107930802AEliminate compressibilitySolving unbreakable problemsGrain treatmentsPressesEngineeringEnergy consumption

The invention relates to the technical field of biomass pulverization, specifically a crushing method of bagasse. The crashing method comprises the following steps that (1), the bagasse is extruded and compressed mechanically; and (2), the bagasse after mechanically squeezed and compressed is broken. The bagasse is firstly mechanically squeezed and compressed; squeezability of the bagasse is greatly eliminated, so that the bagasse can fully be accepted the crushing pressure in the process of crushing to solve the unbreakable problem caused by originally processed loose characteristics of the bagasse; in addition, the bagasse is intertwined into a ball after mechanically squeezed and compressed and the bagasse in a chopping missing state can be effectively solved in the shattering process;the single machine processing quantity can be obviously improved; the crushing efficiency is improved, and the crushing efficiency is higher than that of the traditional crushing device by more than 50%; and the crushing size is uniform and the energy consumption is reduced.

Owner:广西巨桂科技有限公司

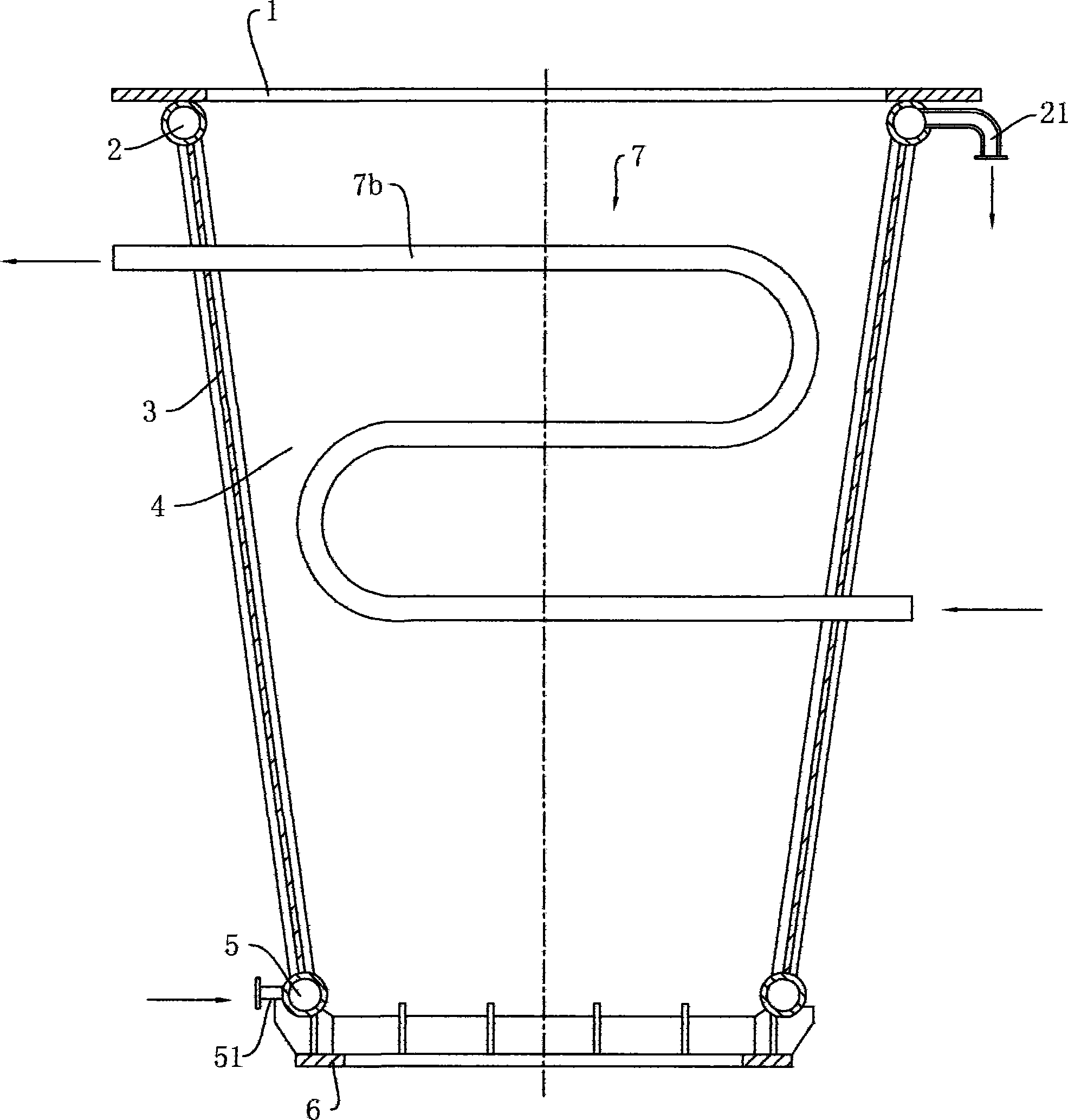

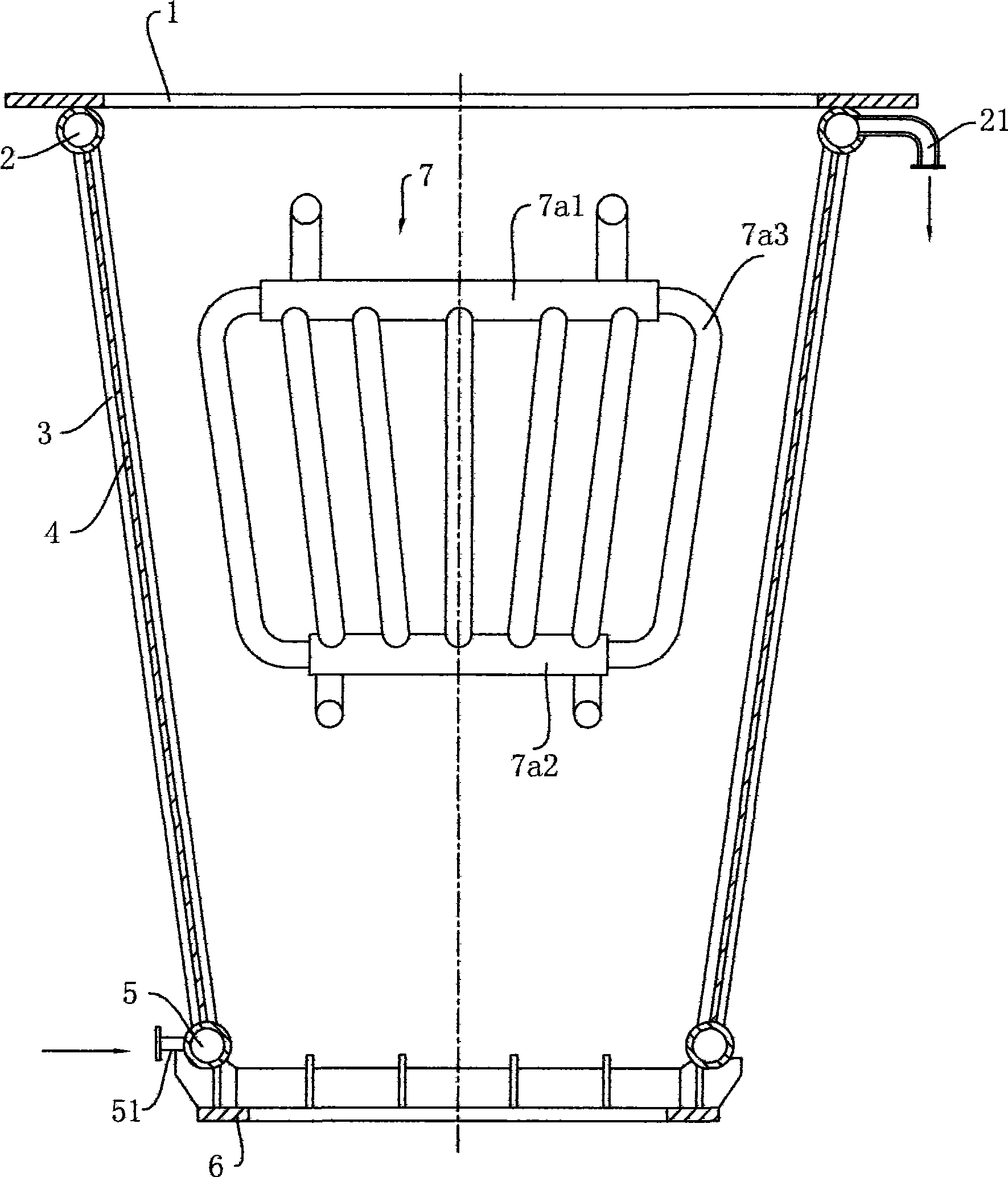

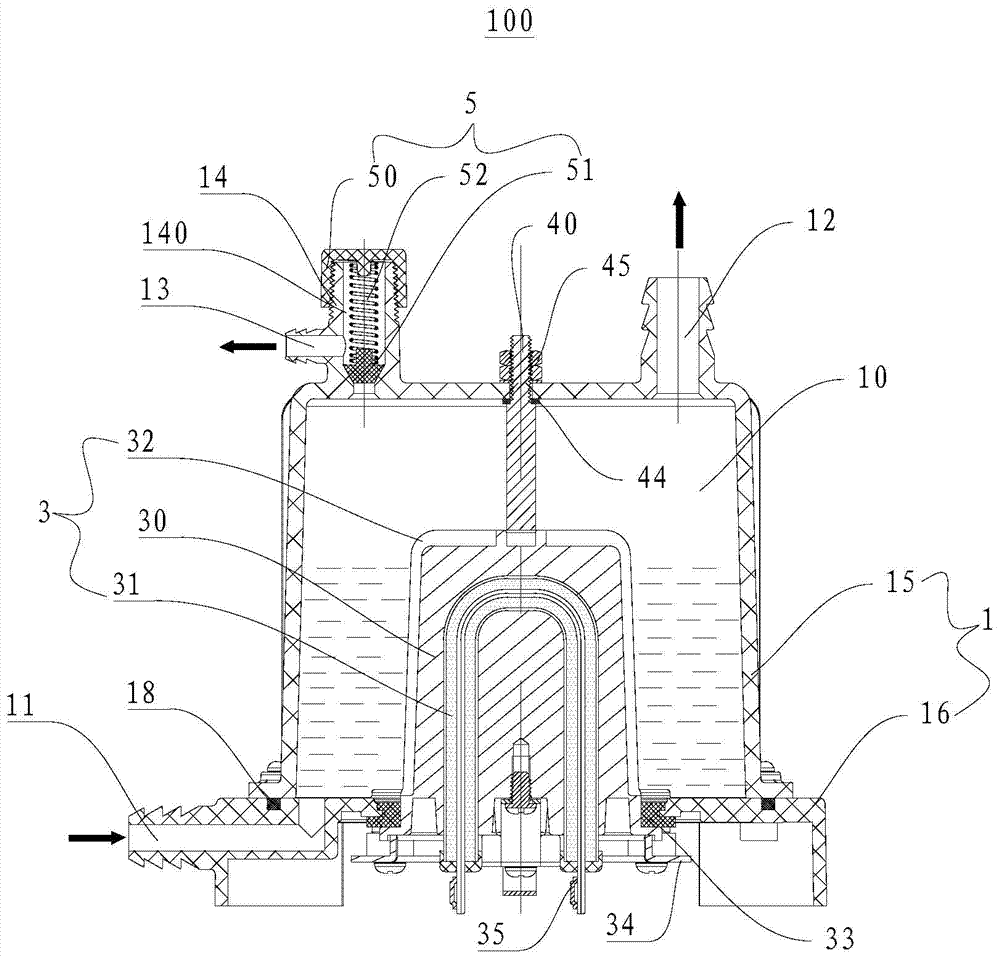

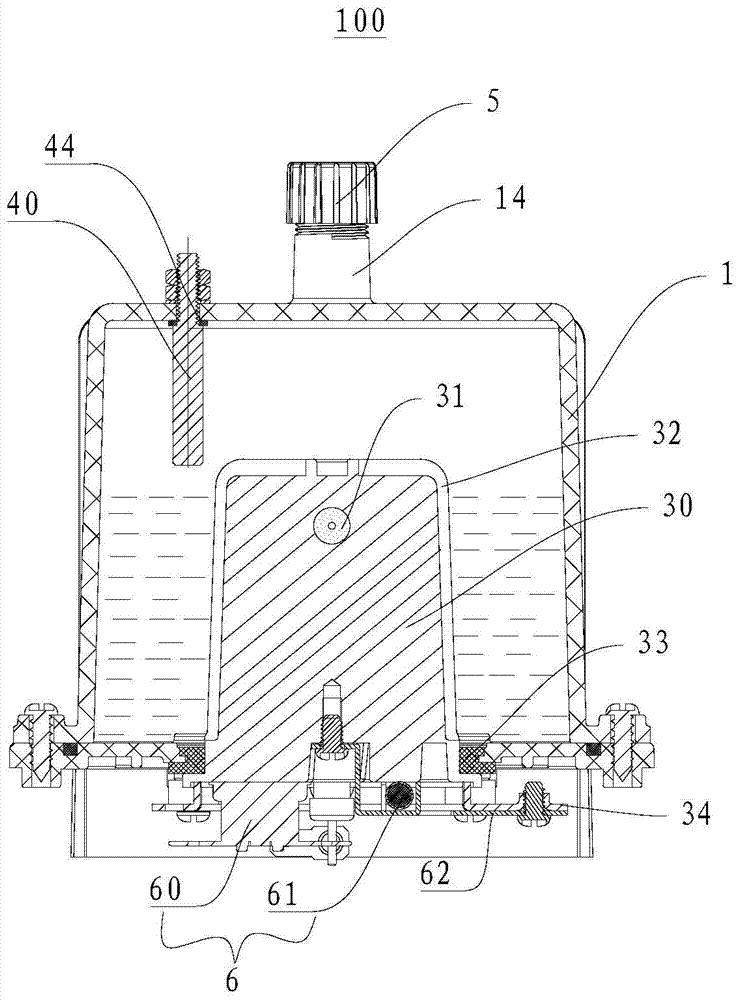

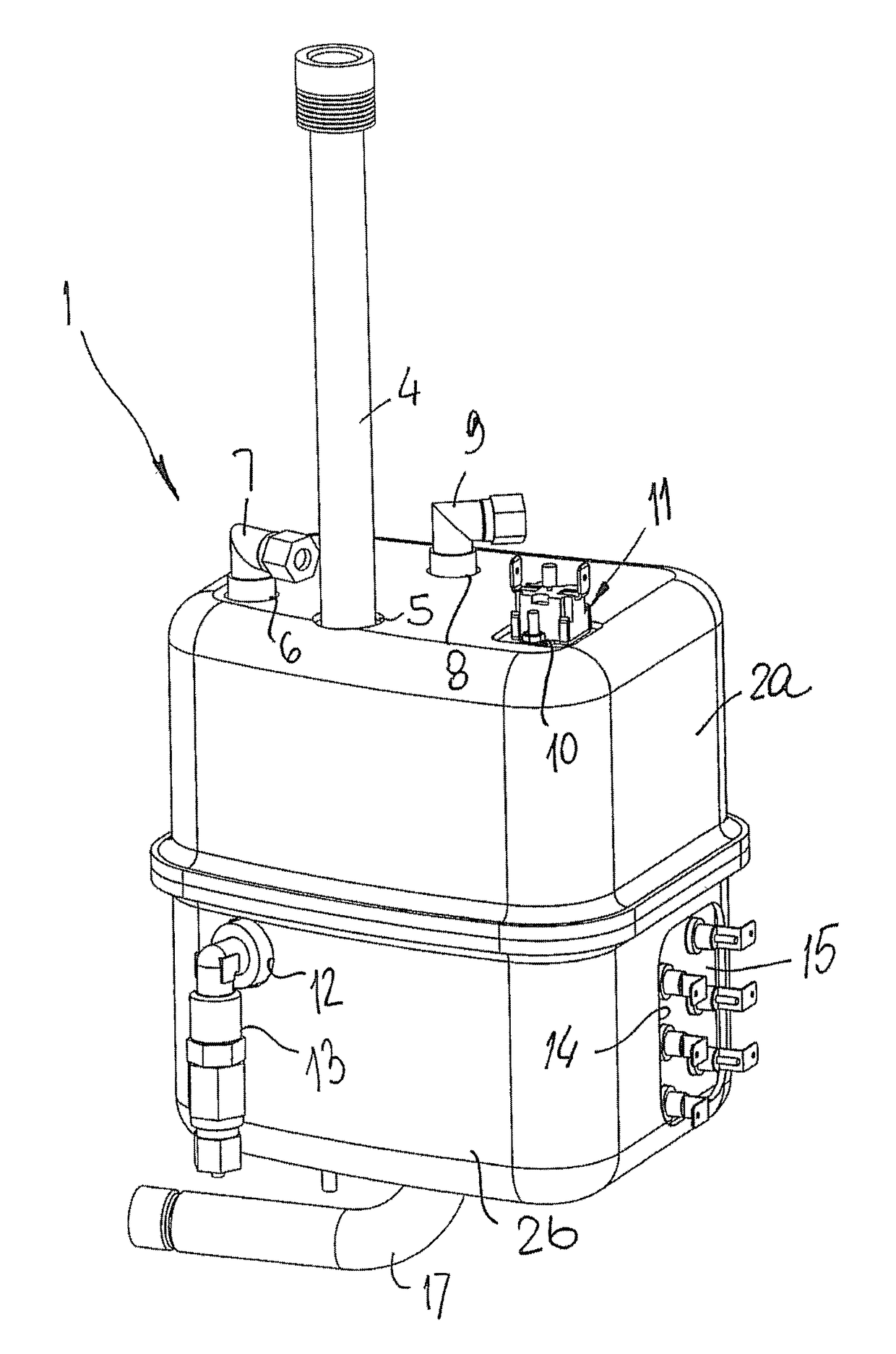

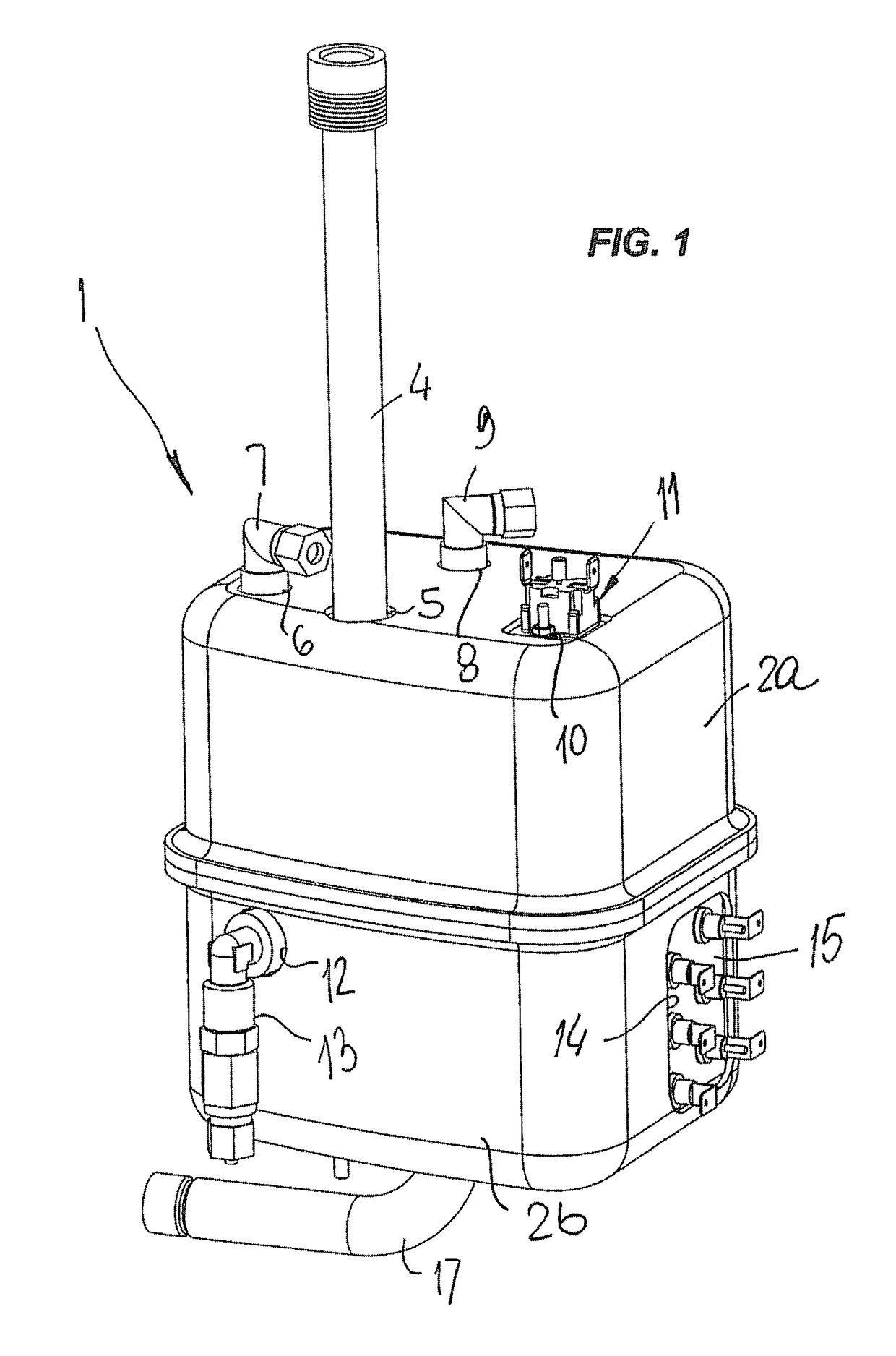

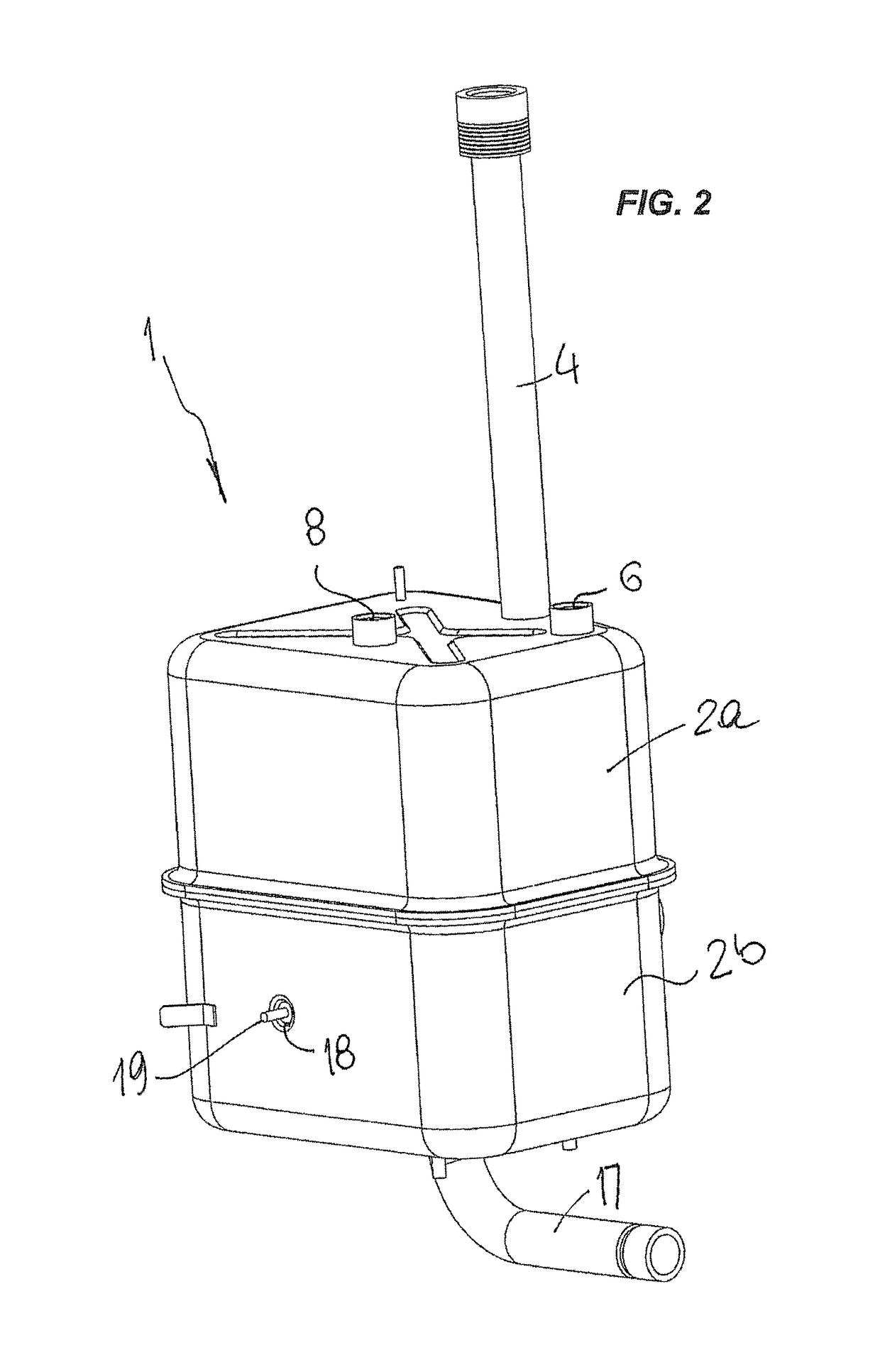

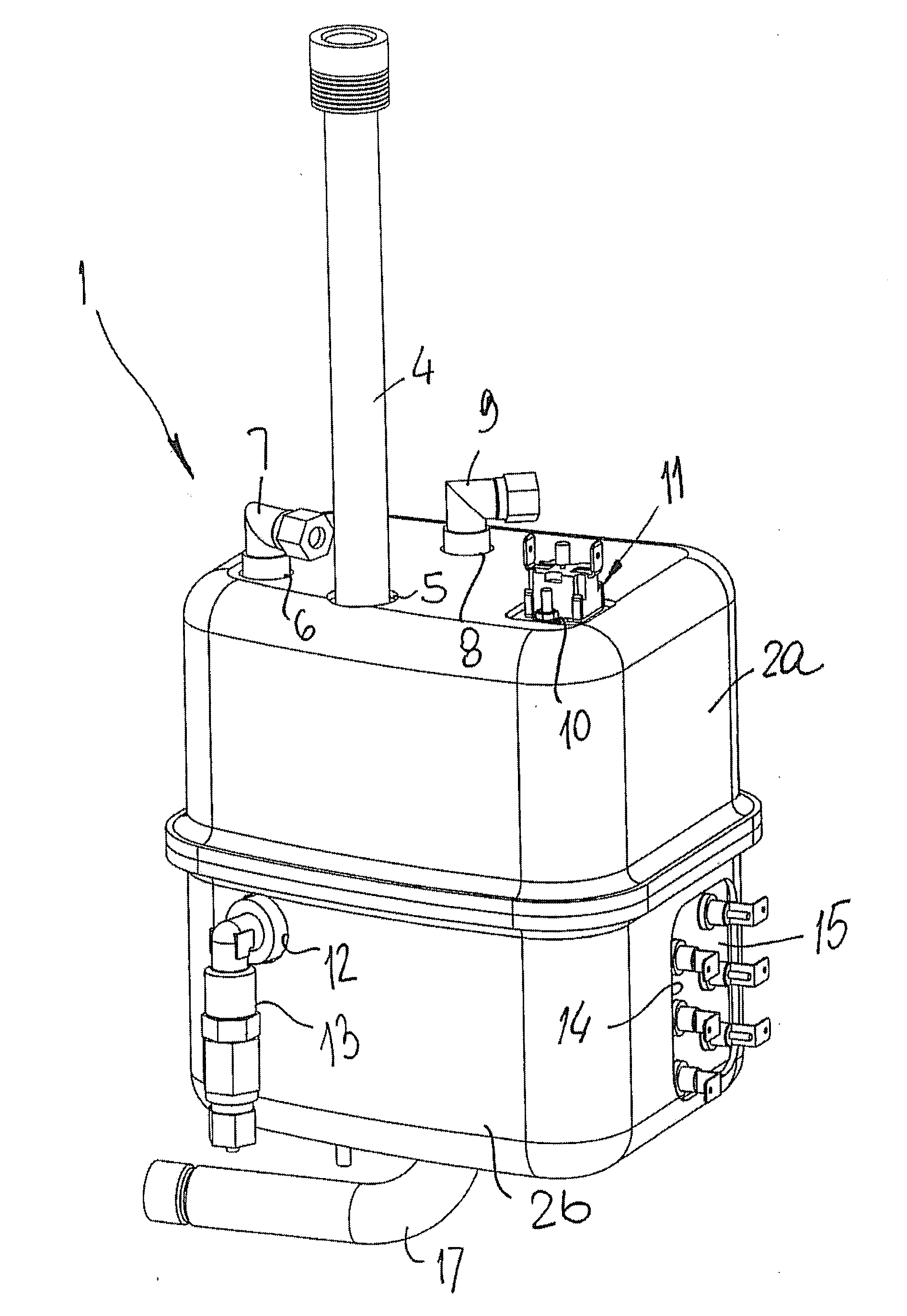

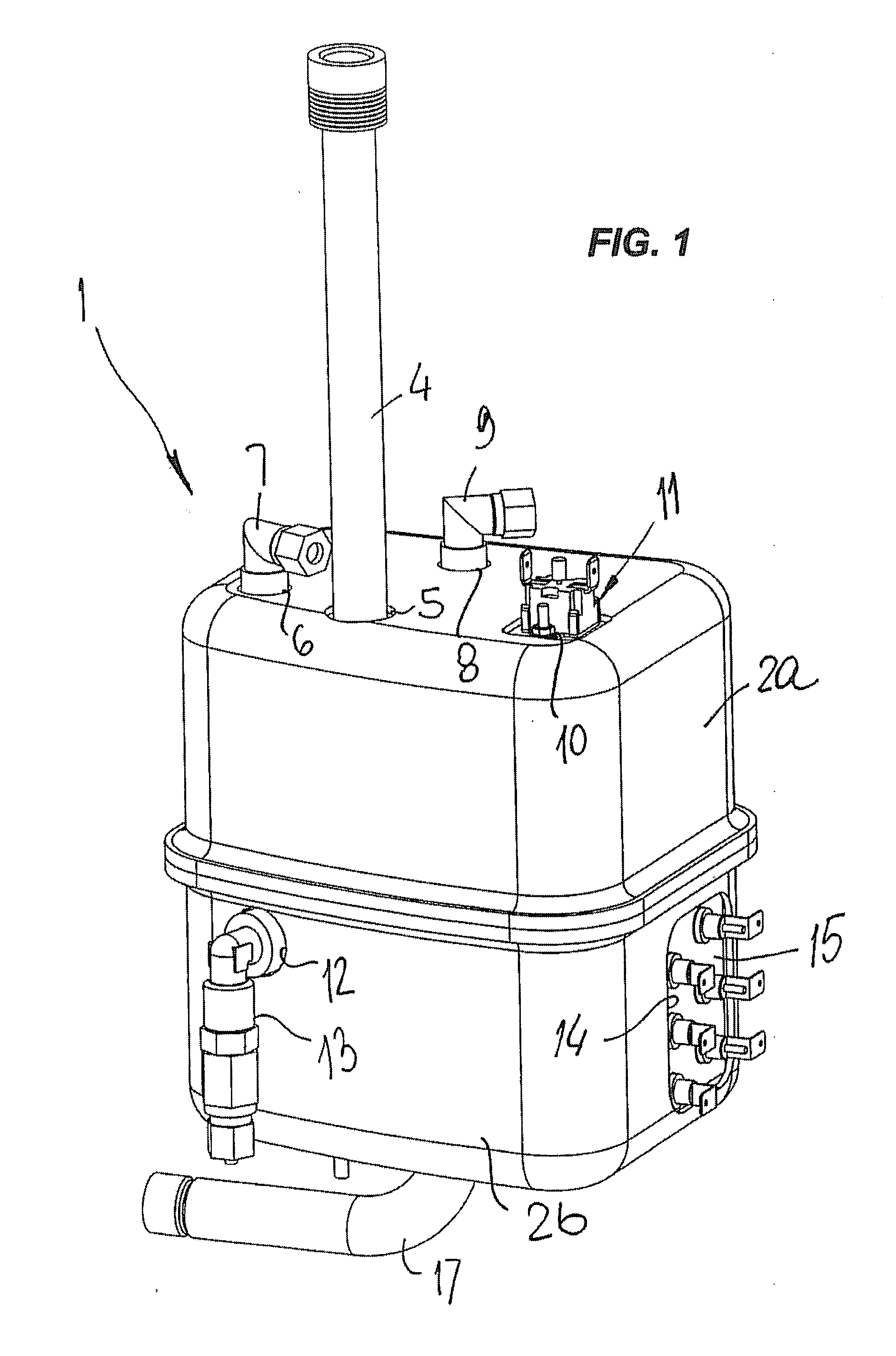

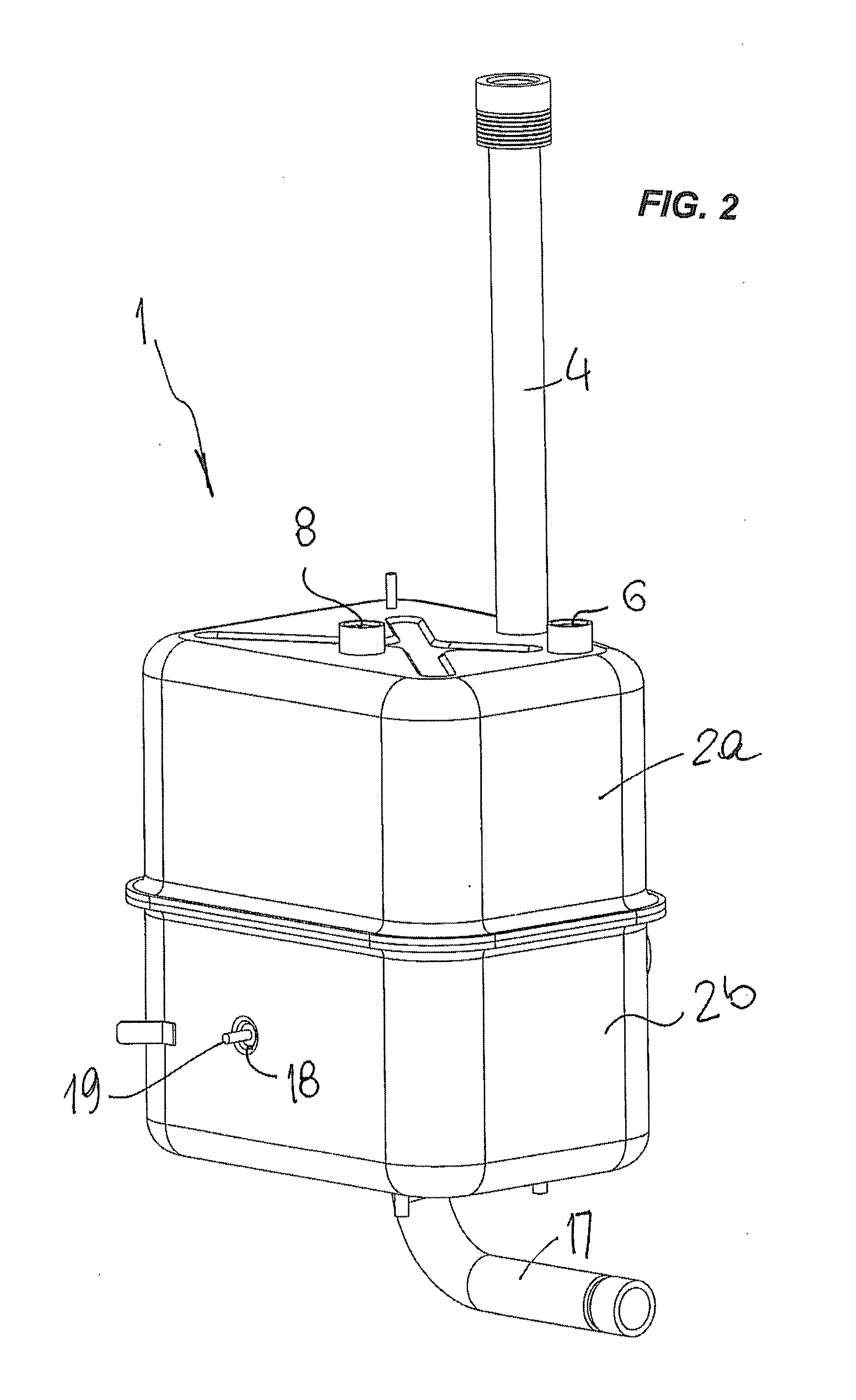

Boiler for domestic appliances and water heating systems with steam production for home and industrial use

ActiveUS9702544B2Reduce capacitySmall sizeRespiratorsSteam generation heating methodsProcess engineeringHome appliance

A boiler for domestic appliances and water heating systems with steam production for home and industrial use includes: a container body configured to contain a liquid to be heated and vaporized, and defining an inner containment chamber having a containment volume; a heating device having a radiant heating surface, the heating device including at least one pair of radiant elements having respective radiant surfaces accommodated in the containment chamber, in parallel and spaced relationship, and designed to be immersed in the liquid to cause a convective motion of the liquid between the radiant surfaces.

Owner:T P A IMPEX

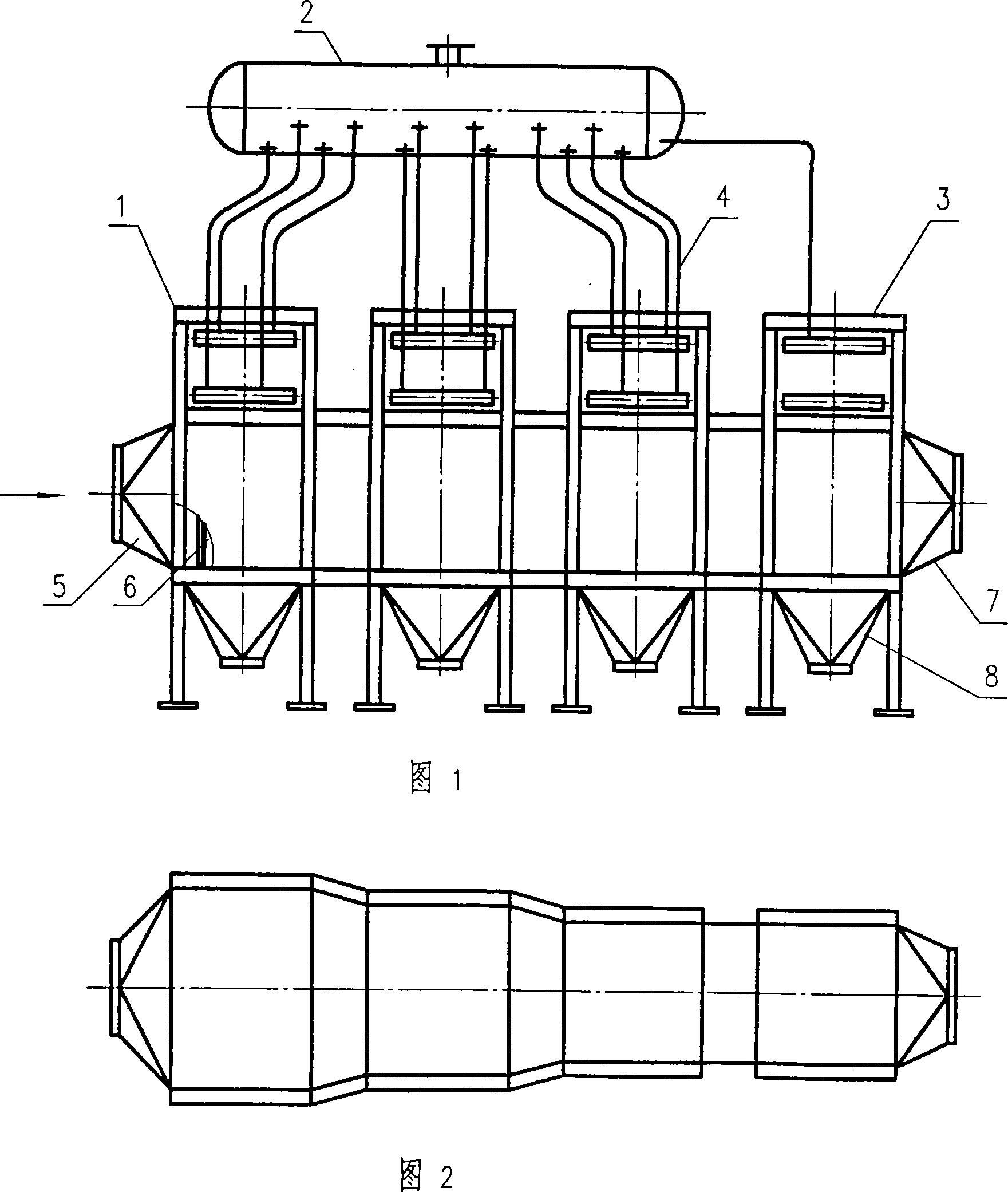

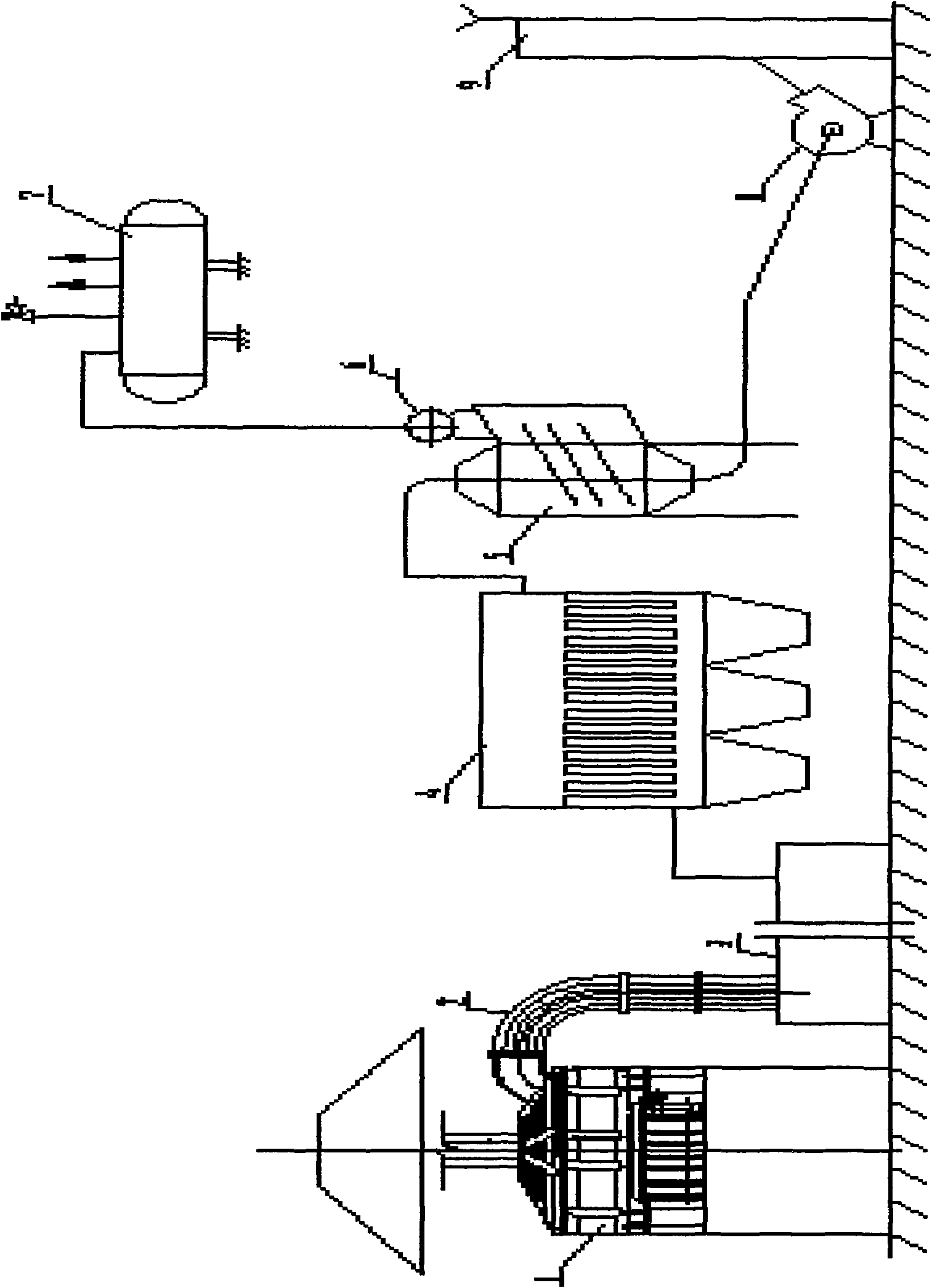

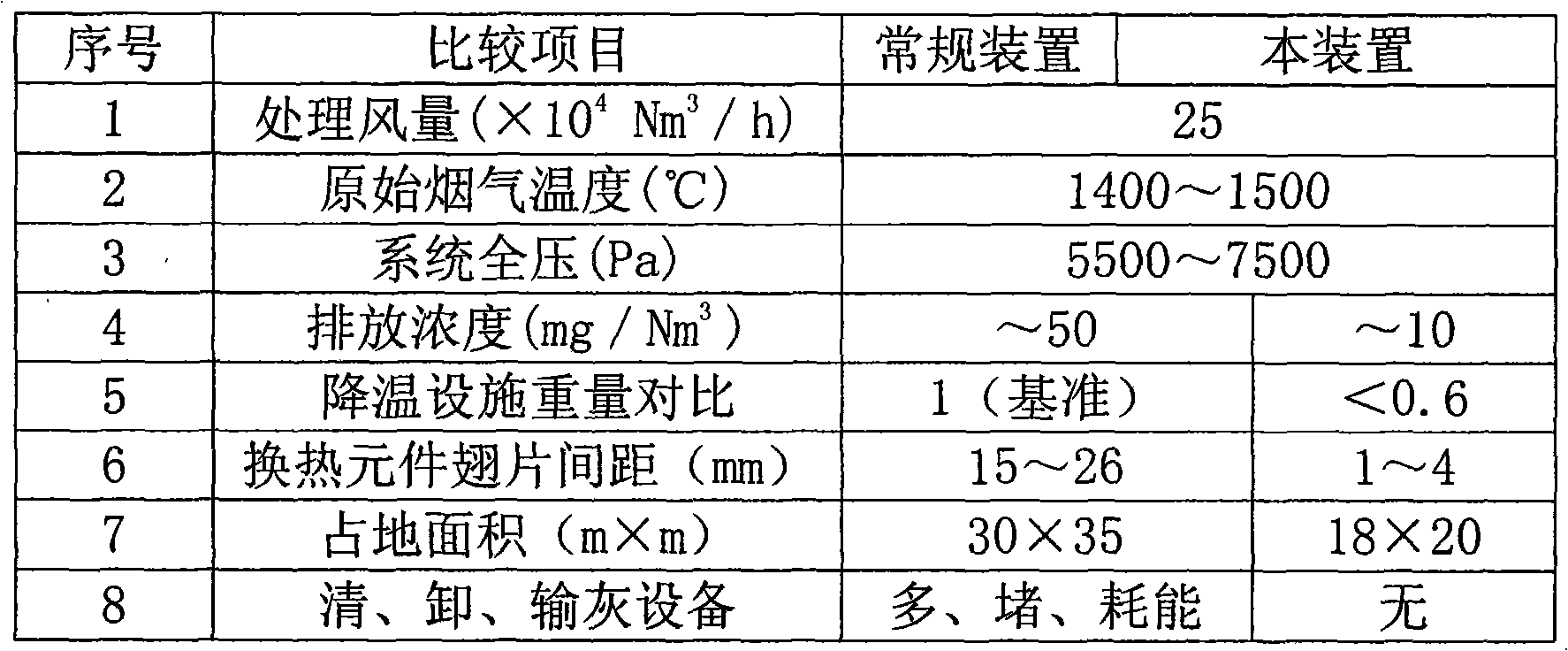

Metallurgical furnace dedusting waste heat recovery machine and method

InactiveCN101995166AReduce volumeReduce maintenanceDispersed particle filtrationEnergy industryRecovery methodWaste heat recovery unit

The invention relates to a metallurgical furnace dedusting waste heat recovery machine and a metallurgical furnace dedusting waste heat recovery method. A technical scheme is that: the metallurgical furnace dedusting waste heat recovery machine comprises high-temperature smoke generating equipment, a draught fan and an exhaust cylinder which are connected with one another sequentially through pipelines. A waste heat utilization facility is placed behind a dust catcher, and the dust content of heat source smoke is low and is not taken into consideration when the equipment is designed and manufactured, so the space between heat exchange core unit fins can be designed to be small and dust-unloading, dust-cleaning and dust-conveying facilities are unnecessary; and the volume of the waste heat utilization facility is reduced, so the maintenance quantity of the waste heat utilization facility is reduced and the service life of the waste heat utilization facility is prolonged.

Owner:无锡市曜通环保机械有限公司

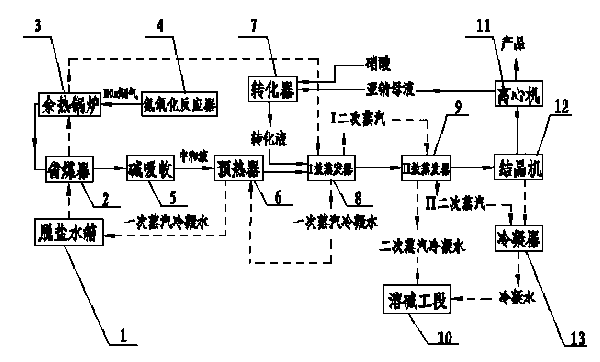

Steam self-supply system for producing sodium nitrate/sodium nitrite

ActiveCN103848443AConducive to emission reductionReduce the temperatureEnergy inputAlkali metal nitrate preparationEngineeringSodium nitrite

The invention discloses a steam self-supply system for producing sodium nitrate / sodium nitrite, which is suitable for preparing sodium nitrate / sodium nitrite. A desalination water tank is connected with a waste heat boiler through a coal economizer, and the waste heat boiler is connected with an ammoxidation reactor; the coal economizer is communicated with a crystallizer through an alkaline absorber, a preheater, an I-effect evaporator and an II-effect evaporator; the preheater is connected with the desalination water tank; a converter is respectively connected with the I-effect evaporator and a centrifugal machine; the II-effect evaporator is respectively connected with an alkaline dissolving workshop section and the crystallizer; the alkaline dissolving workshop section is connected with the centrifugal machine through a condenser and the crystallizer. The steam self-supply system is remarkable in energy saving benefit, convenient for process regulation and pollutant discharge reduction, high in degree of automation, remarkable in steam saving effect and high in recycling ratio.

Owner:襄阳泽东化工集团股份有限公司

Temperature control method for fixed bed gasification furnace oxidation zone and gasification furnace

InactiveCN101486928APrevent channelingImprove carbon conversionChemical industryCombined combustion mitigationChemical synthesisTemperature control

The invention belongs to the gasification technical field, which discloses a fixed bed gasifier oxidation zone temperature control method; water is delivered to the lower part of the oxidation zone in the hearth through an inlet tube on the side face of the lower part of the gasifier, and is vaporized by absorbing heat at the lower part of the oxidation zone in an atomization way, so that the temperature in the oxidation zone is controlled below the ash fusion point of the coking coal; and a fixed bed gasifier is to implement the above method; a spraying temperature control device is arranged between the lower part of the oxidation zone in the hearth and the ash zone; the water sprayed from the annular spraying pipe of the spraying temperature control device is gasified by absorbing the heat, thus reducing the steam dosage of the gasification agent; the gasifier has simple structure, easy operation, energy conservation and environmental protection, and is applicable to systems of coal gasification power generation, coal gasification for urban gas preparation, chemical synthesis, etc.

Owner:刘宏建 +1

Boiler for Domestic Appliances and Water Heating Systems With Steam Production for Home and Industrial Use

ActiveUS20150063791A1High and substantially consistent steam productionAvoid lostRespiratorsSteam generation heating methodsEngineeringProcess engineering

A boiler for domestic appliances and water heating systems with steam production for home and industrial use includes: a container body configured to contain a liquid to be heated and vaporized, and defining an inner containment chamber having a containment volume; a heating device having a radiant heating surface, the heating device including at least one pair of radiant elements having respective radiant surfaces accommodated in the containment chamber, in parallel and spaced relationship, and designed to be immersed in the liquid to cause a convective motion of the liquid between the radiant surfaces.

Owner:T P A IMPEX

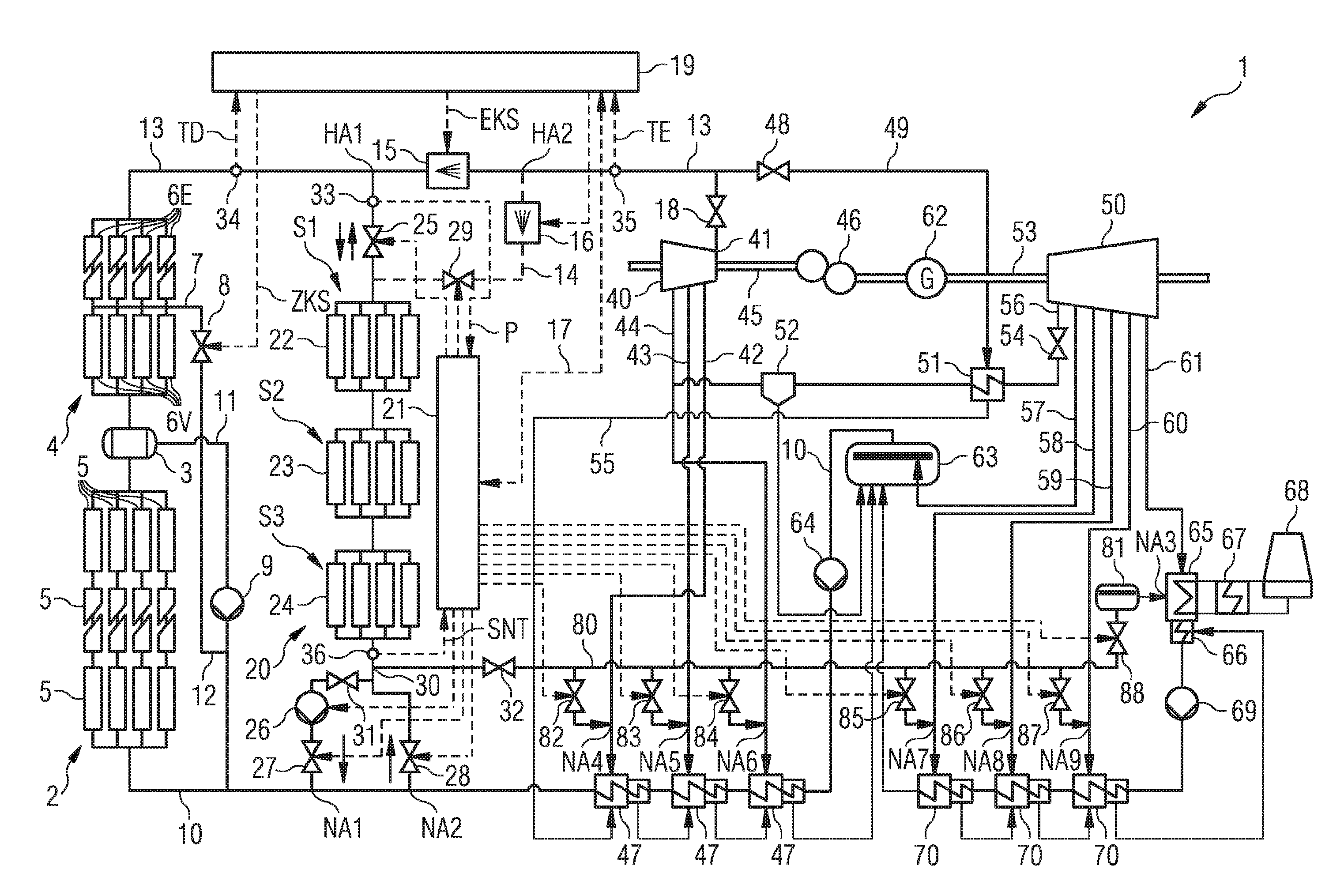

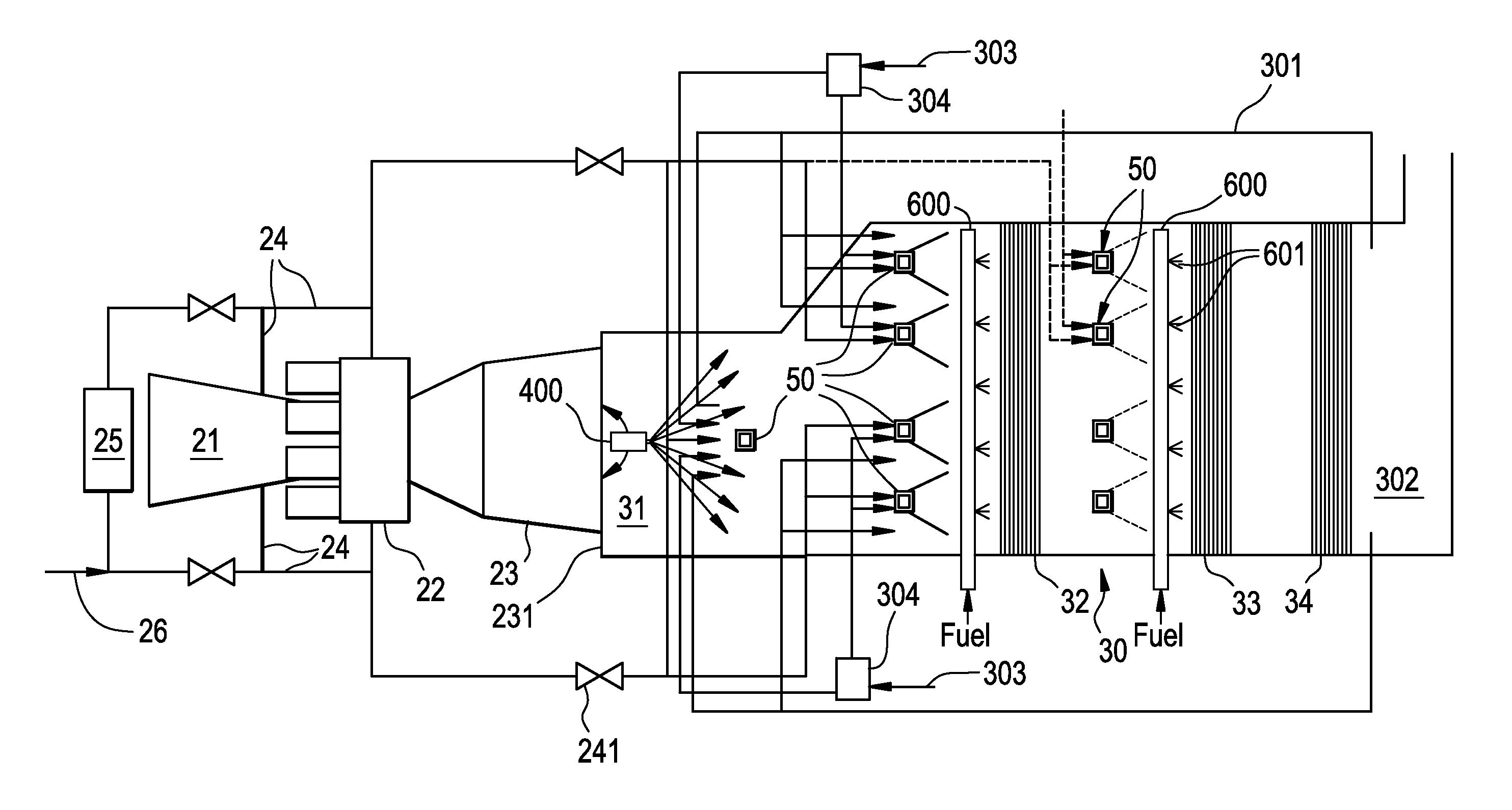

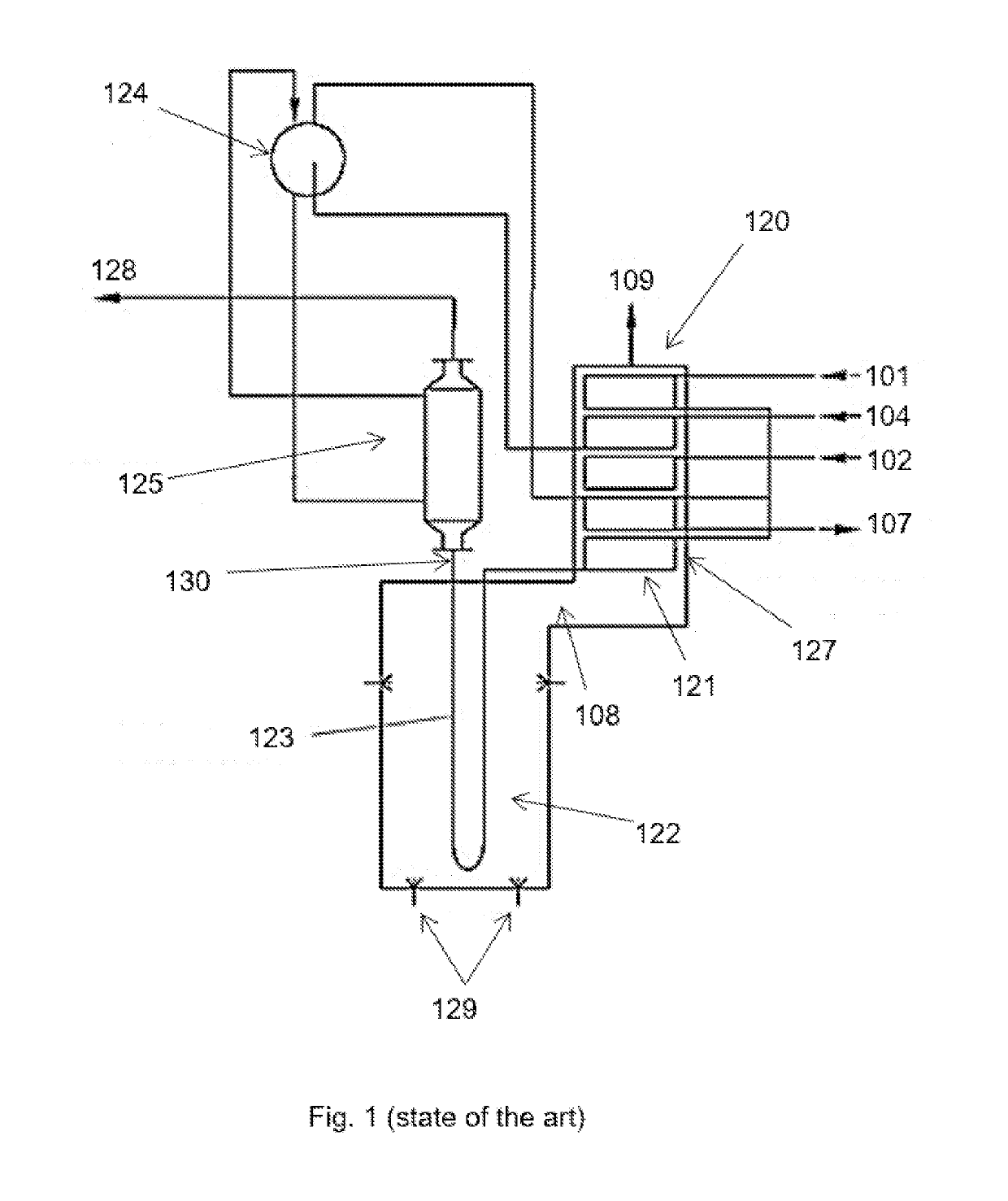

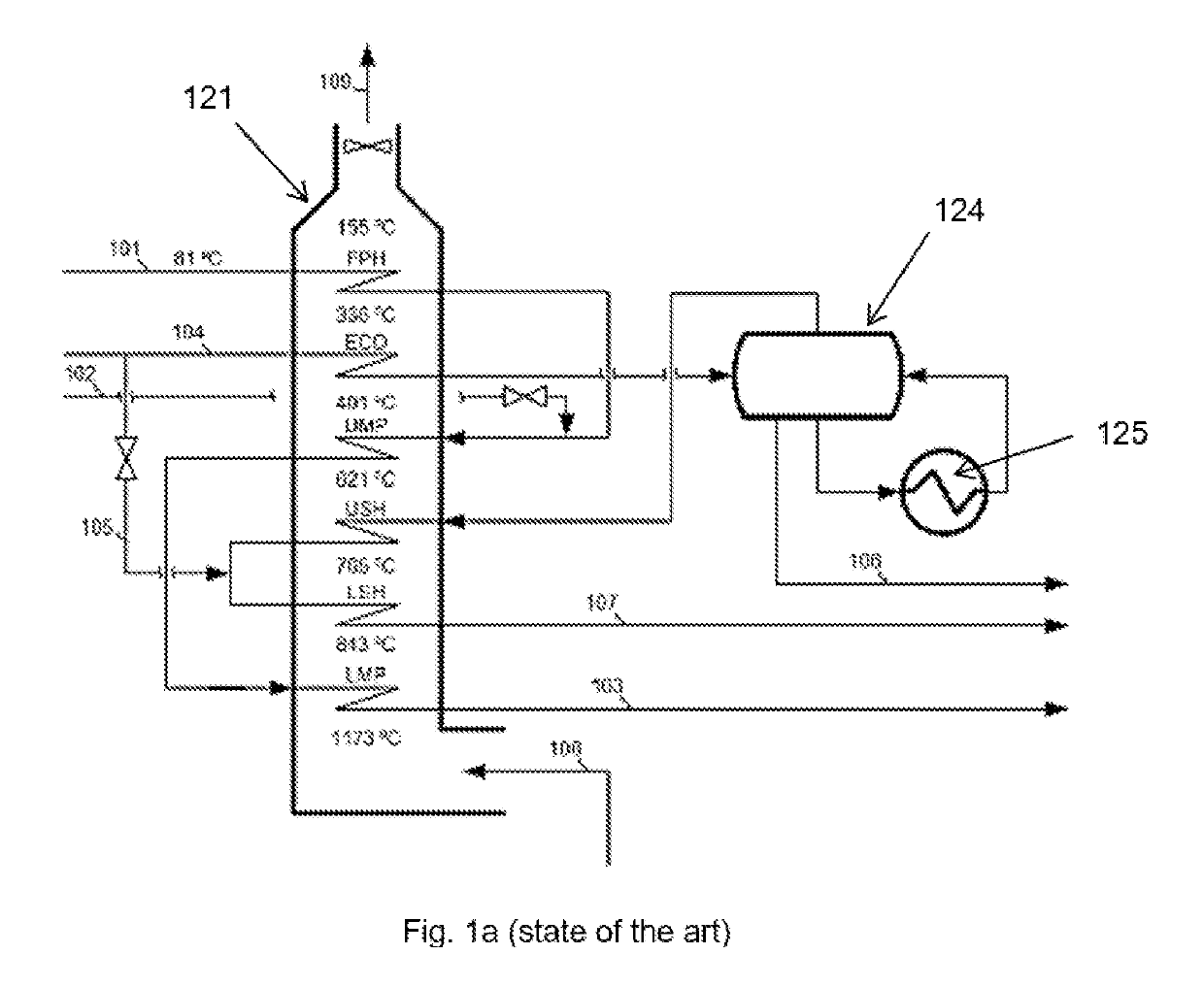

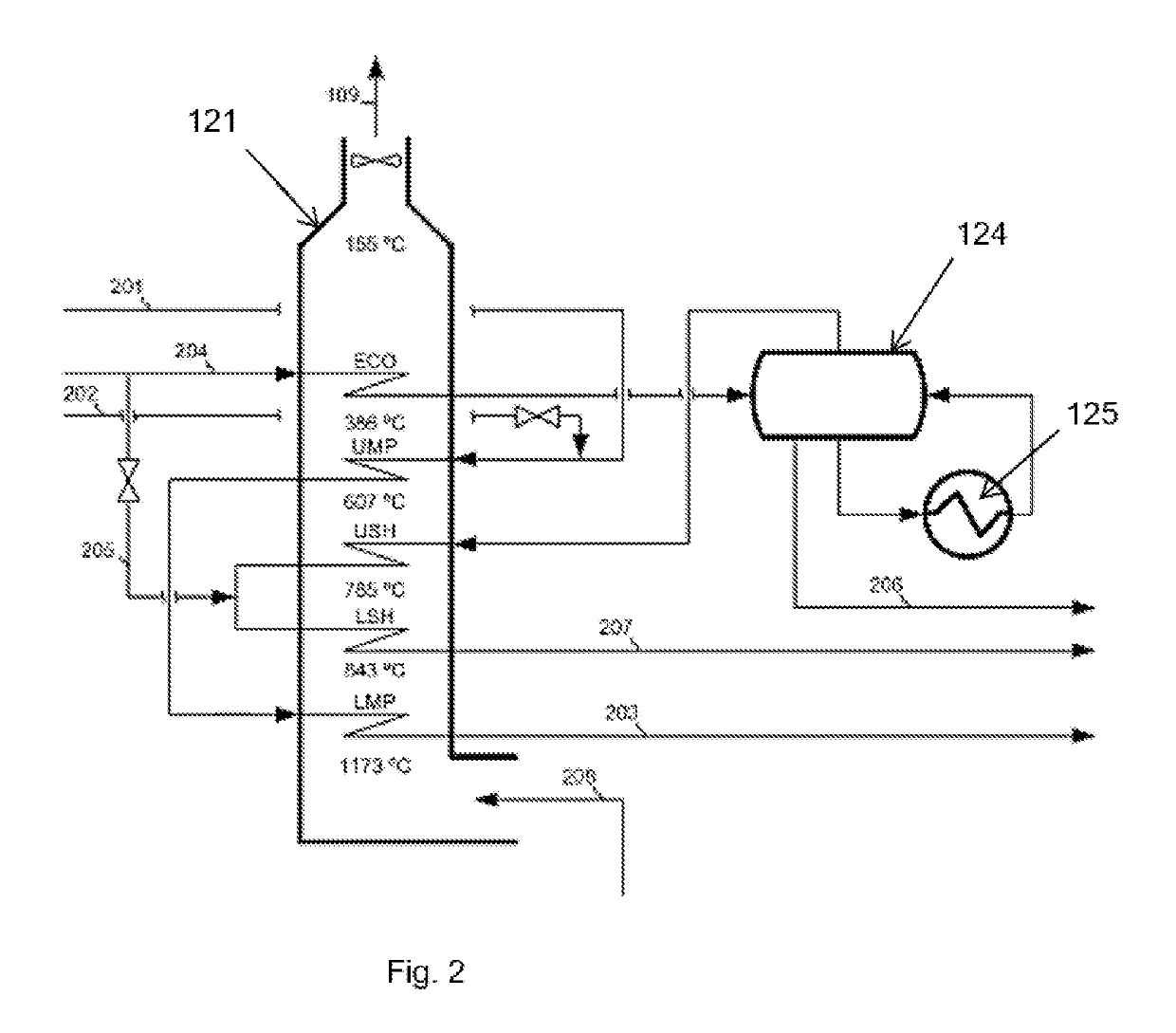

Process and a system for hydrocarbon steam cracking

ActiveUS20190284485A1Simpler and economical processSimple and economical processThermal non-catalytic crackingHigh temperature gas-gas reactionFlue gasSuperheater

A process for steam cracking hydrocarbon feedstock in a steam cracking furnace, the process comprising superheating hydrocarbon feedstock using flue gas from a radiant section of the steam cracking furnace in hydrocarbon feedstock superheating means or the hydrocarbon feedstock superheater, superheating steam from the steam generator using the flue gas from the radiant section of the steam cracking furnace in second heat exchanging means or a second heat exchanger, steam cracking the super-heated hydrocarbon feedstock from the hydrocarbon feedstock superheating means or the hydrocarbon feedstock superheater into cracked gas in a fired tubular reactor, vaporizing the hydrocarbon feedstock, using hydrocarbon feedstock vaporizing means, wherein the hydrocarbon feed-stock vaporizing means or the hydrocarbon feedstock vaporizer are heated with a heat transfer medium having a temperature less than or equal to 350° C. and feeding the vaporized hydrocarbon feedstock to the steam cracking furnace.

Owner:SABIC GLOBAL TECH BV

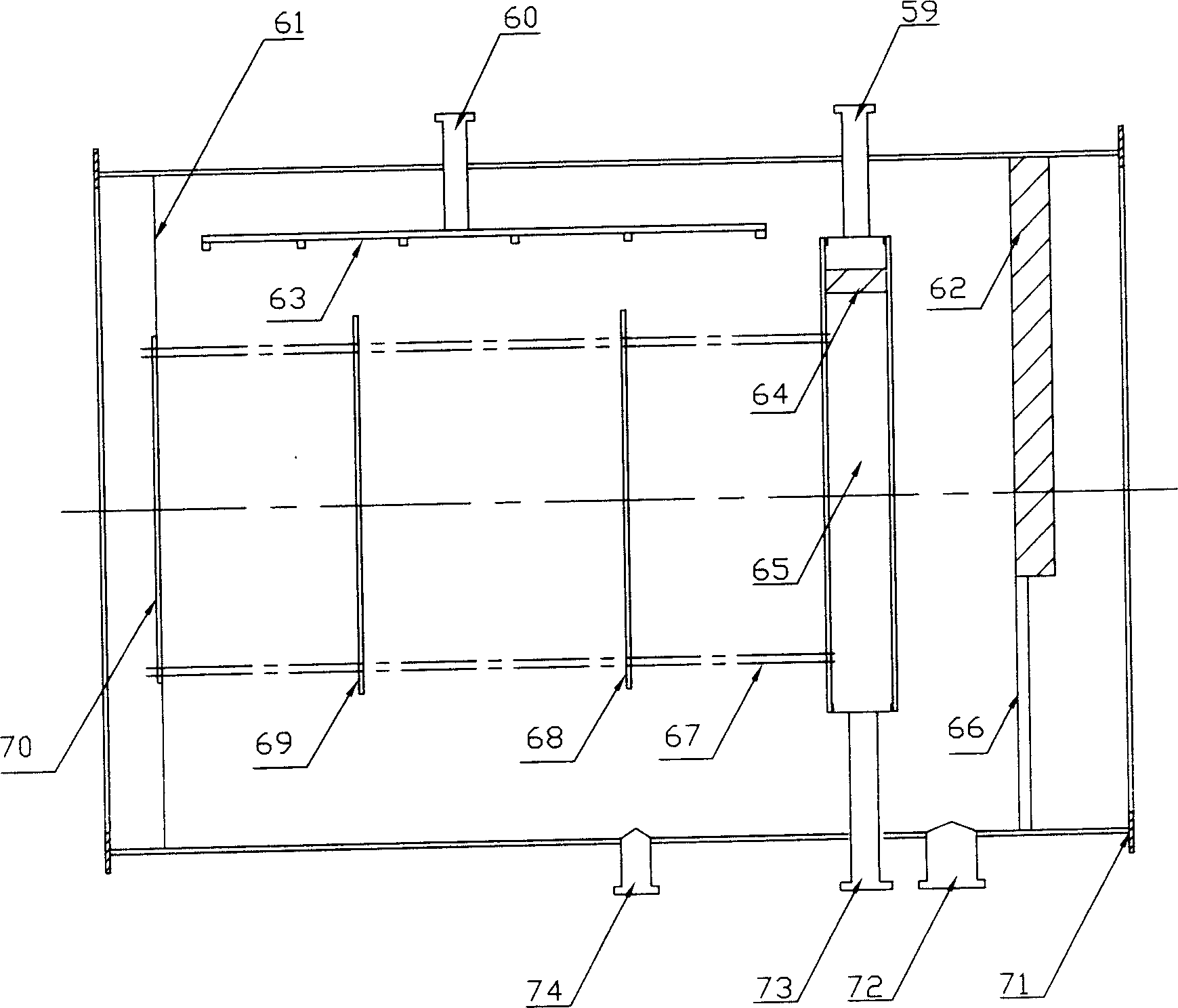

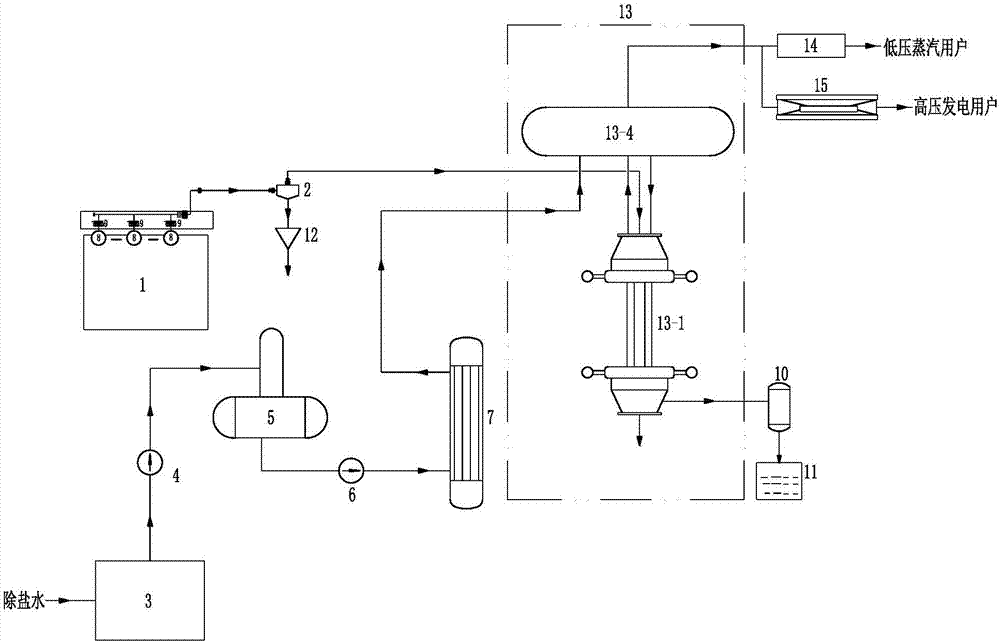

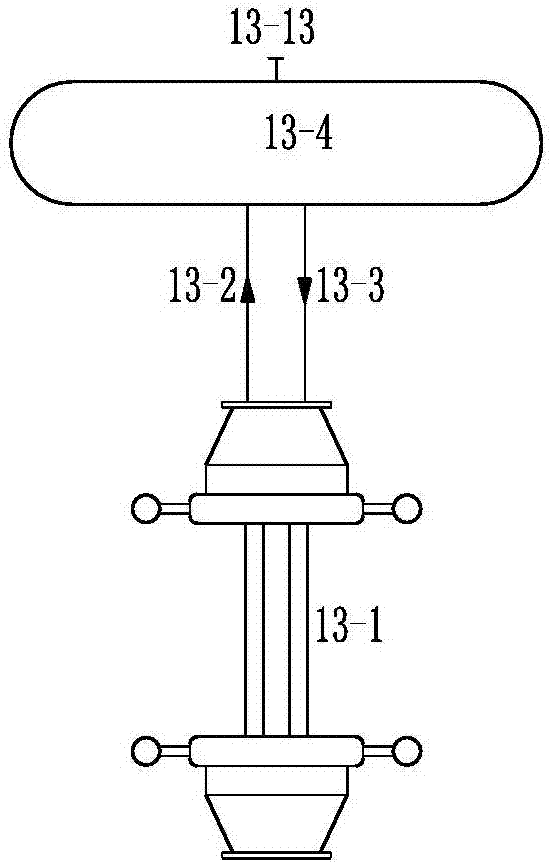

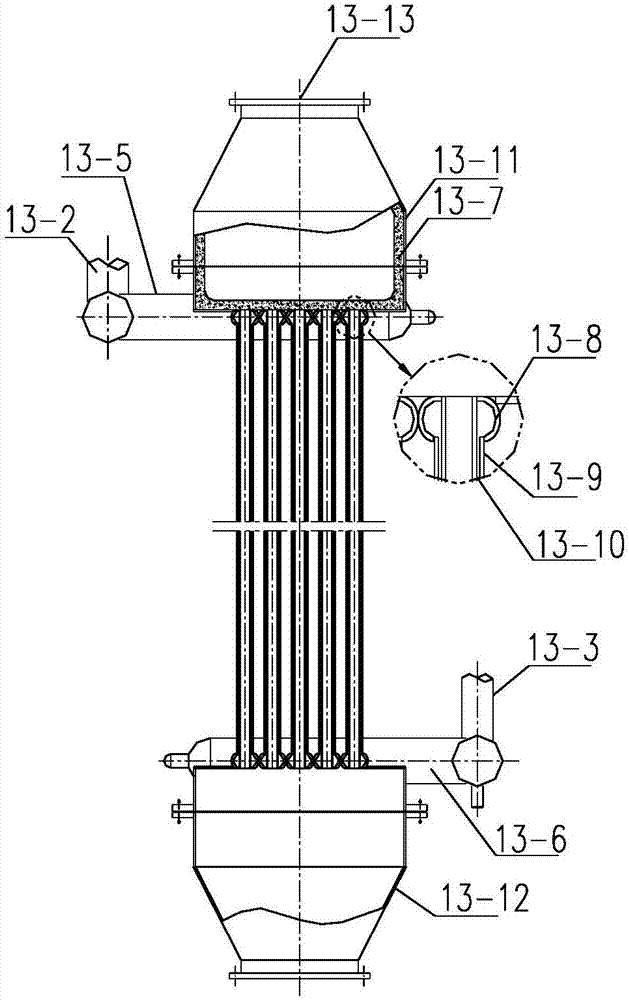

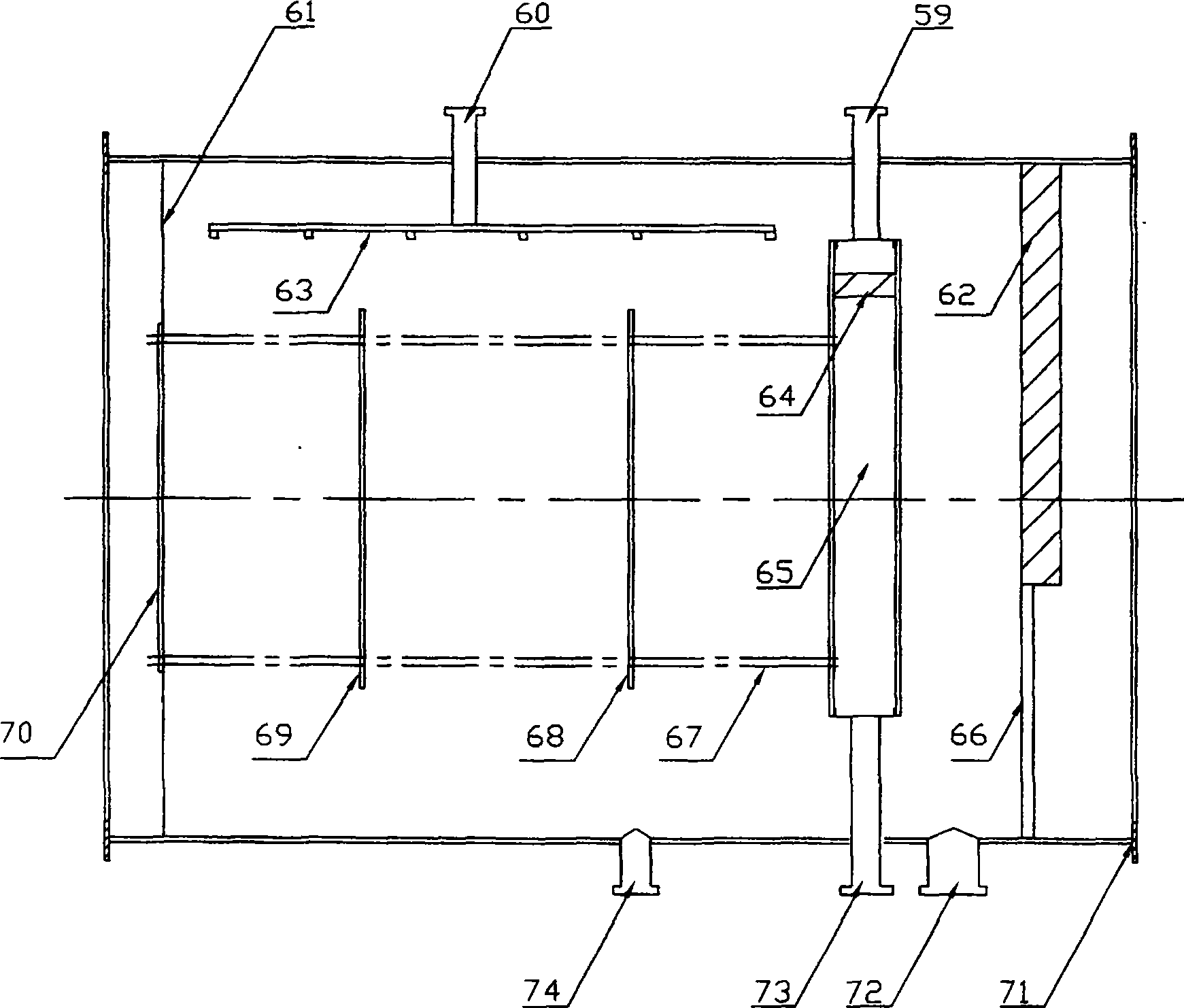

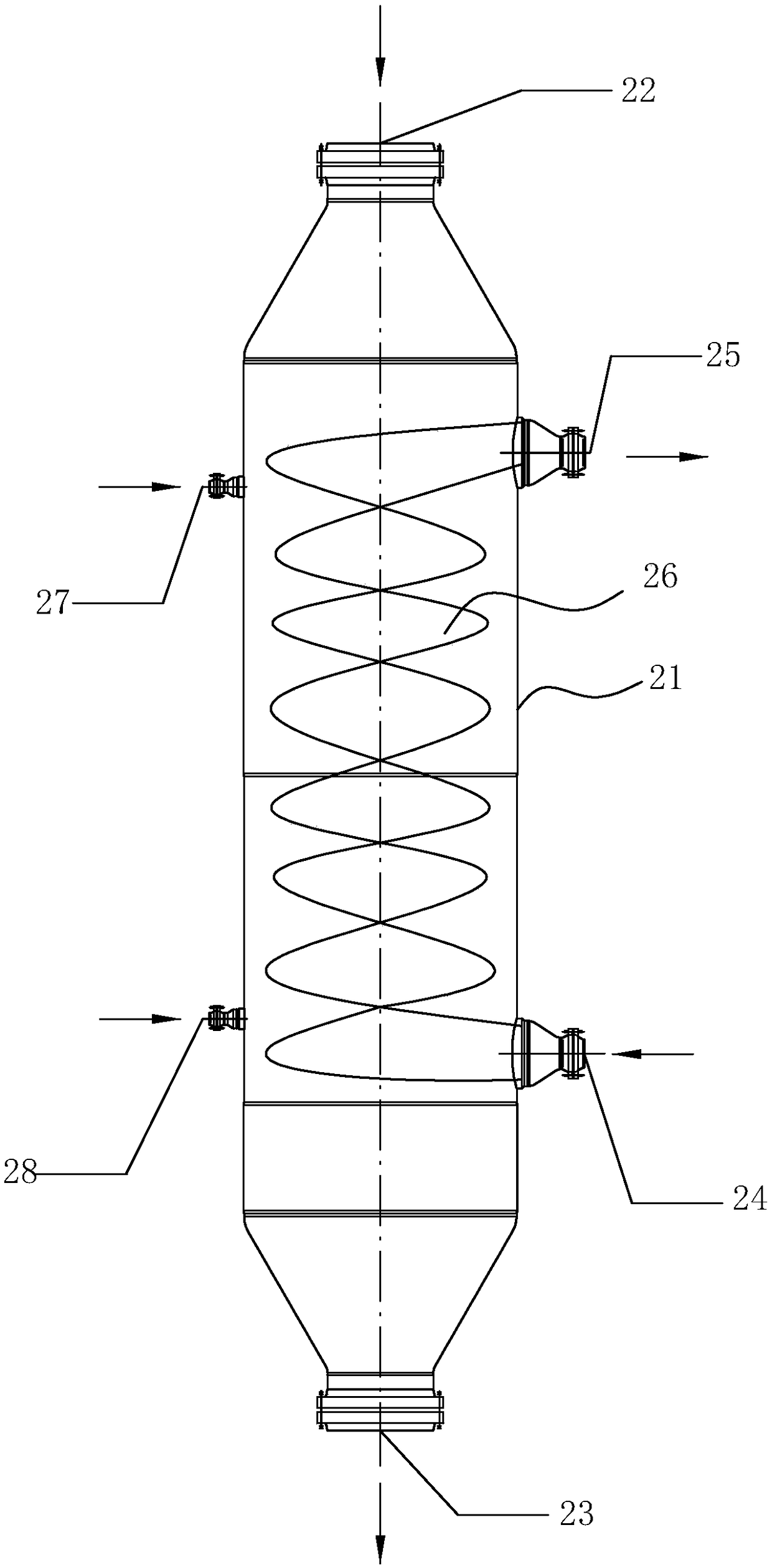

Coke oven raw gas high temperature segment heat high efficient recovering device

InactiveCN107286961AReduce cokingExtend the coking cycleEnergy inputSteam generation using hot heat carriersBoiler feedwater pumpEngineering

The invention relates to a coke oven raw gas high temperature segment heat high efficient recovering device. A vertical pipe sleeve pipe type quenching waste heat boiler is composed of a sleeve pipe type steam heat exchanger and a steam pocket. The air inlet in the top of the sleeve pipe type steam heat exchanger is connected to the air collection pipe in the top of a coke oven through a high temperature deduster. The water inlet of the steam pocket is connected to a desalting water tank though a low temperature heat exchanger, a boiler water pump, an oxygen remover, and a deoxidizing water pump in sequence. The steam outlet in the top of the steam pocket is connected to a low pressure steam user through a temperature reducing and pressure reducing device; or is connected to a high voltage generating user through a steam super-heater. The sewage outlet in the bottom of the sleeve pipe type steam heat exchanger is connected to a drain well through a periodic sewage discharge expander. The provided device can high efficiently recover the heat of the coke oven raw gas high temperature segment and generate high temperature high pressure saturated steam; thus high pressure overheated steam or low pressure saturated steam is produced, at the same time, condensation of polymers in equipment is reduced, the coking period is prolonged, the coke cleaning efficiency is improved, and the stable operation of the system is guaranteed.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Heat recovery system for high temperature flue gas at ammoxidation section

InactiveCN103212280AIncrease steam productionIncrease profitAlkali metal nitratesDispersed particle separationRatio valueFlue gas

A heat recovery system for high temperature flue gases at an ammoxidation section, is used for preparing sodium nitrate / sodium nitrite. An ammoxidation furnace is connected with a waste heat boiler, the waste heat boiler is communicated with an external pipe by a valve 3, a desalinizing water tank is communicated with the waste heat boiler by the valve 1, a coal economizer is added between the waste heat boiler and an alkali absorption section, the coal economizer is communicated with the desalinizing water tank by a valve 2, a pneumatic regulating valve remotely controlled by a distributed control system, is connected between the coal economizer and the desalinizing water tank in series, and the pneumatic regulating valve and a manual regulating valve are connected in parallel. The coal economizer of the invention is used for supplementing water for a boiler for heating, which increases steam production amount, enhances a heat energy utilization rate, and can effectively implement purposes of energy saving and consumption reduction; the coal economizer is used to reduce a process gas temperature, indirectly raises a sodium nitrite / sodium nitrate content ratio value in an alkali absorption liquid in an alkali absorption section, and enables a tail gas content to reach 800mg / m3, and benefits for environmental protection; and the pneumatic regulating valve is mounted on the coal economizer, and is convenient for remote control by the distributed control system.

Owner:襄阳泽东化工集团股份有限公司

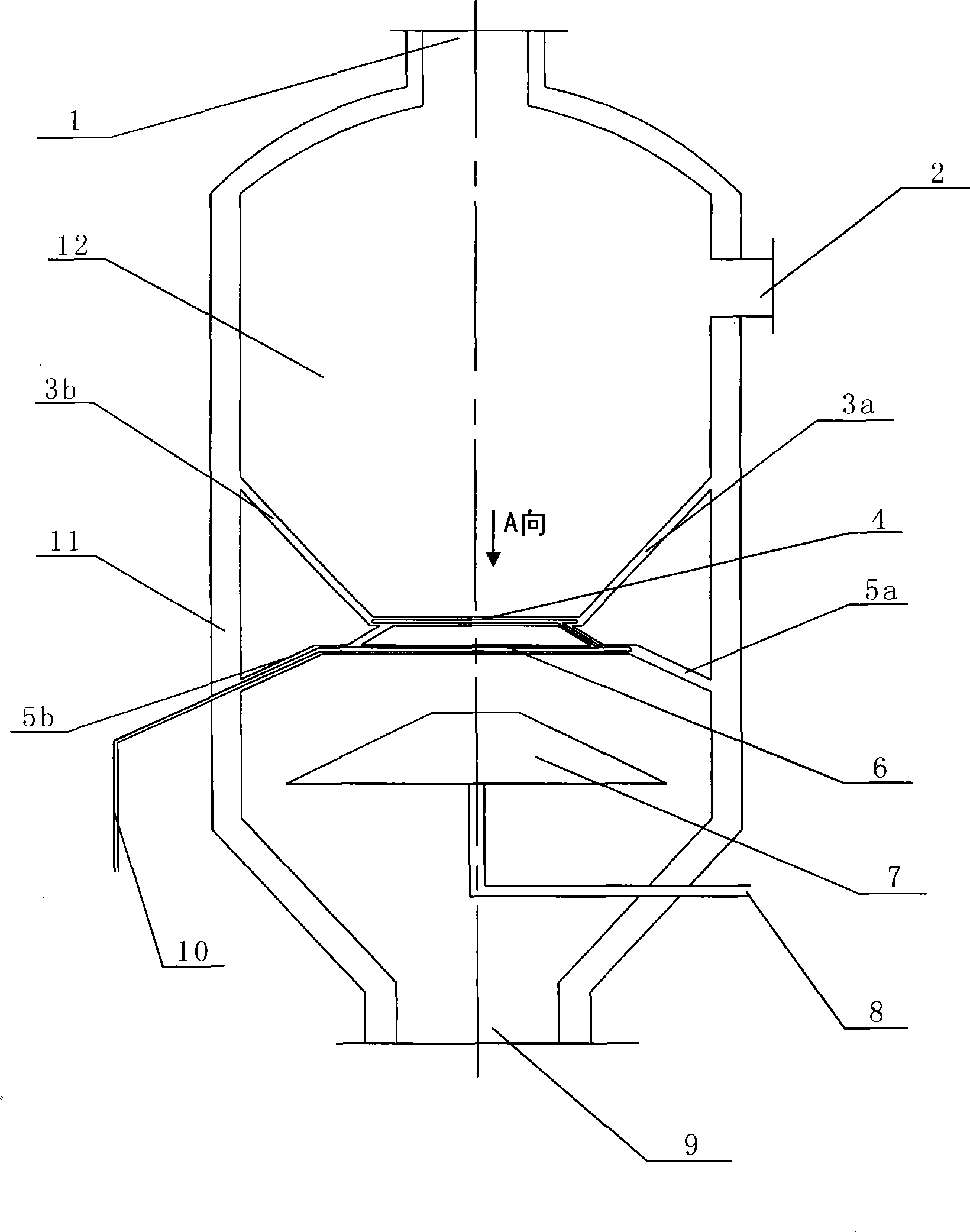

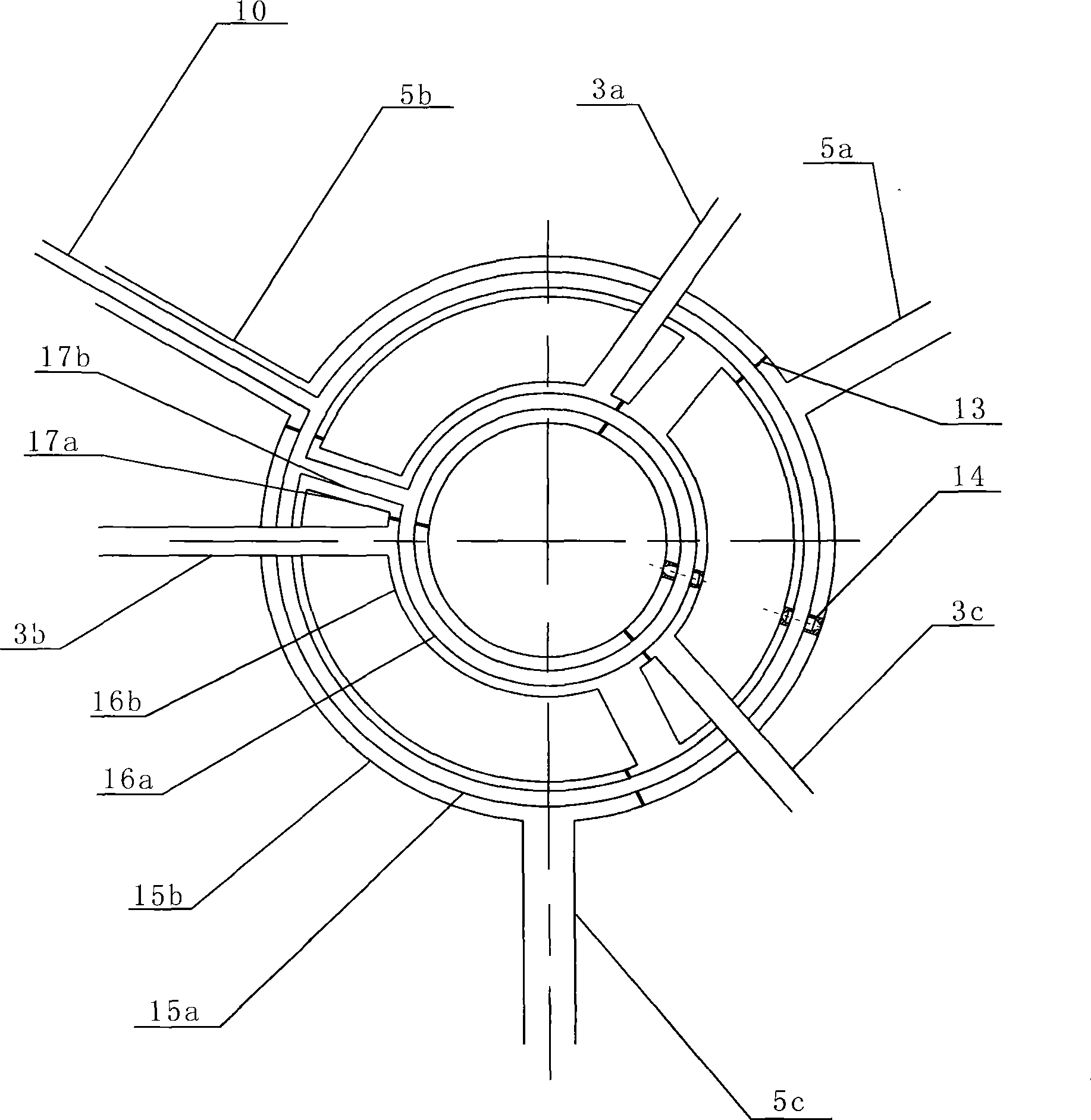

Cooling water jacket of petroleum coke can-type calcine furnace

ActiveCN101362951BNot easy to slitReduce consumptionStationary conduit assembliesCrucible furnacesThermal deformationEngineering

The invention discloses a petroleum coke pot typed calciner cooling water jacket, comprising a step-one heat exchanging device which is used for enclosing a high-temperature material passage; the step-one heat exchanging device comprises a ring-shaped upper container which is provided with a water outlet, a ring-shaped lower container which is provided with a water inlet, a plurality of heat exchanging pipes which are fixedly connected with the upper container and the lower container and communicated with each other respectively, a heat guiding baffle which is fixedly connected between two adjacent heat exchanging pipes; the high-temperature material passage which is enclosed by the step-one heat exchanging device is internally provided with a step-two heat exchanging device. The cooling water sleeve has good rigidity, and is not easy to generate thermal deformation; furthermore, the heat exchanging area is large and the cooling and heat exchanging effect is good; by increasing the step-two heat exchanging device, the uniformity of the temperature inside the whole passage is greatly improved, the temperature of the outgoing material is lowered from 300 DEG C to 150 DEG C; with thereduction of the temperature of the material, the service life of the material drainage valve is prolonged, and the malfunction rate of the material drainage system is reduced.

Owner:SHANDONG LIANXING ENERGY SAVING SERVICE

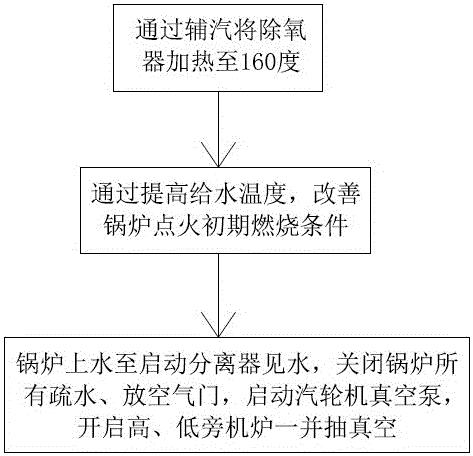

Beryllium oxide generation preventing method for boilers of power plant

InactiveCN106642062APrevention of dry burningOptimizationLiquid degasificationBoiler water tubesEngineeringDeaerator

The invention discloses a beryllium oxide generation preventing method for boilers of a power plane, and the method can effectively avoid dry burning of heated surfaces. The method includes the following steps that firstly, a deaerator is heated, specifically, auxiliary steam is used for heating the deaerator, the heat source can increase the water temperature of the deaerator to 160 DEG C, and the temperature of a start-up separator outlet (or a steam pocket) of the corresponding boiler reaches 75 DEG C or above; secondly, feed water is heated, specifically, feed water heaters for starting of a unit are added through technical transformation or unit high-pressure heaters are directly selected, a steam source is taken from an adjacent unit and connected into the heaters, the feed water temperature is increased to a larger extent, the steam production amount is increased, the temperatures of the heated surfaces are greatly increased, the hearth temperature is increased, and the combustion condition in the ignition preliminary stage of the boilers is greatly improved; and thirdly, water is fed to the boilers till start-up separators encounter water, all drainage and vent valves of the boilers are closed, a steam turbine vacuum pump is started, and high-pressure bypass boilers and low-pressure bypass boilers are started and vacuumized.

Owner:CHANGSHA POWER STATION CO LTD OF HUNAN CHD

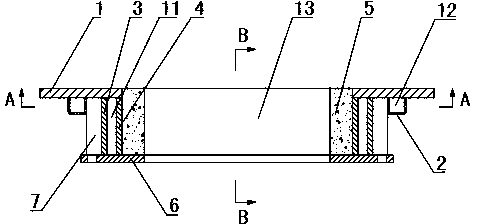

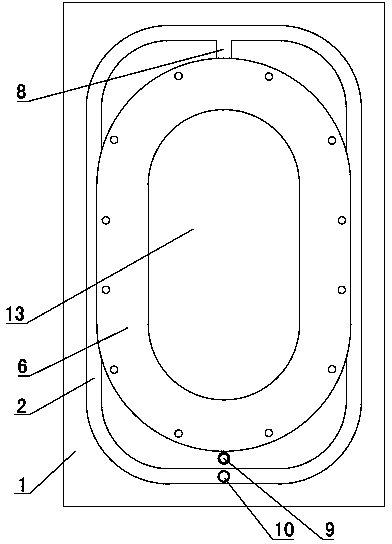

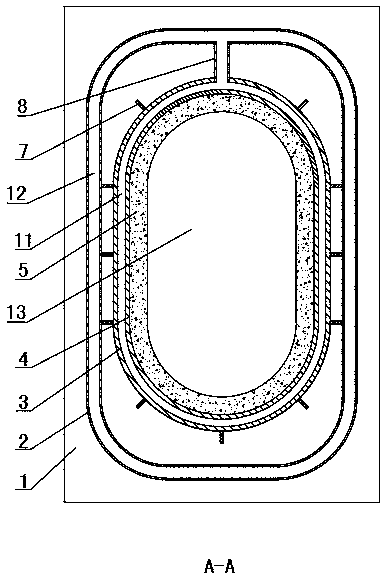

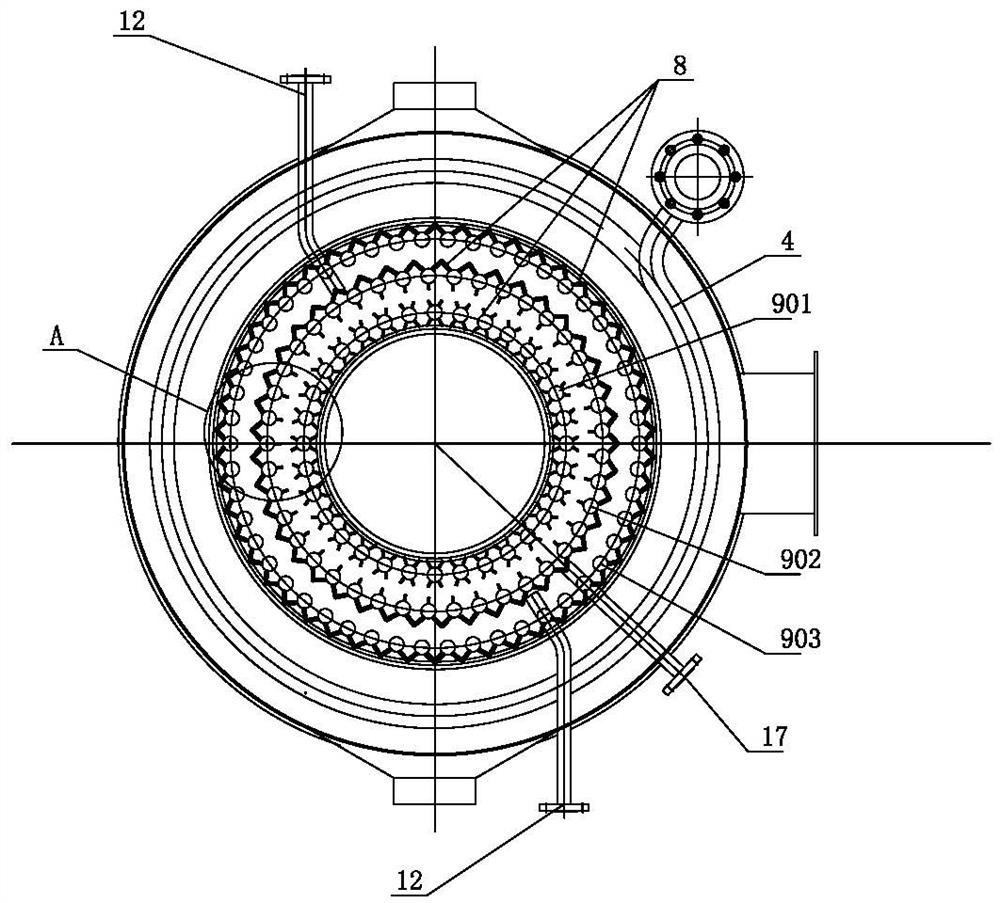

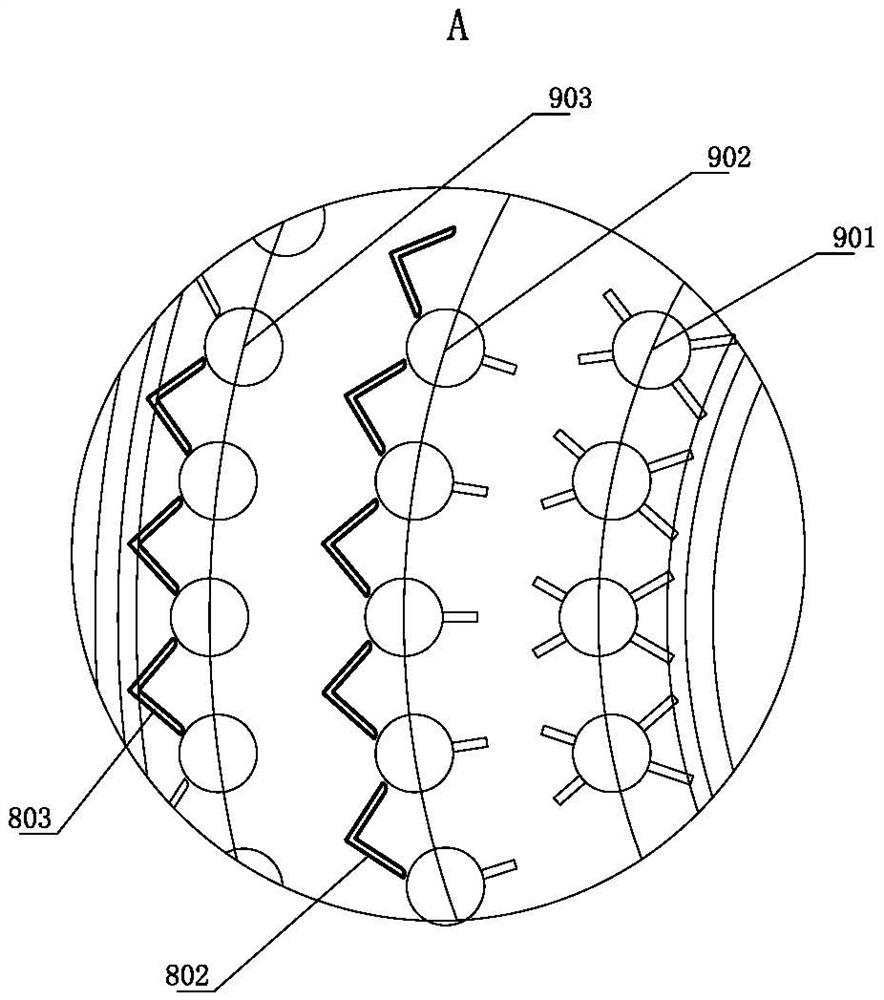

Water-cooling type hearth plate of petroleum coke tank-type calcining furnace

ActiveCN103615902AReduce the temperatureReduce external surface temperatureFurnace coolingHearthPetroleum coke

The invention discloses a water-cooling type hearth plate of a petroleum coke tank-type calcining furnace, and belongs to the technical field of petroleum coke tank-type calcining furnaces. An annular water sleeve inner plate (4) and an annular water sleeve outer plate (3) are fixedly connected between an upper flat plate (1) and a lower flange plate (6), the water sleeve inner plate (4), the water sleeve outer plate (3), the upper flat plate (1) and the lower flange plate (6) form a sealed annular cooling sleeve (11) in a surrounding mode, the lower end surface of the upper flat plate (1) is provided with an annular cooling half pipe (2) at the outer side of the water sleeve outer plate (3), the annular cooling half pipe (2) and the upper flat plate (1) form a sealed annular cooling water passage (12), the annular cooling water passage (12) is communicated with the annular cooling sleeve (11) through a connecting half pipe (8), and annular cooling water passage (12) is communicated with a water outlet pipe (10). The water-cooling type hearth plate of the petroleum coke tank-type calcining furnace has the advantages of lowering the temperature of the hearth plate, improving the work reliability of the hearth plate and the like.

Owner:SHANDONG UNIV OF TECH

Low-temperature multi-effect seawater desalination process

InactiveCN100506706CQuality improvementIncrease productionGeneral water supply conservationSeawater treatmentSpecial designEnergy recovery

This invention refers to a method about low-temperature multiple-effect desalination of sea water, especially about a new method which effectively applied thermal pumping power-saving technology to desalination of sea water. The desalination of sea water system which apply this method has n effect evaporator(n=2-50) and one condensator aggregately, containing six systems of feeding seawater, recirculated salt water, product water, vacuum, incoagulable gas removal, thermal pumping circulation and starting heating in addition. This invention is based on irreversible thermodynamics principle, via organic integration of evaporator, condensator and low-temperature multiple-effect desalination of sea water system in closed circuit thermal pumping system, as well as special design of energy recovery tache in low-temperature multiple-effect desalination of sea water, decreasing irreversible loss of diversified thermal transmission course which the desalination of sea water refers to in maximum limit, sequentially letting the entropy increasing of whole desalination of sea water course be the least, realizing efficient energy-saving desalination of sea water course.

Owner:QINGDAO UNIV

Sushi vinegar

InactiveCN109234140AImprove taste qualityImprove food safetyVinegar preparationSolid componentRice dishes

The invention provides a sushi vinegar and the application thereof. The sushi vinegar comprises 60-65 part of white rice vinegar, 50-55 parts of sorbitol, 20-25 part of sodium citrate, 25-30 parts oftrehalose, 25-30 parts of edible salt and 20-25 parts of wat. The invention also provides the use of the sushi vinegar, which is used in the preparation process of rice. At first, weigh that raw materials accord to the proportion, and then mixing and stirring the raw materials until no solid component remain in the solution. Sushi vinegar is added in the process of turning raw rice into cooked rice. Add water and sushi vinegar to the raw rice, stir and mix, then heat to get cooked rice. 1.5 to 2 percent of raw rice is adde into that sushi vinegar according to the mas percentage. The water consumption of adding sushi vinegar increased by 40%-60%. The sushi vinegar provided by the invention and the use thereof can reduce the rice cost, improve the rice taste, prolong the rice shape holding time, and increase the rice yield when cooking.

Owner:刘懿萱

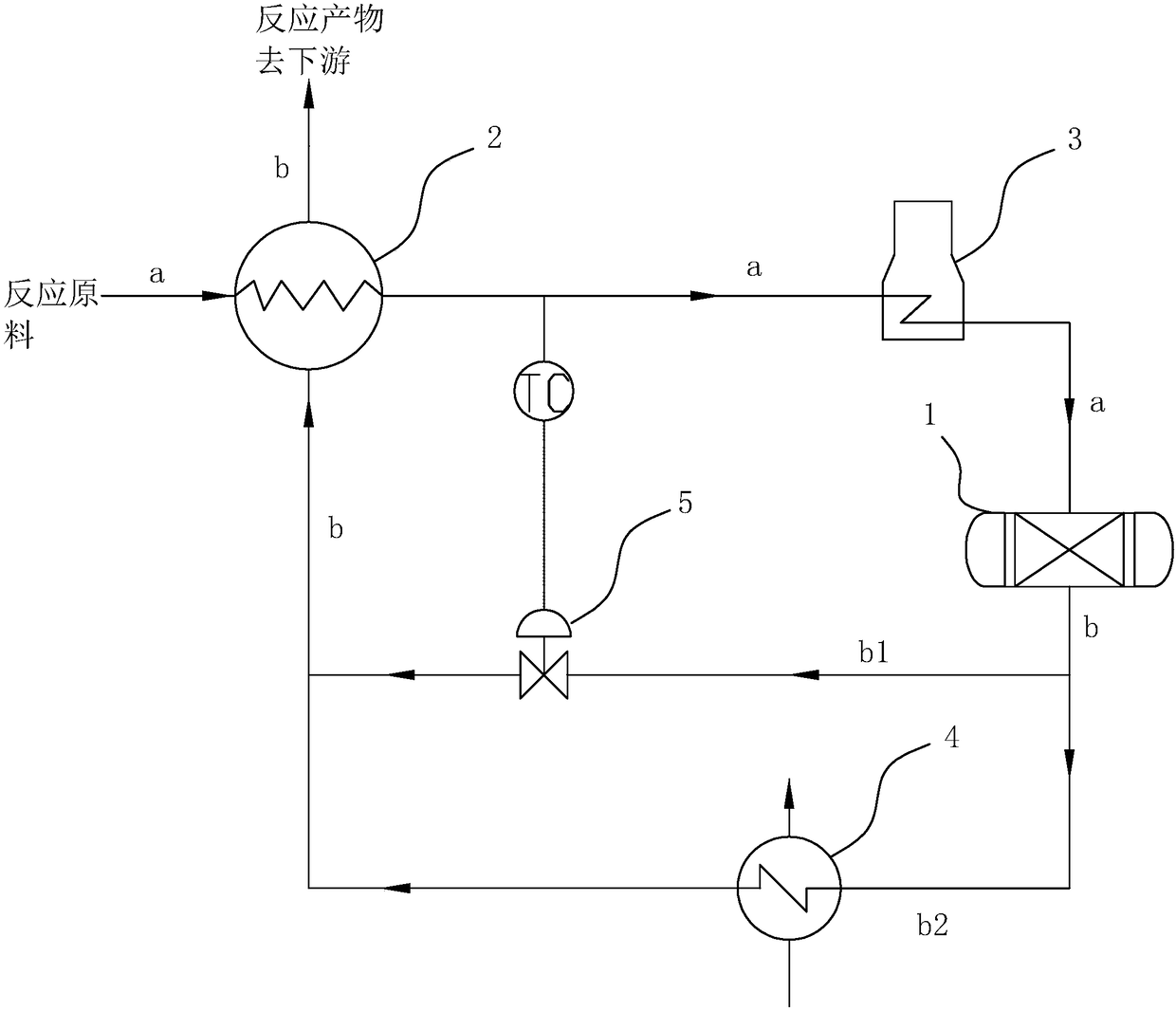

Propane dehydrogenation device and propane dehydrogenation method

PendingCN108160006AImprove stabilityImprove utilization efficiencyChemical industryHydrocarbonsDehydrogenationHeating furnace

The invention relates to a propane dehydrogenation device and a propane dehydrogenation method. The propane dehydrogenation device comprises a dehydrogenation reactor (1) and a heat exchanger (2), wherein a tube pass inlet (24) of the heat exchanger (2) is connected with a reaction raw material conveying pipeline (a); a tube pass outlet (25) of the heat exchanger (2) is connected with an inlet ofthe dehydrogenation reactor (1) through a heating furnace (3); an outlet of the dehydrogenation reactor (1) is connected with a reaction product conveying pipeline (b); the reaction product conveyingpipeline (b) is divided into two paths; a first path of reaction product conveying pipeline (b1) is connected with a shell pass inlet (22) of the heat exchanger (2) through a valve (5); a second pathof reaction product conveying pipeline (b2) is connected with the shell pass inlet (22) of the heat exchanger (2) through a steam generator (4); a shell pass outlet (23) of the heat exchanger (2) is connected with downstream equipment. The propane dehydrogenation device is low in investment and high in heat exchange efficiency, a bias problem occurred among multiple heat exchangers is effectivelyavoided, the stability of the propane dehydrogenation device, the yield of propylene and the steam output are improved, and an operation cycle is prolonged.

Owner:ZHENHAI PETROCHEM JIANAN ENG

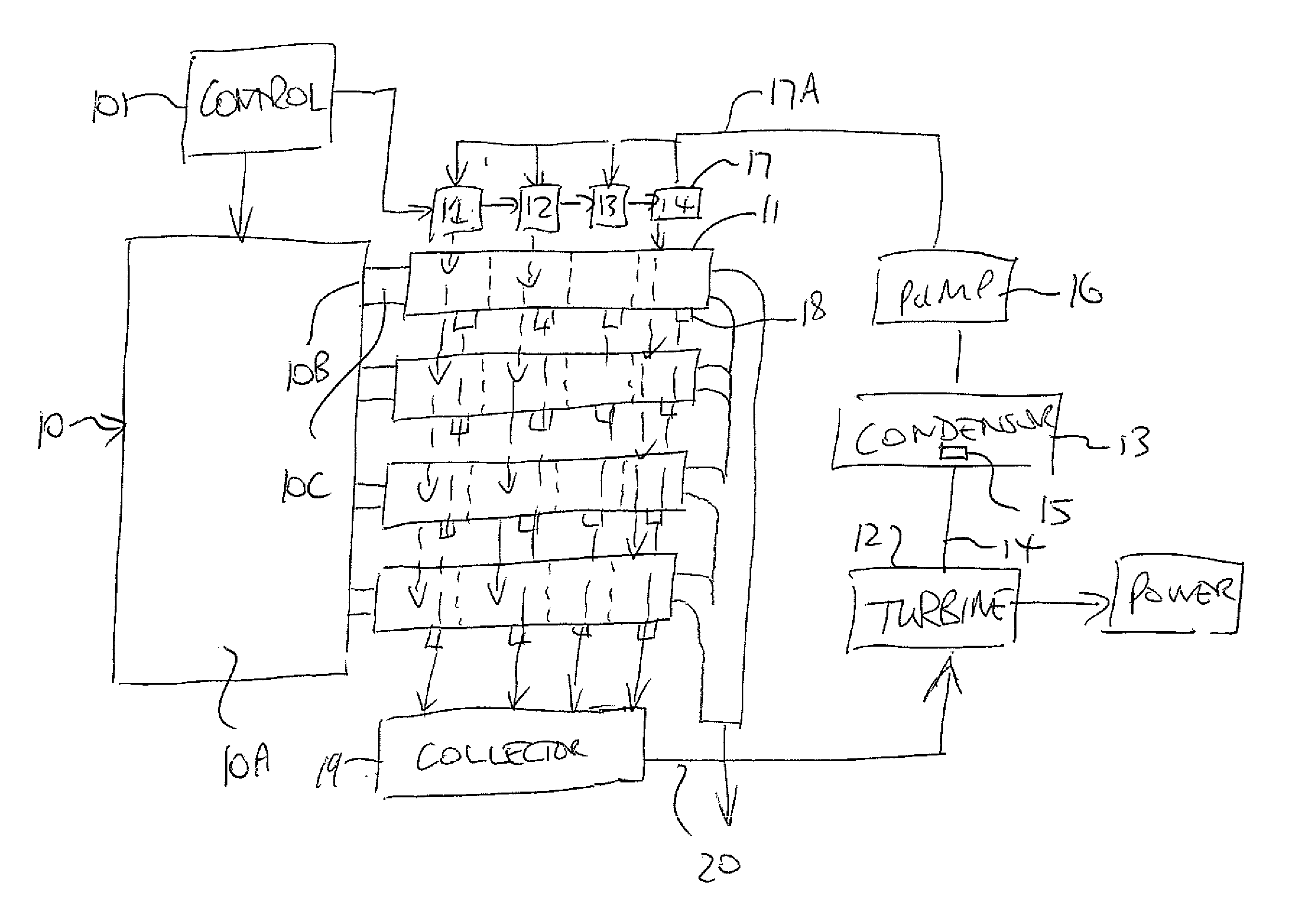

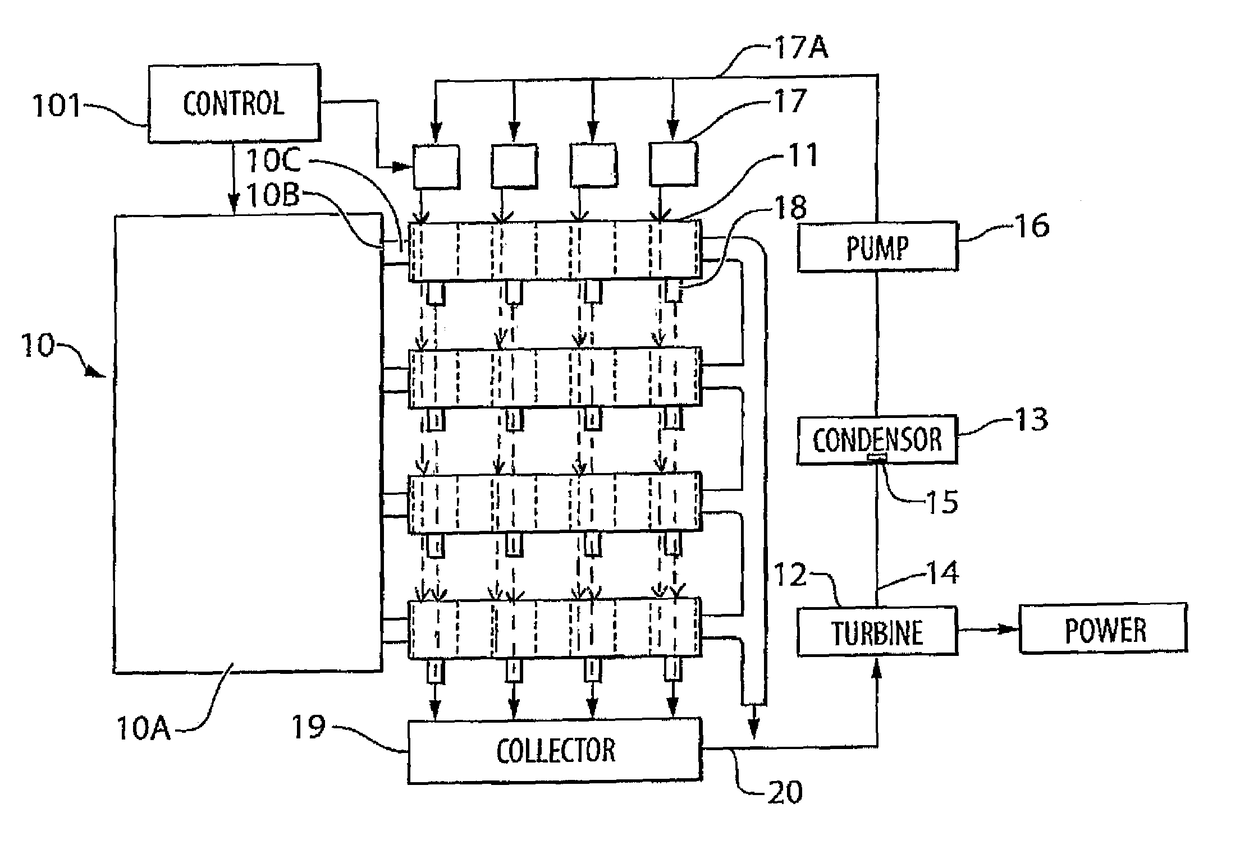

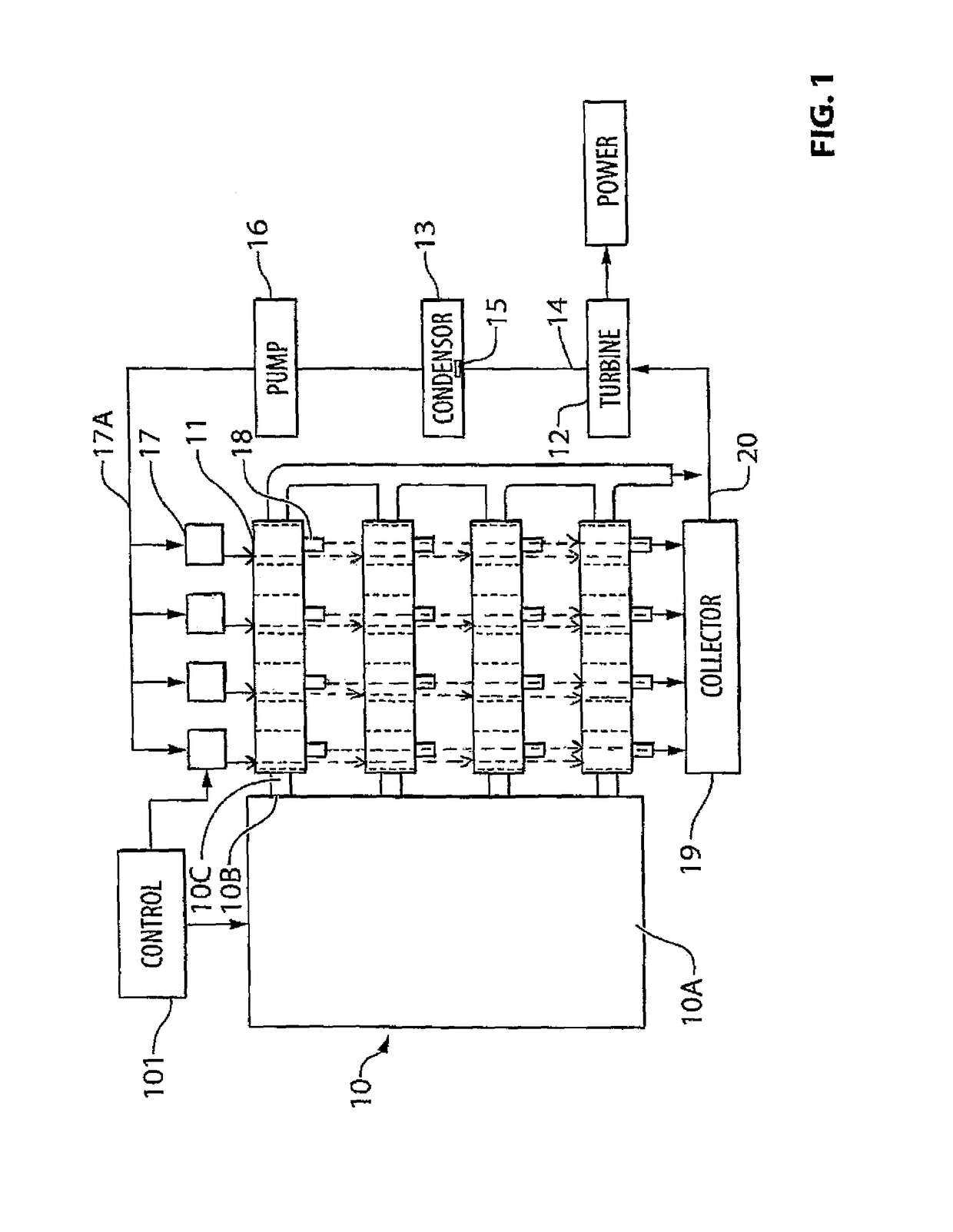

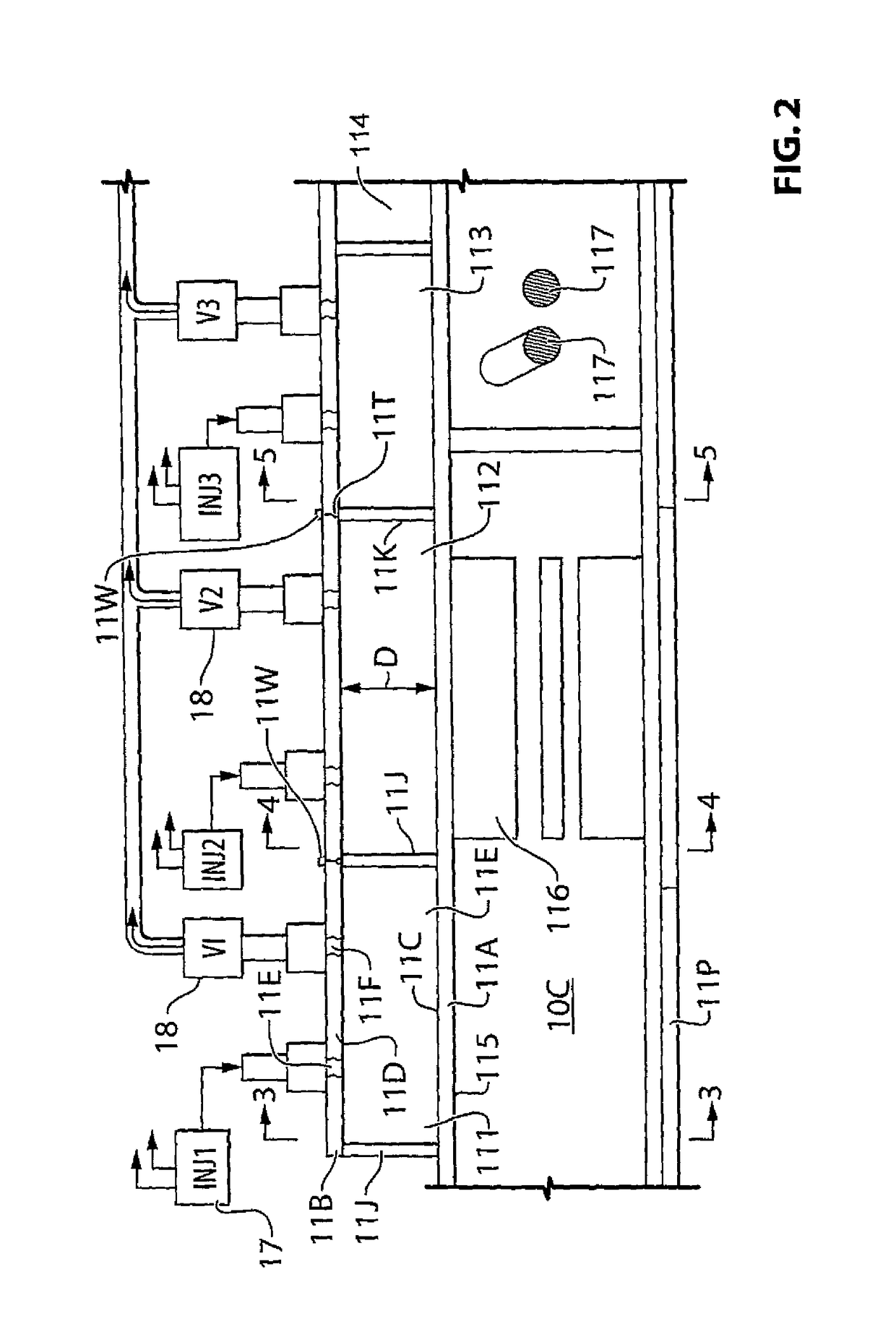

Vaporization Apparatus

ActiveUS20130276448A1Inexpensive source of energyFacilitate contact areaExhaust apparatusSteam useEngineeringSuperheated steam

Liquid is flash evaporated in a series of cells along and surrounding an exhaust duct to generate a pressurized vapor where at least one of the surfaces is in communication with the source of heat sufficient to maintain the surface at a temperature such that the liquid injected into the chamber is substantially instantly converted to a superheated vapor with no liquid pooling within the chamber. The liquid is introduced by controlled injectors operating at a required rate. Each of the cells is periodically discharged by a pressure controlled relief valve and the vapor from the cells combined to form a continuous stream feeding a turbine or other energy conversion device. The outer wall of the cell is offset so that it contacts the inner wall at one point around the periphery. Heat transfer ribs and bars can be provided in the duct to provide increased heat transfer where necessary.

Owner:TINMAN +1

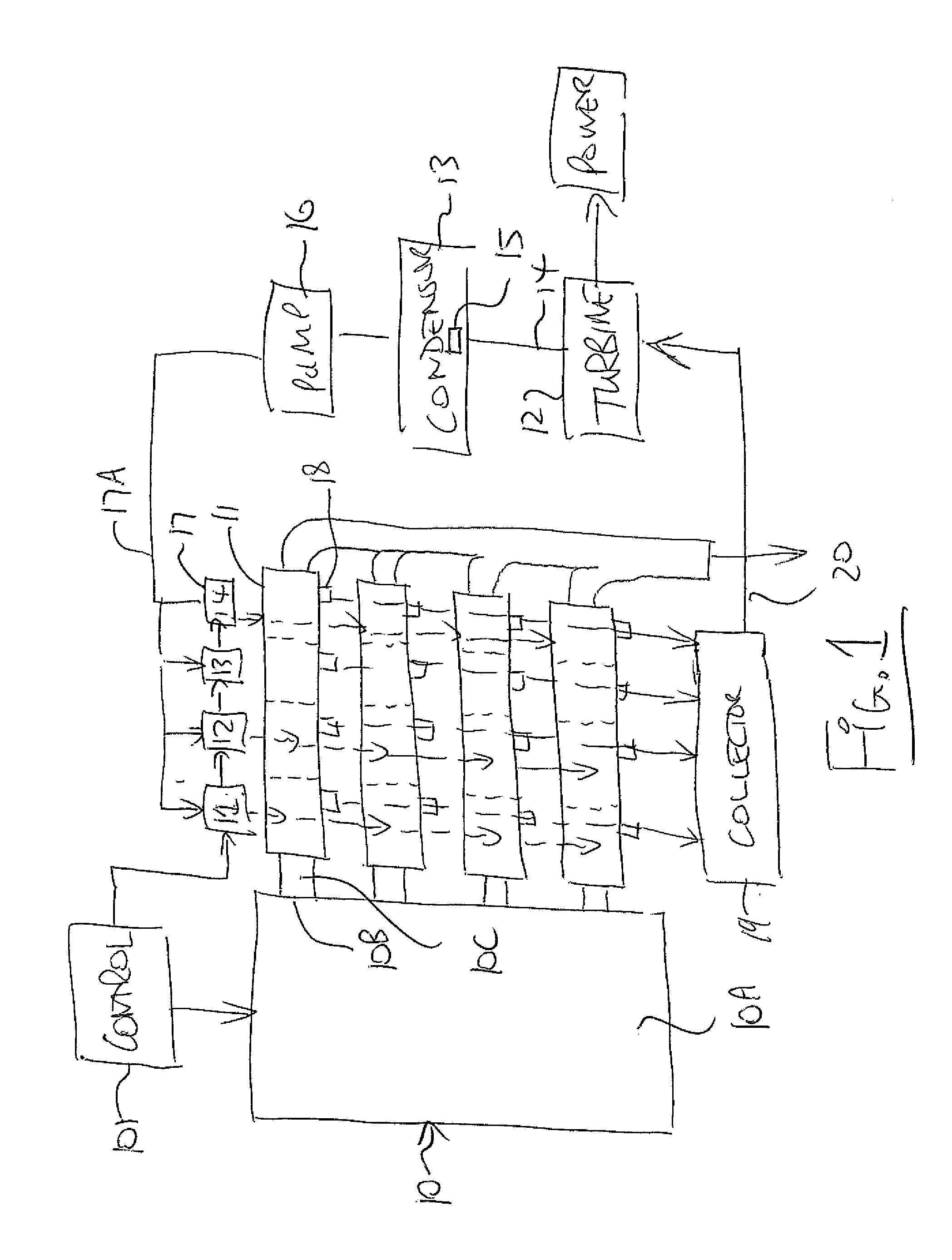

Method of steam generation by spraying water onto a duct within a chamber having divider walls

ActiveUS9945554B2Facilitate contact areaIncrease surface areaExhaust apparatusSteam useEngineeringTurbine

Liquid is flash evaporated in a series of cells along and surrounding an exhaust duct to generate a pressurized vapor where at least one of the surfaces is in communication with the source of heat sufficient to maintain the surface at a temperature such that the liquid injected into the chamber is substantially instantly converted to a superheated vapor with no liquid pooling within the chamber. The liquid is introduced by controlled injectors operating at a required rate. Each of the cells is periodically discharged by a pressure controlled relief valve and the vapor from the cells combined to form a continuous stream feeding a turbine or other energy conversion device. The outer wall of the cell is offset so that it contacts the inner wall at one point around the periphery. Heat transfer ribs and bars can be provided in the duct to provide increased heat transfer where necessary.

Owner:TINMAN +1

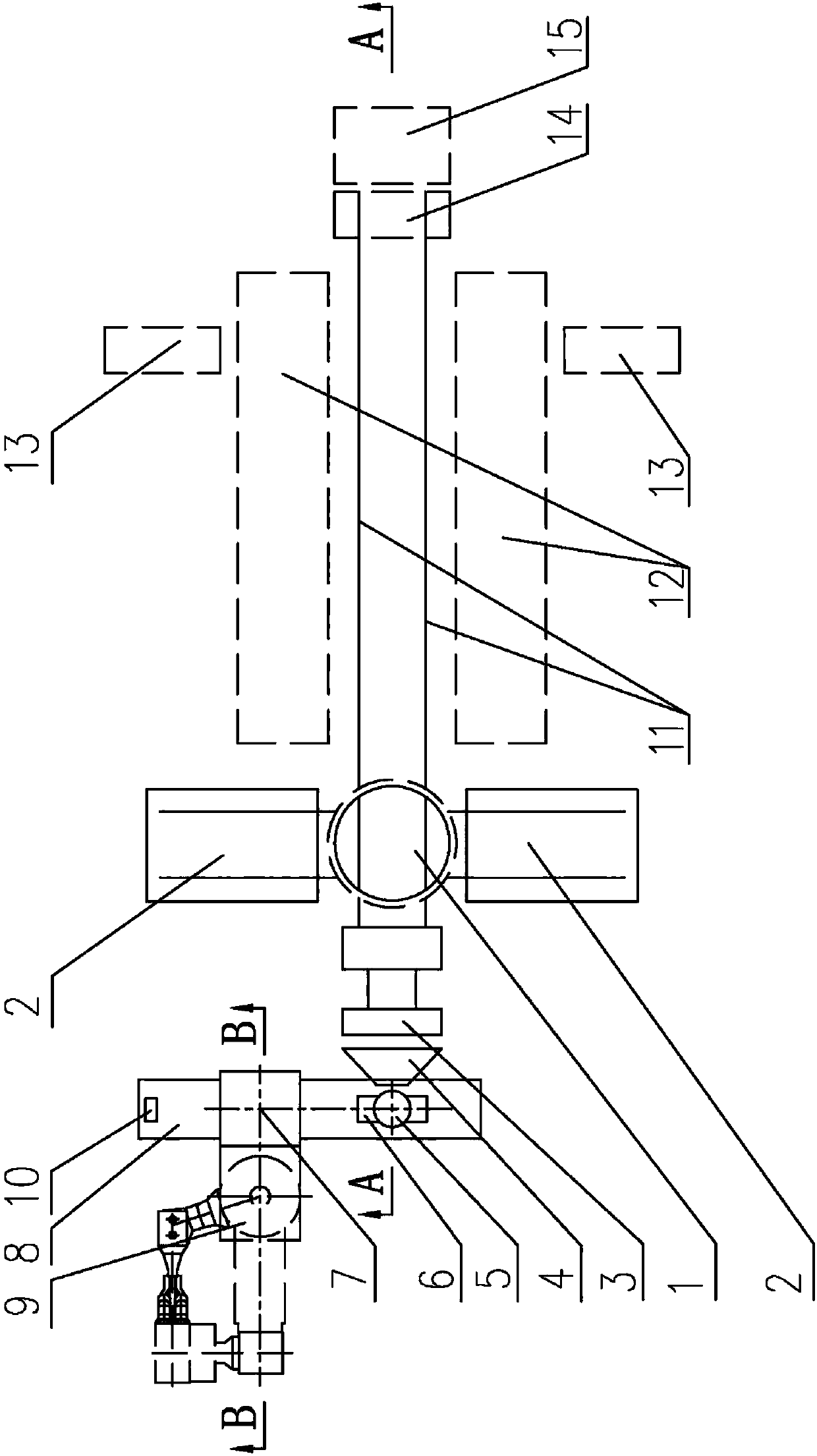

Flame pressing type water tube boiler

PendingCN113606566AReasonable designSufficient heat exchangeSteam generation using pressureWater-tube boilersWater storageFuel oil

The invention discloses a flame pressing type water tube boiler in the field of steam generation devices, which comprises a vertically arranged boiler body, tubes are vertically arranged in the boiler body, the tubes are arranged in a concentric annular array, three layers of tubes are arranged from inside to outside, a flame pressing plate is arranged in a circular cavity formed by the tubes on the inner layer, and a hearth is arranged below the flame pressing plate; a spiral coil pipe is also arranged on the periphery of the tube array in the boiler body; and smoke baffles are arranged between the tubes on the adjacent layers and between the tubes on the outer layer and the spiral coil pipe respectively, flow separation components are arranged between the tubes on the same layer and on the inner sides or the outer sides of the tubes on the same layer, a vertically reciprocating baffling channel is formed between the flow separation components and the smoke baffles in the space in the hearth, and the outermost side of the baffling channel is connected to a smoke outlet. The flame pressing type water tube boiler is small in water storage amount and large in steam production amount. The flame pressing type water tube boiler can be made into fire coal, fuel oil, natural gas or biomass energy boilers and can be applied to various places needing steam.

Owner:扬州大唐热能机械制造有限公司

Red coke transporting apparatus and red coke transporting method suitable for quenching coke

The invention belongs to the field of metallurgy, and relates to a red coke transporting apparatus and a red coke transporting method suitable for quenching coke. According to the red coke transporting apparatus, tracks are arranged on one side of a coke oven and parallel to the direction of the coke oven, a coke quenching vehicle rotation platform is arranged along the track direction, the upperportion of the coke quenching vehicle rotation platform is provided with tracks with the same spacing and the same type, a pit is arranged on one end of the coke quenching vehicle track and below theground perpendicular to the track direction, a dry quenching coke tank is arranged in the pit, the coke tank is positioned on a carrying vehicle, one end of the pit is connected to the end of the cokequenching vehicle track through a coke guide chute, and the other end of the pit is provided with a winch and a winding shaft frame. According to the present invention, the red coke is spread on thecoke receiving groove of the coke quenching vehicle after the red coke is pushed out of the carbonization chamber, the coke quenching vehicle walks along the tracks to the quenching coke tank position, the flipping mechanism under the coke receiving groove pushes the coke receiving groove to flip toward the dry quenching coke tank direction, and the red coke directly flips into the coke guide chute, and then enters the dry quenching coke tank, such that the red coke is pushed out of the coke oven and is transported to the dry quenching coke tank; and the apparatus and the method are especiallysuitable for the red coke transporting of the horizontal heat recovery coke oven using coke dry quenching.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

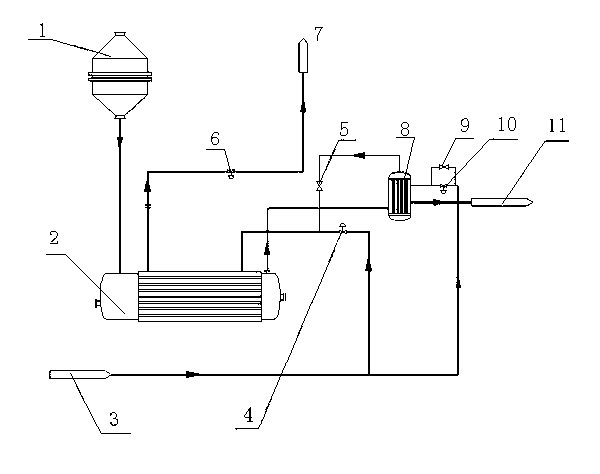

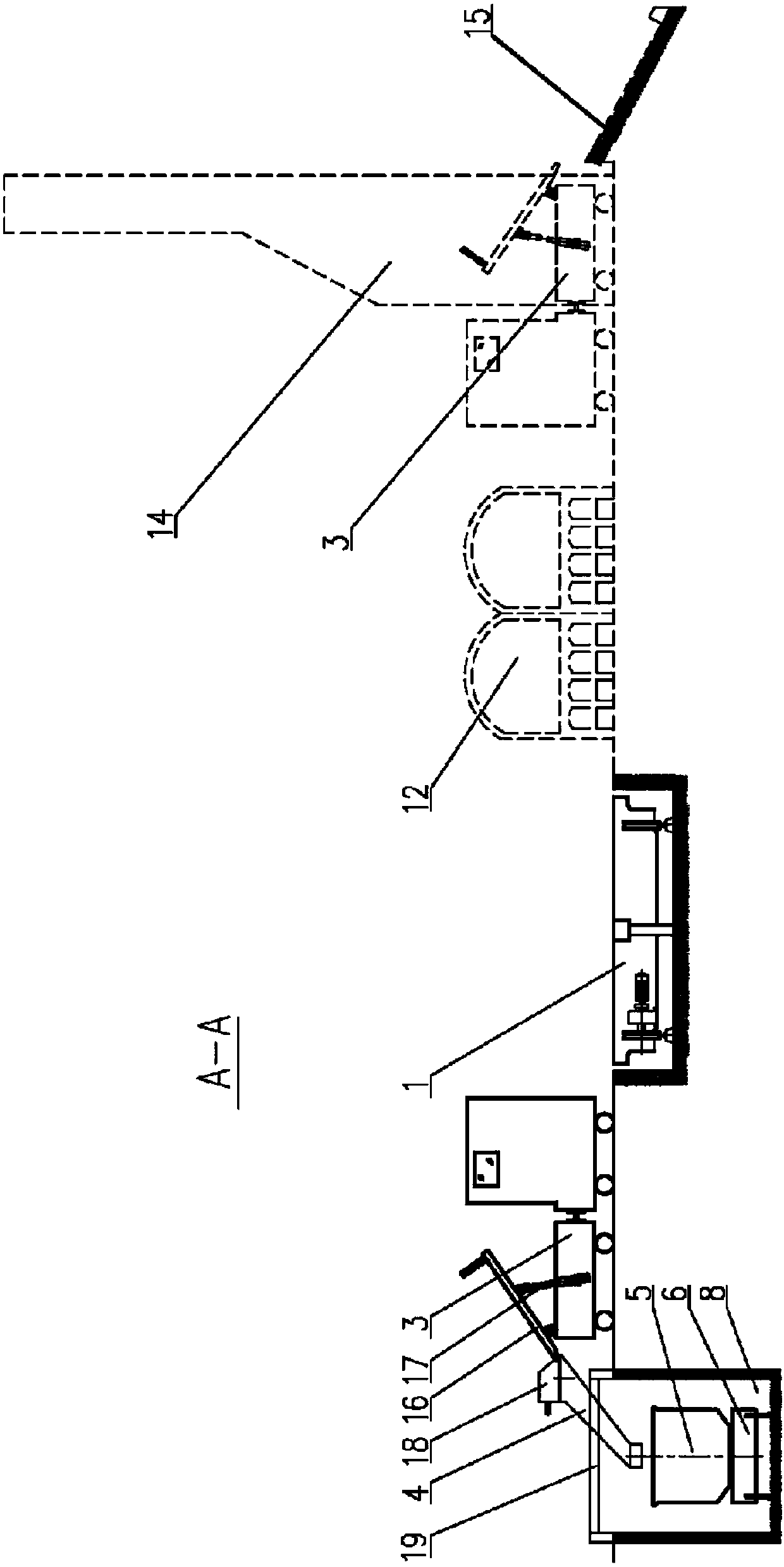

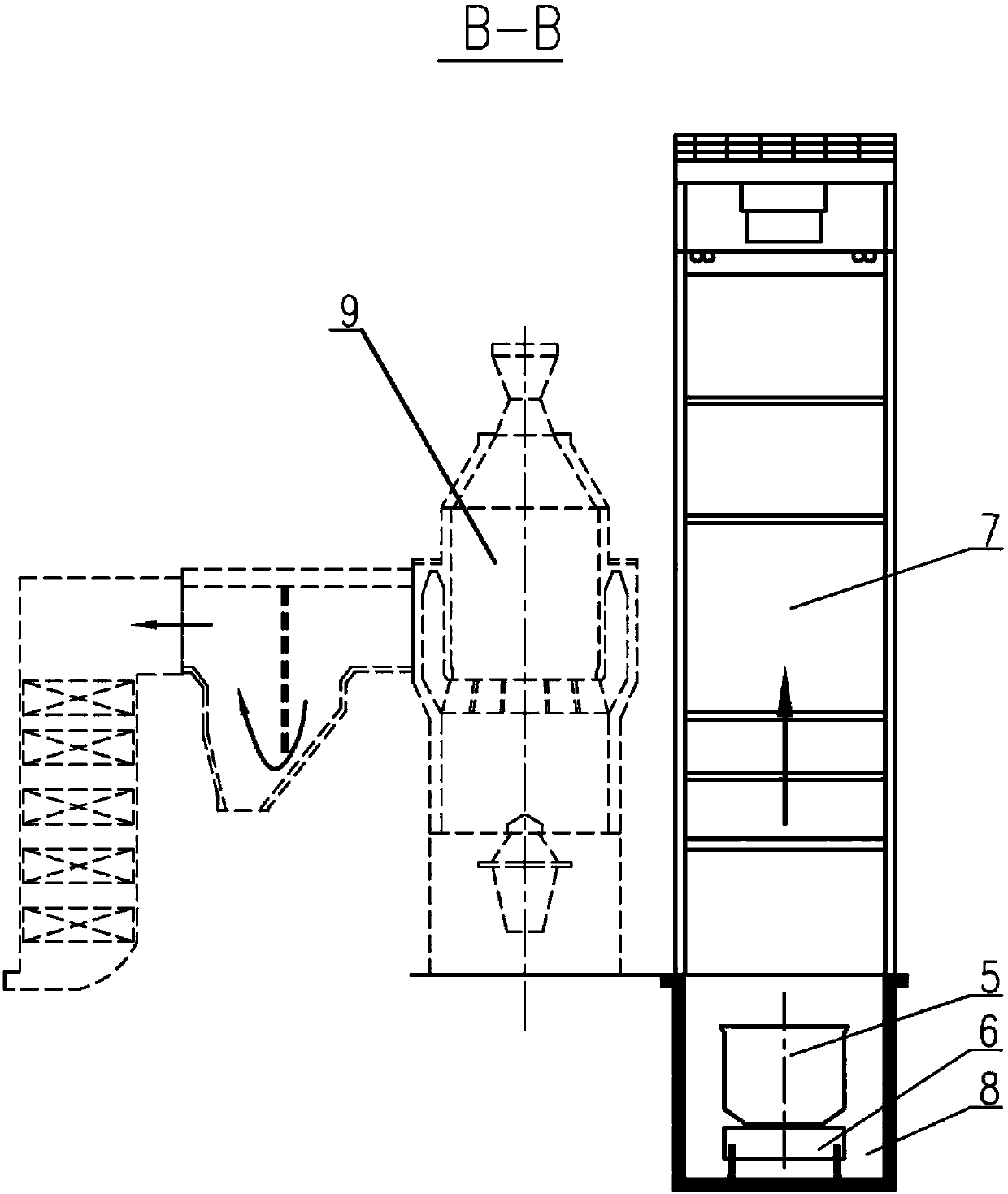

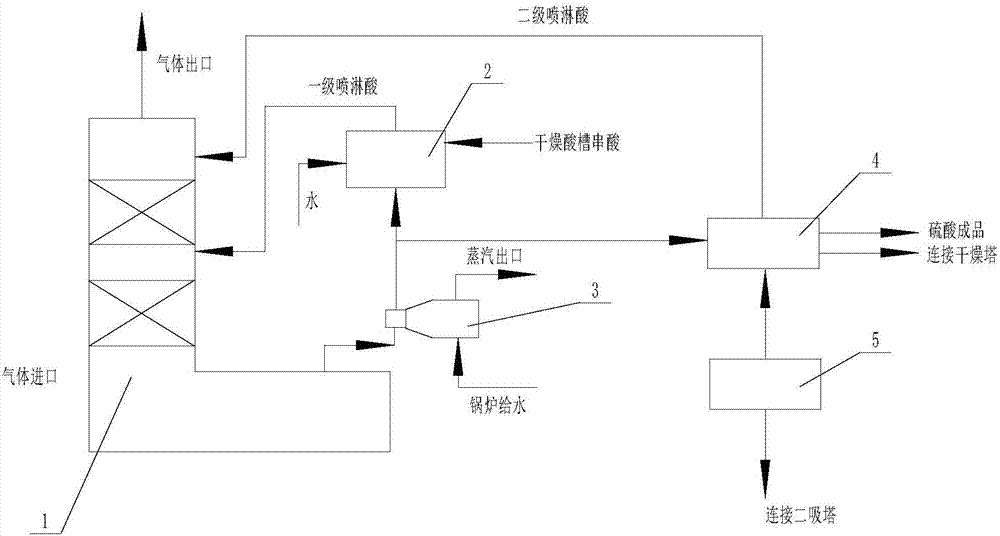

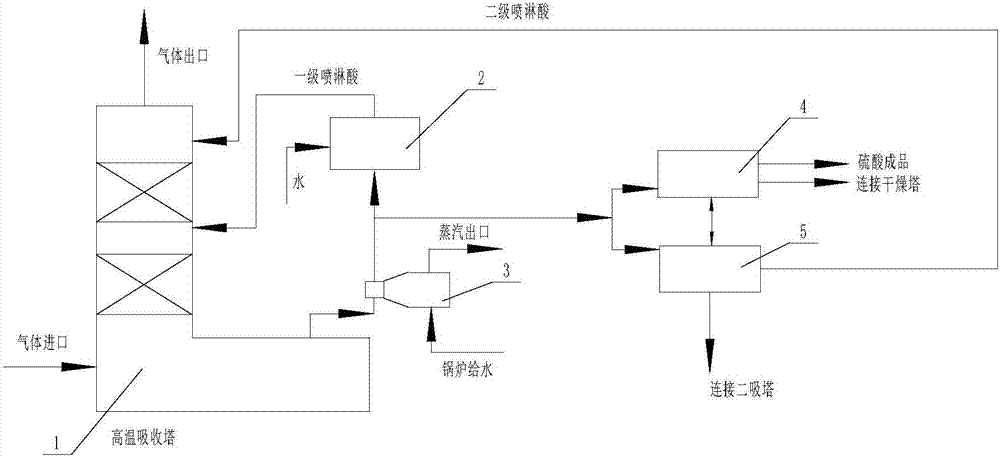

System of increasing steam productivity of low-temperature exhaust heat recovery in acid production from sulfur

InactiveCN107879317ASimple structureIncrease steam productionSteam generation heating methodsSulfur compoundsSulfurAbsorption column

The invention discloses a system of increasing steam productivity of low-temperature exhaust heat recovery in acid production from sulfur. The system includes: a high-temperature absorption column, asteam generator, and a dry absorption section, etc. The steam generator is arranged around a mixer to absorb heat generated therefrom for producing steam and outputs the steam via a pipeline; the dryabsorption section is connected to the high-temperature absorption column and the mixer and is used for absorbing SO3 gas and water in air to produce sulfuric acid; the sulfuric acid then is deliveredto a secondary sprinkling device of the high-temperature absorption column and a finish product acid output pipeline; the sulfuric acid diluted in the mixer is delivered to the dry absorption sectionby means of a primary sprinkling device in the high-temperature absorption column. In the application, the source of secondary sprinkling acid in the secondary sprinkling device in the high-temperature absorption column is changed, and a connection pipeline between the mixer and a dry acid trough in the dry absorption section is optimized, so that acid mixing mode in the dry absorption section ismodified. The system simplifies the structures of the devices and greatly improves the steam productivity in summer.

Owner:襄阳泽东化工集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com