Crushing method of bagasse

A crushing method, bagasse technology, applied in presses, grain processing, manufacturing tools, etc., can solve the problems of reduced crushing capacity, easy mutual entanglement into agglomerates, and low crushing efficiency, so as to reduce energy consumption and improve crushing efficiency , Improve the effect of stand-alone processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The invention discloses a method for crushing sugarcane bagasse. The bagasse is mechanically extruded and compressed by an extrusion crusher, and then the mechanically extruded and compressed bagasse is crushed. The volume ratio of bagasse before and after compression is (3-5):1. The particle size of bagasse after crushing is 0.1-5mm.

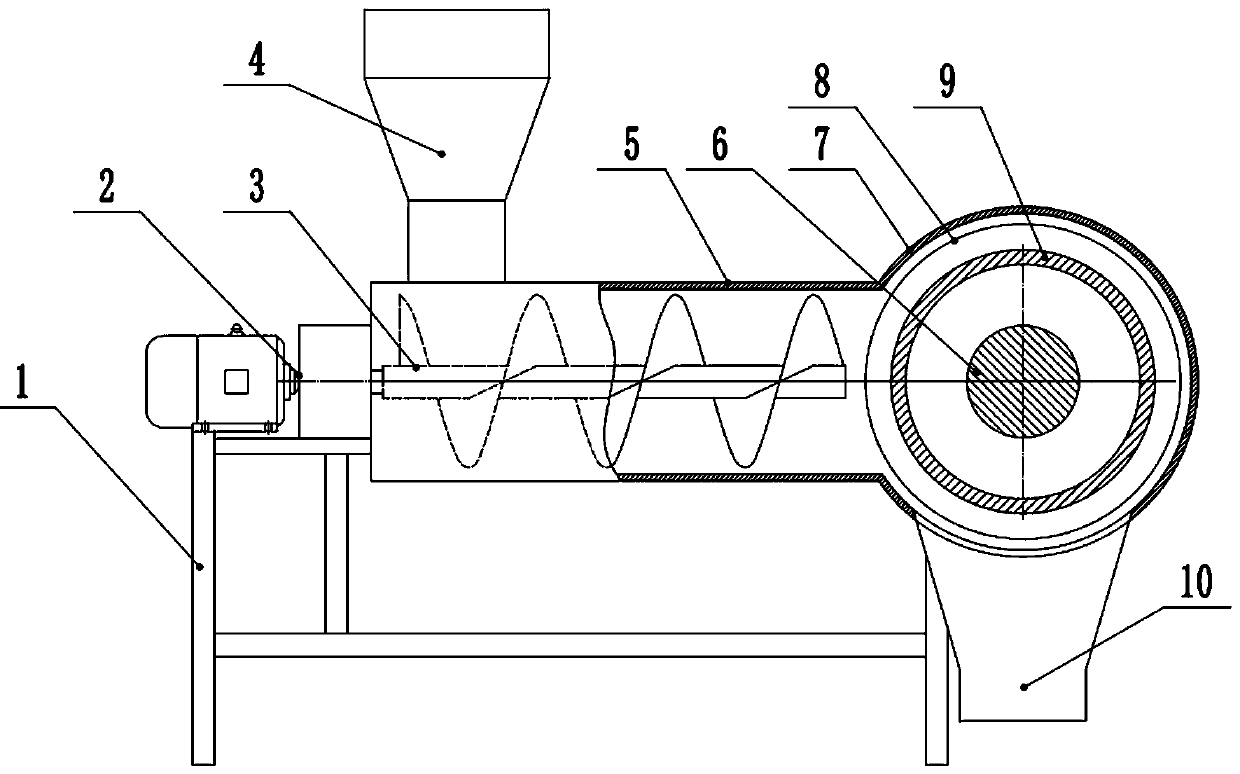

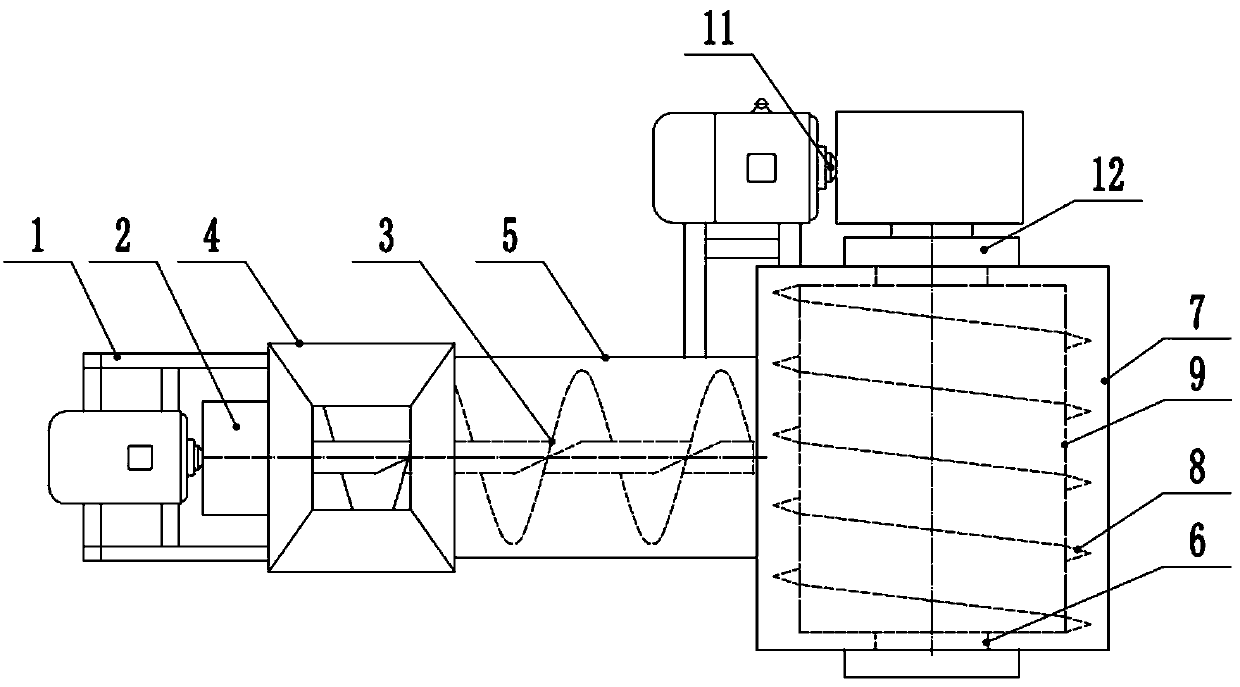

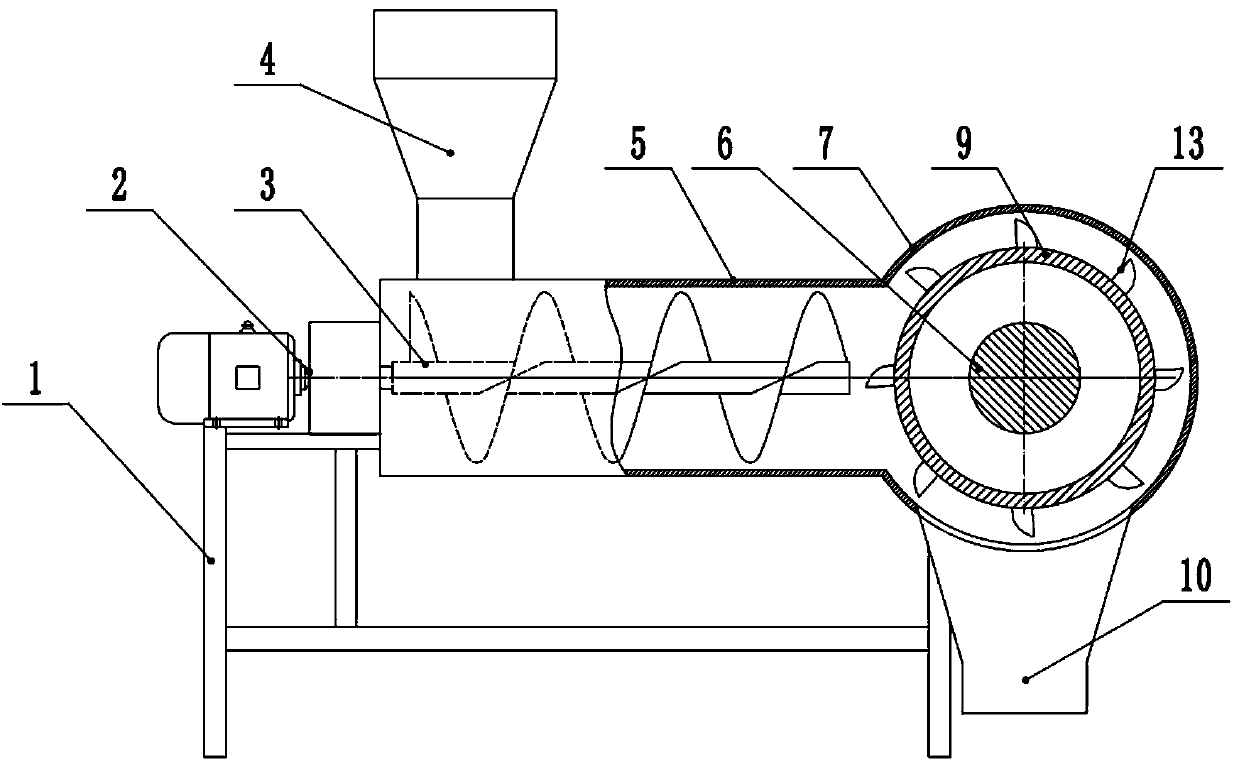

[0039] The extrusion crusher used in the crushing of bagasse includes a machine base 1, an extrusion chamber shell 5 and a crushing chamber shell 7, and the extrusion chamber shell 5 and the crushing chamber shell 7 are installed on the machine base 1 respectively; the extrusion chamber shell 5 One end is equipped with a hopper 4, and the other end is in communication with the crushing chamber 7; the extrusion conveying shaft 3 driven by the extrusion driving device 2 and squeezed to convey the bagasse is installed in the extrusion chamber 5; the crushing chamber 7 passes through The bearing seat 12 is equipped with a crushing shaft 6 d...

Embodiment 2

[0045] The invention discloses a method for crushing sugarcane bagasse. The bagasse is mechanically extruded and compressed by an extrusion crusher, and then the mechanically extruded and compressed bagasse is crushed. The volume ratio of bagasse before and after compression is (3-5):1. The particle size of bagasse after crushing is 0.1-5mm.

[0046] The extrusion crusher used in the crushing of bagasse includes a machine base 1, an extrusion chamber shell 5 and a crushing chamber shell 7, and the extrusion chamber shell 5 and the crushing chamber shell 7 are installed on the machine base 1 respectively; the extrusion chamber shell 5 One end is equipped with a hopper 4, and the other end is in communication with the crushing chamber 7; the extrusion conveying shaft 3 driven by the extrusion driving device 2 and squeezed to convey the bagasse is installed in the extrusion chamber 5; the crushing chamber 7 passes through The bearing seat 12 is equipped with a crushing shaft 6 d...

Embodiment 3

[0052] The invention discloses a method for crushing sugarcane bagasse. The bagasse is mechanically extruded and compressed by an extrusion crusher, and then the mechanically extruded and compressed bagasse is crushed. The volume ratio of bagasse before and after compression is (3-5):1. The particle size of bagasse after crushing is 0.1-5mm.

[0053] The extrusion crusher used in the crushing of bagasse includes a machine base 1, an extrusion chamber shell 5 and a crushing chamber shell 7, and the extrusion chamber shell 5 and the crushing chamber shell 7 are installed on the machine base 1 respectively; the extrusion chamber shell 5 One end is equipped with a hopper 4, and the other end is in communication with the crushing chamber 7; the extrusion conveying shaft 3 driven by the extrusion driving device 2 and squeezed to convey the bagasse is installed in the extrusion chamber 5; the crushing chamber 7 passes through The bearing seat 12 is equipped with a crushing shaft 6 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com