Propane dehydrogenation device and propane dehydrogenation method

A propane dehydrogenation and dehydrogenation reactor technology, applied in the direction of feeding devices, chemical instruments and methods, hydrocarbons, etc., can solve the problem of increasing energy consumption of compressors and heating furnaces, prone to internal leakage of heat exchangers, reducing Product yield and other issues, to achieve the effect of ensuring long-term operation, preventing the removal of coke and scale, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

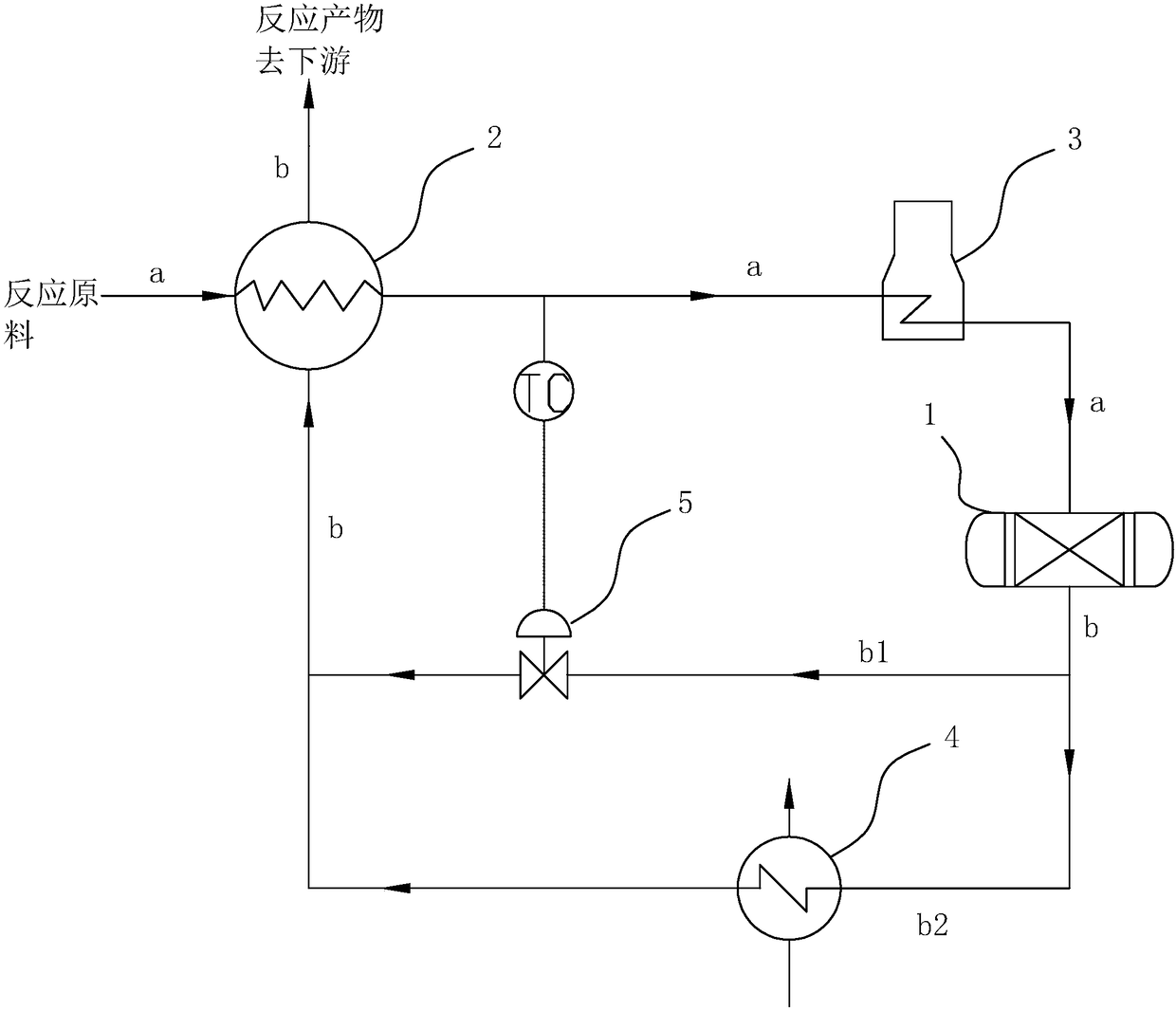

[0019] Such as Figure 1 ~ Figure 2 As shown, the propane dehydrogenation unit includes:

[0020] The dehydrogenation reactor 1 is a conventional propane dehydrogenation reactor, and multiple dehydrogenation reactors 1 are arranged in parallel (not shown in the figure), and each dehydrogenation reactor 1 is switched in time sequence, that is, according to the operation → Purge inside the reactor→catalyst regeneration→reactor reduction→running to complete the production task.

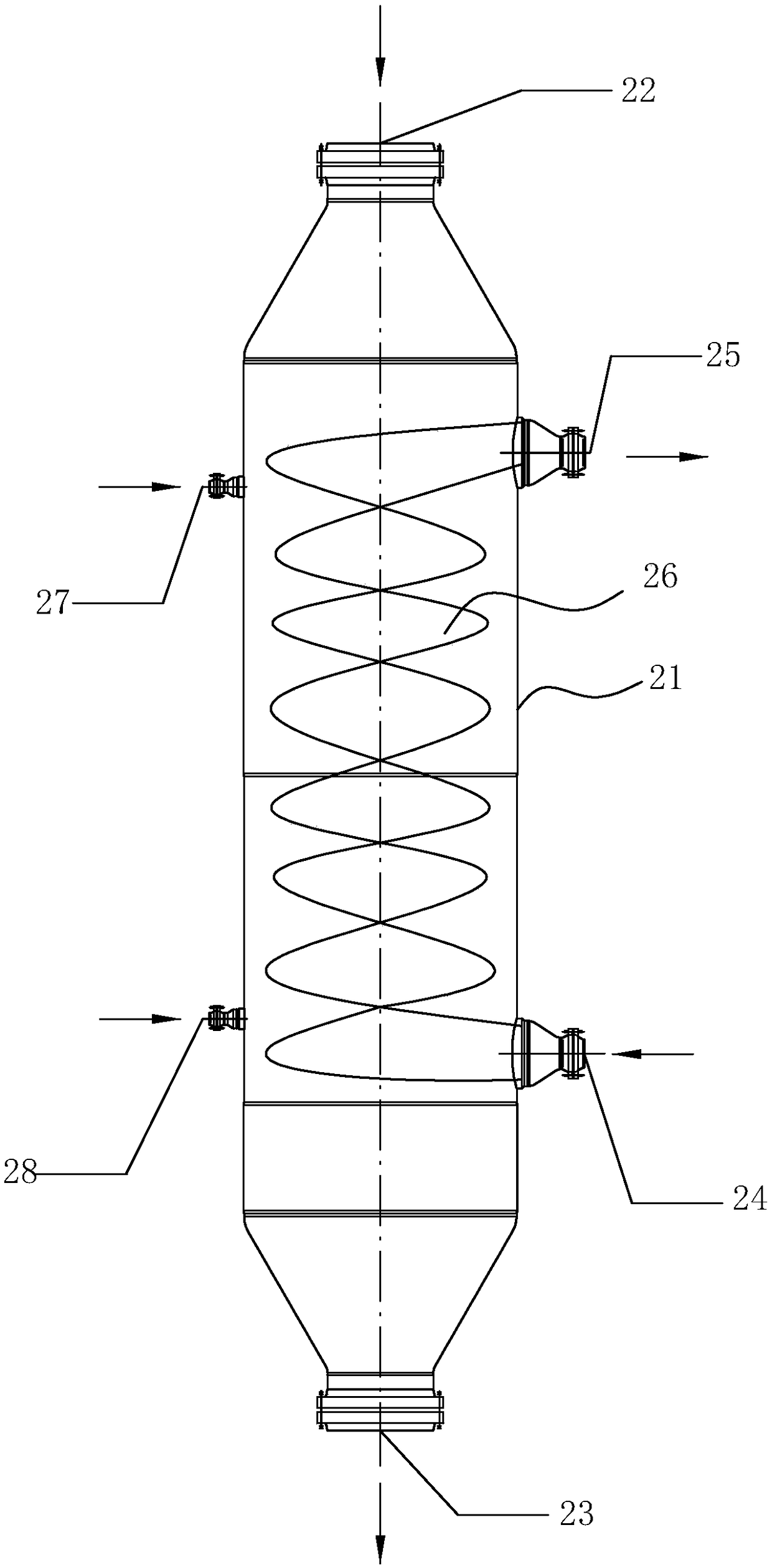

[0021] Heat exchanger 2, the tube-side inlet 24 of the heat exchanger is connected to the reaction raw material delivery pipeline a, and the tube-side outlet 25 of the heat exchanger is connected to the inlet of the dehydrogenation reactor 1 through the heating furnace 3; the outlet of the dehydrogenation reactor 1 Connect the reaction product delivery pipeline b, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com